10. Catalysis and Catalytic Reactors

It isn’t that they can’t see the solution. It is that they can’t see the problem.

—G. K. Chesterton

10.1 Catalysts

Catalysts have been used by humankind for over 2000 years.1 The first observed uses of catalysts were in the making of wine, cheese, and bread. It was found that it was always necessary to add small amounts of the previous batch to make the current batch. However, it wasn’t until 1835 that Berzelius began to tie together observations of earlier chemists by suggesting that small amounts of a foreign substance could greatly affect the course of chemical reactions. This mysterious force attributed to the substance was called catalytic. In 1894, Ostwald expanded Berzelius’s explanation by stating that catalysts were substances that accelerate the rate of chemical reactions without being consumed during the reaction. During the 180 years since Berzelius’s work, catalysts have come to play a major economic role in the world market. In the United States alone, sales of process catalysts will reach over $20 billion by 2018, the major uses being in petroleum refining and in chemical production.

1 S. T. Oyama and G. A. Somorjai, J. Chem. Educ., 65, 765 (1986).

10.1.1 Definitions

A catalyst is a substance that affects the rate of a reaction but emerges from the process unchanged. A catalyst usually changes a reaction rate by promoting a different molecular path (“mechanism”) for the reaction. For example, gaseous hydrogen and oxygen are virtually inert at room temperature, but react rapidly when exposed to platinum. The reaction coordinate (cf. Chapter 3) shown in Figure 10-1 is a measure of the progress along the reaction path as H2 and O2 approach each other and pass over the activation energy barrier to form H2O. Catalysis is the occurrence, study, and use of catalysts and catalytic processes. Commercial chemical catalysts are immensely important. Approximately one-third of the material gross national product of the United States involves a catalytic process somewhere between raw material and finished product.2 The development and use of catalysts is a major part of the constant search for new ways of increasing product yield and selectivity from chemical reactions. Because a catalyst makes it possible to obtain an end product by a different pathway with a lower energy barrier, it can affect both the yield and the selectivity.

2 V. Haensel and R. L. Burwell, Jr., Sci. Am., 225(10), 46.

Catalysts can accelerate the reaction rate but cannot change the equilibrium.

Normally when we talk about a catalyst, we mean one that speeds up a reaction, although strictly speaking, a catalyst can either accelerate or slow the formation of a particular product species. A catalyst changes only the rate of a reaction; it does not affect the equilibrium.

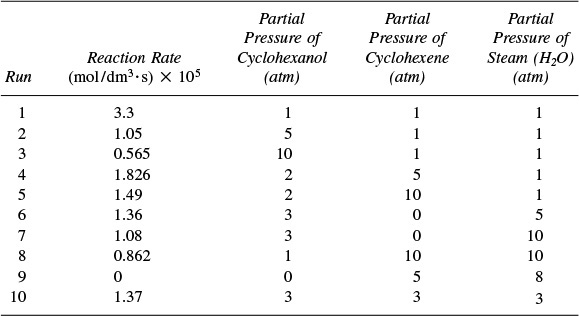

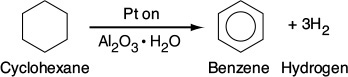

The 2007 Nobel Prize for Chemistry was awarded to Gerhard Ertl for his pioneering work on heterogeneous catalytic reactions. A heterogeneous catalytic reaction involves more than one phase; usually the catalyst is a solid and the reactants and products are in liquid or gaseous form. One example is the production of benzene, which is mostly manufactured today from the dehydrogenation of cyclohexane (obtained from the distillation of petroleum crude oil) using platinum-on-alumina as the catalyst:

The simple and complete separation of the fluid product mixture from the solid catalyst makes heterogeneous catalysis economically attractive, especially because many catalysts are quite valuable and their reuse is demanded.

A heterogeneous catalytic reaction occurs at or very near the fluid–solid interface. The principles that govern heterogeneous catalytic reactions can be applied to both catalytic and noncatalytic fluid–solid reactions. The two other types of heterogeneous reactions involve gas–liquid and gas–liquid–solid systems. Reactions between gases and liquids are usually mass-transfer limited.

Ten grams of this catalyst possess more surface area than a U.S. football field

Catalyst types:

• Porous

• Molecular sieves

• Monolithic

• Supported

• Unsupported

Typical zeolite catalyst

High selectivity to para-xylene

10.1.2 Catalyst Properties

Because a catalytic reaction occurs at the fluid–solid interface, a large interfacial area is almost always essential in attaining a significant reaction rate. In many catalysts, this area is provided by an inner porous structure (i.e., the solid contains many fine pores, and the surface of these pores supplies the area needed for the high rate of reaction), see Figures 10-4(b) and 10-9. The area possessed by some porous catalysis materials is surprisingly large. A typical silica-alumina cracking catalyst has a pore volume of 0.6 cm3/g and an average pore radius of 4 nm. The corresponding surface area is 300 m2/g of these porous catalysts. Examples include the Raney nickel used in the hydrogenation of vegetable and animal oils, platinum-on-alumina used in the reforming of petroleum naphthas to obtain higher octane ratings, and promoted iron used in ammonia synthesis. Sometimes pores are so small that they will admit small molecules but prevent large ones from entering. Materials with this type of pore are called molecular sieves, and they may be derived from natural substances such as certain clays and zeolites, or they may be totally synthetic, such as some crystalline aluminosilicates (see Figure 10-2). These sieves can form the basis for quite selective catalysts; the pores can control the residence time of various molecules near the catalytically active surface to a degree that essentially allows only the desired molecules to react. One example of the high selectivity of zeolite catalysts is the formation of para-xylene from toluene and methane shown in Figure 10-2(b).3 Here, benzene and toluene enter through the zeolite pore and react on the interior surface to form a mixture of ortho-, meta-, and para-xylenes. However, the size of the pore mouth is such that only para-xylene can exit through the pore mouth, as meta- and orthoxylene with their methyl group on the side cannot fit through the pore mouth. There are interior sites that can isomerize ortho-xylene and meta-xylene to para-xylene. Hence, we have a very high selectivity to form para-xylene.

3 R. I. Masel, Chemical Kinetics and Catalysis (New York: Wiley Interscience, 2001), p. 741.

Figure 10-2 (a) Framework structures and (b) pore cross sections of two types of zeolites. (a) Faujasite-type zeolite has a three-dimensional channel system with pores at least 7.4 Å in diameter. A pore is formed by 12 oxygen atoms in a ring. (b) Schematic of reaction CH4 and C6H5CH3. (Note that the size of the pore mouth and the interior of the zeolite are not to scale.) [(a) from N. Y. Chen and T. F. Degnan, Chem. Eng. Prog., 84(2), 33 (1988). Reproduced by permission of the American Institute of Chemical Engineers. Copyright © 1988 AIChE. All rights reserved.]

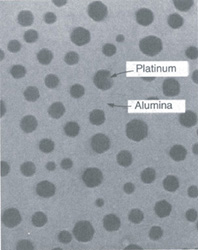

In some cases a catalyst consists of minute particles of an active material dispersed over a less-active substance called a support. The active material is frequently a pure metal or metal alloy. Such catalysts are called supported catalysts, as distinguished from unsupported catalysts. Catalysts can also have small amounts of active ingredients added called promoters, which increase their activity. Examples of supported catalysts are the packed-bed catalytic converter in an automobile, the platinum-on-alumina catalyst used in petroleum reforming, and the vanadium pentoxide on silica used to oxidize sulfur dioxide in manufacturing sulfuric acid. On the other hand, platinum gauze for ammonia oxidation, promoted iron for ammonia synthesis, and the silica–alumina dehydrogenation catalyst used in butadiene manufacture typify unsupported catalysts.

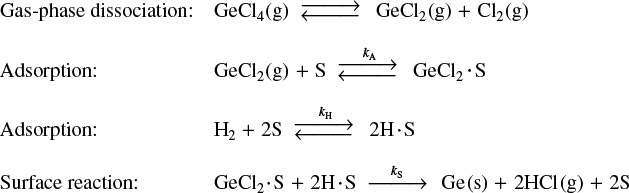

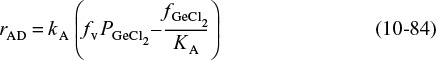

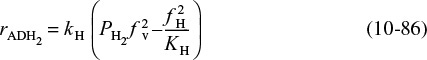

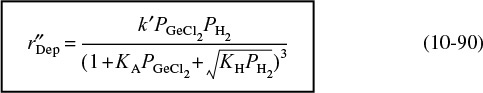

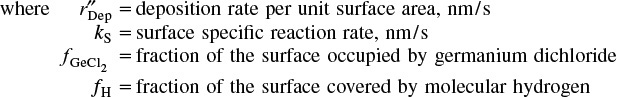

10.1.3 Catalytic Gas-Solid Interactions

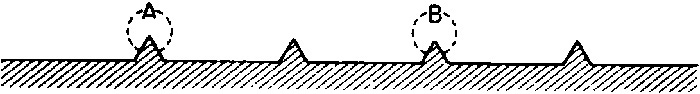

For the moment, let us focus our attention on gas-phase reactions catalyzed by solid surfaces. For a catalytic reaction to occur, at least one and frequently all of the reactants must become attached to the surface. This attachment is known as adsorption and takes place by two different processes: physical adsorption and chemisorption. Physical adsorption is similar to condensation. The process is exothermic, and the heat of adsorption is relatively small, being on the order of 1 to 15 kcal/mol. The forces of attraction between the gas molecules and the solid surface are weak. These van der Waals forces consist of interaction between permanent dipoles, between a permanent dipole and an induced dipole, and/or between neutral atoms and molecules. The amount of gas physically adsorbed decreases rapidly with increasing temperature, and above its critical temperature only very small amounts of a substance are physically adsorbed.

The type of adsorption that affects the rate of a chemical reaction is chemisorption. Here, the adsorbed atoms or molecules are held to the surface by valence forces of the same type as those that occur between bonded atoms in molecules. As a result, the electronic structure of the chemisorbed molecule is perturbed significantly, causing it to be extremely reactive. Interaction with the catalyst causes bonds of the adsorbed reactant to be stretched, making them easier to break.

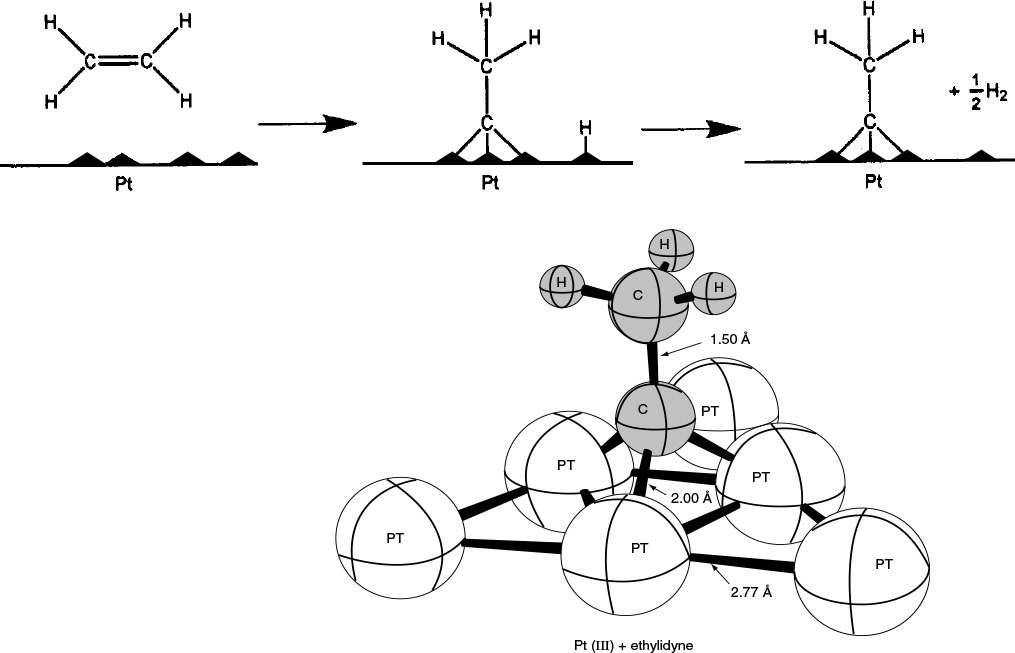

Figure 10-3 Ethylidyne chemisorbed on platinum. (Adapted from G. A. Somorjai, Introduction to Surface Chemistry and Catalysis. © 1994 John Wiley & Sons, Inc. Reprinted by permission of John Wiley & Sons, Inc. All rights reserved.)

Figure 10-3 shows the bonding from the adsorption of ethylene on a platinum surface to form chemisorbed ethylidyne. Like physical adsorption, chemisorption is an exothermic process, but the heats of adsorption are generally of the same magnitude as the heat of a chemical reaction (i.e., 40 to 400 kJ/mol). If a catalytic reaction involves chemisorption, it must be carried out within the temperature range where chemisorption of the reactants is appreciable.

In a landmark contribution to catalytic theory, Taylor suggested that a reaction is not catalyzed over the entire solid surface but only at certain active sites or centers.4 He visualized these sites as unsaturated atoms in the solids that resulted from surface irregularities, dislocations, edges of crystals, and cracks along grain boundaries. Other investigators have taken exception to this definition, pointing out that other properties of the solid surface are also important. The active sites can also be thought of as places where highly reactive intermediates (i.e., chemisorbed species) are stabilized long enough to react. This stabilization of a reactive intermediate is key in the design of any catalyst. Consequently, for our purposes we will define an active site as a point on the catalyst surface that can form strong chemical bonds with an adsorbed atom or molecule.

4 H. S. Taylor, Proc. R. Soc. London, A108, 105 (1928).

Chemisorption on active sites is what catalyzes the reaction.

One parameter used to quantify the activity of a catalyst is the turnover frequency (TOF), f. It is the number of molecules reacting per active site per second at the conditions of the experiment. When a metal catalyst such as platinum is deposited on a support, the metal atoms are considered active sites. The TOFs for a number of reactions are shown in Professional Reference Shelf R10.1. The dispersion, D, of the catalyst is the fraction of the metal atoms deposited on a catalyst that are on the surface.

10.1.4 Classification of Catalysts

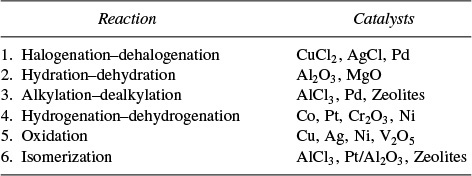

One common way to classify catalysts is in terms of the type of reaction they catalyze.

Table 10-1 gives a list of representative reactions and their corresponding catalysts. Further discussion of each of these reaction classes and the materials that catalyze them can be found on the CRE Web site’s Professional Reference Shelf R10.1.

If, for example, we were to form styrene from an equimolar mixture of ethylene and benzene, we could first carry out an alkylation reaction to form ethyl benzene, which is then dehydrogenated to form styrene. We need both an alkylation catalyst and a dehydrogenation catalyst:

10.2 Steps in a Catalytic Reaction

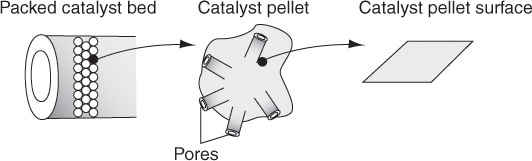

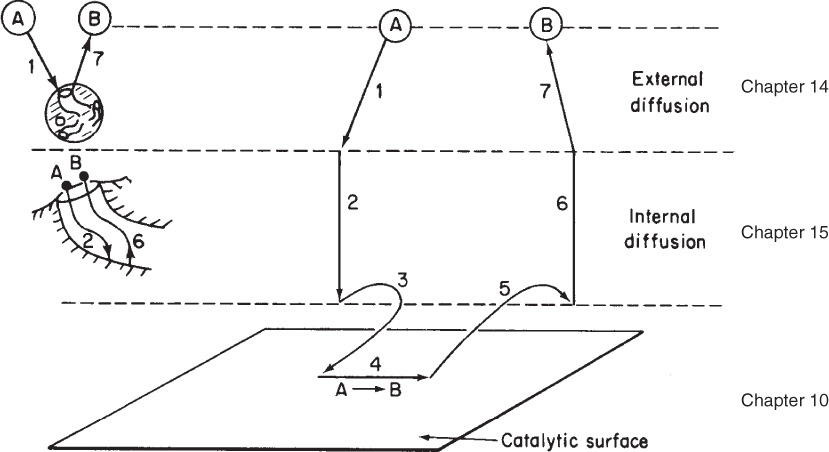

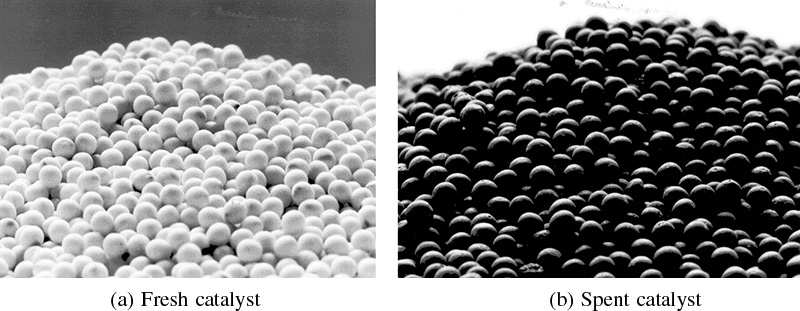

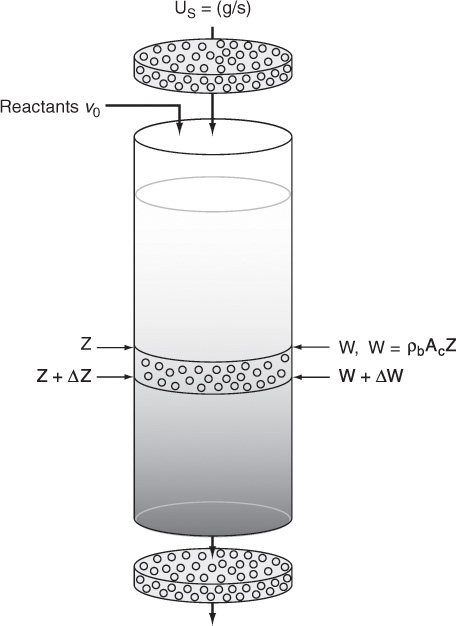

A photograph of different types and sizes of catalysts is shown in Figure 10-4a. A schematic diagram of a tubular reactor packed with catalytic pellets is shown in Figure 10-4b. The overall process by which heterogeneous catalytic reactions proceed can be broken down into the sequence of individual steps shown in Table 10-2 and pictured in Figure 10-5 for an isomerization reaction.

Figure 10-4a Catalyst particles of different shapes (spheres, cylinders) and sizes (0.1 cm to 1 cm). (Photo courtesy of the Engelhard Corporation.)

Each step in Table 10-2 is shown schematically in Figure 10-5.

A reaction takes place on the surface, but the species involved in the reaction must get to and from the surface.

The overall rate of reaction is limited by the rate of the slowest step in the sequence. When the diffusion steps (1, 2, 6, and 7 in Table 10-2) are very fast compared with the surface reaction-rate steps (3, 4, and 5), the concentrations in the immediate vicinity of the active sites are indistinguishable from those in the bulk fluid. In this situation, the transport or diffusion steps do not affect the overall rate of the reaction. In other situations, if the reaction steps are very fast compared with the diffusion steps, mass transport does affect the reaction rate. In systems where diffusion from the bulk gas or liquid to the external catalyst surface or to the mouths of catalyst pores affects the rate, i.e., steps 1 and 7, changing the flow conditions past the catalyst should change the overall reaction rate (see Chapter 14). Once inside the porous catalysts, on the other hand, diffusion within the catalyst pores, i.e., steps 2 and 6, may limit the rate of reaction and, as a result, the overall rate will be unaffected by external flow conditions even though diffusion affects the overall reaction rate (see Chapter 15).

1. Mass transfer (diffusion) of the reactant(s) (e.g., species A) from the bulk fluid to the external surface of the catalyst pellet

2. Diffusion of the reactant from the pore mouth through the catalyst pores to the immediate vicinity of the internal catalytic surface

3. Adsorption of reactant A onto the catalyst surface

4. Reaction on the surface of the catalyst (e.g., ![]() )

)

5. Desorption of the products (e.g., B) from the surface

6. Diffusion of the products from the interior of the pellet to the pore mouth at the external surface

7. Mass transfer of the products from the external pellet surface to the bulk fluid

TABLE 10-2 STEPS IN A CATALYTIC REACTION

There are many variations of the situation described in Table 10-2. Sometimes, of course, two reactants are necessary for a reaction to occur, and both of these may undergo the steps listed above. Other reactions between two substances may have only one of them adsorbed.

In this chapter we focus on:

3. Adsorption

4. Surface reaction

5. Desorption

With this introduction, we are ready to treat individually the steps involved in catalytic reactions. In this chapter, only steps 3, 4, and 5—i.e., adsorption, surface reaction, and desorption—are considered as we assume that the diffusion steps (1, 2, 6, and 7) are very fast so that the overall reaction rate is not affected by mass transfer in any fashion. Further treatment of the effects involving diffusion limitations is provided in Chapters 14 and 15.

Where Are We Heading?† As we saw in Chapter 7, one of the tasks of a chemical reaction engineer is to analyze rate data and to develop a rate law that can be used in reactor design. Rate laws in heterogeneous catalysis seldom follow power-law models and hence are inherently more difficult to formulate from the data. To develop an in-depth understanding and insight as to how the rate laws are formed from heterogeneous catalytic data, we are going to proceed in somewhat of a reverse manner than what is normally done in industry when one is asked to develop a rate law. That is, we will postulate catalytic mechanisms and then derive rate laws for the various mechanisms. The mechanism will typically have an adsorption step, a surface reaction step, and a desorption step, one of which is usually rate-limiting. Suggesting mechanisms and rate-limiting steps is not the first thing we normally do when presented with data. However, by deriving equations for different mechanisms, we will observe the various forms of the rate law one can have in heterogeneous catalysis. Knowing the different forms that catalytic rate equations can take, it will be easier to view the trends in the data and deduce the appropriate rate law. This deduction is usually what is done first in industry before a mechanism is proposed. Knowing the form of the rate law, one can then numerically evaluate the rate-law parameters and postulate a reaction mechanism and rate-limiting step that are consistent with the rate data. Finally, we use the rate law to design catalytic reactors. This procedure is shown in Figure 10-6. The dashed lines represent feedback to obtain new data in specific regions (e.g., concentrations, temperature) to evaluate the rate-law parameters more precisely or to differentiate between reaction mechanisms.

† “If you don’t know where you are going, you’ll probably wind up someplace else.” Yogi Berra

An algorithm

We will discuss each of the steps shown in Figure 10-5 and Table 10-2. As mentioned earlier, this chapter focuses on Steps 3, 4, and 5 (the adsorption, surface reaction and desorption steps) by assuming that Steps 1, 2, 6, and 7 are very rapid. Consequently, to understand when this assumption is valid, we shall give a quick overview of Steps 1, 2, 6, and 7. These steps involve diffusion of the reactants to and within the catalyst pellet. While these diffusion steps are covered in detail in Chapters 14 and 15, it is worthwhile to give a brief description of these two mass-transfer steps to better understand the entire sequence of steps. If you have had the core course in Mass Transfer or Transport Phenomena you can skip Sections 10.2.1 and 10.2.2, and go directly to Section 10.2.3.

Chance Card: Do not pass go proceed directly to Section 10.2.3.

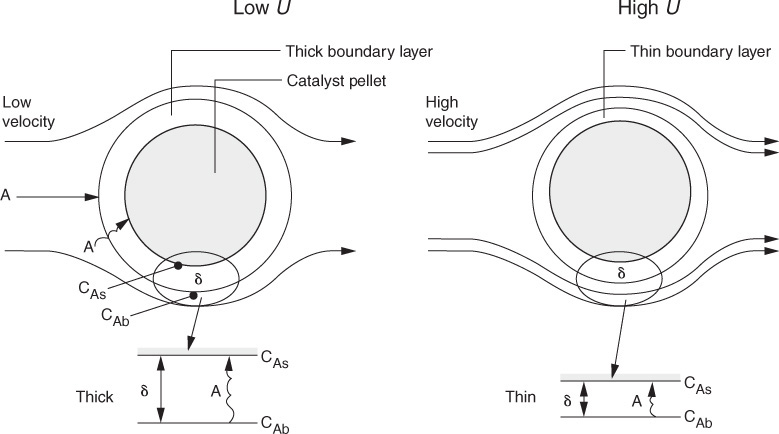

10.2.1 Step 1 Overview: Diffusion from the Bulk to the External Surface of the Catalyst

For the moment let’s assume that the transport of A from the bulk fluid to the external surface of the catalyst is the slowest step in the sequence. We lump all the resistance to transfer from the bulk fluid to the surface in the mass-transfer boundary layer surrounding the pellet. In this step the reactant A, which is at a bulk concentration CAb must travel (diffuse) through the boundary layer of thickness δ to the external surface of the pellet where the concentration is CAs, as shown in Figure 10-7. The rate of transfer (and hence rate of reaction, ![]() ) for this slowest step is

) for this slowest step is

Rate = kC (CAb – CAs)

External and internal mass transfer in catalysis are covered in detail in Chapters 14 and 15.

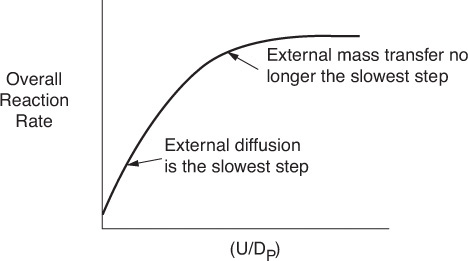

where the mass-transfer coefficient, kC, is a function of the hydrodynamic conditions, namely the fluid velocity, U, and the particle diameter, Dp.

Figure 10-7 Diffusion through the external boundary layer (also see Figure 14-3).

External mass transfer

“The thick and thin of it.”

As we see (Chapter 14), the mass-transfer coefficient is inversely proportional to the boundary layer thickness, δ, and directly proportional to the diffusion coefficient (i.e., the diffusivity DAB).

At low velocities of fluid flow over the pellet, the boundary layer across which A and B must diffuse is thick, and it takes a long time for A to travel to the surface, resulting in a small mass-transfer coefficient kC. As a result, mass transfer across the boundary layer is slow and limits the rate of the overall reaction. As the velocity over the pellet is increased, the boundary layer becomes thinner and the mass-transfer rate is increased. At very high velocities, the boundary layer thickness, δ, is so small it no longer offers any resistance to the diffusion across the boundary layer. As a result, external mass transfer no longer limits the rate of reaction. This external resistance also decreases as the particle size is decreased. As the fluid velocity increases and/or the particle diameter decreases, the mass-transfer coefficient increases until a plateau is reached, as shown in Figure 10-8. On this plateau, CAb ≈ CAs, and one of the other steps in the sequence, i.e., Steps 2 through 6, is the slowest step and limits the overall reaction rate. Further details on external mass transfer are discussed in Chapter 14.

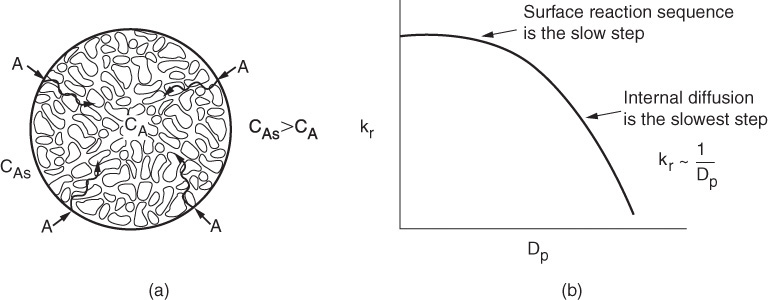

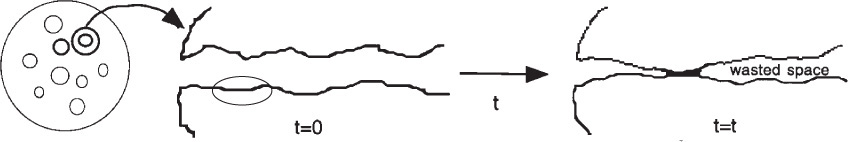

10.2.2 Step 2 Overview: Internal Diffusion

Now consider that we are operating at a fluid velocity where external diffusion is no longer the rate-limiting step and that internal diffusion is the slowest step. In Step 2 the reactant A diffuses from the external pellet surface at a concentration CAs into the pellet interior, where the concentration is CA. As A diffuses into the interior of the pellet, it reacts with catalyst deposited on the sides of the catalyst pellet’s pore walls.

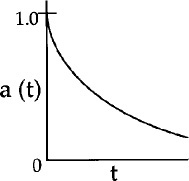

For large pellets, it takes a long time for the reactant A to diffuse into the interior, compared to the time that it takes for the reaction to occur on the interior pore surface. Under these circumstances, the reactant is only consumed near the exterior surface of the pellet and the catalyst near the center of the pellet is wasted catalyst. On the other hand, for very small pellets it takes very little time to diffuse into and out of the pellet interior and, as a result, internal diffusion no longer limits the rate of reaction. When internal mass transfer no longer limits the rate of reaction, the rate law can be expressed as

Rate = kr CAs

where CAs is the concentration at the external pellet surface and kr is an overall rate constant, which is a function of particle size. The overall rate constant, kr, increases as the pellet diameter decreases. In Chapter 15, we show that Figure 15-5 can be combined with Equation (15-34) to arrive at the plot of kr as a function of DP, shown in Figure 10-9(b).

We see in Figure 10-9 that at small particle sizes, internal diffusion is no longer the slow step and that the surface reaction sequence of adsorption, surface reaction, and desorption (Steps 3, 4, and 5 in Figure 10-5) limit the overall rate of reaction. Consider now one more important point about internal diffusion and surface reaction. These steps (2 through 6) are not at all affected by flow conditions external to the pellet.

Figure 10-9 Effect of particle size on the overall reaction-rate constant. (a) Branching of a single pore with deposited metal; (b) decrease in rate constant with increasing particle diameter. (See the CRE Web site, Chapter 12.)

Internal mass transfer

In the material that follows, we are going to choose our pellet size and external fluid velocity such that neither external diffusion nor internal diffusion is limiting as discussed in Chapters 14 and 15. Instead, we assume that either Step 3 (adsorption), Step 4 (surface reaction), or Step 5 (desorption), or a combination of these steps, limits the overall rate of reaction.

10.2.3 Adsorption Isotherms

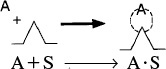

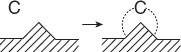

Because chemisorption is usually a necessary part of a catalytic process, we shall discuss it before treating catalytic reaction rates. The letter S will represent an active site; alone, it will denote a vacant site, with no atom, molecule, or complex adsorbed on it. The combination of S with another letter (e.g., A ·S) will mean that one unit of species A will be chemically adsorbed on the site S. Species A can be an atom, molecule, or some other atomic combination, depending on the circumstances. Consequently, the adsorption of A on a site S is represented by

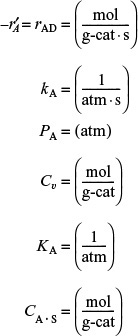

The total molar concentration of active sites per unit mass of catalyst is equal to the number of active sites per unit mass divided by Avogadro’s number and will be labeled Ct (mol/g-cat). The molar concentration of vacant sites, Cv (mol/g-cat), is the number of vacant sites per unit mass of catalyst divided by Avogadro’s number. In the absence of catalyst deactivation, we assume that the total concentration of active sites, Ct, remains constant. Some further definitions include

Pi = partial pressure of species i in the gas phase, (atm or kPa)

Ci·S = surface concentration of sites occupied by species i, (mol/g-cat)

A conceptual model depicting species A and B adsorbed on two different sites is shown in Figure 10-10.

For the system shown in Figure 10-10, the total concentration of sites is

Site balance

This equation is referred to as a site balance. A typical value for the total concentration of sites could be the order of 1022 sites/g-cat.

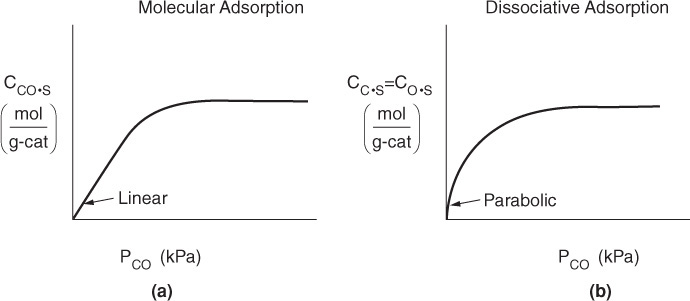

Now consider the adsorption of a nonreacting gas onto the surface of a catalyst. Adsorption data are frequently reported in the form of adsorption isotherms. Isotherms portray the amount of a gas adsorbed on a solid at different pressures at a given temperature.

Postulate models; then see which one(s) fit(s) the data.

First, an adsorption mechanism is proposed, and then the isotherm (see Figure 10-11, page 413) obtained from the mechanism is compared with the experimental data. If the isotherm predicted by the model agrees with the experimental data, the model may reasonably describe what is occurring physically in the real system. If the predicted curve does not agree with the experimental data, the model fails to match the physical situation in at least one important characteristic and perhaps more.

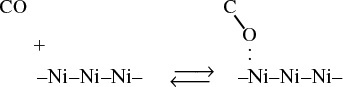

We will consider two types of adsorption: molecular adsorption and dissociative adsorption. To illustrate the difference between molecular adsorption and dissociative adsorption, we will postulate two models for the adsorption of carbon monoxide on metal surfaces. In the molecular adsorption model, CO is adsorbed as molecules, CO,

as is the case on nickel

Two models:

1. Adsorption as CO

2. Adsorption as C and O

In the dissociative adsorption model, carbon monoxide is adsorbed as oxygen and carbon atoms instead of molecular CO

as is the case on iron5

5 R. I. Masel, Principles of Adsorption and Reaction on Solid Surfaces (New York: Wiley, 1996).

The former is called molecular or nondissociated adsorption (e.g., CO) and the latter is called dissociative adsorption (e.g., C and O). Whether a molecule adsorbs nondissociatively or dissociatively depends on the surface.

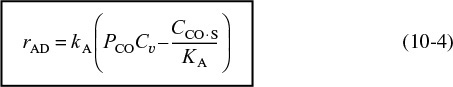

The adsorption of carbon monoxide molecules will be considered first. Because the carbon monoxide does not react further after being adsorbed, we need only to consider the adsorption process:

Molecular Adsorption

In obtaining a rate law for the rate of adsorption, the reaction in Equation (10-2) can be treated as an elementary reaction. The rate of attachment of the carbon monoxide molecules to the active site on the surface is proportional to the number of collisions that these molecules make with a surface active site per second. In other words, a specific fraction of the molecules that strike the surface become adsorbed. The collision rate is, in turn, directly proportional to the carbon monoxide partial pressure, PCO. Because carbon monoxide molecules adsorb only on vacant sites and not on sites already occupied by other carbon monoxide molecules, the rate of attachment is also directly proportional to the concentration of vacant sites, Cv. Combining these two facts means that the rate of attachment of carbon monoxide molecules to the surface is directly proportional to the product of the partial pressure of CO and the concentration of vacant sites; that is,

Rate of attachment = kAPCOCv

The rate of detachment of molecules from the surface can be a first-order process; that is, the detachment of carbon monoxide molecules from the surface is usually directly proportional to the concentration of sites occupied by the adsorbed molecules (e.g., CCO ·S):

Rate of detachment = k–ACCO·S

The net rate of adsorption is equal to the rate of molecular attachment to the surface minus the rate of detachment from the surface. If kA and k–A are the constants of proportionality for the attachment and detachment processes, then

The ratio KA = kA/k–A is the adsorption equilibrium constant. Using KA to rearrange Equation (10-3) gives

Adsorption

The adsorption rate constant, kA, for molecular adsorption is virtually independent of temperature, while the desorption constant, k–A, increases exponentially with increasing temperature. Consequently, the equilibrium adsorption constant KA decreases exponentially with increasing temperature.

Because carbon monoxide is the only material adsorbed on the catalyst, the site balance gives

At equilibrium, the net rate of adsorption equals zero, i.e., rAD ≡ 0. Setting the left-hand side of Equation (10-4) equal to zero and solving for the concentration of CO adsorbed on the surface, we get

Using Equation (10-5) to give Cv in terms of CCO ·S and the total number of sites Ct, we can solve for the equilibrium value of CCO·S in terms of constants and the pressure of carbon monoxide

CCO · S = KA Cv PCO = KAPCO(Ct – CCO · S)

Rearranging gives us

This equation thus gives the equilibrium concentration of carbon monoxide adsorbed on the surface, CCO ·S, as a function of the partial pressure of carbon monoxide, and is an equation for the adsorption isotherm. This particular type of isotherm equation is called a Langmuir isotherm.6 Figure 10-11(a) shows the Langmuir isotherm for the amount of CO adsorbed per unit mass of catalyst as a function of the partial pressure of CO. For the case of dissociative adsorption, Equation (10-11), Figure 10-11(b), shows the concentration of the atoms C and O adsorbed per unit mass of catalyst.

6 Named after Irving Langmuir (1881–1957), who first proposed it. He received the Nobel Prize in 1932 for his discoveries in surface chemistry.

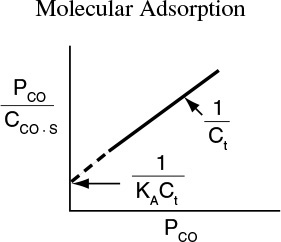

One method of checking whether a model (e.g., molecular adsorption versus dissociative adsorption) predicts the behavior of the experimental data is to linearize the model’s equation and then plot the indicated variables against one another. For example, the molecular adsorption isotherm, Equation (10-7), may be arranged in the form

and the linearity of a plot of PCO/CCO ·S as a function of PCO will determine if the data conform to molecular adsorption, i.e., a Langmuir single-site isotherm.

Next, we derive the isotherm for carbon monoxide disassociating into separate atoms as it adsorbs on the surface, i.e.,

Dissociative adsorption

When the carbon monoxide molecule dissociates upon adsorption, it is referred to as the dissociative adsorption of carbon monoxide. As in the case of molecular adsorption, the rate of adsorption is proportional to the pressure of carbon monoxide in the system because this rate is governed by the number of gaseous collisions with the surface. For a molecule to dissociate as it adsorbs, however, two adjacent vacant active sites are required, rather than the single site needed when a substance adsorbs in its molecular form. The probability of two vacant sites occurring adjacent to one another is proportional to the square of the concentration of vacant sites. These two observations mean that the rate of adsorption is proportional to the product of the carbon monoxide partial pressure and the square of the vacant-site concentration, ![]() .

.

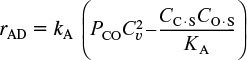

For desorption to occur, two occupied sites must be adjacent, meaning that the rate of desorption is proportional to the product of the occupied-site concentration, (C · S) × (O · S). The net rate of adsorption can then be expressed as

Factoring out kA, the equation for dissociative adsorption is

where

Rate of dissociative adsorption

For dissociative adsorption, both kA and k–A increase exponentially with increasing temperature, while the adsorption equilibrium constant KA decreases with increasing temperature.

At equilibrium, rAD ≡ 0, and

For CC·S = CO·S

Substituting for CC·S and CO·S in a site balance equation (10-1),

Solving for Cv

Cv = Ct/(1+2(KCOPCO)1/2)

This value may be substituted into Equation (10-10) to give an expression that can be solved for the equilibrium value of CO·S. The resulting equation for the isotherm shown in Figure 10-11(b) is

Langmuir isotherm for carbon monoxide dissociative adsorption as atomic carbon and oxygen

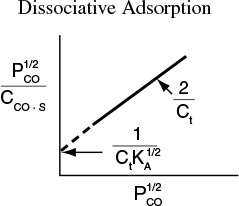

Taking the inverse of both sides of the equation, then multiplying through by (PCO)1/2, yields

If dissociative adsorption is the correct model, a plot of ![]() ver sus

ver sus ![]() should be linear with slope (2/Ct).

should be linear with slope (2/Ct).

When more than one substance is present, the adsorption isotherm equations are somewhat more complex. The principles are the same, though, and the isotherm equations are easily derived. It is left as an exercise to show that the adsorption isotherm of A in the presence of another adsorbate B is given by the relationship

When the adsorption of both A and B are first-order processes, the desorptions are also first order, and both A and B are adsorbed as molecules. The derivations of other Langmuir isotherms are relatively easy.

In obtaining the Langmuir isotherm equations, several aspects of the adsorption system were presupposed in the derivations. The most important of these, and the one that has been subject to the greatest doubt, is that a uniform surface is assumed. In other words, any active site has the same attraction for an impinging molecule as does any other active site. Isotherms different from the Langmuir isotherm, such as the Freundlich isotherm, may be derived based on various assumptions concerning the adsorption system, including different types of nonuniform surfaces.

Note assumptions in the model and check their validity.

is given by

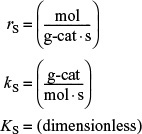

Surface reaction models

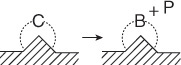

After a reactant has been adsorbed onto the surface, i.e., A · S, it is capable of reacting in a number of ways to form the reaction product. Three of these ways are:

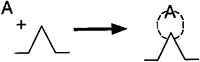

1. Single site. The surface reaction may be a single-site mechanism in which only the site on which the reactant is adsorbed is involved in the reaction. For example, an adsorbed molecule of A may isomerize (or perhaps decompose) directly on the site to which it is attached, such as

The pentane isomerization can be written in generic form as

Each step in the reaction mechanism is elementary, so the surface reaction rate law is

Single Site ![]()

Ks = (dimensionless)

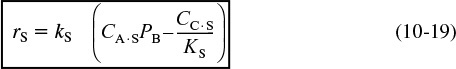

where KS is the surface-reaction equilibrium constant KS = kS/k–S

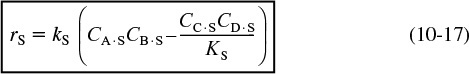

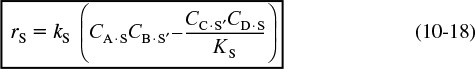

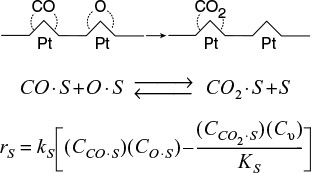

2. Dual site. The surface reaction may be a dual-site mechanism in which the adsorbed reactant interacts with another site (either unoccupied or occupied) to form the product.

First type of dual-site mechanism

For example, adsorbed A may react with an adjacent vacant site to yield a vacant site and a site on which the product is adsorbed, or as in the case of the dehydration of butanol, the products may adsorb on two adjacent sites.

C4H9OH · S + S → C4Hg · S + H2O · S

For the generic reaction

the corresponding surface-reaction rate law is

Dual Site

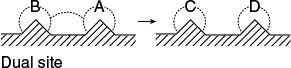

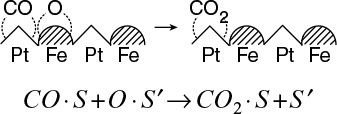

A second dual-site mechanism is the reaction between two adsorbed species, such as the reaction of CO with O.

For the generic reaction

the corresponding surface-reaction rate law is

A third dual-site mechanism is the reaction of two species adsorbed on different types of sites S and S’, such as the reaction of CO with O.

For the generic reaction

the corresponding surface-reaction rate law is

Reactions involving either single- or dual-site mechanisms, which were described earlier, are sometimes referred to as following Langmuir–Hinshelwood kinetics.

Langmuir–Hinshelwood kinetics

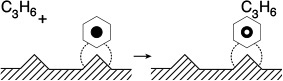

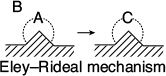

3. Eley–Rideal. A third mechanism is the reaction between an adsorbed molecule and a molecule in the gas phase, such as the reaction of propylene and benzene (cf. the reverse reaction in Figure 10-13)

For the generic reaction

the corresponding surface-reaction rate law is

This type of mechanism is referred to as an Eley–Rideal mechanism.

10.2.5 Desorption

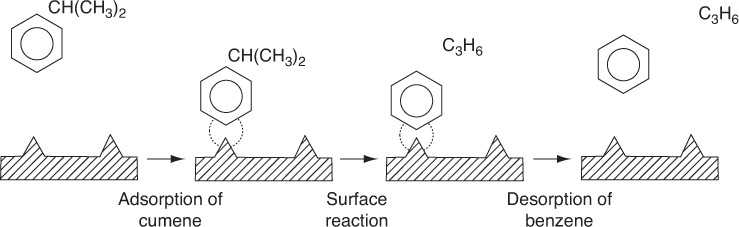

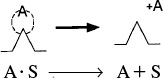

In each of the preceding cases, the products of the surface reaction adsorbed on the surface are subsequently desorbed into the gas phase. For the desorption of a species (e.g., C)

the rate of desorption of C is

where KDC is the desorption equilibrium constant with units of atm. Now let’s look at the above adsorption from right to left. We note that the desorption step for C is just the reverse of the adsorption step. Consequently, the rate of desorption of C, rDC, is just opposite in sign to the rate of adsorption of C, rADC

rDC = –rADC

In addition, we see that the desorption equilibrium constant KDC is just the reciprocal of the adsorption equilibrium constant for C, KC

in which case the rate of desorption of C can be written

In the material that follows, the form of the equation for the desorption step that we will use to develop our rate laws will be similar to Equation (10-21).

10.2.6 The Rate-Limiting Step

When heterogeneous reactions are carried out at steady state, the rates of each of the three reaction steps in series (adsorption, surface reaction, and desorption) are equal to one another

However, one particular step in the series is usually found to be ratelimiting or rate-controlling. That is, if we could make that particular step go faster, the entire reaction would proceed at an accelerated rate. Consider the analogy to the electrical circuit shown in Figure 10-12. A given concentration of reactants is analogous to a given driving force or electromotive force (EMF). The current I (with units of Coulombs/s) is analogous to the rate of

reaction, ![]() (mol/s · g-cat), and a resistance Ri is associated with each step in the series. Because the resistances are in series, the total resistance Rtot is just the sum of the individual resistances, for adsorption (RAD), surface reaction (RS), and desorption (RD). The current, I, for a given voltage, E, is

(mol/s · g-cat), and a resistance Ri is associated with each step in the series. Because the resistances are in series, the total resistance Rtot is just the sum of the individual resistances, for adsorption (RAD), surface reaction (RS), and desorption (RD). The current, I, for a given voltage, E, is

Because we observe only the total resistance, Rtot, it is our task to find which resistance is much larger (say, 100 Ω) than the other two resistances (say, 0.1 Ω). Thus, if we could lower the largest resistance, the current I (i.e., ![]() ), would be larger for a given voltage, E. Analogously, we want to know which step in the adsorption–reaction–desorption series is limiting the overall rate of reaction.

), would be larger for a given voltage, E. Analogously, we want to know which step in the adsorption–reaction–desorption series is limiting the overall rate of reaction.

The concept of a rate-limiting step

Who is slowing us down?

The approach in determining catalytic and heterogeneous mechanisms is usually termed the Langmuir–Hinshelwood approach, since it is derived from ideas proposed by Hinshelwood based on Langmuir’s principles for adsorption.7 The Langmuir–Hinshelwood approach was popularized by Hougen and Watson and occasionally includes their names.8 It consists of first assuming a sequence of steps in the reaction. In writing this sequence, one must choose among such mechanisms as molecular or atomic adsorption, and single- or dual-site reaction. Next, rate laws are written for the individual steps as shown in the preceding section, assuming that all steps are reversible. Finally, a rate-limiting step is postulated, and steps that are not rate-limiting are used to eliminate all coverage-dependent terms. The most questionable assumption in using this technique to obtain a rate law is the hypothesis that the activity of the surface is essentially uniform as far as the various steps in the reaction are concerned.

7 C. N. Hinshelwood, The Kinetics of Chemical Change (Oxford: Clarendon Press, 1940).

8 O. A. Hougen and K. M. Watson, Ind. Eng. Chem., 35, 529 (1943).

Industrial Example of Adsorption-Limited Reaction

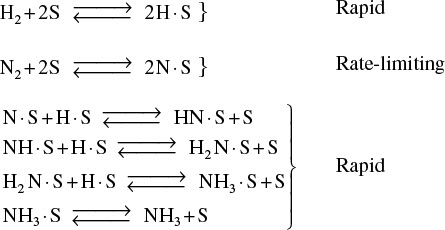

An example of an adsorption-limited reaction is the synthesis of ammonia from hydrogen and nitrogen

over an iron catalyst that proceeds by the following mechanism:9

9 From the literature cited in G. A. Somorjai, Introduction to Surface Chemistry and Catalysis (New York: Wiley, 1994), p. 482.

Dissociative adsorption of N2 is rate-limiting

The rate-limiting step is believed to be the adsorption of the N2 molecule as an N atom.

Industrial Example of Surface-Limited Reaction

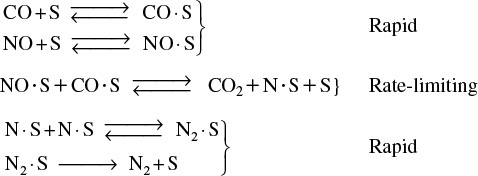

An example of a surface-limited reaction is the reaction of two noxious automobile exhaust products, CO and NO

carried out over a copper catalyst to form environmentally acceptable products, N2 and CO2

Surface reaction is rate-limiting

Analysis of the rate law suggests that CO2 and N2 are weakly adsorbed, i.e., have infinitesimally small adsorption constants (see Problem P10-9B).

10.3 Synthesizing a Rate Law, Mechanism, and Rate-Limiting Step

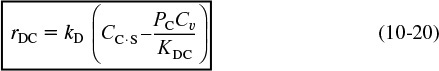

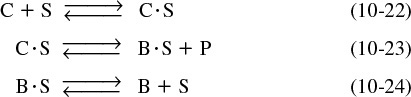

We now wish to develop rate laws for catalytic reactions that are not diffusion-limited. In developing the procedure to obtain a mechanism, a rate-limiting step, and a rate law consistent with experimental observation, we shall discuss a particular catalytic reaction, the decomposition of cumene to form benzene and propylene. The overall reaction is

A conceptual model depicting the sequence of steps in this platinum-catalyzed reaction is shown in Figure 10-13. Figure 10-13 is only a schematic representation of the adsorption of cumene; a more realistic model is the formation of a complex of the π orbitals of benzene with the catalytic surface, as shown in Figure 10-14.

• Adsorption

• Surface reaction

• Desorption

The nomenclature in Table 10-3 will be used to denote the various species in this reaction: C = cumene, B = benzene, and P = propylene. The reaction sequence for this decomposition is shown in Table 10-3.

These three steps represent the mechanism for cumene decomposition.

Equations (10-22) through (10-24) represent the mechanism proposed for this reaction.

When writing rate laws for these steps, we treat each step as an elementary reaction; the only difference is that the species concentrations in the gas phase are replaced by their respective partial pressures

Ideal gas law PC = CCRT

There is no theoretical reason for this replacement of the concentration, CC, with the partial pressure, PC; it is just the convention initiated in the 1930s and used ever since. Fortunately, PC can be calculated easily and directly from CC using the ideal gas law (i.e., PC = CCRT).

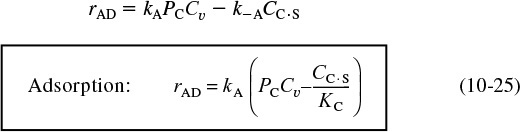

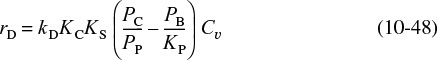

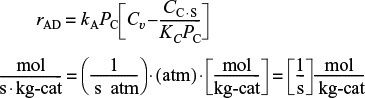

The rate expression for the adsorption of cumene as given in Equation (10-22) is

If rAD has units of (mol/g-cat·s) and CC·S has units of (mol cumene adsorbed/g-cat), then typical units of kA, k–A, and KC would be

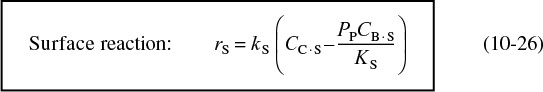

The rate law for the surface-reaction step producing adsorbed benzene and propylene in the gas phase

is

rS = kS CC·S – k–SPPCB·S

with the surface reaction equilibrium constant being

Typical units for kS and KS are s–1 and kPa, respectively.

Propylene is not adsorbed on the surface. Consequently, its concentration on the surface is zero.

CP·S = 0

The rate of benzene desorption [see Equation (10-24)] is

Typical units of kD and KDB are s–1 and kPa, respectively. By viewing the desorption of benzene

from right to left, we see that desorption is just the reverse of the adsorption of benzene. Consequently, as mentioned earlier, it is easily shown that the benzene adsorption equilibrium constant KB is just the reciprocal of the benzene desorption constant KDB

and Equation (10-28) can be written as

Because there is no accumulation of reacting species on the surface, the rates of each step in the sequence are all equal as discussed in Figure 10-12:

For the mechanism postulated in the sequence given by Equations (10-22) through (10-24), we wish to determine which step is rate-limiting. We first assume one of the steps to be rate-limiting (rate-controlling) and then formulate the reaction-rate law in terms of the partial pressures of the species present. From this expression we can determine the variation of the initial reaction rate with the initial partial pressures and the initial total pressure. If the predicted rate varies with pressure in the same manner as the rate observed experimentally, the implication is that the assumed mechanism and rate-limiting step are correct.

We will first start our development of the rate laws with the assumption that the adsorption step is rate-limiting and derive the rate law, and then proceed to assume that each of the other two steps’ surface reaction and desorption limit the overall rate and then derive the rate law for each of these other two limiting cases.

10.3.1 Is the Adsorption of Cumene Rate-Limiting?

To answer this question we shall assume that the adsorption of cumene is indeed rate-limiting, derive the corresponding rate law, and then check to see if it is consistent with experimental observation. By postulating that this (or any other) step is rate-limiting, we are assuming that the reaction-rate constant of this step (in this case kA) is small with respect to the specific rates of the other steps (in this case kS and kD).10 The rate of adsorption is

10 Strictly speaking, one should compare the product kA PC with kS and kD.

Dividing rAD by kAPC, we note ![]() . The reason we do this is that in order to compare terms, the ratios

. The reason we do this is that in order to compare terms, the ratios ![]() , and

, and ![]() must all have the same units

must all have the same units ![]() . Luckily for us, the end result is the same, however.

. Luckily for us, the end result is the same, however.

Need to express Cv and CC·S in terms of PC, PB, and PP

Because we cannot measure either Cv or CC·S, we must replace these variables in the rate law with measurable quantities for the equation to be meaningful.

For steady-state operation we have

For adsorption-limited reactions, kA is very small and kS and kD are very, very large by comparison. Consequently, the ratios rS/kS and rD/kD are very small (approximately zero), whereas the ratio rAD/kA is relatively large.

The surface reaction-rate law is

Again, for adsorption-limited reactions, the surface-specific reaction rate kS is large by comparison, and we can set

and solve Equation (10-31) for CC·S

To be able to express CC·S solely in terms of the partial pressures of the species present, we must evaluate CB·S. The rate of desorption of benzene is

However, for adsorption-limited reactions, kD is large by comparison, and we can set

Using ![]() to find CB·S and CC·S in terms of partial pressures

to find CB·S and CC·S in terms of partial pressures

and then solve Equation (10-29) for CB·S

After combining Equations (10-33) and (10-35), we have

Replacing CC·S in the rate equation by Equation (10-36) and then factoring Cv, we obtain

Let’s look at how the thermodynamic constant pressure equilibrium constant, KP, found its way into Equation (10-37) and how we can find its value for any reaction. First we observe that at equilibrium rAD = 0, Equation (10-37) rearranges to

We also know from thermodynamics (Appendix C) that for the reaction

also at equilibrium (![]() ), we have the following relationship for partial pressure equilibrium constant KP

), we have the following relationship for partial pressure equilibrium constant KP

Consequently, the following relationship must hold

The equilibrium constant can be determined from thermodynamic data and is related to the change in the Gibbs free energy, ΔG°, by the equation (see Appendix C)

where R is the ideal gas constant and T is the absolute temperature.

The concentration of vacant sites, Cv, can now be eliminated from Equation (10-37) by utilizing the site balance to give the total concentration of sites, Ct, which is assumed constant11

11 Some (I won’t mention any names) prefer to write the surface reaction rate in terms of the fraction of the surface of sites covered (i.e., fA) rather than the number of sites CA · S covered, the difference being the multiplication factor of the total site concentration, Ct. In any event, the final form of the rate law is the same because Ct, KA, kS, and so on, are all lumped into the reaction-rate constant, k.

Because cumene and benzene are adsorbed on the surface, the concentration of occupied sites is (CC·S + CB·S), and the total concentration of sites is

Site balance

Substituting Equations (10-35) and (10-36) into Equation (10-40), we have

Solving for Cv, we have

Combining Equations (10-41) and (10-37), we find that the rate law for the catalytic decomposition of cumene, assuming that the adsorption of cumene is the rate-limiting step, is

Cumene reaction rate law if adsorption were the limiting step

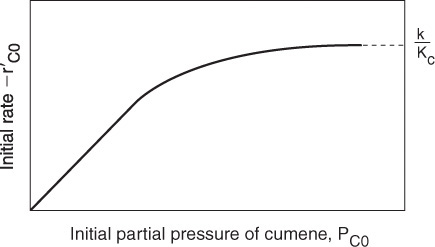

We now wish to sketch a plot of the initial rate of reaction as a function of the partial pressure of cumene, PC0. Initially, no products are present; consequently, PP = PB = 0. The initial rate is given by

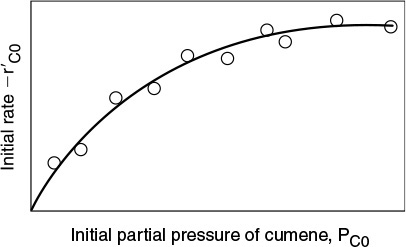

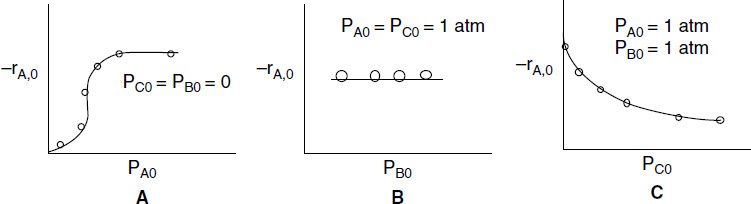

If the cumene decomposition is adsorption rate limited, then from Equation (10-43) we see that the initial rate will be linear with the initial partial pressure of cumene, as shown in Figure 10-15.

Before checking to see if Figure 10-15 is consistent with experimental observation, we shall derive the corresponding rate laws for the other possible rate-limiting steps and then develop corresponding initial rate plots for the case when the surface reaction is rate-limiting and then for the case when the desorption of benzene is rate-limiting.

If adsorption were rate-limiting, the data should show ![]() increasing linearly with PCO.

increasing linearly with PCO.

10.3.2 Is the Surface Reaction Rate-Limiting?

The rate of surface reaction is

Single-site mechanism

Since we cannot readily measure the concentrations of the adsorbed species, we must utilize the adsorption and desorption steps to eliminate CC·S and CB·S from this equation.

From the adsorption rate expression in Equation (10-25) and the condition that kA and kD are very large by comparison with kS when the surface reaction is limiting (i.e., rAD/kA ![]() 0),12 we obtain a relationship for the surface concentration for adsorbed cumene

0),12 we obtain a relationship for the surface concentration for adsorbed cumene

12 See footnote 10 on page 424.

CC⋅S = KCPCCv

In a similar manner, the surface concentration of adsorbed benzene can be evaluated from the desorption rate expression, Equation (10-29), together with the approximation

Using ![]() to find CB·S and CC·S in terms of partial pressures

to find CB·S and CC·S in terms of partial pressures

then we get the same result for CB·S as before when we had adsorption limitation, i.e.,

CB⋅S = KBPBCv

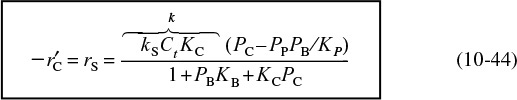

Substituting for CB·S and CC·S in Equation (10-26) gives us

where the thermodynamic equilibrium constant was used to replace the ratio of surface reaction and adsorption constants, i.e.,

The only variable left to eliminate is Cv and we use a site balance to accomplish this, i.e.,

Site balance

Substituting for concentrations of the adsorbed species, CB·S, and CC·S, factoring out CV, and rearranging yields

Substituting for CV in Equation (10-26a)

Cumene rate law for surface-reaction-limiting

The initial rate of reaction is

Figure 10-16 shows the initial rate of reaction as a function of the initial partial pressure of cumene for the case of surface-reaction-limiting.

At low partial pressures of cumene

and we observe that the initial rate will increase linearly with the initial partial pressure of cumene:

At high partial pressures

and Equation (10-45) becomes

If surface reaction were rate-limiting, the data would show this behavior.

and the initial rate is independent of the initial partial pressure of cumene.

10.3.3 Is the Desorption of Benzene Rate-Limiting?

The rate expression for the desorption of benzene is

From the rate expression for surface reaction, Equation (10-26), we set

For desorption-limited reactions, both kA and kS are very large compared with kD, which is small.

to obtain

Similarly, for the adsorption step, Equation (10-25), we set

to obtain

CC·S = KCPCCv

then substitute for CC·S in Equation (10-46) to obtain

Combining Equations (10-26b), (10-29), and (10-47) gives us

where KC is the cumene adsorption constant, KS is the surface-reaction equilibrium constant, and KP is the thermodynamic gas-phase equilibrium constant, Equation (10-38), for the reaction. The expression for Cv is obtained from a site balance:

After substituting for the respective surface concentrations, we solve the site balance for Cv

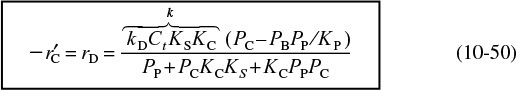

Replacing Cv in Equation (10-48) by Equation (10-49) and multiplying the numerator and denominator by PP, we obtain the rate expression for desorption control

Cumene decomposition rate law if desorption were limiting

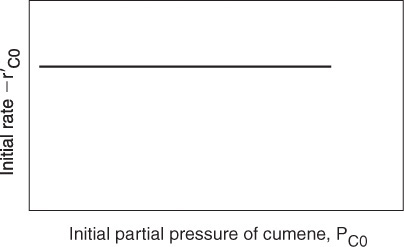

To determine the dependence of the initial rate of reaction on the initial partial pressure of cumene, we again set PP = PB = 0, and the rate law reduces to

If desorption limits, the initial rate is independent of the initial partial pressure of cumene.

with the corresponding plot of ![]() shown in Figure 10-17. If desorption were rate limiting, we would see that the initial rate of reaction would be independent of the initial partial pressure of cumene.

shown in Figure 10-17. If desorption were rate limiting, we would see that the initial rate of reaction would be independent of the initial partial pressure of cumene.

10.3.4 Summary of the Cumene Decomposition

The experimental observations of ![]() as a function of PC0 are shown in Figure 10-18. From the plot in Figure 10-18, we can clearly see that neither adsorption nor desorption is rate-limiting. For the reaction and mechanism given by

as a function of PC0 are shown in Figure 10-18. From the plot in Figure 10-18, we can clearly see that neither adsorption nor desorption is rate-limiting. For the reaction and mechanism given by

Cumene decomposition is surface-reaction-limited

Surface-reaction-limited mechanism is consistent with experimental data.

the rate law derived by assuming that the surface reaction is rate-limiting agrees with the data.

The rate law for the case of no inerts adsorbing on the surface is

The forward cumene decomposition reaction is a single-site mechanism involving only adsorbed cumene, while the reverse reaction of propylene in the gas phase reacting with adsorbed benzene is an Eley–Rideal mechanism.

If we were to have an adsorbing inert in the feed, the inert would not participate in the reaction but would occupy active sites on the catalyst surface:

Our site balance is now

Because the adsorption of the inert is at equilibrium, the concentration of sites occupied by the inert is

Substituting for the inert sites in the site balance, the rate law for surface reaction control when an adsorbing inert is present is

Adsorbing inerts

One observes that the rate decreases as the partial pressure of adsorbing inerts increases.

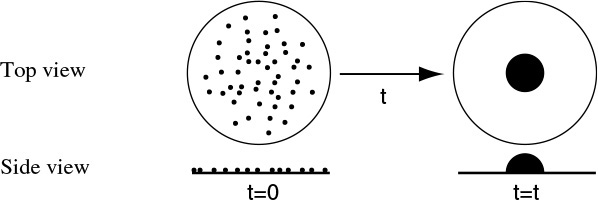

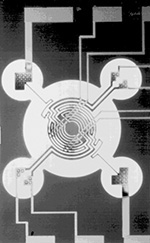

10.3.5 Reforming Catalysts

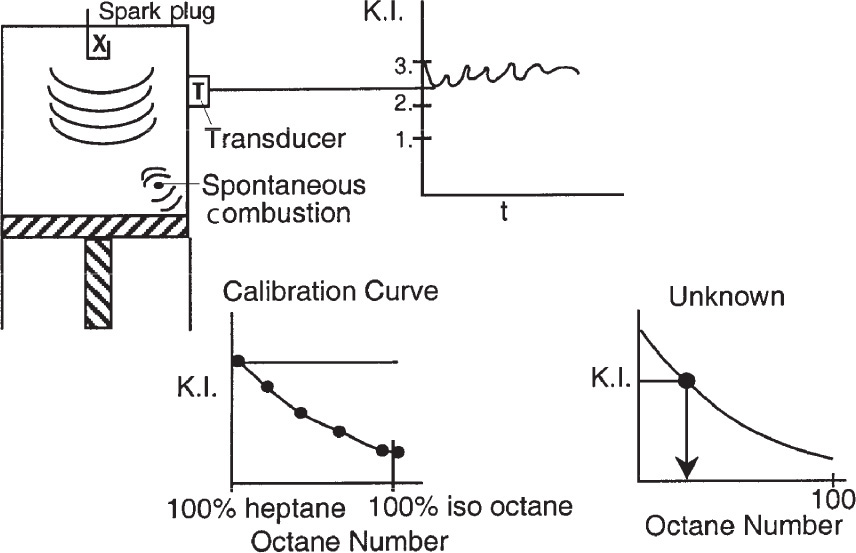

We now consider a dual-site mechanism, which is a reforming reaction found in petroleum refining to upgrade the octane number of gasoline.

Catalyst manufacture

One common reforming catalyst is platinum on alumina. Platinum on alumina (Al2O3) (see SEM photo in Figure 10-19) is a bifunctional catalyst that can be prepared by exposing alumina pellets to a chloroplatinic acid solution, drying, and then heating in air at 775 K to 875 K for several hours. Next, the material is exposed to hydrogen at temperatures around 725 K to 775 K to produce very small clusters of Pt on alumina. These clusters have sizes on the order of 10 Å, while the alumina pore sizes on which the Pt is deposited are on the order of 100 Å to 10,000 Å (i.e., 10 nm to 1000 nm).

Figure 10-19 Platinum on alumina. (Masel, Richard. Chemical Kinetics and Catalysis, p. 700. © John Wiley & Sons, Inc. Reprinted by permission of John Wiley & Sons, Inc. All rights reserved.)

As an example of catalytic reforming, we shall consider the isomerization of n-pentane to i-pentane

Gasoline

Normal pentane has an octane number of 62, while iso-pentane, which is more compact, has an octane number of 90! The n-pentane adsorbs onto the platinum, where it is dehydrogenated to form n-pentene. The n-pentene desorbs from the platinum and adsorbs onto the alumina, where it is isomerized to i-pentene, which then desorbs and subsequently adsorbs onto platinum, where it is hydrogenated to form i-pentane. That is

We shall focus on the isomerization step to develop the mechanism and the rate law

The procedure for formulating a mechanism, rate-limiting step, and corresponding rate law is given in Table 10-4.

Isomerization of n-pentene (N) to i-pentene (I) over alumina

Step 1. Select a mechanism. (Let’s choose a Dual Site Mechanism)

Treat each reaction step as an elementary reaction when writing rate laws.

Reforming reaction to increase octane number of gasoline

Step 2. Assume a rate-limiting step. We choose the surface reaction first, because more than 75% of all heterogeneous reactions that are not diffusion-limited are surface-reaction-limited. We note that the PSSH must be used when more than one step is limiting (see Section 10.3.6). The rate law for the surface reaction step is

Step 3. Find the expression for concentration of the adsorbed species Ci·S. Use the other steps that are not limiting to solve for Ci·S (e.g., CN ·S and CI·S). For this reaction

Step 4. Write a site balance.

Ct = Cv + CN·S + CI·S

Step 5. Derive the rate law. Combine Steps 2, 3, and 4 to arrive at the rate law

Step 6. Compare with data. Compare the rate law derived in Step 5 with experimental data. If they agree, there is a good chance that you have found the correct mechanism and rate-limiting step. If your derived rate law (i.e., model) does not agree with the data:

a. Assume a different rate-limiting step and repeat Steps 2 through 6.

b. If, after assuming that each step is rate-limiting, none of the derived rate laws agrees with the experimental data, select a different mechanism (e.g., a single-site mechanism)

and then proceed through Steps 2 through 6.

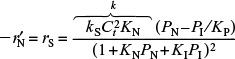

The single-site mechanism turns out to be the correct one. For this mechanism, the rate law is

c. If two or more models agree, the statistical tests discussed in Chapter 7 (e.g., comparison of residuals) should be used to discriminate between them (see the Supplementary Reading).

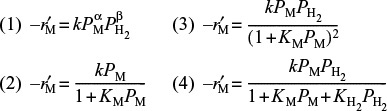

We note that in Table 10-4 for the dual-site mechanism, the denominator of the rate law for –![]() is squared (i.e., in Step 5 [1/( )2)]), while for a single-site mechanism, it is not squared (i.e., Step 6 [1/( )]). This fact is useful when analyzing catalyzed reactor data.

is squared (i.e., in Step 5 [1/( )2)]), while for a single-site mechanism, it is not squared (i.e., Step 6 [1/( )]). This fact is useful when analyzing catalyzed reactor data.

TABLE 10-4 ALGORITHM FOR DETERMINING THE REACTION MECHANISM AND RATE-LIMITING STEP

Table 10-5 gives rate laws for different reaction mechanisms that are irreversible and surface-reaction-limited.

We need a word of caution at this point. Just because the mechanism and rate-limiting step may fit the rate data does not imply that the mechanism is correct.13 Usually, spectroscopic measurements are needed to confirm a mechanism absolutely. However, the development of various mechanisms and rate-limiting steps can provide insight into the best way to correlate the data and develop a rate law.

13 R. I. Masel, Principles of Adsorption and Reaction on Solid Surfaces (New York: Wiley, 1996), p. 506, www.masel.com. This is a terrific book.

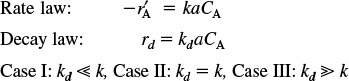

10.3.6 Rate Laws Derived from the Pseudo-Steady-State Hypothesis (PSSH)

In Section 9.1 we discussed the PSSH, where the net rate of formation of reactive intermediates was assumed to be zero. An alternative way to derive a catalytic rate law rather than setting

is to assume that each species adsorbed on the surface is a reactive intermediate. Consequently, the net rate of formation of species i adsorbed on the surface will be zero

The PSSH is primarly used when more than one step is rate-limiting. The isomerization example shown in Table 10-4 is reworked using the PSSH in the Chapter 10 Expanded Material on the CRE Web site.

10.3.7 Temperature Dependence of the Rate Law

Consider a surface-reaction-limited irreversible isomerization

in which both A and B are adsorbed on the surface, and the rate law is

The specific reaction rate, k, will usually follow an Arrhenius temperature dependence and increase exponentially with temperature. However, the adsorption of all species on the surface is exothermic. Consequently, the higher the temperature, the smaller the adsorption equilibrium constant. That is, as the temperature increases, KA and KB decrease resulting in less coverage of the surface by A and B. Therefore, at high temperatures, the denominator of catalytic rate laws approaches 1. That is, at high temperatures (low coverage)

The rate law could then be approximated as

Neglecting the adsorbed species at high temperatures

or for a reversible isomerization we would have

Algorithm

Deduce

Rate law

Find

Mechanism

Evaluate

Rate-law parameters

Design

PBR

CSTR

The algorithm we can use as a start in postulating a reaction mechanism and rate-limiting step is shown in Table 10-4. Again, we can never really prove a mechanism to be correct by comparing the derived rate law with experimental data. Independent spectroscopic experiments are usually needed to confirm the mechanism. We can, however, prove that a proposed mechanism is inconsistent with the experimental data by following the algorithm in Table 10-4. Rather than taking all the experimental data and then trying to build a model from the data, Box et al. describe techniques of sequential data collection and model building.14

14 G. E. P. Box, W. G. Hunter, and J. S. Hunter, Statistics for Engineers (New York: Wiley, 1978).

10.4 Heterogeneous Data Analysis for Reactor Design

In this section we focus on four operations that chemical reaction engineers need to be able to accomplish:

(1) Developing an algebraic rate law consistent with experimental observations,

(2) Analyzing the rate law in such a manner that the rate-law parameters (e.g., k, KA) can readily be determined from the experimental data,

(3) Finding a mechanism and rate-limiting step consistent with the experimental data

(4) Designing a catalytic reactor to achieve a specified conversion

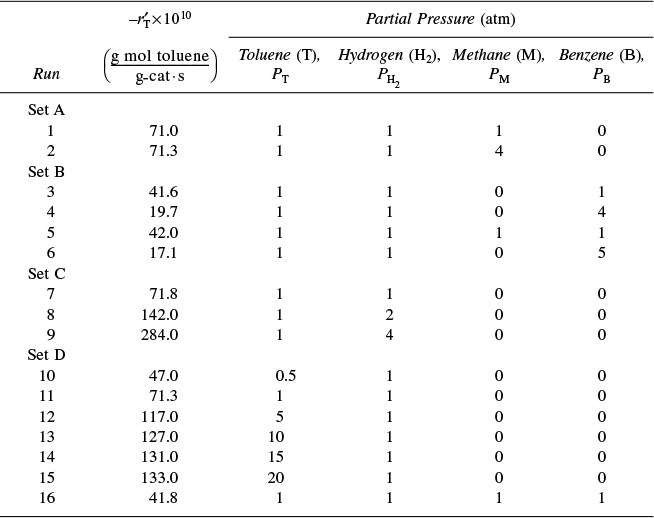

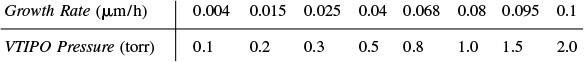

We shall use the hydrodemethylation of toluene to illustrate these four operations.

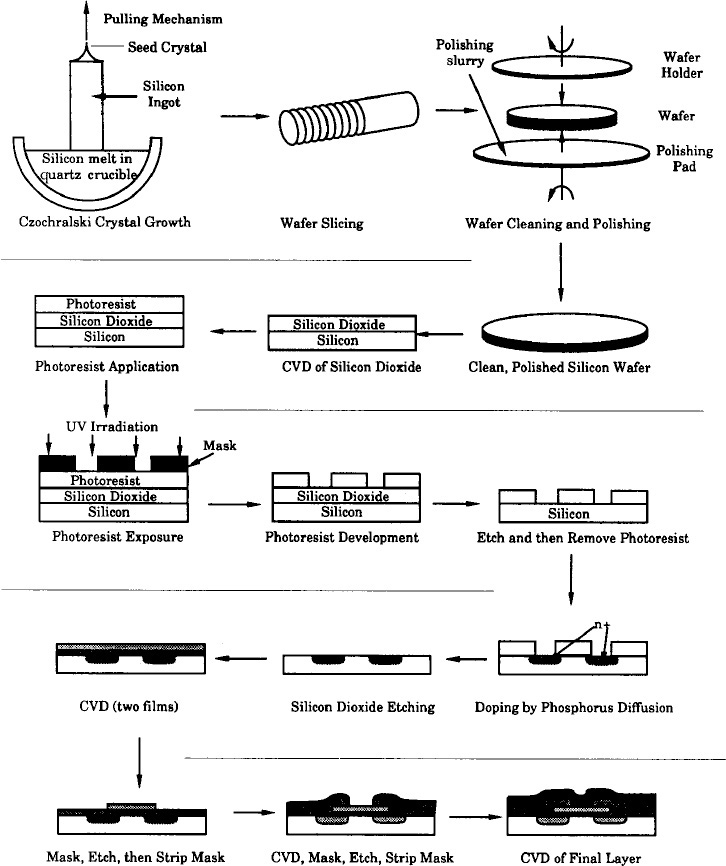

Hydrogen and toluene are reacted over a solid mineral catalyst containing clinoptilolite (a crystalline silica-alumina) to form methane and benzene15

15 J. Papp, D. Kallo, and G. Schay, J. Catal., 23, 168.

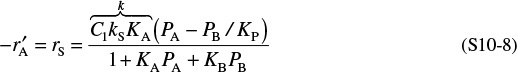

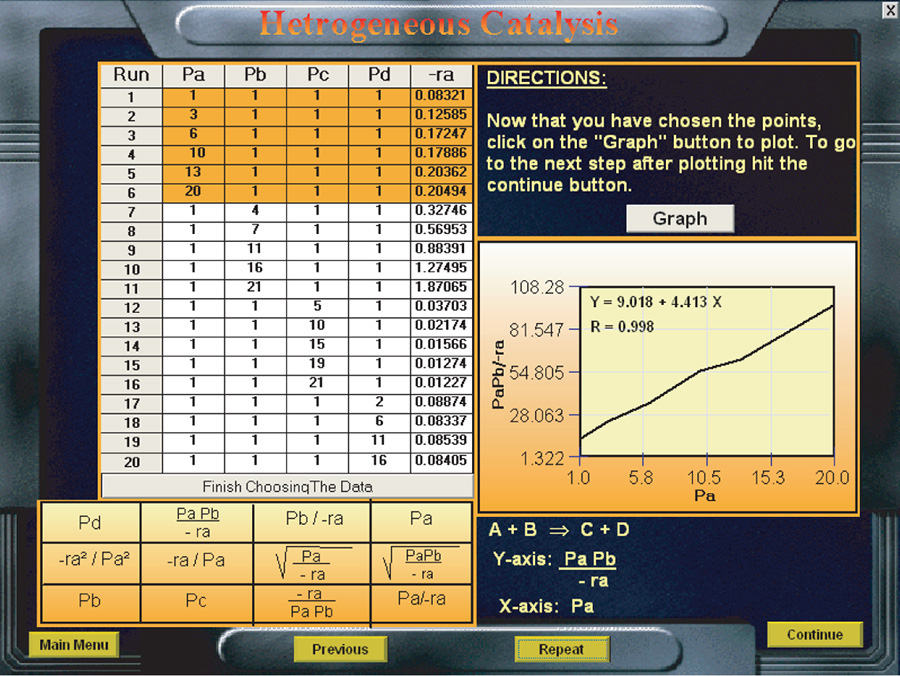

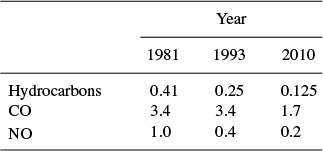

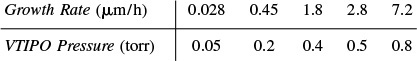

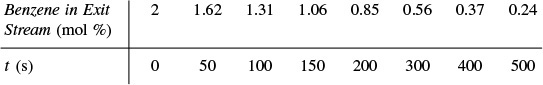

We wish to design a packed-bed reactor and a fluidized CSTR to process a feed consisting of 30% toluene, 45% hydrogen, and 25% inerts. Toluene is fed at a rate of 50 mol/min at a temperature of 640°C and a pressure of 40 atm (4052 kPa). To design the PBR, we must first determine the rate law from the differential reactor data presented in Table 10-6. In this table, we are given the rate of reaction of toluene as a function of the partial pressures of hydrogen (H2), toluene (T), benzene (B), and methane (M). In the first two runs, methane was introduced into the feed together with hydrogen and toluene, while the other product, benzene, was fed to the reactor together with the reactants only in runs 3, 4, and 6. In runs 5 and 16, both methane and benzene were introduced in the feed. In the remaining runs, none of the products was present in the feedstream. Because the conversion was less than 1% in the differential reactor, the partial pressures of the products, methane and benzene, formed in these runs were essentially zero, and the reaction rates were equivalent to initial rates of reaction.

Unscramble the data to find the rate law

10.4.1 Deducing a Rate Law from the Experimental Data

First, let’s look at run 3. In run 3, there is no possibility of the reverse reaction taking place because the concentration of methane is zero, i.e., PM = 0, whereas in run 5 the reverse reaction could take place because all products are present. Comparing runs 3 and 5, we see that the initial rate is essentially the same for both runs, and we can assume that the reaction is essentially irreversible.

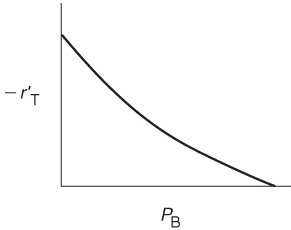

We now ask what qualitative conclusions can be drawn from the data about the dependence of the rate of disappearance of toluene, ![]() , on the partial pressures of toluene, hydrogen, methane, and benzene.

, on the partial pressures of toluene, hydrogen, methane, and benzene.

1. Dependence on the product methane. If methane were adsorbed on the surface, the partial pressure of methane would appear in the denominator of the rate expression and the rate would vary inversely with methane concentration

However, comparing runs 1 and 2 we observe that a fourfold increase in the pressure of methane has little effect on ![]() . Consequently, we assume that methane is either very weakly adsorbed (i.e., KMPM

. Consequently, we assume that methane is either very weakly adsorbed (i.e., KMPM ![]() 1) or goes directly into the gas phase in a manner similar to propylene in the cumene decomposition previously discussed.

1) or goes directly into the gas phase in a manner similar to propylene in the cumene decomposition previously discussed.

If it is in the denominator, it is probably on the surface.

2. Dependence on the product benzene. In runs 3 and 4, we observe that, for fixed concentrations (partial pressures) of hydrogen and toluene, the rate decreases with increasing concentration of benzene. A rate expression in which the benzene partial pressure appears in the denominator could explain this dependency

The type of dependence of ![]() on PB given by Equation (10-68) suggests that benzene is adsorbed on the clinoptilolite surface.

on PB given by Equation (10-68) suggests that benzene is adsorbed on the clinoptilolite surface.

3. Dependence on toluene. At low concentrations of toluene (runs 10 and 11), the rate increases with increasing partial pressure of toluene, while at high toluene concentrations (runs 14 and 15), the rate is virtually independent of the toluene partial pressure. A form of the rate expression that would describe this behavior is

A combination of Equations (10-68) and (10-69) suggests that the rate law may be of the form

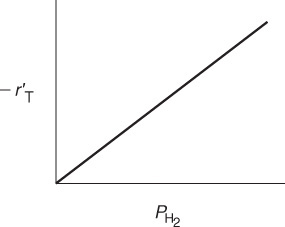

4. Dependence on hydrogen. When we compare runs 7, 8, and 9 in Table 10-6, we see that the rate increases linearly with increasing hydrogen concentration, and we conclude that the reaction is first order in H2. In light of this fact, hydrogen is either not adsorbed on the surface or its coverage of the surface is extremely low (1 » KH2PH2) for the pressures used. If H2 were adsorbed, ![]() would have a dependence on PH2 analogous to the dependence of

would have a dependence on PH2 analogous to the dependence of ![]() on the partial pressure of toluene, PT [see Equation (10-69)]. For first-order dependence on H2,

on the partial pressure of toluene, PT [see Equation (10-69)]. For first-order dependence on H2,

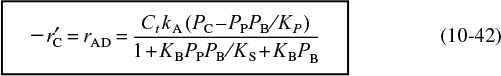

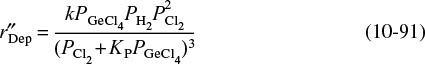

Combining Equations (10-67) through (10-71), we find that the rate law

is in qualitative agreement with the data shown in Table 10-6.

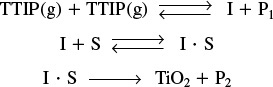

10.4.2 Finding a Mechanism Consistent with Experimental Observations

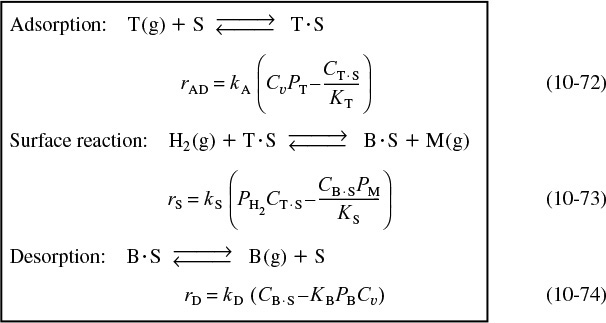

We now propose a mechanism for the hydrodemethylation of toluene. We assume that the reaction follows an Eley-Rideal mechanism where toluene is adsorbed on the surface and then reacts with hydrogen in the gas phase to produce benzene adsorbed on the surface and methane in the gas phase. Benzene is then desorbed from the surface. Because approximately 75% to 80% of all heterogeneous reaction mechanisms are surface-reaction-limited rather than adsorption- or desorption-limited, we begin by assuming the reaction between adsorbed toluene and gaseous hydrogen to be reaction-rate-limited. Symbolically, this mechanism and associated rate laws for each elementary step are

Approximately 75% of all heterogeneous reaction mechanisms are surface-reaction-limited.

Proposed Mechanism

Eley–Rideal mechanism

For surface-reaction-limited mechanisms

we see that we need to replace CT·S and CB·S in Equation (10-73) by quantities that we can measure.

For surface-reaction-limited mechanisms, we use the adsorption rate Equation (10-72) for toluene to obtain CT·S16, i.e.,

16 See footnote 10 on page 424.

Then

and we use the desorption rate Equation (10-74) for benzene to obtain CB·S:

Then

The total concentration of sites is

Perform a site balance to obtain Cv.

Substituting Equations (10-75) and (10-76) into Equation (10-77) and rearranging, we obtain

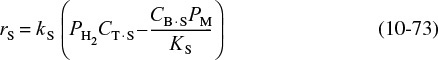

Next, substitute for CT·S and CB·S, and then substitute for Cv in Equation (10-73) to obtain the rate law for the case when the reaction is surface-reaction-rate-limited

We have shown by comparing runs 3 and 5 that we can neglect the reverse reaction, i.e., the thermodynamic equilibrium constant KP is very, very large. Consequently, we obtain

Rate law for Eley–Rideal surface-reaction-limited mechanism

Again we note that the adsorption equilibrium constant of a given species is exactly the reciprocal of the desorption equilibrium constant of that species.

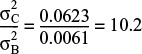

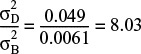

10.4.3 Evaluation of the Rate-Law Parameters

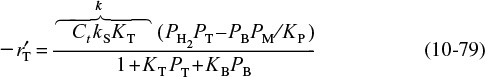

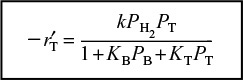

In the original work on this reaction by Papp et al.,17 over 25 models were tested against experimental data, and it was concluded that the preceding mechanism and rate-limiting step (i.e., the surface reaction between adsorbed toluene and H2 gas) is the correct one. Assuming that the reaction is essentially irreversible, the rate law for the reaction on clinoptilolite is

17 Ibid.

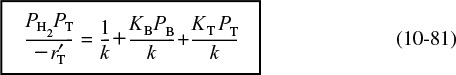

We now wish to determine how best to analyze the data to evaluate the rate-law parameters, k, KT, and KB. This analysis is referred to as parameter estimation.18 We now rearrange our rate law to obtain a linear relationship between our measured variables. For the rate law given by Equation (10-80), we see that if both sides of Equation (10-80) are divided by PH2PT and the equation is then inverted

18 See the Supplementary Reading (page 492) for a variety of techniques for estimating the rate-law parameters.

Linearize the rate equation to extract the rate-law parameters.

The regression techniques described in Chapter 7 could be used to determine the rate-law parameters by using the equation

A linear least-squares analysis of the data shown in Table 10-6 is presented on the CRE Web site.

One can use the linearized least-squares analysis (PRS 7.3) to obtain initial estimates of the parameters k, KT, KB, in order to obtain convergence in nonlinear regression. However, in many cases it is possible to use a nonlinear regression analysis directly, as described in Sections 7.5 and 7.6, and in Example 10-1.

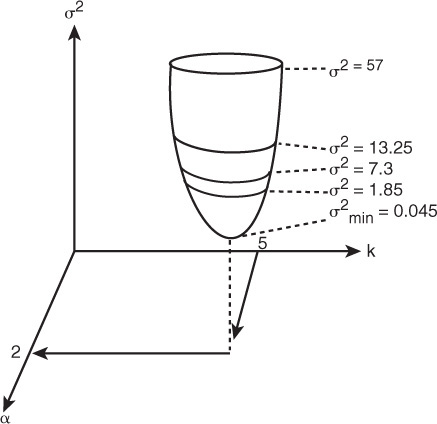

Example 10–1 Nonlinear Regression Analysis to Determine the Model Parameters k, KB, and KT

(a) Use nonlinear regression, as discussed in Chapter 7, along with the data in Table 10-6, to find the best estimates of the rate-law parameters k, KB, and KT in Equation (10-80).

(b) Write the rate law solely as a function of the partial pressures.

(c) Find the ratio of the sites occupied by toluene, CT•S, to those occupied by benzene, CB•S, at 40% conversion of toluene.

Solution

The data from Table 10-6 were entered into the Polymath nonlinear least-squares program with the following modification. The rates of reaction in column 1 were multiplied by 1010, so that each of the numbers in column 1 was entered directly (i.e., 71.0, 71.3, ...). The model equation was

Following the step-by-step regression procedure in Chapter 7 and on the CRE Web site Summary Notes, we arrive at the following parameter values shown in Table E10-1.1.

(a) The best estimates are shown in the upper-right-hand box of Table E10-1.1.

(b) Converting the rate law to kilograms of catalyst and minutes,

we have

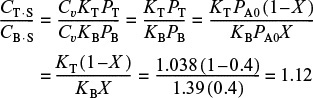

Ratio of sites occupied by toluene to those occupied by benzene

(c) After we have the adsorption constants, KT and KB, we can calculate the ratio of sites occupied by the various adsorbed species. For example, taking the ratio of Equation (10-75) to Equation (10-76), the ratio of toluene-occupied sites to benzeneoccupied sites at 40% conversion is

We see that at 40% conversion there are approximately 12% more sites occupied by toluene than by benzene. This fact is common knowledge to every chemical engineering student at Jofostan University, Riça, Jofostan.

Analysis: This example shows once again how to determine the values of rate-law parameters from experimental data using Polymath regression. It also shows how to calculate the different fraction of sites, both vacant and occupied, as a function of conversion.

10.4.4 Reactor Design

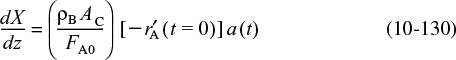

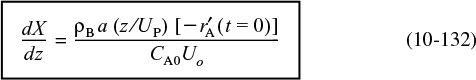

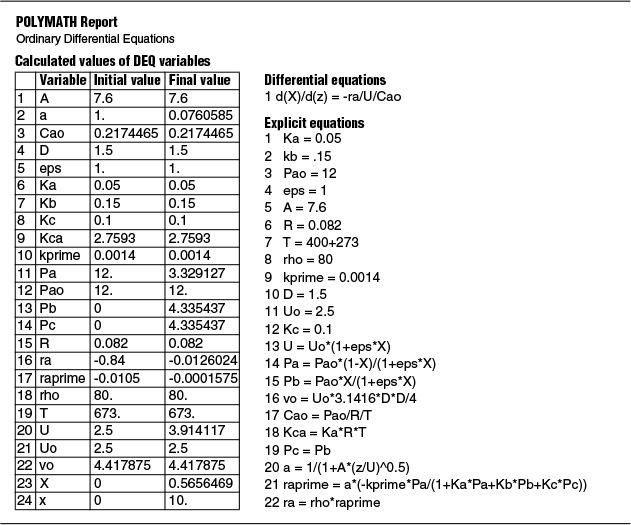

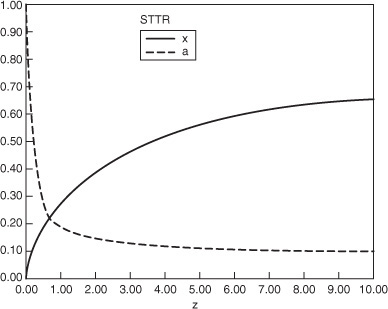

Our next step is to express the partial pressures PT, PB, and PH2 as a function of X, combine the partial pressures with the rate law, ![]() , as a function of conversion, and carry out the integration of the packed-bed design equation

, as a function of conversion, and carry out the integration of the packed-bed design equation

Example 10–2 Catalytic Reactor Design

The hydrodemethylation of toluene is to be carried out in a PBR catalytic reactor.

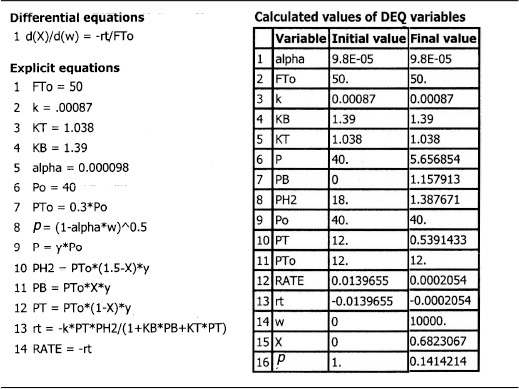

The molar feed rate of toluene to the reactor is 50 mol/min, and the reactor inlet is at 40 atm and 640°C. The feed consists of 30% toluene, 45% hydrogen, and 25% inerts. Hydrogen is used in excess to help prevent coking. The pressure-drop parameter, α, is 9.8 × 10–5 kg–1.

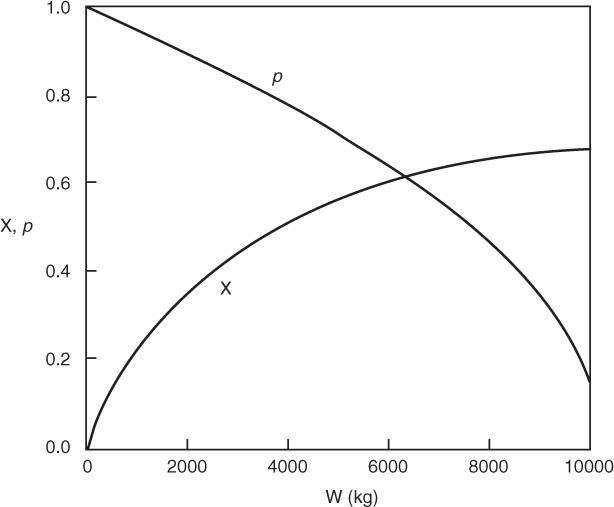

(a) Plot and analyze the conversion, the pressure ratio, p, and the partial pressures of toluene, hydrogen, and benzene as a function of PBR catalyst weight.

(b) Determine the catalyst weight in a fluidized CSTR with a bulk density of 400 kg/m3 (0.4 g/cm3) to achieve 65% conversion.

Solution

(a) PBR with pressure drop

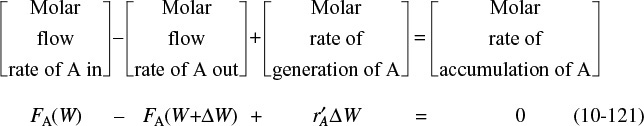

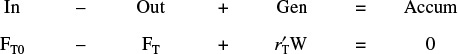

1. Mole Balance:

Balance on toluene (T)

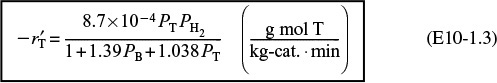

2. Rate Law: From Equation (E10-1.1) we have

with k = 0.00087 mol/atm2/kg-cat/min, KB = 1.39 atm–1, and KT = 1.038 atm–1.

3. Stoichiometry:

Relating Toluene (T) Benzene (B) Hydrogen (H2)

Because ε = 0, we can use the integrated form of the pressure-drop term.

P0 = total pressure at the entrance

Note that PT0 designates the inlet partial pressure of toluene. In this example, the inlet total pressure is designated P0 to avoid any confusion. The inlet mole fraction of toluene is 0.3 (i.e., yT0 = 0.3), so that the inlet partial pressure of toluene is

PT0 = (0.3)(40) = 12 atm

Pressure drop in PBRs is discussed in Section 5.5.

We now calculate the maximum catalyst weight we can have, such that the exiting pressure will not fall below atmospheric pressure (i.e., 1.0 atm) for the specified feed rate. This weight is calculated by substituting the entering pressure of 40 atm and the exiting pressure of 1 atm into Equation (5-33), i.e.,

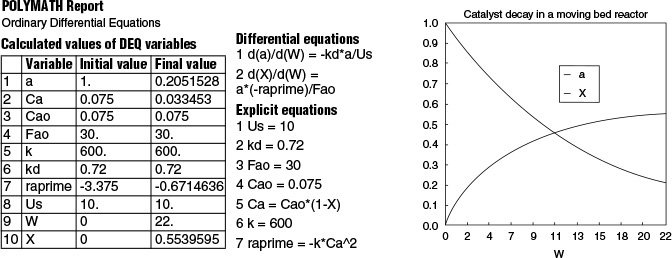

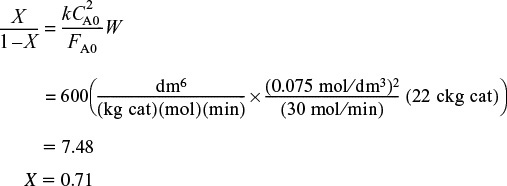

4. Evaluate: Consequently, we will set our final weight at 10,000 kg and determine the conversion profile as a function of catalyst weight up to this value. Equations (E10-2.1) through (E10-2.5) are shown in the Polymath program in Table E10-2.1. The conversion is shown as a function of catalyst weight in Figure E10-2.1, and profiles of the partial pressures of toluene, hydrogen, and benzene are shown in Figure E10-2.2. We note that the pressure drop causes (cf. Equation E10-2.5) the partial pressure of benzene to go through a maximum as one traverses the reactor.

Conversion profile down the packed bed

Note the partial pressure of benzene goes through a maximum. Why?

PBR Analysis: For the case of no pressure drop, the conversion that would have been achieved with 10,000 kg of catalyst would have been 79%, compared with 68.2% when there is pressure drop in the reactor. To carry out this calculation, use the Living Example Program (LEP) on the CRE Web site and simply multiply the pressure-drop parameter by zero, i.e., line (5) would read α = 0.00098*0. For the feed rate given, eliminating or minimizing pressure drop would increase the production of benzene by up to 61 million pounds per year! Finally, we note in Figure E10-2.2 that the partial pressure of benzene (PB) goes through a maximum. This maximum can be explained by recalling that PB is just the product of the benzene mole fraction (yB) times the total pressure (P) [i.e., PB = yBPT]. Near the middle to end of the bed, benzene is no longer being formed so that yB stops increasing. However, because of the pressure drop, the total pressure decreases and, as a result, so does PB.

If one had neglected ΔP it could have been very embarrassing.

See YouTube video, “Reaction Engineering Gone Wrong,” accessible from the CRE Web site home page.

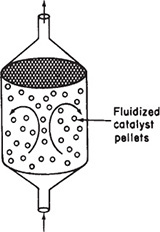

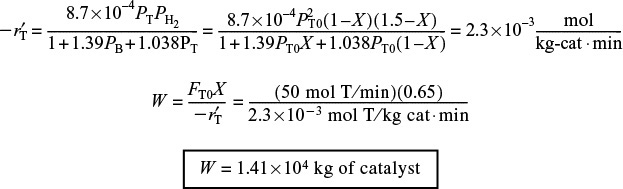

(b) Fluidized CSTR

We will now calculate the fluidized CSTR catalyst weight necessary to achieve the same (ca.) conversion as in the packed-bed reactor at the same operating conditions. The bulk density in the fluidized reactor is 0.4 g/cm3. The design equation is

Rearranging

Fluidized CSTR

2. Rate Law and 3. Stoichiometry same as in part (a) PBR calculation

4. Combine and Evaluate: Writing Equation (E10-2.2) in terms of conversion (E10-2.3) and then substituting X = 0.65 and PT0 = 12 atm, we have

The corresponding reactor volume is