5.2

NATURAL GAS STORAGE

Natural gas is constantly moving through pipelines. To avoid wasting gas, it must be used, stored, or sent somewhere else when it arrives. Pipelines can’t stop delivering gas. They must send a constant supply of gas from producing regions to consuming regions. Although the rate of flow can be adjusted somewhat, it is important that it never be stopped or interrupted completely.

Because the demand for natural gas is highly cyclical, and pipelines need to operate continuously, it is seldom possible to precisely match the supply of gas coming out of a pipeline with the amount demanded from each consuming region. Storage facilities are necessary to take in surplus during periods of oversupply, and deliver gas in shortages. Storage facilities stockpile gas during periods of low demand (buying cheap) for use in higher demand periods (selling high). Common trading opportunities are nights versus days, weekends versus weekdays, or shoulder months versus peak demand months.

Fortunately, natural gas is chemically stable. It can be safely stored in underground facilities for extended periods. It is nontoxic, so leaks don’t hurt the environment, and it has already survived millions of years in storage. While it might evaporate, it isn’t going to spoil or poison the environment. Natural gas storage provides a crucial margin of safety for short-term regional fluctuations in demand.

The most common type of storage facilities are depleted gas reservoirs. These are underground caverns that once contained natural gas. It is possible to reuse gas reservoirs after they have been depleted by pumping gas back in. Other types of facilities are salt caverns and aquifers. The main difference between facilities is the cost of construction, the quantity of gas that they can store, and how quickly they can inject and remove gas from storage.

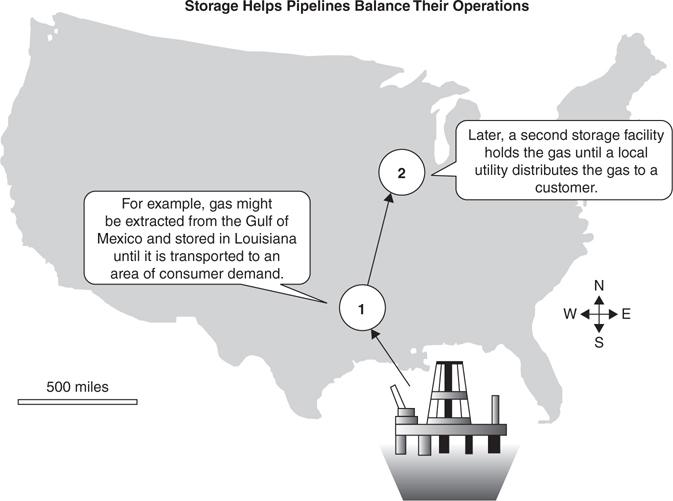

It is common for gas to be stored in several storage facilities before it is finally delivered to the customer (Figure 5.2.1). The first set of storage facilities are typically in producing regions like the U.S. Gulf Coast near refineries and major pipeline hubs. The second set of storage facilities are near consumer regions at the far end of the pipeline.

Figure 5.2.1 Benefits of storage

All storage facilities work in a similar fashion—a facility with a large volume suitable for storing natural gas is found and connected to a gas pipeline. To maximize the amount of gas that can be stored in a limited amount of space, the storage facility will usually keep the gas at higher pressure than a pipeline. As a result, gas will need to be compressed to get it into the storage facility. This compression is done by applying suction to a pipeline (similar to attaching a vacuum cleaner to it). As long as the suction is stronger than the pressure in the storage area, the gas will flow into the storage area and not back into the pipeline. When the suction is turned off, the connection between the storage facility and pipeline will need to be closed.

The speed at which gas can be inserted or extracted from storage depends on the relative pressure of a storage facility and the pipeline. When the storage facility is nearly full, gas can easily be removed from storage. It is possible to open up the pipeline connection and have the gas flow into the pipeline. However, as the pressure decreases, it takes progressively longer to get the gas out of storage.

As a result, the extractable gas is generally divided into two pieces—base gas (or cushion gas) and working gas. The base gas is used to create sufficient pressure to get the working gas out of the storage facility in a reasonable amount of time. Base gas is rarely removed during normal operation. Operators of a storage facility have to trade off having a large volume of working gas that can only be removed slowly or a smaller volume of working gas that can be removed quickly. During periods of peak demand, some of the base gas can be removed from the facility and delivered as working gas. However, over the long run, since removing the gas cushion slows down the speed at which gas can be removed (because removing gas lowers the pressure of the storage facility), keeping a fixed cushion of gas is required to meet performance targets.

This last major physical constraint on a storage facility is its maximum pressure. Higher pressure means that you can store more gas in a given volume and that you can get the gas out more quickly. However, higher pressure can also cause structural problems—more stress on the facility—and a greater possibility of gas escaping into the environment. Since there are a fairly limited number of locations suitable for the storage of natural gas, the pressure constraint is usually a function of what can be found, rather than what is desired.

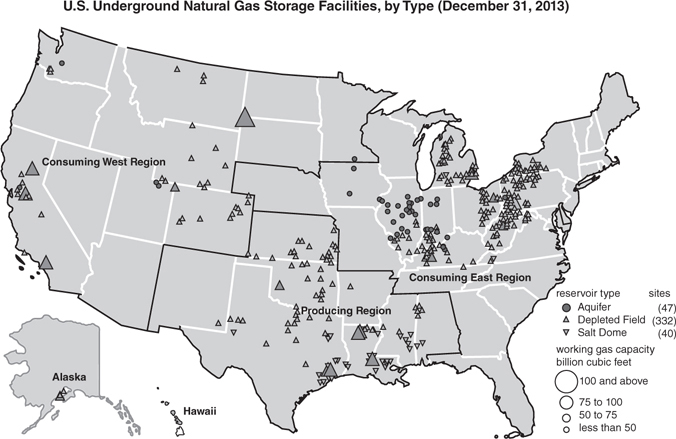

For a particular area, there is a limited inventory of possible locations suitable for storing natural gas (Figure 5.2.4). The cheapest and most reliable storage is depleted gas reservoirs. The highest performance facilities are converted salt caverns. In an area where neither of those two is available, aquifers can be used. Aquifers are permeable layers of underground rock often containing ground water. Methane is nontoxic and present in the air we breathe every day. It doesn’t present the health threat that other fuels might create if they start leaking into the environment. From a performance perspective, salt caverns are far superior to the other options—they can stand up to significantly higher pressures.

Figure 5.2.4 Natural gas storage in the United States

(Source: U.S. Energy Information Administration)

Geology

A storage facility is a large underground area where gas can dissolve, surrounded by an impermeable area that prevents the gas from escaping (Figure 5.2.5). Overall, natural gas storage facilities are similar to other types of pressurized containers and identical to wells where natural gas is found in nature.

Figure 5.2.5 Inserting gas into a storage facility

Natural gas storage facilities are often located underground. They aren’t usually excavated with pressurized metal walls. Instead, they are commonly constructed in areas where naturally existing porous rock is surrounded by a layer of impermeable rock. There are several advantages to reusing existing geological formations. All of this rock makes the facilities fairly sturdy. Equally important is the low cost of reusing existing rock formations. Finding an appropriate existing reservoir is one of the largest jobs in building a new natural gas storage facility.

Natural gas storage shares terminology with natural gas extraction. Porosity is a measure of empty space in a rock. Even though many rocks look solid, they often contain microscopic openings where gas can dissolve. These openings are called pores. If the pores in a rock are connected together, the rock is said to be permeable. Having connected pores allows the gas trapped in the rock to flow in and out of the storage facility quickly. The greater the size of the pores, and the more they are interconnected, the faster the gas can enter or leave the facility.

A storage facility requires a porous, permeable pocket of rock to be surrounded by a layer of impermeable rock. Since gas rises, it is especially important for the layer of rock directly above the storage volume to be impermeable. In every gas storage facility, some gas becomes permanently embedded into the walls. This is called physically unrecoverable gas. Even when the facility closes, it is impossible to recover this gas (Figure 5.2.6).

Figure 5.2.6 Physically unrecoverable gas

The greater the pressure in the storage volume, the more gas gets pushed into the walls. If enough pressure is added, gas will eventually reach a more permeable area and start to escape from the storage facility. This level is different for each facility. It is determined by the specific geology of the rocks that form the storage facility.

Depleted Gas Reservoirs

Once a natural gas reservoir has been emptied, it can be refilled. This is a very easy way of creating a storage facility. While not all reservoirs are suitable for refilling, if one exists in the right area, is close to pipelines in a consuming region, and has the right geological properties, this can be a very fast, reliable, and cost-effective way of getting a storage facility operational.

The physical characteristics of depleted gas reservoirs are usually well known since they already had wells on them. The maximum pressure and geological stability of the area would have been under continuous observation for years. Additionally, since natural gas has been stored in the reservoir for millions of years, there are few concerns about the geological impact of using the facility.

Another advantage of depleted reservoirs is that many still have the equipment that was originally used to remove the gas. Since this equipment can be reused, this allows for substantially lower startup costs than buying all of the equipment again.

Finally, storage facilities and reservoirs tend to have similar constraints on unrecoverable gas. Because unrecoverable gas can’t be removed from a reservoir, it will still exist in the storage volume. As a result, a depleted reservoir won’t require additional gas to be injected to form an unrecoverable gas barrier. When natural gas was exceptionally cheap in the early 1980s, pumping in unrecoverable natural gas was not a huge economic concern. However, because natural gas prices have risen substantially, unrecoverable gas is now an important economic consideration.

Overall, depleted gas reservoirs are quick and cost-effective to bring into service. Historically, depleted natural gas reservoirs have been the most abundant form of natural gas storage. Given the cost effectiveness of reusing an existing gas reservoir, alternative storage facilities must either provide better functionality or have a location advantage compared to a depleted gas reservoir. Depleted gas reservoirs need to reserve about 50 percent of their total capacity as a gas “cushion.” Salt caverns, which only need to reserve about 33 percent, provide better performance characteristics. Aquifers, which often need to reserve about 80 percent of their capacity, are the least desirable type of storage facility.

Salt Caverns

Underground salt caverns offer excellent properties for natural gas storage. They are more expensive to develop than depleted gas reservoirs but have much better performance characteristics. These caverns allow very little gas to leak out, have extremely strong walls, and are generally resistant to damage. Essentially, they are high pressure storage vessels. They can operate at higher pressures than the other types of storage facilities, allowing gas to be cycled in and out of the facility more often. This is a huge benefit for customers who require erratic supplies of natural gas.

These storage facilities are constructed by removing salt from deposits and reusing the remaining cavern for gas storage. The best type of salt deposit to use for a storage facility is a “salt dome.” Salt domes can be several miles across and over a mile high. Typically, salt domes are formed when a marine basin evaporates and is covered with sediment. The salt, being lighter than the surrounding sediment, will tend to move upward forming a dome.

Salt domes are typically excavated by injecting water into the rock formation and dissolving the salt deposit. This leaves a large empty cavern suitable for storing natural gas. The usual method for doing this is to drill down into the formation and cycle enough clean water through the salt deposit to fully dissolve the softer materials. After all the salt is dissolved, the remaining walls are extremely strong—they are the rock layers that proved impenetrable to the rising salt formation.

In areas where it is not possible to find well-formed domes, it may be possible to form storage facilities out of salt beds. Salt beds are much shallower, thinner formations usually a couple hundred feet in height. Because of their wide, thin construction, salt bed caverns are much more prone to collapse than caverns formed from salt domes. Compared to salt domes, salt beds also contain a higher quantity of insoluble rock. This slows down the speed at which gas can flow inside the facility. In general, salt beds tend to be more expensive to excavate and maintain than salt domes.

Because salt caverns store natural gas at high pressure, they require more specialized equipment than other types of storage facilities. Salt caverns are often pressurized to double the level of a standard gas pipeline. As a result, the pipes and fittings used to extract the gas from the facility often need to be much heavier grade than standard pipeline equipment. In addition, since the temperature of gas increases with pressure, gas being discharged from a salt cavern can be extremely hot. All of the pipes, fittings, and valves need to be rated for very high temperature gases, and resistant to the greater corrosion that comes with higher temperatures.

From an economic perspective, salt caverns are much more profitable than the other types of natural gas storage. The ability to insert and remove gas quickly allows salt caverns to benefit from short-term shortages in the natural gas supply. Combined with a fast-starting gas turbine electrical generator, they can provide a good way to benefit from short-term spikes in electricity prices.

Aquifers

Aquifers are the least desirable and most expensive type of natural gas storage. Aquifer storage facilities are water reservoirs modified to store natural gas. They are only built if they have a large geographical advantage—they are in the right place when nothing else is available. Most of the gas in aquifer storage facilities is unrecoverable. Aquifers have the lowest percentage of working gas to total volume of any storage facility, and the slowest injection/withdrawal cycle of any storage type.

Since there is no gas present when a facility is built, a large volume of gas must be placed into a facility. Compared to other storage types, there is also less leeway to remove the gas cushion before impairing the ability of the facility to operate. All existing aquifer facilities were built when natural gas was relatively inexpensive, and it would be difficult to economically make the initial investment in unrecoverable gas today.

The U.S. government has placed restrictions on building new facilities in areas where the water is usable for human consumption or irrigation. This policy, combined with the limited economic viability of aquifers, has made it unlikely that substantial future development in aquifer storage will occur.

Trading Example—Natural Gas Storage

A high-performance natural gas storage facility in the New Jersey area has just been constructed. The storage capacity in the facility is being auctioned off to the highest bidder.

1. The Opportunity. There is a limited amount of natural gas storage facilities anywhere on the East Coast. Because of this, natural gas prices see more cyclical variations than other parts of the country. Capacity in the storage facility is being sold at auction, so it is necessary to develop an appropriate bid.

2. The Intuition. A natural gas storage facility will allow a trader to buy during periods of low demand, hold the gas, and resell it during periods of high demand.

3. The Strategy. The valuation of the strategy will examine a number of trades limited by the physical characteristics of the storage facility. The best combination of trades will determine the value of the bid.

• Seasonal Trade. The largest amount of gas will be purchased during the spring and fall months when natural gas is normally inexpensive. It will be resold in the summer and winter when prices are higher. Many storage facilities can only empty and refill once a year—they can’t meet both the summer and winter demand. However, in this case, the facility is a high-performance facility that can be emptied and refilled twice in a single year.

• Weekday/Weekend. The trader is also considering buying gas on weekends and reselling it during weekdays. This will affect the seasonal trade by slowing down the speed at which gas is injected and removed from the facility. Instead of seven days of insertion or removal of gas, there will only be three net days of insertion or delivery for the seasonal trade. On the two weekend days, gas will be placed into the facility so that it can be sold on a weekday.

An optimization of trading will be required to determine which combination of trades is expected to be the most profitable. For example, the operational limits of the facility might make it impossible to do both the weekday/weekend trade and the seasonal trade throughout the year.

4. The Risks. Since this is a competitive bidding process, there is a risk of doing the analysis wrong and bidding too high. If that happens, the trader will probably end up winning the auction and overpaying. This is an asymmetric risk, because if the bid was much too low, someone else would always win the auction. Traders use a term from economics, the “winner’s curse,” to describe this possibility.

Another risk of the trade is a change in seasonal dynamics. For example, in the mid-1980s there were very few natural-gas-fired power plants. As a result, there was relatively little demand for natural gas during the summer. Natural gas was almost exclusively used during the winter by homeowners. Twenty-five years of building natural-gas-fired power plants has changed that dynamic. Natural gas is now a major fuel used for electrical generation. As a result, summer natural gas prices have skyrocketed.

5. Executing the Trade. Owning a physical storage facility means hiring an operations team to coordinate the physical delivery and sale of natural gas. This is no longer a financial deal—it is a 20-year commitment to keep a staff in place to service this contract. Even if a lot of the trading is arranged ahead of time in the futures market, there will be a substantial amount of daily housekeeping that is required.

6. The Results. One side benefit of owning a storage facility wasn’t mentioned yet. In addition to being a potential profit opportunity, a storage facility gives a natural gas trader the ability to deliver and receive natural gas. This might make it possible for the trader to enter into other trading opportunities. For example, the trader might decide to sell other traders insurance that their natural gas deliveries would occur. He would make an up-front premium for the insurance, and if he had to cover deliveries in the event of a shortfall, he wouldn’t have to resort to buying the gas on the (probably skyrocketing) spot market.

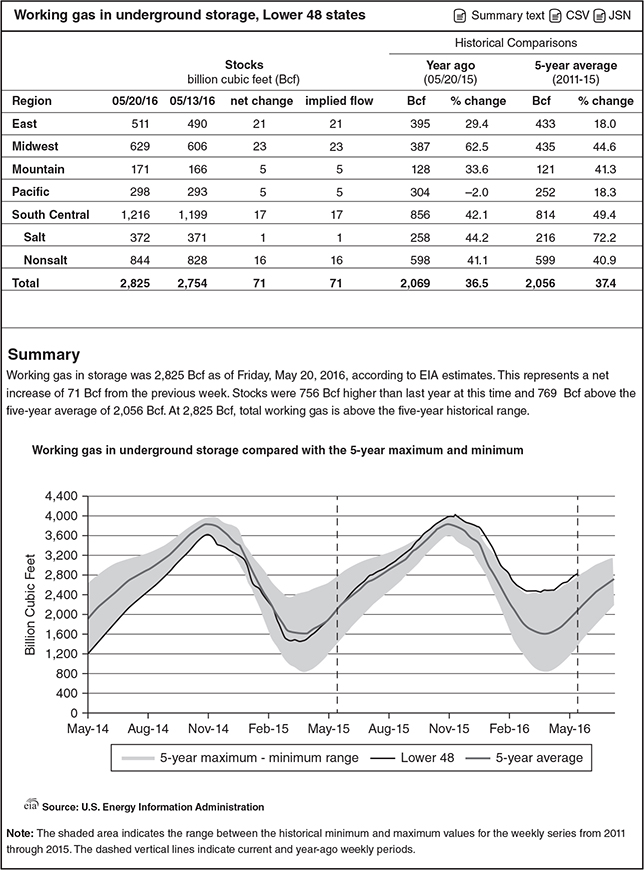

Natural Gas Storage Reports

The U.S. government agency responsible for producing natural gas statistics is the Energy Information Agency. It publishes a weekly report that indicates the amount of natural gas currently being stored. There are two main parts to this report. The first part is a table indicating the amount of natural gas stored in each region. The second part is a graph that shows the total amount of natural gas currently in storage relative to the past five years (Figure 5.2.7).

Figure 5.2.7 EIA natural gas storage report

(Source: U.S. Energy Information Agency