Abdel-Rahman K, Achmus M. Behavior of foundation piles for offshore wind energy plants under axial cyclic loading. In: Proceedings of the SIMULIA Customer Conference, 17–19th May 2011, Barcelona, Spain. Paris, France: Dassault Systèmes Press; 2011:331–341.

Achmus M, Kuo Y.-S, Abdel-Rahman K. Behavior of monopile foundations under cyclic lateral load. Computers and Geotechnics. 2009;36(5):725–735.

Achmus M. Design of axially and laterally loaded piles for the support of offshore wind energy converters. In: Proceedings of the Indian Geotechnical Conference GEOtrendz, 16–18th December 2010, Mumbai, India. 2010:92–102.

Adhikari S, Bhattacharya S. Vibrations of wind-turbines considering soil‒structure interaction. Wind and Structures. 2011;14(2):85–112.

Adhikari S, Bhattacharya S. Dynamic analysis of wind turbine towers on flexible foundations. Shock and Vibration. 2012;19(1):37–56.

API (American Petroleum Institute). API RPA2: Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms – Working Stress Design. twenty-second ed. Washington, DC: API; 2010.

Arshad M, O'Kelly B.C. Offshore wind-turbine structures: a review. Proceedings of the Institution of Civil Engineers, Energy. 2013;166(4):139–152.

Arshad M, O'Kelly B.C. Development of a rig to study model pile behaviour under repeating lateral loads. International Journal of Physical Modelling in Geotechnics. 2014;14(3):54–67.

Atkinson J.H, Sallfors G. Experimental determination of stress–strain–time characteristics in laboratory and in-situ tests. In: Proceedings of the 10th European Conference on Soil Mechanics and Foundation Engineering, 26–30th May 1991. vol. 3. 1991:915–956 Florence, Italy. Balkema: Rotterdam, The Netherlands.

Babcock and Brown Company. The Future of Offshore Wind Energy. 2012 See. http://bluewaterwind.com (accessed 20.08.12.).

Basack S, Dey S. Influence of relative pile-soil stiffness and load eccentricity on single pile response in sand under lateral cyclic loading. Geotechnical and Geological Engineering. 2012;30(4):737–751.

Basack S, Sen S. Numerical solution of single piles subjected to pure torsion. Geotechnical and Geoenvironmental Engineering. 2014;140(1):74–90.

Batchelor G.K. An Introduction to Fluid Dynamics. Cambridge, UK: Cambridge University Press; 1967.

Bhattacharya S, Adhikari S. Experimental validation of soil-structure interaction of offshore wind turbines. Soil Dynamics and Earthquake Engineering. 2011;31(5–6):805–816.

Bhattacharya S, Lombardi D, Muir Wood D. Similitude relationships for physical modelling of monopile-supported offshore wind turbines. International Journal of Physical Modelling in Geotechnics. 2011;11(2):58–68.

Bhattacharya S, Cox J, Lombardi D, Muir Wood D. Dynamics of offshore wind turbines supported on two foundations. Proceedings of the Institution of Civil Engineers, Geotechnical Engineering. 2013;166(2):159–169.

Bienen B, Dührkop J, Grabe J, Randolph M.F, White D. Response of piles with wings to monotonic and cyclic lateral loading in sand. Geotechnical and Geoenvironmental Engineering. 2012;138(3):364–375.

Bisoi S, Haldar S. Dynamic analysis of offshore wind turbine in clay considering soil–monopile–tower interaction. Soil Dynamics and Earthquake Engineering. 2014;63(2014):19–35.

Blanco M.I. The economics of wind energy. Renewable and Sustainable Energy Reviews. 2009;13(6–7):1372–1382.

Broms B. Lateral resistance of piles in cohesionless soils. Soil Mechanics and Foundation Engineering Division, ASCE. 1964;90(3):123–156.

Byrne B.W, Houlsby G.T. Foundations for offshore wind turbines. Philosophical Transactions of the Royal Society of London. 2003;361(1813):2909–2930.

Carswell W, Arwade S.R, DeGroot D.J, Lackner M.A. Soil–structure reliability of offshore wind turbine monopile foundations. Wind Energy. 2015;18(3):483–498.

Cerda Salzmann D.J. Dynamic Response Calculations of Offshore Wind Turbine Monopile Support Structures (M.Sc. thesis). Delft, The Netherlands: Delft University of Technology; 2004.

Cuéllar P, Georgi S, Baeßler M, Rucker W. On the quasi-static granular convective flow and sand densification around pile foundations under cyclic lateral loading. Granular Matter. 2012;14(1):11–25.

Wang S.T, Reese L.C. COM624P—Laterally Loaded Pile Analysis Program for the Microcomputer, Version 2.0 Final report FHWA-SA-91-048. Washington, DC: Federal Highway Administration; 1993.

Das B.M. Advanced Soil Mechanics. New York, NY: CRC Press; 2008.

De Vries W.E. Project UpWind WP4 Deliverable D4.2.1: Assessment of Bottom-Mounted Support Structure Types with Conventional Design Stiffness and Installation Techniques for Typical Deep Water Sites. 2007 See. http://www.upwind.eu/Publications/∼/media/UpWind/Documents/Publications/4%20-%20Offshore%20Foundations/UpwindWP4D421%20Assessment%20of%20bottommounted%20support%20structure%20types.ashx (accessed 15.03.15.).

De Vries W.E, van der Tempel J. Quick monopile design. In: Proceedings of the European Offshore Wind Conference and Exhibition, Berlin, Germany, 4–6th December 2007. 2007.

De Vries W.E, Vemula N.K, Passon P, Fischer T, Kaufer D, Matha D, Schmidt B, Vorpahl F. Support Structure Concepts for Deep Water Sites. 2011 Final report WP 4.2. UpWind Project: Offshore Foundations and Support Structures Deliverable D4.2.8. See. http://repository.tudelft.nl/view/ir/uuid%3A4d009175-4cc4-4a90-881c-9ffb056b0806/ (accessed 30.05.15.).

DIN (Deutsches Institut für Normung). DIN 1054: Baugrund Sicherheitsnachweise im Erd und Grundbau. Berlin, Germany: DIN; 2005 See. http://www.baunormenlexikon.de/Normen/DIN/DIN%201054/1b69b621-74a0-4c33-8b29-a82a24afd4d4 (accessed 15.03.15.).

DNV (Det Norske Veritas). DNV-OS-J101: Design of Offshore Wind Turbine Structures. Oslo, Norway: DNV; 2011.

Dobry R, Vicenti E, O'Rourke M.J, Roesset J.M. Horizontal stiffness and damping of single piles. Journal of Geotechnical Engineering Division, ASCE. 1982;108(3):439–459.

Doherty P, Kirwan L, Gavin K, Igoe D, Tyrrell S, Ward D, O'Kelly B. Soil properties at the UCD geotechnical research site at Blessington. In: Proceedings of the Bridge and Concrete Research in Ireland Conference (BCRI 2012), Dublin, Ireland, 6–7th September 2012. vol. 1. 2012:499–504. http://www.tara.tcd.ie/handle/2262/67119.

Dührkop J. On the Influence of Expanders and Cyclic Loads on the Deformation Behavior of Lateral Stressed Piles in Sand (Ph.D. thesis). Hamburg, Germany: Hamburg University of Technology; 2009.

El Naggar M.H, Wei J.Q. Response of tapered piles subjected to lateral loading. Canadian Geotechnical Journal. 1999;36(1):52–71.

Esteban M, Lopes-Gutierrez J, Diez J, Negro V. Foundations for offshore wind farms. In: Proceedings of the 12th International Conference on Environmental Science and Technology, Rhodes, Greece. 2011:516–523.

Fischer T. Executive Summary – Upwind Project WP4: Offshore Foundations and Support Structures. 2011 See. http://www.upwind.eu/Publications/∼/media/UpWind/Documents/Publications/4%20-%20Offshore%20Foundations/WP4_Executive_Summary_Final.ashx (accessed 15.03.15.).

Gavin K.G, O'Kelly B.C. Effect of friction fatigue on pile capacity in dense sand. Geotechnical and Geoenvironmental Engineering. 2007;133(1):63–71.

GL (Germanischer Lloyd WindEnergie GmbH). Rules and Guidelines, IV Industrial Services, Guideline for the Certification of Offshore Wind Turbines, Ch. 2 and 6. 2005 See. http://onlinepubs.trb.org/onlinepubs/mb/Offshore%20Wind/Guideline.pdf (accessed 17.09.15.).

Guo W.D. On limiting force profile, slip depth and response of lateral piles. Computer and Geotechnics. 2006;33(1):47–67.

Guo W.D. Pu-based solutions for slope stabilizing piles. International Journal of Geomechanics. 2013;13(3):292–310.

Haiderali A, Cilingir U, Madabhushi G. Lateral and axial capacity of monopiles for offshore wind turbines. Indian Geotechnical Journal. 2013;43(3):181–194.

Haritos N. Introduction to the analysis and design of offshore structures—an overview. Electronic Journal of Structural Engineering. 2007;2007:55–65.

IEC (International Electrotechnical Commission), . IEC 61400–1: Wind Turbines — Part 1: Design requirements. third ed. 2005 IEC, Geneva, Switzerland.

Igoe D.J.P, Gavin K.G, O'Kelly B.C. Shaft capacity of open-ended piles in sand. Geotechnical and Geoenvironmental Engineering. 2011;137(10):903–913.

Igoe D, Gavin K, O'Kelly B. An investigation into the use of push-in pile foundations by the offshore wind sector. International Journal of Environmental Studies. 2013;70(5):777–791.

Igoe D.J.P, Gavin K.G, O'Kelly B.C, Byrne B. The use of in-situ site investigation techniques for the axial design of offshore piles. In: Coutinho R.Q, Mayne P.W, eds. Proceedings of the Fourth International Conference on Geotechnical and Geophysical Site Characterization (ISC'4), 18th–21st September 2012. Pernambuco, Brazil. vol. 2. 2013:1123–1129.

Igoe D, Gavin K, O'Kelly B. Field tests using an instrumented model pipe pile in sand. In: Springman S, Laue J, Seward L, eds. Proceedings of the Seventh International Conference on Physical Modelling in Geotechnics, Zurich, Switzerland, 28th June–1st July 2010. vol. 2. Leiden, The Netherlands: CRC Press/Balkema; 2010:775–780.

Irvine J.H, Allan P.G, Clarke B.G, Peng J.R. Improving the lateral stability of monopile foundations. In: Newson T.A, ed. Proceedings of the International Conference on Foundations: Innovations, Observations, Design and Practice. 2nd–5th September 2003, Dundee, UK. London: Thomas Telford; 2003:371–380.

Jaimes O.G. Design Concepts for Offshore Wind Turbines: A Technical and Economic Study on the Trade-off between Stall and Pitch Controlled Systems (M.Sc. thesis). Delft, The Netherlands: Delft University of Technology; 2010.

Journée J.M.J, Massie W.W. Offshore Hydrodynamics. first ed. Delft, The Netherlands: Delft University of Technology; 2001.

Junginger M, Agterbosch S, Faaij A, Turkenburg W. Renewable electricity in the Netherlands. Energy Policy. 2004;32(9):1053–1073.

Karg C. Modelling of Strain Accumulation Due to Low Level Vibrations in Granular Soils (Ph.D. thesis). Ghent, Belgium: Ghent University; 2007.

Karthigeyan S, Ramakrishna V.V.G.S.T, Rajagopal K. Influence of vertical load on the lateral response of piles in sand. Computers and Geotechnics. 2006;33(2):121–131.

Karthigeyan S, Ramakrishna V.V.G.S.T, Rajagopal K. Numerical investigation of the effect of vertical load on the lateral response of piles. Geotechnical and Geoenvironmental Engineering. 2007;133(5):512–521.

Klinkvort R.T, Hededal O. Lateral response of monopile supporting an offshore wind turbine. Proceedings of the Institution of Civil Engineers, Geotechnical Engineering. 2013;166(2):147–158.

Kopp D.R. Foundations for an Offshore Wind Turbine (M.Sc. thesis). Cambridge, MA: Massachusetts Institute of Technology; 2010.

Kuo Y.S, Achmus M, Abdel-Rahman K. Minimum embedded length of cyclic horizontally loaded monopiles. Geotechnical and Geoenvironmental Engineering. 2012;138(3):357–363.

Lai S. Similitude for shaking table test on soil-structure-fluid model in 1-g gravitational field. Soils and Foundations. 1989;29(1):105–118.

LeBlanc C. Design of Offshore Wind Turbine Support Structures: Selected Topics in the Field of Geotechnical Engineering (Ph.D. thesis). Aalborg, Denmark: Aalborg University; 2009.

LeBlanc C, Houlsby G.T, Byrne B.W. Response of stiff piles in sand to long-term cyclic lateral loading. Géotechnique. 2010;60(2):79–90.

Lesny K, Wiemann J. Design aspects of monopiles in German offshore wind farms. In: Gourvenec S, Cassidy M, eds. Proceedings of the First International Symposium on Frontiers in Offshore Geotechnics. Perth, Australia, 19th–21st September 2005. Leiden, The Netherlands: Balkema; 2005:383–389.

Li D, Haigh S.K, Bolton M.D. Centrifuge modelling of mono-pile under cyclic lateral loads. In: Springman S, Laue J, Seward L, eds. Proceedings of the Seventh International Conference on Physical Modelling in Geotechnics, 28th June–1st July 2010, Zurich, Switzerland. vol. 2. Leiden, The Netherlands: CRC Press; 2010:965–970.

Lin S.-S, Liao J.-C. Permanent strains of piles in sand due to cyclic lateral loads. Geotechnical and Geoenvironmental Engineering. 1999;125(9):798–802.

Little R.L, Briaud J.L. Full Scale Cyclic Lateral Load Tests on Six Single Piles in Sand Miscellaneous paper GL-88–27. College Station, TX: Geotechnical Division, Civil Engineering Department, Texas A&M University; 1988.

Lombardi D, Bhattacharya S, Muir Wood D. Dynamic soil–structure interaction of monopile supported wind turbines in cohesive soil. Soil Dynamics and Earthquake Engineering. 2013;49(2013):165–180.

Long J, Vanneste G. Effects of cyclic lateral loads on piles in sand. Journal of Geotechnical Engineering, ASCE. 1994;120(1):225–244.

Malhotra S. Design and construction considerations for offshore wind turbine foundations in North America. In: Fratta D.O, Puppala A.J, Muhunthan B, eds. Proceedings of GeoFlorida 2010: Advances in Analysis, Modeling & Design, Orlando, Florida, 20–24th February 2010, GSP 199. 2010:1533–1542.

Matlock H, Reese L.C. Generalized solutions for laterally loaded piles. Journal of the Soil Mechanics and Foundations Division ASCE. 1960;86(5):63–94.

Moayed R.Z, Mehdipour I, Judi A. Undrained lateral behaviour of short pile under combination of axial, lateral and moment loading in clayey soils. Kuwait Journal of Science and Engineering. 2012;39(1B):59–78.

Morison J.R, Johnson J.W, Schaff S.A. The forces exerted by surface waves on piles. Journal of Petroleum Technology. 1950;2(5):149–154.

Muir Wood D, Crewe A.J, Taylor C.A. Shaking table testing of geotechnical models. International Journal of Physical Modelling in Geotechnics. 2002;2(1):1–13.

Naughton P.J, O'Kelly B.C. The induced anisotropy of Leighton Buzzard sand. In: Jardine R.J, Potts D.M, Higgins K.G, eds. Proceedings of Advances in Geotechnical Engineering: The Skempton Conference, 28th–31st March 2004, London, UK. vol. 1. London, UK: Thomas Telford; 2004:556–567.

Naughton P.J, O'Kelly B.C. Yield behaviour of sand under generalized stress conditions. In: Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, 12–16th September 2005. vol. 2. Osaka, Japan: IOS Press; 2005:555–558.

Nicolai G, Ibsen L.B. Small-scale testing of cyclic laterally loaded monopiles in dense saturated sand. Journal of Ocean and Wind Energy. 2014;1(4):240–245.

Niemunis A, Wichtmann T, Triantafyllidis T. A high-cycle accumulation model for sand. Computers and Geotechnics. 2005;32(4):245–263.

OSPAR Commission. Inventory of Measures to Mitigate the Emission and Environmental Impact of Underwater Noise. Biodiversity Series. London, UK: OSPAR Commission; 2014 See. http://www.ospar.org/documents/dbase/publications/p00626/p00626_inventory_of_noise_mitigation.pdf (accessed 03.06.15.).

O'Kelly B.C, Naughton P.J. Development of a new hollow cylinder apparatus for stress path measurements over a wide strain range. Geotechnical Testing Journal. 2005;28(4):345–354.

O'Kelly B.C. Compression and consolidation anisotropy of some soft soils. Geotechnical and Geological Engineering. 2006;24(6):1715–1728.

O'Kelly B.C, Naughton P.J. Local measurements of the polar deformation response in a hollow cylinder apparatus. Geomechanics and Geoengineering. 2008;3(4):217–229.

O'Kelly B.C, Naughton P.J. Study of the yielding of sand under generalized stress conditions using a versatile hollow cylinder torsional apparatus. Mechanics of Materials. 2009;41(3):187–198.

Pappusetty D, Pando M.A. Numerical evaluation of long term monopile head behaviour for ocean energy converters under sustained low amplitude lateral loading. International Journal of Civil and Structural Engineering. 2013;3(4):669–684.

Peng J, Clarke B, Rouainia M. A device to cyclic lateral loaded model piles. Geotechnical Testing Journal. 2006;29(4):1–7.

Peng J.-R, Rouainia M, Clarke B.G. Finite element analysis of laterally loaded fin piles. Computers and Structures 88 (21–22). 2010:1239–1247.

Peng J, Clarke B, Rouainia M. Increasing the resistance of piles subject to cyclic lateral loading. Geotechnical and Geoenvironmental Engineering. 2011;137(10):977–982.

Peralta P, Achmus M. An experimental investigation of piles in sand subjected to lateral cyclic loads. In: Springman S, Laue J, Seward L, eds. Proceedings of the Seventh International Conference on Physical Modelling in Geotechnics, 28th June–1st July 2010, Zurich, Switzerland. vol. 2. Leiden, The Netherlands: CRC Press; 2010:985–990.

Poulos H.G. Cyclic stability diagram for axially loaded piles. Journal of Geotechnical Engineering, ASCE. 1988;114(8):877–895.

Rahim A, Stevens R.F. Design procedures for marine renewable energy foundations. In: Proceedings of the First Marine Energy Technology Symposium, 10–11th April 2013, Washington, DC. 10 p. 2013.

Ramakrishna V.G.S.T, Rao S.N. Critical cyclic load levels for laterally loaded piles in soft clays. In: Sing S.K, Lacasse S, eds. Proceedings of the International Conference on Offshore and Nearshore Geotechnical Engineering, Panvil, Mumbai, India. 1999:301–307.

Randolph M.F. The response of flexible piles to lateral loading. Géotechnique. 1981;31(2):247–259.

Rani S, Prashant A. Estimation of the linear spring constant for a laterally loaded monopile embedded in nonlinear soil. International Journal of Geomechanics. 2015;15(6) doi: 10.1061/(ASCE)GM.1943-5622.0000441.

Rosquoet F, Thorel L, Garnier J, Canepa Y. Lateral cyclic loading of sand-installed piles. Soils and Foundations. 2007;47(5):821–832.

Şahin A.D. Progress and recent trends in wind energy. Progress in Energy and Combustion Science. 2004;30(5):501–543.

Saleem Z. Alternatives and Modifications of Monopile Foundation or its Installation Technique for Noise Mitigation. Delft, The Netherlands: Delft University of Technology; 2011 See. http://www.vliz.be/imisdocs/publications/223688.pdf (accessed 03.08.15.).

Schaumann P, Böker C. Can tripods and jackets compete with monopiles? In: Proceedings of the European Offshore Wind Conference and Exhibition, 26–28th October 2005, Copenhagen, Denmark. 2005 10 p. See. http://wind.nrel.gov/public/SeaCon/Proceedings/Copenhagen.Offshore.Wind.2005/documents/papers/Low_cost_foundations/P.Schaumann_Can_jackets_and_tripods_compete_with_monopile.pdf (accessed 30.06.15.).

van der Tempel J, Molenaar D.-P. Wind turbine structural dynamics — a review of the principles for modern power generation, onshore and offshore. Wind Engineering. 2002;26(2):211–220.

Tomlinson M.J. Foundation Design and Construction. seventh ed. Harlow, Essex, UK: Pearson; 2001.

Tong W. Wind Power Generation and Wind Turbine Design. Southampton, UK: WIT Press; 2010.

van der Tempel J. Design of Support Structures for Offshore Wind Turbines (Ph.D. thesis). Delft, The Netherlands: Delft University of Technology; 2006.

van der Tempel J, Zaaijer M.B, Subroto H. The effects of scour on the design of offshore wind turbines. In: Proceedings of the Third International Conference on Marine Renewable Energy, 7–9th July 2004, Blyth, UK. London, UK: Institute of Marine Engineering, Science, and Technology; 2004:27–35.

Verdure L, Garnier J, Levacher D. Lateral cyclic loading of single piles in sand. International Journal of Physical Modelling in Geotechnics. 2003;3(3):17–28.

Wichtmann T, Rondón H.A, Niemunis A, Triantafyllidis T, Lizcano A. Prediction of permanent deformations in pavements using a high-cycle accumulation model. Geotechnical and Geoenvironmental Engineering. 2010;136(5):728–740.

Zhu B, Byrne B.W, Houlsby G.T. Long-term lateral cyclic response of suction caisson foundations in sand. Geotechnical and Geoenvironmental Engineering. 2013;139(1):73–83.

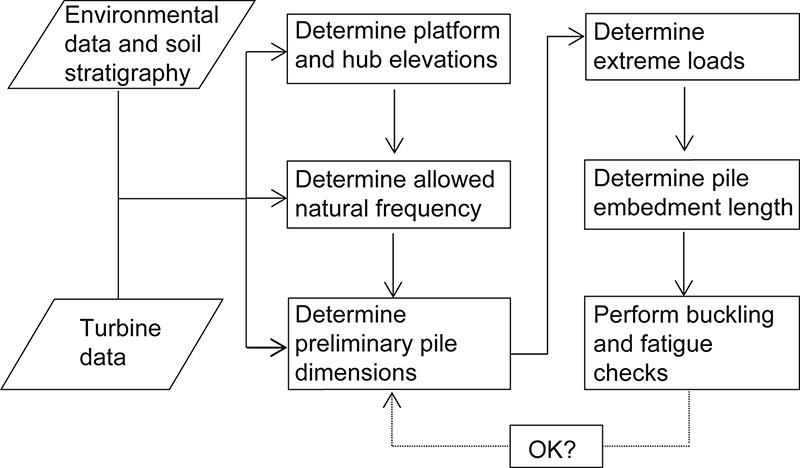

![]() [20.1]

[20.1]