Economics of building and operating offshore wind farms

Abstract

In a number of countries, offshore turbines are taking on an increasingly important role in the development of wind power, particularly in the north-western part of Europe. Expectations are that a total offshore wind capacity of 43 GW will be implemented in the European Union by 2020. This chapter focuses on the economics of building and operating offshore wind farms, addressing the key economic drivers, investments, operating costs and levelised cost of energy. The main emphasis is on the costs of offshore wind farms and how these costs have developed over time.

Keywords

Investments; Key economic drivers; Offshore wind; Operating costs2.1. Introduction

2.1.1. Expectations to offshore wind power

2.1.2. Development of offshore wind power

2.2. Investment costs

2.2.1. Development in investment costs

2.2.2. Investment costs split into cost components

Table 2.1

Investment costs split into a number of cost components

| Cost components | Examples for detailed cost items |

| Development and project management | Design, management, consenting, consultancy fees |

| Turbines | Tower, rotor blades, rotor hub, rotor bearings, main shaft, main frame, gear box, generator, yaw system, pitch system, power converter, transformer, brake system, nacelle housing, cables |

| Foundations | Foundations, transition piece |

| Electrical installations (offshore) (including balance of plant) | Collection system, integration system, offshore substation. Transmission system, reactive power compensation system, electrical devices, export cable (main cable to coast) |

| Grid connection (onshore) | Dedicated cables onshore, isolators, switchgear under control of onshore network operator |

| Installation (of turbines, foundations, cables and electrical equipment) | Transportation cost, vessel chartering costs, labour cost |

| Financial costs | Financing, bank fees, securities |

| Miscellaneous | Services, insurance and other overheads |

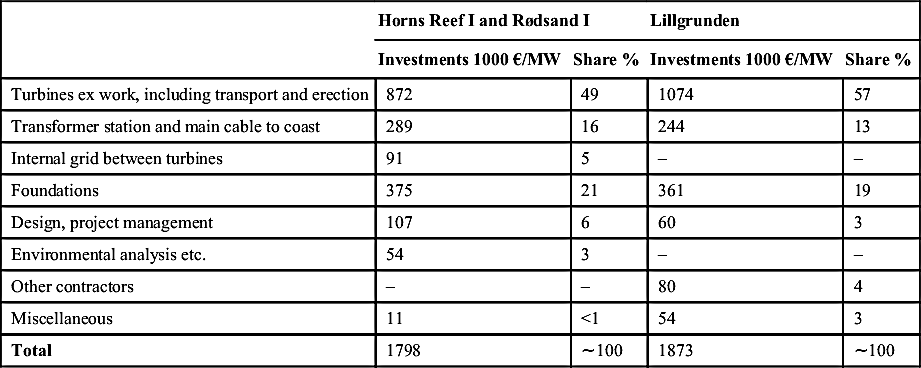

Table 2.2

Average investment costs per MW related to offshore wind farms at Horns Rev, Nysted and Lillgrunden (split into main components)

| Horns Reef I and Rødsand I | Lillgrunden | |||

| Investments 1000 €/MW | Share % | Investments 1000 €/MW | Share % | |

| Turbines ex work, including transport and erection | 872 | 49 | 1074 | 57 |

| Transformer station and main cable to coast | 289 | 16 | 244 | 13 |

| Internal grid between turbines | 91 | 5 | – | – |

| Foundations | 375 | 21 | 361 | 19 |

| Design, project management | 107 | 6 | 60 | 3 |

| Environmental analysis etc. | 54 | 3 | – | – |

| Other contractors | – | – | 80 | 4 |

| Miscellaneous | 11 | <1 | 54 | 3 |

| Total | 1798 | ∼100 | 1873 | ∼100 |

2.3. Operating costs

Table 2.3

Estimates of O&M costs for offshore turbines (all prices converted to Euros, real 2012)

| O&M cost (€/MWh) | |

| Operating farms, EU, 2002–2009 (Morthorst et al., 2009) | 18 |

| Danish technology data catalogue, 2015 (DEA, 2014) | 19 |

| German projects, 2010 (KPMG, 2010) | 27 |

| Offshore farms in Europe (IRENA, 2012) | 25–49 |

2.4. Key economic drivers for offshore wind energy

2.4.1. Project size

2.4.2. Turbine capacity

2.4.3. Project lifetime

2.4.4. Distance to shore and water depth

2.5. Levelised cost of energy