4. Stoichiometry

If you are thinking about someone while reading this book, you are most definitely in love.

—Tim Newberger

Undergraduate ChE Student W2013

Now that we have shown how the rate law can be expressed as a function of concentrations, we need only express concentration as a function of conversion in order to carry out calculations similar to those presented in Chapter 2 to size reactors. If the rate law depends on more than one species, we must relate the concentrations of the different species to each other. This relationship is most easily established with the aid of a stoichiometric table. This table presents the stoichiometric relationships between reacting molecules for a single reaction. That is, it tells us how many molecules of one species will be formed during a chemical reaction when a given number of molecules of another species disappears. These relationships will be developed for the general reaction

Recall that we have already used stoichiometry to relate the relative rates of reaction for Equation (2-1):

This stoichiometric relationship relating reaction rates will be used in Chapters 6 and 8.

In formulating our stoichiometric table, we shall take species A as our basis of calculation (i.e., the limiting reactant) and then divide through by the stoichiometric coefficient of A

in order to put everything on a basis of “per mole of A."

Next, we develop the stoichiometric relationships for reacting species that give the change in the number of moles of each species (i.e., A, B, C, and D).

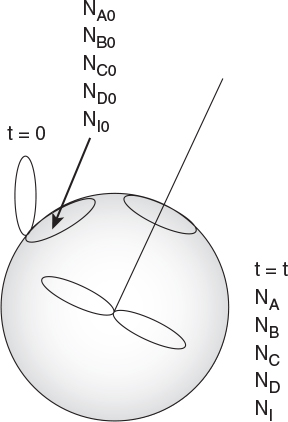

Figure 4-1 Batch reactor. (Schematic with special permission by Renwahr.) (http://encyclopedia.che.engin.umich.edu/Pages/Reactors/Batch/Batch.html)

4.1 Batch Systems

Batch reactors are primarily used for the production of specialty chemicals and to obtain reaction rate data in order to determine reaction rate laws and rate-law parameters such as k, the specific reaction rate.

Figure 4-1 shows a starving artist’s rendition of a batch system in which we will carry out the reaction given by Equation (2-2). At time t = 0, we will open the reactor and place a number of moles of species A, B, C, and D, and inerts I (NA0, NB0, NC0, ND0, and NI0, respectively) into the reactor.

Species A is our basis of calculation, and NA0 is the number of moles of A initially present in the reactor. After a time t, NA0X moles of A are consumed in the system as a result of the chemical reaction, leaving (NA0 – NA0X) moles of A in the system. That is, the number of moles of A remaining in the reactor after a conversion X has been achieved is

NA = NA0 – NA0X = NA0(1 – X)

We now will use conversion in a similar fashion to express the number of moles of B, C, and D in terms of conversion.

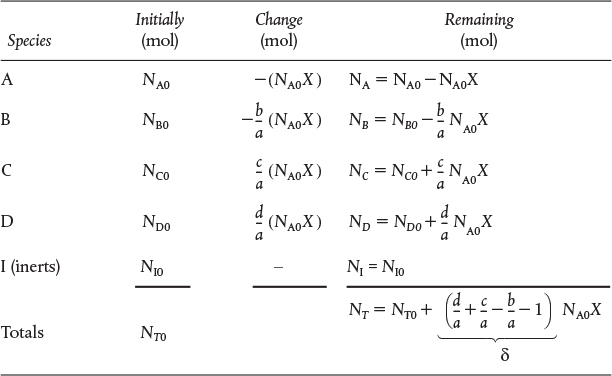

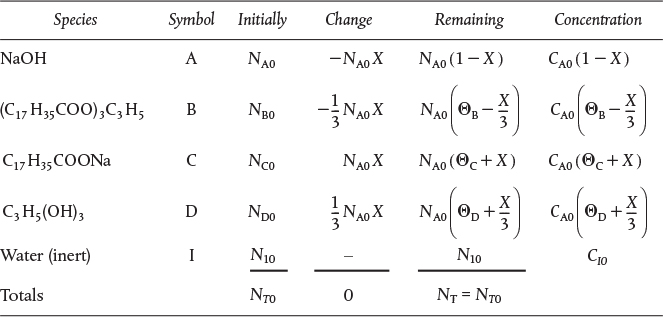

To determine the number of moles of each species remaining after NA0X moles of A have reacted, we form the stoichiometric table (Table 4-1). This stoichiometric table presents the following information:

Components of the stoichiometric table

Column 1: the species in the reaction

Column 2: the number of moles of each species initially present

Column 3: the change in the number of moles brought about by reaction

Column 4: the number of moles remaining in the system at time t

To calculate the number of moles of species B remaining at time t, we recall that at time t the number of moles of A that have reacted is NA0X. For every mole of A that reacts, b / a moles of B must react; therefore, the total number of moles of B that have reacted is

Because B is disappearing from the system, the sign of the “change” is negative. NB0 is the number of moles of B initially in the system. Therefore, the number of moles of B remaining in the system, NB, at a time t, is given in the last column of Table 4-1 as

The complete stoichiometric table delineated in Table 4-1 is for all species in the general reaction

Let’s take a look at the totals in the last column of Table 4-1. The stoichiometric coefficients in parentheses (d/a + c/a – b/a – 1) represent the change in the total number of moles per mole of A reacted. Because this term occurs so often in our calculations, it is given the symbol δ:

Definition of δ

The parameter δ

The total number of moles can now be calculated from the equation

NT = NT0 + δ(NA0X)

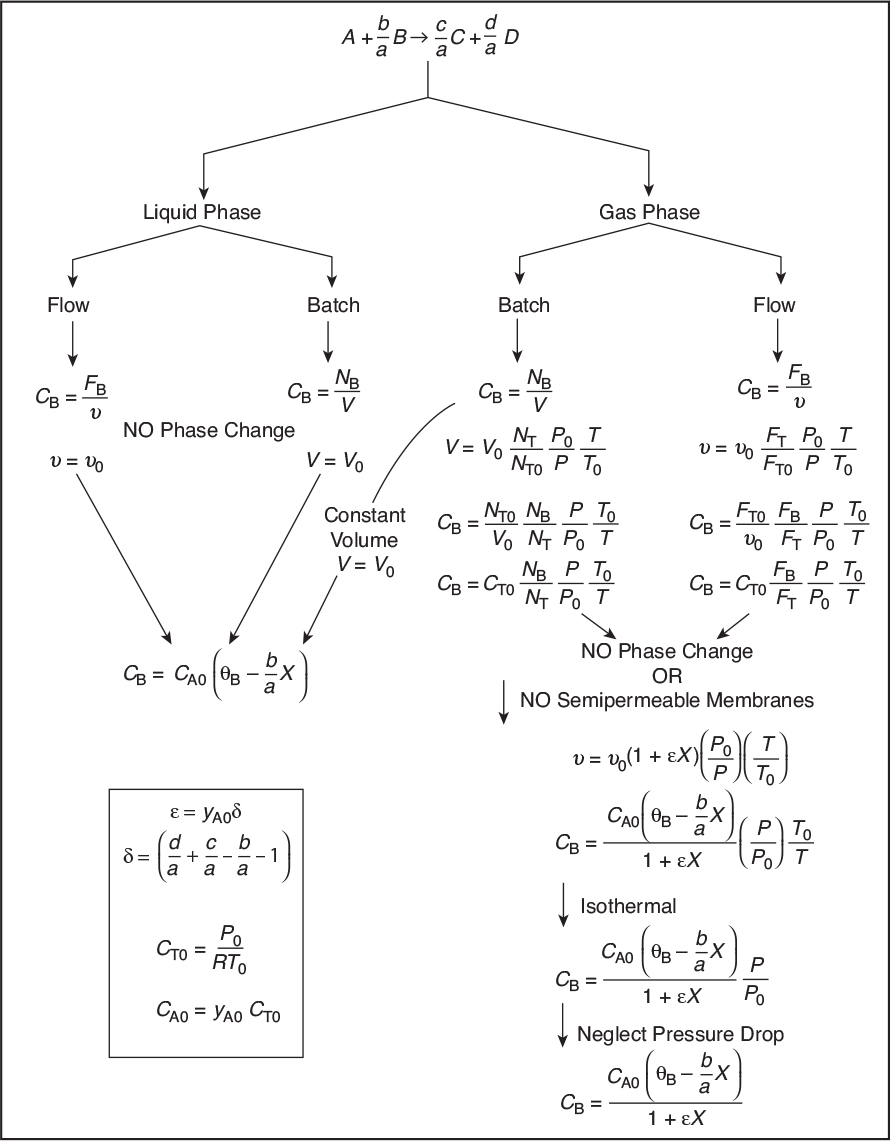

We want Cj = hj (X)

We recall from Chapter 1 and Chapter 3 that the kinetic rate law (e.g., ) is a function solely of the intensive properties of the reacting system (e.g., temperature, pressure, concentration, and catalysts, if any). The reaction rate, –rA, usually depends on the concentration of the reacting species raised to some power. Consequently, to determine the reaction rate as a function of conversion, Χ, we need to know the concentrations of the reacting species as a function of conversion, Χ.

4.1.1 Batch Concentrations for the Generic Reaction, Equation (2-2)

Batch concentration

The concentration of A is the number of moles of A per unit volume

After writing similar equations for B, C, and D, we use the stoichiometric table to express the concentration of each component in terms of the conversion Χ:

Because almost all batch reactors are solid vessels, the reactor volume is constant, so we can take V = V0, then

We will soon see that Equation (4-6) for constant volume batch reactors also applies to continuous-flow liquid-phase systems.

We further simplify these equations by defining the parameter Θi, which allows us to factor out NA0 in each of the expressions for concentration

Feed

Equalmolar:

ΘB = 1

Stoichiometric:

for an equalmolar feed ΘB = 1 and for a stoichiometric feed ΘB = ba. Continuing for species C and D

Concentration for constant-volume batch reactors and for liquid phase continuous-flow reactors

For constant-volume batch reactors, e.g., steel containers V = V0, we now have concentration as a function of conversion. if we know the rate law, we can now obtain –rA = f(X) to couple with the differential mole balance in terms of conversion in order to solve for the reaction time, t.

For liquid-phase reactions taking place in solution, the solvent usually dominates the situation. For example, most liquid-phase organic reactions do not change density during the course of the reaction and represent still another case for which the constant-volume simplifications apply. As a result, changes in the density of the solute do not affect the overall density of the solution significantly and therefore it is essentially a constant-volume reaction process, V = V0 and υ = υ0. Consequently, Equations (4-6) through (4-9) can be used for liquid-phase reactions as well. An important exception to this general rule exists for polymerization processes.

For liquids V = V0 and υ = υ0

To summarize for constant-volume batch systems and for liquid-phase reactions, we can use a rate law for reaction (2-2) such as –rA = kACACB to obtain –rA = f(X); that is,

Substituting for the given parameters k, CA0, and ΘB, we can now use the techniques in Chapter 2 to size the CSTRs and PFRs for liquid-phase reactions.

Choosing a basis of calculation

Example 4-1 Expressing Cj = hj (X) for a Liquid-Phase Batch Reaction

Soap is necessary to clean such things as dirty softball and soccer players’ uniforms, dirty hands, and foul mouths. Soap consists of the sodium and potassium salts of various fatty acids, such as oleic, stearic, palmitic, lauric, and myristic acids. The saponification reaction for the formation of soap from aqueous caustic soda and glyceryl stearate is

3NaOH(aq) + (C17H35COO)3C3H5 → 3C17 H35COONa + C3H5(OH)3

Letting Χ represent the conversion of sodium hydroxide (the moles of sodium hydroxide reacted per mole of sodium hydroxide initially present), set up a stoichio-metric table expressing the concentration of each species in terms of its initial concentration and the conversion, Χ.

Solution

Because we have taken sodium hydroxide as our basis of calculation, we divide through by the stoichiometric coefficient of sodium hydroxide to put the reaction expression in the form

We may then perform the calculations shown in Table E4-1.1. Because this is a liquid-phase reaction, the density ρ is considered to be constant; therefore, V = V0.

Analysis: The purpose of this example was to show how the generic reaction in Table 4-1 is applied to a real reaction.

Stoichiometric table (batch)

Example 4-2 What Is the Limiting Reactant?

Having set up the stoichiometric table in Example 4-1, one can now readily use it to calculate the concentrations at a given conversion. if the initial mixture consists of sodium hydroxide at a concentration of 10 mol/dm3 (i.e., 10 mol/L or 10 kmol/m3) and glyceryl stearate at a concentration of 2 mol/dm3, what are the concentrations of glycerol stearate, B, and of glycerine, D, when the conversion of sodium hydroxide is (a) 20% and (b) 90%?

Solution

Only the reactants NaOH and (C17H35COO)3C3H5 are initially present; therefore, ΘC = ΘD = 0 .

(a) For 20% conversion of NaOH

(b) For 90% conversion of NaOH

Let us find CB

Oops!! Negative concentration—impossible! What went wrong?

Analysis: We chose the wrong basis of calculation! We must choose the limiting reactant as our basis of calculation. Ninety-percent conversion of NaOH is not possible because glyceryl stearate is the limiting reactant and is used up before 90% of the NaOH can be reacted. Glyceryl stearate should have been our basis of calculation and therefore we should not have divided the reaction as written by the stoichi-ometric coefficient of 3. It’s always important to make sure you learn something from a mistake, such as choosing the wrong basis of calculation. There is no such thing as failure, unless one fails to learn from it.

The basis of calculation must be the limiting reactant.

4.2 Flow Systems

The form of the stoichiometric table for a continuous-flow system (see Figure 4-2) is virtually identical to that for a batch system (Table 4-1), except that we replace Nj0 by Fj0 and Nj by Fj (Table 4-2). Again taking A as the basis, we divide Equation (2-1) through by the stoichiometric coefficient of A to obtain

TABLE 4-2 STOICHIOMETRIC TABLE FOR A FLOW SYSTEM

Species |

Feed Rate to Reactor (mol/time) |

Change within Reactor (mol/time) |

Effluent Rate from Reactor (mol/time) |

A |

FA0 |

-FA0E |

FA = FA0 (1 – X) |

B |

FB0 = ΘBFA0 |

||

C |

FC0 = ΘCFA0 |

||

D |

FD0 = ΘDFA0 |

||

I |

FI0 = ΘIFA0 |

– |

FI = FA0ΘI |

Totals |

FT0 |

Stoichiometric table for a flow system

and ΘC, ΘD, and ΘI, are defined similarly

and, as before,

4.2.1 Equations for Concentrations in Flow Systems

For a flow system, the concentration CA at a given point can be determined from the molar flow rate FA and the volumetric flow rate υ at that point:

Definition of concentration for a flow system

Units of υ are typically given in terms of liters per second, cubic decimeters per second, or cubic feet per minute. We now can write the concentrations of A, B, C, and D for the general reaction given by Equation (2-2) in terms of their respective entering molar flow rates ( FA0, FB0, FC0, FD0 ), the conversion, X, and the volumetric flow rate, υ.

We now focus on determining the volumetric flow rate, υ.

4.2.2 Liquid-Phase Concentrations

For liquids, the fluid volume change with reaction is negligible when no phase changes are taking place. Consequently, we can take

υ = υ0

For liquids

CA = CA0 (1 – X)

Therefore, for a given rate law we have –rA = g(X)

Then

and so forth for CC and CD.

Consequently, using any one of the rate laws in Chapter 3, we can now find –rA = f(X) for liquid-phase reactions. However, for gas-phase reactions the volumetric flow rate most often changes during the course of the reaction because of a change in the total number of moles or a change in temperature or pressure. Hence, one cannot always use Equation (4-13) to express concentration as a function of conversion for gas-phase reactions.

4.2.3 Gas-Phase Concentrations

In our previous discussions, we considered primarily systems in which the reaction volume or volumetric flow rate did not vary as the reaction progressed. Most batch and liquid-phase and some gas-phase systems fall into this category. There are other systems, though, in which either V or υ does vary, and these will now be considered.

A situation where one encounters a varying flow rate occurs quite frequently in gas-phase reactions that do not have an equal number of product and reactant moles. For example, in the synthesis of ammonia

4 mol of reactants gives 2 mol of product. In flow systems where this type of reaction occurs, the molar flow rate will be changing as the reaction progresses. Because equal numbers of moles occupy equal volumes in the gas phase at the same temperature and pressure, the volumetric flow rate will also change.

In the stoichiometric tables presented on the preceding pages, it was not necessary to make assumptions concerning a volume change in the first four columns of the table (i.e., the species, initial number of moles or molar feed rate, change within the reactor, and the remaining number of moles or the molar effluent rate). All of these columns of the stoichiometric table are independent of the volume or density, and they are identical for constant-volume (constant-density) and varying-volume (varying-density) situations. Only when concentration is expressed as a function of conversion does variable density enter the picture.

Flow Reactors with Variable Volumetric Flow Rate. To derive the concentrations of each species in terms of conversion for a gas-phase flow system, we shall start by using the relationships for the total concentration. The total concentration, CT, at any point in the reactor is the total molar flow rate, FT, divided by the volumetric flow rate, υ [cf. Equation (4-10)]. In the gas phase, the total concentration is also found from the gas law, CT = P/ZRT. Equating these two relationships gives

At the entrance to the reactor

Taking the ratio of Equation (4-14) to Equation (4-15) and assuming negligible changes in the compressibility factor occur, i.e., Z ≌ Z0, during the course of the reaction, we have upon rearrangement

Gas-phase reactions

We can now express the concentration of species j for a flow system in terms of its flow rate, Fj, the temperature, T, and total pressure, P.

Use this concentration equation for membrane reactors (Chapter 6) and for multiple reactions (Chapter 8).

The total molar flow rate is just the sum of the molar flow rates of each of the species in the system and is

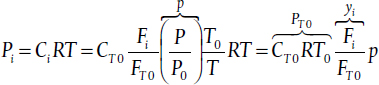

We can also write Equation (4-17) in terms of the mole fraction of species j, yj, and the pressure ratio, p, with respect to the initial or entering conditions, i.e., sub “0”

The molar flow rates, Fj, are found by solving the mole balance equations. The concentration given by Equation (4-17) will be used for measures other than conversion when we discuss membrane reactors (Chapter 6) and multiple gas-phase reactions (Chapter 8).

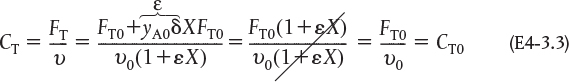

Now, let’s express the concentration in terms of conversion for gas flow systems. From Table 4-2, the total molar flow rate can be written in terms of conversion and is

FT = FT0 + FA0 δX

We divide this equation through by FT0

Then

where yA0 is the mole fraction of A at the inlet (i.e., (FA0/FT0)), and where δ is given by Equation (4-1) and ε is given by

Relationship between δ and ε

Equation (4-21) holds for both batch and flow systems. To interpret ε, let’s rearrange Equation (4-20) at complete conversion (i.e., X = 1 and FT = FTf)

Interpretation of ε

Gas-phase volumetric flow rate

Substituting for (FT/FT0 ) in Equation (4-16) for the volumetric flow rate, υ, we have

The concentration of species j in a flow system is

The molar flow rate of species j is

where Vj is the stoichiometric coefficient for species j, which is negative for reactants and positive for products. For example, for the reaction

Substituting for the gas volumetric flow rate, υ, using Equation (4-23) and for Fj, we have

Gas-phase concentration as a function of conversion

Rearranging

Recall that yA0 = FA0/FT0, CA0 = yA0CT0, and ε is given by Equation (4-21) (i.e., ε = yA0δ).

The stoichiometric table for the gas-phase reaction (2-2) is given in Table 4-3.

TABLE 4-3 CONCENTRATIONS IN A VARIABLE-VOLUME GAS FLOW SYSTEM

At last!

We now have Cj = hj (X ) and

— rA = g (X )

for variable-volume gas-phase reactions.

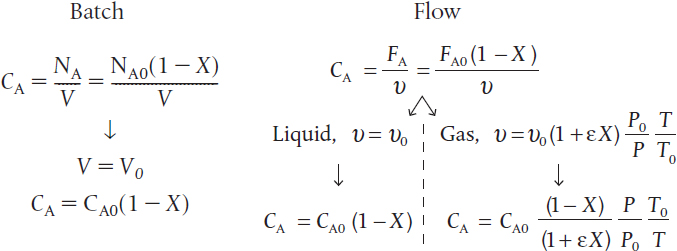

One of the major objectives of this chapter is to learn how to express any given rate law – rA as a function of conversion. The schematic diagram in Figure 4-3 helps to summarize our discussion on this point. The concentration of the reactant species B in the generic reaction is expressed as a function of conversion in both flow and batch systems for various conditions of temperature, pressure, and volume.

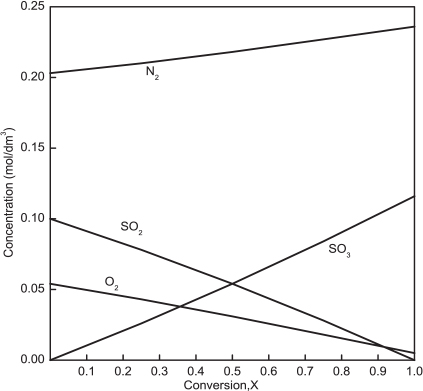

Example 4-3 Determining Cj = hj (X) for a Gas-Phase Reaction

A mixture of 28% SO2 and 72% air is charged to a flow reactor in which SO2 is oxidized.

(a) First, set up a stoichiometric table using only the symbols (i.e., Θi, Fi).

(b) Next, prepare a second table evaluating the species concentrations as a function of conversion for the case when the total pressure is 1485 kPa (14.7 atm) and the temperature is constant at 227°C.

(c) Evaluate the parameters and make a plot of each of the concentrations SO2, SO3, N2 as a function of conversion

Solution

(a) Stoichiometric table. Taking SO2 as the basis of calculation, we divide the reaction through by the stoichiometric coefficient of our chosen basis of calculation

The stoichiometric table is given in Table E4-3.1.

TABLE E4-3.1 STOICHIOMETRIC TABLE FOR

Species |

Symbol |

Initially |

Change |

Remaining |

| SO2 | A | FA0 | −FA0X | FA = FA0(1−X) |

| O2 | B | |||

| SO3 | C | 0 | +FA0X | FC = FA0X |

| N2 | I | − | ||

| Totals | FT0 |

(b) Expressing the concentration as a function of conversion.

From the definition of conversion, we substitute not only for the molar flow rate of SO2 (A) in terms of conversion but also for the volumetric flow rate as a function of conversion

Neglecting pressure

drop, P = P0,

Recalling Equation (4-23), we have

Neglecting pressure drop in the reaction, P = P0 , yields

If the reaction is also carried out isothermally, T = T0, we obtain

Similarly for B also with T = T0 and P = P0, (i.e., p = 1)

(c) Parameter evaluation and concentrations of a function of conversion plot. The inlet concentration of A is equal to the inlet mole fraction of A multiplied by the total inlet molar concentration. The total concentration can be calculated from an equation of state such as the ideal gas law. Recall that yA0 = 0.28, T0 = 500 K, and P0 = 1485 kPa.

The total concentration at constant temperature and pressure is

We now evaluate ε.

Initially, 72% of the total number of moles is air containing 21% O2 and 79% N2, along with 28% SO2.

Substituting for CA0 and ε in the species concentrations:

Note: Because the volumetic flow rate varies with conversion, υ = υ0(1 - 0.14X), the concentration of inerts (N2) is not constant.

Now we could use techniques presented in Chapter 2 to size reactors.

The concentrations of different species at various conversions are calculated in Table E4-3.2 and plotted in Figure E4-3.1. Note that the concentration of N2 is changing even though it is an inert species in this reaction!!

TABLE E4-3.2 CONCENTRATION AS A FUNCTION OF CONVERSION

|

|

|

|

Ci (mol/dm3) |

|

|

Species |

|

X = 0.0 |

X = 0.25 |

X = 0.5 |

X = 0.75 |

X = 1.0 |

SO2 |

CA = |

0.100 |

0.078 |

0.054 |

0.028 |

0.000 |

O2 |

CB = |

0.054 |

0.043 |

0.031 |

0.018 |

0.005 |

SO3 |

CC = |

0.000 |

0.026 |

0.054 |

0.084 |

0.116 |

N2 |

CI = |

0.203 |

0.210 |

0.218 |

0.227 |

0.236 |

Total |

CT = |

0.357 |

0.357 |

0.357 |

0.357 |

0.357 |

We are now in a position to express –rA as a function of X and use the techniques in Chapter 2. However, we will use a better method to solve CRE problems, namely a Table of Integrals (Appendix A) or the Polymath or MATLAB software, discussed in the next chapter.

Analysis: In this example, we formed a stoichiometric table in terms of molar flow rates. We then showed how to express the concentrations of each species in a gas-phase reaction in which there is a change in the total number of moles. Next, we plotted each species concentration as a function of conversion and noted that the concentration of the inert, N2, was not constant but increased with increasing conversion because of the decrease in the total molar flow rate, FT, with conversion.

As previously mentioned many, if not most, rate laws for catalyst reactions are given in terms of partial pressures. Luckily, partial pressures are easily related to conversion with the aid of the ideal gas law and Equation (4-17).

The following equation is used when the mole balance is written in terms of molar flow rates

However, when the mole balance is written in terms of conversion, we use Equation (4-25)

For example, the rate law for the hydrodemethylation of toluene (T) to form methane (M) and benzene (B) given by Equation (10-80) on page 461 can now be written in terms of conversion.

T + H2 → M + B

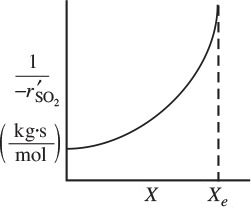

If you haven’t decided which computer to buy or borrow, or don’t have your integral tables, I suppose you could resort to the graphical techniques in Chapter 2 and use a Levenspiel plot, (FA0/— r’A) versus X, to achieve a specified conversion of toluene.

Example 4-4 Expressing the Rate Law for SO2 Oxidation in Terms of Partial Pressures and Conversions

The SO2 oxidation discussed in Example 4-3 is to be carried out over a solid platinum catalyst. As with almost all gas-solid catalytic reactions, the rate law is expressed in terms of partial pressures instead of concentrations. The rate law for this SO2 oxidation was found experimentally to be1

1 Uychara, O.A., and K. M. Watson, Ind. Engrg. Chem. 35 p.541.

where Pi (atm) is the partial pressure of species.

The reaction is to be carried out isothermally at 400°C. At this temperature the rate constant k per gram of catalyst (g-cat), the adsorption constants for O2 (KO ) and SO2 ( KSOi2 ), and the pressure equilibrium constant, KP were experimentally found to be:

k = 9.7 mol SO2/atm3/2/h/g-cat

KO2 = 38.5 atm-1, KSO3 = 42.5 atm-1, and KP = 930 atm-1/2

The total pressure and the feed composition (e.g., 28% SO2) are the same as in Example 4-3. Consequently, the entering partial pressure of SO2 is 4.1 atm. There is no pressure drop.

(a) Write the rate law as a function of conversion evaluating all other parameters.

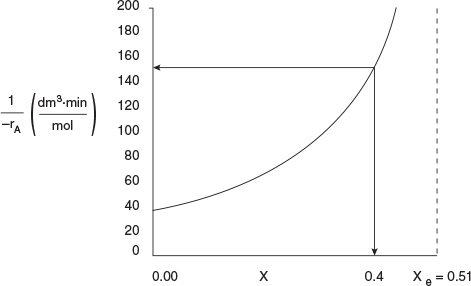

(b) Prepare a Levenspiel plot by sketching the reciprocal rate [1 /(— rA)] as a function of X up to the equilibrium conversion Xe, and note where the rate goes to zero and [1 /( — rA)] goes to infinity.

Solution

Part (a)

No Pressure Drop and Isothermal Operation

For SO2

First we need to recall the relationship between partial pressure and concentration, followed by the relationship between concentration and conversion. Because we know how to express concentration as a function of conversion, we know how to express partial pressure as a function of conversion.

For no pressure drop P = P0, i.e., p = 1

PSO2 ,0 = ySO2,0 P0 = 4.1 atm. (E4-4.3)

For SO3

For O2

From Example 4-3

ΘB = 0.54

Factoring out in Equation (E4-4.5) gives

From Equation (E4-3.5)

ε = -0.14

Substitute for the partial pressure in the rate-law equation (E4-4.1)

with k = 9.7 mol SO2/atm3/2/h/g-cat PSO2,0 = 4.1 atm, = 8.3 atm3/2

Part (b)

We can now use Equation (E4-4.8) to plot the reciprocal rate as a function of X as shown in Figure E4-4). We note at the equilibrium conversion, Xe, the reciprocal rate goes to infinity. We could now use a Levenspiel plot to find the catalyst weight W in a packed-bed reactor (PBR) to achieve a specified conversion.

However, we will see in the next chapter there is a much, much better way to solve for the catalysis weight, W, by using numerical software packages. For example, we would couple Equation (E4-4.8) with Equation (2-17) and use an ordinary differential equation (ODE) solver, such as Polymath, to find the conversion X as a function of catalyst weight W. So, be sure to buy or borrow a laptop computer before attempting to solve the problems in Chapter 5 and beyond.

Analysis: In most heterogeneous catalytic reactions, rate laws are expressed in terms of partial pressures instead of concentration. However, we see that through the use of the ideal gas law we could eas.ly express the partial pressure as a function of concentration then conversion in order to express the rate law as a function of conversion. In addition, for most all heterogeneous reactions you will usually find a term like (1 + KAPA + KBPB + . . .) in the denominator of the rate law, as will be explained in Chapter 10.

Need to first calculate Xe

4.3 Reversible Reactions and Equilibrium Conversion

Thus far in this chapter, we have focused mostly on irreversible reactions. The procedure one uses for the isothermal reactor design of reversible reactions is virtually the same as that for irreversible reactions, with one notable exception: the maximum conversion that can be achieved at the reaction temperature is the equilibrium conversion, Xe. In the following example, it will be shown how our algorithm for reactor design is easily extended to reversible reactions.

Example 4-4 Calculating the Equilibrium Conversion

The reversible gas-phase decomposition of nitrogen tetroxide, N2O4, to nitrogen dioxide, NO2,

is to be carried out at constant temperature. The feed consists of pure N2O4 at 340 K and 202.6 kPa (2 atm). The concentration equilibrium constant, KC, at 340 K is 0.1 mol/dm3 and the rate constant kN2o4 is 0.5min-1.

(a) Set up a stoichiometric table and then calculate the equilibrium conversion of N2O4 in a constant-volume batch reactor.

(b) Set up a stoichiometric table and then calculate the equilibrium conversion of N2O4 in a flow reactor.

(c) Assuming the reaction is elementary, express the rate of reaction solely as a function of conversion for a flow system and for a batch system.

(d) Determine the CSTR volume necessary to achieve 80% of the equilibrium conversion.

Solution

At equilibrium, the concentrations of the reacting species are related by the relationship dictated by thermodynamics (see Equation (3-10) and Appendix C).

(a) Batch system—constant volume, V = V0.

TABLE E4-5.1 STOICHIOMETRIC TABLE FOR BATCH REACTOR

| Species | Symbol | Initial | Change | Remaining |

| N2O4 | A | NA0 | −NA0X | NA = NA0(1−X) |

| NO2 | B | 0 | +2NA0X | NB = 2NA0X |

| NT0 = NA0 | NT = NT0 + NA0X |

Living Example Problem

There is a Polymath tutorial in the Summary Notes for Chapter 1 on the CRE Web site.

For batch systems Ci = Ni/V

At equilibrium in a batch reactor, X = Xeb, we substitute Equations (E4-5.2) and (E4-5.3) into Equation (E4-5.1)

(math-math-math-math) to get

We will use the software package Polymath to solve for the equilibrium conversion and let Xeb represent the equilibrium conversion in a constant-volume batch reactor. Equation (E4-5.4) written in Polymath format becomes

f(Xeb) = Xeb — [Kc*(1 — Xeb)/(4*Cao)]^0.5

The Polymath program and solution are given in Table E4-5.2.

When looking at Equation (E4-5.4), you probably asked yourself, "Why not use the quadratic formula to solve for the equilibrium conversion in both batch and flow systems?"

That is from Equation (E4-5.4) we would have

and from Equation (E4-5.8) we would have

TABLE E4-5.2 POLYMATH PROGRAM AND SOLUTION FOR BOTH BATCH AND FLOW SYSTEMS

The answer is that future problems will be nonlinear and require Polymath solutions; therefore, this simple exercise increases the reader’s ease in using Polymath.

The equilibrium conversion in a constant-volume batch reactor is

Polymath Tutorial Chapter 1

Summary Motes

Summary Motes

Note: A tutorial on Polymath can be found in the summary notes for Chapter 1 on the CRE Web site (www.umich.edu/~elements/5e/index.html).

(b) Flow system. The stoichiometric table is the same as that for a batch system except that the number of moles of each species, Ni, is replaced by the molar flow rate of that species, Fi.

For constant temperature and pressure, the volumetric flow rate is υ = υ0 ( 1 + εX), and the resulting concentrations of species A and B are

TABLE E4-5.2 STOICHIOMETRIC TABLE FOR CONTINUOUS FLOW REACTOR

| Species | Symbol | Entering | Change | Leaving |

| N2O2 | A | FA0 | −FA0X | FA = FA0(1−X) |

| NO2 | B | 0 | +2FA0X | FB = 2FA0X |

| FT0 = FA0 | FT = FT0 + FA0X |

At equilibrium, X = Xef, we can substitute Equations (E4-5.5) and (E4-5.6) into Equation (E4-5.1) to obtain the expression

Simplifying gives

Rearranging to use Polymath yields

For a flow system with pure N204 feed, ε = yA0 δ = 1 (2 — 1) = 1.

We shall let Xef represent the equilibrium conversion in a flow system. Equation (E4-5.8) written in the Polymath format becomes

f(Xef) = Xef -[kc*(1 — Xef)*( 1 + eps*Xef)/4/cao]^0.5

This solution is also shown in Table E4-5.2 .

Note that the equilibrium conversion in a flow reactor (i.e., Xef = 0.51), with no pressure drop, is greater than the equilibrium conversion in a constant-volume batch reactor (Xeh = 0.44). Recalling Le Châtelier’s principle, can you suggest an explanation for this difference in Xe? This example is continued in problem P4-1A (a).

(c) Rate laws. Assuming that the reaction follows an elementary rate law, then

1. For a constant volume (V = V0) batch system

Here, CA = NA/V0 and CB = NB/V0. Substituting Equations (E4-5.2) and (E4-5.3) into the rate law, we obtain the rate of disappearance of A as a function of conversion

2. For a flow system

Here, CA = FA/v and CB = FB/v with υ = υ0 (1 + eX). Consequently, we can substitute Equations (E4-5.5) and (E4-5.6) into Equation (E4-5.9) to obtain

-rA = f(X) for a batch reactor with V = V0

-rA = f(X) for a flow reactor

As expected, the dependence of reaction rate on conversion, i.e., -rA = f(X), for a constant-volume batch system [i.e., Equation (E4-5.10)] is different than that for a flow system [Equation (E4-5.11)] for gas-phase reactions.

If we substitute the values for CA0, Kc, ε, and kA = 0.5 min-1 in Equation (E4-5.11), we obtain -rA solely as a function of X for the flow system.

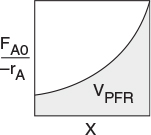

We can now prepare our Levenspiel plot to find either the cSTR or PFR volume.

We see as we approach equilibrium, Xe = 0.15, -rA goes to zero and (1/-rA) goes to infinity.

(d) CSTR volume. Just for fun (and this really is fun), let’s calculate the CSTR reactor volume necessary to achieve 80% of the equilibrium conversion of 51% (i.e., X = 0.8Xe = (0.8)(0.51) = 0.4) for a molar feed rate of A of 3 mol/min.

Plotting the reciprocal of Equation (E4-5.12) to obtain Levenspiel plot as we did in Chapter 2, it can be seen in Figure E4-5.1 when X = 0.4 then as

then for FA0 = 3 mol/min

A quicker way to find the CSTR volume, rather than drawing a Levenspiel plot, is to simply evaluate Equation (E4-5.12) at X = 0.4

Using Equation (2-13), we can now find the reactor volume

The CSTR volume required to achieve 40% conversion is 0.171 m3. See Problem P4-1A (b) to calculate the PFR volume.

Analysis: The purpose of this example was to calculate the equilibrium conversion first for a constant volume batch reactor in part (a), and then for a constant pressure flow reactor in part (b). One notes that there is a change in the total number of moles in this reaction and, as a result, these two equilibrium conversions are not the same!! We next showed in part (c) how to express –rA = ƒ(X) for a reversible gas-phase reaction. Here we noted that the equations for the reaction rate laws as a function of conversion, i.e., –rA = ƒ(X), are different for batch and flow reactors. Finally, in Part (d) having –rA = ƒ(X), we specified a molar flow rate of A (i.e., 3.0 mol A/min) and calculated the CSTR volume necessary to achieve 40% conversion. We did this calculation to give insight to the types of analyses we, as chemical reaction engineers, will carry out as we move into similar but more complex calculations in Chapters 5 and 6.

Summary

1. The stoichiometric table for the reaction given by Equation (S4-1) being carried out in a flow system is

2. In the case of ideal gases, Equation (S4-3) relates volumetric flow rate to conversion. Batch constant volume:

Flow systems: Gas:

Liquid:

| Species | Entering | Change | Leaving |

| A | FA0 | -FA0X | FA0(1 – X) |

| B | FB0 | ||

| C | FC0 | ||

| D | FD0 | ||

| I | F10 | --- | F10 |

| ________ | ________ | ________ | ________ |

| Totals | FT0 | δFA0X | FT = FT0 +δFA0X |

Definitions of δ and ɛ For the general reaction given by (S4-1), we have

3. For incompressible liquids or for batch gas phase reactions taking place in a constant volume, V = V0, the concentrations of species A and C in the reaction given by Equation (S4-1) can be written as

Equations (S4-7) and (S4-8) also hold for gas-phase reactions carried out in constant-volume batch reactors.

4. For gas-phase reactions in continuous-flow reactors, we use the definition of concentration (CA = FA/υ) along with the stoichiometric table and Equation (S4-3) to write the concentration of A and C in terms of conversion.

with

5. In terms of gas-phase molar flow rates, the concentration of species i is

Equation (S4-11) must be used for membrane reactors (Chapter 6) and for multiple reactions (Chapter 8).

6. Many catalytic rate laws are given in terms of partial pressure, e.g.,

The partial pressure is related to conversion through the stoichiometric table. For any species “i” in the reaction

For species A

CRE Web Site Materials

• Expanded Materials (http://umich.edu/~elements/5e/04chap/expanded.html)

1. Web P4-1B Puzzle Problem “What’s Four Things Are Wrong with This Solution?” (http://umich.edu/~elements/5e/04chap/expanded_ch04_puzzle.pddf)

• Learning Resources (http://umich.edu/~elements/5e/04chap/learn.html)

1. Summary Notes for Chapter 4 (http://umich.edu/~elements/5e/04chap/summary.html)

2. Self-Tests

A. Exercises

(http://www.umich.edu/~elements/5e/04chap/add.html)

B. i>clicker Questions (http://www.umich.edu/~elements/5e/04chap/iclicker_ch4_q1.html)

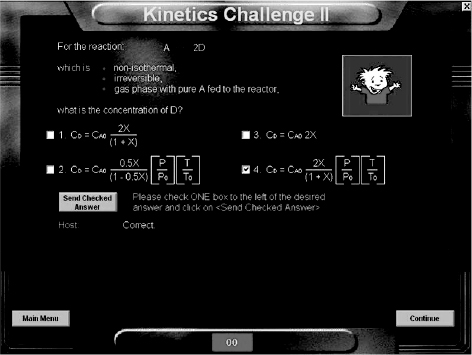

3. Interactive Computer Games (http://umich.edu/~elements/5e/icm/index.html) Quiz Show II (http://umich.edu/~elements/5e/icm/kinchal2.html)

4. Solved Problems

CDP4-BB Microelectronics Industry and the Stoichiometric Table (http://umich.edu/~elements/5e/04chap/add-ahp03-b.html)

• Living Example Problem

1. Example 4-4 Rate Law for SO2 Oxidation

2. Example 4-5 Calculating the Equilibrium Conversion (http://umich.edu/~elements/5e/04chap/live.html)

• FAQs (Frequently Asked Questions) Typos and Updates (http://umich.edu/~elements/5e/04chap/faq.html)

• Professional Reference Shelf (http://umich.edu/~elements/5e/04chap/prof.html)

Questions and Problems

The subscript to each of the problem numbers indicates the level of difficulty: A, least difficult; D, most difficult.

A = • B = ▪ C = ♦ D = ♦♦

Questions

Q4-1A i>clicker. Go to the Web site (http://www.umich.edu/~elements/5e/04chap/iclicker_ch4_q1.html) and view at leave five i>clicker questions. Choose one that could be used as is, or a variation thereof, to be included on the next exam. You also could consider the opposite case, explaining why the question should not be on the next exam. In either case, explain your reasoning.

Q4-2A (a) List the important concepts that you learned from this chapter. Make a list of concepts that you are not clear about and ask your instructor or colleague about them.

(b) Explain the strategy to evaluate reactor design equations and how this chapter expands on Chapters 2 and 3.

Q4-3A Example 4-1. Would the example be correct if water were considered an inert? Explain.

Q4-4A Example 4-2. How would the answer change if the initial concentration of glyceryl stearate were 3 mol/dm3? Rework Example 4-2 correctly using the information given in the problem statement.

Q4-5A Example 4-3. Under what conditions will the concentration of the inert nitrogen be constant? Plot Equation (E4-5.2) in terms of (1/–rA) as a function of X up to value of X = 0.99. What did you find?

Computer Simulations and Experiments

P4-1A (a) Example 4-4: SO2 Oxidation

Wolfram

(i) What is the critical value of entering pressure of SO2, such that the reaction rate first increases and then decreases at a given conversion? Explain this behavior.

(ii) Vary the parameters and list the parameters that have the greatest and the least effect on the reaction rate.

(iii) Vary ΘB and observe the change in reaction rate. At what value of ΘB does the rate of reaction become zero when 50% conversion is achieved?

(iv) Write a conclusion about the experiments you carried out by varying the sliders in parts (i) through (iii).

Polymath

(v) Using the molar flow rate of SO2 (A) of 3 mol/h and Figure E4-4.1, calculate the fluidized bed (i.e., CSTR catalyst weight) necessary for 4o% conversion.

(vi) Next, consider the entering flow rate of SO2 is 1,000 mol/h. Plot (FA0/–rA) as a function of X to determine the fluidized bed catalyst weight necessary to achieve 3o% conversion, and 99% of the equilibrium conversion, i.e., X = 0.99 Xe.

(b) Example 4-5: Equilibrium Conversion

(i) Using Figure E4-5.1 and the methods in Chapter 2, estimate the PFR volume for 40% conversion.

Wolfram

(ii) Plot the equilibrium conversion as a function of the mole fraction of inerts for both a PFR and a constant-volume batch reactor. Describe what you find.

(iii) What values of Kc and CA0 cause Xf to be the farthest away from Xeb?

(iv) What values of Kc and CA0 will cause and Xef to be the closest together?

(v) Plot the ratio of as a function of yA0 for different values of Kc and CT0. What conclusions can you draw?

Interactive Computer Games

P4-2A Load the Interactive Computer Games (ICG) Kinetic Challenge from the CRE Web site. Play the game and then record your performance number for the module that indicates your mastering of the material. Your professor has the key to decode your performance number. ICG Kinetics Challenge Performance #_________.

Kinetics Challenge II

| Rate | Law | Stoich |

| 100 | 100 | 100 |

| 200 | 200 | 200 |

| 300 | 300 | 300 |

Problems

P4-3A The elementary reversible reaction

is carried out in a flow reactor where pure A is fed at a concentration of 4.0 mol/dm3. If the equilibrium conversion is found to be 60%,

(a) What is the equilibrium constant, KC if the reaction is a gas phase reaction? (Ans.: Gas: KC = 0.328 dm3/mol)

(b) What is the KC if the reaction is a liquid-phase reaction? (Ans.: Liquid: KC = 0.469 dm3/mol)

(c) Write — rA solely as a function of conversion (i.e., evaluating all symbols) when the reaction is an elementary, reversible, gas-phase, isothermal reaction with no pressure drop with kA = 2 dm6/mol•s and KC = 0.5 all in proper units.

(d) Repeat (c) for a constant-volume batch reactor.

P4-4B Stoichiometry. The elementary gas reaction

2A + B → C

is carried out isothermally in a PFR with no pressure drop. The feed is equal molar in A and B, and the entering concentration of A is 0.1 mol/dm3. Set up a stoichiometric table and then determine the following.

(a) What is the entering concentration (mol/dm3) of B?

(b) What are the concentrations of A and C (mol/dm3) at 25% conversion of A?

(c) What is the concentration of B (mol/dm3) at 25% conversion of A? (Ans.: CB = 0.1 mol dm3)

(d) What is the concentration of B (mol/dm3) at 100% conversion of A?

(e) If at a particular conversion the rate of formation of C is 2 mol/min/dm3, what is the rate of formation of A at the same conversion?

(f) Write —rA solely as a function of conversion (i.e., evaluating all symbols) when the reaction is an elementary, irreversible, gas-phase, isothermal reaction with no pressure drop with an equal molar feed and with CA0 = 2.0 mol/dm3 at, kA = 2 dm6/mol•s.

(g) What is the rate of reaction at X = 0.5?

P4-5A Set up a stoichiometric table for each of the following reactions and express the concentration of each species in the reaction as a function of conversion, evaluating all constants (e.g., ε, Θ). Next, assume the reaction follows an elementary rate law, and write the reaction rate solely as a function of conversion, i.e., -rA = ƒ(X).

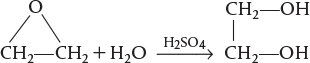

(a) For the liquid-phase reaction

the entering concentrations of ethylene oxide and water, after mixing the inlet streams, are 16.13 mol/dm3 and 55.5 mol/dm3, respectively. The specific reaction rate is K = 0.1 dm3/mol.s at 300 K with E = 12,500 cal/mol.

(1) After finding –rA = ƒ(X), calculate the CSTR space-time, τ, for 90% conversion at 300 K and also at 350 K.

(2) If the volumetric flow rate is 200 liters per second, what are the corresponding reactor volumes? (Ans.: At 300 K: V = 439 dm3 and at 350 K: V = 22 dm3)

(b) For the isothermal gas-phase pyrolysis

C2H6 → C2H4 + H2

pure ethane enters a flow reactor at 6 atm and 1100 K, with ΔP = 0. Set up a stoichiometric table and then write –rA = ƒ(X). How would your equation for the concentration and reaction rate, i.e., –rA = f(X), change if the reaction were to be carried out in a constant-volume batch reactor?

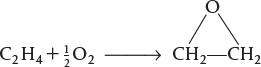

(c) For the isothermal, isobaric, catalytic gas-phase oxidation

the feed enters a PBR at 6 atm and 260°C, and is a stoichiometric mixture of only oxygen and ethylene. Set up a stoichiometric table and then write — r’ as a function of partial pressures. Express the partial pressures and - r’ as a function of conversion for (1) a fluidized batch reactor and (2) a PBR. Finally, write - rA solely as a function of the rate constant and conversion.

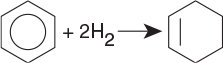

(d) Set up a stoichiometric table for the isothermal, catalytic gas-phase reaction carried out in a fluid-ized CSTR.

The feed is stoichiometric and enters at 6 atm and 170°C. What catalyst weight is required to reach 80% conversion in a fluidized CSTR at 170°C and at 270 C? The rate constant is defined with respect to benzene and υ0 = 50 dm3/min.

First write the rate law in terms of partial pressures and then express the rate law as a function of conversion. Assume Δ = 0 .

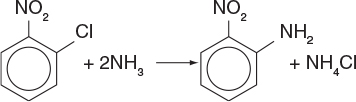

P4-6A Orthonitroanaline (an important intermediate in dyes—called fast orange) is formed from the reaction of orthonitrochlorobenzene (ONCB) and aqueous ammonia (see explosion in Figure E13-2.1 in Example 13-2).

The liquid-phase reaction is first order in both ONCB and ammonia with k = 0.0017 m3/kmol · min at 188°C with E = 11,273 cal/mol. The initial entering concentrations of ONCB and ammonia are 1.8 kmol/m3 and 6.6 kmol/m3, respectively (more on this reaction in Chapter 13).

(a) Set up a stoichiometric table for this reaction for a flow system.

(b) Write the rate law for the rate of disappearance of ONCB in terms of concentration.

(c) Explain how parts (a) and (b) would be different for a batch system.

(d) Write –rA solely as a function of conversion.

(e) What is the initial rate of reaction (X = 0)

(f) What is the rate of reaction when X = 0.90

–rA =_____

at 188°C? –rA =_____

at 25°C? –rA =_____

at 288°C? –rA =_____

at 188°C? –rA =_____

at 25°C? –rA =_____

at 288°C? –rA =_____

(g) What would be the corresponding CSTR reactor volume at 25°C to achieve 90% conversion and at 288°C for a feed rate of 2 dm3/min

at 25°C? V =_____

at 288°C? V =_____

P4-7B Consider the following elementary gas-phase reversible reaction to be carried out isothermally with no pressure drop and for an equal molar feed of A and B with CA0 = 2.0 mol/dm3.

2A + B ⇄ C

(a) What is the concentration of B initially? CB0 =_____(mol/dm3)

(b) What is the limiting reactant?_____

(c) What is the exit concentration of B when the conversion of A is 25%? CB = _____ (mol/dm3)

(d) Write -rA solely as a function of conversion (i.e., evaluating all symbols) when the reaction is an elementary, reversible, gas-phase, isothermal reaction with no pressure drop with an equal molar feed and with CA0 = 2.0 mol/dm3, kA = 2 dm6/mol2,⋅s, and KC = 0.5 all in proper units –rA = _____.

(e) What is the equilibrium conversion?

(f) What is the rate when the conversion is

(1) 0%?

(2) 50%?

(3) 0.99 Xe?

P4-8B The gas-phase reaction

is to be carried out isothermally first in a flow reactor. The molar feed is 50% H2 and 50% N2, at a pressure of 16.4 atm and at a temperature of 227°C.

(a) Construct a complete stoichiometric table.

(b) Express the concentrations in mol/dm3 of each for the reacting species as a function of conversion. Evaluate CA0, δ, and ε, and then calculate the concentrations of ammonia and hydrogen when the conversion of H2 is 60%. (Ans.: CH2 = 0.1 mol/dm3)

(c) Suppose by chance the reaction is elementary with kN2 = 40 dm3/mol/s. Write the rate of reaction solely as a function of conversion for (1) a flow reactor and for (2) a constant-volume batch reactor.

P4-9B The elementary reversible reaction

2A ⇆ B

is carried out isothermally in a flow reactor with no pressure drop and where pure A is fed at a concentration of 4.0 mol/dm3. If the equilibrium conversion is found to be 60%

(a) What is the equilibrium constant, KC, if the reaction occurs in the gas phase?

(b) What is the KC if the reaction is a liquid-phase reaction?

P4-10B Consider the elementary gas-phase reversible reaction is carried out isothermically

A ⇆ 3C

Pure A enters at a temperature of 400 K and a pressure of 10 atm. At this temperature, KC =

0.25(mol/dm3)2. Write the rate law and then calculate the equilibrium conversion for each of the following situations:

(a) The gas-phase reaction is carried out in a constant-volume batch reactor.

(b) The gas-phase reaction is carried out in a constant-pressure batch reactor.

(c) Can you explain the reason why there would be a difference in the two values of the equilibrium conversion?

P4-11b Repeat parts (a) through (c) of Problem P4-10B for the reaction

3A ⇆ C

Pure A enters at 400 K, 10 atm and the equilibrium constant is KC = 2.5 (dm3/mol)2.

(d) Compare the equilibrium conversions in P4-10B and P4-11B. Explain the trends, e.g., is Xe for constant pressure always greater than Xe for constant volume? Explain the reasons for the similarities and differences in he equilibrium conversions in the two reactions.

P4-12c Consider a cylindrical batch reactor that has one end fitted with a frictionless piston attached to a spring (Figure P4-11C). The reaction

A + B → 8C

with the rate law

–rA = K1 C2A CB

is taking place in this type of reactor.

(a) Write the rate law solely as a function of conversion, numerically evaluating all possible symbols. (Ans.: –rA = 5.03 × 10-9 [(1 - X)3/(1 + 3X)3/2]lb mol/ft3· s.)

(b) What is the conversion and rate of reaction when V = 0.2 ft3? (Ans.: X = 0.259, –rA = 8.63 X 10-10 lb mol/ft3 · s.)

Additional information:

Equal moles of A and B are present at t = 0

Initial volume: 0.15 ft3

Value of k1: 1.0 (ft3/lb mol)2 · s-1

The spring constant is such that the relationship between the volume of the reactor and pressure within the reactor is

V = (0.1)(P) (V in ft3, P in atm)

Temperature of system (considered constant): 140°F Gas constant: 0.73 ft3 · atm/lb mol. °R

Supplementary Reading

Further elaboration of the development of the general balance equation may be found on the CRE Web site www.umich.edu/~elements/5e/index.html and also may or may not be found in

KEILLOR, GARRISON and TIM RUSSELL, Dusty and Lefty: The Lives of the Cowboys (Audio CD), St. Paul, MN: Highbridge Audio, 2006.

FELDER, R. M., and R. W. ROUSSEAU, Elementary Principles of Chemical Processes, 4th ed. New York: Wiley, 2015, Chapter 4.