Regulation of Chemical Process Safety

Current Approaches and Their Effectiveness

Daryl Attwood1 Lloyd's Register EMEA, London, UK

1 Corresponding author: email address: [email protected]

Abstract

The regulation of process safety is described, with emphasis on the oil and gas industry. The migration of the general approach from prescriptive legislation to the currently favored goal setting/safety case method is described, as are the steps involved in developing a typical safety case. Some examples of equipment used to ensure process safety are given, which are of two basic types—that for which its failure would cause a major accident, and that which is intended to prevent or mitigate the effects of a major accident. The current regulatory regimes utilized to ensure process safety in several countries are described. The causes of several infamous process accidents are evaluated, particularly with respect to whether effectively implemented regulation could have prevented them. The general role of classification societies in chemical process safety is described, as are some of the project management and organizational processes utilized for megaprojects by one classification society, Lloyd's Register. The work's overall conclusion is that, while effectively implemented regulation, whether prescriptive or goal setting in nature, can play a significant role in process safety, implementation failures can, and do lead to accidents with devastating consequences.

Keywords

Process safety; Regulation; Prescriptive regime; Safety case; Safety equipment; Safety critical elements; Performance standards; Process accidents; Classification societies

1 Glossary

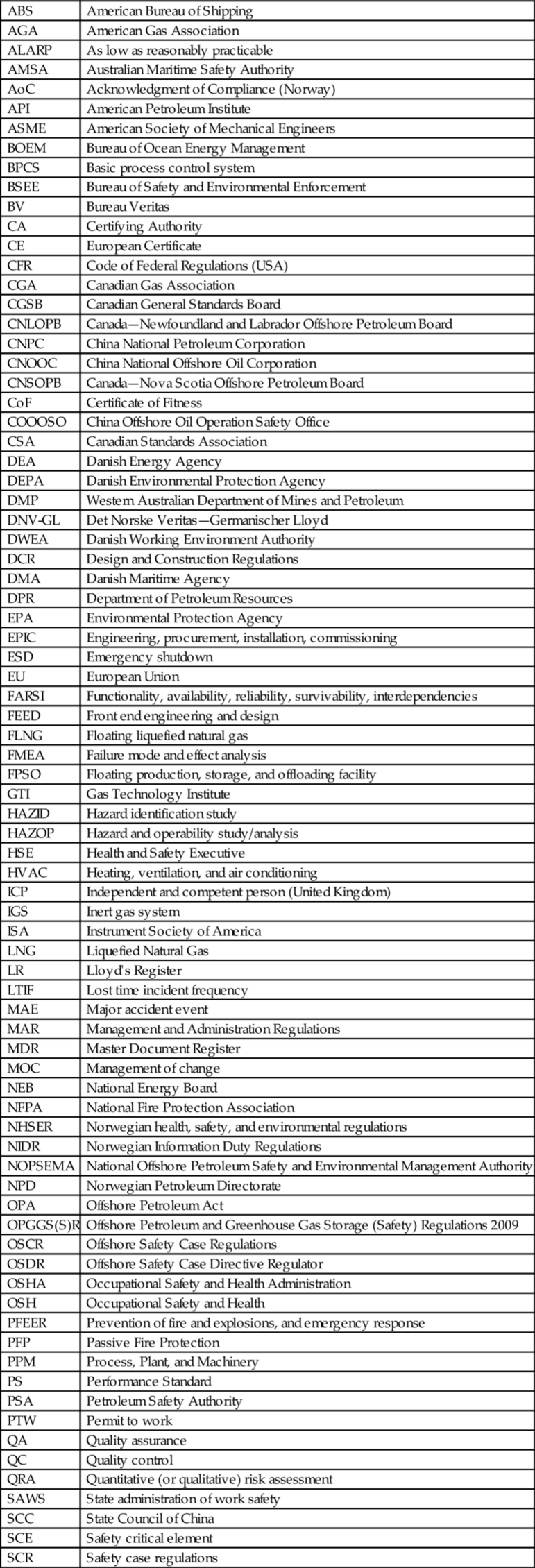

| ABS | American Bureau of Shipping |

| AGA | American Gas Association |

| ALARP | As low as reasonably practicable |

| AMSA | Australian Maritime Safety Authority |

| AoC | Acknowledgment of Compliance (Norway) |

| API | American Petroleum Institute |

| ASME | American Society of Mechanical Engineers |

| BOEM | Bureau of Ocean Energy Management |

| BPCS | Basic process control system |

| BSEE | Bureau of Safety and Environmental Enforcement |

| BV | Bureau Veritas |

| CA | Certifying Authority |

| CE | European Certificate |

| CFR | Code of Federal Regulations (USA) |

| CGA | Canadian Gas Association |

| CGSB | Canadian General Standards Board |

| CNLOPB | Canada—Newfoundland and Labrador Offshore Petroleum Board |

| CNPC | China National Petroleum Corporation |

| CNOOC | China National Offshore Oil Corporation |

| CNSOPB | Canada—Nova Scotia Offshore Petroleum Board |

| CoF | Certificate of Fitness |

| COOOSO | China Offshore Oil Operation Safety Office |

| CSA | Canadian Standards Association |

| DEA | Danish Energy Agency |

| DEPA | Danish Environmental Protection Agency |

| DMP | Western Australian Department of Mines and Petroleum |

| DNV-GL | Det Norske Veritas—Germanischer Lloyd |

| DWEA | Danish Working Environment Authority |

| DCR | Design and Construction Regulations |

| DMA | Danish Maritime Agency |

| DPR | Department of Petroleum Resources |

| EPA | Environmental Protection Agency |

| EPIC | Engineering, procurement, installation, commissioning |

| ESD | Emergency shutdown |

| EU | European Union |

| FARSI | Functionality, availability, reliability, survivability, interdependencies |

| FEED | Front end engineering and design |

| FLNG | Floating liquefied natural gas |

| FMEA | Failure mode and effect analysis |

| FPSO | Floating production, storage, and offloading facility |

| GTI | Gas Technology Institute |

| HAZID | Hazard identification study |

| HAZOP | Hazard and operability study/analysis |

| HSE | Health and Safety Executive |

| HVAC | Heating, ventilation, and air conditioning |

| ICP | Independent and competent person (United Kingdom) |

| IGS | Inert gas system |

| ISA | Instrument Society of America |

| LNG | Liquefied Natural Gas |

| LR | Lloyd's Register |

| LTIF | Lost time incident frequency |

| MAE | Major accident event |

| MAR | Management and Administration Regulations |

| MDR | Master Document Register |

| MOC | Management of change |

| NEB | National Energy Board |

| NFPA | National Fire Protection Association |

| NHSER | Norwegian health, safety, and environmental regulations |

| NIDR | Norwegian Information Duty Regulations |

| NOPSEMA | National Offshore Petroleum Safety and Environmental Management Authority |

| NPD | Norwegian Petroleum Directorate |

| OPA | Offshore Petroleum Act |

| OPGGS(S)R | Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulations 2009 |

| OSCR | Offshore Safety Case Regulations |

| OSDR | Offshore Safety Case Directive Regulator |

| OSHA | Occupational Safety and Health Administration |

| OSH | Occupational Safety and Health |

| PFEER | Prevention of fire and explosions, and emergency response |

| PFP | Passive Fire Protection |

| PPM | Process, Plant, and Machinery |

| PS | Performance Standard |

| PSA | Petroleum Safety Authority |

| PTW | Permit to work |

| QA | Quality assurance |

| QC | Quality control |

| QRA | Quantitative (or qualitative) risk assessment |

| SAWS | State administration of work safety |

| SCC | State Council of China |

| SCE | Safety critical element |

| SCR | Safety case regulations |

| SI | Statutory instrument |

| SIL | Safety integrity level |

| SIMOPS | Simultaneous operations |

| SIS | Safety instrumented system |

| SoV | Scope of Validation |

| TEMA | Tubular Exchanger Manufacturers Association |

| TEMPSC | Totally enclosed motor propelled survival craft |

| TRIR | Total recordable incident rate |

| UARB | Utilities and Review Board |

| UK | United Kingdom |

| USCG | United States Coast Guard |

2 Summary

Approaches to chemical process safety regulation differ from one country to the next. The two basic approaches are (i) those based on specific prescriptive requirements and (ii) the currently more prevalent safety case/goal setting regimes, comprising owner-defined major accidents, safety critical elements (SCEs), and performance standards (PSs). The key principle of the latter is that risks to individuals are expected to be reduced to a level known as ALARP, as low as reasonably practicable.

Even in countries where the approach is primarily prescriptive, elements of safety case methodology are gradually being introduced. Slightly different terminology is sometimes used, for example, safety program instead of safety case, and items critical to safety instead of SCEs.

This chapter describes the origins and history of the safety case approach and the basics of safety case generation. The 1988 explosion of the North Sea oil and gas platform Piper Alpha and the subsequent investigation led by Lord Cullen were the key drivers that changed global preferences from prescription to safety cases and goal setting.

Some of the typical equipment, structures, and systems used to ensure process safety are described. There are two main types. First, that for which its failure could lead to a major accident, for example, pressure vessels and primary structure, and second, that which is intended to prevent or mitigate the effects of an accident, for example, gas detection, deluge systems, and lifeboats.

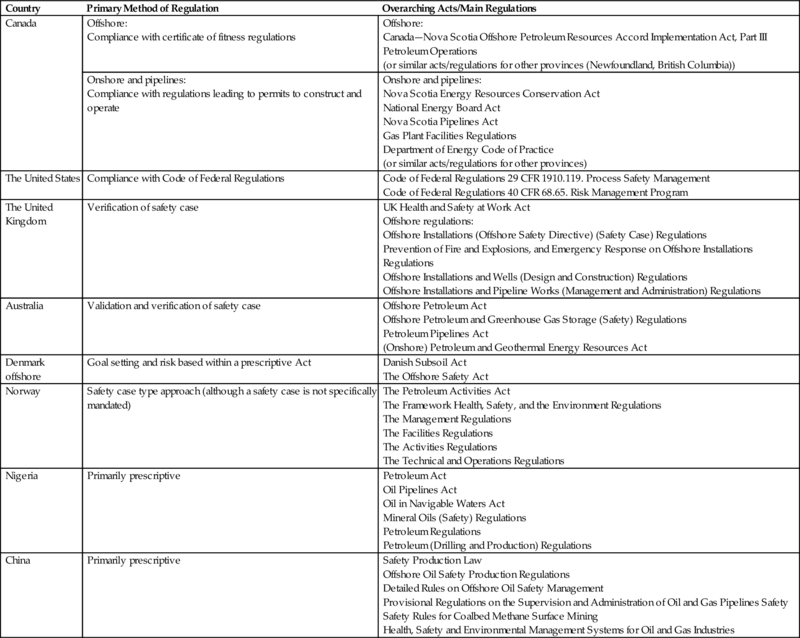

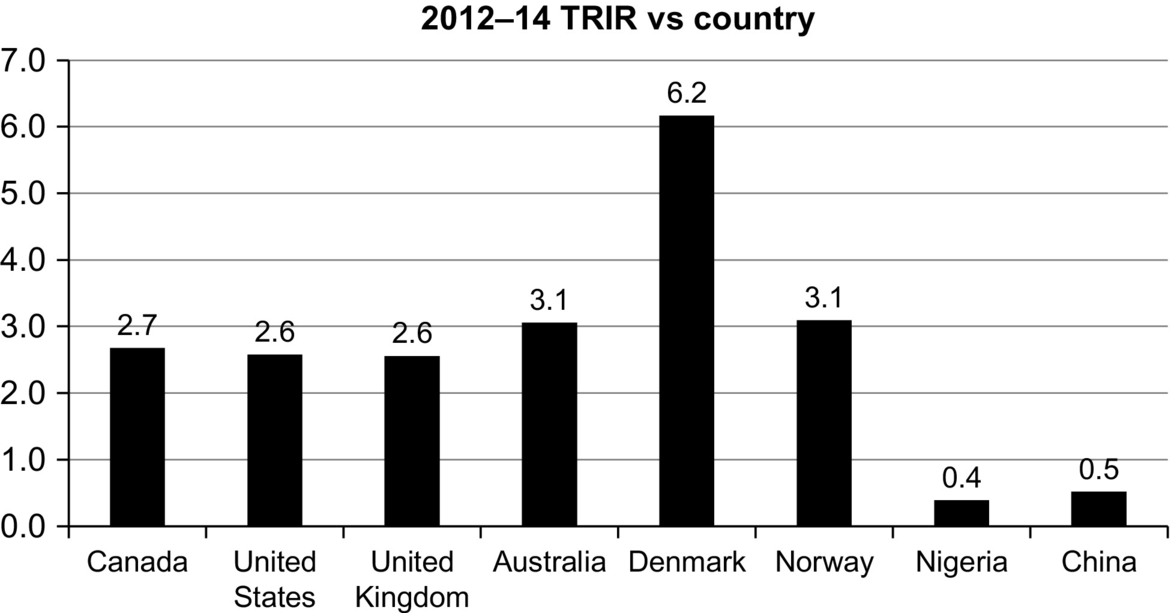

The approaches used to regulate chemical process safety in eight countries—Canada, the United States, the United Kingdom, Australia, Denmark, Norway, Nigeria, and China are described. The regimes in the countries chosen show the full range in approach from primarily prescriptive (China, Nigeria) to full safety case regimes (the United Kingdom, Australia).

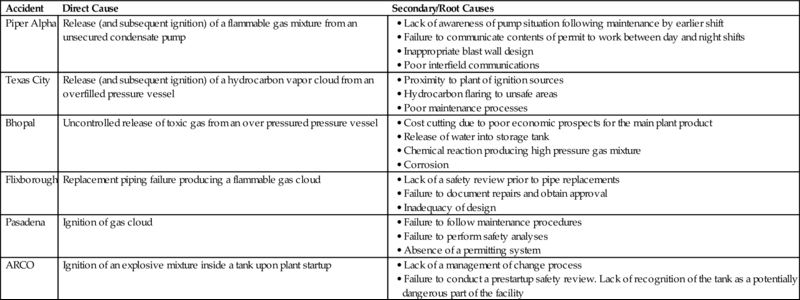

Several infamous chemical process industry disasters (Piper Alpha, Bhopal, Texas City, Flixborough, England, Pasadena, Texas, and ARCO, Channelview, Texas) are described, particularly from the perspective of how an effective and systematic regulatory process might have averted them. The root causes are different for the events, but in general they all included failure to comply with the principles of currently mandatory safety cases and quality management systems. Common themes included inadequate communications, inadequate attention to detail during modifications and repairs, ineffective adherence to maintenance programs, and breakdowns in permit to work (PTW) implementation.

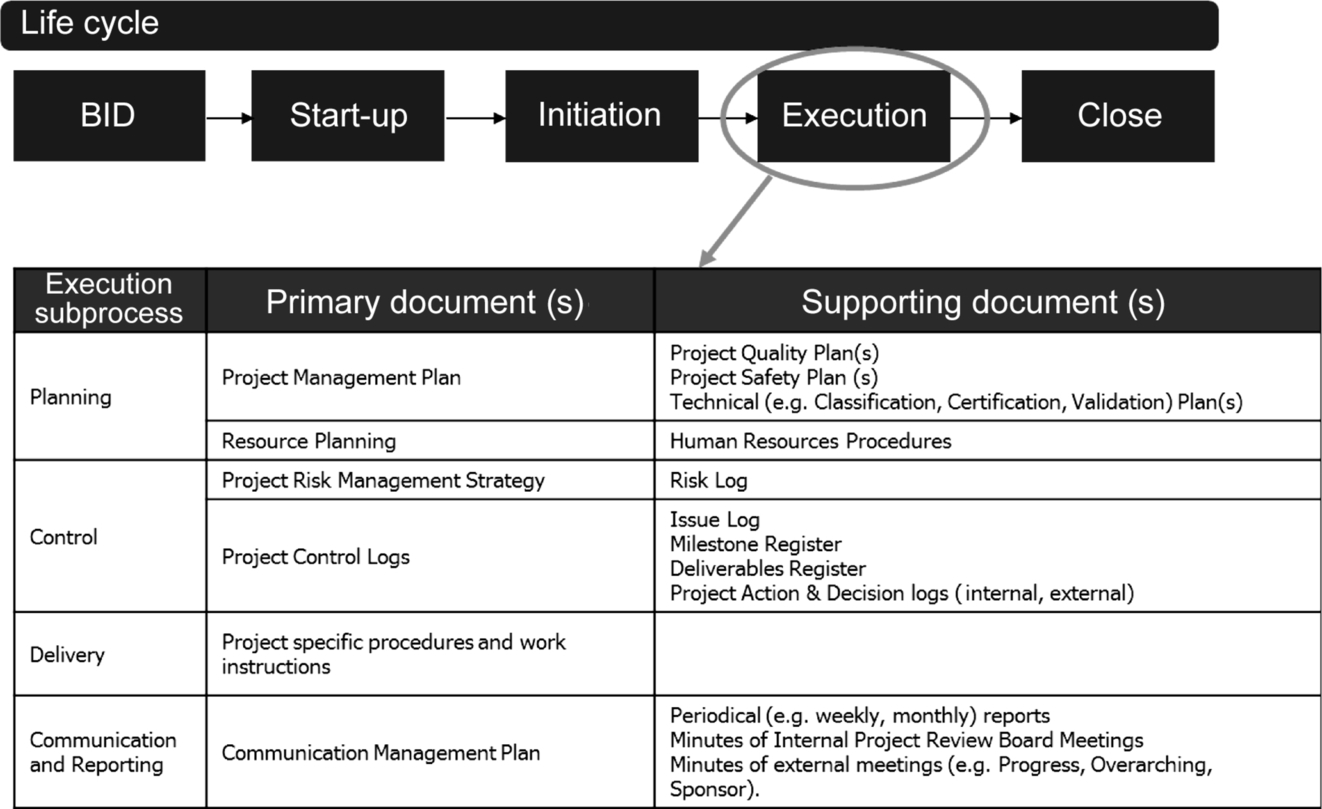

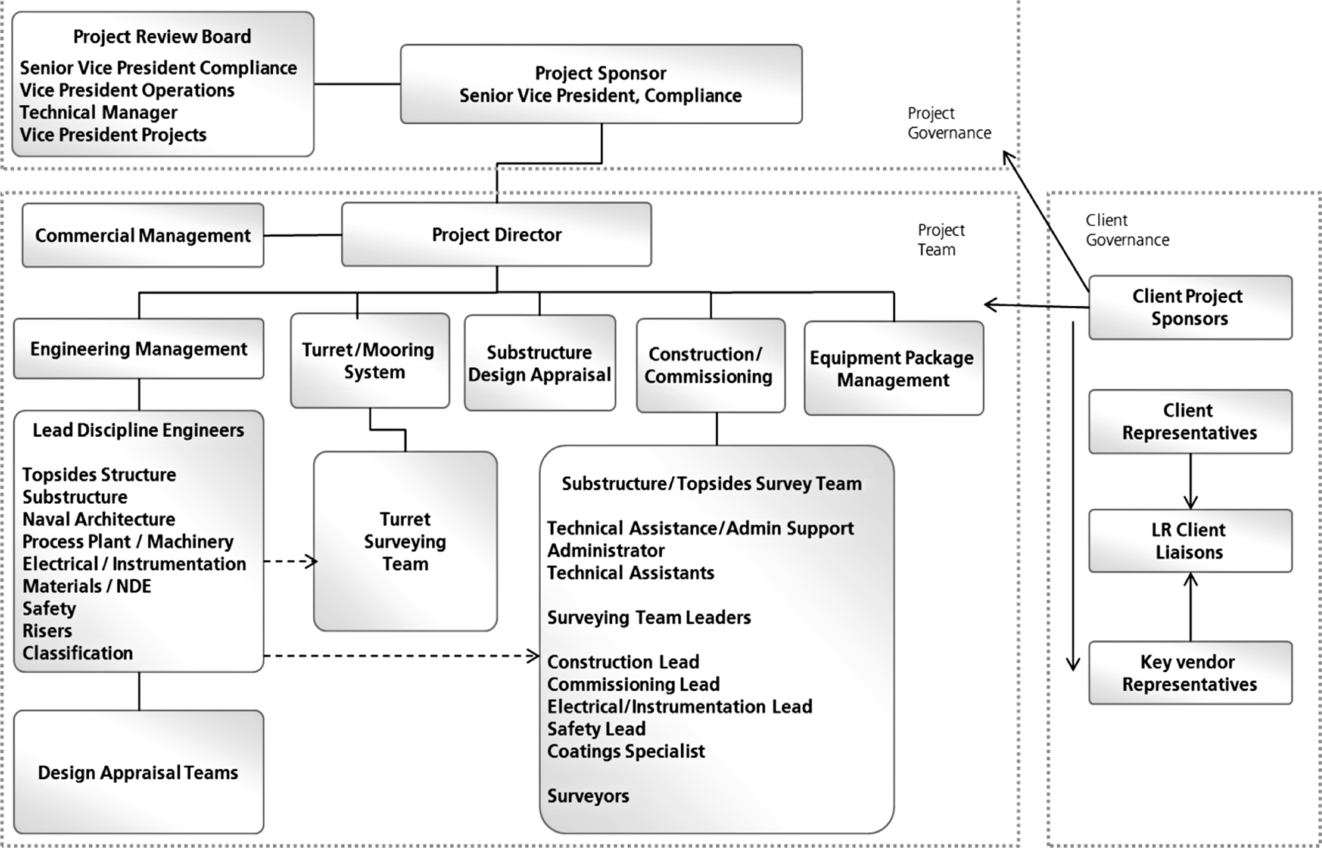

The role of the classification societies in chemical process safety is discussed. The societies provide a completely independent overview of facilities, without the internal cost and schedule pressures experienced by owners. Some details are provided of how one of the societies (Lloyd's Register) organizes itself to manage megaprojects.

The chapter is organized as shown in Table 1.

Table 1

Summary

| Section | Content |

| One | Glossary |

| Two | Summary |

| Three | Introduction |

| Four | Overall approaches, history, and the basic process of generating a safety case. The definitions of and processes used to establish major accident hazards, safety critical elements, and performance standards are described |

| Five | Brief descriptions of some equipment, structures, and systems utilized to make personnel safe in the chemical process industry, primarily related to oil and gas production. The types of equipment can be divided into two categories—first, equipment which, if it failed or was compromised, might lead to a major accident event (MAE), and second, equipment or structures which are meant to prevent or mitigate the effects of an MAE |

| Six | Descriptions of the regulatory regimes, from top level legislation to practical requirements, utilized in Canada, the United States, the United Kingdom, Australia, Denmark, Norway, Nigeria, and China. The descriptions included do not represent an exhaustive list, and they are primarily related to the oil and gas industry. Nevertheless, the Americas, Europe, and Asia are all represented in the sample chosen. Variations of the approaches described are used in many other countries |

| Seven | Review of six historical chemical process accidents (Piper Alpha, Bhopal, Texas City, Flixborough, Pasadena, Texas, and ARCO, Texas), and descriptions of how effective, or more effective, regulation could have averted them |

| Eight | Role of classification societies in chemical process safety regulation. Brief descriptions of four prominent societies are provided: Lloyd's Register, Det Norske Veritas/Germanischer Lloyd, The American Bureau of Shipping, and Bureau Veritas. Lloyd's Register's approach to organization, project management, and quality assurance on megaprojects is described |

| Nine | Concluding remarks |

| References |

3 Introduction

Oil and gas have provided energy for human activity for centuries. Large-scale extraction from beneath the earth's surface and oceans has been undertaken for more than 80 years. Protecting property and keeping people safe while conducting this potentially dangerous work have challenged engineers for just as long.

Participation in the early days of oil and gas extraction was an extremely dangerous vocation, considered a badge of courage by some. Hollywood's portrayals included films such as “There Will Be Blood,” starring Daniel Day-Lewis, and “Hellfighters,” which starred John Wayne and was loosely based on the life of legendary oilfield fire-fighter Red Adair. Other documentaries and TV programs (e.g., “Dallas”) continued to romanticize the macho world of the oil and gas business.

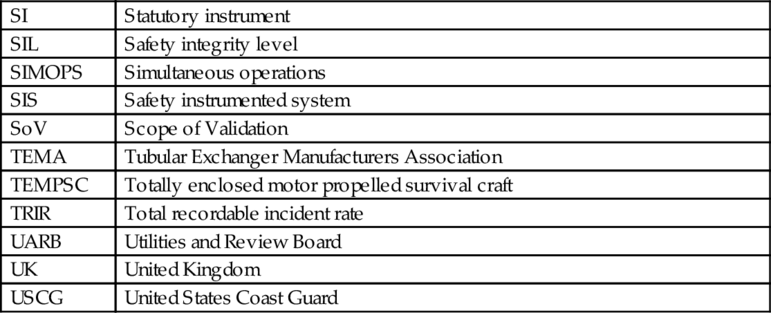

But thankfully, those “bad old days” have come to a close in most locations. Fig. 1 shows the continuing improvement in the oil and gas industry's total recordable incident rate (TRIR*) between 2005 and 2014.

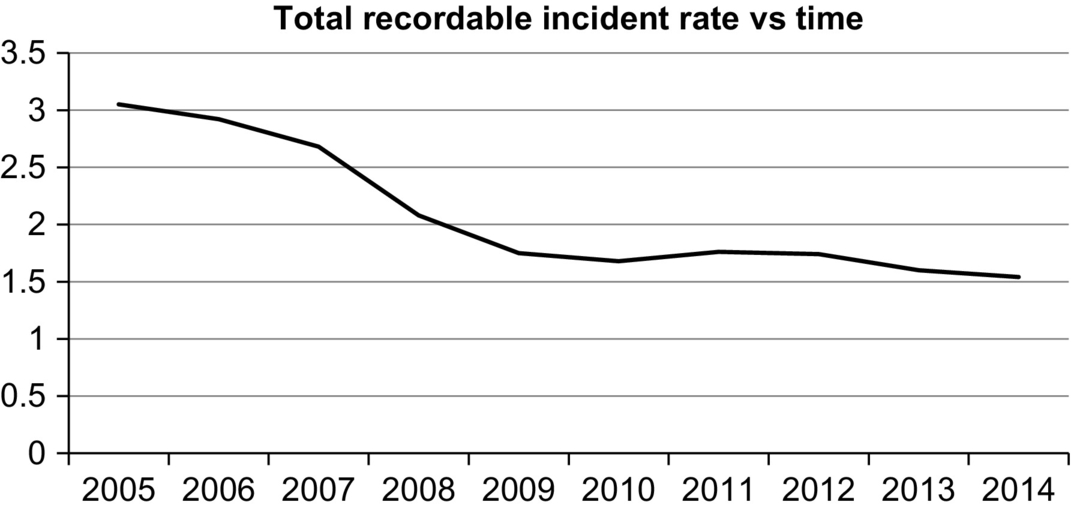

Furthermore, statistics show that by some measures, the oil and gas business is now safer than many other industries such as mining, agriculture, and even education and retail, and certainly safer than participation in many forms of leisure activity such as American football, surfing, and mountain climbing. Fig. 2 shows a comparison of lost time incident frequency (LTIF**) in several industries.

*TRIR—the number of recordable injuries (fatalities+lost work day cases+restricted work day cases+medical treatment cases) per million hours worked.

**LTIF—the number of lost time injury (fatalities+lost work cases) incidents per million hours worked.

Some would even say that the pendulum has swung too far, that health and safety measures have in some cases strangled creativity and threatened to stagnate progress. But the motives are beyond criticism. There is never a good reason to be injured or killed, but having a serious accident while trying to do one's job is no longer tolerated by workers or management in the process industry.

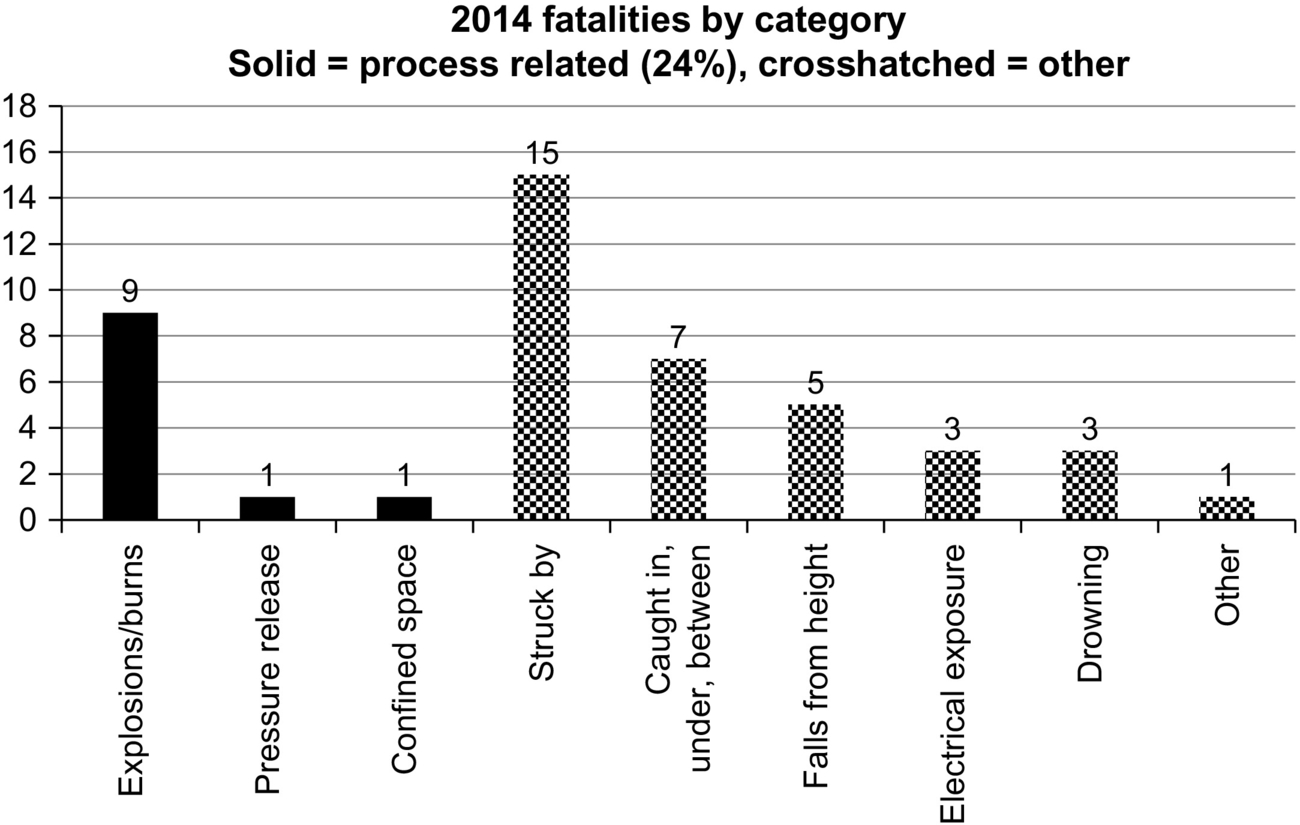

Some statistics show that about 25% of oil and gas industry fatalities are related to the production process. Fig. 3 shows that 11 of the 45 fatalities reported in 2014 by the International Association of Oil and Gas Producers were related to explosions, burns, pressure releases, or confined space entries. The remainder were related to nonprocess events such as being struck by or caught between objects, falls from height, electrocution, and drowning.

One of the positive elements used to drive this continuous improvement in chemical process industry safety has been the regulatory process, which itself has evolved significantly from the early days of strict prescriptive regulation to today's more popular approach of operator conceived, generated, and enacted safety case regimes. Lord Cullen's investigation of the 1988 Piper Alpha disaster and subsequent recommendations were the main drivers in the gradual migration of offshore oil and gas safety approaches from prescriptive regimes to the more modern safety case approaches.

The key concept in the safety case approach is that risk to individuals should be reduced to “ALARP,” as low as reasonable practicable. All stakeholders recognize that there will inevitably be things that could be done to make any facility safer—extreme examples being building causeways from distant offshore platforms to shore or replacing floating installations with artificial islands irrespective of water depth. However, budgets are not unlimited and therefore reasonable and practical expectations of personal safety and individual risk have been adopted. The ALARP principle, when applied to proposed safety improvement measures, has come to be interpreted in the industry as: a proposed change should not be implemented if its time or monetary cost is grossly disproportionate to the risk reduction actually achieved.

The types of equipment governed by the regulations can be divided into two categories. First, equipment which, if it failed or was compromised, might lead to an MAE, for example, primary structure, pressure vessels, process piping, and electrical wiring; and second, equipment or structures which are meant to prevent or mitigate the results of an existing event, for example, gas detection, temporary refuges, lifeboats, fixed and portable fire-fighting equipment, and blast walls.

Some countries (Australia and the United Kingdom) operate primarily goal setting/safety case regimes, while others (Nigeria and China) continue to use mostly prescriptive approaches. A hybrid approach is taken in countries (Canada, the United States, Norway, and Denmark) where elements of safety case approaches are introduced into existing prescriptive regulations. In general, the movement globally is toward more goal setting methods which place more responsibility on the duty holder, who is considered to be better placed to understand the specific requirements of the project and its location-specific hazards. The gradual reduction of accident frequency and general improvement in most safety statistics over time validates the direction of this philosophical movement.

A review of historical accidents is useful in helping to decide future approaches to chemical process safety, either from the regulator's or the duty holder's perspective. A rigorous and systematically implemented regulatory program could have provided the tools necessary to prevent some infamous process related disasters, such as the Piper Alpha production facility explosion and fire in the UK North Sea and well known process related disasters in Texas City, United States, and Bhopal, India. In every case more than one root cause can be identified and good arguments can be made that an effectively implemented regulatory program may have prevented the accidents. Some of the common root causes were lack of PTW systems, noncode-compliant design, improper modifications, failure to perform or improperly performed maintenance, general noncompliance with safety procedures, lack of appropriate management/supervisory sign-off of work, and inadequacies in hazard identification and mitigative measures. These elements are key components in both the goal setting/safety case and prescriptive regimes utilized in today's process industry.

Classification societies play an important role in the regulation of process safety. In some cases, the societies offer consultancy services and technical expertise directly to clients, but more often they provide an independent assessment of compliance with codes, standards, and regulations. In most cases this is mandated by law, but occasionally the verification is done as part of the duty holder's due diligences process. The societies can offer a view based solely on the technical details of the facility, unfettered by schedule and cost constraints. The process is based on (i) a review of the facility's design plans and (ii) surveys during construction, commissioning, and installation. Four prominent classification societies are: The UK-based Lloyd's Register (LR), the Norway/Germany-based DNV-GL, formed by the merger of previously Norwegian Det Norske Veritas and German Germanischer Lloyd, The French-based Bureau Veritas, and the Houston-based American Bureau of Shipping. Each society has specific strengths, and it is quite common to see more than one organization employed on megaprojects, as operators capitalize on their respective abilities.

4 Overall Approaches: Prescriptive and Safety Case Regimes

4.1 Origins of Safety Case Regimes

On July 6, 1988, the Piper Alpha platform, located in the United Kingdom sector of the North Sea, exploded and burned, resulting in the deaths of 165 of the 226 personnel on board, and £1.7 billion worth of property damage. At the time, the platform's production accounted for approximately 10% of North Sea output. The structure was almost completely destroyed within a few hours and the direct cause was a lack of containment of flammable hydrocarbon vapors.

Prior to the Piper Alpha tragedy, offshore process safety was regulated by prescriptive regimes, wherein a series of regulations specified exactly what was required to meet a country's safety expectations. This approach, still used in some countries (e.g., Nigeria and China), is unpopular with many operators due to its inflexible nature. Operators, however, do see at least one overall benefit in the approach—the perceived retention by governments of accident liability when operators comply with all the specific requirements of the prescribed regulations.

A downside of prescriptive regulation occurs when operators install equipment they consider unnecessary or inappropriate for the sole purpose of complying with regulatory requirements and obtaining a classification certificate, permit to operate, or similar. Doing so can mean missing opportunities to apply best industry practice and/or installing the latest and best safety equipment and systems.

Following the Piper Alpha disaster, a public inquiry, chaired by Lord Cullen, was initiated by the United Kingdom government. In addition to his original mandate to investigate the event's causes, Lord Cullen offered 106 recommendations to prevent reoccurrences. In view of its failure to prevent the disaster, the previous prescriptive regulatory approach was rejected in favor of a safety case regime for offshore oil and gas installations.

Lord Cullen's recommendation to adopt a safety case/goal setting regime was accepted in the United Kingdom and has gradually been utilized to different degrees and with different formats in other locations. Under these regimes, the operator is completely responsible for any and all accidents and is required to establish a safety case to ensure that the risk to personnel due to MAEs is ALARP.

The ALARP principle is a key element of the safety case approach and was based on a judgment by Lord Justice Asquith in the United Kingdom in 1949 and subsequently confirmed by the Australian high court. It is interpreted in the industry as meaning that the cost, in terms of either time or money, to further reduce an identified level of risk is disproportionate to the risk reduction potentially achieved.

The goal setting/safety case approach is popular in that it provides flexibility in how the zero accident goal is achieved, but the duty holders have realized there is nowhere to hide—by definition any accident is a failure in the safety case's suitability.

In some countries retaining primarily prescriptive regulatory approaches, for example, the United States and Canada, some form of safety case, or at least the basic elements of one, is often one of the prescriptive requirements.

4.2 Safety Case Development

The format for safety cases is similar globally, but differences in emphasis exist between countries and operators. In the United Kingdom, for example, the template requires the inclusion of the following main sections:

• Description of safety systems.

• Safety management system.

• Management of major hazards.

• Justification for continued operation (including following repairs, modifications, or unexpected events).

Examples of the steps, elements, and terminology used to develop and execute a safety case are as follows:

• Safety reviews: These consider the overall safety of an installation and usually comprise multiday workshop style meetings attended by qualified and knowledgeable safety representatives of the owner and any of its contractors familiar with the facility's safety arrangements.

• Hazard and operability studies (HAZOPs): These are formal, facilitated, documented systematic workshops intended to identify and classify the facility's hazards and their causes. They are most effective when representatives from many departments and disciplines are included.

• Hazard identification studies (HAZIDs): Similar to HAZOP studies, these are formal documented workshops intended to systematically identify all credible hazards in a facility or plant. They benefit from multidiscipline participation, including, for example, the responsible design engineer, project manager, installation manager, maintenance engineer, and several project engineers. The HAZID output is usually a list of hazards which can be used, for example, in quantitative or qualitative risk assessments (QRAs).

• Development and population of a hazard/safety risk register: This is usually the output from safety reviews, HAZOPs and HAZIDs. Experienced facilitators are often employed to ensure that sufficient rigor is applied to the process and all hazards have been evaluated.

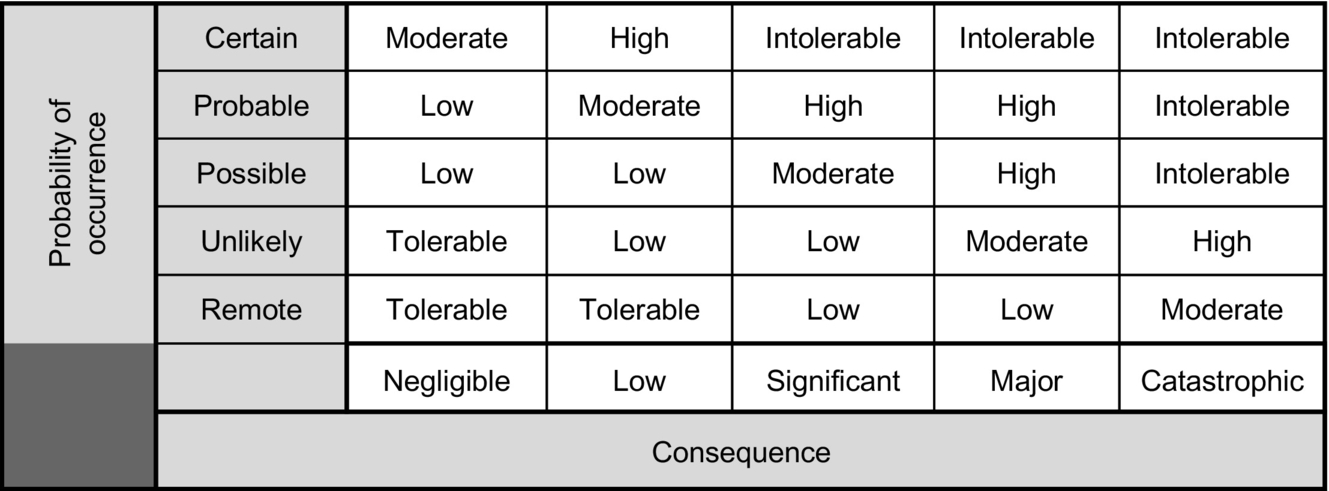

• Quantitative/qualitative risk assessment studies (QRAs): The purpose of these activities is to assess the risk, comprised of both probability of occurrence and consequence, of each identified event.

Quantitative approaches involve calculating risk by multiplying together the assigned numerical values of probability of occurrence and consequence. The process has drawn criticism from some industry participants who questioned the accuracy and suitability of applying numbers to some risk elements, for example, the value of a human life. Conclusions based on the result of multiplying what are sometimes very small numbers together to produce an even smaller number were also considered by some to be somewhat unconvincing and difficult to accept.

Qualitative approaches have become more popular, wherein probability of occurrence is subjectively evaluated along a range, for example, from “remote” to “certain,” and consequences are categorized from “negligible” to “catastrophic.” Plotting both results along orthogonal axes then leads to an overall risk assessment, with conclusions potentially including actions such as “tolerate,” “monitor controls,” and “stop all production until corrective action is effectively implemented.” An example of this system is shown in Fig. 4.

• Generation of a list of potential MAEs: These are project specific and can include natural events. Most often they are defined as an event having the potential to cause multiple fatalities. In some cases, however, the definition is expanded to include, for example, environmental damage, asset damage, and even corporate reputational damage. It is noteworthy that in many cases events having the potential to result in only a single fatality are excluded from safety case analyses. These would then include the events which, statistically, produce the most offshore injuries and fatalities—slips, trips, and falls.

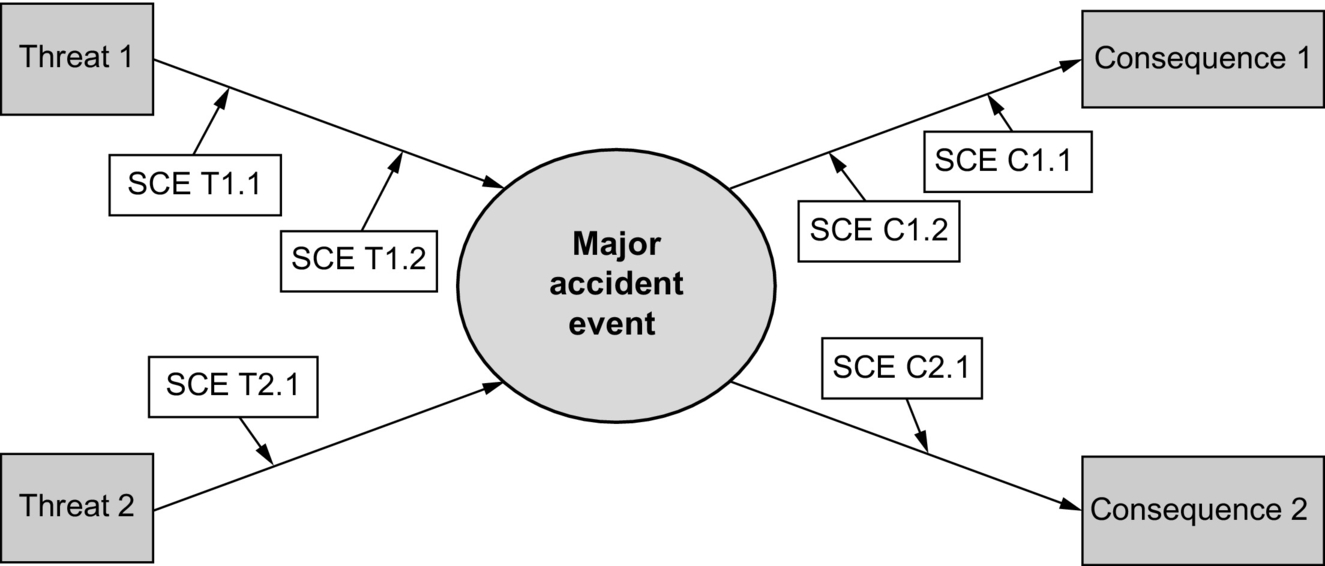

• “Bow-tie” analysis and workshop: The title originates from the shape of a pictorial description of the work (see Fig. 5): The MAE is at the center of the “tie,” with threats and consequences forming the opposite sides. The SCE form barriers on either side of the MAE, with those on the threat side representing steps taken to ensure that the threats do not cause a MAE, and those on the consequence side representing the effective performance of SCEs meant to mitigate the effects of MAEs.

One of the outputs of the bow-tie analysis is a list of SCEs. There are two types:

• Structure, plant, equipment, system, or other elements, the failure of which could lead to a MAE. Examples would be pressure vessels, main structure, process piping, and electrical cabling.

• Equipment or systems whose purpose is to prevent or limit the consequences of a MAE. Examples of this type of SCE would be gas detection equipment, deluge systems, fire pumps, life boats, and temporary refuges.

Care needs to be taken to include both types of SCEs in safety case discussions and considerations, and not only the second type, which are traditionally considered to comprise a project's safety equipment.

• Establishment of PSs, which, if complied with, ensure SCE effectiveness: Each SCE has an associated specific PS or series of PSs. In theory, if the PS is complied with, the SCE is effective in doing its part to prevent the occurrence or mitigate the effects of a MAE. Examples of PSs might be:

– Firewater pumps to provide a given flow rate.

– Main structure to withstand the effects of a hurricane of a given strength for a given time period.

– Temporary refuge to provide safe cover for personnel for a given time period following the most intense credible identified fire or explosion.

– Cables supplying power to emergency equipment to remain operational for a given time period following initiation of the most intense identified fire.

– Hull structure to meet all requirements of a recognized classification society's applicable rules.

• PS requirements are of five types: functionality, availability, reliability, survivability, and interdependencies, often referred to by the acronym “FARSI.” These terms are defined as follows:

– Functionality: The specific functions required to be performed by the SCE—for example, hydrocarbon carrying piping should withstand, without loss of containment, all static and dynamic loads applied by internal fluid motion and external supports.

– Availability: The ability of the SCE to perform its function under the specific expected conditions—for example, systems should not be adversely affected by electromagnetic interference generated by other proximate equipment.

– Reliability: The probability that the equipment will operate without failure under the expected conditions. In some cases, the probability is defined in project-specific programs such as QRA or a defined safety integrity level (SIL). In others, the probability of failure is defined in external codes and standards.

– Survivability: The ability of the SCE to operate for as long as is required following an event—for example, a temporary refuge is required to provide protection for occupants for as long as is required to safely evacuate all persons on board under the most extreme fire and/or explosion event. Similarly, passive fire protection (PFP) would be required to prevent any collapse of the structure which would jeopardize evacuation for as long as it would take to safely evacuate all personnel under the most extreme fire and/or explosion event.

– Interdependencies: Any other systems upon which an SCE depends to perform properly—for example, process emergency shutdown (ESD) valves require that the cabling carrying signals to them operate properly under the expected conditions, and that the control logic governing their use has been correctly developed and coded within the ESD system. Additionally, an ESD system typically requires interfaces with other SCE systems such as ignition prevention, fire and gas detection and signaling, and emergency power.

• It is usually a regulatory requirement that compliance with the PSs is verified. This needs to be done by the builders and operators as a normal part of project due diligence. There is also usually a regulatory requirement to have an independent third party assess the arrangements and confirm PS compliance. This role is usually performed by one of the classification societies.

5 Some SCEs Related to Process Safety

There are two types of SCE:

• Those, which are not traditionally considered to be “safety equipment,” for which their failure could lead to a MAE.

• Those, which are more frequently considered to comprise a facility's safety equipment, whose function is to either prevent or mitigate the effects of an MAE.

Following are some examples of SCEs related to process equipment. The below is not an exhaustive list.

5.1 SCEs, the Failure of Which Could Lead to a MAE

• Main structure supporting process equipment: The structures (e.g., beams supporting decks, decks themselves, and pipe supports) supporting process equipment need to be sufficiently robust to allow the equipment to operate under normal operating conditions. Failure to do so could lead to, for example, piping or pressure vessel failure, subsequent release of hydrocarbon, and, upon ignition, an explosion or fire resulting in multiple fatalities and/or other serious events.

• Pressure vessels, heat exchangers, fired heaters: This equipment needs to be designed and constructed properly, thereby preventing either sudden catastrophic explosive failures or process leaks. The former would likely lead to serious fires and/or explosions, the latter, in combination with a source of ignition, could likewise lead to serious explosions and/or fires.

• Storage tanks: Leaks in storage tanks, in combination with a source of ignition, can quickly lead to serious fires and explosions. If under pressure, undetected fabrication or design flaws in tanks can lead to more sudden explosions.

• Piping systems: Failures in piping systems, whether induced by design or fabrication flaws, can lead to MAEs either through sudden explosions or the production of standing hydrocarbons, which provide a fuel source for fires/explosions. Pipe supporting arrangements are critical in the prevention of piping systems induced MAEs. For floating offshore installations, forces induced by the movement of the carried fluids combined with those related to vessel movement all need to be considered in pipe support design and installation.

5.2 SCEs Expected to Prevent or Mitigate the Effects of a MAE

5.2.1 SCEs Expected to Prevent the Occurrence of a MAE

• Hazardous area ventilation: The purpose is to prevent the formation of hazardous flammable gas mixtures in hazardous areas such as paint stores, battery storage rooms, and areas around process equipment with some likelihood of the presence of leaked gaseous hydrocarbons. Equipment used to ensure effective hazardous area ventilation management include, for example, heating, ventilation, and air conditioning (HVAC) dampers, fire dampers, and forced draft ventilation.

• Inert gas system: The system provides an inert gas (e.g., nitrogen) blanket in tanks in order to displace oxygen and prevent the development of a flammable atmosphere, which could enable a fire or explosion.

• Relief system: Comprised of, for example, pressure relief valves and/or rupture disks on individual process lines and/or vessels. The purpose is to ensure that line pressures do not build-up to the point where an explosion could occur.

• ESD system: The system is designed to shut down appropriate process equipment upon detection of abnormal situations within the system—for example, high pressure, temperature, or level within individual vessels, or detection of smoke, fire, or gas anywhere on the installation. The shutdown philosophy forms the basis for verifiable cause and effects charts. Systems usually include manual hand switches allowing operator intervention in the event of emergencies.

• Fire and gas detection: These systems use various methods to detect the presence of, for example, flames, heat, smoke, or flammable gas mixtures. Manual call points are also frequently part of the system. Outputs from the system, depending on the situation, can be alarms or shutdown signals to the appropriate process equipment.

• Flame retardant and fire resistant cabling: Specific types of cables are specified dependent on their use. For example, different requirements would apply for cables supplying safety-related equipment such as fire and gas detectors than for cabling supplying nonsafety critical equipment such as entertainment appliances.

5.2.2 SCEs Designed to Mitigate the Effects of a MAE

• Main structure: As stated earlier, this is also an SCE of the first type. The main structure also needs to maintain sufficient structural integrity during and after an MAE for long enough to allow all personnel to evacuate safely. In this way, it mitigates the effects of an MAE that has already happened.

• Flare and vent system: Flare towers on offshore facilities can be greater than 150 m in height. Their purpose is to allow the safe removal of hydrocarbon inventory, thereby eliminating a fire's fuel source and minimizing damage to equipment and danger to personnel.

• Deluge and water monitor systems: These systems include pipework, control instrumentation, and fixed and oscillating monitors. Their purpose is to prevent escalation of fires by supplying cooling water to ignited hydrocarbons when called upon either automatically or manually.

• Structural fire and explosion protection: This usually refers to bulkheads, structural decks, doors, etc. The structural items are designed to contain explosions and/or limit the spread of fires for defined periods. Their ability to maintain integrity is usually proved and documented by type approval tests. These tests are performed remotely and subject test structures of the same design and construction as provided on the facility to fires having defined intensities and periods.

• Temporary refuge: This is meant to provide an initial safe haven for personnel for sufficient time to allow their safe evacuation from the facility to be planned and executed.

• Passive fire protection (PFP): Although it can take several forms, PFP is usually a sprayed on coating which limits or delays the effects of fire on the structure, piping, or vessels on which it is applied. The extent and thickness of PFP application is determined by the overall safety philosophies of the installation/plant. The overriding philosophy is that PFP should prevent failure of, for example, structures, piping, or pressure vessels for sufficient time to allow personnel to be safely evacuated.

• Water mist systems: These are usually used to extinguish fires in equipment rooms such as diesel generator rooms, etc. The equipment usually includes pipework, pumps, water supply tanks, and control equipment. The purpose of the system is to prevent the escalation of fires in the protected area.

• Fixed foam systems: These are usually utilized at helicopter landing facilities and can be initiated either manually or automatically. The systems extinguish or limit the effects of hydrocarbon fuel fires, essentially by cutting off the supply of oxygen to the fire. Components include pipework, pumps, instrumentation, storage tanks, and fixed and oscillating monitors.

• Process and ESD valves: The purpose of these valves is to isolate the process or riser inventory feed and thereby limit the time that fuel is provided to an existing fire. The equipment is usually operated pneumatically or hydraulically, upon an either automatically or manually initiated instrument signal.

• Lifeboats and life rafts: These are the ultimate means of personnel protection when the decision has been made to evacuate an offshore platform. Modern lifeboats are usually of the totally enclosed motor propelled survival craft (TEMPSC) type, need to be available for all persons on board, and usually rely only on gravity for deployment. Life rafts are deployed at strategic locations on offshore facilities, both to comply with statutory requirements and provide alternatives to personnel not able to get to the primary evacuation location for any reason.

• Emergency power: A dedicated generator is designed and installed to start automatically and provide power to essential and emergency services in the event that main power is lost. Special arrangements are made to protect the space enclosing the emergency generator from the most intense identified fire and explosion events.

6 Some Examples of Regulatory Regimes

6.1 Overview

The process whereby chemical process safety is regulated varies from country to country. Some, for example, Nigeria and China, operate primarily prescriptive regimes, wherein detailed safety requirements are specified in regulations. Others, for example, the United Kingdom and Australia, regulate process safety within safety case regimes. For the latter, the operator generates and is responsible for all aspects of a safety case, wherein a series of SCEs and PSs are defined. Theoretically, if the PSs are complied with, a level of safety ALARP is achievable. Other countries, for example, Canada, the United States, Norway, and Denmark, operate hybrid regimes wherein many of the elements present in safety cases are embedded within prescriptive regulations.

Key elements and philosophies of the regimes in Canada, the United States, the United Kingdom, Australia, Denmark, Norway, Nigeria, and China are described in this section. Because of differences in the various regimes’ structures and the style of information available in the literature describing each, the descriptions are not completely consistent in their presentation. Emphasis has been placed on any distinctive aspects of the countries’ contributions to process safety regulation, for example, the UK's influence on all the other regimes resulting from its formal adoption of a safety case approach, and Australia's definition of Validation as an activity to be kept separate and distinct from all other aspects of facility regulation.

Table 2 summarizes each country's primary methods of regulation and their overarching acts and main regulations.

Table 2

Country Summary

| Country | Primary Method of Regulation | Overarching Acts/Main Regulations |

| Canada | Offshore: Compliance with certificate of fitness regulations | Offshore: Canada—Nova Scotia Offshore Petroleum Resources Accord Implementation Act, Part III Petroleum Operations (or similar acts/regulations for other provinces (Newfoundland, British Columbia)) |

| Onshore and pipelines: Compliance with regulations leading to permits to construct and operate | Onshore and pipelines: Nova Scotia Energy Resources Conservation Act National Energy Board Act Nova Scotia Pipelines Act Gas Plant Facilities Regulations Department of Energy Code of Practice (or similar acts/regulations for other provinces) | |

| The United States | Compliance with Code of Federal Regulations | Code of Federal Regulations 29 CFR 1910.119. Process Safety Management Code of Federal Regulations 40 CFR 68.65. Risk Management Program |

| The United Kingdom | Verification of safety case | UK Health and Safety at Work Act Offshore regulations: Offshore Installations (Offshore Safety Directive) (Safety Case) Regulations Prevention of Fire and Explosions, and Emergency Response on Offshore Installations Regulations Offshore Installations and Wells (Design and Construction) Regulations Offshore Installations and Pipeline Works (Management and Administration) Regulations |

| Australia | Validation and verification of safety case | Offshore Petroleum Act Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulations Petroleum Pipelines Act (Onshore) Petroleum and Geothermal Energy Resources Act |

| Denmark offshore | Goal setting and risk based within a prescriptive Act | Danish Subsoil Act The Offshore Safety Act |

| Norway | Safety case type approach (although a safety case is not specifically mandated) | The Petroleum Activities Act The Framework Health, Safety, and the Environment Regulations The Management Regulations The Facilities Regulations The Activities Regulations The Technical and Operations Regulations |

| Nigeria | Primarily prescriptive | Petroleum Act Oil Pipelines Act Oil in Navigable Waters Act Mineral Oils (Safety) Regulations Petroleum Regulations Petroleum (Drilling and Production) Regulations |

| China | Primarily prescriptive | Safety Production Law Offshore Oil Safety Production Regulations Detailed Rules on Offshore Oil Safety Management Provisional Regulations on the Supervision and Administration of Oil and Gas Pipelines Safety Safety Rules for Coalbed Methane Surface Mining Health, Safety and Environmental Management Systems for Oil and Gas Industries |

6.2 Canada: Offshore—Certificate of Fitness; Onshore—Permits to Construct and Operate

6.2.1 Offshore Certificate of Fitness Regime

Canada has operated joint federal—provincial Certificate of Fitness (CoF)-based safety regimes for its offshore oil and gas industry since its beginnings with the Cohasset Panuke project, near Sable Island, southeast of Nova Scotia, in 1991. Since then, other projects, including Newfoundland's Hibernia, Terra Nova, White Rose, and Hebron, and Nova Scotia's Sable and Deep Panuke, have been regulated under the same regime, using a CoF approach. The regulatory agencies and governing regulations for offshore facilities are different than those for pipelines, as described later. Platforms and floating installations are overseen by the Canada—Nova Scotia (and Newfoundland) Offshore Petroleum Boards (CNSOPB, CNLOPB), pipelines by a combination of the foregoing and the National Energy Board (NEB).

The overarching legal instrument governing offshore activity in Nova Scotia is the Canada—Nova Scotia Offshore Petroleum Resources Accord Implementation Act, Part III, Petroleum Operations (Croston, 2016). Similar legislation governs offshore activity in other provinces. Under this act, the Governor in Council is authorized, for the purposes of safety and the protection of the environment, to make various regulations covering, for example:

• The production, processing, and transportation of petroleum.

• The management and control of petroleum production.

• The removal of petroleum from the offshore area.

• The design, construction, operation, and abandonment of pipelines within the offshore area.

The primary regulation governing nonpipeline offshore activity is the overarching “Certificate of Fitness Regulations,” which, in turn, references specific clauses from the next tier of regulations, including:

• Occupational safety and health regulations.

• Production and conservation regulations.

These regulations reference specific codes and standards related to chemical process safety, which are required to be complied with. Such compliance is expected to minimize the likelihood of process related accidents.

While the regime is primarily prescriptive, goal-oriented approaches are being introduced. There are specific requirements for the operator to generate and comply with a concept safety analysis, a safety plan, and to set safety target levels such as the risk to life. Unlike the systems utilized in the United Kingdom and Australia, however, these and other goal setting requirements do not comprise the regime's overarching philosophy. Some specific prescriptive requirements similar to safety case elements are as follows:

• The concept safety analysis is required to encompass all phases of the facility's life, including design, construction, installation, commissioning, operation, and abandonment.

• A determination of probability of occurrence and consequences are required for each potential accident.

• Provision for the safe evacuation of all personnel from the production installation is required.

The future direction of the regime's philosophy can be anticipated by the 2009 publishing of Safety Plan Guidelines, which include concepts similar to those required in the United Kingdom safety cases, stating, for example, that:

• “While the concept ‘as low as reasonably practicable’ (ALARP) is not discussed in the regulations, this will be a factor when considering a safety plan under the regulations.”

• “Industry may demonstrate incorporation of ALARP into their risk reduction and associated mitigating measures through a number of means, including by a combination of qualitative analysis, quantitative analysis, and good industry practice.”

• “The safety plan is to include a listing of all structures, facilities, equipment, and systems critical to safety (analogous to SCEs).”

• “The methodology used to develop the list of safety critical items should include links to the overall risk assessment, design processes, and ALARP studies.”

The operator is required to obtain a permit to operate prior to commencing production, and a CoF is a prerequisite for obtaining this. The petroleum boards rely on classification societies, acting as Certifying Authorities (CAs), to perform sufficient design appraisal and construction surveillance to confirm to the boards that the requirements of the CoF regulations have been complied with.

After production has commenced, the ongoing validity of the CoF is confirmed by the CA via a series of periodical surveys, the frequency of which is determined by the complexity of the installation. The most common frequency is annual, but for larger and more complicated installations, semiannual or quarterly visits are made.

6.2.2 Pipelines

In addition to CNSOPB/CNLOPB oversight for offshore pipelines, all pipelines are subject to regulation by the NEB. The primary regulatory documents are the NEB Act and the Canadian Onshore Pipeline Regulations. The regulations set down prescriptive requirements related to other Canadian national standards, and in some high risk cases (e.g., as defined by Canadian standard Z662, or within 500 m of a railway or paved road) also require submission of a documented risk assessment.

The regulations also specify the submission of several manuals and programs which are very similar to those required by safety case regimes—for example:

• Maintenance safety manual.

• Emergency procedures manual.

• A training program including safety regulations, procedures, and working practices.

• Safety program.

6.2.3 Onshore Facilities: Permits to Construct and Licenses to Operate

6.2.3.1 Introduction and Organizations Offering Applicable Codes and Standards

Onshore facilities in Nova Scotia, including liquefied natural gas (LNG) plants, are subject to the requirements of the Nova Scotia Energy Resources Conservation Act, which in turn references the Pipeline Act (Act) (Province of Nova Scotia, 2000), the Gas Plant Facilities Regulations (Regulations) (Province of Nova Scotia, 2013), and the Nova Scotia Department of Energy Code of Practice for Liquefied Natural Gas (Code of Practice) (Nova Scotia Department of Energy, 2005). These regulations, enforced in Nova Scotia by the Nova Scotia Utilities and Review Board (UARB), require the operator to obtain a permit to construct prior to construction commencement and a license to operate prior to startup. The Code of Practice includes references to various organizations’ codes and standards applicable to chemical process safety, as follows.

• American Gas Association for purging procedures.

• American Petroleum Institute for construction of low pressure storage tanks and associated relief devices.

• American Society of Mechanical Engineers for design of piping and pressure vessels and associated relief devices.

• Canadian Gas Association for cryogenic liquid standards.

• Canadian General Standards Board for piping systems and qualification of personnel conducting nondestructive examination.

• Canadian Standards Association for LNG facilities and equipment.

• Gas Technology Institute for information on modeling of LNG releases.

• Instrument Society of America for design of safety instrumented systems (SISs).

• National Fire Protection Association for fire protection systems.

• Tubular Exchanger Manufacturers Association for design of heat exchangers.

Requirements also include the submission and approval of the proposed facility's quality assurance (QA) plans and policies, and procedures for design, material control, construction, and operation.

6.2.3.2 Prescribed Safety Case Requirements

Many of the main elements of a safety case are required prescriptive elements for issuance of a license to operate, including the following:

• Hazard Operability (HAZOP) Report: Describing the hazard identification activity performed during detailed engineering design, including a list of any changes made after the HAZOP and a copy of the action plan showing the resolution of all action items.

• Emergency Response Plan: Developed in conjunction with the facility security assessment.

• Prestartup Safety Review Report: Summarizing the review and documentation of the identification and subsequent resolution of any action items.

• Operational Phase Process Safety Management (PSM) System procedures: A complete set of PSM procedures to be followed during operation; specifically the remaining procedures not already developed during design and construction, including:

– Prestartup safety review following any changes.

– Process hazard analysis—revalidation of the HAZOP.

– Incident investigation.

– Emergency planning and response.

6.2.3.3 Some Example Process Safety Equipment Requirements

The Code of Practice includes specific requirements for many process safety equipment items, for example:

• Building ventilation: Air intakes to be provided with gas detectors which shutdown air handling units and inhibit startup in the event of gas detection, in order to prevent the introduction of toxic or flammable gas. Control room HVAC system to be designed to cater for the maximum possible thermal radiation flux.

• Relief devices: Sizing to be based on fire exposure, process upsets, thermal expansion, sudden change in barometric pressure, thermal expansion, control malfunction, improper valve position, mechanical failure, and loss of utilities.

• Boil off recovery system: To be installed to collect LNG boil off. Vapors to be safely disposed of through reliquefaction, used as fuel, returned to storage tanks or marine tankers, recompression to a gas pipeline network, or as a last resort, flared or released to atmosphere.

• Flare and venting system: Sized for the maximum expected accidental gas flow.

• Check valves: To be installed downstream of block valves in the direction of flow. In this manner, any LNG trapped between the check valve and block valve will be relieved on expansion into the downstream piping.

• ESD valves: Closure time to be adjusted to ensure closing does not result in pressure surges that could cause piping or pipe support failure. ESD valves to meet the following criteria:

– Valves that may be operated for process control by the basic process control system (BPCS) shall only be operated for emergency reasons by the SIS.

– Valves shall fail in a safe position as identified in the HAZOP.

– Valves which are used also to isolate inventories of flammable materials shall be designed as fire safe.

• Emergency power: Designed to ensure, in case of main power supply failure, continued availability of all vital safety functions.

• Safety instrumented system (SIS): Designed to protect equipment and personnel from process upsets and emergency conditions. Required to automatically detect unsafe conditions and activate automatically or manually the appropriate equipment, unit, process, or ESD. Main functions to include:

– Activate automatically the appropriate shutdown system and protection equipment.

– Inform the operator of an incident.

– Inform the BPCS of SIS activation.

– Monitor and control the protection equipment (e.g., fixed fire protection systems).

– Monitor and control protection system auxiliaries (e.g., fire pumps, foam agent pumps, and fire water system valves).

6.2.3.4 Approval Process and Classification Societies

The onshore approval process includes the direct engagement by the UARB of a classification society to act as a CA. The essential scope is to certify that the applicable requirements of the regulations have been complied with during the design, construction, operation, and abandonment phases of the facility's life cycle. The CA scope of work can include the following:

• A review of QA plans, policies, and procedures prepared by project proponents, in order to confirm that they reflect the applicable standards referenced in the Regulations.

• A review of, and provision of advice to the UARB regarding, applications made by project proponents for permits to construct. The advice can include recommendations regarding terms and conditions which should be attached to the permit.

• Prior to issuance of the UARB's permit to construct, certification that the LNG plant has been designed in accordance with the applicable provisions of the Regulations, including all applicable codes and standards.

• A review of the QA and quality control (QC) programs and procedures of major equipment fabrication, to ensure they reflect all applicable standards referred to in the Regulations. The CA attends at the manufacturing plants for such time at it considers necessary in order to meet the requirements of this section.

• Provision of a report to the UARB describing the work performed and certifying that the fabricated equipment fully meets the requirements of the Act, Regulations, and all applicable codes and standards.

• Monitoring, on both a scheduled and random audit basis, of all plant construction activities including the implementation of field testing programs, and communication of any concerns to the UARB.

• A review of, and provision of advice to the UARB regarding, applications made by project proponents for licenses to operate. The advice can include recommendations regarding terms and conditions which should be attached to the permit.

• Prior to issuance of the UARB's license to operate, certification that the LNG plant has been constructed in accordance with the applicable provisions of the Regulations, including all applicable codes and standards.

• Provision of requested advice, assistance, reports, certifications, or other related work required in relation to abandonment of facilities, including support for any permits or licenses which the UARB may need to issue.

6.3 The United States: Code of Federal Regulations

Crowl and Louvar (2002) describe the United States government process for generating and enacting laws and regulations, as summarized below.

6.3.1 Establishment of Laws

The United States laws are put in force using the following process:

1. A member of congress proposes a bill, which is a document that, if approved, becomes a law, or act.

2. If both houses of congress approve the bill, it is sent to the president, who has approval or veto rights. If approved, it becomes a law.

3. The complete text of the law is published in the US Code (USC), which is the official record of all federal laws.

6.3.2 Establishment of Regulations

Laws do not specify detailed requirements to be complied with. These are provided in regulations, which are generated by organizations so authorized by congress, for example:

• Environmental Protection Agency (EPA).

• Occupational Safety and Health Administration (OSHA).

• Bureau of Ocean Energy Management (BOEM).

• Bureau of Safety and Environmental Enforcement (BSEE).

The process for generating regulations is as follows:

1. The authorized organization or agency decides when a regulation is needed and then researches, develops, and proposes the regulation document. The proposal is listed in the federal register for public evaluation and comment. The comments are used to finalize the regulation.

2. After a regulation is finalized, it is posted to the federal register as a final rule, and it is simultaneously codified by publishing it in the Code of Federal Regulations (CFR).

Many acts and regulations are in force related to chemical process safety. The number of federal laws related to process safety has increased from less than 10 in 1950 to more than 50 today. Two of the more prominent and widely used regulations, both of which were generated in response to the Bhopal chemical accident in 1985, are:

• 29 CFR 1910.119—Process Safety Management.

• 40 CFR 68.65—Risk Management Program.

Some details of these two important chemical process safety documents are offered below.

6.3.3 Content of the PSM Regulations

The PSM regulation, formally titled “Process Safety Management of Highly Hazardous Chemicals,” is comprised of the following 14 sections:

2. Process safety information.

3. Process hazard analysis.

4. Operating procedures.

5. Training.

6. Contractors.

7. Prestartup safety review.

8. Mechanical integrity.

9. Hot work permits.

10. Management of change (MOC).

11. Incident investigation.

12. Emergency planning and response.

13. Audits.

14. Trade secrets.

Details of each section are included in Crowl and Louvar (2002). This regulation is primarily designed to protect personnel inside a process plant. It is noteworthy that within this primarily prescriptive document, many of the elements required by a safety case are specified (process safety information, process hazard analysis, prestartup safety review, incident investigation, emergency planning and response).

There is also significant consistency between the requirements prescribed within many of the regulation's sections and those of most safety cases utilized globally, for example:

• The process hazard analysis is required to be performed by experts, including duly qualified engineers and industrial hygienists. For complex processes, a HAZOP is required, and for less complicated processes, “what if” scenarios, fault trees and failure mode and effects analyses (FMEAs) are utilized.

• The prestartup review is conducted before restarting a facility following modifications or repairs. Elements of the review include design appraisal, confirmation that appropriate safety and emergency procedures are in place, and that suitable training has been conducted.

• A MOC process is required to be developed and effectively implemented. Changes need to be evaluated, particularly with respect to safety, prior to their implementation. Employee training and a prestartup review are both postchange requirements.

6.3.4 Content of the Risk Management Plan

Protection of citizens outside a process plant is provided by the risk management plan. Its primary elements, detailed in Crowl and Louvar (2002), are as follows:

2. Prevention program.

3. Emergency response program.

4. Site-based documentation maintained on site, submitted to federal, state, and local authorities, and shared with the local community.

Again, elements of safety case content are present in these prescriptive requirements (hazard assessment, emergency response program). Some noteworthy comments are as follows:

• Both worst case and more likely scenarios are required to be assessed in the hazard assessment. The use of risk matrices is encouraged in the analysis.

• The prevention program includes many of the same elements as the Process Safety Management Regulations, for example, a prestartup review, MOC process, emergency response, and safety audits.

• The emergency response program includes the requirement to notify local authorities and agencies in the event of an accident. This is similar to notifications processes required by both prescriptive and safety case-based regimes in other countries.

6.3.5 US Offshore Regulation

The US offshore oil and gas industry is overseen by the BSEE. The regime can be generally classified as prescriptive, requiring the issuance of United States Coast Guard (USCG) certificates of compliance and inspection. A classification certificate issued by a recognized classification society can be accepted as partial input to the USCG certificate of compliance.

6.4 The United Kingdom: Safety Case/Verification Regime

6.4.1 The United Kingdom: Health and Safety at Work Act

Under the United Kingdom (UK) legislative process, an Act of Parliament is a law, enforced in all applicable areas of the UK. The Act is approved by a majority in the UK Parliamentary House of Commons and House of Lords, the two separate houses of the UK Parliamentary system, and formally agreed by the UK monarch.

The Health and Safety at Work Act (Act) is the top level UK health and safety legislation (Russell, 2016). This Act places a duty on all employers to ensure, as far as is reasonably practicable, the health, safety and welfare at work of their employees.

6.4.2 Piper Alpha and the Cullen Enquiry

Following the 1988 Piper Alpha disaster, Lord Cullen's UK government-initiated enquiry (described in more detail earlier) rejected prescriptive regulation in favor of a safety case regime for offshore oil and gas installations. This was implemented into legislation in 1992 through the Offshore Installations (Safety Case) Regulations, Statutory Instrument (SI 1992/2885).

The Safety Case Regulations require that specific safety cases and associated safety requirements be defined and established by the duty holder for each offshore oil and gas installation. The safety case has to be accepted by the UK Health and Safety Executive (HSE).

6.4.3 Supporting Regulations

Lord Cullen recommended that the offshore safety case regime should not rely solely on the facility-specific safety cases, and that the Safety Case Regulations should be complemented by other regulations dealing with specific features of offshore safety. This led to the following three additional sets of offshore-specific regulations:

• Prevention of Fire and Explosions, and Emergency Response on Offshore Installations Regulations (PFEER).

• Offshore Installations and Wells (Design and Construction) Regulations (DCR).

• Offshore Installations and Pipeline Works (Management and Administration) Regulations (MAR).

The UK HSE then used the combined requirements of the Offshore Installations (Safety Case) Regulations, PFEER, DCR, and MAR, under the overall UK Health and Safety at Work Act requirements for all employers, “to ensure, so far as is reasonably practicable, the health, safety and welfare at work,” of all UK employees.

6.4.4 Subsequent Amendments

In 2005 the Offshore Installations (Safety Case) (OSCR) Statutory Instruments were finalized, and came into force on April 6, 2006. They replaced and revoked the previous 1992 Regulations along with certain transitional arrangements.

In 2015 the Offshore Installations (Offshore Safety Directive) (Safety Case) Regulations (SCR 2015), Statutory Instruments were finalized and came into force on July 19, 2015. They apply to oil and gas operations in the territorial sea adjacent to Great Britain and any designated area within the UK continental shelf. They replaced the 2005 Offshore Installations (Safety Case) Regulations (SCR 2005) in these waters, subject to certain transitional arrangements.

A change under the 2015 Safety Case Regulations requires that safety cases be submitted for assessment to the competent authority, the Offshore Safety Case Directive Regulator (OSDR).

The 2015 Safety Case Regulations incorporate additional safety-related requirements of certain European Union (EU) Directives together with a requirement to ensure improved incident response mechanisms.

6.4.5 Verification by an Independent Body

The 2015 Safety Case Regulations require that a verification scheme be established by the duty holder. Furthermore, an “independent and competent person” (ICP) is required to be engaged by the duty holder to confirm that the SCEs are suitable and remain in good order. The ICP role is usually fulfilled by one of the classification societies. The independence of the ICP organization is defined in the regulations, paraphrased as follows:

• The ICP scope is not to include examination of something for which the ICP bears or has borne responsibility, or where the ICP's objectivity may be compromised.

• The ICP is required to be sufficiently independent of a management system which has, or has had, any responsibility for any aspect of something liable to be examined by the ICP, so as to ensure objectivity in carrying out the ICP function under the scheme.

Some activities of a classification society acting as an ICP are also suggested in the regulations, as below:

• Examination, including testing where appropriate, of the SCEs.

• Examination of any design, specification, certificate, marking, or standard relating to the SCEs.

• Examination of work in progress.

• The creation of reports covering the examination and testing carried out, findings, and any remedial action recommended.

• The documentation of appropriate action by the duty holder following a report.

• The reporting to the duty holder of any instances of noncompliance with the scheme's standards.

6.5 Australia: Safety Case Validation/Verification Regime

6.5.1 Offshore/Onshore/Pipelines Regulatory Summary

Onshore and offshore regulatory regimes in Australia are similar, relying on goal setting and safety cases and their associated SCEs and PSs. In addition to the management of major accidents, risk-based regulation in Australia also includes occupational accident management, which is somewhat unusual. Australian guidance on safety case generation recognizes the benefits of both qualitative and quantitative approaches to risk management.

All offshore facilities and pipelines within Australian commonwealth waters fall under The Offshore Petroleum Act (OPA). This act is administered by the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA).

Supporting this act are the Offshore Petroleum and Greenhouse Gas Storage (Safety) Regulations which set out the requirements for the contents of safety cases and general requirements for Validation and Verification. Further applicable regulations are as follows:

• Petroleum (Submerged Lands) (Occupational Safety and Health) Regulations.

• Petroleum (Submerged Lands) (Management of Safety on Offshore facilities) Regulations.

• Petroleum (Submerged Lands) (Management of Well Operations) Regulations.

• Petroleum (Submerged Lands) (Pipelines) Regulations.

• Petroleum (Submerged Lands) (Diving Safety) Regulations.

Onshore activities are regulated by the Resources Safety Department of the Western Australian Department of Mines and Petroleum (DMP). The overarching act is the Petroleum and Geothermal Energy Resources Act. The governing regulations, which have very similar requirements to their offshore counterparts, are as follows:

• Petroleum and Geothermal Energy Resources (Occupational Safety and Health) Regulations.

• Petroleum and Geothermal Energy Resources (Management of Safety) Regulations.

Pipelines (onshore and offshore) fall under the Petroleum Pipelines Act. The governing regulations are:

• Petroleum Pipelines (Management of Safety of Pipeline Operations) Regulations.

• Petroleum Pipelines (Occupational Safety and Health) Regulations.

Since the onshore and offshore regulatory regimes are similar, the remaining discussion in this section will specifically describe the offshore requirements. The distinctive element of the Australian regime is the differentiation between Validation and Verification, which, in other regimes, are jointly known as Verification. The differences will be described in detail below.

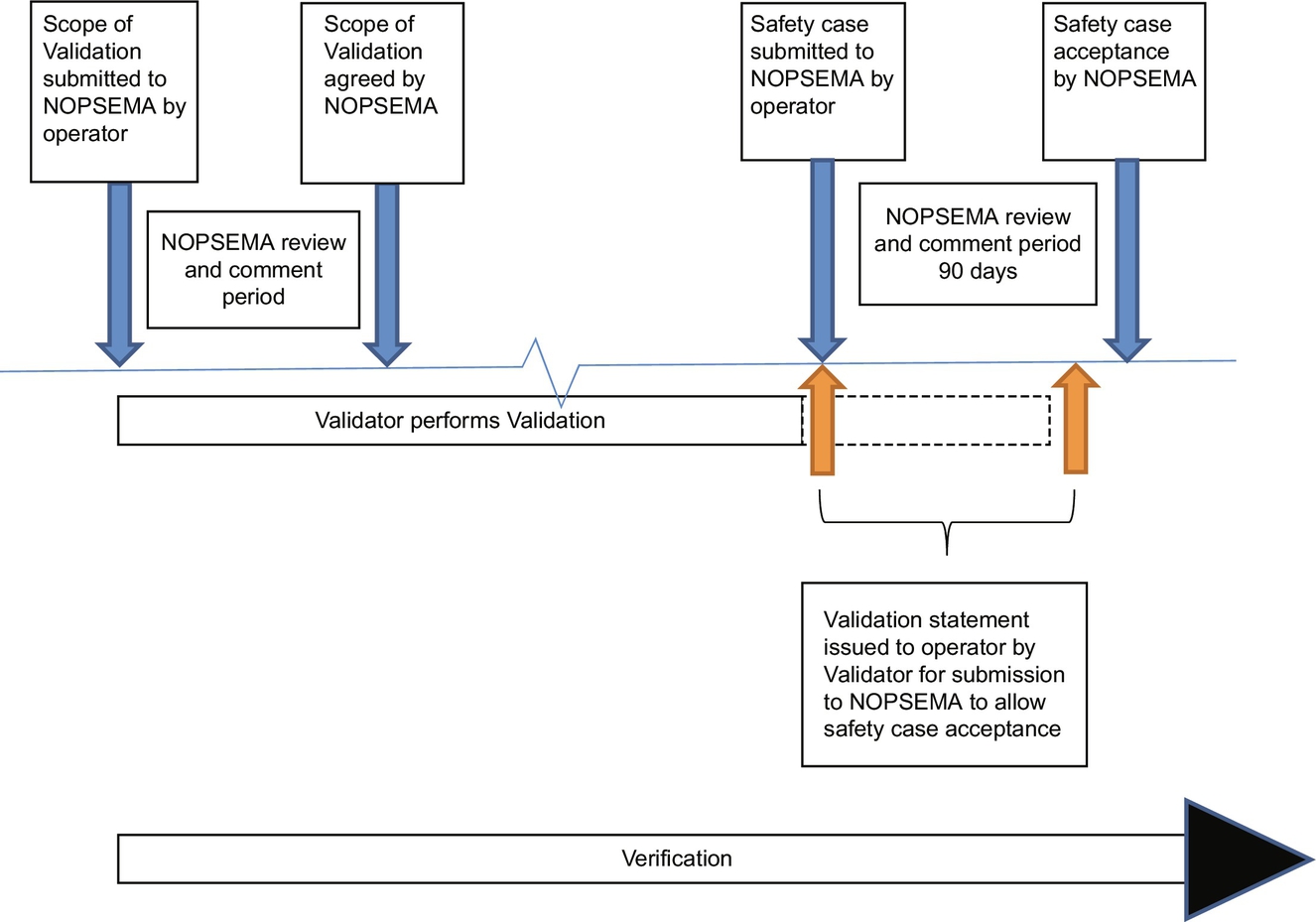

6.5.2 Steps in the Validation Process

The steps whereby NOPSEMA approval is achieved are as follows:

1. NOPSEMA requests Validation for new facilities and significant modifications.

2. NOPSEMA and the operator reach agreement on the Scope of Validation (SoV), specifically which SCEs are required to be Validated and against which codes and standards.

3. The SoV is agreed by NOPSEMA in writing and Validation commences.

4. The operator submits the facility safety case.

5. Safety case assessment is underway (including formal comment from NOPSEMA).

6. Validation is finalized and a “clean” statement delivered.

7. Final safety case decision making is delivered.

Verification is a separate process which applies throughout, in parallel with and continuing after Validation.

6.5.3 The Validation and Verification Processes

The separation of Validation and Verification is unique to Australian safety regulation. The Australian versions of the two activities are generally captured under the term Verification in other regimes.

Validation, as applied in Australia, is a documentation review exercise that can, in theory, be completed before or by the early stages of construction, provided sufficient documentation on the design, construction, and installation of the SCEs has been made available to the Validator and all comments resolved.

Verification requires a physical check to ensure that safety critical equipment has been installed correctly and is fit for its function and use. Verification is a survey process, including routine surveillance, witness and hold points, and attendance at final factory and site acceptance tests.

Safety case regulations detail Verification requirements that must be addressed in the safety case. NOPSEMA require that Validation can be documented as a separate assurance process, provided by the regulations and tied to safety case decision making.

More details describing the two processes are as follows.

6.5.3.1 Validation

Validation is a process undertaken by an independent competent party, known as the Validator, which is required to be separate from the duty holder. The process is meant to ensure that the design, construction, and installation of the facility's SCEs will incorporate appropriate measures to protect the health and safety of personnel. Validation activities related to construction and installation are limited to a review of related documentation (e.g., inspection and test plans and welding instructions) and do not include physical survey of equipment.

Validation is required for an operator to obtain safety case acceptance. The operator produces a SoV and obtains NOPSEMA approval. A Validator then performs Validation in accordance with the approved SoV and issues a Validation statement. The statement allows NOPSEMA to be assured that the design, construction, and installation of safety critical systems will incorporate measures that protect the health and safety of persons to the extent required by the SoV, provided the agreed codes and standards are implemented as specified in the documentation reviewed by the Validator. Validation of design, construction, and installation can be defined as follows:

• Validation of design is the review of design documentation against nominated codes and standards in order to form a view about the appropriateness of the standards for the SCEs and to confirm that they are consistent with the safety case.

• Validation of construction and installation are reviews of documentation to ensure that the intent of the design is specified to be carried forward into actual facility build. Typically, this would include construction and installation specifications such as piping or structural fabrication specifications, procedures such as anchor pile installation procedures, and inspection and test plans. Again, the codes and standards must be appropriate and consistent with the safety case.

Since it relies upon forward-looking project documentation, it is possible for Validation to be completed before construction is complete and prior to installation.

The scheduling and relationships between the SoV, the Validation and safety case acceptance are illustrated in Fig. 6.

6.5.3.2 Verification

NOPSEMA require that Verification is documented as a separate and distinct process from Validation and generally should be addressed within the safety case for the facility rather than documented in combination with Validation. Fig. 6 shows that Verification can take place along an independent timeline from Validation, at the discretion of the duty holder.

Verification is not required in relation to the acceptance of a safety case but is a requirement within the safety case. The safety case will contain a commitment from the operator that a suitable verification process has been performed. Verification is the determination that “the SCEs have been designed, constructed, installed, tested, and commissioned in accordance with the nominated codes and standards.” It is the physical survey of the facility's onshore procurement, construction, testing and precommissioning and offshore installation, testing, and final commissioning.

6.6 Denmark Offshore

Energy supply administration in Denmark is the responsibility of the Danish Energy Agency (DEA), which is part of the Ministry of Energy, Utilities, and Climate (Ens.dk (2016)). The Minister grants licenses to produce oil and gas when all legislation has been complied with. The overarching legislation is the Danish Subsoil Act together with its accompanying executive orders, guidelines, etc. Safety of offshore installations is regulated by the Offshore Safety Act (Act). The regime can be considered to be primarily prescriptive, in that the requirements of the Act must be complied with. However, many of the Act's requirements are similar to those defined within operator-generated safety cases utilized in other regimes. This section describes the Danish offshore safety regime only.

6.6.1 Definitions and Requirements Included in the Offshore Safety Act

The purposes of the Offshore Safety Act are “to promote a high level of health and safety offshore which is in accordance with technical and social developments in society” and “to create a framework that allows enterprises themselves to address health and safety issues offshore.” The latter is consistent with the “operator is completely responsible” fundamental philosophy utilized in fully goal setting/safety case regimes. Several key definitions and requirements of the Act, which are similar to those seen in operator-defined safety cases, are as follows:

Definitions

• “Emergency response plan” is a document. A plan is required to be prepared and submitted and must have a strategy to prevent escalation and/or limit the consequences of a major accident.

• “Risk” is defined as the product of the probability of occurrence of an event and its consequences.

• “Safety critical elements” are defined as “parts of an installation, equipment, or components, including computer programs, the purpose of which is to prevent or limit the consequences of a major accident, or the failure of which could cause or contribute substantially to a major accident.”

• “Major accidents” are defined as either of three types of incidents:

– Incidents involving explosions, fires, loss of well control, or release of oil, gas, or dangerous substances or materials with potential to cause fatalities or serious personal injury.

– Incidents leading to serious damage to the facility and having the potential to cause fatalities or serious personal injury.

– Any other incident having the potential to cause fatalities or serious injury to five or more persons.

It is noteworthy that the definitions include details of the types of incidents, make reference to facility damage, and even specify the number of persons to be seriously injured. In regimes considered to be totally goal setting in nature, the operator would be responsible for defining such things.

Requirements

• A “safety and health document” is required to be submitted by the owner. The document is required to contain or comply with many of the same elements included in operator-generated safety cases in goal setting regimes. Examples are:

– Identification and assessment of safety risks.

– Demonstration that the risks have been reduced to a level ALARP.

– Provision of efficient and controlled methods for safe escape, evacuation, and rescue of all persons on board during emergency situations.

– Documentation that the management system ensures compliance with all of the Act's and Regulations’ requirements.