6

Chemistry of Engineering Materials

6.1 Semiconducting and super conducting materials

According to conductivity elements (or) materials are broadly classified into three categories. They are

1. Conductors

2. Semiconductors

3. Insulators

Conductors

They allow the maximum portion of the applied thermal or electric field to flow through them.

Example: Metals are good conductors.

Insulators

They do not practically allow the heat (or) electricity to flow through them.

Example: Most of the organic and Inorganic solids (except graphite).

Semiconductors

The thermal and electrical conductivity of a semiconductor at normal temperature lies between that of a conductor and Insulator.

Actually semiconductors are those solids which are perfect insulators at absolute zero, but conduct electric current at room temperature.

Example: Silicon and Germanium are two very important elements used as semiconductors.

6.1.1 Semiconductor

At room temperature, semiconductors allow a portion of electric current to flow through them. The electrical conductivity of a semiconductor at normal temperature lies between that of a good conductor and an insulator; it is in range of 10–9 to 102 ohm–1cm–1.

Actually, semiconductors are those solids which are perfect insulators at absolute zero, but conduct electric current at room temperature. Silicon and germanium are two very important elements used as semiconductors. Pure samples (≥ 99.999 % pure) of these elements are obtained by zone refining and to these some impurity is added deliberately by a process called doping. These are of two types intrinsic and extrinsic.

- Intrinsic semiconductors (semiconductors due to thermal defects):

Pure silicon or germanium acts as insulators because electrons fixed in covalent bonds and are not available for conduction. At high temperatures, electrons are released by breaking of some of the covalent bonds. These electrons move freely in the crystal and can conduct electricity. Here, without introducing an external substance, these materials show conduction. Hence, these are known as intrinsic semiconductors.

- Extrinsic semiconductors (semiconductors due to impurity defects):

Silicon and germanium (group 14 elements) in pure state, have very low electrical conductivity. However, the low electrical conductivity of these elements is greatly enhanced by the addition of even traces of an element belonging to groups 13 (iii) or group 15 (v) to the crystals of group 14 (iv) elements, i.e. silicon or germanium. Induction of group 15 and group 13 elements to the crystal lattice of group 14 elements (Si or Ge) produces n-type semiconductors and p-type semiconductors respectively.

- n-type semiconductors: (n stands for negative):

This type of semiconductor is produced by

- Due to metal excess defect (explained earlier) or

- By addition of trace amount of group 15 element (P, As) to extremely pure germanium or silicon by a process called doping.

When an element of group 15(As) is added to germanium (group 14 element) crystal, some atoms of germanium are replaced by arsenic. In such cases, four electrons of the impurity element (As) are used in forming bonds to Ge, while the Fifth electron remains unused. The extra electrons can move freely and conduct electricity in the metals. Hence, arsenic-doped germanium exhibits fairly high electrical conductivity.

- p-type semiconductor: (p stands for positive):

This type of semiconductors are formed by

- Due to metal deficiency defects, or

- By addition of impurity atoms containing less electrons (i.e., atoms of group 13) then the parent insulator to the insulator lattice, behaves like a conductor – electron.

When a group 13 element (like B, Ga, In) substitutes for a germanium atom (group 14 element), i.e., when a group 13 element (say B, having only 3 electrons in the outer shell) is added in small traces to group 14 elements (say germanium), the atoms of B are not able to complete tetrahedral covalent structures because they have one electron short of the requirement. Hence some of the sites normally occupied by electrons will be left empty. This gives rise to electron-vacancies, commonly known as positive holes because the net charge at these sites is positive. With an electric field, adjacent electrons move into the positive holes and form other positive holes. The current is passed in the crystal due to migration of positive holes. Electrical conductivity of germanium (Group 14 element) crystal increases by the doping trace amount of B (Group 13 element). Here, current is carried by positive holes, hence this type of conduction is known as p-type semiconduction.

Unlike metals, the conductivity of semiconductors increases with increases in temperature. This is due to the fact that extra electron or positive hole (as the case may be) is bound weakly with the crystal and when energy supplied in the form of heat, they become force from the crystal lattice for the conduction of electricity.

- n-type semiconductors: (n stands for negative):

6.1.2 Applications of Semiconductors

A large variety of semiconductors has been prepared by the following types of combination.

- Elements of group 14 (Se, Ge) and group 15 (P, As, Sb)

- Elements of group 13 (B, Ga) and group 14 (Si, Ge)

- Elements of group 13 and group 15 (In Sb, Al, P)

- Elements of group 12 and group 16 (ZnS, CdS, CdSe, Hg, Te)

Properties of a semiconductor are considerably changed depending upon the nature of the impurity. Semiconductors are used in transistors and in exposure metals as photoelectric devices. Combination of p– and n-type of semiconductors (known as p-n junction) allow electric current from outside to flow through it in one direction. This type of p-n junction is known as a rectifier and is used for converting alternating current to direct current.

6.1.3 Super-conductors

The electrical resistance of metals depends upon temperature. Electrical resistance decreases with decreases in temperature and becomes almost zero near the absolute temperature. Materials in this state are said to possess super-conductivity. Thus super-conductivity may be defined as a phenomenon in which metals, alloys and chemical compounds become perfect conductors with zero resistivity at temperatures approaching absolute zero. Super-conductors are diamagnetic. The phenomenon was first discovered by Kammerlingh Onner in 1913 when he found that mercury becomes super–conducting at 4K. The temperature at which a substance states behaving as super-conductor is called transition temperature. Which lies between 2 and 5K is most of the metals exhibiting this phenomenon.

Efforts are going on to find materials that behave as a super-conductor at room temperature because attaining low temperature with liquid helium is highly expensive. The highest temperature at which super conductivity has been observed is 23K for alloys of niobium (Nb3Ge) since 1987, many complex metal oxides have been found to possess super-conductivity at fairly high temperatures. Some examples are given below.

YBa2Cu3O7 90K

Bi2Ca2Sr2Cu3O10 105K

Tl2Ca2Ba2Cu3O10 125K

Super-conductors have many application in electronics, building magnets, aviation transportation (trains which move in air without rails) and power transmission.

6.2 Magnetic materials

Magnetism is the ability of matter in which there is a force of attraction or repulsion between unlike or like poles. More than 2000 years ago, the ancient Greeks first discovered a mineral that attracts things made of iron. This mineral was found in Magnesia, a part of Turkey, hence it was named as magnetite. Magnets are very common things in workplace and house hold.

6.2.1 General Properties of Magnetic Materials

- Earth acts as a big bar magnet through its core. North pole of magnets and compass needles point to earth‚s magnetic south pole, which is near earth‚s geographic north pole.

- All the magnets have two poles. If a magnet is allowed to rotate freely the north pole will always point to the north and the other is called south pole.

- Opposite magnetic poles attract each other and like magnetic poles repel.

- Every magnet is surrounded by a magnetic field. Magnetic field lines can explain the shape of the field.

- According to Becquerel and Faraday, all matter including liquids and gases were affected by magnetism, but few respond to a noticeable extent and others do not.

6.2.2 Classification

According to Faraday‚s law of magnetic induction, the magnetic forces of the material electrons will be affected when a material is placed within a magnetic field. But in the magnetic field material, electrons can react quite differently (attract/repel). This mainly depends on atomic or molecular structure of the material and net magnetic field associated with the atom. Depending on attraction and repulsion in the magnetic field, materials can be classified into five categories. They are:

- Diamagnetic materials – weak repulsion to field

- Paramagnetic materials – weak attraction to field

- Ferromagnetic materials – strong attraction to field

- Ferrimagnetic materials – strong attraction to field

- Antiferromagnetic materials – no magnetic moment

(i) Diamagnetic Materials

Diamagnetic materials have a weak magnetic susceptibility, hence, they repel slightly in a magnetic field and the material does not retain the magnetic properties when the external field is removed. Such materials have no permanent net magnetic moment due to paired electrons. In the external magnetic field electron paths are realigned, hence, material shows weak repulsion.

E.g. Copper, silver, gold, etc.

(ii) Paramagnetic Materials

Paramagnetic materials have a small positive susceptibility, hence, they attract slightly in a magnetic field and the material does not retain the magnetic properties when the external field is removed. Due to presence of some unpaired electrons and the realignment of the electron path with the external magnetic field materials show paramagnetism.

E.g. Magnesium, molybdenum, lithium, tantalum, etc.

(iii) Ferromagnetic Materials

Ferromagnetic materials have a large positive susceptibility, hence, they exhibit strong attraction to magnetic field and the materials retain their magnetic properties after the external field has been removed due to presence of magnetic domains. Due to presence of unpaired electrons, ferromagnetic materials have net magnetic moment. Here, all the magnetic dipoles are aligned parallel and oriented in the same direction.

E.g. Iron, nickel, cobalt, etc.

Curie Temperature

At a particular temperature electronic exchange forces in ferramagnets are very large, thermal energy eventually overcomes the exchange and produces a randomizing effect, and that temperature is known as ‘Curie temperature.‚ Below the Curie temperature, the ferromagnet is ordered and above disordered.

Hysteresis

Retaining of magnetic properties after the removal of external magnetic field is known as hysteresis.

Magnetic Domain

In ferro and ferrimagnetic materials, below Curie temperature, large number of atom moments is aligned parallel as a small volume regions and it is known as ‘domain.‚ Adjacent domains are separated by boundaries and are shown in the figure given hereunder.

(iv) Ferrimagnetic Materials

Ferrimagnetism is similar to ferromagnetism, but it is observed in complex crystals not in atoms in which the magnetic moments of neighbouring ions are antiparallel and unequal in magnitude.

E.g. Magnatite

Magnetite was considered as a ferromagnet until 1940. In 1940, Neel provided the theoretical framework about ferrimagnetism.

(v) Antiferromagnetic Materials

Antiferromagnetism is a phenomenon exhibited by materials in which complete magnetic moment is cancelled with antiparallel coupling of adjacent atoms or ions. That is, the successive magnetic dipoles are aligned in opposite directions with same magnitude, hence, it has no net magnetic moment.

E.g. Manganous oxide, chromium, etc.

Magnetic material and their spin alignment are shown in the figure provided hereunder.

6.2.3 Applications of Magnetic Materials

Magnets are used in a vast array of products from loud speakers to space research.

- Power conversion (electrical to mechanical): As a motors (starter motor, power steering motors, washer pumps), generators and electromagnets.

- Power adaptation and signal transfer: Transformers.

- Permanent magnets: Loud speaker, sensors, navigation and information systems.

- Data storage analogue: Video and audio tapes.

- Data storage digital: Hard disk, floppy disk.

- Quantum devices: MRAM, GMR reading head.

- Instrumentation: Dashboard instruments, nanoscience and technology, medicine, research, etc.

6.3 CEMENT

Concrete is the widely used non-metallic material in construction. Cement is the important bonding material and can bond sand and rock with water in concrete. It has adhesive and cohesive nature and also having capability to bond with bricks, stones, etc.

6.3.1 Classification of Cements

Cement is broadly classified into Natural, Puzzolana, Slag and Portland cement. These are briefly discussed below.

(a) Natural Cement

Natural cement is prepared with calcination and pulverization of naturally occurring argillaceous lime stone at high temperature. During calcination, calcium silicates and aluminates are formed.

Natural cement is quite setting cement and it possesses hydraulic qualities and relatively low strength.

Combination of sand with natural cement is known as mortar and is used in laying bricks and setting stones. Mortar is also used in construction of dams and foundations as bulk masses of concrete.

(b) Puzzolana Cement

Puzzolana cement is the oldest cement. It is invented by Romans and used by them for the construction of walls and domes.

Mixing and grinding of natural puzzolana and slaked lime gives puzzolana cement. Volcanic ash produced by rapid cooling of lava, is known as natural puzzolana. It is a molten mixture of silicates of calcium, aluminium and iron, and has hydraulic properties too.

(c) Slag Cement

Slag cement is a mixture of lime and blast furnace slag. A mixture of calcium and aluminium silicates (blast furnace slag) is granulated by pouring into a stream of cold water, dried mixed with hydrated lime and pulverized to fine powder.

Setting of slag cement is too slow, poor in abrasion resistance and lower in strength. Hence, slag cement has limited applications and is used for making concrete in bulk construction.

(d) Portland Cement

In 1824, William Aspdin prepared Portland cement by heating limestone and clay by crushing the resulting product to a fine powder. Hence, he is known as father of Portland cement. The cement upon mixing with water set to give a hard stone-like mass and resembles stone of Portland, England. Hence, it is known as magic powder and Portland cement.

6.3.2 Raw Materials Used in the Manufacture of Portland Cement

It primarily consists of lime, silica, alumina and iron.

The following materials are used for manufacture of cement.

- Calcareous materials, CaO (such as limestone, chalk, marl, etc.)

- Argillaceous materials, Al2O3 (such as clay, shale, aluminium ore refuse, fly ash, etc.)

- Siliceous material, SiO2 (Such as clay, shale, sand, etc.)

- Powdered coal or fuel oil

- Gypsum (CaSO4 · 2H2O) and

- Iron components, Fe2O3 (Ferriferous materials such as clay, iron ore, etc.,)

Importance and their Effects of the Ingredients on the Cement

All the ingredients‚ proportion should be maintained properly; otherwise, the following effects may be observed on the characteristics of cement.

- Strength: Lime, silica, iron oxide and alumina plays a vital role on strength of the cement. But excess/loss amount of lime and alumina reduces the strength due to expansion and disintegration.

- Colour and hardness: Iron oxide provides colour and hardness to the cement.

- Soundness: Small amount of sulphur trioxide imparts soundness to cement; however, in excess reduces the soundness.

- Setting: Alumina and lime help in quick setting. Gypsum helps to retard the setting action of cement and enhances the initial setting time.

- Efflorescent: Excess alkali causes the efflorescent.

6.3.3 Manufacture of Portland Cement

Manufacture of portland cement involves following steps:

- Crushing

- Mixing

- Burning

- Grinding

- Packing

(1) Crushing

Crushing of raw materials is done with two crushers. The primary crushers reduces the size of raw material to an approximately 5 – inches and the secondary crusher further reduces the size to ¾ inches. Then these are ground to fine powder (in ball mills or tube mills). Each separate powdered ingredient is stored in separate hoopers (Figure 6.1).

Figure 6.1 Crushing: stone is first reduced to 5–in, size, then ¾–in, and stored

(2) Mixing

Mixing of raw materials can be done either by (a) dry process or (b) wet process.

(a) Dry Process

The following proportions of the powdered materials, i.e., lime 60–69 per cent, silica 17–25 per cent, alumina 3–8 per cent, iron oxide 2–4 per cent, magnesium oxide 1–5 per cent, alkali oxides like Na2O + K2O 0.3–1.5 per cent and sulphur trioxide 1–3 per cent are mixed and thus we get a raw mix. It is stored in silos (storage bins) and send to a rotary kiln for burning, and this process is shown in Figure 6.2.

.png)

Figure 6.2 (a) Dry process: Mixing of raw material; (b) Wet Process: Mixing of raw materials with water

(b) Wet Process

The calcareous raw material is crushed, powdered stored and the argilaceous material (clay) is thoroughly mixed with water for removing organic material in wash mills stored in basins. These two are led to grinding mills (tube mill/ball mill) through channels in the right proportions and they are mixed to form a paste called slurry. The chemical composition of slurry may be adjusted with correcting basins, and it contains about 38–40 per cent of water and is stored in tanks for feeding to a rotary kiln.

Differences between Dry and Wet Process

(3) Burning

Burning process is done in a rotary kiln containing a steel tube, lined inside with refractory bricks, having 2.5–3.0 m in diameter and 90–120 m in length. The kiln is in a slightly inclined position and is capable of rotating at 1 rpm along its longitudinal axis. Fuel and air are injected at the lower end for burning, which produce long hot flames that heat the interior of the kiln up to 1750°C temperature.

From the upper end of the kiln raw mix or corrected slurry is injected. From the lower end of the kiln, hot flames are forced with slow rotation and through slope of the kiln, fed material move towards bottom of the kiln and the material descends gradually with temperature.

Depending on the temperature, kiln is divided into three zones. They are drying zone, calcination zone and clinkering zone.

- Drying zone: It is the upper part of the kiln having temperature around 400°C, here water in the slurry gets evaporated.

- Calcination zone: It is the central part of the kiln having temperature around 1000°C. Here, limestone of dry mix or slurry is decomposed to give quick lime as small lumps, also called modules and carbon dioxide, escapes out.

- Clinkering zone: It is the lower part of the kiln having the temperature between 1500 and 1700°C. Here, chemical interaction of fusion occurs between lime and clay to form calcium aluminates and silicates.

The silicates and aluminates of calcium fuse to form about 0.5–1 cm diameter hard, greyish stones, known as clinkers, and these are hot at about 1000°C. These are cooled with cool air in another small rotary kiln at base of the main kiln and collected in small trolleys (Figure 6.3).

Figure 6.3 Burning: Burning changes raw mix chemically into cement clinker

(4) Grinding

In ball mills or tube mills the cooled clinkers are ground to fine powder and 2–3 per cent of gypsum is added to avoid quick setting and also acts as a retarding agent for early setting of cement. This is shown in Figure 6.4. Gypsum reacts with tricalcium aluminate to form insoluble tricalcium sulphoaluminate, and it prevents too quick reaction of setting and hardening (Figure 6.4).

![]()

Figure 6.4 Grinding: Clinker with gypsum added into portland cement and shipped

After the initial set, the cement water paste becomes stiff, but gypsum retards the dissolution of C3A by forming tricalciumsulphoaluminate (3CaO · Al2O3 · x · CaSO4 · + H2O), which is insoluble (Figure 6.5).

Thus:

![]()

Formation of insoluble C3A prevents too early further reactions of setting and hardening.

(5) Packing

The ground cement is stored in silos, from which it is fed to automatic packing machines. Each bag, usually contains 50 kg of cement.

Flow diagram for the manufacture of portland cement is shown in Figure 6.5.

6.3.4 Chemical Composition of Portland Cement and their Importance

Portland cement contains mainly dicalcium silicate (C2S), tricalcium silicate (C3S), tricalcium aluminate (C3A) and tetracalcium alumina ferrite (C4AFe). Each component exhibits particular special behaviour, hence the behaviour of cement can be altered by changing the relative percentages of the above compounds.

(1) Dicalcium Silicate (C2S)

Due to slow reaction with water, it gets hardened slowly and strengthen after 1 week with the formation of tobermonitegel with high surface area. Moist curing continuing up to 6 months.

![]()

Figure 6.5 Flow diagram for the manufacture of portland cement

(2) Tricalcium Silicate (C3S)

Due to rapid reaction with water, this material is responsible for initial setting and early strength with the formation of hydrolgel, it is having binding action between the aggregates.

![]()

(3) Tricalcium Aluminate (C3A)

Due to fast hydration, this compound forms hydrated tricalcium aluminate and is responsible for first few days of strength. This reaction is highly exothermic, hence cement is made with less C3A, and at that time it generates less heat, develop higher strengths and show greater resistance to sulphate attacks.

![]()

Due to high heat generation and reactiveness with soil, C3A is the least preferable component in the cement.

(4) Tetracalcium Alumina Ferrite (C4AF)

It hydrates very rapidly, reducing the clinkering temperature and gives little strength to concrete.

![]()

Importance of Gypsum in Cement

Tricalcium aluminate (C3A) combines with water very rapidly with the evolution of large amount of heat (exothermic reaction).

C3A + 6H2O → C3A · 6H2O + Heat

After the initial set, the paste becomes somewhat stiff. But in the presence of gypsum, it reacts with tricalcium aluminate to form insoluble tricalcium sulphoaluminate which helps to retard the speed of the initial set and does not show any tendency to rapid hydration.

![]()

![]()

The above reaction prevents high concentrations of alumina in the cement solution and retarding the early initial set of the cement.

6.3.5 Setting and Hardening of Cement

When water is added and mixed to cement to form cement paste, start hydration, convert into gel and crystalline material. Solidification, interlocking and binding of the aggregates into a rock-like matter is two-step process, they are setting and hardening.

Setting: It is the stiffening of the cement paste with the formation of gel setting that is divided into initial setting and final setting.

Initial setting: It is hydration and gel formation from the different constituents of cement.

During the hydration of dicalcium, silicate gives tobermonite gel, which possesses very high surface area and high adhesive property.

![]()

Final setting: It is the complete formation of tobermonite gel.

Hardening: Hardening is the development of strength with the crystallization of calcium hydroxide and hydrated tricalcium aluminate.

Two theories are proposed for explaining the hardening of the cement.

(a) Colloidal Theory by Michaels

According to this theory, silicate gels are formed with hydration and are responsible for hardening.

(b) Crystalline Theory by Le Chatelier

According to this theory, crystalline products are formed with hydration, and undergo interlocking are responsible for hardening.

Hence, setting and hardening of cement is due to the interlocking crystallization of gels, which are formed by hydrolysis of constitutional ingredients (Figure 6.6).

Figure 6.6 Schematic diagram of setting and hardening of cement

Ingredients Reaction Sequence During Setting and Hardening of Cement

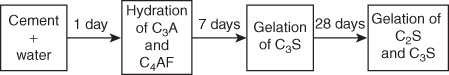

When water is added to cement, various ingredients undergo hydration and crystallization with different rates (Figure 6.7).

Figure 6.7 Sequence of changes during setting and hardening of cement

6.3.6 Specifications of Cement

According to Indian Standard 269–1975, composition of ordinary portland cement shall satisfy the following conditions:

Chemical Requirement of Cement

- Ratio of the percentage of lime (CaO) to that of silica (SiO2), alumina (Al2O3) and iron oxide (Fe2O3) when calculated by the formula

- Ratio of percentage of alumina (Al2O3) to that of iron oxide (Fe2O3) shall not be less than 0.66.

- Weight of insoluble residue shall not exceed 2%.

- Weight of magnesia shall not be more than 6%.

- Total sulphur contents, calculated as sulphuric anhydride (SO3) shall not be more than 2.75%.

- Total loss on ignition shall not exceed 4%.

Physical Requirements of Cement

- Setting time:

Initial: Not less than 30 minutes, Final: Not more than 600 minutes.

- Compressive Strength (of 1:3 cement mortar cube of cement ampers; Ennore sand):

3 days: Not less than 1.6 kg/mm2 (or 16 N/mm2)

7 days: Not less than 2.2 kg/mm2 (or 22 N/mm2)

- Soundness:

By Le-Chatelier‚s method: It expresses the expansivity of the cement set in 24 hours between 25°C to 100°C.

Unaerated Cement: Maximum 10 mm.

Aerated Cement: Maximum 5 mm.

- Fineness:

Not less than 215 m2/kg. Finer the grinding the greater is the rate of reactions thereby hastening the early development of strength. However finer cement generates heat quickly, thereby the cement mortar/concrete is likely to develop cracks.

6.3.7 Analysis of Cement

The quality of cement is maintained by conducting various tests from raw material stage right upto the cement in packing stage, at every half an hour to one hour intervals. In fact various physical and chemical characteristics are tested. The quality of a sample of cement is determined from a number of measurements. For Example.

- Soundness: The analysis of a cement for soundness is done by Le-chatelier technique. It expresses expansivity of cement set for one day, between 80°F and the boiling point of water. The analysis for soundness can also be done by autoclave method. According to I.S.I specifications.

Soundness by auto clave method: Expansion not more than 0.8% and

Soundness by Le-chatelier method:

Aerated cement: maximum 5 mm

Unaerated cement: maximum 100 mm

- Fitness: By Turbidmetic method: 1600 cm2/gm. By plain permeability method (As specific surface) ≥ 215 m2/Kg.

- Compressivestrength: As per ISI specifications.

- TensileStrength: As per ISI specifications.

- SpecificGravity: Specific gravity should be 3.1–3.2.

6.3.8 Plaster of Paris/Gypsum Plaster

The mineral gypsum (hydrated calcium sulphate CaSO4 · 2H2O) is extensively used as raw material for the manufacture of plates, which are almost universally used for coating the inner walls of dwellings.

It is hemihydrate of calcium sulphate 2CaSO4 · H2O(or CaSO4 · ![]() H2O).

H2O).

Preparation: It is produced by heating pure Gypsum to a temperature of about 120°C–160°C. If the Gypsum heated above 200°C, the anhydrous sulphate is produced, which loses the power of readily combining with water.

The preparation of plaster of paris from gypsum consists the following operations:

- Crushing and grinding of gypsum

- Calcination of ground gypsum in kilns by heating about 150°C, and

- Pulverizing the calcined product.

Setting and Hardening

Plaster of paris forms a plastic mass when it is mixed with water. This plastic mass quickly sets or hardness, expanding in the process and regains the closely packed crystalline structure of gypsum. Setting of plaster of paris can be accelerated by admixing it with alkali sulphates like K2SO4, Na2SO4or alums, which initiate as well as hasten the crystallization process.

Applications

- Its slight expansion on setting renders plaster of paris suitable for making mould, since some details are there by accurately reproduced.

- It is used in making surgical bandages, structural tiles and castings.

- It is used as plaster for walls and in plaster boards, which is made up of alternate layers of a fibrous material such as felt or paper.

6.4 REFRACTORIES

Refractories are ceramic materials that can withstand high temperatures as well as abrasive and corrosive actions of molten metals, slags, and gases, without suffering a deformation in shape. The main objective of a refractory is to confine heat.

6.4.1 Characteristics of Good Refractory Materials

- A good refractory material should have excellent heat, corrosion, and abrasion resistance.

- It should possess low thermal coefficient of expansion and should expand and contract uniformly with increase and decrease of temperature, respectively.

- It should possess high fusion temperature. It should be infusible at operating temperatures.

- It should be able to withstand the overlying load of structure, at operating temperatures.

- They should be chemically inert towards corrosive action of molten metal, gases, and slags produced in its immediate contact with furnaces.

- They should not crack at the operating temperatures.

6.4.2 Failures of Refractory Materials

If a given refractory material does not have the above-mentioned good characteristics, it will fail in service. Thus we can easily summarize conditions, which lead to failures of a refractory materials as follows:

- Using a refractory material which does not have required heat, corrosion, and abrasion resistance

- Using refractory material of higher thermal expansion

- Using a refractory of refractoriness less than that of the operating temperature

- Using of lower quality refractory bricks than the actual load of raw materials in products

- Using basic refractory in a furnace in which acidic reactants and/or products are being processed and vice versa

- Using refractories that undergo considerable volume changes during their use at high temperatures.

6.4.3 Classification of Refractories

On the basis of chemical properties, refractories are broadly classified into three main categories.

- Acidic Refractories: Refractories which consist of acidic materials are known as acidic refractories. These are easily attacked by basic materials and not by acidic materials.

Eg.: Alumina, silica and fireclay refractories.

- Basic Refractories: Refractories which consist of basic materials are known as basic refractories. There are easily attacked by acidic materials and not by basic materials.

Eg.: Magnesite and dolomite.

- Neutral Refractories: Refractories which consist of weakly acidic/basic materials are known as neutral refractories.

Eg.: Zirconia, graphite, chromite and carborundum.

6.4.4 Properties of Refractories

Important properties of refractories are:

(i) Refractoriness

It is the ability of a material to withstand the heat, without appreciable deformation. It is commonly measured as the softening or melting temperature of the material. The softening temperatures of refractory materials are determined by using “pyrometric cones (seger cones) test” (Figure 6.8). Refractory should have a softening temperature much higher than the operating temperature of the furnace in which it is to be used.

Refractoriness is generally determined by comparing the behaviour of heat on cone of material to be tested with that of a series of seger cones of standard dimensions. The Refractoriness is expressed in terms of pyrometric cone equilent. Cones are 38 mm height, 19 mm long sides with triangular base pyramids, and at definite temperatures they can melt or fuse. The temperature at the apex touching the base is indication of fusion/softening of the test cone. The number of the standard cones fuses along with test cone is the pyrometric cone equivalent (PCE) of that particular refractory. If the test cone fuses later than one standard cone and earlier than next cone, the PCE is the average value of the two.

Figure 6.8 Seger cone-test

(ii) Porosity

Porosity is the property of a sold which contains opening or spaces or minute channels. It can be expressed as

![]()

where W = weight of saturated specimen

D = weight of dry specimen

α = weight of saturated specimen submerged in water

If the refractory is having pores, then entry of gases, slags, etc. is easy and can react up to a greater depth. This can reduce the life of the refractory material. Consequently, it can affect many important properties of the refractory such as decreasing the strength, resistance to corrosion, resistance to abrasion but increased resistance to thermal spalling. Hence, a good refractory should have a low porosity.

(iii) Strength or Refractorines–under Load

The refractory material must possess high mechanical strengths, even at operating temperatures to bear the maximum possible load, without breaking.

(iv) Dimension Stability

It is the resistance of a material to any volume changes, which may occur on its exposure to high temperature, over a prolonged time. It may reversible or irreversible.

(v) Chemical Inertness

A refractory does not easily form fusible products with gases, ash, slags, etc. and hence should be chemically inert.

(vi) Thermal Expansion

A refractory material should have least possible thermal expansion because

- Expansion of a refractory decreases the capacity of the furnace.

- Repeated expansion and contraction contribute much towards rapid breakdown, and wear and tear of the material structure.

(vii) Thermal Conductivity

Depending upon the type of furnace refractory material of both high thermal conductivity and low thermal conductivity are required. In most cases, furnace is lined with refractories of low heat conductivities to reduce the heat losses to the outside by radiation; otherwise maintenance of high temperatures inside the furnace will become difficult. In muffle furnace walls, coke-oven batteries a good heat conductivity of refractory is desirable for effective heat transmission.

(viii) Thermal Spalling

Under high temperature breaking, cracking, peeling off or fracturing of a refractory brick or block are known as thermal spalling.

Thermal spalling may be due to;

- Rapid change in temperature and

- Slag penetration into the refractory brick

Thermal spalling can be decreased by taking following precausions:

- Using high porosity, low coefficient of expansion and good thermal conductivity refractory bricks,

- Avoiding sudden temperature changes,

- By overfiring the refractories,

- By modifying the furnace design.

(ix) Heat Capacity

It depends on

- Thermal conductivity

- Specific heat and

- Specific gravity of refractory

(x) Resistance to Abrasion or Corrosion

Refractory is desirable that least abraded by descending hard charge, flue gases escaping at high speeds, particles of carbon or grit etc.

(xi) Electrical Conductivity

Refractories specially used for lining electric furnaces should have low electrical conductivity. Except graphite, all refractories are poor conductors.

(xii) Permeability

Rate of diffusion of gases, liquids and molten solids through a refractory is known as permeability. It mainly depends on the size and number of connected pores. Permeability increases with temperature.

(xiii) Texture

Due to large porosity, coarse- or light-textured bricks are less in weight; hence, they are more resistance to sudden temperature changes.

6.4.5 Manufacture of High-Alumina Bricks, Magnesite Bricks, and Zirconia Bricks

(i) High-Alumina Bricks

High-alumina bricks contain 50% or more of Al2O3 and are, generally, made by mixing calcined bauxite (Al2O3) with clay bind.

Properties

They possess very low coefficient of expansion, high porosity, great resistance to slags, very little tendency to spall high temperature, load-bearing capacity, excellent wear-resistance, and stability, both in oxidizing and reducing conditions, and are particularly inert to the action of gasses like CO2, H2, and natural gas. They are thus very good refractories, but they are very expensive and hence their use is limited.

Uses

“Medium-duty bricks” (i.e., containing 50–60% Al2O3) are used for zones of vertical shaft kilns for burning limes, linings of Portland Cement rotary kilns, soaking pits, reheating furnaces, hearths and walls, etc., which are subjected to high abrasion. On the other hand, “high-duty bricks” (i.e., containing 75% Al2O3) find applications specially in the sintering or hottest zones of cement rotary kilns, lower parts of soaking pits, brass melting reverberatories, lead-dressing reverberatory furnaces, aluminium melting furnaces, combustion zones of oil-fired furnaces, etc.

(ii) Magnesite Bricks

Most widely used basic refractories are magnesite bricks. Calcined magnesite is powdered to a proper size, then mixed with caustic magnesia or iron oxide as a binding material. This mixture is grounded with water and moulded into bricks, then slowly heated to 1500°C for about 8 h and then cooled slowly.

Properties

Magnesite bricks can be used without load up to 3000°C and with load of 3.5 kg/cm2 up to 1500°C. They possess good resistance to basic slags, good crushing strength and less shrinkage. They have a lot of spalling with sudden temperature changes and their resistance to abrasion is poor.

They show lot of tendency to combine with water and CO2.

Uses

These are mainly used in open-hearth furnaces where high temperature required. Also used in hot mixer linings, copper converters, reverberatory furnaces for smelting antimony, copper, lead etc., ores, refining furnaces and hot zones of cement rotary kilns.

(iii) Zirconia Bricks

These are prepared by heating Zirconite mineral (ZrO2) and colloidal Zirconite or alumina as binding material at 1700°C. This is stabilized by adding of MgO or CaO without undergoing any volume changes on heating and cooling.

Properties

Zirconia bricks are usually known as neutral refractories, but they have no quite resistance to acids, slags etc., hence they are between neutral and basic refractories. Without load they can withstand up to 2000°C, but specially prepared bricks can be used up to 2600°C and with load of 3.5 kg/cm2 up to 1900°C. These have quite resistance to thermal shocks.

Uses

These are very costly, hence used only in high frequency electric furnaces.

6.5 Lubricants

In all types of machines lot of wear and tear is observed due to friction. Due to this, large amount of energy is also lost in the form of heat and moving parts get heated and damaged. The ill effects of frictional resistance can be minimized by using a suitable substance called lubricant, which can form a thin layer in between the moving parts and keep the sliding or moving surfaces apart. Hence, frictional resistance and consequent destruction of material is minimized.

‘The process of minimizing frictional resistance between moving or sliding surfaces by the introduction of lubricants in between them is called lubrication.‚

6.5.1 Important Functions of Lubricants

- It avoids direct contact between the rubbing surfaces and reduces surface deformation, wear, tear and seizure.

- It acts as a coolant by reducing loss of energy in the form of heat.

- It enhances efficiency of a machine by reducing wastage of energy and expansion of metal by local frictional heat.

- It avoids seizure and relative motion of moving surfaces, such that running cost of the machine will be reduced.

- Lubricant used between piston and the cylinder wall of an internal combustion engine acts as a seal and can prevent the leakage of gases from the cylinder under high pressure.

6.5.2 Mechanism of Lubrication

There are mainly three types of mechanism by which lubrication is done.

- Thick film (or) fluid film or hydrodynamic lubrication: In this mechanism, moving or sliding surfaces are separated by thick film of lubricant fluid, hence it is known as thick film or fluid film lubrication. This thick film of lubricant covers entire moving surfaces and fills irregularities.

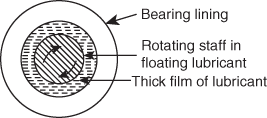

Therefore, there is no direct contact between the surfaces of machine and consequently it reduces the wear. This is shown in Figure 6.9. Here only internal resistance is observed between the particles of lubricant; hence, chosen lubricant should have minimum viscosity under the working conditions.

Hydrodynamic friction occurs in the case of shaft running places like journal bearings, which is shown in Figure 6.10. Thick film lubrication hydrocarbon oils are considered as satisfactory lubricants. Hydrocarbon lubricants are blended with selected long-chain polymers to maintain viscosity of the oil throughout the year.

Figure 6.9 Fluid-film lubrication

Figure 6.10 Hydrodynamic lubrications

- Boundary or thin film lubrication: In this kind of lubrication moving surfaces are separated by thin layer of lubricant, which is absorbed by physical or chemical forces on the metallic surfaces as shown in Figure 6.11. Here continuous film of lubricant cannot persist due to the following reasons:

Figure 6.11 Boundary lubrication

- a shaft starts moving from rest or

- the speed is very low (or)

- the load is very high and

- viscosity of the oil is too low.

Vegetable oils, animal oils and their soaps possess the property of adsorption either physically or chemically to the metal surfaces and form a thin film of metallic soap, which acts as a good lubricant. Fatty oils possess a greater adhesion property than mineral oil, and to improve the oiliness of mineral oils small amount of fatty oils are added. Graphite and molybdenum disulphide are also used for boundary lubrication.

- Extreme Pressure lubrication: In this mechanism the moving or sliding surfaces are under very high pressure and speed, hence this is known as extreme pressure lubrication. Under such conditions, a high local temperature is attained, and due to this liquid lubricants fail to stick and may decompose or vaporize.

Special additives are added to mineral oils to meet the extreme pressure conditions and are called extreme pressure additives. Organic compounds which are having active radicals or groups such as chlorine, sulphur or phosphorous act as good additives. These compounds react with metallic surfaces to form metallic chlorides, sulphides or phosphides as more durable films, capable of withstanding very high loads and temperatures.

6.5.3 Classification of Lubricants

On the basis of physical state, lubricants can be classified into three categories as listed hereunder.

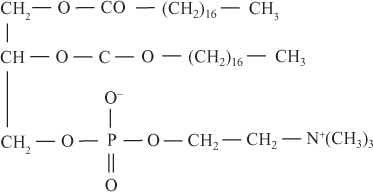

- Liquid lubricants or lubricating oils: Lubricating oil also acts as a cooling medium sealing agent, corrosion preventer, etc. along with reducing friction and wear. According to origin, lubricating oils are classified into (a) animal and vegetable oils, (b) mineral or petroleum oils and (c) blended oils.

- Animal and vegetable oils: Vegetable and animal oils possess good oiliness but they are costly, they undergo oxidation easily, forming gummy and acidic products, get thickened on coming in contact with air, etc. Hence, they are rarely used as lubricant, but they are used as blending agent.

- Mineral or petroleum oils: Mainly mineral oils are obtained by distillation of petroleum. These are widely used lubricants because they are cheap, abundantly available and quiet stable under service conditions. The hydrocarbon oil chain length varies between 12 to 50 carbon atoms. The shorter chain hydrocarbons have lower viscosity than longer chain hydrocarbons. When compared to animal and vegetable oils mineral oils possess poor oiliness; therefore, to increase oiliness high molecular weight compounds like oleic, steric acids are added.

- Blended oils: In many modern machinery, no single oil serves as the most satisfactory lubricant. Improving of important properties by incorporating specific additives is known as blending of oils and blended oils give desired lubricating properties.

Properties of Good Lubricating Oil

A good lubricating oil must possess

- Low pressure

- High boiling point

- Adequate viscosity to particular service conditions

- Low freezing point

- High oxidation resistance

- Heat stability

- Non-corrosive property and

- Stability to decomposition at the operating temperatures.

- Greases or semi-solid lubricants: Lubricating grease is semi-solid, consisting of a soap dispersed throughout a liquid lubricating oil. The liquid lubricant may be a petroleum oil or even a synthetic oil, and it may contain any of the additives for specific requirements.

Greases are prepared by saponification of fat with alkali, followed by adding hot lubricating oil while under agitation. The total amount of mineral oil added determines the consistency of the finished grease.

The structure of lubricating greases is like that of a gel. Soaps are gelling agents, which give an interconnected structure (held together by intermolecular forces) containing the added oil. The soap dissolves in the oil at high temperature; hence, inorganic solid, thickening agents are added to improve the heat resistance of grease. Greases have higher shear or frictional resistance than oils and can support much heavier loads at lower speeds.

Greases are used:

- In situations where oil cannot remain in place, due to high load, low speed, intermittent operation, sudden jerks, etc., for example, rail axle boxes

- In bearing and gears that work at high temperatures

- In situations where bearing needs to be sealed against entry of dust, dirt, grit, or moisture, because greases are less liable to contamination by these

- In situations where dripping or spurting of oil is undesirable, because unlike oils, greases if used do not splash or drip over articles being prepared by the machine, for example, in machines preparing paper, textiles, edible articles, etc.

The main function of soap is that it acts as a thickening agent so that grease sticks firmly to the metal surfaces. However, the nature of the soap decides the temperature up to which the grease can be used, its consistency, and its water and oxidation resistance. So, greases are classified after soap is used in their manufacture.

Important greases are:

- “Calcium-based greases” or cup-greases are emulsions of petroleum oils with calcium soaps. They are, generally, prepared by adding requisite amount of calcium hydroxide to a hot oil while under agitation. These greases are the cheapest and the most commonly used. They are insoluble in water, so they are water resistant. However, they are satisfactory for use at low temperatures, because above 80°C, oil and soap begins to separate out.

- “Soda-base greases” are petroleum oils, thickened by mixing sodium soaps. They are not water resistant, because the sodium soap content is soluble in water. However, they can be used up to 175°C. They are suitable for use in ball bearings, where the lubricant gets heated due to friction.

- “Lithium-based greases” are emulsions of petroleum oils with lithium soaps. These are having high water resistance and suitable only below 15°C.

- Axle greases are cheap resin greases and are prepared by adding lime or heavy metal hydroxide to resin and fatty oils. The resulting mixture is thoroughly mixed, allowed to stand and tack or mica like fillers are added finally. These are water resistant and also suitable for less delicate equipment working under heavy loads at low speeds.

Besides the above, there are greases prepared by dispersing solids (like graphite, soapstone, etc.) in mineral oil.

- Solid Lubricants: Graphite and molybdenum disulphide are the important solid lubricants. These are used in the following conditions.

- The operating temperature or load is too high.

- Blended lubricating oil or mixed grease is unacceptable.

- To avoid combustible lubricants.

Layered structure of graphite and sandwich-like structure of molybdenum disulphide are shown in Figures 6.12 (a) and (b).

Figure 6.12 (a) Layered structure of graphite (b) Sandwitch-like structure of molybdenum disulphide

Hence, the force to shear the crystals parallel to the layers is low and consequently the parallel layers slide over one another easily. Usually some organic substances are mixed with solid lubricants so that they may stick firmly to the metal surface.

Solid lubricants are used either in the dry powder form or mixed with water or oil. Graphite is the most widely used lubricant because it is very soapy to touch, non-inflammable and not oxidized in air below 375°C. Graphite is used in the form of powder or suspension in oil or water with the help of emulsifying agent tannin. Graphite is dispersed in oil is called ‘oildag‚ and when dispersed in water it is called ‘aquadag.‚

In the absence of air, it can be used up to very higher temperature. Graphite is used either in powdered form or as suspension. Graphite greases are used at higher temperature.

6.5.4 Properties of Lubricants

- Neutralization number: The acidity or alkalinity of lubricating oil is determined in terms of neutralization number. Determination of acidity is more common and is expressed as acid value or acid number. It is defined as the “number of milligrams of potassium hydroxide required to neutralize all the free acid present in 1 gram of the lubricating oil”.

Even the most carefully refined oil may have a slight acidity. This is due to the presence of minute amount of organic constituents that are not completely neutralized during the refining treatment or due to traces of residues from the refining process. This small intrinsic acidity may not be harmful in itself, but the degree to which it increases in already used oil is usually taken as a measure of the deterioration of the oil due to oxidation or contamination. In fact, acid number greater than 0.1 is usually taken as an indication of oxidation of the oil.

- Saponification number: The saponification value of an oil is defined as the “number of milligrams of potassium hydroxide required to saponify one gram of the oil”. This is usually determined by refluxing a known quantity of the oil with a known excess of standard KOH solution and determining the alkali consumed by titrating the unreacted alkali.

Animal and vegetable oils undergo saponification but mineral oils do not. Further most of the animal and vegetable oils process their own characteristic saponification values. Hence, the determination of saponification value helps to ascertain the presence of animal and vegetable oils in a lubricant. Conversely, since each of the fined oil has got its own specific saponification number, any deviation from this value in a given sample indicates the probability and extent of adulteration.

- Aniline point: The aniline point of an oil is defined as ‘The minimum equilibrium solution temperature for equal volumes of aniline and oil sample.‚ Aromatic hydrocarbons have lot of tendency to dissolve natural and synthetic rubbers, this tendency can be determined on the basis of aniline point of an oil. A higher aniline point means lower percentage of hydrocarbons; therefore, having higher aniline point is desirable.

Aniline point is determined by thoroughly mixing equal volumes of aniline and the oil sample in a tube and heating the mixture until a homogeneous solution is obtained. Then, it is allowed to cool at a specified rate until the two phases just separate out. The temperature corresponding to this particular observation is reported as the aniline point.

- Cloud point and pour point: Petroleum oils are complex mixtures of chemical compounds and they do not show a fixed freezing point. When they are sufficiently cooled, they become plastic solids due to the formation of solid crystals or due to congealing of the hydrocarbons present. “The cloud point is the temperature at which this crystallization of solids in the form of a cloud or haze first becomes noticeable”, when the oil is cooled in a standard apparatus at a standard rate. The pour point is “the temperature at which the oil just ceases to flow when cooled at a standard rate in a standard apparatus”.

The pour point has a greater significance for lubricating oil because it determines the suitability of an hydraulic oil for low temperature installations. Refrigerator plants, air-craft engines, etc. are some important examples, which may be required to start and operate at subzero temperatures.

- Flash point and fire point: The flash point of an oil is defined as ‘the minimum temperature at which the oil gives off sufficient vapour to ignite momentarily when a flame of standard dimensions‚ is brought near the surface of the oil. The fire point of an oil is defined as ‘the lowest temperature at which the vapours of the oil burn continuously for at least five seconds‚ when the standard flame is brought near the surface of the oil.

Lubricating oil should have flash point that is reasonably above its working temperature. This ensures safety against fire hazards during usage, storage and transport. The flash point of lubricating oil can be determined by Pensky Marten‚s apparatus.

- Viscosity and viscosity index: Viscosity is one of the most important properties of lubricating oil. The formation of a fluid film of a lubricant between the friction surfaces and the generation of frictional heat under particular conditions of load, bearing spread and lubricant supply mostly depend upon the viscosity of the lubricant and, to some extent, on its oiliness. When large working clearances exist between the friction surfaces, a high viscosity oil is generally recommended to “cushion” the intermediate application of load. However, it is often necessary to sacrifice some of the cushioning effect of viscous oil by the partial substitution of a thinner oil to provide good oil circulation to dissipate the frictional heat.

The fluid lubricant film cannot be maintained between the moving surfaces, if the viscosity of the oil is too low, since with this excessive wear may take place. On the other hand, if the viscosity of lubricating oil is too high, excessive friction due to shearing of oil itself would result. Hence in hydrodynamic lubrication, the lubricant selected must possess a sufficiently high viscosity due to adherence to the bearing and prevent its being squeezed out due to high pressure and yet fluid enough so that the resistance to the shear is not too high. Hence it is essential to have knowledge of the viscosity of lubricating oil.

Viscosity is a measure of the internal resistance to the motion of a fluid and is mainly due to forces of cohesion between the fluid molecules. Absolute viscosity can be defined as the tangential force per unit area required to maintain a unit velocity gradient between two parallel planes in the fluid unit distance apart. The units of absolute viscosity η (eta) in CGS system are poise and centipoise (1/100th of a poise). Poise is equal to one dyne per second per square centimeter. The viscosity of water at 20°C is about centipoise.

The ratio of absolute viscosity to density for any fluid is known as the absolute kinematic viscosity. It is denoted by η, and in CGS system, its units are stokes and centistokes (1/100th of a stoke).

where n = absolute kinematic viscosity

η = absolute dynamic viscosity

r = density of the fluid.

The dimensions of dynamic viscosity are HL–1T–1, and the dimensions of kinematic viscosity are L2T–1.

For academic purposes, viscosity is usually expressed in centistoke, but a more common practical measure of the viscosity of an oil is the time in seconds for a given quantity of the oil to flow through a standard orifice under the specified set of conditions. Thus viscosities are usually determined with Redwood viscometer in commonwealth countries with Engler‚s viscometer in the Europe and with Saybolt‚s viscometer in USA. In these commercial viscometers, a fixed volume of the liquid is allowed to flow through the standard orifice of particular standard apparatus used, for example, viscosity of the oil is 156. Redwood (No. 1) seconds at 25°C. The viscosity of the oil so determined in the time units is sometimes called relative viscosity. Since the instruments used are of standard dimensions, kinematic viscosity of the oil in centistokes can be calculated from the time taken by the oil to flow through the standard orifice of the instrument, with the help of the following equations:

m = Ct (for fluids whose kinematic viscosity is more than centistokes) and

m = Ct – b/t (for fluids having kinematic viscosities lesser than or equal to 10 centistokes)

m = Kinematic viscosity in centistokes

t = Time of flow in seconds

C = Viscometer constant

B = Coeffiecient of kinetic energy, which may be determined experimentally or eliminated by choosing long flow times

For routine purposes, the test viscometer may be calibrated and the constant C determined by using solutions of known viscosity. The primary standard used is freshly distilled water whose kinematic viscosity is 1.0008 centistokes. Other standards usually employed are:

40% sucrose solution:

n = 4.390 cs at 25°C, r = 1.17395

60% sucrose solution:

n = 33.66 cs at 25°C, r = 1.28335

For Redwood No. 1 viscometer, the values for the constants are as below:

These constants are based on the results of the work carried out at the National Physical Laboratory at a temperature of 70°F (21.11°C) and with the ranges of viscosity; at that temperature, the results are accurate to ±1%.

Redwood No. 2 viscometer is used for every viscous liquids and gives 1/10th the value of Redwood No. 1 viscometer.

- Viscosity index: The viscosity of an oil decreases with increase of temperature as a result of decrease in intermolecular attraction due to expansion. Hence, it is always necessary to state the temperature at which the viscosity is determined.

In many applications, lubricating oil will have to function in a machinery over considerably wide range of operating temperatures. If this is due to seasonal variations in atmospheric temperature adjustments can be affected by selecting different oils of appropriate viscosity for different seasons. However, in case of internal combustion engines, aeroplanes, etc, the lubricant used must function both at low starting temperatures as well as at very high operating temperatures. Since the viscosity of lubricating oils decreases with temperature, it is impossible to select an oil having same viscosity over such a wide range of operating temperatures. However, one can select an oil whose variation in viscosity with temperature is minimum. This variation can be indicated either by viscosity temperature curves or by means of the viscosity index. Viscosity index is the numerical expression of the average slope of the viscosity temperature curve of lubricating oil between 100°F to 210°F. The oil under examination is compared with two standard oils having the same viscosity at 210°F as the oil under test. Oils of the Pennsylvanian type crudes thin down the least with increase of temperature, whereas oils of Gulf coast origin thin down the most as the temperature is increased.

Hence the viscosity index of Pennsylvanian oil is taken as 100 and that of the Gulf oil as zero. Then the viscosity of the oil under investigation is deducted as follows:

Viscosity index of the oil under test =

where VL = Viscosity at 100°F of Gulf oil standard, which has the same viscosity at 210°F as that of oil under test

VX = Viscosity of the oil under test

VH = Viscosity at 100°F of Pennsylvanian standard oil, which has the same viscosity at 210°F as that of oil under test

Thus the higher the viscosity index, the lower the rate at which its viscosity decreases with increase of temperature. Hence, oils of high viscosity index, that is, those having that viscosity temperature curves are demanded for air-cooled internal combustion engines and aircrafts engines. In general, oils of high specific gravity have steeped viscosity temperature curves. However, all oils tend to attain the same viscosity above 300°C.

By and large, light oils of low viscosity are used in plain bearings for high-speed equipment such as turbines, spindles, and centrifuges, whereas high viscosity oils are used with plain bearings of low-speed equipment.

- Mechanical stability: Four-balls extreme-pressure test is one of the important mechanical tests to judge the suitability of a lubricant under conditions of very high pressure, and the same is shown in Figure 6.13. In this test lubricant under test is powered in a machine containing four balls. Here, upper ball is rotated and lower three balls are stationary. Load is gradually increased, the ball is withdrawn and examined at specific intervals for scale formation, etc. and under a given load, the ball bearings after the test comes out clean if the lubricant desirable. When the load is progressively increased the liberated heat welds the ball together, here lubricant is said to be failed completely. Hence this test enables us to determine the maximum load that can be carried safely by a lubricant. Four – balls extreme – pressure lubricant tester is shown in Figure 6.13.

Figure 6.13 Four-balls extreme-pressure lubricant tester

6.5.5 The Redwood Viscometer

The Redwood viscometer is made in two sizes. The Redwood No. 1 viscometer is commonly used for determination of viscosities of lubricating oils and has on efflux time of 2,000 seconds or less. The Redwood No. 2 viscometer is similar to Redwood No. 1 type but the jet for the out flow of the oils is of a larger diameter and hence gives an efflux time of approximately 1/10th of that obtained with Redwood 1 instrument under otherwise identical experimental conditions. Redwood No. 2 instrument is therefore used for the oils having higher viscosities such as fuel oils.

The Redwood viscometer does not give a direct measure of viscosity in absolute units but it enables the viscosities of oils to be compared by measuring the time of efflux of 50 ml of oil through the standard orifice of the instrument under standard conditions. The results given by these two viscometers are reported as Redwood No. 1 viscosity or Redwood No. 2 viscosity followed by the efflux time in seconds of the experimental temperature.

Description

The Redwood No. 1 viscometer shown in Figure 6.14 essentially consists of a standard cylindrical oil cup made up of brass and silvered from inside and has 90 mm height and 46.5 mm in diameter. The cup is open at the upper end. It is fixed with an agate jet in the base. The diameter of the orifice is 1.62 mm and the internal length is 10 mm. The upper surface of the agate is ground to concave depression into which a small silver-plated brass ball is attached to a stout wire can be placed in such a way that the channel is totally closed and no leakage of the oil from the cup through the orifice can take place. The cup is provided with a pointer, which indicates the level up to which the oil should be filled in a cup. The lid of the cup is provided with an arrangement to fix a thermometer to indicate the oil temperature. The oil cup is surrounded by a cylindrical, copper vessel containing water, which serves as a water bath used for maintaining the desired oil temperature with the help of electrical heating oils or by means of a gas burner as the case may be. A thermometer is provided to measure the temperature of water. A stirrer with four blades is provided in a water bath to maintain uniform temperature in the bath and hence enabling uniform heating of the oil. The stirrer contains a broad, curved flange at the top to act as a shield for preventing any water splashing into the oil cylinder. The entire apparatus rests on a sort of tripod stand provided with levelling screws at the three legs. The water bath is provided with an outlet for removing water as and when needed. A sprit level is used for levelling the apparatus, and a 50 ml flask for receiving the oil from the jet outlet is also provided.

Figure 6.14 Redwood viscometer No. 1

Working

The instrument is levelled with the help of the levelling screws on the tripod. The water bath is filled with water to the height corresponding to the tip of the indicator up to which the oil is to be filled in the cylindrical cup. The orifice is sealed by keeping the brass ball in position. Then the oil under test is carefully poured into the oil cup up to the tip of the indicator. The 50 ml flask is placed in position below the jet. The oil and water are kept well stirred; respective temperatures are noted. The ball is raised and suspended from the thermometer bracket. Simultaneously, a stop-watch is started. When the level of the oil dropping into the flask just reaches the 50 ml mark, the stop-watch is stopped, and time is noted in seconds. The ball value is replaced in the original position to prevent the overflow of the oil. The experiment is repeated, and the mean value of time of flow for 50 ml of the oil is reported as t seconds, Redwood 1 at T°C. The usual test temperatures stipulated are 21.11°C (70°F), 60°C (140°F), and 93.33°C (200°F).

During the test, the measuring flask should be shielded from draughts with the help of metal shields usually supplied with instrument.

6.5.6 Englers Viscometer

This instrument is diagrammatically presented in Figure 6.15. The water bath is heated by a gas ring, and its temperature is kept uniform with the help of the stirrer. The oil cylinder is fitted with three gauge points, which indicate the amount of oil required and also serve as a means of levelling the instrument. The loosely fitting cover carrying thermometer can be gently rotated to agitate the oil. The jet is slightly tapered and is made of platinum for standard work and nickel for general work. The valve pin, which seats itself in the jet, is lifted at the commencement of a test and supported in the cover by a cross pin. As the valve pin is lifted, stop-watch is started, and the time of outflow of 200 ml of the oil is determined.

Figure 6.15 Englers viscometer

The viscosity is expressed in Engler degrees or degree E by using water as standard. The time of outflow of 200 ml of water at 20°C is taken as 52 seconds. The viscosity in degrees E is calculated by dividing the time m seconds for the outflow of 200 ml of oil by time of outflow of 200 ml of water at 20°C.

6.5.7 Saybolt Viscometer

A single unit Saybolt universal viscometer is shown in Figure 6.16. In the multiple-unit viscometer, a number of oil cups can be accommodated in the same bath thus enabling tests on a number of oils to proceed at the same time. Instruments can be fitted with an electric immersion heater, a U-tube for steam heating or water cooling, and a gas ring, which is placed inside the air jacket surrounding the water bath. The bath liquid is stirred by rotating the cover by means of the two handles as a turn-table arrangement. Its temperature can be regulated by running cold or warm water through the U-tube whatever may be the heating arrangement used. The jet is made of a hard non-corrodible metal such as monel or stainless steel. The lower end of the jet opens into a larger tube. This tube when stoppered by a cork becomes a closed air chamber preventing the oil flowing out (Figure 6.16).

Figure 6.16 Saybolt viscometer

To start with the test, the bath is brought to the test temperature and the oil is heated to the same temperature in a separate vessel. The oil is then poured into the oil cylinder and stirred with the oil thermometer, any excess oil flowing over into the surrounding gallery. When the oil and the bath are at the same temperature, the oil thermometer is removed, the excess oil drawn off from the gallery with a pipette, the cork withdrawn, and the stop-watch started. The collecting flask is arranged such that the oil stream will strike its neck, thus avoiding the formation of foam. The time of outflow of 60 ml of the oil is the viscosity in seconds Saybolt universal at the test temperature.

For very viscous fuels, a viscometer with a larger jet known as the Saybolt furol viscometer is used. The Saybolt universal viscometer can be used for oils having flow times of more than 32 seconds. There is no maximum unit, but in general, for liquids having flow times over 1000 seconds, Saybolt furol viscometer is better.

6.5.8 U-Tube Viscometer

Standard U-tube viscometer (Figures 6.17(a) and (b)) is an improved form of the Ostwald viscometers, which is used for the determination of the absolute viscosity of lubricating oils. The determination of absolute viscosity of lubricating oils by the U-tube viscometer based on Poiseuille‚s law.

Figure 6.17 U-tube viscometers (a) Standard U-tube viscometer (b) Ubbelohde suspende level viscometer

![]()

where V = volume of the liquid flowing through a capillary tube of length l (cm) of uniform radius ‘r‚ (cm) in a times ‘t‚ (seconds) and η (poise) is the coefficient of viscosity of the liquid at the particular temperature.

The determination of absolute viscosity by the U-tube viscometer essentially consists of measurement of the time of passage through the capillary of a fixed volume of liquid under a fixed mean hydrostatic head ρ of the liquid. If the density of the liquid is ‘d‚, then P ∝ d, and since, for a given viscometer, η ∝ td.

η = ktd

where k is the constant of proportionality and has to be determined for each viscometer from its known dimensions or by caliberation with a liquid (such as water) whose viscosity coefficient is known

![]()

6.5.9 Conversion of Redwood, Engler and Saybolt Viscosities into Absolute Units

Redwood, Engler and Saybolt instruments are not the ideal methods of determining the absolute viscosities, the conversion values are only considered as good approximations and that too only when taken at the same temperature.

So the conversion of the above relative viscosities to absolute viscosities is done with the help of the following equations

n = ct – b/t

where n = Kinematic viscosity in centistokes,

t = time flow in seconds,

c and β are constants.

Values of c and β are tabulated below.

6.6 Explosives and Propellants

Explosives

An explosive is a “substance (or) compound (or) mixture, which when subjected to thermal and mechanical shock, gets very rapidly oxidized exothermically with a sudden release of potential energy”.

The explosive reaction is exothermic, so the products get heated to a high temperature and a high pressure is exerted on the surrounding. The amount of power available from a given weight (or) volume of explosive, is called “power to weight ratio”.

6.6.1 Some Important Terms about Explosives

- Explosive strength: It is the energy liberated per unit mass of the explosive (cal/g).

- Velocity of detonation: It is the velocity with which the given explosive detonates.

- Sensitivity: It is to impact (or) friction (or) heat (or) electric spark (or) detonator wave. Some explosives may detonate by a feather touch, some may not detonate even with hammer blow. Sensitivity plays a key role in the selection of explosives for a particular purpose.

- Brisance: It indicates to the shattering power of explosive.

6.6.2 Classification of Explosives

Explosives are broadly classified into three groups.

- Detonators (or) Primary explosives (or) Initiating explosives:

There are highly sensitive, which explode on receiving a slight-shock or by fire. So they should be handled with the atmost care. Some of examples are,

- Lead azide (PbN6 ): It is very popular for military uses due to low cost, excellent initiating action and stability in storage.

- Mercury fulminate [Hg(CNO2 )]: It is more sensitive as well as more expensive them lead azide. It is slightly toxic.

- Tetracene (C2η7N7O): It is low initiating ignites easily, has high heat of explosion and produces a large volume of gases.

- Diazodinitro Phenol (DDNP): It is quite sensitive and has high brisance and consequently can initiate explosion even in less sensitive high explosives.

- Propellents (or) Low explosives:

These are simply burns and do not explode suddenly. The chemical reactions taking place in such explosives are slow and their burning proceeds from the surface inwards in layers at an approximate rate. The gases evolved disperse readily without building high pressures and consequently they can be controlled easily. Some of examples are,

- Gun-Powder (or) Black Powder :

It is a mixture of 75% potassium nitrate, 15% charcoal and 10% sulphur. The explosive reaction is

10KNO3 + 3S + 8C (3K2SO4) + 2K2CO3 + 6CO2 ↑ + 5N2↑

If excess of carbon and sulphur take part in slower processes leads to evolution of more gases.

It is an excellent and cheap explosive for blasting down of coal, as its low velocity gives it a slow heaving action that does not shatter the coal unduly. It is time in delay-fuses, for blasting and in shells, igniters and primer assemblies for propellants, practice bombs and saluting charges.

- Nitrocellulose:

It is prepared by treating cellulose with nitric and sulphuric acids. Formed nitrocellulose is dissolved in a mixture of ether and alcohol and then solvent is evaporated, when a jelly like solid is left behind. It is stead by adding stabilizer like diphenylamine and pressed into cylindrical rods. It is called smokeless powder due to producing of smokeless gases like CO2, CO, N2 and water vapour.

- Gun-Powder (or) Black Powder :

- High explosives:

Explosives which have high energy content than the primary explosives are high explosives. These are quite stable and insensitive to fire, mechanical shocks, etc. Hence, to start a rapid chemical reaction some amount of primary explosives are placed with high explosives.

These are broadly divided into four groups:

- Single compounds explosives:

These contain only one chemical compound. Some of examples are,

- Ammonium nitrate: It is very stable, nontoxic, cheap and has low brisance-value. It is about half as powerful as TNT and mostly employed in making binary explosives. It is dangerous to store near any inflamable material.

- TNT (Trinitrotoluene): It is high explosive. It is most widely used in shell-firing and under-water explosions and is well-suited for loading in containers, due to low melting point. It is safe explosive in manufactures, transportation, storage, non–hydroscopic, violent disruptive explosive, does not react with metals so it is used as military use.

- PETN (Pentaerythritol tetra nitrate): It is an extremely powerful, sensitive and standard military explosive.

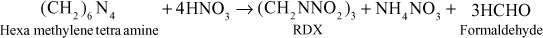

- RDX (or) Cyclonite: It is a powerful most sensitive, less toxic high explosive. RDX came into prominence as military as well as an industrial explosive.

- Binary explosives:

Binary explosives are a mixture of TNT and other explosives, and these are more convenient and superior than single explosives. Due to its low melting point, TNT is one of the ingredients in all binary explosives.

Ex:

- TNT + Ammonium nitrate is amatol.

- TNT + PETN is pentolite.

- TNT + Tetryl is tetrytol.

- TNT + RDX + Al powder is tropex.

- TNT + Al flakes is titronal.

- Plastic explosive:

These are combination of explosives which are in plastic state, they can be hand moulded and made into various shapes without any serious risk. They are mainly used for industrial applications and military uses. A simple combination to get plastic explosive is a high explosive. Due to their engineering applications they are available as flexible-sheets.

- Dynamites:

These are explosives containing nitroglycerin as the main ingredient, by pressure or shock detonates.

The explosion is so sudden it would shatter the breech of rifile, before the bullet had time to move. It also pulverizes rock, instead of breaking it into fragments of unable size. It is danger in handling and transporting. So it is usually mixed with an insert absorbent likes would pulp, starch,meals etc. Some of examples are,

- Straight-dynamites: It contains 15 to 60% nitroglycerine in wood meal with sodium nitrate. Important uses are blasting of hard rocks, coal and other mineral.

- Blasting gelatin-dynamites: It is the combination of NG (Nitro glycerene) (91.5%) with partly gelatinized by nitro-cotton (8%) (or) colladion cotton and CaCO3 (0.5%). These are very powerful, water proof, stick well in holes into which they have been loaded. They can be used under wet conditions, where high loading density is desired. Important uses are submarine blasting tunnel driving, deep-well shooting, and at places where maximum shattering effects are desired.

- Gun cotton (or cellulose nitrate): Cotton is steeped for half-an hour in a cooled mixture of conc.nitric and conc.sulphuric acids it is formed.

C6H7O2(OH)3 + 3HNO3( C6H7O2(NO3)3 + 3H2O