6

The BIVEE Framework and the Collaborative Innovation Capability Maturity Model (CICMM)

Similar to most software development projects, the business innovation in virtual enterprise environment (BIVEE) solutions are also based on a framework to provide a guiding structure. The BIVEE framework is described within this chapter, starting with its objectives and methodological rooting. Additionally, the concept of the collaborative innovation capability maturity model (CICMM) is described, which is a model for the assessment of a network’s management maturity and conformity concerning collaborative innovation management.

One main notion of the BIVEE project is the differentiation between the innovation space and the production space of virtual enterprises. Accordingly, the BIVEE framework supports this approach in order to provide specific structure for both parts of the collaboration. The BIVEE framework differs between improvement processes that mainly appear within the production space and innovation projects emerging from the business space. Due to the addition of a separate monitoring framework (MF), the BIVEE framework is composed of three subframeworks (Figure 6.1):

- – The construction of the BIVEE framework is based on the virtual enterprise modeling framework (VEMF). It contains a framework for the general setup of the virtual enterprise, and defines its production processes by providing a modeling framework for the general structure of operative business.

- – The second part of the BIVEE framework is the business innovation reference framework (BIRF). It is called a reference as it does not enforce a strict structure, but a guiding reference to innovation projects, because the latter usually does not progress in defined ways, especially during the early stages of idea creation. Additional to a reference of operational activities, the BIRF adds characteristics of four areas of innovation by defining templates for specific information input and output mapping related to each activity.

- – The third component is provided by the MF, which adds metrics that are aligned to business (Table 6.5) or sustainability objectives (Table 6.6). These metrics are key performance indicators (KPIs) that either address the production (P-KPIs) or refer to innovation activities (I-KPIs).

Figure 6.1. Overview of the BIVEE framework components

In addition to the three subframeworks and their methodological rooting, the concept of the CICMM is also described in the following sections.

6.1. The virtual enterprise modeling framework (VEMF)

The VEMF has been designed to provide a guiding structure during the setup of a virtual enterprise and its production processes.

6.1.1. VEMF: methodological background

The structure for the VEMF is mainly based on the value reference model (VRM) and the supply chain operations reference (SCOR).

The VRM is an open source dictionary developed by the value chain group and accordingly focuses on value chains. Because value chains represent a specific, although static, form of market-oriented collaboration, it has been possible to adapt the VRM to virtual enterprises in order to build upon a proven methodology. The structure of the VRM model supports and enables corporations to integrate their four critical domains: enterprise management, product development, supply chain integration and customer relationship management, using one reference model to support the vision of an integrated value chain [KIR 11]. Key elements of the standard process VRM dictionary include inputs/outputs, metrics and best practices. Processes described by VRM differentiate in three hierarchical levels:

- – Govern: this level is composed of decision-based processes that identify and enable a value chain by establishing the rules, policies and procedures to control the implementation of plan and execute processes.

- – Plan: this level is composed of processes which meet the current strategic objectives to current resources, and produce decisions on activities to reach organizational goals.

- – Execute: this level is composed of processes that concern transformation of work and material to product or services to meet customer requirements. The processes in execute level operate within the limits of management criteria and parameters defined by the processes in plan level.

For the setup of the virtual enterprise, the processes concerning the value chain setup of the plan and govern sections are relevant. The other elements and processes of the execute section are replaced by the content of the BIRF and the production model of the VEMF, which provide structure for the operative business.

A second influence to the VEMF arises from the SCOR. SCOR is a product of the supply chain council (SCC) and serves as a process reference that proposes standard guidelines for supply chain management [STE 01]. The framework is built around two basic sets: a standard library for the modeling of supply chain processes, which allows companies to set up environments for collaboration and process alignment, and a set of standardized semantically defined metrics, which allows supply chain managers to quantify and benchmark processes and thus to drive supply chain management strategies.

The SCOR process map is structured into five recurring phases:

- – Plan: this stage concerns developing plans to operate supply chain. This process describes aggregation and prioritization of requirements, inventory and capacity planning, and projection of appropriate resources to meet requirements of supply chain for long time period.

- – Source: this process concerns scheduling of deliveries, reception of goods and services, authorization payment for materials and other purchases.

- – Make: this process concerns conversion of materials or creation of the content of services. It is starting with requests for materials – linking to source process – and ending with product release linking to deliver process.

- – Deliver: this process concerns the creation, maintenance and fulfillment of customer orders, scheduling order delivery, packing and shipment and invoicing customer.

- – Return: this process concerns reverse flow of goods. The return process is composed of identification of the need to return, the disposition decision-making, the scheduling of the return and the shipment and receipt of the returned goods.

6.1.2. VEMF: virtual enterprise setup

The VRM represents a reference framework that provides a guideline for the management of value chains. As value chains can be characterized as a specific type of network, some elements apply to virtual enterprises as well. In particular, the govern section that is describing that the setup of the value chain can be used to support the virtual enterprise setup.

The section “Govern Value Chain” of the VRM resembles the setup phase of a value chain that defines a common strategy and vision as well as necessary policies concerning all common fields of action. This set of processes has to be executed by the initiating partners of a virtual enterprise as well. The policies and the prioritization of business objectives that are defined here are necessary for further progression. Based on this section, the “Govern Virtual Enterprise” section of the VEMF can be created (Table 6.1).

Table 6.1. VEMF govern processes

| Name | Description |

| GVE01 – Rules & Objectives | To develop the strategy, vision, goals and business objectives for the virtual enterprise |

| GVE02 – Process Policy | To establish the process performance criteria, priority dimensions and supporting metrics |

| GVE03 – Information Policy | To define the creation, management, storage, distribution, retrieval and disposal of information in the virtual enterprise |

| GVE04 – Financial Policy | To define the accounting, financial decision support, routing and reporting for the virtual enterprise |

| GVE05 – Asset Policy | To define the use of intellectual, brand, physical, human and working capital of the virtual enterprise |

| GVE06 – Organizational Policy | To define the way the virtual enterprise partners will interact with the stakeholders as a corporate citizen to comply with regulation |

| GVE07 – Extended Network Policy | To define rules and policies governing partner interaction |

| GVE08 – Change Guidelines | To define how the virtual enterprise will deal with changing external/internal factors and evolve to meet stakeholder expectations |

| GVE09 – Compliance Policy | To define how the virtual enterprise partners will comply with regulations and legal requirements |

| GVE10 – Lifecycle Policy | Define lifecycle policies of a virtual enterprise |

The govern processes are executed by an initial Virtual Enterprise (VE) consortium in order to define the rules and objectives as well as the policies regarding all important areas of business. This part provides the definition and prioritization of business objectives (GVE01) that are important within the monitoring framework (MF) as well as policies that impact the exchanged information within the business innovation reference framework (BIRF).

The definition of the network structure is a recurring process, as the need for resources and competencies may change during operation. Within the VRM, this part is resembled by the plan value chain section. This plan section is implemented into the VEMF with the plan virtual enterprise section, as shown in Table 6.2. It resembles the process of matching the virtual enterprises’ resources to its needs by gathering the requirements, assessing and aligning resources and the creation of a business plan. The planning processes are executed whenever the needs of the virtual enterprises change. This mapping is checked and used within activities of both spaces.

Table 6.2. VEMF plan processes

| Name | Description |

| PVE01 – Gather VE Requirements | The process of gathering virtual enterprise requirements necessary to fulfill market demand for comparison against available resources |

| PVE02 – Assess VE Resources | The process of assessing virtual enterprise resources for alignment with requirements needed to fulfill market demands |

| PVE03 – Align VE Resources | The process of aligning demand with required resources to capitalize on market opportunities |

| PVE04 – Create VE Business Plan | The establishment and communication of plans and actions over appropriate time horizons representing a projected appropriation of virtual enterprise resources to meet market requirements |

These govern and plan sections represent the virtual enterprise framework. Other parts of the VRM are either not practical or are covered by other parts of the BIVEE framework. The production space processes are aligned to the operational level and replace the execute section of the VRM. These processes are described in the following section.

6.1.3. VEMF: modeling framework for production processes

The production process modeling framework of the VEMF is based on the SCOR processes. The processes of the SCOR model have been adopted, as well as regrouped in order to account for the distributed structure of VEs and the separation of business from production. The VEMF encompasses all activities related to the production spaces toward the goals of virtual enterprise. The four resulting phases are plan, source, build and deliver, which are described below:

- – Plan: in this process level, requirement results of the global competition, the requirements of customers, stockholders, workforce, suppliers, as well as economic, technological, social, legal and political environments are taken as inputs, and as outputs, key performance objectives of virtual enterprise are defined and design decisions, such as business models and a business strategy map, are created. Furthermore, according to strategic decisions, products and services are designed, and detail production processes and appropriate resources meeting production processes for each production unit (PU) in value production space (VPS) in virtual enterprise are defined.

- – Source: after products and services are designed and production processes are defined, appropriate resources are defined in this phase allocation, provided that deliveries and logistic works of resources are considered.

- – Build: as products and services are designed, production processes are defined and appropriate resources are provided, in this process level, conversions of materials and immaterial into product or creation of the content of services with execution of production process that occurs in each PU take place.

- – Deliver: this process level concerns order management, pricing and product configuration through managing orders, invoicing and credits, to customer-specific packing, labeling and shipping.

Additionally, the design and monitor process is defined. This process is not aligned to a specific phase, but instead spans across plan, source, build and deliver as a cross-cutting action. The related metrics are provided with the key performance indicators (KPIs) of the MF. An overview of the phases and their processes along with a short description is listed in Table 6.3.

Table 6.3. Production space processes and phases

| Phases | Processes | Short description |

| Plan phase | VPS-P01 Sales Trend Analysis | Results of an initial market analysis show demands for production |

| VPS-P02 Order Evaluation | An order may initiate a production process – needs to be evaluated | |

| VPS-P03 Product Definition | Order analysis and product allocation | |

| VPS-P04 Network Setup | Creation of a network to fulfill production demands | |

| Source phase | VPS-S01 Stock Analysis | Analysis of individual stocks for purchase management |

| VPS-S02 Supplier Selection | Selection of suppliers for raw materials | |

| VPS-S03 Purchase Management | Allocation of resources for production | |

| VPS-S04 Component Storage | Storage of allocated resources | |

| Build phase | VPS-B01 Component Manufacturing | Manufacturing of components |

| VPS-B02 Finishing | Final post processing of the production | |

| VPS-B03 Production Assembly | Assembly of components | |

| VPS-B04 Quality Control | Quality checks of manufactured goods | |

| Deliver phase | VPS-D01 Packing | Packaging and preparing for delivery |

| VPS-D02 Order Preparation | Commissioning of ordered products | |

| VPS-D03 Shipping | Carrier selection and shipping of manufactured goods | |

| VPS-D04 Delivery | Final release and delivery of manufactured goods |

6.2. Business innovation reference framework

The BIRF aims to support collaborative innovation management by providing a structure for the necessary actions and the exchanged information depending on the innovation area.

6.2.1. BIRF: methodological background

The BIVEE approach with respect to innovation tries to find a compromise between guidance and freedom; since the latter is the natural nurturing ground for innovation but in absence of the former endless loops may be encountered that are very risky in a business context. So, in order to give some guidance to the innovation space, the BIRF is organized into four main waves that are based on the findings of the LABORANOVA Project [THO 07]:

- – Creativity wave: the first wave starts with an innovation idea or a problem to be solved, providing a first sketchy idea to be developed and put into the business context of the virtual enterprise undertaking it.

- – Feasibility wave: this second wave provides and clarifies with elements and information in order to justify in economical and operational terms the actual undertaking and the further development of the original idea.

- – Prototyping wave: this wave puts into concrete actions the previous collected information and elements producing a first implementation of the initial idea in the form of a prototype.

- – Engineering wave: in this wave, the original idea transformed into a prototype is attentively analyzed to generate production and engineering plans.

Figure 6.2. The four BIVEE waves of innovation within the innovation space

The four waves can be represented as shown in Figure 6.2. The innovation waves are not in a strict sequence, they are partially overlapped and they develop in cycles. We can assume that, for example, during the prototyping wave there may be a problem that requires a focused activity to look back into the creativity wave. A goal-decomposition approach is, therefore, extensively adopted in the BIRF, so there may be activities in each wave that proceed faster and can lead to partial prototyping while other activities that are still in the feasibility wave. This approach gives more flexibility and freedom to the innovation space. However, what guarantees a certain order is the concept of gates or innovation gates. At a given point of a wave, each project could set its own gate from which the activities of the next wave could start to activate. This notion is designed in the style of the Stage-Gate model [COO 02]. However, given the nature of the waves, the gates are not then a fixed point but can differ from project to project. Once again, this should ensure flexibility in the innovation cycle for each innovation project and for each virtual enterprise that is created ad hoc for that defined project, but, at the same time, should ensure the flowing of cycle itself.

The intention of this part of the BIRF is to include the differences between certain types of innovation in the BIVEE framework. Therefore, it differs between four areas of innovation. These areas are based on the approach of systematic business innovation by Kotelnikov [KOT 08], as shown in Figure 6.3. Regarding the more technical view of the BIVEE project, the areas of product, process, service and technology innovation are included. The differences between these areas are characterized mainly by the information that is processed within these activities and is resembled by the input/output mapping of this subframework.

Figure 6.3. The four BIVEE waves of innovation within the innovation space [KOT 08]

6.2.2. BIRF: reference framework for innovation projects

As previously described, the BIVEE project imagines the innovation activities to be divided into four waves instead of the more classical and linear phases. Each wave contains a certain number of activities to be carried out in order for a wave to be completed. These activities have been identified through a combination of the VRM, the findings from the LABORANOVA project and analysis of the BIVEE end-user’s innovation practices. The resulting activities are listed in Table 6.4.

Table 6.4. Innovation space activities and waves

| Waves | Activities | Description |

| Creativity wave | BIS-C01 Idea & Solution Generation | This initial activity produces an idea |

| BIS-C02 Idea & Solution Analysis | First check of the idea | |

| BIS-C03 Initial Market Analysis | First market check and approximation of expected turnover | |

| BIS-C04 Final Solution Assessment | Decision to proceed or not with the idea validation | |

| Feasibility wave | BIS-F01 Resource Analysis | Analyzing and comparing the available and needed resources |

| BIS-F02 Feasibility Study | Creating a feasibility study of the concept for further processing | |

| BIS-F03 Proof of Concept | Approval or rejection of the concept | |

| Prototyping wave | BIS-P01 Resource Allocation | Allocation of resources for prototype design |

| BIS-P02 Design Prototype | Designing of the prototype | |

| BIS-P03 Validate Prototype | Validation and improvement of the design | |

| Engineering wave | BIS-E01 Acquire Resources | Allocation of resources for final engineering |

| BIS-E02 Build and Optimize | Building and optimizing the solution | |

| BIS-E03 Launch Planning | Marketing, communication and sales activities to support the launch of the solution | |

| BIS-E04 Release | Final process to support the production of the solution |

Each of the activities is linked to an individual set of KPIs and information artifacts. The KPIs are part of the MF and the information artifacts are also dependent on the area of innovation – as described within the following section.

The first part of the BIRF contains a set of activities. These activities process information that either applies for all areas of innovation and improvement or is characteristic for only a few or a single area.

The BIVEE approach is “document-based”. An innovation project needs to walk through the waves and its activities before entering the production space. It does so by producing certain documents for each wave and more specifically for each activity of each wave. For each activity and for each wave, therefore, a set of documents can be defined that needs to be followed and completed in order to start the following activity and/or the following wave. These document templates can be found in the production and innovation knowledge repository (PIKR).

The innovation documents can be accomplished in any possible sequence, as long as some precedence constraints are satisfied (e.g. cost analysis cannot be performed before knowing the composition of a product). Each document has quality check criteria associated, to be used (together with the phase specific criteria) in checking if a phase has been accomplished.

The document templates selected from the PIKR are then progressively instantiated, while the innovation project proceeds. However, the sequencing is quite flexible and new documents could be added if needed. Furthermore, it is possible to move forward and backward across phases, but at the given moment each phase should be accomplished according to the defined criteria (local to each selected doc and global to each phase) and certified by an assessment document.

6.3. Monitoring framework

The MF aims to make the innovation activities and production processes manageable. Therefore, two sets of KPIs have been developed in order to monitor the activities within the two spaces.

The KPIs are aligned to a set of business objectives that have been developed according to the VRM and in close cooperation with the end-users of the BIVEE project. These objectives are identical for both spaces and listed in Table 6.5.

Table 6.5. Business objectives of the monitoring framework

| Name | Description |

| Reliability | The objective of constantly achieving operative goals |

| Velocity | The objective of fast reaction and short cycle times |

| Adaptability | The objective of being able to adapt to varying external or internal demands |

| Cost orientation | The objective of operating on minimal costs |

| Asset orientation | The objective of generating tangible and intangible profit |

| Innovative potential | The objective of successfully carrying new ideas to the market |

| Customer orientation | The objective of satisfying customers |

| Network orientation | The objective of a maximal efficient network |

BIVEE addresses manufacturers, who usually operate within socio-technical systems. The sustainability of these systems is usually dependent on economic, social and ecological dimensions [HOL 01]. Therefore, social and ecological aspects are added. The social performance of a system is defined by its ability to fulfill the needs of its stakeholders. The satisfaction of these needs is a complex topic that expands into multiple categories [DIE 97, GEI 06]. Social performance determines the dedication of a system toward society and ethical business. Categories of social performance have been refined from the work of [VAL 12] and [EDU 09]. These categories are employment, well-being, skill development, community interaction and accountability.

Due to the subjective nature of many indicators within the social performance context, their related measurements cannot be taken automatically by sensors. They are not based on artificial system properties, but instead on individual opinions of human beings. Therefore, in most of the cases, the performance within these categories can only be measured indirectly by interpretation of causal effects (e.g. ratio of staff away sick) or by conduction of surveys among the system’s stakeholders. As a third dimension of sustainability, the ecological performance of VEs can also be assessed by certain indicators. The ecological performance comprises all interactions of the VE with its natural environment, which can be sorted into ecological input and ecological output. A brief description of the sustainability objectives is provided Table 6.6.

Table 6.6. Sustainability objectives of the monitoring framework

| Name | Description |

| Employment | The objective of social benefit in the contractual relationship between an organization and its staff |

| Well-being | The objective of satisfaction of employees |

| Skill development | The objective of providing options for training and skill enhancement for employees |

| Community interaction | The objective of quality and quantity in social interactions with the environment |

| Accountability | The objective of an organization to take responsibility for its actions |

| Ecological input | The objective of achieving an environmentally friendly use of resources of a system |

| Ecological output | The objective of achieving an environmentally friendly emission of a system |

The performance of a VE within these objectives can be measured through its impacts on environmental factors, e.g. which may concern global warming, acidification, toxic contamination, biodiversity or radiation. Such environmental themes have been taken from [WAL 00] and create the basis for the design of ecological KPIs. The Canadian Environmental Sustainability Indicators (CESIs) are an example of the transparent publication of an organization’s ecological KPIs, whereby the organization in this case is Canada itself.

Based on the objectives described in Tables 6.5 and 6.6, a set of reference KPIs has been developed in interaction with the BIVEE end-users. The MF currently holds a total of 69 KPIs for the production space, 100 KPIs for the innovation space and 29 KPIs concerning the sustainability context in both spaces. The selection of the KPIs that are communicated globally within the VE is made during the govern process (GVE02 – Process Policy).

6.4. Collaborative innovation capability maturity model (CICMM)

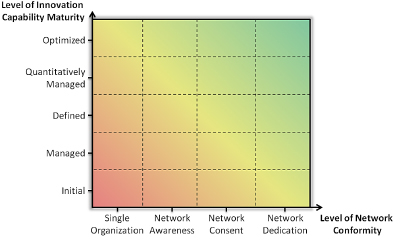

Through governing processes, collaborating organizations should aim for a conjoint set of KPIs and a high level of management maturity. To guide both, the improvement of innovation actions and the consolidation of the network’s methodology, the concept of CICMM can be applied [KNO 13]. This concept is based on the capability maturity model (CMM) [CMM 02]. The CMM was initially developed to increase the maturity of software development processes, but can also be applied on innovation management [ESS 10]. The following five levels of innovation capability maturity are used within the CICMM:

- – initial: the processes are unpredictable, poorly controlled and reactive;

- – managed: the processes are characterized for projects and are often reactive;

- – defined: the processes are characterized for the organization and are proactive;

- – quantitatively managed: the processes are measured and controlled;

- – optimized: focus on process improvement.

In addition to the maturity monitoring, a second dimension is added to account for the consolidation of the network’s approach on innovation management. This notion of network conformity consists of four additional levels:

- – Single organization: the approach is realized in a smaller part of the network. Practices of other partners in this area are unknown.

- – Network awareness: the approach is implemented by a single or a few partners. Other partners are informed about this best practice and invited to join.

- – Network consent: all relevant innovators within the network agree to this approach, but it is not working or used properly.

- – Network dedication: the lowest level of innovation capability maturity that has been gained by all relevant innovators within the network.

The data to assess a network’s maturity and conformity can be gathered either through observation or a Web-based questionnaire. Once collected, the assessment can be visualized in a two-dimensional chart, as shown in Figure 6.4.

Figure 6.4. Collaborative innovation capability maturity model [KNO 13]

An initial proof-of-concept has been developed within the BIVEE project to account for the dimensions of change management, communication management, human resources and technology management. This methodology and its dimensions can be applied to assess the management maturity and conformance within a collaboration concerning collaborative innovation projects.

6.5. Conclusion and outlook

This chapter has described the BIVEE framework, consisting of the VEMF, BIRF and MF. Additionally, the CICMM has been introduced as a methodology to support the governing of collaborative innovation.

Although BIVEE defines the innovation space and production space separately, it has to be stated that both spaces are closely connected. Innovations that are the outcome of the innovation space are transferred into the production space and experience made within the production space may be injected into the innovation space.

The project has developed entities and tools, such as the mission control room (MCR), virtual innovation factory (VIF) and PIKR, which allow transferring the approach of the BIVEE framework into industrial practice. This has resulted in multiple alterations of the framework, but is still an ongoing process that will continue in the future.

6.6. Bibliography

[CMM 02] CMMI Product Team, Capability Maturity Model® Integration (CMMI®), Version 1.1, CMMI® for Systems Engineering, Software Engineering, Integrated Product and Process Development, and Supplier Sourcing (CMMI-SE/SW/IPPD/SS, v1.1), Carnegie-Mellon Software Engineering Institute, Pittsburgh, 2002.

[COO 02] COOPER R.G., Top oder Flop in der Produktentwicklung: Erfolgsstrategien: von der Idee zum Launch, Wiley-VCH, 2002.

[DIE 97] DIENER E., SUH E., “Measuring quality of life: economic, social, and subjective indicators”, Social Indicators Research, vol. 40, nos. 1–2, pp. 189–216, 1997.

[EDU 09] EDUM-FOTWE F.T., PRICE A.D., “A social ontology for appraising sustainability of construction projects and developments”, International Journal of Project Management, vol. 27, no. 4, pp. 313–322, 2009.

[ESS 10] ESSMANN H., PREEZ N., “An innovation capability maturity model – development and initial application”, International Journal of Human and Social Sciences, vol. 5, no. 1, pp. 44–55, 2010.

[HOL 01] HOLLING C.S., “Understanding the complexity of economic, ecological, and social systems”, Ecosystems, vol. 4, no. 5, pp. 390–405, 2001.

[KIR 11] KIRCHMER M., “Reference models to empower MPE”, High Performance Through Process Excellence, Springer Berlin, Heidelberg, pp. 87–101, available at http://link.springer.com/book/10.1007/978-3-642-21165-2, 2011.

[KNO 13] KNOKE B., “A short paper on innovation capability maturity within collaborations”, NGEBIS Short Papers, pp. 7–11, 2013.

[KOT 08] KOTELNIKOV V., Systemic innovation, available at http://www.1000 advices.com/guru/innovation_systemic_vk.html, [Accessed on 23 March 2012], 2008.

[STE 01] STEPHENS S., Supply Chain Council & Supply Chain Operations Reference (SCOR) Model Overview, Supply Chain Council, Inc., Pittsburgh, USA, 2001.

[THO 07] THOBEN K.-D., “LABORANOVA: a collaborative innovation vision (session 1: mechanisms for collaborative innovation in living labs)”, ESoCE Net Industrial Forum, Rome, Italy, 3 December 2007.

[VAL 12] VALIENTEA J.M.A., AYERBEA G., FIGUERAS M.S., “Social responsibility practices and evaluation of corporate social performance”, Journal of Cleaner Production, vol. 35, pp. 25–38, 2012.

[VON 06] VON GEIBLER J., LIEDTKE C., WALLBAUM H. et al., “Accounting for the social dimension of sustainability: experiences from the biotechnology industry”, Business Strategy and the Environment, vol. 15, no. 5, pp. 334–346, 2006.

[WAL 00] WALZ R., “Development of environmental indicator systems: experiences from Germany”, Environmental Management, vol. 25, no. 6, pp. 613–623, 2000.