4

CUSTOMER-FOCUS STRATEGY 2: PERSONALIZATION IS NOT A LUXURY

PERSONALIZATION—MAKING PRODUCTS OR SERVICES that are tailored to each individual—is revolutionizing businesses. Personalization challenges all the fundamental concepts business leaders were taught from the day they started their career—concepts like “bigger is better” and “standardization.” These concepts date from the Industrial Revolution, when companies didn’t offer customers many choices but customers bought the mass-produced products anyway because they were so inexpensive.

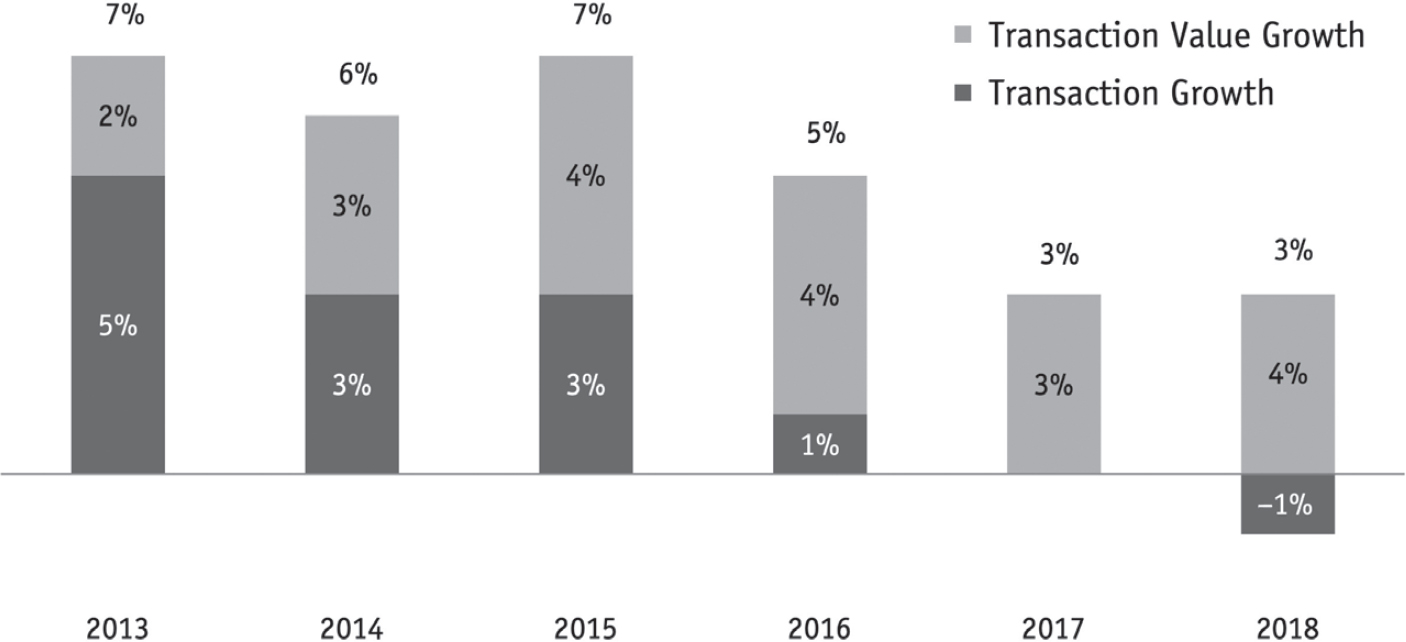

That was then. Now, customers everywhere want personalized products and services, and they want them at affordable prices. Even companies beloved by their customers struggle with this. For example, although millennials love Starbucks and can’t seem to resist a personalized cup of coffee with service, Starbucks’s transactions haven’t increased. That much is public knowledge, as are the company’s repeated price increases. Starbucks’s same-store sales growth has been steadily declining, as figure 14 shows. Same-store growth from transactions was reduced from 5% in 2013 to −1% in 2018, whereas value growth stayed between 2% and 4%. Thus, growth in the United States probably comes from current customers spending more, not more customers coming into the stores.1

The larger lesson here: personalization has to be affordable to attract customers. The younger generations, millennials in particular, want personalized products and services but won’t pay premium prices for them. Thus, affordability is key for all companies now.

FIGURE 14 Starbucks same-store growth (percentage). Source: “Starbucks: Same-Store Sales,” eMarketer Retail, https://goo.gl/DF3Zin.

Personalization is inherently expensive, but it can be made affordable by thinking outside the box about how to design, create, manufacture, and deliver products and services. A few companies are experimenting with personalization, but no one is doing it on a large scale. It’s a big opportunity and a threat to all businesses.

The first to figure out how to produce affordable personalized products will gain huge competitive advantages. To make personalization affordable, leaders will have to think completely differently, create flexible operations, and reduce waste. Big factories producing large volumes won’t work in the new personalization world. Production sizes will become smaller as products are custom-built for each customer. Companies will have to hire skilled labor to produce customized products instead of unskilled labor repeating tasks on production lines. Companies will have to rethink the supply chain and streamline it for different types of customer demands. And at the same time, they will have to find ways to avoid the waste that often comes with customization. Planning and optimizing operations to handle all this will take effort—and solutions will be unique to each company and its customers.

But affordability, being willing to start over completely, and being able to think outside the box are crucial for all companies venturing into personalization. If you’re wondering whether you need to personalize, consider the following questions.

• How adept is your company at addressing customer needs rather than merely selling products or services?

• How personalized are your company’s products or services?

• How affordable are your personalized offerings?

The degree to which you are doing any of these things is the degree to which your company is set up to sell to newer generations. Once millennials and Gen Z start dominating spending—and that will happen within the next five to ten years—everyone, like it or not, will be operating in a new world, with new rules, and personalization is one of them. Your company will either figure out how to personalize or it will wither away.

THE PERSONALIZATION REVOLUTION

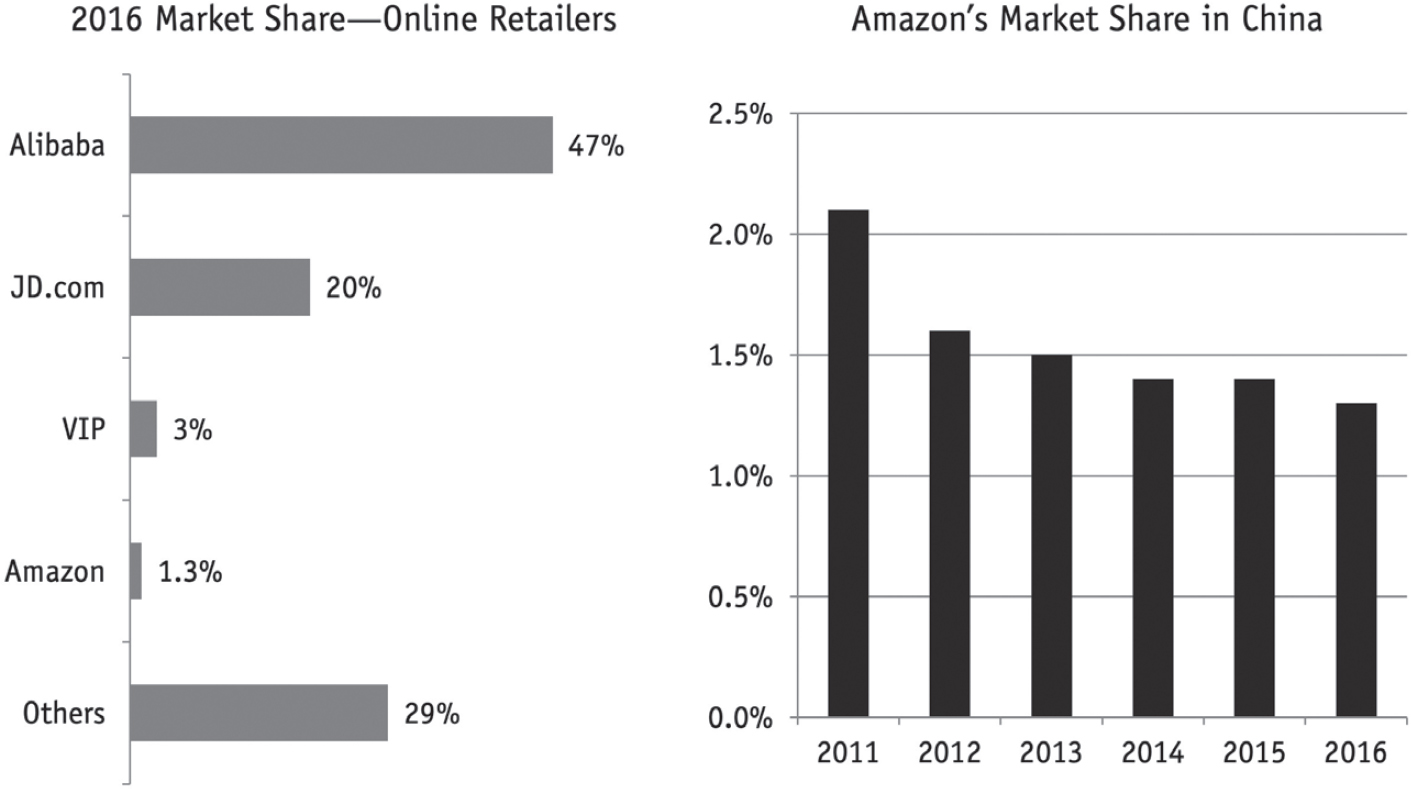

Personalization is revolutionizing customer demand worldwide. Even Japan—once a bastion of luxury goods—has seen luxury companies’ sales decline by 10% to 30%. In countries such as China, India, and others in the Asia-Pacific region, local brands are winning over international brands. Customers in developing markets are looking for products that are tailored to their needs and not to the needs of those in the West. Look at Amazon’s struggle in China. Their 2016 market share was 1.3% of all online retail—down from 2.1% in 2011—while Chinese e-commerce giants Alibaba and JD.com continue to hold a sizable market share (see figure 15).2

So why is the company credited with changing the U.S. retail landscape barely making a dent in China? It’s not nationalism, which is the explanation most Western executives give. It’s that Amazon’s global offering does not attract Chinese customers. Memberships of any kind, even those providing free shipping, aren’t popular in China. This is true of all generations in China.

FIGURE 15 Amazon’s share of China online market. Source: Euromonitor, embedded figure, in Liza Lin and Laura Stevens, “Why Amazon Isn’t Ready for Prime Time in China,” Wall Street Journal, August 27, 2017, https://goo.gl/DKnQHk.

Worldwide, millennials are rejecting the concept of buy, buy, buy—and some boomers are becoming converts as they retire or downsize. Millennials don’t want to pay twenty dollars for movie tickets or hundreds or thousands of dollars on fixing big houses or playing golf at country clubs.3 Many don’t want cars, if they can manage without them (they’d rather live where they can walk or ride-share), or expensive jewelry. They embrace simple living or minimalism, and some of their values are rubbing off on boomers. Some retirees are downscaling to tiny houses. Born out of frustration at too much clutter and growing debt, more and more people in all generations have become aware of how our consumption affects not only our wallets but also our planet. Many are rejecting paper napkins, plastic straws, and even clothes that clutter our landfills. This has resulted in some companies, including Burberry and H&M, burning tons of unsold clothes.4

But although the new generations of shoppers—millennials and Gen Z—are conscious of waste, averse to risk, and less likely to spend money unnecessarily, they do spend money. And they will pay for personalized services they love. Some will pay to have gourmet meals delivered, or even for their own (temporary) butlers or personal chefs.

Companies struggling to remain relevant and profitable can use this trend to breathe new life into their customer connections by offering affordable personalized services. Charging premium prices for “customization”—or, worse, trying to make money off of premium services—won’t work. Coming up with ways to deliver affordable personalization to the masses will, and that will generate far more revenue and profit than premium services for just a select few.

Personalization is becoming increasingly in demand worldwide, and making it affordable is the way forward.

Early Attempts at Personalization

The trend toward personalization started with websites. As customers searching sites grew frustrated at all the irrelevant information, tech companies figured out how to show only relevant content. E-commerce sites took that a step further by recommending new items based on previous purchases—though many early attempts were (and still are) clumsy and annoying. No one likes to be shown a new laptop just after buying one!

Sephora, a cosmetics store, found a novel way to use customer data. They began recommending products based on the shopper’s skin tone. In the past, women often found cosmetics that matched their coloring by trial and error. Sephora alone had 110 shades, and finding the right one took a lot of effort and time on the part of the salesperson and customer. But Sephora customers could create profiles, and with those, Sephora could quickly and easily match products to each shopper. Customers loved the personalized recommendations. While the rest of the retail cosmetics industry declines, Sephora continues to grow.

Other companies are figuring out how to recommend clothes, furniture, and many other items. For example, Stitch Fix and Nordstrom Trunk provide online personal assistant services that could recommend clothes and send a box of them based on customer preference and style. All the customer has to do is complete an interactive questionnaire comparing different styles, and with that, the company learns what the customer likes.

Other ways in which companies are personalizing products include more fun packaging and labeling. To celebrate its fiftieth anniversary in the United Kingdom, Heinz (whose beans are very popular there) gave customers the option of putting their names on the beans can. Similarly, sneaker companies such as Nike and Adidas are providing limited customization by allowing customers to choose shoes’ color, type, and logo size.

However, these efforts are nowhere near the personalization the new generations want. Recommending existing products or services based on customer data and personalization are not personalization. Personalization means creating unique products or solutions based on an individual’s wishes. True personalization wouldn’t be choosing your sneaker color; it would be sneakers made just for you. The sneakers would be shaped precisely for your foot measurements, arch height, and even how you walk or run. So we are a long way from real personalization.

Personalizing Luxury Goods Now

Luxury companies that have successfully weathered many market changes—and even those that offer personalization to a select few—are having a difficult time surviving in the new era. The industry is in a steady decline due to a long, steady decline in new customer growth. Millennials don’t spend on luxury. Fundamentally, luxury brands’ use of exclusivity as an enticement doesn’t resonate with millennials, Gen Z, and some boomers. Instead, these customers prefer more personalized, affordable luxuries. Uber and Airbnb are the new luxury players. They are making luxuries like chauffeur-driven cars and apartments or cottages in desirable locations available to millennials at affordable prices and on demand.

Traditional luxury companies are having a difficult time adjusting. For some time, growth in the luxury business has come from price increases, not volume. Now, when even the rich are reluctant to pay exorbitant prices, luxury goods companies need to reach out to millennials. But they don’t do this well. They shun online sales, and their old ways of advertising don’t resonate with millennials, either. Millennials think of status symbols as excesses of the rich.5 Celebrity endorsements for luxuries don’t fly with millennials.

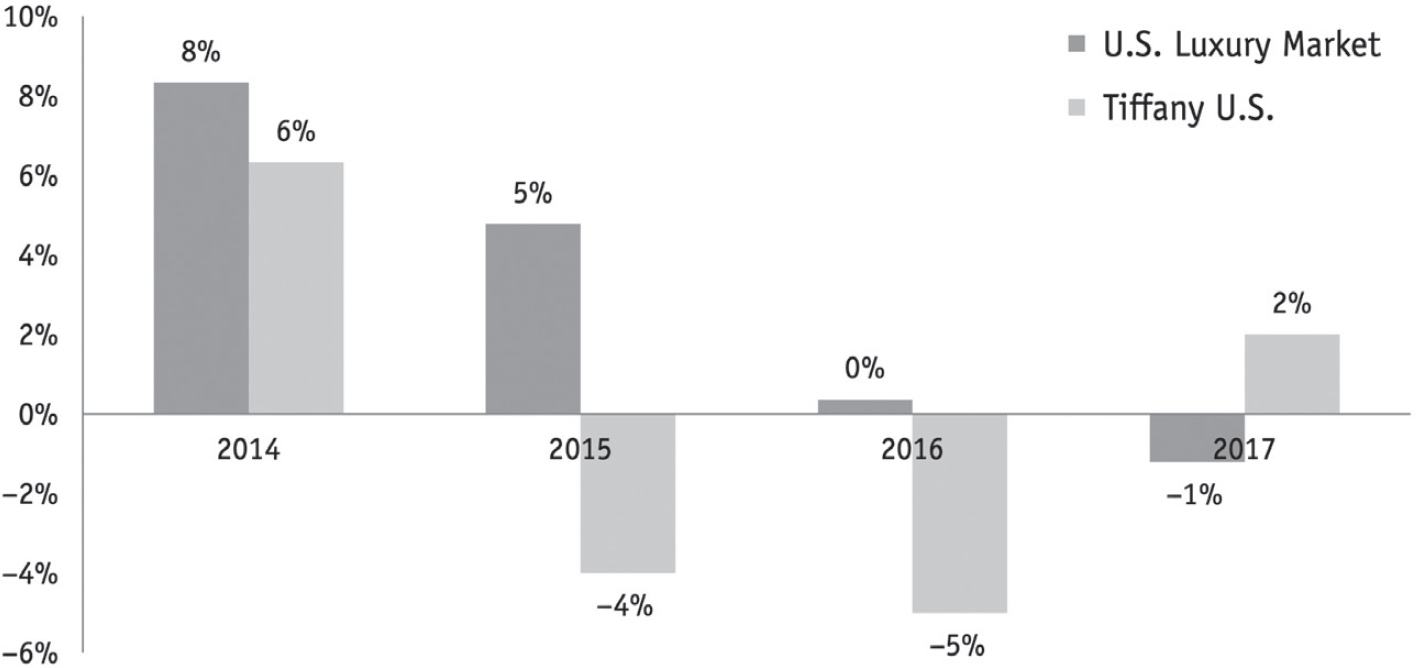

Consider Tiffany. They had a brutal 2016 holiday sales season, and a host of executives, including the CEO, left the company. The trend toward declining sales started in mid-2014 and continued into 2017. Tiffany’s U.S. yearly growth declined from 6% in 2014 to 2% in 2017, while total U.S. luxury market sales declined from 8% to −1% (see figure 16).

FIGURE 16 Year-over-year growth of luxury sales, Tiffany’s and U.S. market. Sources: “Market Value of Luxury Goods in the United States from 2013 to 2018 (in Million U.S. Dollars),” Statistica, https://goo.gl/xoeAWQ; “Tiffany & Co.: Revenues and Sales—Americas,” eMarketer Retail, https://goo.gl/6rf4YL.

Tiffany & Co. is not alone. Other luxury companies are facing troubles as well. Neiman Marcus, Saks Fifth Avenue, and Nordstrom are dealing with a continued sales decline in all markets except China. Even the largest luxury brand, LVMH (Louis Vuitton Moët Hennessy), is cautious about growth prospects.

Disrupters are providing the quality, style, artistry, and design that are associated with luxury goods, at an affordable price point. Luxury goods companies will have a better chance of success if they embrace affordable personalization.

PERSONALIZATION THEN AND NOW

Complexity and costs are the biggest challenges companies face when trying to provide personalization. Before the industrial revolution, all products were personalized. If you needed something, you either made it yourself or you hired someone to make it for you. The cost of many things was so high that only the rich could afford them. In the Middle Ages, for example, a nobleman’s goblet or a lady’s dress could cost as much as a middle-class person’s farm. Most people owned very little.

Then companies began standardizing and mass producing products so that more people could buy them, as Henry Ford did when he made a car for the masses. But there was no choice; as he said, buyers could have their cars painted any color, “as long as it’s black.” There was a trade-off: no choices, but you could actually own a car. There was no option to pay a little more to have red instead of black or four doors instead of two. The production processes didn’t allow for variation. They were designed according to the principles of economy of scale and “bigger is better.”

This is basically how many products are still manufactured, though, over time, companies started providing the customer with some choices. You can now get cars in different sizes and colors, but only the very, very rich can have a car made just for them. You have to pick what’s available in the market. Companies still try to lower costs with bigger factories. Globalization has centralized production even more, with large factories catering to customers all around the world. Think of Apple’s megafactories in China that employ 450,000 people doing repetitive work.

At factories like this, personalization is a disaster waiting to happen. Big factories are geared toward high-volume production, and modifying a single item is difficult. Increased cost and complexity continue beyond production, to managing the new personalized products, marketing them, storing them, and getting them to customers. And besides all this, someone has to customize what is being made for each customer. If you get your clothes tailored, you know that fitting your clothes can cost as much as the clothes themselves. Why? You have to hire a tailor locally, and their time costs more than that of the people making the clothes in other countries.

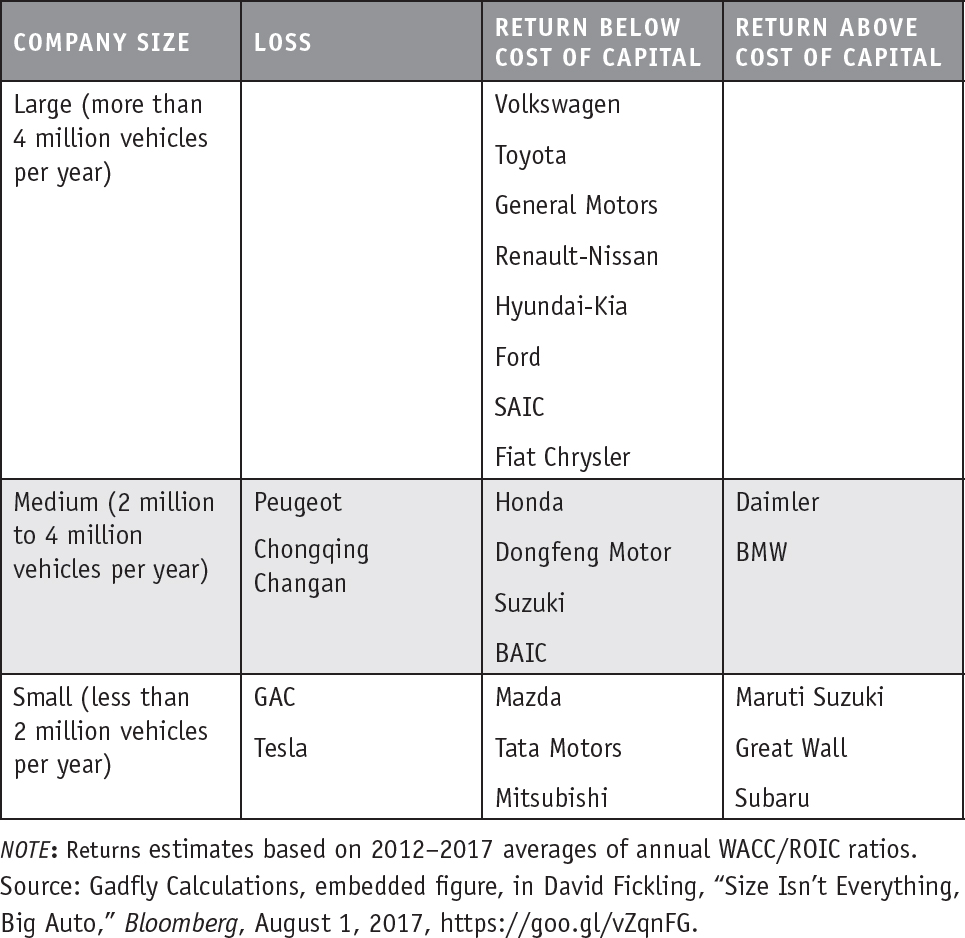

More and more research is showing that, even without personalization, the linkage between volume and profit is diminishing. In some industries, such as the automobile industry, volume is actually an impediment to increasing profit. This is because companies have to produce in such large volumes to keep their factories running that, as customer demand shifts, they either discount the products or write off their production costs. Only five automakers worldwide—Subaru, Great Wall (China), Maruti Suzuki (India), BMW, and Daimler/Mercedes—made money beyond the cost of capital (which is the minimum return expected by investors) during the 2012 to 2017 period.6 As table 2 shows, the companies making money are small to midsize. Big is no longer better in the auto industry!

Subaru is able to deliver returns above the cost of capital because it makes different cars for different customer segments, and does so skillfully. Subaru first focused on customers seeking good off-road vehicles, then expanded its offerings to other segments.7 This strategy brings the company loyal customers who are willing to pay full price—Subaru rarely discounts its cars. So although Subaru is a small company with only one quarter the revenue of Toyota, its profit margin is close to double Toyota’s.

TABLE 2

Size and Profitability of the Auto Industry

Subaru’s small size works well for it. Yasuyuki Yoshinaga, the Subaru CEO, said in May 2017, “We only make a million cars. I have absolutely no intention to make that two million.”8 The fact that Subaru has stayed small and stayed profitable is one more example of how the old bigger is better strategy no longer works, though the rest of the auto industry still seems to think it does.

The concept of scale is getting questioned in other industries, too—in consumer goods, high tech, and many others—as smaller companies have started to beat larger companies with niche products that better address customers’ needs. And this trend will only increase as more and more companies begin to personalize their offerings.

HOW TO DELIVER AFFORDABLE PERSONALIZATION

Whoever figures out how to make personalization affordable will be the next Amazon. Someone will. It is possible, if you do three things.

• First, rethink your offerings. Instead of thinking of them as products and services, think of them as solutions addressing customer needs, for which customers will pay.

• Then overhaul your operations by moving to distributed manufacturing and involving local suppliers.

• Finally, reduce waste.

Companies can only do all of this if they think outside the box and challenge their traditional ways of doing business. There is no one way to do it that will work for all companies. Each company and industry has unique challenges to overcome and advantages to leverage. What is common to all of them, when implementing personalization affordably, is a willingness to start over. Leaders who are prepared to let go of their old assumptions, traditions, and previously successful methodologies and open their minds to new ones are best positioned for reinvention and growth.

Step 1: Rethink Offerings

Most industries think of their offerings as something tangible—products and services. So they create a range of products and try to fit customer needs to them. Look at the apparel industry and its brands. They all produce trousers, shirts, suits, and other garments in a few sizes and fits. You can buy the same shirt at Ralph Lauren, Calvin Klein, Hugo Boss, Michael Kors, Banana Republic, and other stores, with a little variation in fabric or cut. Most will sell you the shirt based on your collar size and body structure (fit). You can expect to pay anywhere from $20 to $200, depending on the brand you choose. Though these companies like you to believe it’s their brand that makes you look better, actually it’s the fabric and how the garment fits your body. That’s why tailoring is coming back in vogue.

What if companies took a different approach and sold individually tailored clothes (offering a selection of fabric and fitting) to each customer? People will love these clothes because they’ll look better in them—and even when they buy them online, the clothes will fit. What we are talking about here goes way beyond what the garment industry now offers, such as suits tailor-made for you. In New York City, that will cost you a few thousand or more, depending on fabric and timing. During the holidays, tailors are busy, and you pay more. After New Year’s, prices drop. Those who don’t want to pay for a custom-made suit can buy one and then have it altered. It will not fit as well as one made for you, but the alterations will cost less.

What doesn’t exist now is an affordable fully tailored suit. Tailors in large metropolitan cities are expensive—not just because of their own cost of living and expenses but because of low volumes. In the past, companies in Hong Kong tailored suits for U.S. customers at affordable prices, through the mail. However, the younger generations in Hong Kong preferred other professions, so tailors were in short supply and prices went up.9

Now, a company called A Suit That Fits is bringing back the concept of bespoke (made to order) suits at an affordable price. You visit a local style advisor, who helps you choose the fabric. They measure you, make the suit in a developing country like India, and then do the final fitting locally. You only have to wait a few weeks—less than you normally wait for a New York tailor to make you a suit. And you will end up paying a quarter of the cost of a bespoke suit made in the United States, and about half what you’d pay for a good suit you had altered.

Why does it cost so much less? The company buys fabric in bulk, uses inexpensive labor, and doesn’t waste any finished products. A lot of factory-made clothes never sell and end up in landfills if they don’t sell after deep discounts. This has a considerable cost. With bespoke suits, there is no waste of the finished products, and the companies can pass these savings on to customers. Not surprisingly, A Suit That Fits is getting rave reviews. The company already has thirty-four studios across the United Kingdom, Ireland, and the United States, and is growing quickly.

Similar approaches could work for much of the garment industry if customers were willing to pay just a little more and companies were willing to think outside of the box. Some companies are already starting. J. Hilburn provides custom-made shirts, trousers, and accessories. Their products are of higher quality and last longer than most. A typical office shirt costs between $100 and $200, and dress pants range from $200 to $600, with a limited selection of fabric. The mass appeal at this price point is likely limited. However, if the company could reduce the cost by 50% or more, it could completely change the apparel industry.

Mtailor, on the other hand, takes your measurements with an app and provides custom-fit clothes at a more reasonable price. They claim that their measurements are 20% better than those of professional tailors. But you don’t get to select the fabric before buying. You have to rely on the company to make the right choice for you.

Companies could offer custom tailoring in a variety of ways—customers could go to a local style advisor, who would measure them (for a fee) or do the measuring themselves, with their smartphones. The company could let customers choose the fabric, then send everything to be made either closer to where the customer lives or offshore. Customers also could be offered flexibility when it comes to delivery; the clothes made close to them might cost more but arrive sooner. Or customers could choose to pay a fixed delivery fee per year, like Amazon Prime customers. Final fittings (if needed) could be done locally, again for a fee. The company could store your measurements and offer seasonal promotions.

Personalization can work affordably in other industries, too. Ride-hailing companies are already offering it, using underemployment and unused cars as resources to provide personalized services. The drivers aren’t making enough money to buy cars, so Uber and others are aggressively pushing for autonomous vehicles to replace their drivers. The user benefits of autonomous vehicles over ride-hailing services is unclear. The assumption is that it will reduce customers’ costs, but the cars’ prices may make the rides just as expensive for customers as hiring a driver. These autonomous cars may be workable only in high-traffic areas such as large cities. In low-traffic suburban areas, autonomous cars could mean higher costs for companies and customers or longer wait times for rides. It’s too soon to tell whether any of these will appeal to people more than current and emerging solutions, such as Via, do.

But what if car companies thought outside the box? Commuters spend a lot of time stuck in traffic. What if a flying taxi took you to work? Drones with electric engines (lighter than gasoline engines) and autonomous flying may make this affordable. As we discussed in chapter 1, Boeing, Airbus, and a host of companies are experimenting with the flying taxi concept. Would you be willing to pay a little more for a faster commute, one that allowed you to live in a less expensive suburb that didn’t work for you when your commute time was longer? More customers might love this kind of economic trade-off and time-saving option.

To make personalization happen, companies will have to change their points of view. They’ll have to think about what to offer and how to deliver it by starting with their customers’ needs, not with their own products. For example, most car companies presently think of themselves as manufacturers of vehicles. If they changed their point of view to start thinking of themselves as providers of transportation services, they’d be more likely to see personalized solutions that appeal to customers.

The same kind of change in thinking is needed in any industry, to make personalization happen. For example, most pharmaceutical companies think of themselves as companies producing medicines. If they thought of themselves as companies that improve their customers’ quality of life and health, they’d succeed better with personalization.

Step 2: Create Flexible Operations

For personalization to work, companies will need operations that can create and deliver individual products in a cost-effective manner. Operations have to become flexible. How this will happen, of course, depends upon the company, but these are some of the ways to make operations flexible enough for affordable personalization.

Rethink manufacturing, from centralized to distributed. The most significant barrier to personalization is how companies think about operations. Most manufacturing sites are designed to produce large volumes with few variations. They employ unskilled labor to do simple jobs and depend on substantial capital investment. They trade flexibility for quantity and low per-unit manufacturing cost.

This trade-off doesn’t work with personalization. To personalize, you need more flexible manufacturing that can create many variations. Companies will have to reduce output to increase variations.

You can see how this could affect the apparel industry. Huge clothing factories producing large volumes with unskilled labor can’t personalize their clothes. Doing that takes tailors who can cut and make clothes for each order differently. So, to personalize, companies will have to hire more skilled workers. They’ll also need to specialize in optimizing processes. Some in the garment industry might produce only men’s suits (which require heavier materials and different cutting tools), while others concentrate on shirts. In other words, you need an entirely new way of thinking about production: distributed manufacturing.

In a distributed manufacturing environment, smaller production sites cater to demands quickly and creatively. The sites are flexible and specialized enough to produce personalized products, which for most companies means hiring and training more skilled labor. Companies can achieve both expertise and savings by using local vendors and talent. Local vendors and talent will bring a host of knowledge about unique local conditions—and possible savings in areas like buying supplies or getting things fixed.

In some industries, new technologies may provide opportunities and possibilities for personalization. For example, 3-D printing is changing how companies make prosthetic arms. You could consider 3-D printing as a form of distributed manufacturing. Instead of buying arms from a medical devices company, hospitals or doctor’s offices print them locally for their patients. In other industries, programmable machines and robots could provide personalized products and services.

The challenge will be to make these affordable for mass adoption. And no one should overly rely on technology; it may be cheaper to use labor. That’s plentiful throughout the world and variable in cost, unlike technology. But we’re still at the beginning of the personalization revolution. The choices may not be that stark, and robots or other things we can’t even imagine today may become affordable aids to humans in the future.

Create different supply chains for different demand. Personalization requires flexible supply chains, too. Most companies have a single supply chain that caters to all customers. This—like all one-size-fits-all approaches—impedes growth. The supply chain gets bogged down by complexity. To achieve flexibility, companies must create supply chains that cater to different demand patterns differently. They need suppliers that specialize in specific areas. For example, suppliers of synthetic clothes may be different from suppliers for cotton clothes. Only by analyzing the customer demand can companies figure out how to best configure their supply base to support their personalized offering.

The critical question is where to separate the supply chain by demand patterns. Do you separate them at supplier, in manufacturing, or at distribution centers? It mostly depends on where the customization is happening. In the case of the apparel industry, if the customization is happening at the manufacturing site, then the supply chains should be separated at manufacturing. However, if fabrics are customized, then the supply chain should be separated from the supplier end. Managing separate supply chains increases cost and effort, so design should be done carefully.

Reduce lead time. The second biggest customer complaint about personalized products is that they take too long to arrive. Though customers love personalized products, they will not wait long for them. Improving supply chain network design, changing the focus of supplier relationships from costs to flexibility, simplifying transaction processing, and improving information connectivity with partners all have been shown to reduce time to market.

In many companies, supply chain designs are rarely reviewed periodically. That won’t work with personalization. Supply chain designs must be evaluated every few years to optimally service changes in demand. And companies should be prepared for this to entail opening or closing manufacturing sites or warehouses.

Suppliers play a critical role in getting products to market in a timely fashion. Most supplier contracts now focus far too heavily on cost and don’t require flexibility. Contracts need to include the capacity to accommodate peak demand, scaling for new products, the ability to switch products quickly, and many other stipulations. Similar conditions also should be specified with logistics providers, contract manufacturers, and any other partners that help the company deliver its products or services to customers.

Transaction processing involves cutting purchase orders, approving invoices, and paying suppliers, among other things. In many companies, processing transactions has become highly bureaucratic, with multiple approvals required to reduce risk. In some cases, getting a purchase order takes as long as getting a supplier to deliver products! To respond quickly, companies must simplify the process—and they must do that without compromising on risk. Technology can help. Catalogs with agreed pricing and algorithms to flag exceptions can streamline transaction processing significantly.

Sharing information with suppliers continues to be a challenge in many industries. Companies have invested heavily in enterprise resource planning systems to get up-to-date information about demand and supply. Unfortunately, many still use e-mails to share order and other transaction information with their suppliers. This not only introduces error but also significantly increases lag time, since someone has to code the e-mailed information into the software. A better approach would be to link the information systems with suppliers, with adequate network protection against hacking. Many companies reply to this suggestion with the excuse that connecting with the supplier systems is too expensive. However, this doesn’t wash. The cost of connecting with supplier systems has gone down significantly in recent years—and the benefits far outweigh the costs.

Step 3: Reduce Raw Material Waste

Waste of raw material is a real concern in a personalized product world because every order is different and has to be made to customer specification. In some industries, a significant amount of material could be wasted. In the apparel industry, for example, cutting out one garment from a few yards of fabric instead of using the same fabric for thousands of garments and using almost every scrap—could waste fabric. So it’s essential that operations be designed efficiently to reduce waste throughout the process. For example, to minimize waste, computer programs could be created that would optimize fabric utilization based on current and anticipated demand. Without this kind of planning, personalized products can’t be affordable. Optimization of operations will become one source of competitive advantage.

Affordability is vital to personalization. Companies that achieve it sustainably will dominate their markets.

MAKING AFFORDABLE PERSONALIZATION A REALITY

Personalization is a 180-degree change for most corporations. They are all tuned for mass production and would rather sit out the personalization fad. But new generations have made the fad a permanent reality. You either choose to play or go home.

With Sephora and others, we see very initial efforts at personalization. They are matching personal customer information with products that fit customer preference. Vistaprint and Shutterfly are making personalized photo albums, enabling users to design their own photo albums with a variety of layouts, fonts, and colors. Squarespace is doing the same for websites, offering hundreds of different templates for customized looks. Services like these cost a fraction of what a graphic designer would charge. More and more retailers are providing personal stylist services, if users are willing to share their personal preferences. However, we are still a long way from real personalization.

The challenges with personalization stem primarily from the costs associated with providing these services. To make personalization a reality, companies will have to think differently. They have to think from a customer’s perspective instead of beginning from their products and services. Affordability is key—and the benefits to both companies and their customers could literally be life-changing.

Consider health care. Today, only the rich in the United States receive home visits and 24/7 access to their own personal doctor. Everyone else has to visit a hospital or doctor’s office—and usually wait. But what if you could have a video visit with a doctor in India or in another country, where health care costs less than it does in the United States? The cost—in both time and money—of answers to non-emergency medical questions could become significantly cheaper. You’d still have to visit a lab for blood work, but the rest could be monitored from a distant location through your smartphone. Only in an emergency would you need to go to a hospital. Health care could become personalized and affordable—if only we think outside the box instead of optimizing an old model.

The stakes may not be as high in other industries—for customers—but the rewards for outside-the-box thinking can be just as high for companies. And in any industry, companies that don’t offer their customers personalized products and services at affordable prices will lose out to companies that do. As millennials and Gen Z become the dominant buying group, the demand for personalized services will increase significantly.

This is both an opportunity and a threat. It’s a threat because none of today’s dominant companies have invested significantly in personalization and are still running on old paradigms. But it’s an opportunity because no one knows who the winners will be. Whoever they are—upstarts or established companies thinking outside the box and unafraid to start over—they will be the next Apples or Amazons, companies that will dominate for a long time. Personalized services are sticky; once customers find a company that gives them exactly what they want, personalized just for them, they keep coming back.