CHAPTER 5

FINITE ELEMENT FORMULATION: LARGE-DEFORMATION, LARGE-ROTATION PROBLEM

In the preceding chapters, the general nonlinear continuum mechanics theory was presented. In order to make use of this theory in many practical applications, a finite dimensional model must be developed. In this model, the partial differential equations of equilibrium are written using approximation methods as a finite set of ordinary differential equations. One of the most popular approximation methods that can be used to achieve this goal is the finite element method. In this method, the spatial domain of the body is divided into small regions called elements. Each element has a set of nodes, called nodal points, that are used to connect this element with other elements used in the discretization of the body. The displacement of the material points of an element is approximated using a set of shape functions and the displacements of the nodes and possibly their derivatives with respect to the spatial coordinates. In this case, the dimension of the problem depends on the number of nodes and number and type of the nodal coordinates used.

Small- and Large-Deformation Problems

In the literature, there are many finite element formulations that are developed for the deformation analysis of mechanical, aerospace, structural, and biological systems. Some of these formulations are developed for small-deformation and small-rotation linear problems, some for large-deformation and large-rotation nonlinear analysis, and the others for large-rotation and small-deformation nonlinear problems. Several numerical solution procedures and computational algorithms are also proposed for solving the resulting system of finite element differential equations.

The following chapter is devoted to the important nonlinear problem of small deformation and large rotation of flexible bodies, which is typical of multibody system (MBS) applications. In the case of small deformations, one can use more efficient formulations that employ smaller number of coordinates. These formulations, as will be discussed in the following chapter, allow for filtering out complex deformation shapes associated with high-frequency modes of oscillations while ensuring correct description of arbitrary rigid-body displacements. To this end, the concept of the intermediate element coordinate system will be introduced. The treatment of the more general problem of large deformation and large rotation, on the other hand, does not allow for such an efficient use of the techniques of coordinate reduction because the shape of deformations can be very complex and higher-order models are required in order to be able to capture the details of the deformation shapes. Nonetheless, in many large-deformation applications, one deals with softer materials that do not exhibit high-frequency oscillations, and for this reason, large-deformation formulations can be efficiently used.

Absolute Nodal Coordinate Formulation (ANCF)

In this chapter, a more general large-rotation and large-deformation finite element formulation is discussed. This formulation, which is called the absolute nodal coordinate formulation (ANCF), imposes no restrictions on the amount of rotation or deformation within the finite element. In addition to its simplicity and its consistency with the nonlinear theory of continuum mechanics, the absolute nodal coordinate formulation has several advantages as compared to other large-rotation and large-deformation finite element formulations that exist in the literature. This formulation leads to a constant mass matrix and zero centrifugal and Coriolis forces; allows for the use of general constitutive models in case of beams, plates, and shells; and accounts for the dynamic coupling between the rigid-body motion and the elastic deformation.

There are three conditions that must be met in order to have the absolute nodal coordinate formulation discussed in this chapter. First, the problem under investigation must be a dynamic problem in order to address the formulation of the inertia forces. Second, consistent mass formulation must be used because lumped mass formulations do not lead to a correct representation of the rigid-body dynamics (Shabana, 2013). Third, global gradients or slopes obtained by differentiation of absolute position vectors with respect to the spatial coordinates are used as nodal coordinates in order to ensure continuity of rotation parameters. The latter requirement is particularly important when finite elements are assembled. In the assembly process, proper gradient transformation must be used instead of the vector transformation often used in the finite element literature. Gradients are tangent to coordinate lines, and therefore, for two gradient vectors to be equal they must be tangent to the same coordinate line. Understanding the concept of gradients is crucial in the ANCF implementation, particularly when discontinuities or initially curved structures are considered. Using ANCF finite elements one can develop a nonincremental solution procedure for solving large-deformation problems.

Chapter Organization

This chapter is organized as follows. In Section 1, the displacement field and coordinates of the finite element are defined. In Section 2, the element connectivity conditions are introduced. In Section 3, the finite element inertia and elastic forces are formulated, whereas in Section 4 the virtual work of the inertia and elastic forces of the element is used to formulate the virtual work expression of the equations of motion of the finite element. This virtual work expression is used to obtain the equations of motion of the deformable body by assembling the equations of its finite elements. Because ANCF finite elements leads to a nonlinear expression of the elastic forces, one must resort in general to evaluate numerically the integrals of these elastic forces, as discussed in Section 5. In Section 6, the basic differential geometry theories of curves and surfaces are briefly reviewed in order to help the reader better understand the modes of deformations of beams, plates, and shells. In Sections 7–13, several examples of two- and three-dimensional finite element shape functions are presented, and the procedures for formulating the elastic forces of these elements are outlined. In Section 14, the performance of the finite elements is discussed, including topics such as the patch test; shear, membrane, and volumetric locking; and reduced and selective integrations. In Section 15, other large-deformation finite element formulations used in the literature are discussed and compared with the ANCF presented in more detail in this chapter. The formulations of the dynamic equations obtained using the updated Lagrangian and Eulerian approaches are compared in Section 16.

5.1 DISPLACEMENT FIELD

In the finite element method, as previously pointed out, the domain of the body is divided into small regions called elements. Assuming that these elements are small, one can use low-order polynomials to describe the displacement field of the element. For example, if the deformation of the body is negligible or small, only six coordinates are sufficient to define the rigid-body translation and rotation. In this special case, first-order polynomials can be used to describe exactly the rigid-body motion. For a small finite element on a deformable body, on the other hand, the deformation within the element can be in general much smaller than the overall deformation of the body, and therefore, one can still justify using a lower-order polynomial to describe the displacement of a small region on the body. After introducing the low-order polynomials to define the equations of motion of the finite elements, the body equations of motion can be obtained by assembling the equations of motion of its elements using the connectivity conditions at the finite element boundaries. By using this procedure, one can develop a powerful tool for the computer-aided analysis of structural components that have complex geometric shapes.

Separation of Variables

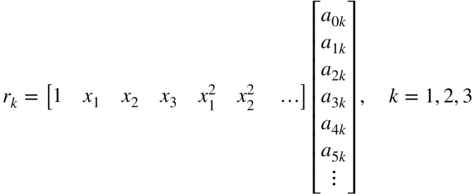

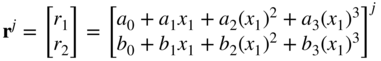

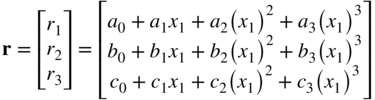

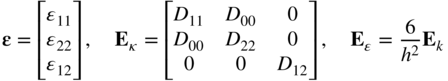

Finite element approximations are based on the concept of the separation of variables briefly introduced in Chapter 1 and used in the examples presented in several chapters of this book. The displacement of the finite element can be written as the product of two sets of functions: one set depends on the spatial coordinates, whereas the other set depends on time only. The separation of variables can conveniently be achieved by assuming that the position vector of arbitrary material points on the element can be written as polynomials of the spatial local coordinates of the element. The coefficients of these polynomials in the case of dynamics are the time-dependent variables. One can select points on the element, called nodes, and assign variables such as displacements, rotations, and slopes as nodal coordinates. Knowing the coordinates of these nodes in the reference configuration, one can write a set of algebraic equations using the assumed polynomial displacement field and determine the polynomial coefficients in terms of the nodal variables. In the formulation discussed in this section, all the components of the position vector are interpolated using polynomials that have the same order. For example, for a given domain defined by the spatial coordinates x1, x2, and x3, the kth component of the position vector can be written as

The coefficients aik, i = 0, 1, 2, 3, …, in the case of dynamics, are assumed to depend only on time. In this case, the above assumed displacement field can be written as the product of functions that depend only on the spatial coordinates x = [x1 x2 x3]T and a vector of time-dependent coordinates. To see this separation of variables, the preceding equation can be written as

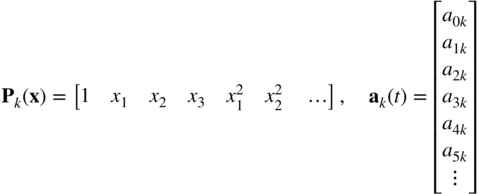

Denoting the space-dependent row in this equation as Pk(x) and the time-dependent vector as ak(t), the preceding equation can be written as

where

One can select, as discussed in Chapter 1 and demonstrated by the examples presented at the end of this section, position coordinates and possibly spatial derivatives of the coordinates at selected points and write the coefficients ak(t) in terms of these position coordinates and their derivatives. The number of the selected position coordinates and their derivatives must be equal to the number of the polynomial coefficients in order to have a number of algebraic equations, which can be solved for these coefficients. Let e be the vector of coordinates that may include position coordinates and their spatial derivatives at selected points at known local positions on the element. Substituting the values of the spatial coordinates in the preceding equation, one can write the following relationship between the selected coordinates and the coefficients of the polynomial:

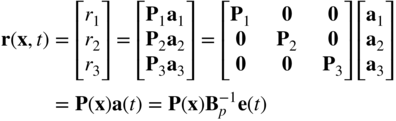

where Bp is a constant square nonsingular matrix and a is the total vector of the polynomial coefficients. The preceding equation can be solved for the coefficients a in terms of the selected coordinates as ![]() . Substituting this equation into the assumed displacement field of Equation 3, one can write the displacement field in terms of the selected coordinates as

. Substituting this equation into the assumed displacement field of Equation 3, one can write the displacement field in terms of the selected coordinates as

In this equation,

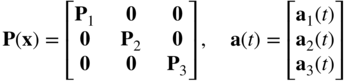

One, therefore, can write the position vector r using Equation 6 as

where ![]() . In this approach, S(x) is called the shape function matrix. The position vector field can then be written as the product of the space-dependent matrix S(x) and the vector of time-dependent coordinates e(t).

. In this approach, S(x) is called the shape function matrix. The position vector field can then be written as the product of the space-dependent matrix S(x) and the vector of time-dependent coordinates e(t).

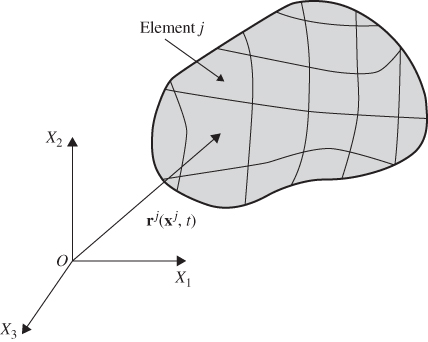

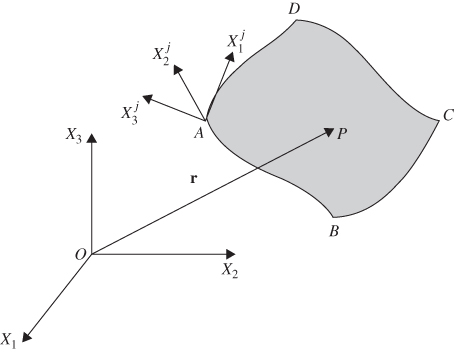

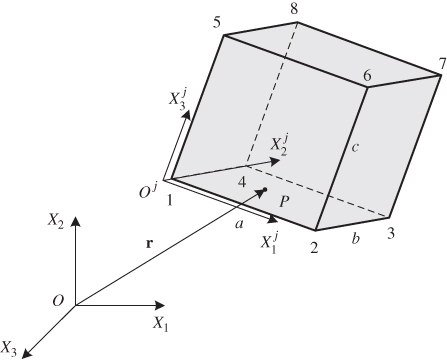

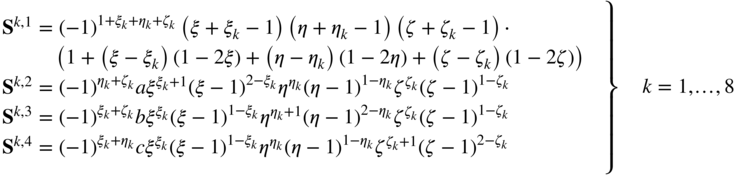

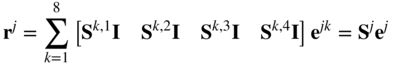

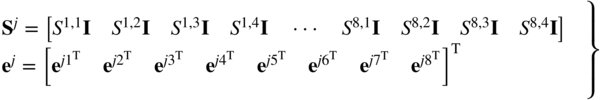

Using this approach of the separation of variables, and assuming that the continuum is divided into a number of ne finite elements as shown in Figure 1, the displacement field of a finite element j can be written as

Figure 5.1 Finite element discretization

where rj is the global position vector of an arbitrary point on the finite element j as shown in Figure 1, Sj = Sj(xj) is a shape function matrix that depends on the element spatial coordinates ![]() defined in the element reference configuration, and ej = ej (t) is the vector of time-dependent nodal coordinates that define the displacements and possibly their spatial derivatives at a set of nodal points selected for the finite element.

defined in the element reference configuration, and ej = ej (t) is the vector of time-dependent nodal coordinates that define the displacements and possibly their spatial derivatives at a set of nodal points selected for the finite element.

Modes of Displacement

The selection of the number of nodal points and the number of coordinates at each node is one of the important factors that determine the accuracy of the finite element approximation. The general theory of continuum mechanics discussed in this book shows that the matrix of position vector gradients leads to nine independent modes of displacements for an infinitesimal volume at a material point. The polar decomposition theorem shows that the matrix of position vector gradients can be decomposed as the product of an orthogonal matrix and a symmetric matrix. The orthogonal matrix is function of three independent parameters that define the rotation of the infinitesimal volume, whereas the symmetric matrix is a function of six independent deformation parameters that define the strain components. Therefore, if the translation of the infinitesimal volume is considered, one has a total of 12 displacement modes for the infinitesimal volume: 3 translations, 3 rotations, and 6 deformation modes. Motivated by this simple and general continuum mechanics description of the motion of the infinitesimal volume, the vector of nodal coordinates can be selected in the three-dimensional analysis to consist of three translations and nine components of the position vector gradients. The nine components of the position vector gradients account for three rotations and six deformation modes. In this case, the vector of nodal coordinates ej of the finite element at a node k can be written as

where rjk is the absolute (global) position vector of the node k of the finite element j and ![]() is the vector of position gradients obtained by differentiation with respect to the spatial coordinate xl, l = 1, 2, 3. Note that

is the vector of position gradients obtained by differentiation with respect to the spatial coordinate xl, l = 1, 2, 3. Note that ![]() is the matrix of the position vector gradients at node k, where

is the matrix of the position vector gradients at node k, where ![]() . Note also that the last three vector elements of the vector of nodal coordinates ejk in Equation 10 are the columns of the matrix of position vector gradients

. Note also that the last three vector elements of the vector of nodal coordinates ejk in Equation 10 are the columns of the matrix of position vector gradients ![]() that enters in the formulation of the strain tensors. It is important that the chosen assumed displacement field and nodal coordinates correctly describe an arbitrary displacement including rigid-body displacement. This is an essential requirement, particularly in problems in the field of MBS dynamics in which the system components may undergo finite rotations.

that enters in the formulation of the strain tensors. It is important that the chosen assumed displacement field and nodal coordinates correctly describe an arbitrary displacement including rigid-body displacement. This is an essential requirement, particularly in problems in the field of MBS dynamics in which the system components may undergo finite rotations.

Nodal Coordinates

In the finite element literature, one can find a large number of finite elements that have been developed to suit varieties of applications. Some elements take the shape of trusses, some the shape of beams, some the shape of rectangle, triangle or plate, solid (prism), tetrahedral, and many other shapes. These elements employ different numbers and types of nodal coordinates. For example, solid, triangle, rectangle, and tetrahedral elements employ, for the most part, only displacement coordinates. Rotations, slopes, or gradients are not commonly used for these elements. Conventional beam, plate, and shell elements employ, in addition to the displacement coordinates, infinitesimal rotation coordinates. Arbitrary rigid body motion, however, cannot be defined as linear functions of infinitesimal rotations. Some newer beam, plate, and shell elements use finite rotations as nodal coordinates and define a rotation field that is independent from the displacement field. Because in the general theory of continuum mechanics, the rotation field is defined from the displacement field using the matrix of position vector gradients, the use of an independent finite rotation field can lead to coordinate redundancy, which can be a source of fundamental and numerical problem (Ding et al., 2014). Discussion on other types of finite elements and finite element formulations is presented in a later section.

In the ANCF discussed in this chapter, no infinitesimal or finite rotations are used as nodal coordinates. In this formulation, only absolute position vectors consistent with the general continuum mechanics are interpolated, and the position vector gradient field is obtained by differentiation of the position vector field with respect to the spatial coordinates of the finite element. As will be shown in this chapter, in addition to having a description consistent with the general continuum mechanics theory, the formulation discussed in this chapter has many unique features that make it suited for the analysis of large deformation and large rotation of very flexible structures.

5.2 ELEMENT CONNECTIVITY

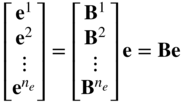

In order to obtain the equations of motion of the continuum, the finite elements that form the continuum domain must be properly connected at the nodal points. Let the vector of nodal coordinates of all elements before connecting them be denoted as eb. This vector is then given by

where ej is the vector of nodal coordinates of the finite element j and ne is the total number of finite elements. Let e be the vector of all nodal coordinates of the continuum after the elements are connected. It is assumed that the finite element coordinates are defined in the same coordinate system as the continuum coordinates. The case in which the element nodal coordinates are defined in a coordinate system different from the continuum reference coordinate system will be also discussed. The vector of the element j coordinates can be written in terms of the nodal coordinates of the body as

where Bj is a Boolean matrix that includes zeros and ones and maps the element coordinates to the body coordinates. If the finite elements have different orientations, which is the case of slope discontinuity, a constant transformation can be defined and can be systematically introduced into the preceding equation (Shabana and Mikkola, 2003; Shabana, 2011). In this case, one can first define the element coordinates by the vector ēj and write this vector in terms of element nodal coordinates defined in the same coordinate system as the continuum (body) nodal coordinates, that is, ēj = Tjej, where Tj is an element transformation matrix (Shabana and Mikkola, 2003; Shabana, 2011) and ej is a vector of nodal coordinates defined in the same coordinate system as the body nodal coordinates. The Boolean matrix Bj can then be used to write the vector of the element nodal coordinates in terms of the body nodal coordinates as ēj = TjBje. In the case of using position vector gradients as nodal coordinates, a proper transformation for the gradients must be used. In the remainder of this chapter, for simplicity, we will assume that such a transformation is applied and use Equation 12 with the understanding that the element and the body nodal coordinates ej and e are properly defined in the same coordinate system.

Using Equation 12, one can then write

where B is the Boolean matrix formed using the element Boolean matrices as

This matrix has a number of rows equal to the dimension of the vector eb and a number of columns equal to the dimension of the vector e. This procedure of assembling the finite elements is demonstrated by the following simple example.

5.3 INERTIA AND ELASTIC FORCES

In this section, the formulation of the finite element inertia and elastic forces is discussed. It will be shown that the finite element formulation discussed in this chapter leads to a simple expression for the inertia forces and to a more complex expression for the elastic forces. This is in contrast with the floating frame of reference (FFR) formulation discussed in the following chapter and used mainly for the small-deformation, large-rotation analysis. The FFR formulation leads to a complex expression for the inertia forces and to a simple expression for the elastic forces.

Inertia Forces

In order to formulate the inertia forces of the finite element, one must obtain an expression for the acceleration vector. Differentiating the global position vector of Equation 9 with respect to time, the absolute velocity vector vj of an arbitrary material point on the element j can be written as

Differentiating this equation with respect to time, the acceleration vector aj can be written in the case of the ANCF as

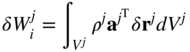

The virtual work of the inertia forces of the finite element can then be defined as

where ρj and Vj are, respectively, the mass density and volume of the finite element. It is important to point out that because of the principle of conservation of mass, ρjdVj = constant, the mass density ρj, and the volume Vj in the reference configuration can be used. For the simplicity of the notation in this chapter, we use ρj instead of ![]() to denote the density in the reference configuration because in most of the developments presented in this chapter and the following one, the inertia can be formulated using the reference configuration. A specific mention will be made if ρj is the mass density associated with the current configuration, as it is the case when the equations that govern the fluid motion are discussed.

to denote the density in the reference configuration because in most of the developments presented in this chapter and the following one, the inertia can be formulated using the reference configuration. A specific mention will be made if ρj is the mass density associated with the current configuration, as it is the case when the equations that govern the fluid motion are discussed.

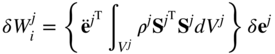

The virtual change in the position vector of the material point can be written as

Using the preceding two equations with the expression for the acceleration of Equation 16 and keeping in mind that the time-dependent nodal coordinates do not depend on the spatial coordinates and can be factored out of the integration sign, one obtains the following equation for the virtual work of the inertia forces:

This equation can be written as

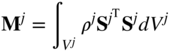

where Mj is the symmetric mass matrix of the finite element j defined as

This mass matrix is constant in both two- and three-dimensional cases. This is a unique feature of the ANCF because other known three-dimensional finite element formulations that give complete information about the rotation at the nodes and use infinitesimal or finite rotation parameters as nodal coordinates do not lead to a constant mass matrix in the case of three-dimensional analysis. This important property of the formulation simplifies the governing equations significantly since it leads to zero centrifugal and Coriolis forces when the body experiences an arbitrary large deformation and finite rotation.

By using the preceding equations, the virtual work of the inertia forces can be written as

where ![]() is the vector of the inertia forces that takes the following simple form:

is the vector of the inertia forces that takes the following simple form:

One can show that, for many ANCF finite elements, the mass matrix remains the same under an orthogonal coordinate transformation.

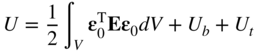

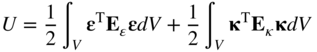

Elastic Forces

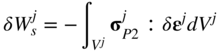

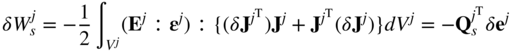

An expression for the virtual work of the stresses of the continuum was obtained in Chapter 3 in terms of the Green–Lagrange strain tensor and the second Piola–Kirchhoff stress tensor. For the finite element j, the virtual work of the stresses can be written as

In this equation, ![]() is the second Piola–Kirchhof stress tensor and ϵj is the Green–Lagrange strain tensor at an arbitrary material point on the finite element j. The stress and strain tensors used in Equation 24 are defined in the reference configuration. The virtual strain can be expressed in terms of the virtual changes of the position vector gradients as

is the second Piola–Kirchhof stress tensor and ϵj is the Green–Lagrange strain tensor at an arbitrary material point on the finite element j. The stress and strain tensors used in Equation 24 are defined in the reference configuration. The virtual strain can be expressed in terms of the virtual changes of the position vector gradients as

The second Piola–Kirchhoff stresses are related to the Green–Lagrange strains using the constitutive equations

where Ej is the fourth-order tensor of elastic coefficients. Substituting the preceding two equations into the expression of the virtual work of the stresses, using the definition of the matrix of position vector gradients, and using the expression of the gradients in terms of the finite element nodal coordinates, one can show that the virtual work of the stresses of the finite element j can be written as

In this equation, ![]() is the vector of the elastic forces associated with the nodal coordinates of the finite element j. This vector, which is the result of the deformation of the continuum, takes a more complex form as compared to the simple expression of the inertia forces obtained previously in this section. Because the integrals for the stress forces are, in general, highly nonlinear functions in the nodal and spatial coordinates, numerical integration methods are often used for the evaluation of the nonlinear generalized stress forces.

is the vector of the elastic forces associated with the nodal coordinates of the finite element j. This vector, which is the result of the deformation of the continuum, takes a more complex form as compared to the simple expression of the inertia forces obtained previously in this section. Because the integrals for the stress forces are, in general, highly nonlinear functions in the nodal and spatial coordinates, numerical integration methods are often used for the evaluation of the nonlinear generalized stress forces.

5.4 EQUATIONS OF MOTION

The equations of motion of the finite elements that form the body can be developed using the principle of virtual work in dynamics (Roberson and Schwertassek, 1988; Shabana, 2001). In the case of unconstrained motion, the principle of virtual work for the continuum can be written as

In this equation, δWi is the virtual work of the inertia forces of the body, δWs is the virtual work of the elastic forces due to the deformation, and δWe is the virtual work of the applied forces such as gravity, magnetic, and other external forces. For instance, the virtual work of an external force Fj acting at a point P defined by the coordinates ![]() on the finite element j can be written as

on the finite element j can be written as

where ![]() is a constant matrix that defines the element shape function at point

is a constant matrix that defines the element shape function at point ![]() and

and ![]() is the vector of generalized forces associated with the element nodal coordinates ej as the result of the application of the force vector Fj. This vector of generalized forces is defined as

is the vector of generalized forces associated with the element nodal coordinates ej as the result of the application of the force vector Fj. This vector of generalized forces is defined as

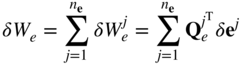

A similar expression can be obtained for all forces acting on the finite elements. One can then write the virtual work of the applied forces acting on the continuum by summing up the virtual work of the forces acting on its finite elements, that is,

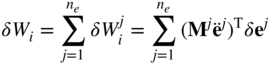

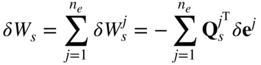

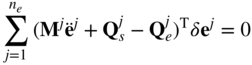

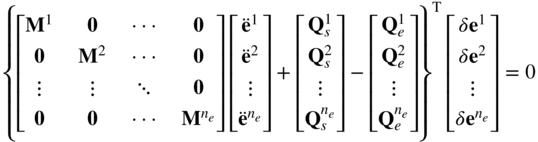

The virtual work of the inertia forces of the body can be obtained by summing up the virtual work of the inertia forces of its finite elements. Using the expression of the virtual work of the finite element inertia forces obtained in the preceding section, one can write

Similarly, the virtual work of the stress forces of the body can be written as

Substituting the preceding three equations into the principle of virtual work in dynamics of Equation 28, one obtains

This equation can also be written as

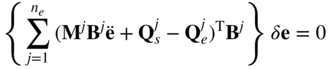

Because δej = Bjδe and ëj = Bjë, where Bj is a Boolean matrix that defines the element connectivity and e is the vector of the body nodal coordinates, Equation 34 can be written in terms of the nodal coordinates of the body as

If the body motion is unconstrained, the elements of the vector δe are independent, and as a consequence, their coefficients in the preceding equation must be equal to zero, that is,

By performing the summation in this equation, one can show that the finite element equation of motion of the body can be written as

where M is the body symmetric mass matrix, Qs is the vector of body elastic forces, and Qe is the vector of the body applied forces. The mass matrix and force vectors that appear in the preceding equation are obtained from the mass matrices and force vectors of the finite elements as

In the finite element formulation discussed in this chapter, the body mass matrix is constant, and therefore, the vectors of centrifugal and Coriolis forces are identically equal to zero in this formulation. The vector of the body elastic forces due to the stresses, on the other hand, is a nonlinear function of the nodal coordinates, as discussed in the preceding section. The fact that the mass matrix is constant can be utilized in developing a computational algorithm for solving the finite element equations. In this case, there is no need to iteratively perform the LU factorization of this matrix. One can use a transformation based on Cholesky coordinates that leads to an identity mass matrix (Shabana, 1998). Such a coordinate transformation leads to an optimum sparse matrix structure when ANCF finite elements are used in MBS algorithms.

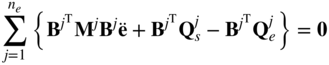

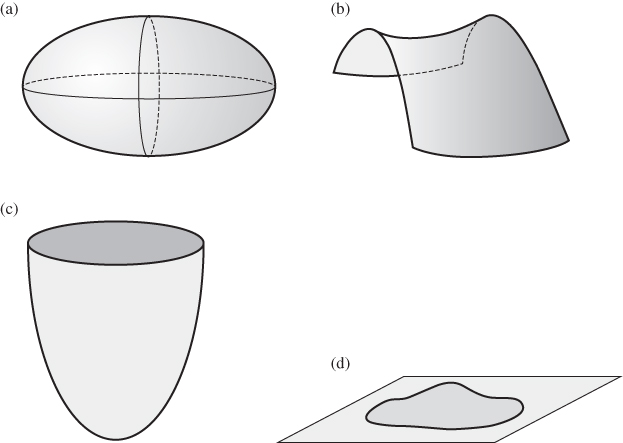

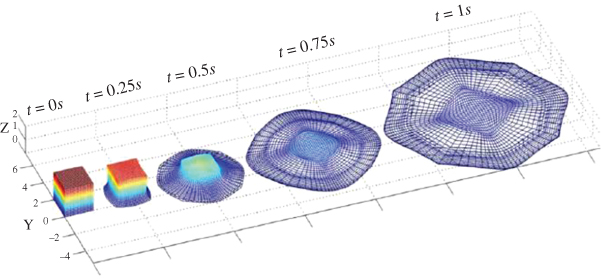

Curved Geometry

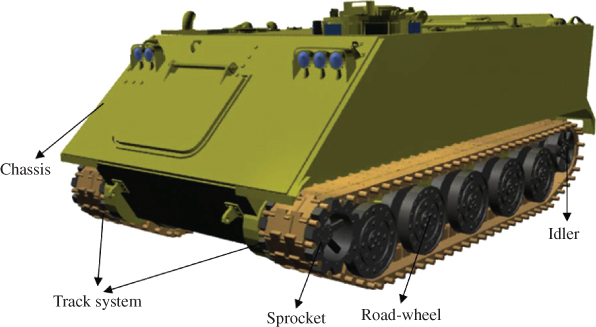

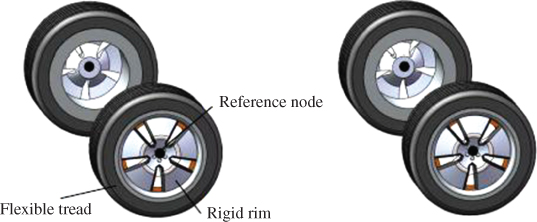

ANCF finite elements can be used to conveniently describe complex shapes. These shapes can represent curved geometry in the undeformed reference configurations. In these cases, the position vector gradients in the undeformed reference configuration are not orthogonal unit vectors because of the continuum initial geometry. Examples of these applications, which were presented in Chapter 2 and include tires, belt drives, and tank cars, are shown in Figure 4. As discussed in Chapter 2, in these cases, the strains evaluated using the matrix of position vector gradients in the initial configuration must be identically equal to zero. In order to explain how the strains are formulated in these cases of initial curved geometry, the three different configurations shown in Figure 5 were considered in Chapter 2. Because complex geometries can always be obtained by changing the shape of simple objects, the first configuration in Figure 5 depicts the simple geometry, which can represent straight metal sheets described conveniently using ANCF finite elements. In this simple geometry configuration, the location of the material points is defined using the position vector ![]() of the ANCF element or an assembly of ANCF finite elements. The second configuration is the reference configuration, which defines the initial undeformed geometry. In this undeformed reference configuration, the position of the material points is defined by the vector

of the ANCF element or an assembly of ANCF finite elements. The second configuration is the reference configuration, which defines the initial undeformed geometry. In this undeformed reference configuration, the position of the material points is defined by the vector ![]() . One can write

. One can write ![]() , where

, where ![]() , and the superscript that indicates the finite element number is dropped for simplicity. The third configuration shown in Figure 5 defines the current deformed configuration. In this configuration, the position of the material points is defined by the vector

, and the superscript that indicates the finite element number is dropped for simplicity. The third configuration shown in Figure 5 defines the current deformed configuration. In this configuration, the position of the material points is defined by the vector ![]() . As discussed in Chapter 2, one can write

. As discussed in Chapter 2, one can write ![]() , with

, with ![]() . It follows that

. It follows that ![]() , where

, where ![]() .

.

Figure 5.4 Initial geometry

Figure 5.5 ANCF description of curved geometry

The volume of the curved structure ![]() is related to the volume of the straight structure

is related to the volume of the straight structure ![]() (Figure 5) using the relationship

(Figure 5) using the relationship ![]() , where

, where ![]() is the determinant of the matrix of position vector gradients

is the determinant of the matrix of position vector gradients ![]() . Therefore, integration with respect to the domain

. Therefore, integration with respect to the domain ![]() can be converted to integration with respect to the straight domain

can be converted to integration with respect to the straight domain ![]() by using the transformation

by using the transformation ![]() . This allows for using the original dimensions of the simpler geometry to carry out the integrations associated with the initially curved configuration. Note that the matrix

. This allows for using the original dimensions of the simpler geometry to carry out the integrations associated with the initially curved configuration. Note that the matrix ![]() is constant.

is constant.

The matrix of position vector gradients ![]() is the matrix, which is used to determine the Lagrangian strain tensor

is the matrix, which is used to determine the Lagrangian strain tensor ![]() as

as ![]() . This matrix can be defined using the ANCF description as

. This matrix can be defined using the ANCF description as

where, as previously defined, ![]() . Therefore, the Lagrangian strain tensor can be written as

. Therefore, the Lagrangian strain tensor can be written as

Note that the relationship between the volume in the current deformed configuration ![]() and the volume in the curved reference configuration

and the volume in the curved reference configuration ![]() can be written as

can be written as ![]() , where

, where ![]() is the determinant of the matrix of position gradients

is the determinant of the matrix of position gradients ![]() . It follows that

. It follows that ![]() . Using the relationship

. Using the relationship ![]() , one has

, one has ![]() .

.

As mentioned in Chapter 2, the procedure described in this section to model the initial curvature, which is the same as the one used in the literature for modeling the initially curved configuration of belt drives and rubber chains (Dufva et al., 2007; Maqueda et al., 2010), will lead to zero strains for an arbitrary initially curved geometry. Using the ANCF finite elements discussed later in this chapter, the constant matrix of position vector gradients ![]() can be determined in a straightforward manner. In the ANCF description, the assumed displacement field can be written as

can be determined in a straightforward manner. In the ANCF description, the assumed displacement field can be written as ![]() , where

, where ![]() is the global position vector,

is the global position vector, ![]() is the vector of the element spatial coordinates,

is the vector of the element spatial coordinates, ![]() is time,

is time, ![]() is the element shape function matrix, and

is the element shape function matrix, and ![]() is the vector of the element nodal coordinates that include absolute position and gradient coordinates. In the ANCF description, the vector of nodal coordinates

is the vector of the element nodal coordinates that include absolute position and gradient coordinates. In the ANCF description, the vector of nodal coordinates ![]() can be written as

can be written as ![]() , where

, where ![]() is the vector of nodal coordinates in the reference configuration and

is the vector of nodal coordinates in the reference configuration and ![]() is the vector of nodal displacements. Using this partitioning, the assumed displacement field can be written as

is the vector of nodal displacements. Using this partitioning, the assumed displacement field can be written as ![]() . Using the general continuum mechanics description

. Using the general continuum mechanics description ![]() , where

, where ![]() is the absolute position vector of an arbitrary point in the reference configuration and

is the absolute position vector of an arbitrary point in the reference configuration and ![]() is the displacement vector, one can write

is the displacement vector, one can write ![]() and

and ![]() . By appropriate choice of the elements of the vector

. By appropriate choice of the elements of the vector ![]() , initially curved structures can be defined in a straightforward manner using ANCF finite elements.

, initially curved structures can be defined in a straightforward manner using ANCF finite elements.

As previously mentioned, integration with respect to the domain ![]() can be converted to integration with respect to the straight element domain

can be converted to integration with respect to the straight element domain ![]() by using the transformation

by using the transformation ![]() , where

, where ![]() is the determinant of the matrix of position vector gradients

is the determinant of the matrix of position vector gradients ![]() . In the ANCF description, the matrix

. In the ANCF description, the matrix ![]() is constant, while

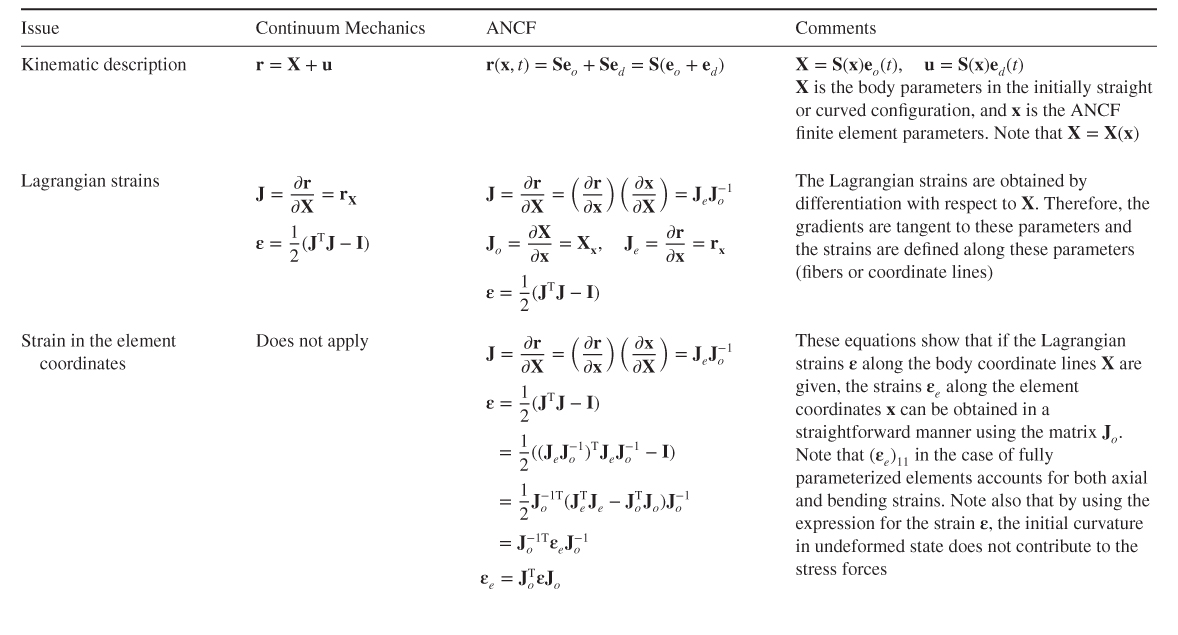

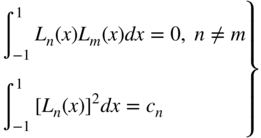

is constant, while ![]() . Table 1 explains how the basic continuum mechanics description is implemented using ANCF finite elements.

. Table 1 explains how the basic continuum mechanics description is implemented using ANCF finite elements.

Table 5.1 ANCF Description of Curved Geometry

5.5 NUMERICAL EVALUATION OF THE ELASTIC FORCES

As previously pointed out and shown in this chapter, the nonlinear large-deformation finite element absolute nodal coordinate formulation leads to a simple expression for the inertia forces and a nonlinear expression for the stress elastic forces. This is in contrast with the small-deformation finite element FFR formulation presented in the following chapter. The FFR formulation leads to a simple expression for the elastic forces and to a highly nonlinear expression for the inertia forces. Nonetheless, as will be shown in the following chapter, the nonlinear inertia forces obtained using the FFR formulation can be expressed in terms of a unique set of inertia shape integrals. These shape integrals can be evaluated in advance of the dynamic simulation using information from existing structural dynamics finite element codes.

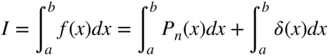

Because closed-form expressions for the nonlinear ANCF elastic forces cannot be, in general, obtained, the numerical evaluation of these forces is discussed in this section. The numerical evaluation of integrals of functions is covered in detail in textbooks on numerical methods (Carnahan et al., 1969; Atkinson, 1978). Therefore, in this section, a brief introduction to this subject is presented. To this end, consider the following integral of a single function f(x) over the interval [a, b]:

If the function f(x) is not simple or is given in a tabulated form, analytical evaluation of the preceding integral can be difficult, or even impossible. In these cases, one must resort to numerical methods in order to evaluate the integral. Formulas used for numerical integration are called quadratures. One approach is to try to find a polynomial Pn(x) of order n that can be a good approximation of f(x). One can then obtain the integral of the polynomial in a closed form. Because Pn(x) is not in general the same as f(x), one can define the following error function:

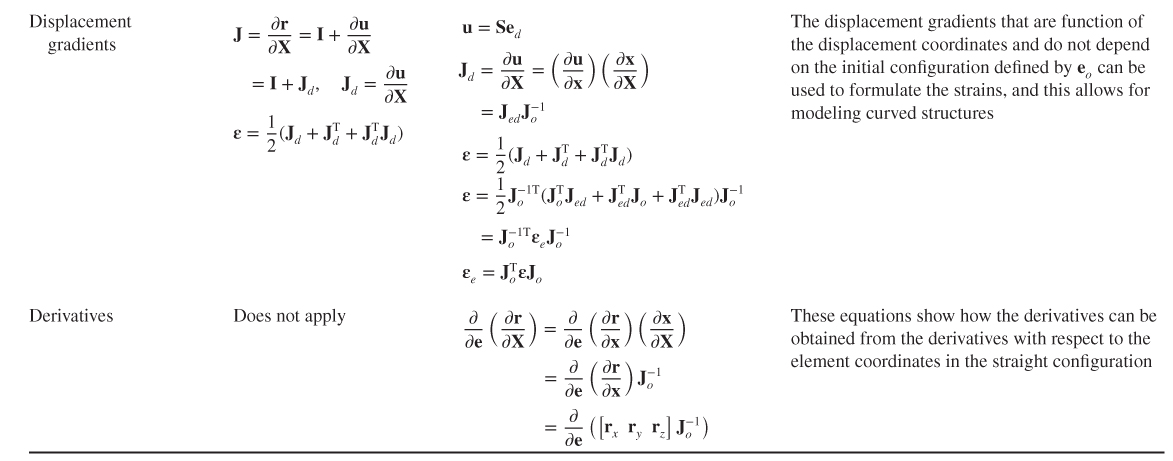

In general, δ(x) can take positive and negative values, and as a consequence, some of the positive errors cancel the effect of the negative errors when the integral ![]() is evaluated even in the case when Pn(x) is not a good approximation of f(x). For this reason, integration is known as a smoothing process (Carnahan et al., 1969). Furthermore, if f(x) is a polynomial or a function, which is described by data representing a polynomial, then one can always find a polynomial Pn(x) such that the integral I is exact. If f(x) is not a polynomial, the numerical integration will give an approximate evaluation of the integral of f(x). If the functions used in the approximation of the integrals are evaluated at equally spaced base points, one obtains the Newton–Cotes formulas, an example of which is the well-known Simpson's rule for numerical integration. If the functions used to approximate the integrals are evaluated using unequally spaced base points, one obtains the Gauss quadrature formulas. In the Gauss quadrature formulas, the locations of the base points are selected to achieve the best accuracy. In these formulas, the properties of orthogonal polynomials are used. Examples of orthogonal polynomials are the Legendre, Laquerre, Chebyshev, and Hermite polynomials. For example, the first few Legendre polynomials are defined as (Carnahan et al., 1969)

is evaluated even in the case when Pn(x) is not a good approximation of f(x). For this reason, integration is known as a smoothing process (Carnahan et al., 1969). Furthermore, if f(x) is a polynomial or a function, which is described by data representing a polynomial, then one can always find a polynomial Pn(x) such that the integral I is exact. If f(x) is not a polynomial, the numerical integration will give an approximate evaluation of the integral of f(x). If the functions used in the approximation of the integrals are evaluated at equally spaced base points, one obtains the Newton–Cotes formulas, an example of which is the well-known Simpson's rule for numerical integration. If the functions used to approximate the integrals are evaluated using unequally spaced base points, one obtains the Gauss quadrature formulas. In the Gauss quadrature formulas, the locations of the base points are selected to achieve the best accuracy. In these formulas, the properties of orthogonal polynomials are used. Examples of orthogonal polynomials are the Legendre, Laquerre, Chebyshev, and Hermite polynomials. For example, the first few Legendre polynomials are defined as (Carnahan et al., 1969)

In general, the Legendre polynomials are defined by the following general recursion relation:

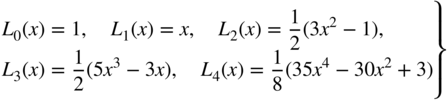

One can show that these polynomials are orthogonal on the interval [−1, 1]. That is,

Because the Legendre polynomials are orthogonal, an arbitrary polynomial can be described as a linear combination of the Legendre polynomials.

Gaussian Quadrature

In the Gaussian quadrature formulas, the integral is evaluated by approximating the function f(x) by a polynomial Pn(x) defined at unequally spaced base points. This function approximation can lead to an error δ(x), as previously mentioned. The locations of the base points are determined by developing a set of algebraic equations that make the integral of the error function equal to zero. The solution of these algebraic equations, which are obtained using the properties of the orthogonal polynomials, defines the base points. One can then write the integral I in the following form:

The domain of integration can be changed from x ∈ [a, b] to ξ ∈ [−1, 1] by using the substitution

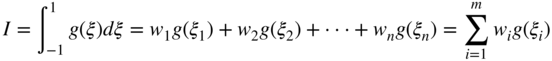

The steps used to determine the base points are first to employ the Lagrangian interpolating polynomials to approximate Pn(x) and δ(x). The Lagrangian interpolating polynomials do not require equally spaced base points. The resulting polynomials are then expressed in terms of the orthogonal Legendre polynomials. The Legendre polynomial orthogonality conditions are used to define a set of algebraic equations that make the integral of the error function equal to zero. This set of algebraic equations defines the base points for different orders of the polynomial Pn(x). The integral can then be written in terms of the function evaluated at these base points multiplied by weight factors or weight coefficients. This procedure for determining the base points is described in detail by Carnahan et al. (1969). The results are weight factors, which depend on the order of the polynomial or the number of base points selected to approximate f(x). These weight factors are presented in tables in mathematics handbooks or in textbooks on the subject of numerical analysis. In general, if the integral of the error function becomes zero and the domain of integration is changed to [−1, 1], the integral I can be written in terms of the function at the base points and the weight coefficients as

where wi, i = 1, 2, …, m, are the weight factors. These weight factors are called Gauss–Legendre coefficients. The weight factors are selected in order to achieve the greatest accuracy. Symmetrically located base points have the same weight coefficients. Note that if g(ξ) is approximated by one quadrature point, there is only one base point ξ1 = 0. In this case, the integral is given by ![]() . If g(ξ) is an arbitrary linear function (n = 1), this integration result obtained using one quadrature point is exact. In this case, w1 represents the length of the domain of integration, that is, w1 = 2, and g(ξ1) is the height used to determine the area under the curve. In this case, the function g(ξ) is evaluated at ξ1 = 0, which represents the center of the interval. If g(ξ), on the other hand, represents a higher-order function, the one-point quadrature integration is an approximation. In general, a polynomial of degree n requires m = (n + 1)/2 quadrature base points for exact integration, where in this simple rule n is assumed an odd number.

. If g(ξ) is an arbitrary linear function (n = 1), this integration result obtained using one quadrature point is exact. In this case, w1 represents the length of the domain of integration, that is, w1 = 2, and g(ξ1) is the height used to determine the area under the curve. In this case, the function g(ξ) is evaluated at ξ1 = 0, which represents the center of the interval. If g(ξ), on the other hand, represents a higher-order function, the one-point quadrature integration is an approximation. In general, a polynomial of degree n requires m = (n + 1)/2 quadrature base points for exact integration, where in this simple rule n is assumed an odd number.

Generalization

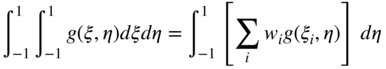

The procedure used for integrating a function that depends on one variable can be generalized to the case in which the function depends on two or three variables, as it is the case in some finite element assumed displacement fields. In the two-dimensional case, consider the function g(ξ, η). It is assumed that the domains of integration are changed as discussed before such that ξ ∈ [−1, 1], and η ∈ [−1, 1]. The integral of the function g(ξ, η) can then be written as

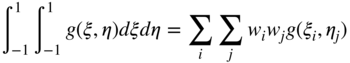

Performing the second integration with respect to η, one obtains

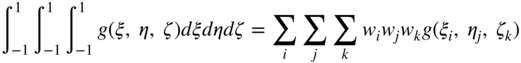

Following a similar procedure, one can show that in the case of a function that depends on three variables, ξ, η, and ζ, one has the following Gauss quadrature formula:

If the original function is expressed in terms of the coordinates x1, x2, and x3, that is, f = f(x1, x2, x3), the preceding formula requires using the relationship dx1dx2dx3 = Jdξdηdζ, where J is the determinant of the Jacobian of the coordinate transformation.

Using the Gauss quadrature formulas presented in this section, a systematic procedure for the numerical evaluation of the nonlinear stress elastic forces of the finite elements can be developed. The number of quadrature points used in the numerical integration defines the accuracy of the integration, and therefore, this number must be carefully selected in order to avoid increasing the computational cost or obtaining inaccurate results. There is no advantage gained from using a number of quadrature points larger than the number that gives exact evaluation of the integral (full integration). In some applications, on the other hand, there is an advantage in selecting a number of points that does not yield exact evaluation of the integrals. This is the case of reduced integration, which is commonly adopted in the finite element computational algorithms and will be discussed in a later section.

5.6 FINITE ELEMENTS AND GEOMETRY

In the following sections, examples of several finite elements that can be used to study the large deformations in a wide range of applications are presented. These elements have been developed over the last few years, and more details on the formulation of their shape functions, the mass matrices, and the vectors of elastic forces can be found in the literature. Some of these elements have been already used in this book in the examples presented in this chapter and preceding chapters.

General Continuum Mechanics Approach and Classical Theories

It is important to point out that in all the finite elements that are discussed in this chapter, classical theories can be used by introducing a local element frame. Therefore, for beam elements, one can still use Euler–Bernoulli and Timoshenko beam theories; and, for plate and shell elements, one can still use Kirchhoff and Mindlin plate theories. This can always be accomplished by using the element local frame, which serves the only purpose of measuring the deformation (Shabana, 2013), and such a frame does not enter into the formulation of the inertia forces. Therefore, it is important to distinguish between this local element frame and the corotational frame used in the finite element literature. If the general continuum mechanics approach is used instead of the classical theories, one obtains more general formulations that relax the assumptions of Euler–Bernoulli, Timoshenko, Kirchhoff, and Mindlin theories. In these general formulations, the element cross section is allowed to deform.

Gradient Vectors

Some of the elements presented in this chapter employ a complete set of gradient vectors as nodal coordinates. These elements allow, in a straightforward manner, for the use of a general continuum mechanics approach to formulate the elastic forces. The use of these elements also allows for using more general constitutive relationships. Elements that do not employ a complete set of parameters required to evaluate all the gradient vectors are called in this book, gradient deficient. The use of a general continuum mechanics approach with these elements is not as straightforward as compared to elements that have a complete set of parameters (spatial coordinates). The latter elements are called fully parameterized elements.

Locking Problems

ANCF finite elements were introduced to deal with very flexible components. These finite elements perform well in the case of very flexible bodies, and efficient solutions for large deformations of very flexible bodies can be obtained because a nonincremental solution procedure can be used with these ANCF elements. As the element stiffness decreases, ANCF elements become more efficient. Some researchers, however, used ANCF finite elements in the analysis of thin and stiff structures. In this case, some elements exhibit locking problems when the general continuum mechanics approach is used to formulate the elastic forces. The general continuum mechanics approach leads to what is called ANCF-coupled deformation modes (Hussein et al., 2007). These modes, which couple the deformation of the cross section and other deformations such as bending, can have high frequencies and can be a source of numerical problems (Schwab and Meijaard, 2005). Several techniques were proposed in the literature to solve the locking problems and improve the element performance.

In order to better understand the behavior of the finite elements introduced in the following sections, an understanding of the geometry is necessary. Some basic results from the theories of curves and surfaces, which are covered in the subject of differential geometry, can help the reader better understand and solve the problems encountered when ANCF finite elements are used.

Theory of Curves

The centerline of a beam element represents a space curve. A curve can be uniquely defined in terms of one parameter. That is, the Cartesian coordinates that define the curve can be determined once this parameter is specified. Let α be the parameter that defines the curve over the interval a ≤ α ≤ b. The curve can then be represented by the following parametric form:

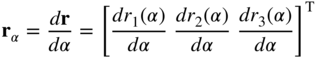

The tangent vector to the curve at α is given by

If at a given point α, |dr(α)/dα| = 0, the point is called a singular point. The parameter α can be selected to be the arc length s. If the arc length is used as a parameter, the tangent vector rs is a unit vector. That is,

In order to mathematically prove this important result, let r be the vector that defines the position of the points on a space curve. One can write the following equation:

If Δα is assumed small, Δr defines the tangent vector. In this case, if s is assumed to be the arc length of the space curve that defines the centerline of the element, then one has

This equation shows that in the limit when Δs approaches zero, one has

That is, the tangent vector obtained by differentiation with respect to the arc length is indeed a unit vector.

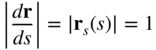

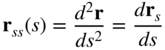

If a curve is parameterized by its arc length, the derivative of the unit tangent vector defines the curvature vector. That is, the curvature vector is defined as

The magnitude of the curvature vector at a given s is called the curvature and given as

Because the tangent vector rs(s) is a unit vector, the curvature κ(s) measures the rate of change of orientation of the tangent vector, that is, it measures the amount of bending of the curve. The preceding two equations show that linear displacement fields lead to zero curvature and, therefore, such fields are not appropriate for describing the displacement of components subjected to bending. Although one can approximate a curve by a large number of straight segments, in the finite element implementation the use of linear field will require the use of a very large number of finite elements. This increases the dimensions of the problem and can lead to a very inefficient solution procedure.

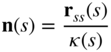

Because the tangent and curvature vectors are orthogonal, a unit vector along the curvature vector defines the unit normal to the curve n given as

The unit tangent and normal vectors form a plane called the osculating plane. The radius of curvature of the curve at s is defined as R = 1/κ(s). A vector normal to the osculating plane, called the binomial vector at s, is given by

The three orthogonal unit vectors rs, n, and b form a coordinate system called the Frenet frame.

Differentiating Equation 62 with respect to s and keeping in mind that the vectors rss(s) and n(s) are parallel, one obtains

This equation shows that bs(s) is normal to rs. Furthermore, because b(s) is a unit vector, bs(s) and b(s) are two orthogonal vectors, and bs(s) is parallel to n. Therefore, bs(s) can be written in the following form:

where τ is called the torsion. The curvature and torsion uniquely define the space curve.

Theory of Surfaces

Whereas a general space curve can be defined in terms of one parameter, a surface can be completely described in terms of two parameters s1 and s2. In general, a surface can be described in the following parametric form (Goetz, 1970; Kreyszig, 1991):

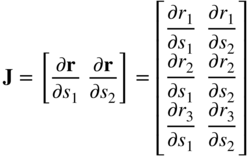

It is required that the mapping in this equation is one to one, and the Jacobian matrix

has a rank equal to two. This condition is satisfied if (∂r/∂s1) × (∂r/∂s2) ≠ 0, which implies that the two columns of the Jacobian matrix in the preceding equation are linearly independent. The two vectors ![]() and

and ![]() represent the two tangent vectors at the point of intersection of the coordinate lines s1 and s2. The unit vector normal to the surface at this point can then be defined as

represent the two tangent vectors at the point of intersection of the coordinate lines s1 and s2. The unit vector normal to the surface at this point can then be defined as

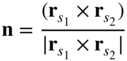

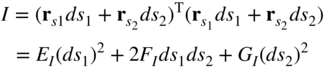

As in the case of curves, the surface can be defined uniquely using local geometric quantities called the first and second fundamental forms. The first fundamental form of a surface is defined as follows:

This equation shows that the first fundamental form I can be used as a measure of distance or length. Using the fact that ![]() , the first fundamental form of the preceding equation can be written as

, the first fundamental form of the preceding equation can be written as

where

These coefficients are called the coefficients of the first fundamental form. One can show that distances, angles, and areas on the surface can be expressed in terms of the first fundamental form (Goetz, 1970; Kreyszig, 1991).

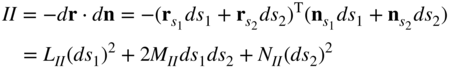

The second fundamental form of a surface is defined as

where n is the unit normal and the coefficients of the second fundamental form are defined as

Because ![]() and

and ![]() are perpendicular to n for all values of the parameters s1 and s2, one has the following identities:

are perpendicular to n for all values of the parameters s1 and s2, one has the following identities:

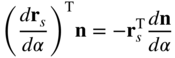

Using these identities, the coefficients of the second fundamental form can be written in an alternate form as follows:

where ![]() . Using the preceding equation, and the fact that

. Using the preceding equation, and the fact that

one can show that the second fundamental form can be written in the following alternate form:

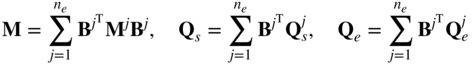

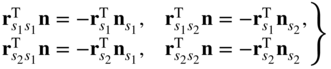

This equation can be used to measure the rate of change of orientation of the tangent plane. The coefficients of the second fundamental form can be used to determine the nature of the surface in the neighborhood of an arbitrary point P. If ![]() , the surface is called elliptic. If

, the surface is called elliptic. If ![]() , the surface is called hyperbolic. If

, the surface is called hyperbolic. If ![]() , the surface is called parabolic. If LII = MII = NII = 0, the surface is called planar. Figure 6 shows examples of such surface geometry

, the surface is called parabolic. If LII = MII = NII = 0, the surface is called planar. Figure 6 shows examples of such surface geometry

Figure 5.6 Surface geometry. (a) Elliptic surface, (b) hyperbolic surface, (c) parabolic surface, and (d) planar surface

Surface Curvature

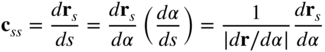

One can always define a curve on a surface if the parameters s1 and s2 are expressed in terms of one parameter α. Let c = c(s1(α), s2(α)) be a regular curve defined on the surface r = r (s1, s2). The normal curvature vector to the curve c at point P denoted by Kn is defined as the projection of the curvature vector css of the curve onto the normal n to the surface at point P and is given by

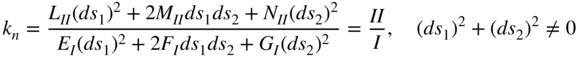

In this equation, s is the arc length of the curve. Note that the curve c can be defined as the intersection of a plane that contains the tangent to c and the normal vector. The norm of the normal curvature vector defined in the preceding equation is called the normal curvature and is defined as

Recall that the curvature vector of the curve at a point P on the surface r is given by

where rs is the tangent vector to the curve at P and s is the curve arc length. In deriving the preceding equation, one utilized the fact that |dr/dα| = |rs|(ds/dα) = (ds/dα), which is the consequence of the fact that |rs| = 1. Because rs is orthogonal to n, one has ![]() , which leads to

, which leads to

Substituting Equation 79 into Equation 78 and using Equation 80, one obtains

Because the first fundamental form I is positive, the sign of kn depends on the sign of the second fundamental form II. Using the preceding equation, one can show that kn = 0 in all directions for a planar point. For an elliptic point, kn ≠ 0 and has the same sign as the ratio ds1/ds2. In the case of a hyperbolic point, kn can be positive, negative, or zero, depending on the sign and value of ds1/ds2. For a parabolic point, kn maintains the same sign and it is zero if the second fundamental form II is equal to zero.

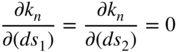

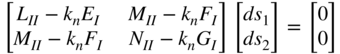

The directions that define the maximum or minimum values of the normal curvature can be obtained by differentiating Equation 81 with respect to the parameters s1 and s2, and setting the results equal to zero. That is,

Substituting Equation 81 into these equations, one obtains

This equation has a nontrivial solution if and only if the determinant of the coefficient matrix is equal to zero, that is,

The solution of this quadratic equation defines two roots k1 and k2. These two roots, which are called the principal curvatures, can be substituted into Equation 83 to determine the principal directions. The mean curvature Km and the Gaussian curvature kG at a point P on the surface are defined in terms of the principal curvatures as

These surface definitions as well as the analysis of curve and surface geometry presented in this section are important to understand the behavior of beams, plates, and shells. Some of the obtained geometric results shed light on the order of approximation that must be used when employing the finite element method to solve beam, plate, and shell problems. For example, as previously discussed, the curvature is obtained from the second derivative of the position vector. Therefore, finite elements that employ linear or bilinear approximation cannot be effectively used in bending problems because the curvature will always be equal to zero. When these linear and bilinear elements are employed, one must use a very fine mesh in order to be able to represent a space curve or a shell by straight lines or flat sections, respectively. This approach tends to be very inefficient and, therefore, the use of structural finite elements that are based on higher-order interpolations is recommended. Some of these ANCF elements are discussed in the following sections.

5.7 TWO-DIMENSIONAL EULER–BERNOULLI BEAM ELEMENT

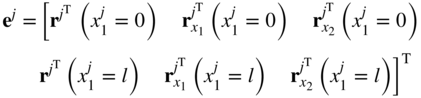

The Euler–Bernoulli beam element presented in this section has two nodes. Each node k for an element j has four coordinates; two translations rjk, and two gradient coordinates ![]() . Therefore, the vector of nodal coordinates has eight elements and is defined as

. Therefore, the vector of nodal coordinates has eight elements and is defined as

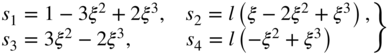

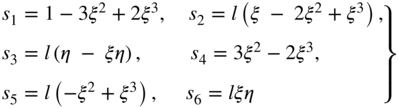

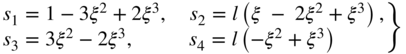

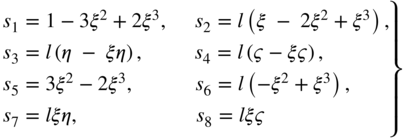

The shape function matrix of the element can be defined by using the following interpolation functions:

where ai and bi, i = 0, 1, 2, 3, are the polynomial coefficients. Using this interpolation and the nodal coordinates of Equation 86, one can follow the procedure previously described in this chapter to define the element shape function matrix. For this element, the shape function matrix Sj is a 2 × 8 matrix and is defined as

In this equation, I is a 2 × 2 identity matrix and

where ![]() . This beam element shape function matrix, which does not allow for shear deformations, was also used by Milner (1981) to study static problems.

. This beam element shape function matrix, which does not allow for shear deformations, was also used by Milner (1981) to study static problems.

Kinematics of the Element

In order to understand the kinematics of the two-dimensional Euler–Bernoulli finite element discussed in this section, some differential geometry results are required. For simplicity, the superscript that indicates the element number is dropped in the following discussion.

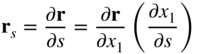

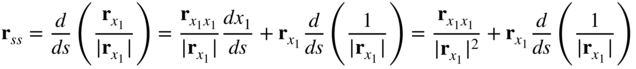

The displacement field of the Euler–Bernoulli beam element is function of one spatial coordinate x1 only. For a given, deformed shape of the element, the element centerline defines a space curve. The unit tangent to this space curve is defined by the vector

In this equation, s is the arc length. Because rs is a unit vector, that is, ![]() , it follows by differentiating this equation that

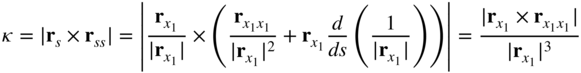

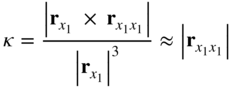

, it follows by differentiating this equation that ![]() . This implies that the derivative of the unit tangent with respect to the arc length defines the curvature vector rss, which is perpendicular to rs. The magnitude of the curvature vector κ, called the curvature, measures the rate of change of the tangent vector rs along the arc length. Therefore, the curvature, as previously defined in this chapter, is

. This implies that the derivative of the unit tangent with respect to the arc length defines the curvature vector rss, which is perpendicular to rs. The magnitude of the curvature vector κ, called the curvature, measures the rate of change of the tangent vector rs along the arc length. Therefore, the curvature, as previously defined in this chapter, is

This curvature can be expressed in terms of derivatives with respect to the element spatial coordinate x1(Goetz, 1970; Dmitrochenko and Pogorelov, 2003; Gerstmayr and Shabana, 2006). To this end, recall that ![]() . Because

. Because ![]() has the same direction as the unit tangent rs, one can write

has the same direction as the unit tangent rs, one can write ![]() and

and ![]() . It follows that

. It follows that

Because rs is a unit vector perpendicular to rss, the curvature can be written upon utilizing the preceding equation as

This definition of the curvature does not imply any linearization or simplifications and can be used to define the bending strain in the large-deformation analysis of the Euler–Bernoulli beam element described in this section.

The discussion on the geometry presented in this section shows that if linear interpolation instead of the cubic interpolation is used for this element, the curvature will be zero everywhere inside the element, as previously pointed out. That is, one cannot bend this element. Therefore, a finite element mesh that employs linear interpolation will require a very large number of elements to achieve convergence in beam-bending problems. If quadratic interpolation is used, one obtains, at most, constant curvature. Elements that employ quadratic interpolations lead to zero shear forces as can be demonstrated using simple equilibrium considerations. It is, therefore, recommended to use cubic interpolation to represent beam bending.

Formulation of the Element Elastic Forces

In the case of the Euler–Bernoulli beam element, one can define one gradient vector only because the element assumed displacement field is expressed in terms of one spatial coordinate x1. That is, this element is gradient deficient. Therefore, for this element, the only nonzero strain component is the axial strain, and the shear strain is assumed to be zero. When one or more gradient vectors are missing, the formulation of the elastic forces using the general continuum mechanics approach is not straightforward. Elements that are not gradient deficient have two gradient vectors in the planar analysis and three gradient vectors in the spatial analysis.

Because one spatial coordinate only is used for the Euler–Bernoulli beam element, ![]() cannot be determined using the element assumed displacement field. In this case, the normal to the centerline of the element remains normal, and as a consequence, the shear deformation is assumed to be equal to zero and the cross section of the element is assumed to remain rigid and perpendicular to the element centerline. For this shear nondeformable element, only the strain component ϵ11 can have nonzero value, and it measures only the extensional strain. The bending strain can be defined using the curvature. In the case of two-dimensional elements, which are not gradient deficient, the component ϵ11 is a function of the spatial coordinate x2, and such a component contributes to the bending strain of the finite element, as will be demonstrated in later sections. In this case of shear deformable elements, the use of the curvature definition to define the bending strain energy is not necessary.

cannot be determined using the element assumed displacement field. In this case, the normal to the centerline of the element remains normal, and as a consequence, the shear deformation is assumed to be equal to zero and the cross section of the element is assumed to remain rigid and perpendicular to the element centerline. For this shear nondeformable element, only the strain component ϵ11 can have nonzero value, and it measures only the extensional strain. The bending strain can be defined using the curvature. In the case of two-dimensional elements, which are not gradient deficient, the component ϵ11 is a function of the spatial coordinate x2, and such a component contributes to the bending strain of the finite element, as will be demonstrated in later sections. In this case of shear deformable elements, the use of the curvature definition to define the bending strain energy is not necessary.

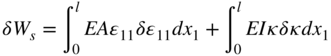

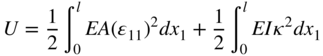

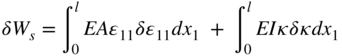

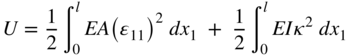

The elastic forces of the two-dimensional Euler–Bernoulli beam element can be obtained by using the virtual work or the strain energy. The virtual work of the elastic forces can be written as

In this equation, l is the length of the element, E is the modulus of elasticity, A is the cross-sectional area, and I is the second moment of area. It is assumed in the preceding equation that the curvature and strain are defined in terms of the reference spatial coordinate x1. Therefore, one can use undeformed geometry data in the integrations of the preceding equation.

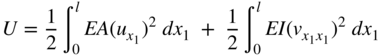

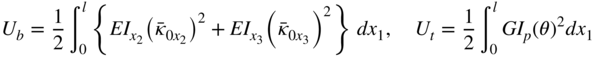

The strain energy for the Euler–Bernoulli beam element can be written as

The first integral in the preceding equation represents the strain energy due to the extension, whereas the second integral is the strain energy due to bending. It is important to note that because this element is gradient deficient, one must resort to the curvature definition in order to account for the bending deformation. The curvature definition requires the evaluation of the second derivatives, which is one of the disadvantages of this element. If the element has a complete set of gradients, as it is the case of the shear deformable beam element discussed in the following section, one can use the Green–Lagrange strain tensor to evaluate the elastic forces. This tensor is a function of only first derivatives of the absolute position vector.

The expression of the total strain energy presented in the preceding equation can be used in the large-deformation analysis because no assumptions are made regarding the amount of axial and bending deformations. The strain and curvature can be expressed in terms of the element nodal coordinates. The vector of the elastic forces can be determined using the virtual work as previously described or by using the strain energy as Qs = −(∂U/∂e)T. Different elastic force models can be developed for the Euler–Bernoulli beam element presented in this section, as discussed in the literature (Berzeri and Shabana, 2000).

Special Case

As previously mentioned, the expression of the strain energy presented in this section imposes no restrictions on the amount of the axial and bending deformations of the element. The resulting elastic forces are nonlinear functions of the element nodal coordinates. These nonlinear forces include terms that couple the axial and bending deformations. This coupling has a significant effect on the dynamics of rotating beams. The ANCF element automatically accounts for this coupling when nonlinear strain displacement relationships as the ones employed in this section are used (Berzeri and Shabana, 2002).

In many structural applications, Euler–Bernoulli beam theory has been used for small-deformation analysis. In these structural applications, the rigid-body motion is eliminated. In this special case, an assumption is made that s = x1. Using this assumption, one has ![]() . It follows that the curvature in this special case can be written as

. It follows that the curvature in this special case can be written as

Recall that the curvature vector can be written as

For structural systems in which the rigid-body motion is eliminated, r1 = u is the axial displacement, and r2 = v is the bending displacement. In this case, the strain ϵ11 is approximated as ![]() . Furthermore, the effect of the derivatives of

. Furthermore, the effect of the derivatives of ![]() on the curvature is neglected. The curvature can then be approximated as

on the curvature is neglected. The curvature can then be approximated as ![]() . Using these assumptions, the strain energy that does not account for the coupling between the axial and bending displacements can be written as

. Using these assumptions, the strain energy that does not account for the coupling between the axial and bending displacements can be written as

This expression for the strain energy can only be used in the small-deformation analysis of structural systems, and the use of such an expression in the case of rotating beams can lead to significant errors as the result of the neglect of the effect of the coupling between bending and axial deformations.

5.8 TWO-DIMENSIONAL SHEAR DEFORMABLE BEAM ELEMENT

The two-dimensional shear deformable beam element, which was used in several examples in this book, has two nodes. Each node k of element j has six degrees of freedom: two translational coordinates rjk and four gradient coordinates defined by the two vectors ![]() and

and ![]() . The vector of nodal coordinates has 12 elements and is defined at η = 0 as

. The vector of nodal coordinates has 12 elements and is defined at η = 0 as

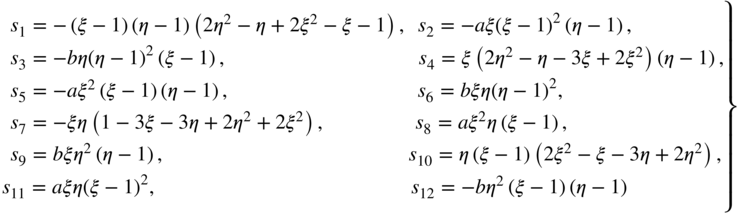

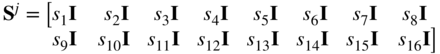

The shape function matrix for this element is given by

where I is a 2 × 2 identity matrix and the shape functions si, i = 1, 2, …, 6, were obtained in Example 2 as (Omar and Shabana, 2001)

where ![]() and

and ![]() . Note that this fully parameterized element has a complete set of gradient vectors and allows for the deformation of the cross section. Therefore, the element relaxes the assumptions of the Euler–Bernoulli beam theory. Because the cross section does not remain rigid when this element is used, one also obtains a model that is more general than the one based on Timoshenko beam theory.

. Note that this fully parameterized element has a complete set of gradient vectors and allows for the deformation of the cross section. Therefore, the element relaxes the assumptions of the Euler–Bernoulli beam theory. Because the cross section does not remain rigid when this element is used, one also obtains a model that is more general than the one based on Timoshenko beam theory.

Formulation of the Elastic Forces

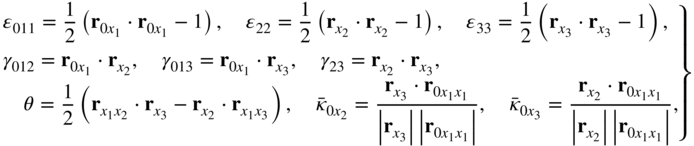

Because the shear deformable beam element used in this section is not gradient deficient, one can use the general continuum mechanics approach to formulate the element elastic forces. For simplicity, superscript j that indicates the element number will be again dropped in the discussion presented in the remainder of this section. The matrix of position vector gradients of the element can be written in this case as

The Green–Lagrange strain tensor can then be evaluated to define two normal strain components ϵ11 and ϵ22, and one shear strain component ϵ12. The general procedure described previously in this chapter can be employed to define the elastic forces by using the constitutive equations that relate the second Piola–Kirchhoff stress tensor to the Green–Lagrange strain tensor.

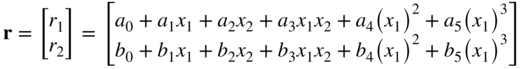

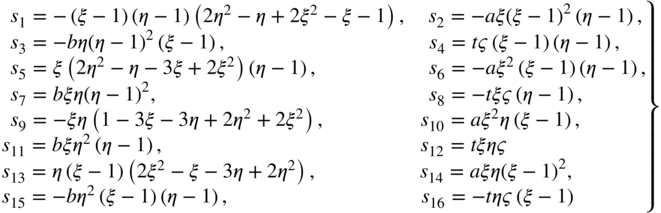

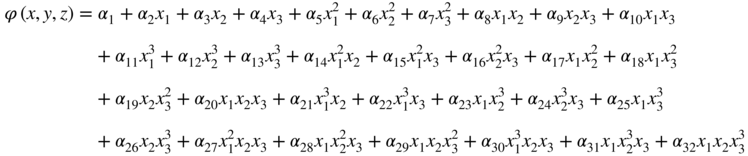

The interpolating polynomials used to develop the two-dimensional shear deformable element shape function matrix were introduced in Chapter 1. These polynomials were defined as

where ai and bi, i = 0, 1, …, 5, are the polynomial coefficients. Note that using this representation, which is cubic in x1 and linear in x2, one can write the vector r as

where r0 = r(x2 = 0) defines the global position of the material points on the centerline of the finite element and ![]() defines the location of the points on the cross section with respect to the centerline. Note that if

defines the location of the points on the cross section with respect to the centerline. Note that if ![]() remains a unit vector perpendicular to the tangent to the centerline, one obtains the Euler–Bernoulli beam model. If, on the other hand,

remains a unit vector perpendicular to the tangent to the centerline, one obtains the Euler–Bernoulli beam model. If, on the other hand, ![]() remains a unit vector that does not remain perpendicular to the tangent to the centerline, one obtains a model similar to the Timoshenko beam model. Using the preceding equation, the strain components can be written as (Sugiyama et al., 2006)

remains a unit vector that does not remain perpendicular to the tangent to the centerline, one obtains a model similar to the Timoshenko beam model. Using the preceding equation, the strain components can be written as (Sugiyama et al., 2006)

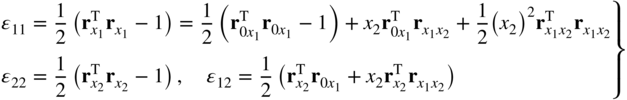

In this equation, ![]() is the tangent to the centerline of the element, and

is the tangent to the centerline of the element, and ![]() describes the rate of change of the gradient vector

describes the rate of change of the gradient vector ![]() with respect to the spatial coordinate x1. Because a linear interpolation with respect to x2 is used, one can show for the finite element described in this section that

with respect to the spatial coordinate x1. Because a linear interpolation with respect to x2 is used, one can show for the finite element described in this section that

where ![]() is the gradient vector

is the gradient vector ![]() defined at node k, k = 1, 2. One can verify that in the case of a rigid-body motion