Chapter Five. Modeling and Design

Objectives

After studying the material in this chapter, you should be able to:

1. Describe modeling methods available to represent your design.

2. List model qualities that can help you select among them.

3. Describe how models can be used in refining designs.

4. Describe which modeling method contains the most information about a design.

5. Describe how a constraint-based modeler differs from a traditional solid modeler.

6. Define design intent and how it is reflected in a constraint-based model.

7. Define the basic functions of a constraint-based modeler.

8. Identify the role of a base feature.

9. Identify constraint relationships and driving dimensions.

Refer to the following standards:

• ANSI/ASME Y14.100 Engineering Drawing Practices

• ASME Y14.41 Digital Product Definition Data Practices

The ENV hydrogen fuel cell motorbike was designed from the fuel cell outward. During its development many refinements were made both technologically and visually. Models in this phase must represent the design accurately enough to be used for testing as well as to convey the details of the design for implementation. (Courtesy of Seymourpowell.)

Refinement and Modeling

From the solutions generated during ideation, only a few are selected for further consideration. The design review process determines whether money will be committed for further development of a design.

The process of refining and analyzing the design is iterative. As the refined design is tested, the test results suggest modifications to the design, and once the design is changed, it needs further analysis.

Creating a CAD model is an important step in the refinement process. A huge amount of design information can be stored in CAD models that are easily modified. The CAD model can be used to test and evaluate the design. By making changes easy—and in some cases, automating the update process—CAD modeling can eliminate some barriers to a thorough review and refinement of the design.

CAD models also encourage refinement by making it easier and less costly to get feedback about a design while it is in development. Accurate part descriptions allow you to test how well parts will fit together. Customer acceptance and styling issues can be assessed early in the design process using realistically shaded models. Analysis programs can import 3D CAD files or run as part of the CAD software, saving much time. Some analysis packages suggest optimizations to incorporate directly in the CAD model. Animation and kinematic analysis uses CAD data to determine whether the design will function properly before any parts are actually built.

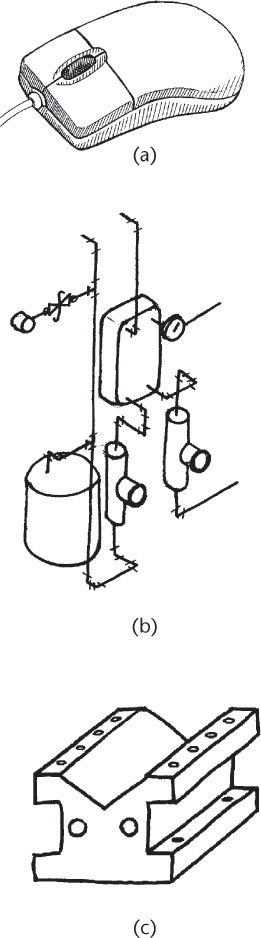

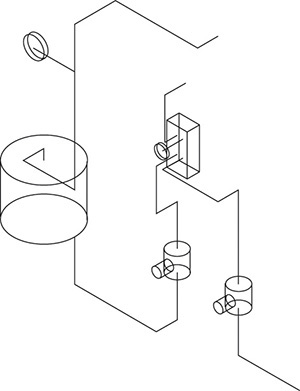

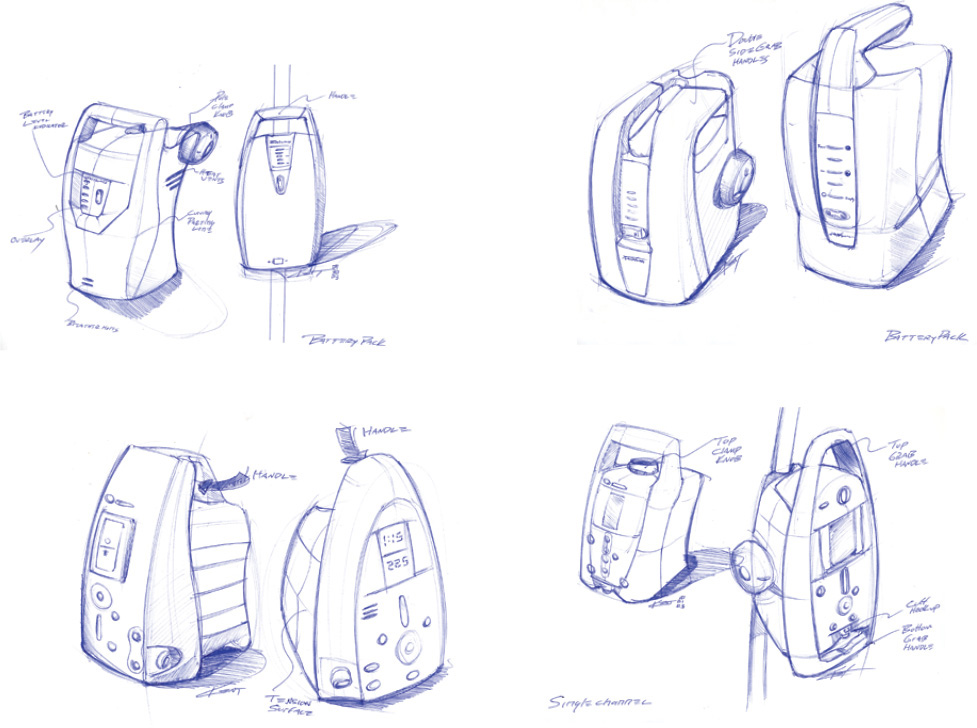

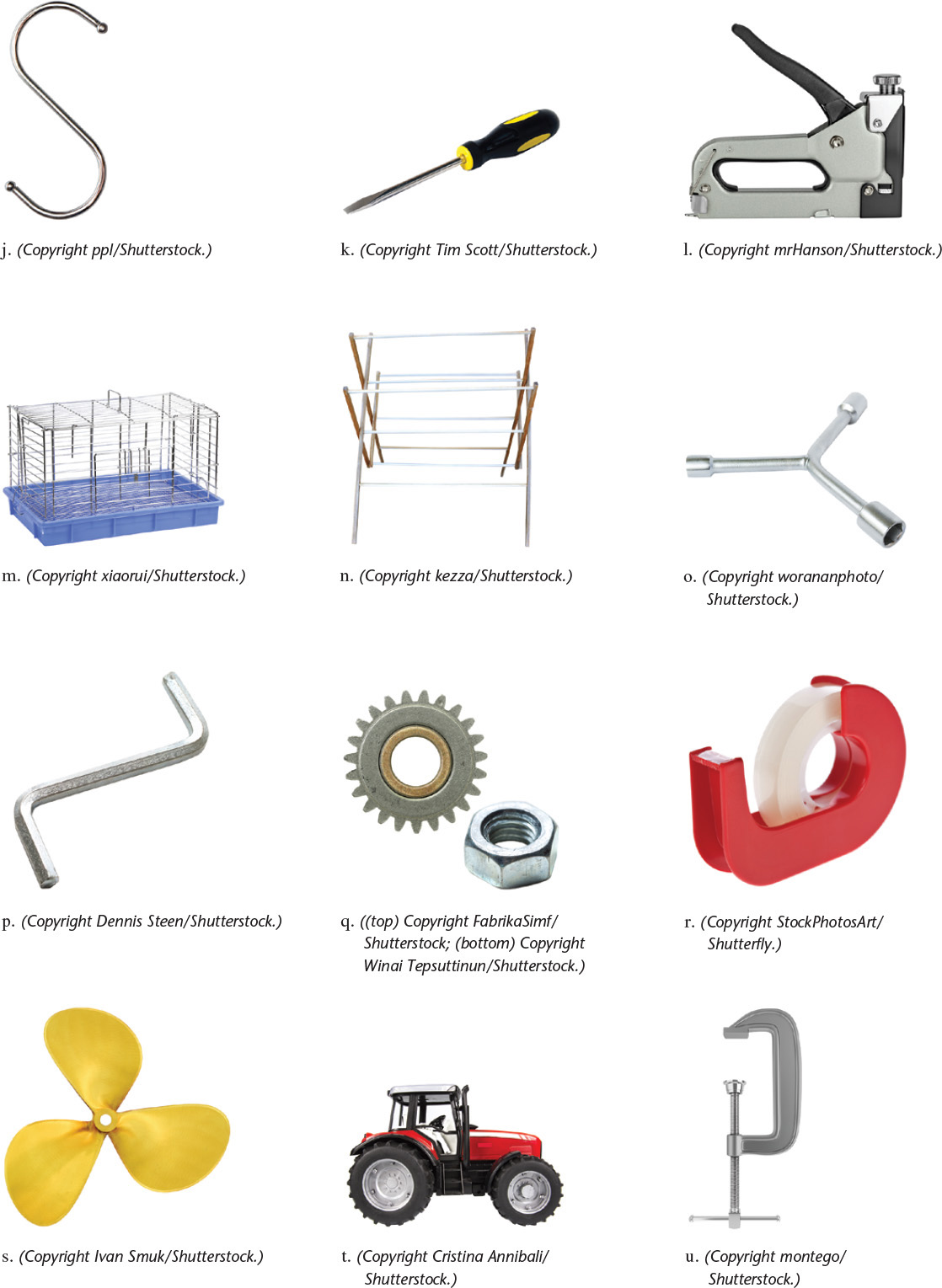

Many different methods are used to create CAD models, each with its strengths and weaknesses for capturing design information. Each item shown in Figure 5.1 may be modeled differently, possibly requiring different software and techniques.

5.1 The same modeling software may be used to model (a) the ergonomic mouse, (b) the piping system, and (c) the V-block, but different modeling methods may be best suited to each.

In this chapter, you will learn how different modeling methods represent and store design information, and the advantages and disadvantages of each. This information will aid you in choosing the most effective method for a particular design problem.

Descriptive Models

Descriptive models represent a system or device in either words or pictures. Descriptive models sometimes use representations that are simplified or analogous to something that is more easily understood. The key function of a descriptive model is to describe, that is, to provide enough detail to convey an image of the final product.

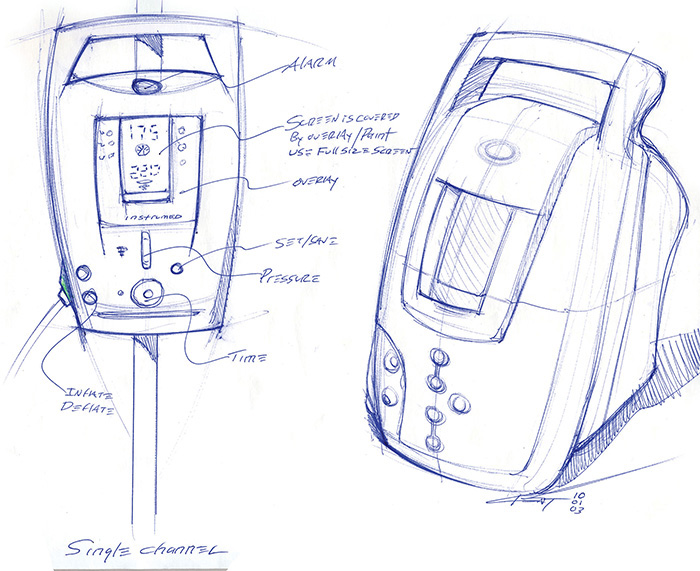

A set of written specifications for a design is a descriptive model. If all the specifications are followed, the system will perform correctly. Sketching is also a type of descriptive model for your design ideas on paper. 2D and 3D CAD drawings are also descriptive models. A physical model or prototype is another type of descriptive model, although sometimes physical models are made to a smaller scale (called a scale model).

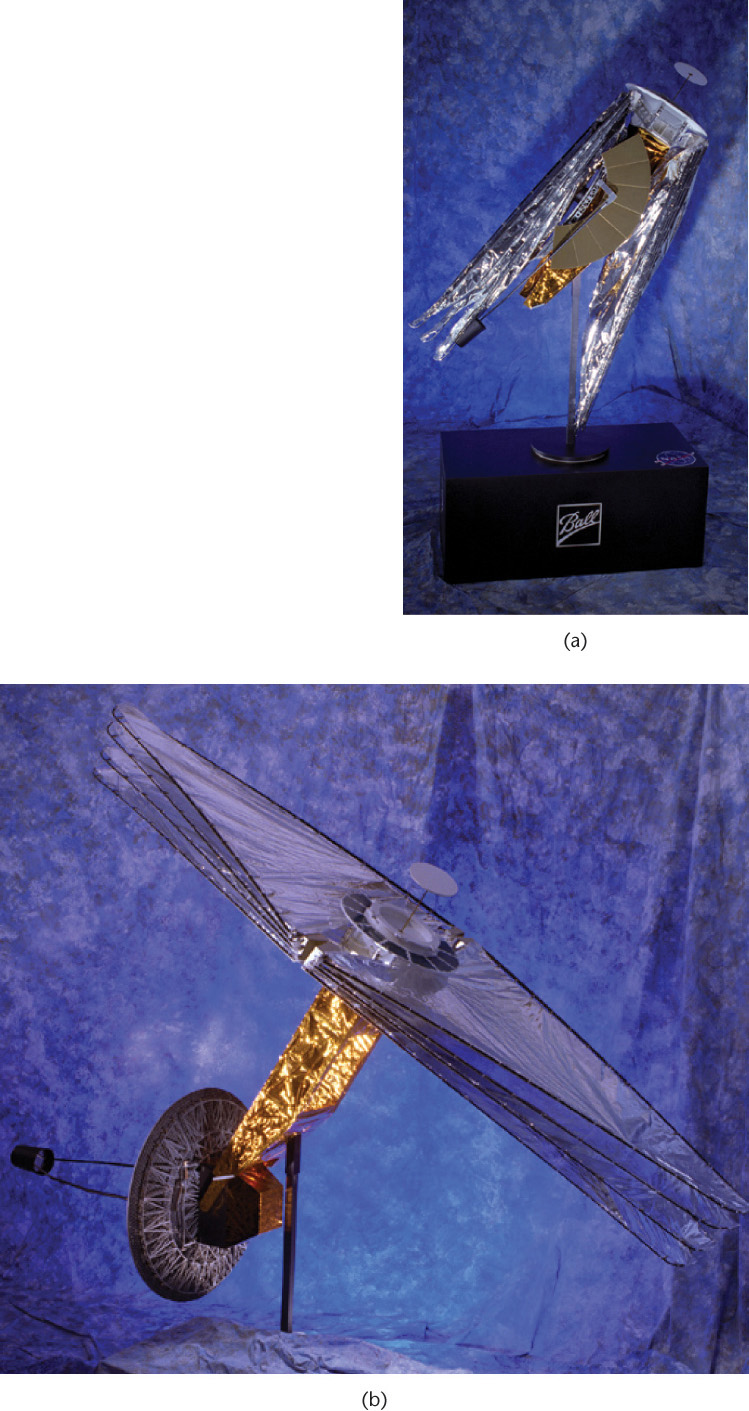

The figures at right show a scale model of a design for the Next Generation Space Telescope (NGST) developed by NASA. A model helps you visualize the design. It has the added benefit of being easy for non-engineers to understand while decisions are being made about the next step in the project.

Analytical Models

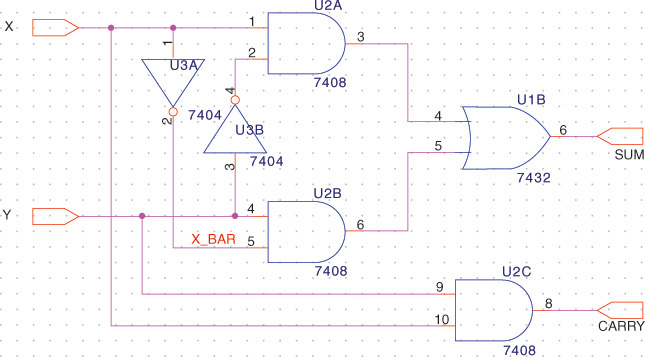

An analytical model captures the behavior of the system or device in a mathematical expression or schematic that can be used to predict future behavior. The electrical circuit model shown in Figure 5.2 is an example of an analytical model. The circuit and its properties are represented in the model by equations and relations that simulate the way the component would behave in a real circuit. The designer can change values to make predictions about what will happen in a real circuit that is wired the same way as the model. This makes it easier, less expensive, and faster to test the design.

5.2 A simple circuit design model allows simulation of its function. (Courtesy of Cadence® Design Systems, Inc.)

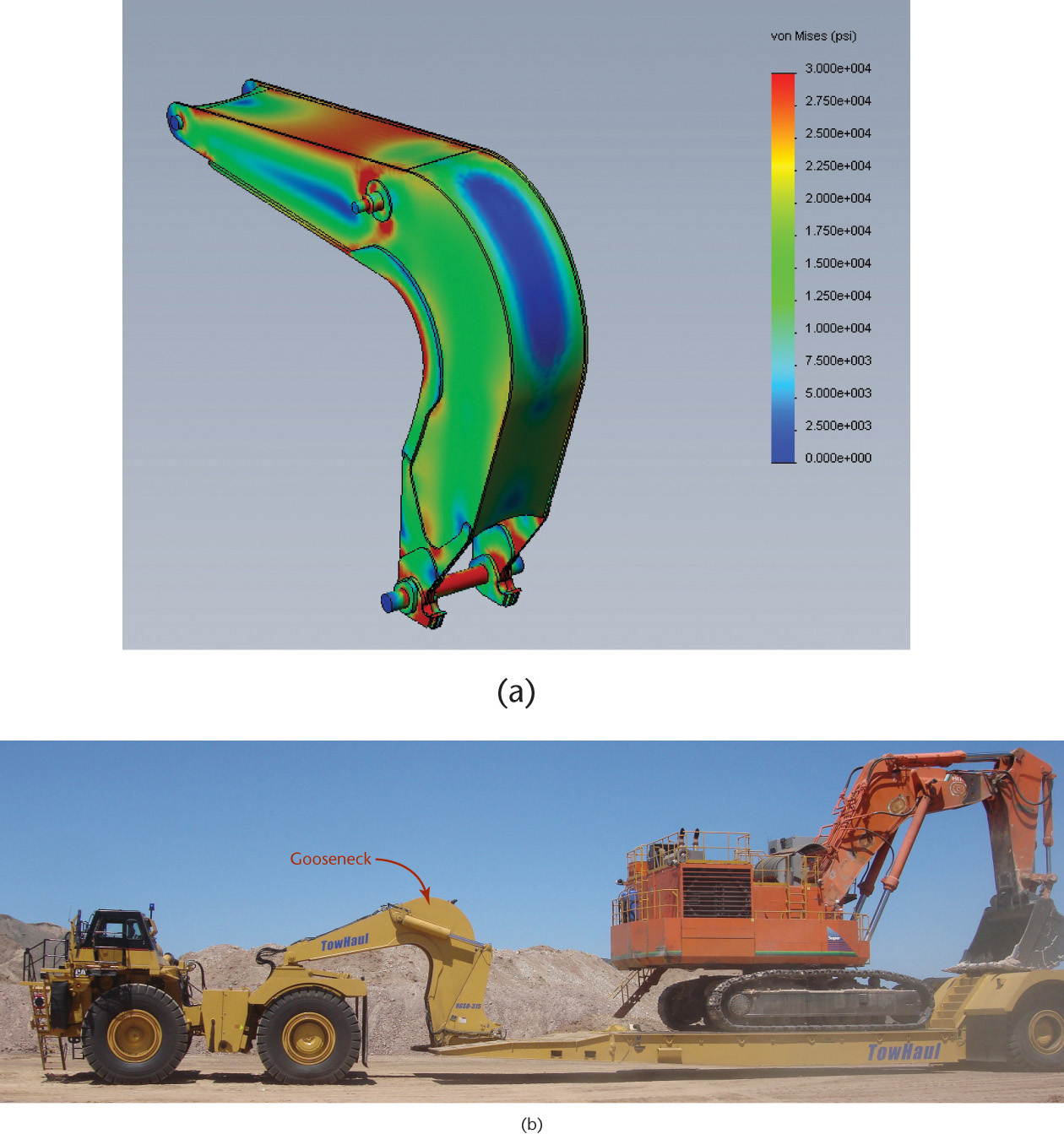

Part of creating an effective analytical model is determining which aspects of the system’s behavior to model. In the circuit model, some information, such as interference between some components, is left out because it is too complex to represent effectively. A finite element analysis (FEA) model, such as that used to generate the stress plot shown in Figure 5.3a, simplifies the CAD model in a similar way. The FEA model breaks the model into smaller elements; reducing a complicated system to a series of smaller systems allows the stresses more easily to be solved. Understanding and using analytical models effectively requires knowing how the model differs from the actual system so the results can be interpreted correctly.

5.3 Finite element analysis (a) is used to calculate the stresses on the gooseneck shown in (b) in designing this heavy-duty equipment. (Courtesy of TowHaul Corporation.)

In the design process, use different types of models where they are appropriate. During the ideation phase of the design, sketching is often the best technique to use. As you begin to refine the design, you will use both descriptive and analytical models to represent the design more accurately and to provide insight into its behavior.

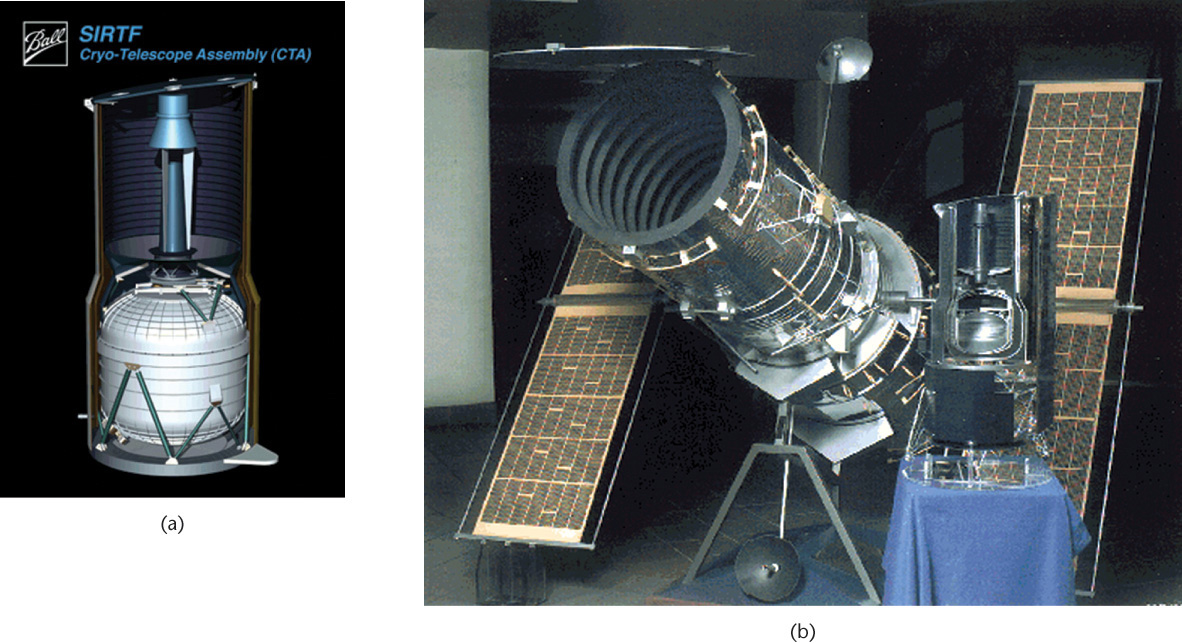

A 3D CAD model combines qualities of descriptive and analytical models. Because a 3D CAD model accurately depicts the geometry of a device, it can fully describe its shape, size, and appearance as a physical or scale model would. Additional information about the final product, such as the materials from which it will be made, can also be added to the model description stored in the computer database. Figure 5.4 shows a CAD model of NASA’s Space Infrared Telescope Facility (SIRTF).

5.4 Descriptive and Analytical. This rendered view of the preliminary CAD model of the SIRTF assembly, shown in (a), looks very similar to the photograph of its 1:10 scale model, shown in (b) next to a 1:10 model of the Hubble Space Telescope. (Courtesy of Ball Aerospace and Technologies Corporation.)

A 3D CAD model can also be used for analytical modeling. The 3D model of the device can be used to study its characteristics (see Figure 5.5). Sophisticated software allows you to analyze, animate, and predict the behavior of the design under various physical conditions. The 3D CAD model is a detailed representation of the final object, suited for testing and study.

5.5 Motion Analysis. These welding robots are programmed with code developed with 3D model data. The motion of the robots is simulated with a 3D model of the part to be welded and 3D models of the robots. Motion paths are then exported and used to program the actual robots. (Courtesy of FANUC America Corporation.)

5.1 2D Models

Paper Drawings

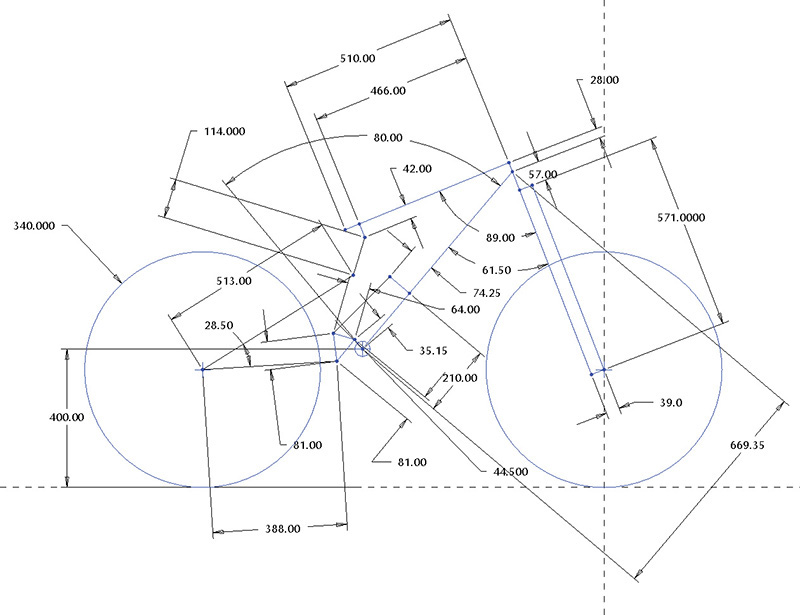

2D sketches and multiview drawings are representations of the design. All the information defining the object may be shown in a paper drawing (see Figure 5.6), although it may require many orthographic views.

5.6 This fully dimensioned paper drawing contains all the information needed to manufacture this part, which will be flame cut from a 96 × 156-inch sheet of steel. (Courtesy of Smith Equipment, USA.)

Multiview drawing techniques were designed to improve the robustness, measurability, and accuracy of paper drawings. These same techniques require some skill to be understood, however, and make multiview drawings harder to understand than a 3D model.

Equipment costs for paper drawings are minimal, but they take as long or longer to create than CAD drawings. Changes involve considerable erasing and redrawing, making them difficult to modify as the design changes. Because paper drawings are difficult to change, the labor costs associated with them usually outweigh the equipment savings.

Paper drawing accuracy is about plus or minus one fortieth the drawing scale. For example, a paper drawing of a map drawn at a scale of 1 inch = 400 feet has good accuracy if you can measure from it to plus or minus 10 feet. This makes paper drawings not particularly measurable or accurate—which is why proper dimensioning technique was developed. Proper dimensioning overcomes this limitation and provides measurements to the desired accuracy on the drawing. It is not good practice to make measurements from paper drawings.

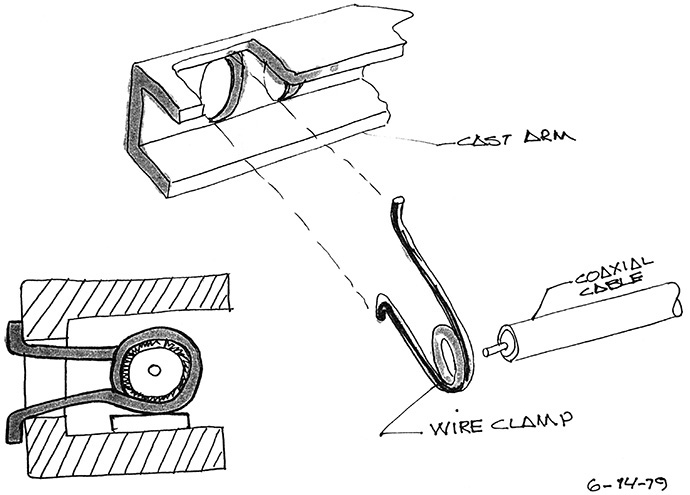

Paper drawings can be very effective for quickly communicating the design of small parts for manufacturing. A properly dimensioned sketch can quickly convey all the information needed to make a part that is needed only one time (see Figure 5.7). Also, manufacturing facilities occasionally are not able to read electronic files and require paper drawings.

2D CAD Models

2D CAD models share the visual characteristics of paper drawings but are more accurate and easier to change. CAD systems have a large variety of editing tools that allow quick editing and reuse of drawing geometry. Standard symbols are easy to add and change.

2D CAD drawings can quickly be printed to different scales. Different types of information can be separated onto different layers that can either be displayed or turned off, making the model more flexible than a paper drawing.

Using CAD, you can accurately define the locations of lines, arcs, and other geometry. In AutoCAD, for example, you can store these locations to at least fourteen decimal places. You can query the database, and the information will be returned as accurately as you originally created it. Of course, the adage Garbage In, Garbage Out (GIGO) applies. If your endpoints do not connect, or you locate distances by eye instead of entering them precisely, you will not have accurate results.

CAD models represent the object full size, unlike paper drawings, so you can make measurements and calculations from 2D CAD models. Also, you can “snap” to locations on objects to determine sizes and distances that may not be dimensioned on a paper drawing. If there must be a clearance of 10 feet from the center of a tank to the location of another piece of equipment, you can measure from the CAD file to determine whether proper clearance is provided in the design.

Text and other information can be saved in a database and linked to the drawing information for later retrieval. The 2D database is limited, however, in its ability to represent information that depends on a 3D definition (such as the volume inside the object), so it is not generally useful for determining mass and other physical properties of the object.

The strengths and weaknesses of paper drawing are shared by 2D CAD models. To create them and read them you must be able to interpret the 2D views to “see” the 3D object. To measure from a 2D CAD model, you must show distances and angles true length in a view. Orthographic projection and descriptive geometry are needed to create these views. Descriptive geometry is the study of producing views of an object that show true lengths, shape, angles, and other information about an engineering design. Mastering these subjects enables you to use auxiliary views created with a 2D CAD system along with the traditional methods of descriptive geometry to solve many engineering problems.

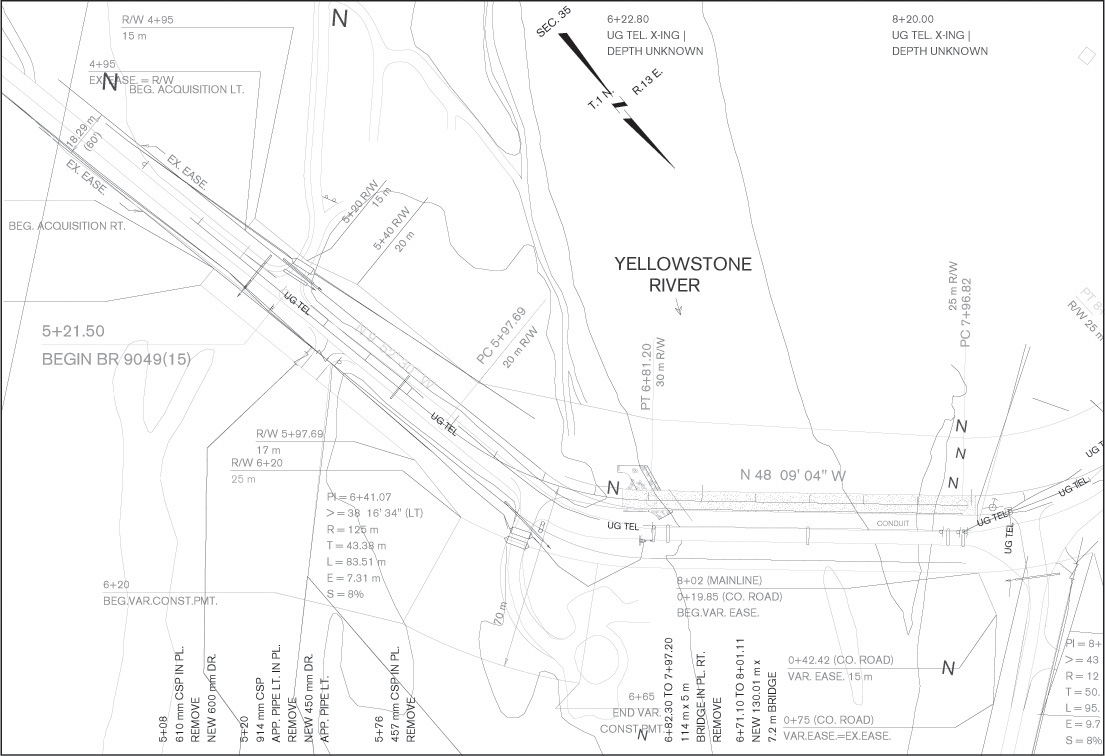

Flexibility and accuracy make 2D CAD systems a cost-effective tool in a wide variety of businesses. For many civil engineering projects, the difficulty of capturing all the 3D information needed to model irregular surfaces, such as terrain, may not be worth the benefits of working in 3D. For projects such as highway design, civil mapping, electrical distribution, and building systems, 2D CAD models may provide enough information and be created more quickly from the information at hand (see Figure 5.8). Areas and perimeters can be calculated accurately, and drawings can be revised quickly. 2D CAD models are more accurate than paper drawings.

5.8 Large-scale projects such as this highway plan are often modeled in 2D CAD. Most 2D CAD systems associate dimension values with the entities they describe, so dimensions can be updated if the drawing changes. (Courtesy of Montana Department of Transportation, MSU Design Section, Bozeman, MT.)

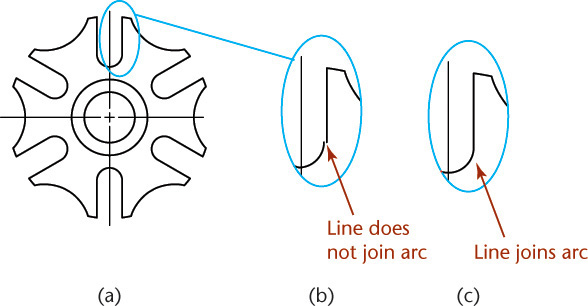

If lines and shapes in a 2D CAD drawing are not drawn using methods that connect exact geometry, they may not actually connect. This can cause a number of different problems. For example, when crosshatching inside a boundary, even a small gap can cause the hatching to “leak” out.

The drawing of the geneva cam below appears fine here and on screen. But when the corner is enlarged, it is clear that the line that should be tangent to the arc does not connect. Because of the algorithm used to generate circles and arcs, line segments used to represent them may not appear to connect when zoomed. But when the CAD drawing is regenerated from the data in the file, the line will—if tangent—clearly touch the arc, as shown in (c).

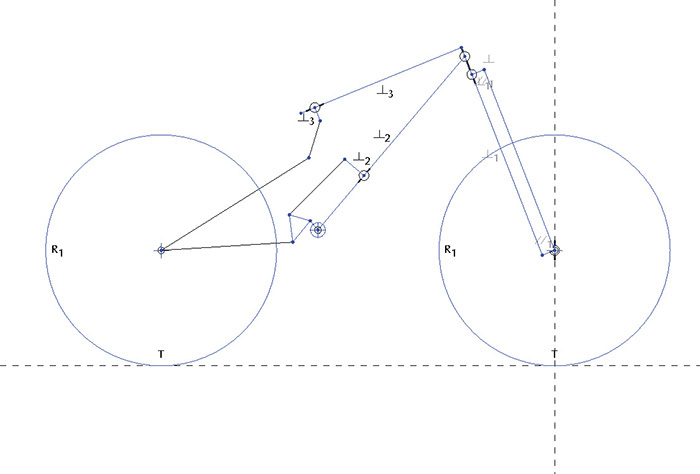

2D Constraint-Based Modeling

Constraint-based modeling originally started as a method for creating 3D models. Constraint-based 2D models provide a mechanism for defining a 2D shape based on its geometry. Relationships like concentricity and tangency can be added between entities in the drawing. For example, once a concentric constraint is added between two circles, they will remain concentric, and you will be alerted if you attempt to make a change that will violate this geometric constraint. Dimensions in the drawing constrain the sizes of features.

Relationships defined between parts of the 2D model are maintained by the software when you make changes to the drawing. Geometric constraints can be a valuable tool, but to benefit from them, you must apply them with a good understanding of basic drawing geometry and the behavior desired when changes are made to the shape.

5.2 3D Models

2D models must be interpreted to visualize a 3D object. To convey the design to individuals unfamiliar with orthographic projection—or to evaluate properties of the design that are undefined in 2D representations—3D models are used.

Physical Models

Physical models provide an easy visual reference. Physical models are called prototypes when they are made full size or used to validate a nearly final design for production. People can interact with them and get a feel for how the design will look and how it will function. Many problems with designs are discovered and corrected when a physical prototype is made.

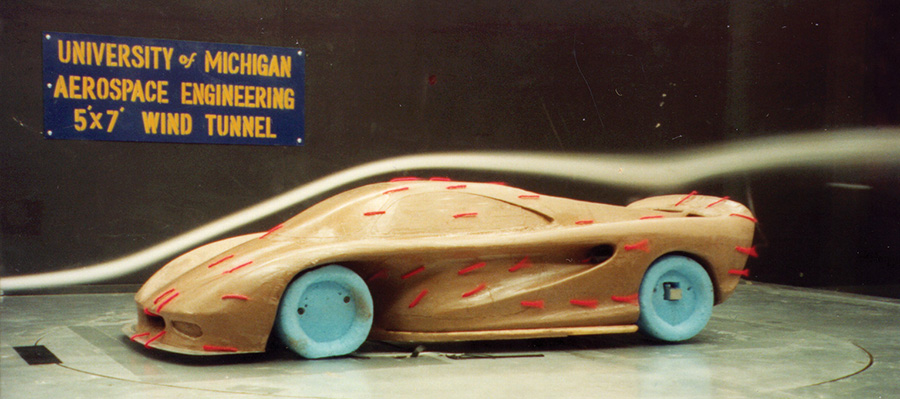

The robustness and cost effectiveness of physical models are often linked. A simple model made of clay or cardboard may be enough for some purposes (see Figure 5.9), but determining the fit of many parts in a large-scale assembly, or producing a model realistic enough for market testing, may be cost prohibitive until very late in the design process. A full-size prototype of the BMW 850I cost more than $1 million to produce. The amount of information and detail built into the model adds to its cost.

5.9 This physical clay model of the Romulus Predator was used to evaluate the aerodynamics of its lines in a wind tunnel at the University of Michigan. (Courtesy of Mark Gerisch.)

The accuracy of a physical prototype also drives up its cost. Many objects are designed to be mass produced so that the cost of individual parts is reduced. When each part in the model must be produced one at a time, the cost of the prototype can be many times greater than the manufacturing cost of the final product. The more the model must match the final product in terms of materials used and final appearance, the greater the cost. Rapid prototyping systems offer quick and relatively inexpensive means of generating a physical model of smaller parts without the cost of machining or forming parts one at a time (see Figure 5.10).

5.10 Prototype parts created using a fused deposition modeling system are useful for design verification. (Courtesy of Stratsys, Inc.)

Physical models are a very good visual representation of the design, but if they are not made from the materials that will be selected for the design, their weight and other characteristics will not match the final product. Sometimes, owing to the size of the project, the physical model must be made to a smaller scale than the final design. The accuracy of the final part also may not be possible with the materials and processes used for the prototype.

Probably the least attractive feature of a physical prototype is its lack of flexibility. Once a physical prototype has been created, changing it is expensive, difficult, and time-consuming. Consequently, full-size physical models are not usually used until fairly late in the design process—when major design changes are less likely. This can limit the usefulness of the model even though it provides important feedback about items that are not working well. When the information comes late in the design process, it can be too expensive to return to a much earlier stage of the design to pursue a different approach. Only critical problems may be fixed. Solutions to problems found late in the process are generally constrained to cause the least amount of redesign while fixing the problem. When a prototype is created late in the process, there may not be time or resources to create a new prototype for the new solution. New problems introduced by the change may not be seen until actual parts are produced.

Despite the trade-offs, even very costly physical models have been a cost-effective way for companies to avoid much more costly errors in manufacturing.

3D CAD Models

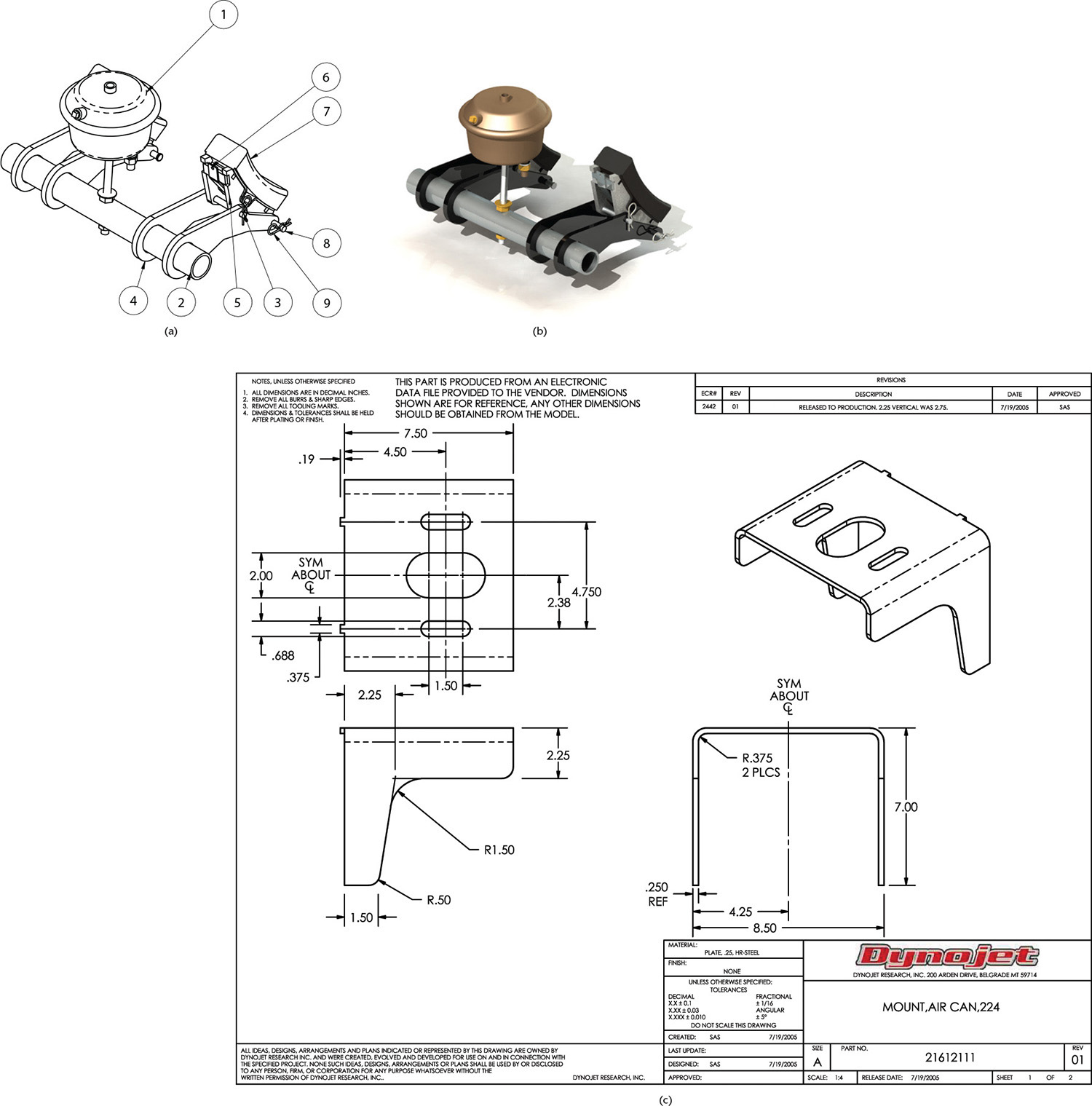

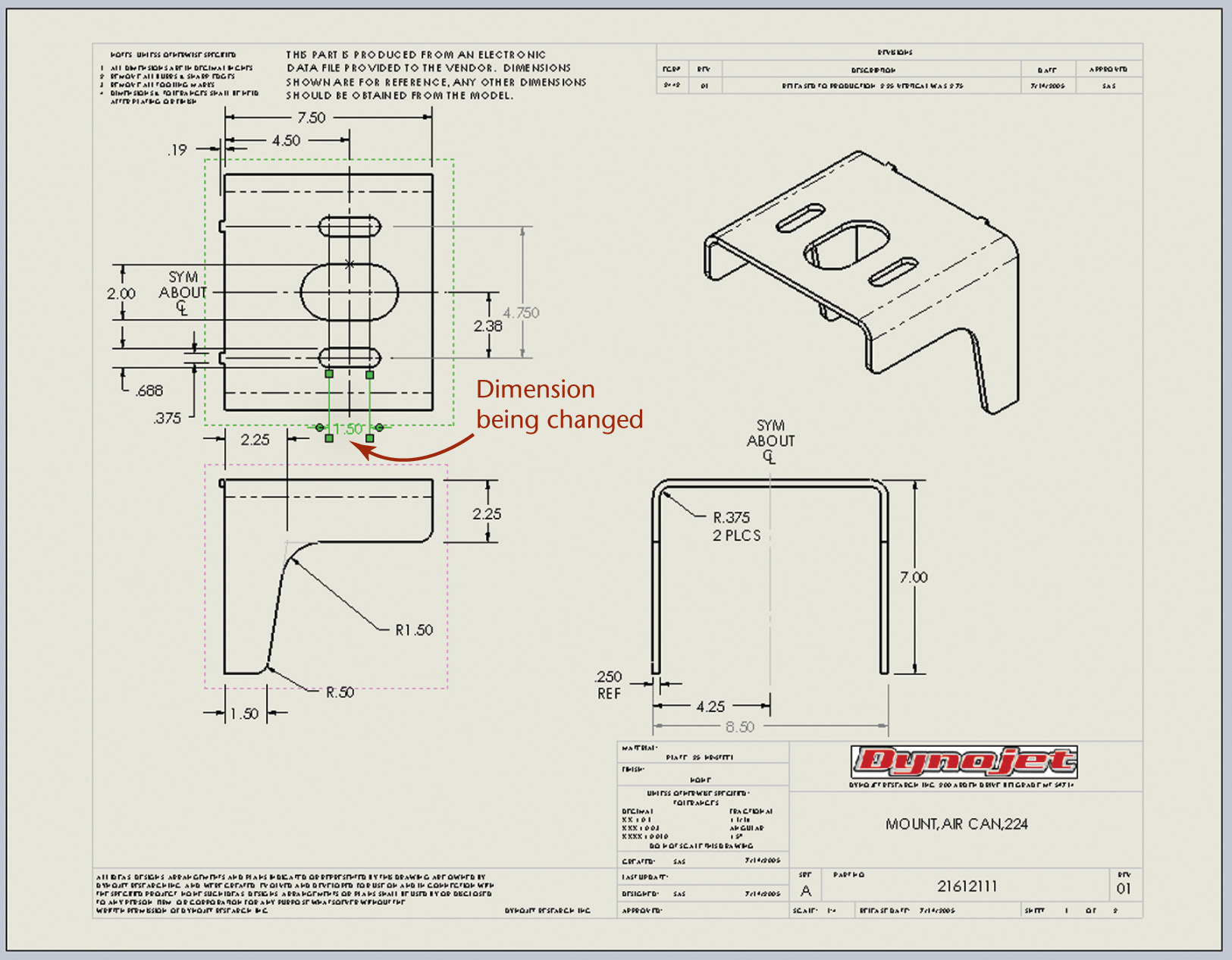

A 3D CAD model offers all the benefits of a 2D model and a physical model. As a visual representation, 3D CAD models can generate standard 2D multiview drawings as well as realistically shaded and rendered views. Because a 3D CAD model accurately depicts the geometry of the device, it may eliminate the need for a prototype—or make it easy to create one from the data stored in the model. Options for viewing the model make it understandable to a wide range of individuals who might be involved with the design’s refinement (see Figure 5.11).

5.11 The 3D model, shown as outline in (a), can also be rendered to produce the realistic view shown in (b) and to generate accurate 2D views for multiview drawings (c). (Courtesy of Dynojet Research, Inc.)

Virtual Reality

Virtual reality (VR) refers to interacting with a 3D CAD model as if it were real—the model simulates the way the user would interact with a real device or system. Using a virtual reality display, users are immersed in the model so that they can move around (and sometimes through) it and see it from different points of view. The headset display shown in Figure 5.12 uses two displays set about 3 inches apart (the typical distance between a person’s eyes). Each display shows a view of the object as it would be seen from the eye looking at it, which creates a stereoscopic view similar to the one sent to the brain by our two eyes. Some headsets let you control the viewpoint by moving your eyes or head, so that as you look around, a new view is created to correspond with the new direction.

5.12 Virtual Reality Headset. Cybermind’s Visette45 has both closed and see-through versions offering an effective screen size of 80 inches at 2 meters. (Courtesy of Cinoptics.)

Some 3D interfaces, such as a 3D mouse or controller, let the user interact with the items in the 3D model in a way that enhances the illusion of reality. Some gloves (similar to those shown in Figure 5.13) even use model data to provide physical feedback to the user when an object is encountered. If a virtual object is squeezed, feedback to the glove provides the feeling of the resistance a solid object would give when squeezed. Systems may even interpret how much force would crush the object and provide this sensation to the user.

5.13 Virtual Reality Gloves. These 5DT Ultra series of data gloves are controlled via a belt-worn wireless kit designed to transmit data for two gloves simultaneously. (Courtesy of 5DT/Fifth Dimension Technologies.)

The term virtual prototype describes 3D CAD systems that represent the object realistically enough for users, designers, and manufacturers to get the same type of information they get from creating a physical prototype.

As more sophisticated software becomes available to analyze, animate, and predict the behavior of the design under various physical conditions, the 3D CAD model becomes a better representation of the final object—and better suited for testing and study.

3D CAD models offer a high degree of accuracy and measurability and a high degree of flexibility. Each new generation of CAD software automates more common tasks, allowing the designer to focus more on the design and less on the mechanics of changing the model. This flexibility allows the CAD model to become a preliminary work that is refined and tested until it is ready to be used as a plan for the final product.

The ability of 3D CAD models to be used throughout the process, serve in lieu of a physical model, and be reused and modified indefinitely makes them very cost effective, especially in designing mechanical assemblies. However, not all 3D CAD models are the same. Familiarity with different types of 3D modeling systems lets you select the method and software most suitable for your design project.

5.3 Types of 3D Models

Each of the major 3D modeling methods—wireframe modeling, surface modeling, solid modeling, and parametric constraint-based modeling—has its advantages and disadvantages. Many CAD systems incorporate all these modeling methods into one single software package. Other software may provide only one or two of these methods.

Wireframe Models

Wireframe modeling represents the edges and contours of an object using lines, circles, and arcs oriented in 3D space. 3D wireframe drawings can be easy to create, are handled by many low-cost software packages, and provide a good tool for modeling simple 3D shapes. The method gets its name from the appearance of the model, which resembles a sculpture made of wires, as shown in Figure 5.14.

5.14 A Wireframe Model. Edges and contours of an object are represented by lines, circles, and arcs oriented in 3D space. 3D wireframe is a suitable method for modeling this snow-melting system.

You create a wireframe model in much the same way that you create a 2D CAD drawing. Each edge where surfaces on the object intersect is drawn in 3D space using simple geometric tools, such as a 3D line or arc. The X-, Y-, and Z-coordinates for the endpoints are stored in the database along with the type of entity.

3D wireframes can quickly display process control, piping, sheet metal parts, mechanical linkages, and layout drawings showing critical dimensions that use relatively simple geometric shapes. Interferences and clearance distances are difficult to visualize in 2D piping drawings. It can be critical that they are not overlooked in the design. For example, to quickly check clearances for the design of an electrical substation, the engineer may create a wireframe model of the high-voltage conductors to ensure that conductors are not too close to other equipment that could produce an electrical arc, causing a short.

A 3D wireframe can be useful for piping layout around other 3D equipment, which can be difficult to visualize in 2D. The centerline of the pipe is easy to represent in a 3D wireframe, as shown in Figure 5.14. This prevents problems with clearances that are acceptable in two dimensions, but not in a third. For a system with moving parts or where complex shapes need to fit, a different 3D modeling method may better allow you to assess interferences.

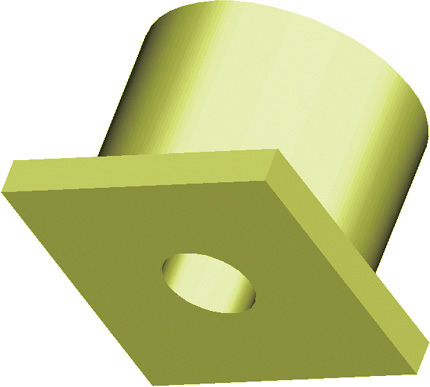

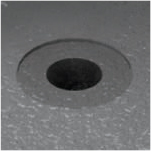

Wireframe models do not include surfaces that can be shaded, so they are not realistic looking. Because you can see through the model, some shapes cannot be represented unambiguously, and it may be difficult to see from a single view which areas are holes and which are surfaces. The model in Figure 5.15 shows a wireframe model. Without rotating or checking coordinate locations, you may visualize the part as showing the hole from the top or the bottom (Figure 5.16).

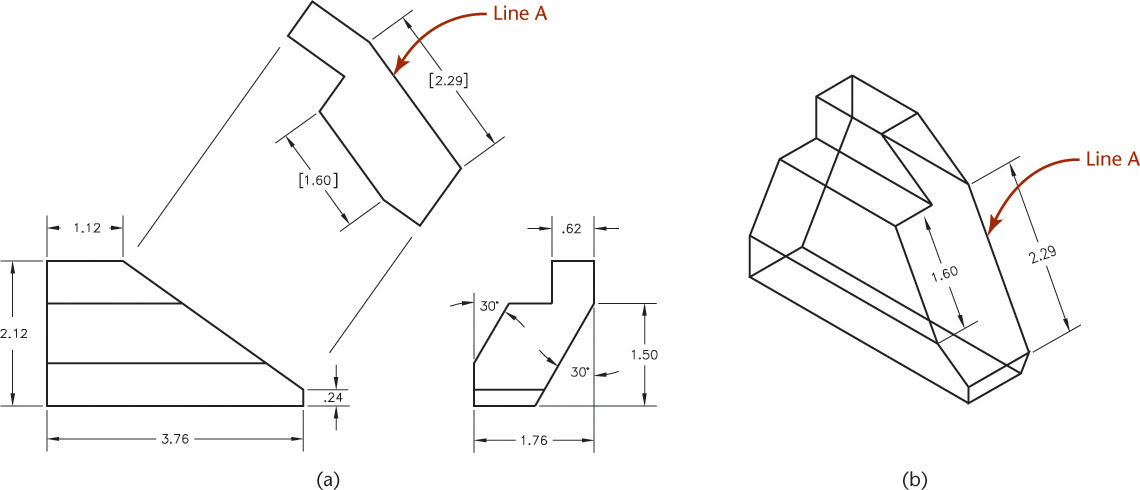

Before you can measure oblique edges and surfaces in a 2D drawing, you must first create an auxiliary view showing that feature true size. The true size is already contained in the 3D wireframe and can be measured directly. For example, the length of edge A in Figure 5.17 can be determined from this 2D AutoCAD drawing only in the auxiliary view. The 3D wireframe model of the same part can show the length of the edge directly.

5.17 (a) The 2D CAD drawing displays the true length of line A in an auxiliary view. (b) The length of the line in the 3D wireframe model can be determined directly from the model.

Surface Models

CAD surface models define a shape by storing its surface information. A surface model is similar to an empty box. The outer surfaces of the part are defined (although unlike an actual box, these surfaces do not have any material thickness). Because the surfaces are defined, they can be shaded to provide a realistic appearance.

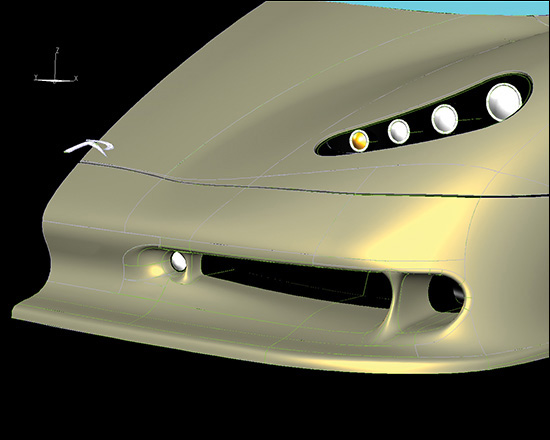

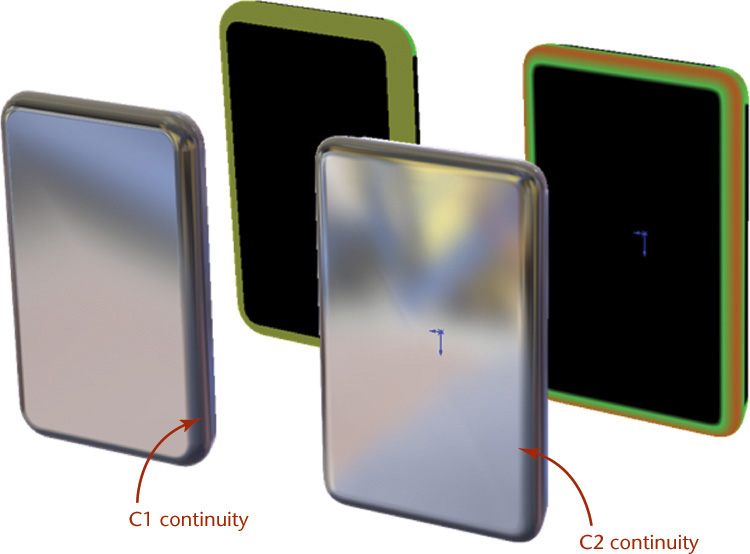

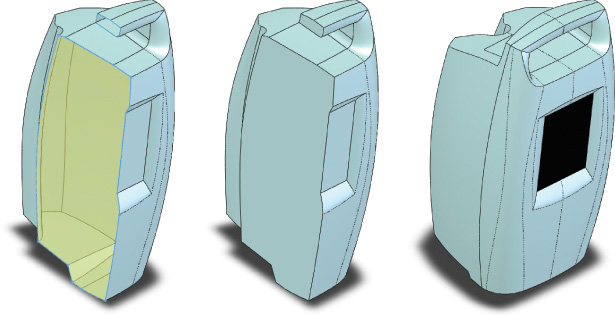

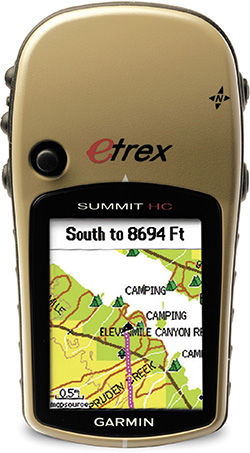

Surface modelers are traditionally used by industrial designers and stylists who create the outside envelope for a device. These designers need modeling tools that convey a realistic image of the final product. Software tools developed for their use focused first on the challenge of modeling the exterior of the product, not the mechanical workings within. Many surface modelers offer specialized tools for lighting and rendering a model, so designers can create photorealistic images that cannot be distinguished from the actual product (see Figure 5.18).

5.18 A Rendered Surface Model. The industrial designer for the Timex TurnAndPull alarm was concerned that the inner rings would look too deep or too busy. A rendered surface model allowed team members to see how it would look when manufactured. (Courtesy of Timex Group USA, Inc.)

Concurrent engineering and the use of the 3D CAD database as the product description contributed to the development of modeling software that satisfies the aesthetic needs of industrial designers as well as the functional information needed by engineers. Understanding surface modeling techniques will help you assess the kinds of features that are available in your modeler—and whether a dedicated surface modeler is required.

Surface Information in the Database

Most surface modeling software stores a list of a part’s vertices and how they connect to form edges in the CAD database. The surfaces between them are generated mathematically from the lines, curves, and points that define them. Some surface modelers store additional information to indicate which is the inside and which is the outside of the surface. This is often done by storing a surface normal, a directional line perpendicular to the outside of the surface. This allows the model to be shaded and rendered more easily.

Storing the definitions of the surfaces in the CAD digital database is termed boundary representation (BREP), meaning that the information contained in the database represents the external boundaries of the surfaces making up the 3D model. Remember that these surfaces have no thickness.

The following are basic methods used to create surface models:

• Extrusion and revolution

• Meshes

• Spline approximations

Extruded and Revolved Surfaces

You can define a surface by a 2D shape or profile and the path along which it is revolved or extruded.

Figure 5.19 shows a surface model created by revolution, and the profile and axis of revolution used to generate it. Regular geometric entities can be revolved or extruded to create surface primitives such as cones, cylinders, and planes. Surface primitives are sometimes built into surface modeling software to be used as building blocks for complex shapes.

5.19 Revolved Surface. The surface model in (a) was created by revolving the profile about the axis shown in (b).

Meshes

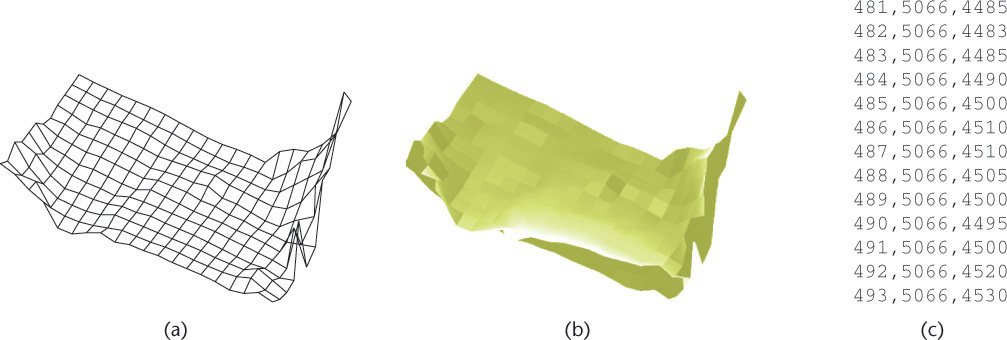

Mesh surfaces are defined by the 3D location of each vertex stored in the CAD database. Each group of vertices is used to define a flat plane surface. Figure 5.20 shows a mesh surface and a list of some of its vertices.

5.20 A Mesh Surface. A mesh surface is composed of a series of planar surfaces defined by a matrix of vertices, as shown in (c). The wireframe view of the mesh in (a) appears more like a surface in the rendered view shown in (b).

Some mesh surfaces are called triangulated irregular networks (TINs), because they connect sets of three vertices with triangular faces to serve as the surface model. A mesh surface can be useful for modeling uneven surfaces, such as terrain, where a completely smooth surface is not necessary. A sufficiently large matrix will result in correspondingly smaller triangles that can better approximate a smooth surface. Refining the mesh will produce a smoother surface, but the size of the CAD file will increase and result in slower software performance. Some modeling packages allow you to define a smoothed representation of the surface instead of the somewhat bumpy appearance of a strictly mesh surface.

NURBS-Based Surfaces

The mathematics of nonuniform rational B-spline (NURBS) curves underlies the method used to create surfaces in most surface modeling systems. A NURBS surface is defined by a set of vertices in 3D space that are used to define a smooth surface mathematically.

Rational curves and surfaces have the advantage that they can be used to generate not only free-form curves but also analytical forms such as arcs, lines, cylinders, and planes. This is an advantage for surface modelers that use NURBS techniques, as the database does not need to accommodate different techniques for surfaces created using a surface primitive, mesh, extrusion, or revolution.

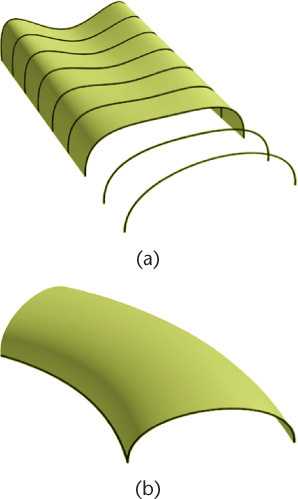

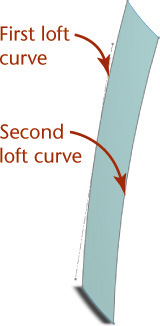

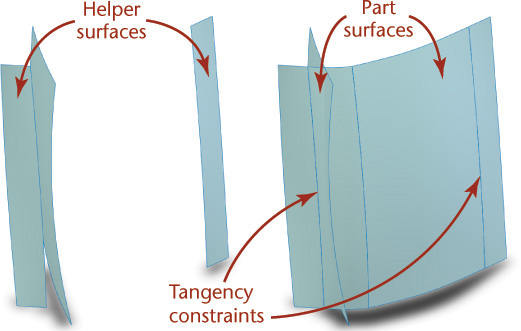

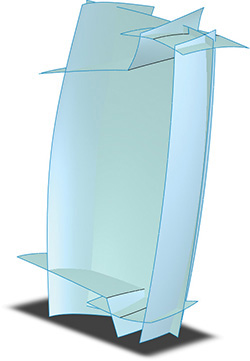

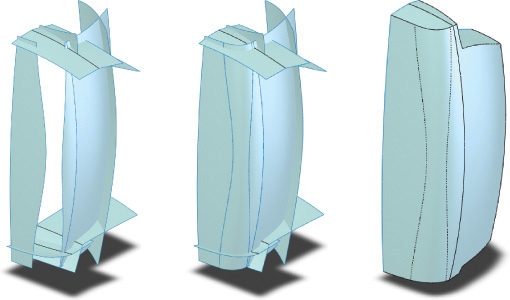

Spline curves can be used as input for revolved and extruded surfaces that can be lofted or swept. Lofting is the term used to describe a surface fit to a series of curves that do not cross each other. Sweeping creates a surface by sweeping a curve or cross section along one or more “paths.” In both cases, the surface blends from the shape of one curve to the next (see Figure 5.21).

5.21 Lofting. A lofted surface (a) blends a series of curves that do not intersect into a smooth surface. A swept surface (b) sweeps a curve along a curved path and blends the influence of both into a smooth surface model.

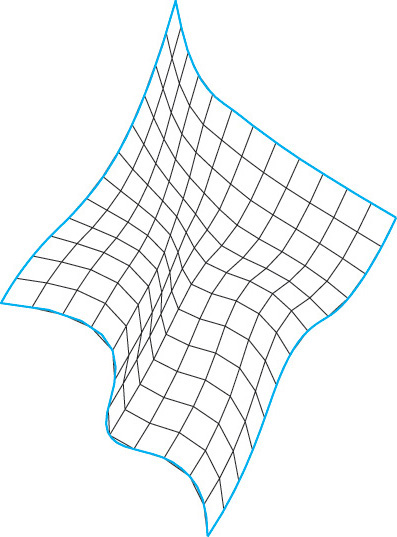

NURBS surfaces can also be created by meshing curves that run perpendicular to each other, as illustrated in Figure 5.22.

5.22 When the spline curves shown here are used to generate a NURBS surface, the functions defining each curve are blended. (Courtesy of Robert Mesaros.)

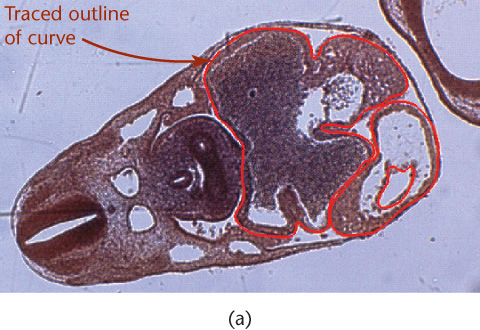

Reverse Engineering

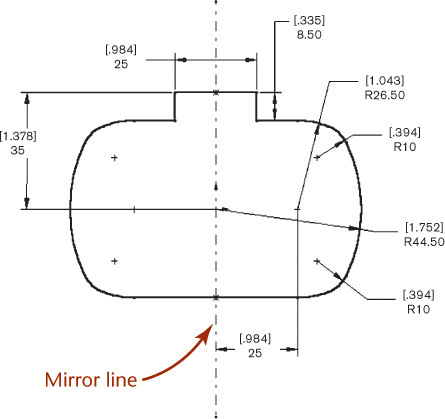

Most reverse engineering software traces a physical object to generate mesh data, or data points for a surface model. Points on the object are captured as vertices, then translated into a digital surface representation. Reverse engineering can be an easy way to capture the surface definition of an existing model. Designers might use traditional surface sculpting methods and then digitize the physical model to create a digital database. An existing part might be reverse engineered so that it can be added to the CAD database (Figure 5.23 shows data for the surface model in Figure 5.24 being created using a reverse engineering process.)

5.23 Digitizing a Model. A coordinate measuring system was used to digitize the clay model of the Romulus Predator. Seventeen hundred data points were captured by digitizing half of the quarter-scale clay model of the Predator. Digitizing the data and mirroring it in the model ensured side-to-side symmetry. (Courtesy of Mark Gerisch.)

5.24 Surface Patches. The lines on the surface model of the Predator prototype indicate individual surface patches that make up the model. Areas of the car with drastic curvature changes are divided into smaller patches, which keeps the mathematical order of the patches lower and reduces the overall complexity of the surface. (Courtesy of Mark Gerisch.)

Complex Surfaces/Combining Surfaces

To create a surface model, you do not create the entire surface at once—just patches to combine into a continuous model. Just as curves can be made of individual segments that are smoothed into a continuous curve, surfaces can be made of entities referred to as patches. Like a spline curve, a patch can be interpolated, or approximated.

A Coon’s patch is a simple interpolated surface that is bounded by four curves. Mathematical methods interpolate the points on the four boundary curves to determine the vertices of the resulting patch (see Figure 5.25).

5.25 Coon’s Patch. The lines between the boundary curves in this Coon’s patch surface represent the shape of the surface and illustrate the influence of the boundary curves on the interpolated surface between them.

Surface patches are joined by blending the edges of the patches. Areas created by blending, or the surfaces created by fillets, corners, or offsets, are called derived surfaces. They are defined by mathematical methods that combine the edges of the patches to create a smooth joint.

Sometimes, complex surface patches are created by trimming. For example, a circular patch may start with a rectangular patch, then be trimmed to a circle, and finally be blended with other surface patches.

Some surface modeling systems include the use of Boolean operations, whereas others do not. Systems that do not include Boolean operations or good tools for trimming surfaces can be difficult to use to create a feature such as a round hole through a curved surface because the exact shape of the surface, including the hole, must be defined by specifying its edges.

Editing Surfaces

Once a surface has been defined, editing depends on the method used by the surface modeler to create and store the surface. Usually, the information describing the locations of vertices is editable, and each vertex can be changed. If the surface modeling software retains the original 2D profile that was extruded or revolved to produce the surface, it can be used to facilitate changes to these surfaces. If not, it can be difficult to efficiently edit the surfaces.

For NURBS surfaces, each control point can be edited to produce local changes in the surface model. (Editing Bezier surfaces, by the same token, produces global changes to the surface.) Grabbing and relocating vertices is a highly intuitive way to edit a surface model that contributes to its usefulness in refinement. The term “tweaking” is used to describe editing a model by adjusting control points individually to see the result. For example, the NURBS surfaces used to define the shape of the Predator’s exterior made it easy to use the surface model to explore design options in several areas (Figure 5.26).

5.26 The roof scoop on the Predator’s clay model was not visible enough, so the designer adjusted the control points in the surface model in real time until the scoop looked just right on screen. (Courtesy of Mark Gerisch.)

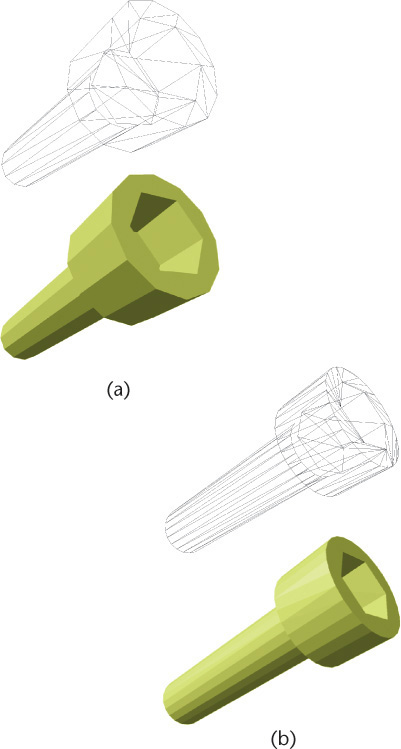

Surface Model Accuracy

Surface model information can be stored with more or less accuracy. Compare the meshes shown in Figure 5.27. The mesh at left contains fewer vertices than the mesh shown in 5.27b. Although the surface shown in 5.27b is more accurate, the additional information makes its file size larger. This requires more computer processing to store and interact with the model. Depending on your purpose, the smaller number of vertices may be satisfactory.

5.27 Accuracy and Surface Mesh. The mesh in (a) has fewer vertices and larger facets than the mesh used in (b). The finer mesh in (b) more accurately represents the cylindrical shape of the bolt.

Surface models used for computer-aided manufacturing (CAM) require a high degree of accuracy to produce smooth surfaces. The trade-off between speed and accuracy may be resolved by setting the surface display to a less accurate faceted representation and storing a smoothed or more highly defined surface definition in the database. It is important to distinguish between the screen display of the model and the surface definition stored in the database.

Splines used to create surfaces can also vary in accuracy. Splines can have more or fewer control points that you can use to shape the surface. To model surfaces smoothly, fewer control points may allow more fluid curves. A mesh surface used to calculate area may not be as accurate as one created using a smoothing algorithm such as NURBS or Bezier.

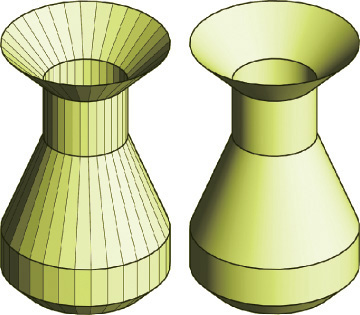

Tessellation lines are used to indicate surfaces in a wireframe view, and they may or may not reflect the accuracy of the surface (see Figure 5.28). It is important to distinguish when tessellation lines represent the accuracy of the view of the model, and when they represent the accuracy of the model stored in the database. If the software accurately represents the actual geometry of the model in the model database, the tessellations simply represent the model in the on-screen view.

5.28 Tesselation Lines. The faceted representation on the left uses planar surfaces to approximate smooth curves.

Using Surface Models

The primary strength of a surface model is improved appearance of surfaces and the ability to convey these complex definitions for computer-aided manufacturing. Customers purchase products not only on their function but also on their styling. A realistically shaded model can be used with potential customers to determine their reactions to its appearance. Lighting and different materials can be applied in most surface modeling software to create very realistic looking results (Figure 5.29). Many consumer products often start with the surface model, then the interior parts are engineered to fit the shape of the styled exterior. When surface models can be used in place of a physical prototype—or in place of the product itself for promotional purposes—the savings add to their cost effectiveness.

5.29 This docking station illustrates the complex curves possible in a surface model. (Image courtesy of ©2016 Dassault Systèmes SolidWorks Corporation.)

Because the relative locations of surfaces from a particular direction of sight can be calculated, surface modeling systems can automatically remove back edges (or represent them as hidden lines). Surface definitions remove the ambiguity inherent in some wireframe models and allow you to see holes and front surfaces by hiding the nonvisible parts of the model.

The complex surfaces defined by a surface model can be exported to numerically controlled machines, making it possible to manufacture irregular shapes that would be difficult to document consistently in 2D views. Both surface and solid models can be used to check for fit and interference before the product is manufactured. Often, surface models can be converted to solid models and vice versa.

Because surface models define surfaces, they can often report the surface area of a part. This information can be useful in calculating heat transfer rates, for example, and can save time, particularly when the surface is complex. The accuracy of the calculations may depend on the method used by the software to store the surface data.

Complex surfaces can be difficult to model. The cost-effectiveness of surface modeling depends on the difficulty of the surface, the accuracy required, and the purpose for which the model will be used. Many modeling software systems offer a combination of wireframe, surface, and solid modeling capabilities, making it possible to weigh the benefits against the difficulties and the time required to create each type of model.

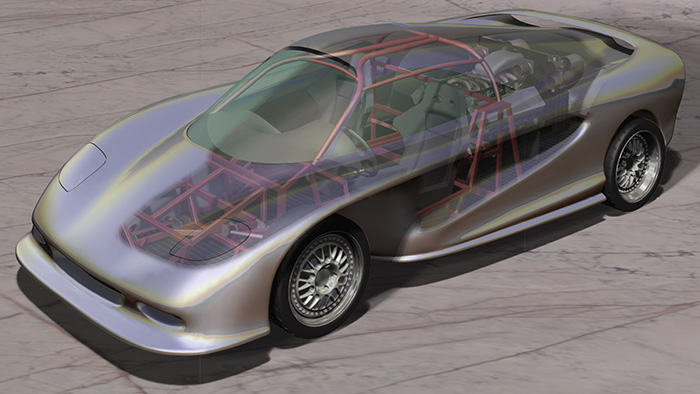

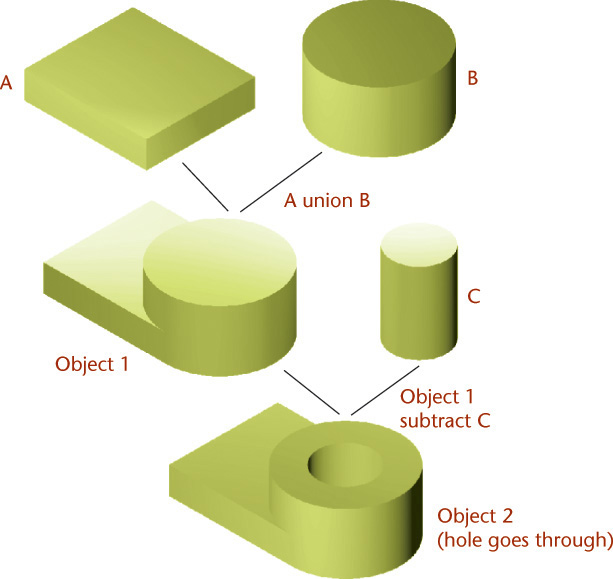

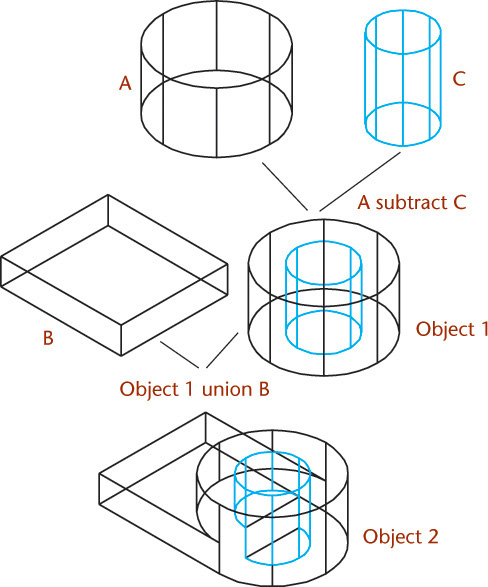

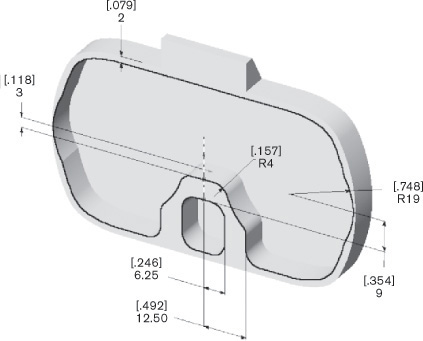

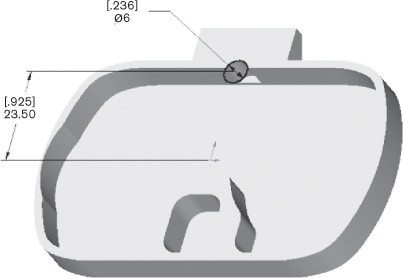

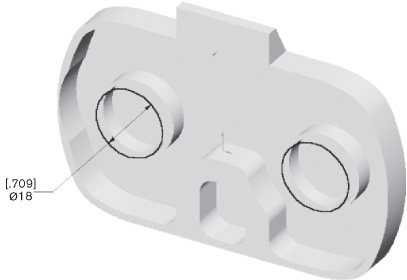

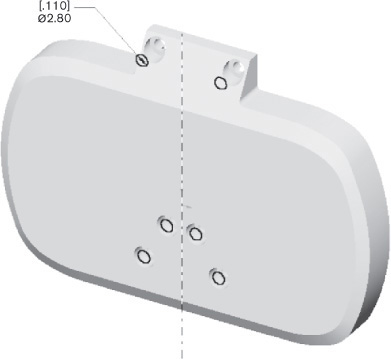

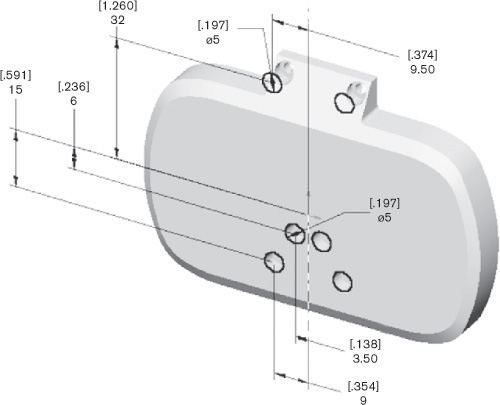

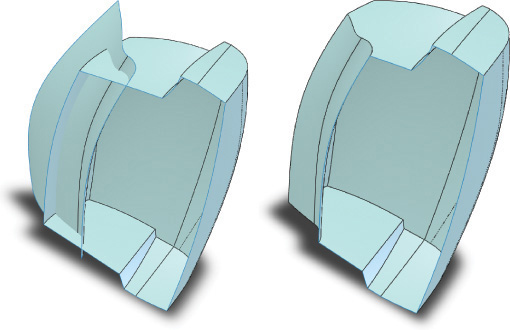

Solid Models

Solid models go beyond surface models to store information about the volume contained inside the object. They store the vertex and edge information of the 3D wireframe modeler, the surface definitions of the surface modeler, plus volume information. Many solid modelers also store the operations used to create features, which makes it possible to edit them quickly (see Figures 5.30 and 5.31). Solid models closely approximate physical models, making them especially useful for defining, testing, and refining the designs they represent.

5.30 Order Matters. The order of operations matters when you use Boolean operations to create a solid model—and when you edit it (see Figure 5.31).

5.31 Joining A and B after the hole is created by subtracting C changes the design—the hole no longer goes through the entire part.

Tip

Understanding basic modeling methods will help you assess the modeling software of tomorrow. Some new modelers, referred to as “direct” or “explicit” modelers, such as Creo and SpaceClaim, offer a broad command set that adopts features from traditional surface and solid modelers.

Using 3D Solid Models

Many of the examples so far illustrated how accurate representation of a 3D object provides valuable engineering information. Solid models are highly visual and easy to understand and measure. They are also highly accurate if modeled accurately. Solid models are often able to replace physical models, as well as control CAM equipment, which adds to their cost-effectiveness.

In addition, 3D solid models are particularly suited for use with analysis packages. They contain all the information about an object’s volume, and volume is important to many engineering calculations. Mass properties, centroid, moments of inertia, and weight can be calculated from the solid model as often as needed during the refinement process. The system behavior can be simulated from the wealth of information available in the model.

Solid models provide information needed for other analyses. Finite element analysis (FEA) methods break up a complex object into smaller shapes to make stress, strain, and heat transfer easier to calculate. Because the solid model defines the entire object, FEA software can use this information to generate an FEA mesh automatically for a part. This allows inclusion of this type of analysis earlier in the design process, incorporation of changes, and testing of the new model with FEA analysis again. Some FEA and solid modeling packages are integrated to provide this analysis within the modeling software. Others even allow direct model optimization based on the FEA results, creating a new version of the model that the designer can then revise further.

5.4 Constraint-Based Modeling

Constraint-based modeling has several advantages for engineering design. As the design evolves, constraint-based models can be updated by changing the sizes and relationships that define the model. In traditional solid modeling methods, changing the size of one feature may require several others to be changed, or the model may need to be totally re-created. Because of the iterative nature of the design process, a design is repeatedly modified as it is refined. The model’s responsiveness can result in more cycles during the refinement stage (or more cycles in less time) and, ultimately, a better design.

Neptune Seatech Oy made the decision to switch from a 2D design method to a constraint-based 3D modeler, SolidWorks, so it could get its products to market faster while preserving the iterations needed for complex, accurate designs. Neptune Seatech is a Finnish engineering company that specializes in the design of vehicles for subsea applications—passenger and research submarines. To meet increasingly rigorous design, performance, and safety standards, the company found 2D methods made it hard to complete the desired number of design iterations and still meet product development deadlines. Its first project using the constraint-based 3D modeler, a floating bridge for ferries, took only 18 weeks to produce (see Figure 5.32).

5.32 Neptune Seatech’s parametric model of the floating bridge for ferries was modified to create a family of designs for the variations in ferry landings. (Courtesy of Neptune Seatech Oy.)

The company enjoyed two other benefits of constraint-based modeling. First, the ease with which constraint-based models can be updated makes it possible to create families of designs. Neptune’s floating bridge allows cars to pass from the ferry to land and vice versa during loading and unloading. Because each landing site is slightly different, the main dimensions of a given bridge vary slightly from one site to another. The bridge manufacturer that hired Neptune had several designs previously created for specific landing sites. To eliminate confusion in manufacturing, the customer wanted a design that could be updated for new bridges. Neptune proposed to design one bridge, then produce the others by changing the length and width factors. The constraint-based model of the bridge made it easy to change the pertinent dimensions and have the software update the related parts to a new size. The investment in the bridge model was used to refine the original bridge design, then used again as a starting point for variations in the product family (see Figure 5.33).

5.33 Neptune Seatech’s bridge model, created in SolidWorks, involved more than 1700 parts. (Courtesy of Neptune Seatech Oy.)

Neptune also enjoyed the software’s ability to analyze mass properties. The weight and volume data for a floating bridge need to be evaluated during design so that the resulting bridge floats at the correct level. Calculating the weight of a floating bridge design would have taken 1 to 2 weeks using Neptune’s previous methods, but the built-in capabilities of SolidWorks made it possible to monitor this data throughout the design process. The ease with which the model could be modified made it possible to analyze the model, make changes, and analyze the model again. The software also made it possible for analysis to occur earlier in the design process, allowing more time to optimize the design.

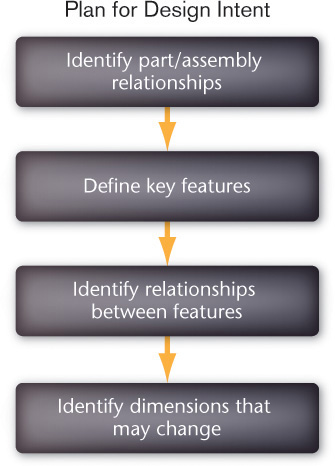

Constraint-based modeling also improves designs by focusing the modeler on the design intent for the product. If a constraint-based model is to be updated successfully when changes are made, the rules for building the model must capture the intended design solution for the system or device. The extra attention and planning required to capture design intent in the model makes the designer carefully consider the function and purpose of the item being designed, which in turn results in better designs.

5.5 Constraints Define the Geometry

In a constraint-based model, an object’s features are defined by sizes and geometric relationships stored in the model and used to generate the part. Two basic kinds of constraints are used to drive the model geometry.

• Size constraints are the dimensions that define the model. The choice of dimensions and their placement is an important aspect of capturing the design intent.

• Geometric constraints define and maintain the geometric properties of an object, such as tangency, verticality, and so on. These geometric constraints are equally important in capturing design intent.

In constraint-based modeling, a parameter is a named quantity whose value can change; it is similar to a variable. Like a variable, a parameter can be used to define other parameters. If the length of a part is always twice the width, you can define its size as “2 × Width,” where Width is the name of the dimension.

Unlike a variable, a parameter is never abstract: it always has a value assigned to it, so that the model can be represented. For example, the parameter Width is defined by a value, such as 3.5. The value for the length parameter is calculated based on the Width, so in this case Length is 7. If the width value is changed to 5, the length is automatically updated to the new value of “Width * 2,” or 10 (see Figure 5.34).

Even something as simple as this rectangular block may have design intent built into its model. As it is being updated, do you want the center of the part to stay fixed and the part to elongate in both directions, or do you want it to lengthen all in one direction? If so which end should stay put?

Figure 5.35 shows a part that has been modeled in a 3D constraint-based design package. The parameters driving the geometry of the model are indicated on the drawing. When the parameter value for the length of the part was changed, the part was updated automatically, as shown in part b of the figure. Notice that the threaded length did not increase. If you wanted the thread length to increase as the bolt was lengthened, you would need to define the constraints and parameters differently.

5.35 When the length dimension increased to .750, the part was updated to reflect this new size constraint. Notice that the threaded length remained the same and the bolt head remained attached after the update. The modeler maintained the size and geometric relationships that were defined.

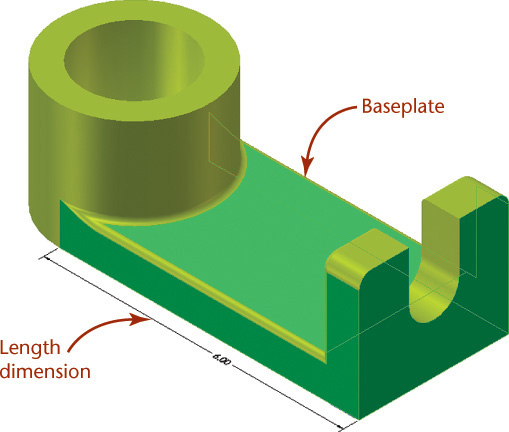

Feature-Based Modeling

Constraint-based modeling is also called feature-based modeling because its models are combinations of features. Creating a constraint-based model is similar to creating any other solid model. However, in constraint-based modeling the resulting part is derived from the dimensions and constraints that define the geometry of the features. Each time a change is made, the part is re-created from these definitions. Individual features and their relationships to one another make up the constraint-based model.

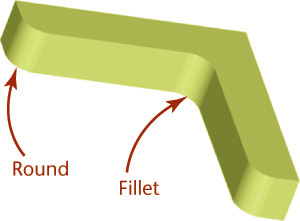

A feature is the basic unit of a constraint-based solid model. Each feature has properties that define it. When you create a feature, you specify the geometric constraints that apply to it, then specify the size parameters. The modeler stores these properties and uses them to generate the feature. If an element of the feature, or a related part of the model, changes, the modeling software regenerates the feature in accordance with the defining properties assigned to it. For example, an edge that is defined to be tangent to an arc will move to preserve the tangency constraint if the size of the arc is changed.

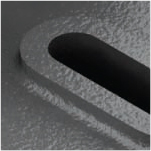

Some features, such as holes and fillets, may use predefined features with additional properties that are maintained as the model is updated. For example, a “through hole” (one that goes completely through the part feature) will be extended if the part thickness increases.

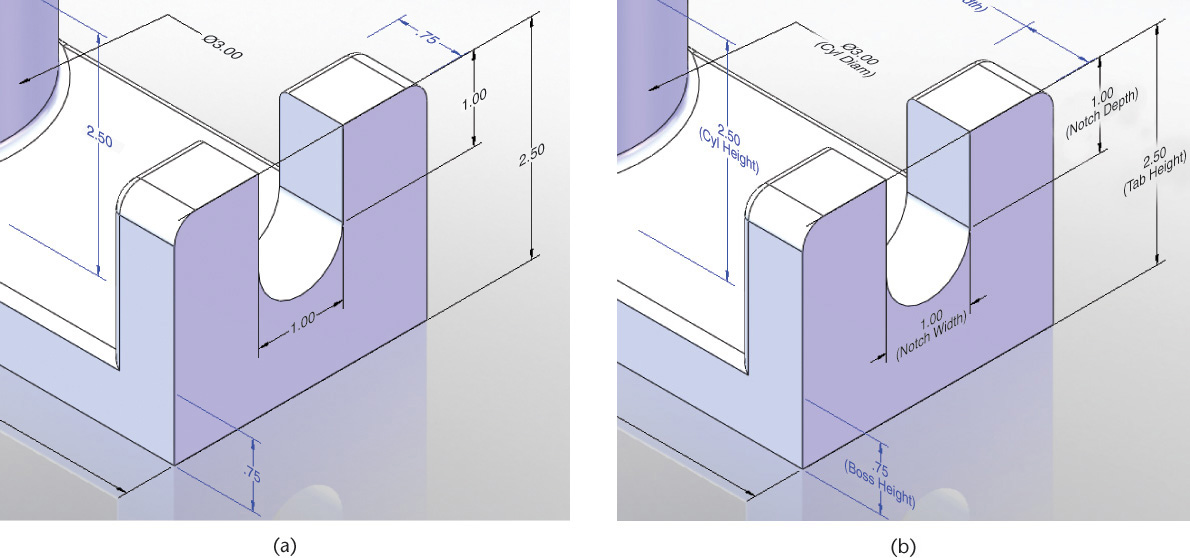

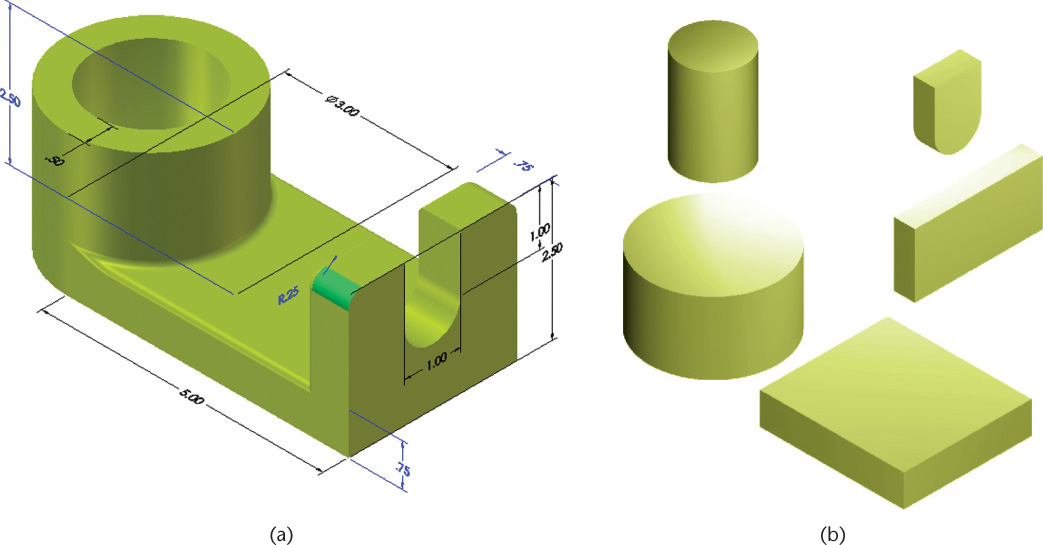

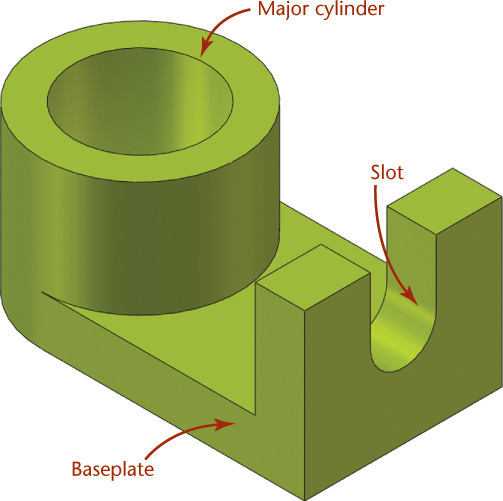

When you look at the fixed-height shaft support shown in Figure 5.37a, can you identify the features that make up its shape? Figure 5.37b shows the major cylinder, hole, plate, end plate, slot, and rounds that form the model of the shaft support.

Being able to update models easily to reflect changes in the design is a key ability of constraint-based modelers. If you are not using a constraint-based solid modeling program, you may have to re-create the feature just to change a size. This can result in considerable time and effort, especially for interrelated features.

In addition to defining relationships between features, constraint-based modeling software also allows you to use constraints and parameters across parts in an assembly. Thus, when a part changes, any related parts in the assembly can also be updated. Because the software regenerates the features and parts from the relationships stored in the database (see Figure 5.38), planning constraint-based relationships that reflect the design intent of the part or product is the key to efficient and useful constraint-based models.

5.38 Model Tree. The window at the left side of the screen called the “model tree” (enlarged here) lists the features in the order in which they were created. The icon next to the feature indicates the operation used to create the feature. Extrusions and extruded cuts were used to form the cylinder, baseplate, and hole. Then, the end feature was extruded and the slot created using an extruded cut. Finally, fillets were added to round the edges.

5.6 Planning Parts for Design Flexibility

Design intent refers to the key dimensions and relationships that must be met by the part. Where does the part need to fit into other parts? Do certain features need to align with other features? How will the part change as the design evolves? By thinking about these relationships, you can organize the features so that the structure of the part and its relationships are the foundation for later features. Four key aspects of planning for design intent are summarized in Figure 5.39. Of course, you cannot know everything about a design before you begin, and there will be changes that will require more work than others; but starting your model with the geometric relationships in the design in mind will allow you to benefit from the power of constraint-based modeling. To see how a constraint-based model can reflect design intent, you should understand some basics about constraint-based modeling software.

Constraint-based modeling software in many ways parallels the design process. To start creating a part, you often start with a 2D sketch of the key shape of a feature, such as that shown in Figure 5.40. The initial sketch may be rough in appearance because the software will apply constraints to define the relationships between the simple 2D geometric elements of your sketch. This process is similar to the way one of your engineering colleagues interprets your hand-drawn sketches. If lines appear to be perpendicular or nearly so, your colleague assumes that you mean them to be perpendicular, without your having to mark the angular dimension between the lines. In a similar way, constraint-based modelers apply constraints to your rough sketch, so that lines that appear nearly perpendicular, parallel, vertical, horizontal, concentric, or collinear will have a constraint relationship added to them so that they function that way in the model. This process is called “solving” the sketch in some modeling software, because the software is interpreting and assigning dimensions and constraints to generate a 2D “profile” of the feature. Before you generate the actual feature, you can review and change the dimensions and geometric constraints so they are what you intended. This step is key to defining your design intent. The sketch constraints in Figure 5.40 have already been added.

5.40 A constrained sketch is used as the basis for a model feature. Geometric constraints are identified by the blue symbols.

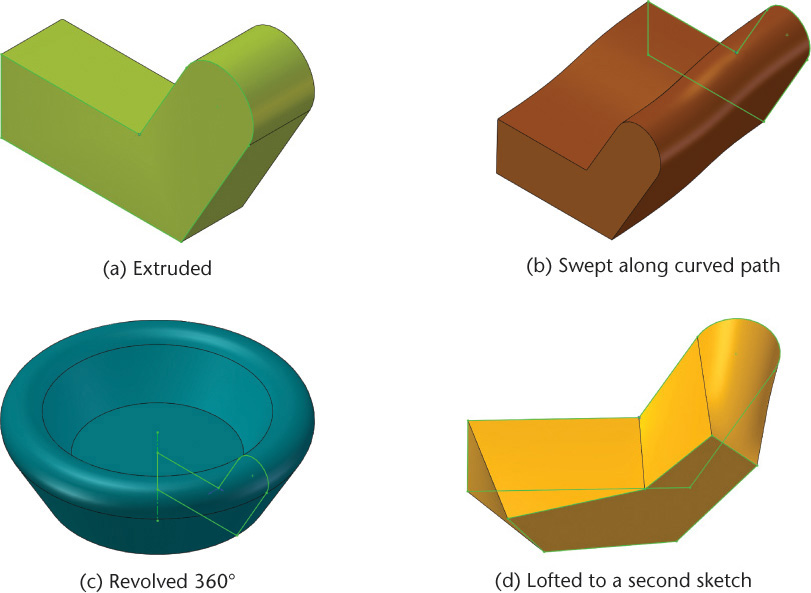

To generate a 3D feature, you then select a command to extrude, revolve, sweep, or blend the profile geometry. Figure 5.41 shows the profile in Figure 5.40 as it would appear after being (a) extruded, (b) swept, (c) revolved, and (d) lofted to create different types of features from the 2D sketch.

5.41 Same Sketch, Different Operations. The same sketch was used to create each of these features. The sketch in (a) was extruded, in (b) swept along a curved path, in (c) revolved 360° about an axis, and in (d) lofted between the sketch and a second sketch with angled lines and a straight top.

5.7 Sketch Constraints

Constraint-based modeling software starts by automatically interpreting your sketch, to define the constraints that it will hold constant. To do so, it evaluates your sketch against a set of rules stored in the software. A line, for example, that is drawn within 3° or 4° of being horizontal will be constrained to remain horizontal. Your sketch will be altered so the line you drew is, in fact, horizontal. The software will apply the constraints it needs to solve the sketch.

Constraint-based modeling programs allow you to review the constraints that are applied to the sketch geometry so you can change them to those needed to reflect your design intent. Table 5.2 describes some possible sketch constraints and shows symbols often used to indicate them on screen. (Different modelers use different symbols and means of displaying the constraints—see Table 5.3 and Figure 5.42). These constraints may create relationships to other lines in the sketch or to geometry in an existing feature.

Constraint |

Rule |

Symbol |

Horizontal |

Lines that are close to horizontal are constrained to be horizontal (usually you can control the number of degrees for this assumption, typically set to 3° or 4°). |

H |

Vertical |

Lines that are close to vertical are constrained to be vertical (usually within 3° or 4°). |

V |

Equal length |

Line segments that appear equal length are constrained to be equal. |

L1, L2, etc. |

Perpendicular |

Lines that appear close to 90° apart are constrained to be perpendicular. |

⊥ |

Parallel |

Lines that appear close to parallel are constrained to be parallel. |

// |

Collinear |

Lines that nearly overlap along the same line are assumed to be collinear. |

No symbol displayed |

Connected |

Endpoints of lines that lie close together are assumed to connect. |

Dot located at intersection |

Equal coordinates |

Endpoints and centers of arcs or circles that appear to be aligned horizontally or vertically will be constrained to have equal X- or equal Y-coordinates. |

Small thick dashes between the points |

Tangent entities |

Entities that appear nearly tangent are constrained to be tangent. |

T |

Concentric |

Arcs or circles that appear nearly concentric are concentric. |

Dot at shared center point |

Equal radii |

Arcs or circles that appear to have similar radii are constrained to have equal radii. |

R |

Points coincide |

Points sketched to nearly coincide with another entity are assumed to coincide. |

No symbol displayed |

Table 5.3 Selected Constraint Relations in SolidWorks

$$$$$Symbol |

Relation |

Entities to Select |

Result |

|

Horizontal or Vertical |

One or more lines or two or more points |

The lines become horizontal or vertical (as defined by the current sketch space). Points are aligned horizontally or vertically. |

|

Collinear |

Two or more lines |

The items lie on the same infinite line. |

Coradial |

Two or more arcs |

Items share the same center point and radius. |

|

|

Perpendicular |

Two lines |

The two items are perpendicular to each other. |

|

Parallel |

Two or more lines. A line and a plane (or a planar face) in a 3D sketch |

The items are parallel to each other. The line is parallel to the selected plane. |

ParallelYZ or ParallelZX |

A line and a plane (or a planar face) in a 3D sketch |

The line is parallel to the YZ (or ZX) plane with respect to the selected plane. |

|

|

Tangent |

An arc, ellipse, or spline, and a line or arc |

The two items remain tangent. |

|

Concentric |

Two or more arcs, or a point and an arc |

The arcs share the same center point. |

Midpoint |

Two lines or a point and a line |

The point remains at the midpoint of the line. |

|

|

Intersection |

Two lines and one point |

The point remains at the intersection of the lines. |

Coincident |

A point and a line, arc, or ellipse |

The point lies on the line, arc, or ellipse. |

|

|

Equal |

Two or more lines or two or more arcs |

The line lengths or radii remain equal. |

Symmetric |

A centerline and two points, lines, arcs, or ellipses |

The items remain equidistant from the centerline, on a line perpendicular to the centerline. |

5.42 Changing Constraint Defaults. The Constraint Settings dialog box in AutoCAD lets you change the priority in which the constraints are applied. You can also set the tolerance for sketched endpoints to be considered coincident, and lines to be assumed horizontal or vertical. Understanding which assumptions are being applied to your sketch can help you define the exact geometry you require. (Autodesk screen shots reprinted courtesy of Autodesk, Inc.)

Not all constraint-based modeling programs apply all these constraints, nor do they apply them in the same fashion. Study the constraints available in the software you use and determine their effect on the sketch. You also may be able to set the threshold values for various constraints. For example, instead of having lines at 1° be automatically constrained as horizontal lines, you may wish to increase this value to 3° (Figure 5.42). If you are having difficulty getting the constraints you desire applied to the sketch, you may want to turn off automatic constraint application and select each specific constraint to apply to your sketch.

Most constraint-based modeling programs let you remove or override a constraint that is applied, or specify that the geometry is exact as drawn. Sometimes, you may have to force the sketch closer to the desired relationship. For example, if two lines are too far off in the sketch to be constrained as perpendicular by the software, you could add an angular dimension of 90° between them to force them to that relationship. With the dimensions driving the geometry to the condition you want, the software may apply the perpendicular constraint. Once the constraint is applied, you often can delete the dimension you added.

It is usually beneficial to let geometric constraints determine much of your sketch geometry, then dimension the sizes and relationships that cannot be defined using constraints. You could use a constraint-based modeler as you would a solid modeler, adding dimension values to define all the features, but this would not build in the intelligence that allows the software to automate updating the model.

Overconstrained Sketches

Sketches used in constraint-based modeling may not be overconstrained. An overconstrained or overdimensioned sketch is one that has too many things controlling its geometry.

The sketch shown in Figure 5.43 is overconstrained. Because the top arc is constrained to be tangent to both vertical lines, and its radius is dimensioned (sd0), the width of the sketch is defined. The horizontal dimension shown at the bottom (sd2) defines this width again. If both the arc radius dimension and the overall width dimension were allowed in the model and one of them changed, it would be difficult or impossible for the part to be updated correctly. If the overall width changed and the tangent constraint or arc radius did not, the sketch geometry would be impossible.

Underconstrained Sketches

An underconstrained or underdimensioned sketch is one that has too few dimensions or constraints and is therefore not fully defined.

The sketch shown in Figure 5.44 is underconstrained. It lacks a height dimension controlling its vertical size. Without this dimension the sketch is not fully defined. Some software will allow you to create a 3D feature from an underconstrained sketch as long as the sketch follows basic rules—for example, the sketch does not cross itself, and the sketch encloses an area. If the sketch is underconstrained, the software assumes values for unspecified dimensions based on the sizes drawn. This can be helpful when you are trying out ideas, but it is best to plan to create a model that reflects your design intent.

Dimensions can easily be changed by typing a new value, so go ahead and guess the size and change it later if needed; but keep in mind that choosing which dimensions to use to define the sketch is a critical aspect of making sketches and features that will be updated as expected when a dimension changes.

Applying Constraints

You should select dimensions that define the proper relationships between the sketched geometry and other existing features in your model. The surfaces between which you choose to create the dimensions are a large factor in creating a model that will be updated in the desired manner. You should not let the rules of your software package determine the dimensions, as it is unlikely that they will reflect your design intent.

When you are dimensioning a sketch used to create a feature, place the dimensions where you can view them clearly. Later, if you create a drawing from your model, you will be able to clean up the appearance of the dimensions if needed. You can move dimensions, change their placement, and arrange them so they follow the standard practices. Good placement practices such as placing dimensions outside the object outline and keeping the dimensions a reasonable distance from one another will make the dimensions in your model easier to read.

3D models are accepted as final design documentation. When you are going to use the model as the design database and not provide drawings, it is even more important to ensure that dimensions and tolerances shown in the model are clear. You will learn more about practices for documenting inside the 3D model in Chapter 11.

If you do a good job selecting the dimensions that control the drawing geometry, you will have little cleanup work to do later when you are creating drawing views.

Setting the Base Point

Some constraint-based modeling software assumes a base point in the sketch for the first feature you create. The base point is fixed on the coordinate system; the other sketch geometry is located on the coordinate system based on its relationship to this base point. The resulting feature will stay fixed on the coordinate system at this base point. When dimension values change, they will change relative to that point. There is only one base point per model.

The base point is indicated in Figure 5.45a by the × in the lower right corner of the sketch. When the width dimension changes, the sketch is updated to the new size while leaving the base point fixed on the coordinates. The rest of the sketch geometry is reoriented, as shown in Figure 5.45b.

5.45 Base Point. The base point fixes the sketch on the coordinate system in this underconstrained sketch. The base point serves as a fixed point when the model is updated. In AutoCAD, adding a Fixed Point constraint lets you identify the base point; otherwise, it is determined by software rules.

If your software uses a base point, it should become the base point for the entire model. When the model is updated, all dimensions will be updated from this point. A good rule of thumb is to identify a fixed point on your model that you would use as a starting point for measuring the part for inspection purposes. Use this point as the base point, or locate your dimensions from it as if it were the base point.

Locating most of your dimensions from a common edge or major surface can be effective for two reasons. First, it helps you create dimensions that will be useful for inspecting the part after manufacture; the dimension values in your model will measure from the same point that an inspector will use to measure the finished part. Second, it helps you anticipate how the model will be updated. When a value is changed, the features on the model will be updated (move) relative to the edge referenced in their dimensions. When you locate dimensions relative to other features you may have difficulty predicting how the model will be updated because you have to add the effect of changes to the intermediate features.

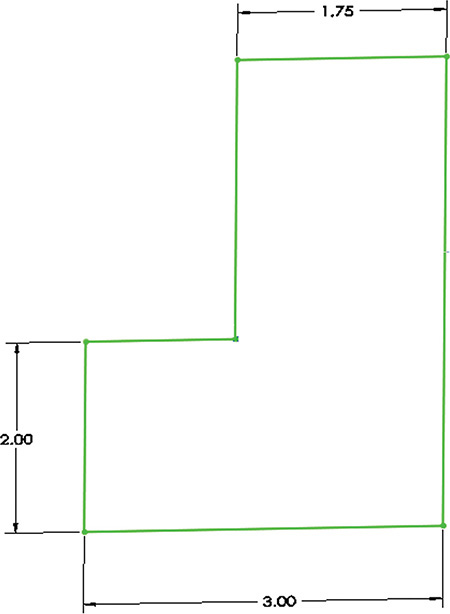

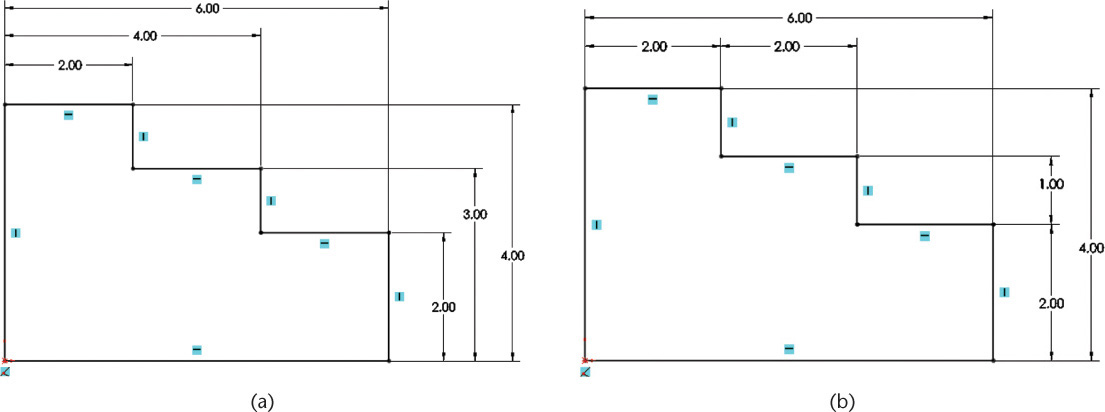

More important than any rule of thumb governing dimension selection or placement is to consider thoroughly the parts you are designing and to make the drawing geometry, constraints, and dimensions reflect the design intent for the part. In some cases, dimensioning a part from another feature is required to reflect the design intent. Figure 5.46 shows two sketches that have the same geometry but are dimensioned differently. When the 2.00 height dimension is changed to 2.50, how will each of these drawings be updated?

5.46 These two sketches of the same part have very different relations built into the dimensions for the sketch. The sketch in (a) relates all dimensions to the left and bottom edges of the part. The sketch in (b) has a chain of relationships built into the dimensions.

In the first case, shown in Figure 5.46a, the height of the 2.00 “step” will change to 2.50, narrowing the gap between it and the 3.00 step. In Figure 5.46b, the height of the 2.00 step will change to 2.50, and the height of the next step will be updated to 3.50 units so it remains 1.00 unit above it. In this case, the narrow gap will occur between the 3.50 and the 4.00 step. Either is correct to the extent that it reflects the intended design.

5.8 The Base Feature

To create useful relationships in a constraint-based model, it is helpful to start out your model with a good base feature. The base feature is the first feature you create. The other features are created using relationships that locate them to the base feature. Subsequent features are updated based on their relationships to the base feature or to one another. You should generally choose a fairly large, significant feature as the base feature.

Figure 5.47 shows the cylinder that could be created as the base feature for the shaft support and the other features that will relate to it. The major cylinder would make a good base feature because it is a significant feature of this part, and the other features make sense related to it. If the design intent of the part centers on the cylinder, its size and location determine the size and shape of other features. The width of the base plate will depend on the stability needed for the size of the cylinder. The hole for the shaft must be centered inside the cylinder and sized to leave enough remaining material for the wall thickness. Using the cylinder as the base feature also makes sense from the standpoint of the part’s role within a larger assembly, as its size could depend on the shaft being designed in a different part. By building your model around the major cylinder, you make it possible to update all features automatically if the cylinder size changes.

5.47 Base Feature. The major cylinder for the shaft support makes a good base feature because the cylindrical shaft to be supported is an important aspect of this design.

Adding Features to the Model

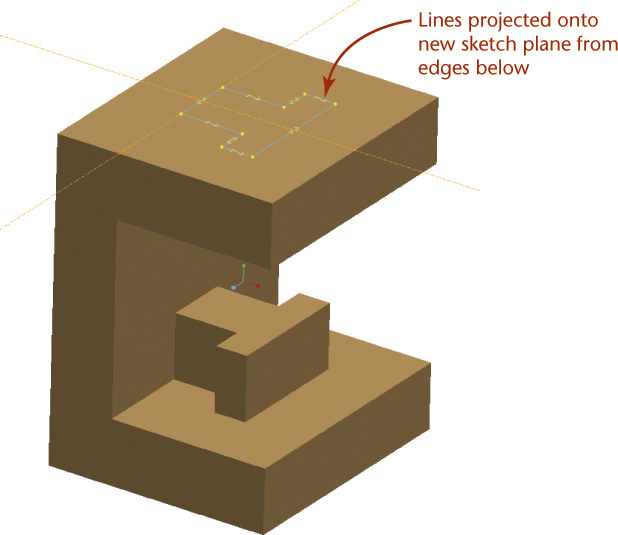

When you add features to the model, the way you constrain the sketch determines how it relates to the other features. Just as the base point serves to locate the base feature, at least one of the constraints applied to subsequent sketches must tell the software how the new feature relates to an existing feature.

To create the second feature, you can use a dimension to locate it relative to an existing edge or use a geometric constraint to align one of the sketch entities to the existing geometry. For example, you could dimension the center point of a hole to be a certain distance from the end of an existing feature or constrain the hole to be concentric to a cylinder or arc on an existing feature.

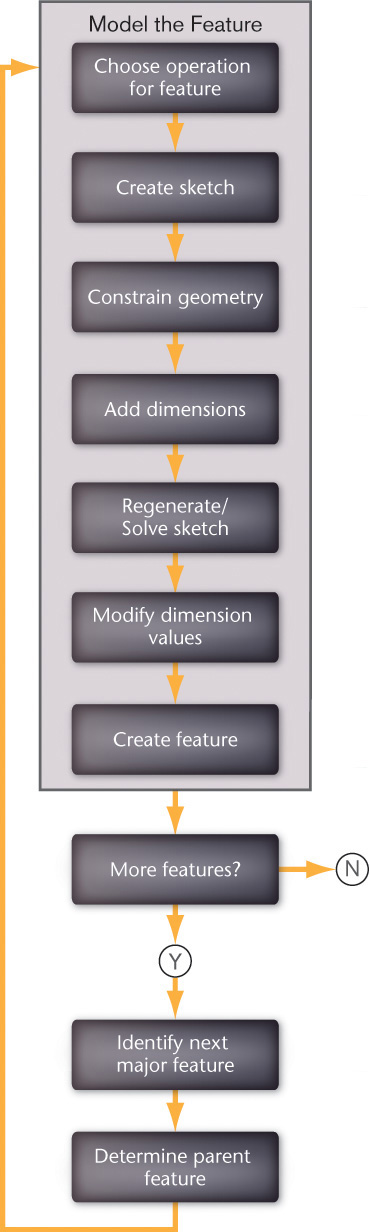

The way you dimension, constrain, or align your second feature determines how it will be updated with respect to the first feature. Use the things you know about the design to add features. Where are the fixed points on the model, and how does the feature you are adding relate to them? What are the conditions that the new feature needs to satisfy at all times? If existing features were to change, how would the feature you are adding need to change? In some cases, a simple dimension from an existing edge may be all that is needed to add the feature. In other cases, you will want to build in geometric or size relationships needed in the design. The basic process of constraint-based part modeling is illustrated in Figure 5.48. Starting with the base feature, you build a model by adding features and relating them to existing features. For each feature, the same basic process applies.

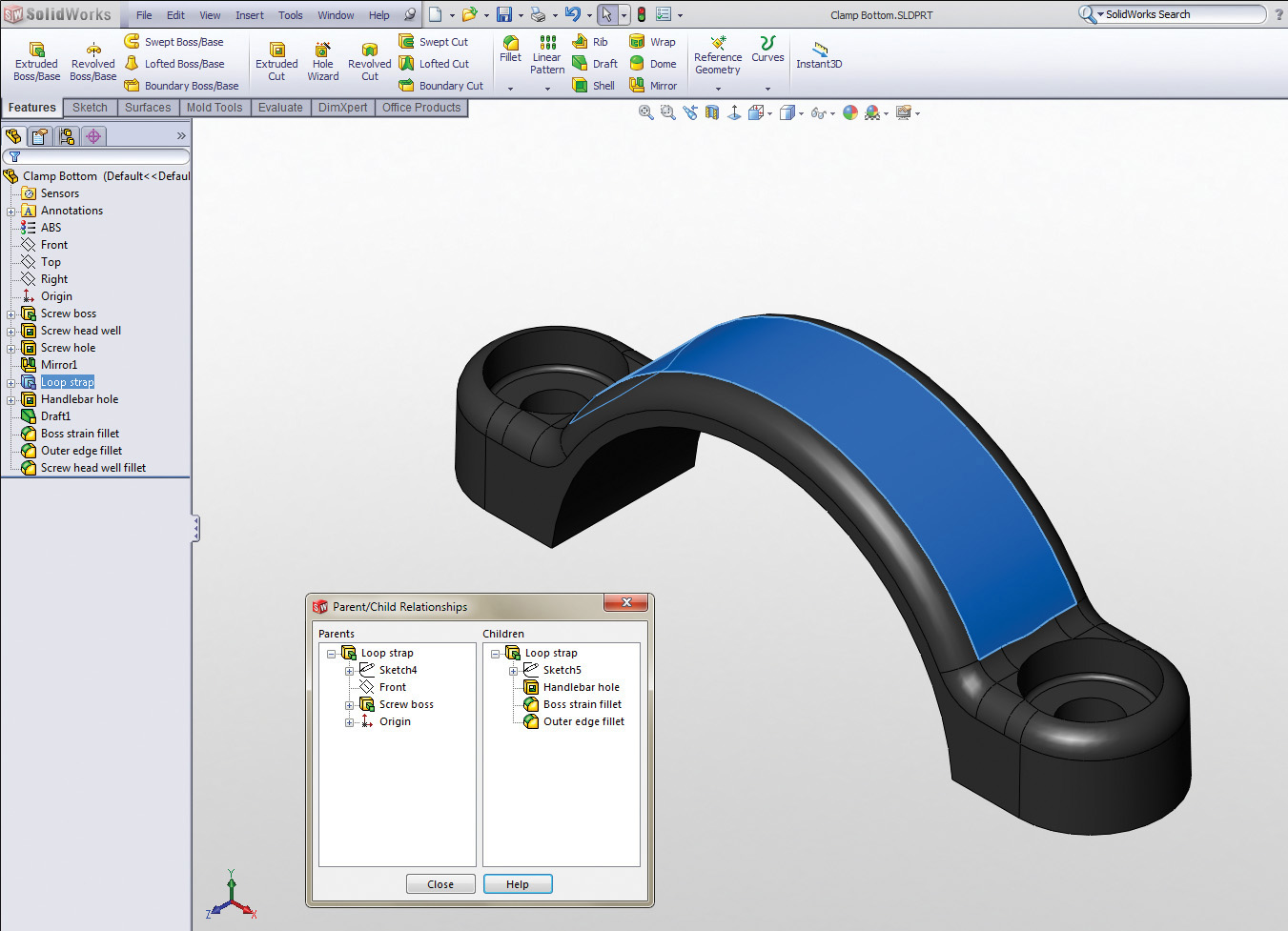

Parent-Child Relationships

Constraint-based modeling software stores information about each feature and its relationship to its parent feature. The term parent-child relationship is used to describe how one feature is derived from another feature. This relationship is defined by the geometric constraints applied to the sketch as well as its dimensioned size constraints. Planning when creating a parent-child relationship is important.

The base feature is the parent feature for the next feature created from it. Just as real children depend on their parents, child features are dependent on their parent features. If a parent feature moves, the child feature moves in relation to it. For example, when the hole feature was added to the shaft support part, its location was defined as concentric with the major cylinder. When the cylinder’s location changes, the hole feature remains concentric with the cylinder (Figure 5.49). If the hole is located relative to the baseplate or to some other feature and the cylinder is moved, the hole will not move with it (Figure 5.50).

5.49 The hole is concentric with the cylinder. As the baseplate length increases, the hole remains concentric.

5.50 The hole dimensioned from the right end of the part is in the wrong location when the baseplate length changes.

If you delete a feature, you will also delete its child features unless you redefine them so that they are related to a different parent feature. This is another reason for selecting a good base feature; you do not want the first feature you create to be something that might be deleted later in the design. Not all features will have child features, but all features other than the base feature must be related to some parent feature.

One way to visualize the parent-child relationships as you plan your model is to build a tree diagram. The relationships in the Clamp Bottom model in Figure 5.51 are illustrated in the Parent/Child Relationships window. The panel labeled Children shows that the feature named Loop strap has Handlebar hole, Boss strain fillet, and Outer edge fillet as its children, along with the sketch that formed its cross-sectional shape. These features may or may not have children (or “grandchildren”) of their own. The panel labeled Parent shows that the parent features for Loop strap are Sketch4, the Front datum plane, the Screw boss feature, and the Origin of the coordinate system.

5.51 A tree diagram showing the dependencies between features can help you plan your parametric model. Notice how the list of parent and child features from this SolidWorks model shows the dependencies between features. (Courtesy of Salient Technologies, Inc. (www.salient-tech.com))

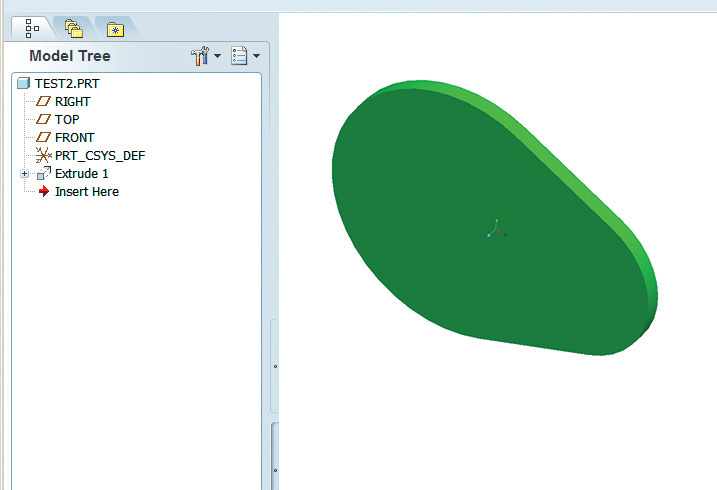

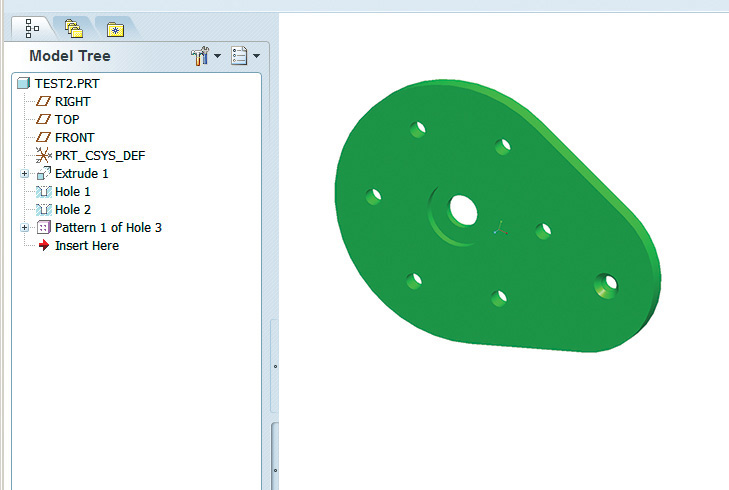

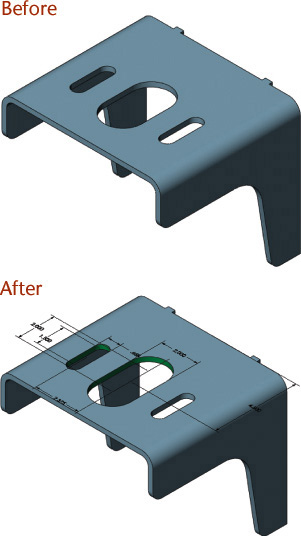

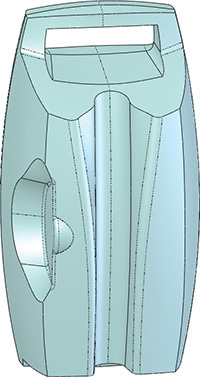

Many constraint-based modelers allow you to “play back” the model to see how it is being generated by the underlying parameters. The sequences shown in Figure 5.52 and Figure 5.53 illustrate how the features used to create the parts are ordered in relationships that reflect the design intent for the parts.

5.52 Base Feature. The base feature (Extrude 1) is the first feature created. (Courtesy of Mark Perkins.)

5.53 Child Features. Subsequent features are children of previous features. (Courtesy of Mark Perkins.)

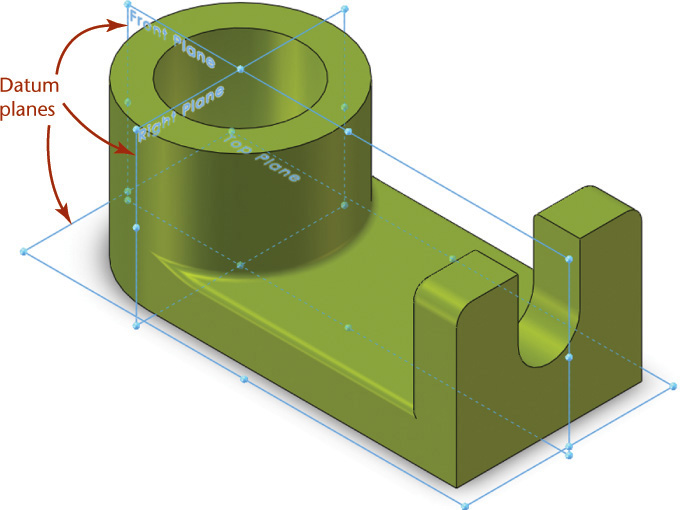

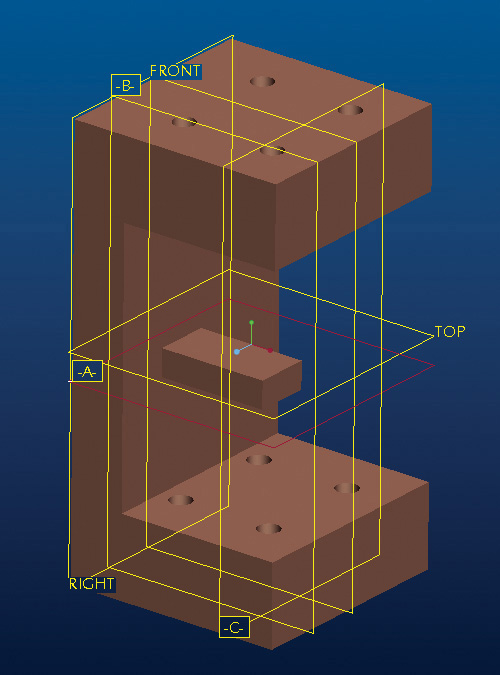

Datum Planes and Surfaces

In engineering drawing, a datum is a theoretically exact point, axis, or plane. A datum provides a reference surface, axis, or point used for inspecting the manufactured part. Theoretically exact planes used in modeling are called datum planes. They are planes used as a reference for model geometry. You can also create datum axes and datum points in 3D models. Features can be constrained and dimensioned relative to these planes, axes, and points, even though they are not solid objects and add no mass to the model. Some modeling packages provide a set of three mutually perpendicular datum planes, located so that they pass through the origin of the coordinate system, as a default. You typically may also create additional datum planes at other orientations and locations.

Often, it is very useful to use a set of datum planes (three mutually perpendicular planes) as the base feature in your drawing. In fact, most software provides them as the default starting features. Figure 5.54 shows the shaft support part with a set of datum planes used as the base feature.

5.54 Datum Planes. The three mutually perpendicular planes in this drawing serve as the base feature for the model.

One of the benefits of starting with a set of datum planes is that they can provide a set of normal surfaces that you can use to orient sketch geometry. This is particularly helpful when there are no planar surfaces on the part that you can use to build subsequent features easily. With a cylinder as the base feature for the shaft support, for example, there is no flat surface to which the end of the base plate can be constrained to be parallel. The datum plane “Right Plane” in Figure 5.54 provides a reference to which the plate is parallel.

Whether or not you start with a set of datum planes as a base feature, consider the surfaces that will serve as datum surfaces on your part. Parts are inspected to see whether they were manufactured acceptably based on a similar set of three mutually perpendicular, theoretically exact planes. Measurements of the finished part are taken from surfaces coincident with one of the datum planes. As you define your features consider the dimensions that will determine whether the part will fit. How will the part be measured after manufacture? If there is a surface from which measurements will be taken, it can be advantageous to identify it as a datum surface in your part (see Figure 5.55).

5.55 Datum Surface. Surface C on this fixture is a datum surface or reference location that will be used to inspect the location of a part feature. (Courtesy of Mark Perkins.)