Water-Cooled Reactors

Abstract

The most common type of nuclear power plant uses water cooling within the reactor core. Water is a good moderator for the fast neutrons generated during nuclear fission and so easily combines the ability to slow the particles generated during fission reactions with the capture of heat. Two types of water-cooled reactor have been developed. In one the water is allowed to boil within the reactor core, generating steam that can be used directly to drive a steam turbine. In the second type, water is circulated through the core under high pressure so that it does not boil. The hot, high-pressure water from the core is then circulated through a heat exchanger/steam generator to produce steam to drive the plant’s turbines. Some water-cooled reactor use deuterium oxide—heavy water—as their coolant.

Keywords

boiling water reactor; pressurized water reactor; pressurized heavy water reactor; reactor; moderator; VVER reactor; RBMK reactor; fuel rod; fuel pellet

Nuclear reactor is the name given to the device or structure in which a controlled nuclear reaction takes place. There are a number of different reactor designs in use, but all have many features in common.

The core of the reactor is its heart, the place where the nuclear fuel is placed and where the nuclear reaction takes place. The fuel is most frequently formed into pellets roughly 2 cm in diameter and 1–2 cm long. These pellets are loaded into a fuel rod, a hollow tube of a special corrosion-resistant metal; this is frequently a zirconium alloy which is transparent to neutrons. Each fuel rod is 3–4 m long and will contain 150–200 pellets. A single reactor core may contain up to 75,000 such rods. Fuel rods must be replaced once the fissile uranium-235 they contain has been used up.1 Refueling a reactor is a lengthy process which can take as much as three weeks to complete during which the reactor normally has to be shut down. However, some designs allow refueling while in operation.

Inside the core, in between the fuel rods, there are control rods, made of boron, boron steel or boron carbide, which are used to control the nuclear reaction. Boron is a good absorber of neutrons. These rods can be moved in and out of the core and they will be of different types. Some may be designed to completely stop the reaction in the core, others to adjust the speed of the reaction. The core will also contain a moderator to slow the neutrons released by the fission of uranium atoms. In many cases the moderator is also the coolant used to carry heat away from the core.

The outside of the core may be surrounded by a material that acts as a reflector to return some of the neutrons escaping from the core. This helps maintain a uniform power density within the core and allows smaller cores to be built. There may also be a similar reflecting material in the center of the core.

The coolant collects heat within the core. This coolant may be the thermodynamic fluid that drives the plant turbine—as in a boiling water reactor (BWR)—or it may transfer its heat through an external heat exchanger to a secondary circuit where it is exploited to raise steam to drive a steam turbine—as in a pressurized water reactor (PWR). The coolant may be water (light water), deuterium (heavy water), a gas such as helium or carbon dioxide or a metal such as sodium. As noted in Chapter 3 the core and its ancillary equipment are normally called the ‘nuclear island’ of a nuclear power plant while any external steam generator,2 the steam turbine and generator are called the ‘conventional island’. The coolant/steam cycle will link the nuclear and conventional islands.

A nuclear power plant will also contain a host of components to ensure that the plant remains safe and can never release radioactive material into the environment. The most important of these is the containment. This is a heavy concrete and steel jacket which completely surrounds the nuclear reactor. In the event of a core failure the containment should be able to completely isolate the core from the surroundings and remained sealed, whatever happens within the core. It should also be able to resist a massive external impact such as an aircraft crashing into the structure.

Water-Cooled Designs

Although there have been a range of reactor designs used commercially since the nuclear power age began, by far the majority of those built use water as both the moderator and the coolant. Water is a good moderator for slowing fast neutrons because the hydrogen atoms in water are the same size as a neutron. If the moderator was composed of very large atoms, then the neutrons would simply bounce off them; if the moderator atoms were much smaller than the neutron, then the latter would simply push them aside without transferring significant kinetic energy during a collision. When the masses are similar, then the optimum conditions for momentum and energy transfer are achieved.

When a fast neutron collides with a proton, it can transfer a large amount of energy to its collision partner, reducing its own kinetic energy in the process. This process in effect transfers excess energy from the neutrons to the water as heat. The heat can then be carried away by the water through the cooling circuit that forms part of the steam generation system of the power plant.

There are two primary types of water-cooled reactor, a BWR and a PWR. The latter includes two types, a pressurized light water reactor and a pressurized heavy water reactor. In addition, there is a Russian-designed reactor that uses graphite as its moderator but water as the coolant.

The Boiling Water Reactor

The BWR is one of the two most important reactor designs in use today. The first BWR was an experimental reactor called Borax I which was built at the Argonne National Laboratory in Idaho, United States in 1952. The purpose of the experiment was to determine if allowing coolant water to boil within the core of the reactor would lead to core instability. The experiment was successful—there was no instability when the water boiled—and the initial unit was upgraded to Borax II and then, in 1954, Borax III was built. The latter is famous for having supplied the first nuclear electric power in the United States, to the city of Arco. In fact the unit was not originally designed to provide power but was rapidly modified in early 1955 to counter a Russian announcement of a 5-MW nuclear power plant that has been built in the USSR. Borax III had a generating capacity of about 2 MW.

The technology developed for the Borax reactors was subsequently adopted by General Electric Co in the United States which developed a commercial nuclear reactor based on the boiling water concept. The first of these reactors, the Dresden Nuclear Power Plant in Illinois, USA, with a generating capacity of 210 MW, began operating in 1960 and is considered the first commercial nuclear power plant in the United States. There were 78 BWR reactors in operation around the world at the end of 2015.

The BWR uses ordinary water (light water) as both its coolant and its moderator. Its unique feature is that steam is generated directly inside the reactor core. In the BWR, the water in the reactor core is permitted to boil under a pressure of 75 atm, raising the boiling point to 285°C and the steam generated is taken from the core and used directly to drive a steam turbine. This steam is then condensed and recycled back to the reactor core. This is shown in Fig. 4.1. Since the steam is exposed to the core, there is some radioactive contamination of the turbines but this is short-lived and turbines can normally be accessed soon after shutdown.

The BWR configuration represents probably the simplest possible for a nuclear reactor because no additional steam generators are required. However the internal systems within a BWR are complex. The BWR uses enriched uranium as its fuel, with an enrichment level of around 2.4% uranium-235. This fuel is placed into the reactor in the form of uranium oxide pellets in zirconium alloy tubes. There may be as much as 140 tonnes of fuel in 75,000 fuel rods. Refueling a BWR involves removing the top of the reactor. The core itself is kept under water, the water shielding operators from radioactivity. Boron control rods enter the core from beneath the reactor. In modern BWRs the control rods are used to keep power generation within the reactor core homogeneous and to compensate for consumption (burn-up) of the fuel. The rate of water flow through the core is then used to control power. However some early BWRs used only natural water circulation with no pumps. In these reactors the control rods had to be able to control the power between 0% and 100%.

There is also a natural moderation feedback process that takes place within the BWR core. The steam above the water in the core is less good at moderating neutrons, so if the core overheats and generates more steam, displacing some of the water around the core, this will tend to reduce the rate of fission.

In common with all reactors the fuel rods removed from a BWR reactor core are extremely radioactive and continue to produce energy for some years. They are normally kept in a carefully controlled storage pool at the plant before, in principle at least, being shipped for either reprocessing or final storage.

Most BWR reactors are typically 900–1100 MW in generating capacity, with an efficiency of 32%. Early plants, mostly entering service in the early 1970s, were around 500–600 MW in capacity. Advanced BWR designs have capacities of up to 1400 MW and an efficiency of around 33%. A small number of these are in operation in Asia.

The Pressurized Water Reactor

The PWR is the second of the two key nuclear power technologies in use today. It emerged from research into submarine propulsion units that took place during and after the Second World War. A prototype was built at the Idaho National Laboratory in the United States in 1953 and the first US submarine with a nuclear power unit, USS Nautilus, was launched in 1955. The technology was taken up by Westinghouse, which went on to build many of the US Navy’s submarine propulsion units, and was developed for power generation. A second US company called Combustion Engineering also became involved in PWR development and was a rival to Westinghouse. Its design eventually became merged with that of Westinghouse.

The first PWR power plant in the United States was the Shippingpoint Atomic Power station. However, this was based on a canceled nuclear aircraft carrier power unit and was of extremely unusual design with highly enriched uranium (93% uranium-235) seed fuel surrounded by a blanket of natural uranium-238. The unit went critical in 1957 and had a power generating capacity of 60 MW. As a result of its unusual design, Shippingport is often considered a demonstration PWR rather than the first commercial nuclear power plant in the United States. That honor instead belongs to Dresden nuclear power plant (see above), a boiling water design which started in 1960. The first commercial PWR was the Yankee Rowe nuclear power station which also started in 1960, but slightly later than Dresden. This plant had a generating capacity of 185 MW. At the end of 2015, there were 283 PWRs operating around the world, making these the most common reactors in use.

The PWR also uses light water as both coolant and moderator. However, in the pressurized water system the cooling water is kept under pressure so that it cannot boil. As a consequence the PWR differs in another respect from the BWR; the primary coolant that flows through the reactor core does not drive the steam turbine. Instead heat from the primary water cooling system is captured in a heat exchanger and transferred to water in a secondary system, as shown in Fig. 4.2. It is the water in this second system which is allowed to boil and generate steam to drive the turbine.

The core of a PWR is filled with water, pressurized to 150 atm, allowing the water to reach 325°C without boiling. Containing this high pressure over the volume of the core presents, one of the major engineering challenges in PWR design. The use of a second water cycle introduces energy losses which make the PWR less efficient at converting the energy from the nuclear reaction into electricity. On the other hand the higher steam temperature and pressure allow for greater thermodynamic efficiency and typical overall efficiency, at 32%, is similar to a BWR. In addition the primary/secondary cooling circuit arrangement has other advantages regarding fuel utilization and power density, making it competitive with the BWR. High-pressure core operation with no steam production allows the reactor to be more compact.

The PWR uses uranium fuel enriched to 3.2%, a slightly higher enrichment level than in a BWR. This is responsible for a higher power density within the reactor core. As with the BWR the fuel is introduced into the core in the form of uranium oxide pellets. A typical PWR will contain 100 tonnes of uranium in around 50,000 fuel rods and 18 million fuel pellets. Refueling is carried out by removing the top of the core. However, in a PWR the control rods are inserted from above too, allowing gravity to act as a fail-safe in the event of an accident.

A typical PWR has a generating capacity of 1000 MW although early plants built in the 1970 s were much smaller. The original Westinghouse design is the starting point for most western PWRs. France also developed a PWR which was originally based on the Westinghouse design, but the designs later diverged so that the French PWR is now an independent design. Advanced PWR designs, some of which are being built today, range in size from 1100 to 1700 MW.

The Pressurized Heavy Water Reactor

While most water-cooled reactors use light water (H2O) as their coolant, one design, the Canadian deuterium uranium (CANDU) reactor, uses heavy water. The CANDU reactor was developed in Canada with the strategic aim of enabling nuclear power to be exploited without the need for imported enriched uranium. Canada is home to some of the richest uranium ores in the world but uranium enrichment is an expensive and highly technical process. If it can be avoided, countries such as Canada with natural uranium reserves can more easily exploit their indigenous reserves to generate energy. This has made the CANDU reactor, which uses unenriched uranium, attractive outside Canada too.

The CANDU reactor uses, as its moderator and coolant, a type of water called heavy water. Heavy water is a form of water in which the two normal hydrogen atoms have been replaced with two of the isotopic form, deuterium. Each deuterium atom weighs twice as much as a normal hydrogen atom, hence the name heavy water. Heavy water occurs in small quantities in natural water.3

Heavy water has to be separated from natural water, so it is much more expensive than light water but it has the advantage that it absorbs fewer neutrons than light water. As a consequence, it is possible to sustain a nuclear reaction using heavy water cooling without the need to enrich the uranium fuel. The CANDU reactor has the additional advantage that it can be refueled without the need to shut it down; in fact this is necessary with natural uranium fueled reactor to keep the plant going. Avoiding lengthy refueling shutdowns provides better operational performance.

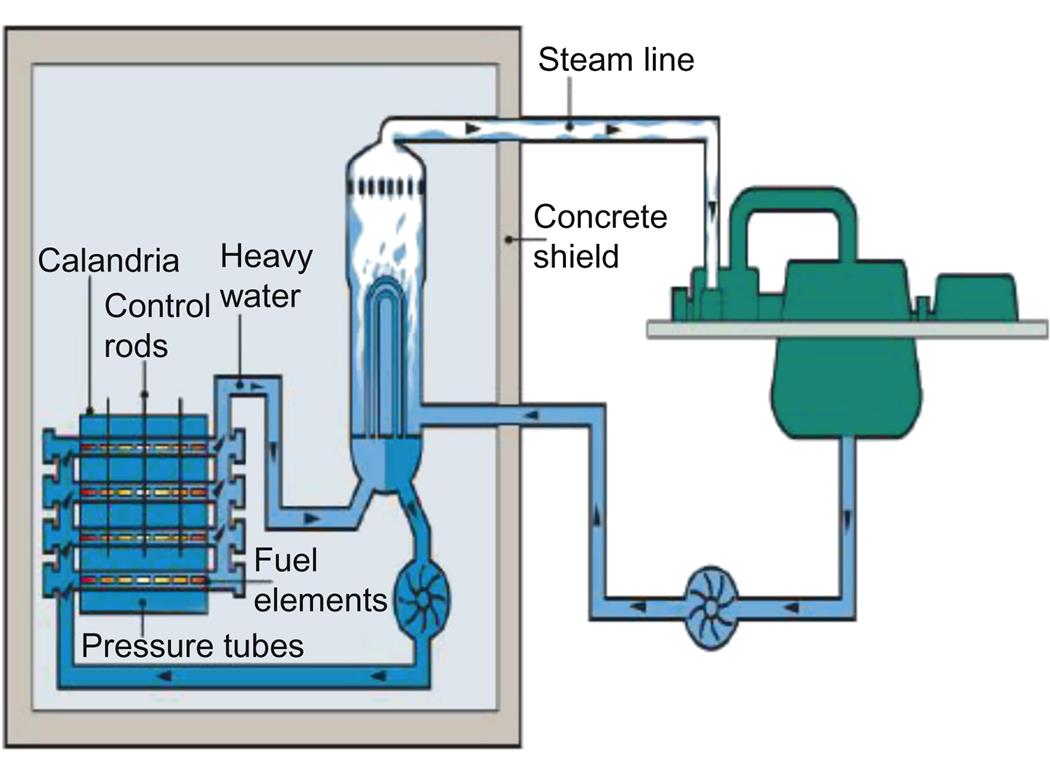

The CANDU fuel is loaded in the form of uranium oxide pellets housed in zirconium alloy rods that are inserted horizontally into pressure tubes penetrating the core instead of vertically as in other PWRs and BWRs. Fuel replacement involves pushing a new rod into a pressure tube which passes through the vessel containing the heavy water (called a calandria) and forcing the old tube out of the other end. The pressure tube must be isolated from the heavy water so that refueling can be carried out without the need to shut down the reactor.

The heavy water coolant in the CANDU reactor is maintained under a pressure of around 100 atm, lower than is a light water PWR, and the water reaches around 290°C without boiling. Heat is transferred through a heat exchanger to a light water system with a steam generator and the secondary system drives a steam turbine in much the same way as a PWR (see Fig. 4.3). Efficiency is slightly lower than light water reactors at around 30%.

The CANDU reactor was developed by Atomic Energy of Canada and that country has the largest CANDU fleet but reactors have also been supplied to countries such as Argentina, South Korea, India and Pakistan. Reactor capacity is typically 600–700 MW, smaller than the alternative light water reactors. There are 49 in operation.

The VVER Reactor

The Russian VVER reactor (the abbreviation comes from Vodo-Vodyanoi Energetichesky Reaktor which translates as Water-Water Power Reactor, i.e., a water-cooled, water-moderated reactor) is a Russian-designed variant of the PWR. The original version of this design to enter service was the VVER-440 with a generating capacity of 440 MW. The first reactors of this type were built at Novovoronezh in 1972 and 1973. Soon after this, boron control rods were introduced, allowing the number of control rods to be reduced and leading to a modified design called V-230. A third design, the V-213 was introduced later in an attempt to apply modern safety standards to VVER nuclear units. Alongside the VVER-440, Russia also developed the VVER-1000, a 1000-MW version based on the same design concept. The first of these entered service at Novovoronezh in 1980.

The VVER typically operates with a coolant pressure of 150 atm and a temperature of 300°C, similar to a western PWR. However, there are a number of minor design variations compared to the typical Westinghouse design. Fuel assemblies in the Russian design are hexagonal rather than square, in principle allowing closer packing of the rods, and the steam generators are oriented horizontally rather than vertically. However, like the Westinghouse PWR, control rods are inserted from above the reactor vessel. The uranium fuel for the VVER reactor is enriched to between 2.4% and 4.4% uranium-235.

There are 23 VVER-440 reactors in operation and 28 VVER-1000 units. A VVER-1200 with an output of 1200 MW is the latest evolution of this design and units to this specification are being built in Russia as well as being offered for construction in the rest of the world.

The RBMK Reactor

The Russian RBMK (Reaktor Bolshoy Moshchnosty Kanalny that translates as high-power channel reactor) is another BWR, but of significantly different design to any other nuclear reactor in use today. The design of this reactor dates to the 1954 when its predecessor, the Obninsk AM-1 reactor, became the first nuclear reactor to generate electricity. The original unit has an output of 30 MW and supplied power to Obninsk between 1954 and 1959. This unit, like reactors in the United Kingdom, United States and France at the time, was intended for plutonium production but was later modified to power generation use.

Like the CANDU reactor, the RBMK reactor addressed the need create a sustainable nuclear reaction without enriched uranium, or in this case with low uranium enrichment. This requires a moderator that has a low absorption coefficient for neutrons. In many early and experimental nuclear reactors, graphite was used because it has a low absorption coefficient and also because it was cheap. Deuterium, while it absorbs fewer neutrons, is much more expensive to produce.

The RBMK reactor was essentially a utilitarian design. the core is loaded with graphite blocks through which holes were cut to allow the fuel rods and control rods to be inserted. Also running through the core are pressure tubes that carry water pumped from a reservoir below the reactor. This is allowed to boil to steam within the pipes and is then collected at the top and fed to steam generator vessels. The water/steam system is pressurized to 68 atm and the water reaches a temperature of 284°C. During operation the graphite moderator reaches a temperature of 730°C. The vessel containing the core is filled with a helium/nitrogen gas mixture which is inert, to prevent oxidation of the graphite and also helps heat transfer between the graphite and the water pressure tubes. A cross-section of an RBMK reactor is shown in Fig. 4.4.

The RBMK reactor has no containment vessel in the sense understood by modern reactor designers. Instead it is placed inside a reinforced, concrete lined cavity. The reactor core sits on a steel plate and is surrounded by a steel casing. The conventional island for this plant which includes the steam separators is located in a concrete housing.

Uranium for use in the RBMK reactor is enriched to 1.8–2.0%. Control rods in the core consist of two types, both based on boron. A number of short control rods are inserted from below to help create a uniform power distribution. The main control rods for controlling the reaction are inserted from above.

The RBMK reactor has a flaw in its design that eventually led to a catastrophic failure. In a traditional BWR, if the core overheats more water is turned into steam. This reduces the amount of water around the core, reduces the moderating of neutrons and so reduces the number of fission reactions and the amount of power production. The RBMK has a graphite moderator but a boiling water coolant. If the core overheats, more steam is again produced. In this case, however, the steam does not significantly affect the degree of neutron moderation which is still controlled by the graphite but it does reduce the absorption of neutrons by water since steam absorbs fewer neutrons that light water. This leaves more neutrons to react in the core, leading to more heat and a potential runaway situation. It was a situation of this type that led to the catastrophic failure of one of the RBMK reactors at the Chernobyl nuclear power plant in 1986.

Since that accident a number of RBMK reactors have been shut down. Others have been modified to improve their safety features. Eleven of these reactors are still operational. Most RBMK reactors had a generating capacity of 1000 MW but a second design increased this to 1500 MW, large even by modern standards. A new generation of RBMK reactors designated the MKER reactor was designed but none has even been completed.