The potential for the Industrial Internet is vast with opportunities spread over wide areas of productivity, such as logistics, aviation, transportation, healthcare, energy production, oil and gas production, and manufacturing. As a result, many use-cases will make industry executives wake up and consider the possibilities of the IIoT. After all, industry only requires a minimal shift in productivity to deliver huge revenue, an example is that even an increase of 1% of productivity can produce huge revenue benefits such as aviation fuel savings. In order to realize these potential profits, industry has to adopt and adjust to the Industrial Internet of Things.

However, spotting, identifying, and then strategically targeting the opportunities of the IIoT is not quite as easy as it might seem. It is important, therefore, to create use-cases that are appropriate to vertical businesses. For instance, the requirements of manufacturing differ from logistics, which also differs to healthcare. Similarly, the innovation, expertise, and financial budget available to deliver specific industry applications will have many diverse constraints. For example, healthcare will consume vast amounts of expenditure with little or no financial return; in contrast, the oil and gas industry will also require immense operational and capital cost but will likely deliver huge profits. Similarly, logistics—which is very reliant on supply chain, product tracking, and transportation—will have different operational requirements. However, what the IIoT offers is a potential solution for all vertical industries, by utilizing the advances in sensor technology, wireless communications, networking, cloud computing, and Big Data analysis. Businesses can, regardless of their size and discipline, leverage these technologies in order to reap the rewards of the IIoT.

To illustrate the potential benefits and advantages to individual industrial disciplines, consider the following use-cases.

Healthcare

In this example, we will strive to explain how utilizing IIoT technology can unlock and deliver value to the heath care industry. In healthcare, and it wasn’t so long ago, doctors made house visits to those too sick or incapacitated through injury to make their way to the doctor’s office. However, this was time consuming and costly. Consequently, doctors restricted home visits to only those who in the doctor’s experience deemed sufficiently seriously incapacitated through illness or injury, and everyone else had to turn up and take their place in the doctor’s office queue. This policy, though understandable, was seriously inconvenient for both patients and doctors, especially patients in rural areas who might have to drive considerable distances while suffering from the debilitating effects of illness or physical injury. Therefore, an alternative arrangement was always desirable.

That is why Guy’s and St. Thomas’s Nation Health Service Foundation Trust in the UK are piloting the use of smartphones to use as health monitors. The patient’s kit compromises a smartphone, scales, blood oxygen sensors, and a blood pressure cuff. The idea is that the patients will take daily readings of their weight, heart rate, blood pressure, and oxygen levels, then upload the data to the smartphone via Bluetooth to be sent to BT’s telehealth service.

Nurses at the service then analyze the data. If there are any abnormalities in the data, the nurses will discuss issues with the patients. By using these homecare kits, patients have more control over their own condition and can manage their own chronic medical conditions in their own homes. It is hoped that the pilot project, which is being tested on 50 heart failure patients, will ultimately save lives.

Another example, of a state-of-the-art IIoT project in today’s healthcare environment is the initiative adopted by Scottish health chiefs to provide a means of automation, supervision, and communication for remote outpatients.

The robot—known as the Giraff —is being used in the homes of patients, particularly those suffering from dementia in the Western Isles and Shetland to allow them to continue living independently. The robots are designed to provide reassurance to friends and family, by enabling a relative or carer to call up the Giraff from a remote computer or smartphone from any location. The 3G audio/video channel displays the carer’s face on the Giraff's video screen, allowing them to chat to the patient via a Skype-like video call.

The Giraff launched in 2013 as a pilot trial. The Giraff robots are just under five feet tall with wheels, and a video screen instead of a head. They are fitted with high-definition cameras to monitor the home and provide remote surveillance. The Giraff allows relatives and carers to keep a vigilant eye on the patients, to ensure they are taking their medication and eating meals, while also providing a method for social exchange potentially from hundreds of miles away. The carer can also manipulate the robot and drive the robot around the house to check for any health or safety issues.

The use of assistive technology is sometimes targeted at specific patients, and, as such, the Giraff would have a specific rather than a generic application. It was initially feared that older patients suffering from dementia would react badly to the presence of a robot. On the contrary, it appears that they found the robot good company, even though it could not hold a conversation (although the likes of Siri could address that immediate problem and neither can a dog or cat). Furthermore, earlier trials in Australia showed that people with dementia were not afraid of the machines. They hope the robots will help people living alone in remote areas to feel less lonely.

Another personal healthcare robot is Baymax , which is a robot with a soft synthetic skin that can detect medical conditions (this was an initiative based on a fictional Disney character in Big Hero 6 but it may not be far from becoming reality). Early versions of a robot teddy bear, developed by MIT Media Lab, are now being put through their paces in a children’s hospital in the United States. An updated version of the bear has been fitted with pressure sensors on two of its paws and several touch sensors throughout its body parts. The screen of the smartphone device in the robot’s head shows animated eyes. The robot can use the phone’s internal speaker, microphone, and camera for sensing changes in a child’s well-being.

Oil and Gas Industry

The Oil and Gas industry depends on the development of high technology as well as scientific intelligence in the quest for discovery of new reservoirs. The exploration and development of newly discovered oil and gas resources requires modern sensors, analytics, and feedback control systems that have enhanced connectivity, monitoring, control, and automation processes. Furthermore, the oil and gas industry obtains for process vast quantities of data with relation to the status of drilling tools and the condition of machinery and processes across an entire field-installation.

Previously, technology targeted oil and gas production but geologists had limited ability to process the vast amounts of data produced by a drilling rig, as there was just so much of it and storage was expensive and just not feasible. Indeed, such was the vast amount of data collected, up to 90% would be discarded, as there was nowhere to store the data let alone have the computational power to analyze it in a timely manner.

However, the Industrial Internet of Things, (IIoT) has changed that wasteful practice and now drilling rigs and research stations can send back the vast quantities of raw data retrieved from drilling and production sensors for storage and subsequent analysis in the cloud. For example, drilling and exploration used to be expensive and unpredictable as it was based on geologist's analysis of the mapping of the sea floor. This proved to be unpredictable and, as a result, major oil and gas exploration and producers are transforming their infrastructures to take advantage of the new technologies that drive the Industrial Internet. These technological advances , such as high bandwidth communications, wireless sensor technology, cloud data storage with advanced analytical tools, and advanced intelligent networks are enabling systems that enhance the predictability of field research, make research more predictable, reduce exploration costs, and also eventually lower field operation expenses.

New industry regulations for well monitoring and reservoir management have, on top of other technical demands, pushed field operators to find efficient ways of addressing existing operational constraints. For example, in the 1990s and 2000s, it was commonplace for field operators to dump almost all of the data they collected during drilling due to a lack of processing and communication capabilities; the amount of data was just too vast to accommodate. In mitigation, most of the data was only relevant to the time it was generated—for example, the temperature of the drill bit, or the revolutions per second—so was only useful at that specific time.

However, with the advances in technology, specifically in down-hole sensors and the subsequent massive influx of data from down-hole drilling tools, which required advanced analysis in both real-time data streaming as well as historical and predictive analysis, demands for more innovative solutions have increased.

Fortunately, just as the demand has grown for such vast data analytics within the oil and gas industry, another technology has come to the fore that provides the necessary compute, data storage, and the industrial scalability to deliver real-time data analysis. Additionally cloud technology is able of batch processing Big Data mining, for historical understanding and predictive forecasting.

Cloud computing and the Industrial Internet now provide the technology to make gathering, storing, and analyzing vast quantities of data economically feasible.

However, the advent of the Industrial Internet has delivered far more than economic and scalable cloud services in compute, storage, and data analytics; it has changed industry profoundly. For example, industry now has the ability through interconnectivity to connect intelligent objects—machines, devices, sensors, actuators, and even people—into collaborating networks, an Internet of Things. At the same time, the designers of these intelligent, smart things have built in self-diagnosis and self-configuration, which greatly enhances reliability and usability. In addition, device connectivity, the requirement for cables and power, which was once a real problem, has been alleviated by wireless communication. New wireless technologies and protocols , along with low power technologies and component miniaturization, enable sensors to be located anywhere, regardless of size, inaccessibility, or cabling restrictions.

Connectivity is at the core of the Industrial Internet; after all, it requires communications over the Internet and interaction with the cloud. Therefore, the communication protocols are all important and this has produced new protocols such as 6LoWLAN and CoAP , which we will discuss in subsequent chapters at a technical level later. These may work well for some industrial use-cases that have low capability devices deployed in end-to-end connectivity.

However, for all systems there are only two ways to detect a remote node’s status —the sensor sends data back to the controller, for example as an event or the controller polls the node at programmable intervals to obtain the nodes status. Both of these are inefficient, but there is a better way (discussed in detail later), which is the publish/subscribe software pattern. It’s a preferable technique as it can instantly inform a subscriber across a common software bus of a change if that subscriber has noted an interest. This is preferable to the subscriber polling the publisher for any updates, as it is far more efficient and quicker. However, not all publish/subscribe models work in the same manner. MQPP and XMPP are very popular as they are well supported; however, they do not support real-time operations, so are not well suited to industrial scenarios.

The data distribution system does support real time operation and it is capable of delivering data at physical speeds to thousands of recipients, simultaneously, with strict control on timing, reliability, and OS translation. These are hugely important qualities when deployed in an industrial environment, such as the oil and gas industry.

It is these new IoT protocols and technologies that have provided the means to change oil and gas exploration and field production beyond what was previously feasible.

As an example of how the oil and gas industry utilizes DDS as a publish/subscribe protocol, let’s examine how they have integrated it into their operational processes.

The first example shows how IoT has enabled remote operations of drilling rigs by automation . This is not only cost effective at a time when field experts are becoming a rarity, but also beneficial with regard to field efficiency, safety, and well quality. It can also lead to—via advanced sensor technology being self diagnostic and self-configurable—a significant decrease in downtime and equipment failures.

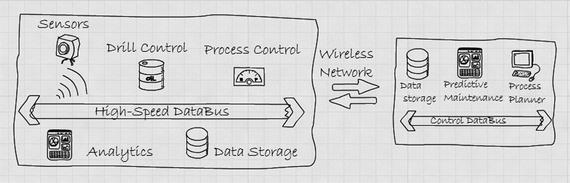

Figure 2-1 shows a block illustration of an automated remote control topology , whereby a high-speed DDS data bus connects all the sensors and actuators with a process controller, which automates the process of drilling and completion.

Figure 2-1. DDS data bus

In addition to automation , the design also facilitates the remote collection and analysis of operational data, equipment health, process activity, and real-time streaming of equipment log data.

The high-speed connectivity provided by either wireless or fiber optic cables connects the field well with the remote control station and ultimately with the enterprise systems. Data collected from the field station, via the DDS bus , can be stored for future historical and predictive analysis. This will allow on-shore analysts and process planners to adjust and control the well operations by sending corrective feedback to the well systems.

Another opportunity that the IIoT delivers is that of enabling massive data collection and subsequent analysis . Prior to the advances and public access to the vast resources in cloud computing, it just was not feasible or economical for even cash rich oil and gas companies to hoard vast quantities of data. After all, the amount of data generated by an operational drilling or production oil well can be vast. However, now that has changed with the Industrial Internet technologies being able to accommodate both the storage and the compute power to analyze these vast data sets. A typical use for such technology would be in intelligent well monitoring, whereby entire fields of sensors are monitored and the data accumulated to provide data to a remote control center for historical and predictive analysis.

Furthermore, an additional use-case for the oil and gas industry of IIoT is in the deployment of intelligent real-time reservoir management . In order to benefit from analytics, whether they are historical or predictive, all the systems within the ecosystem must be connected and contribute to the pool of data. The larger the pool of data, the more reliable the results of algorithms will be, as it can mitigate the risk of irregular data patterns that do not necessarily reflect the true nature of the process. For a simplistic example, consider tossing a coin ten times and then ten million times when considering the probability of heads or tails. This, connectivity of systems is even more important when dealing with real-time analytics on streaming data, where real-time analysis and feedback is required. However, the topology of large-scale analytical networks is not trivial, with systems interfaced and data driven via a data bus to the cloud or to streaming analytical tools. With DDS, a designer can decouple the complexity of the physical connections among computers, machines, systems, and sites by provision of a single logical data bus.

Finally, a last use-case example shows how deploying IIoT protocols and technology can ease the production and deployment of industrial platforms as it decouples software from the operating system, thereby making application development more agile, quicker, and cheaper.

The real potential of the IIoT is to create new, intelligent ways of working, through automation, intelligent machines, and advanced analytics. In the oil and gas industry, IIoT methods and technologies are already being adopted to reduce costs and increase efficiency, safety, and ultimately profits. However, the future of the IIoT must integrate with the cloud, which then has the potential to merge local applications into larger regional or global systems, to become a network of systems that deliver the full potential of Big Data analytics to industry.

Smart Office

Buildings are critical systems, and they are responsible for approximately 40% of the total EU energy consumption. What is worse is that buildings are also to blame for 36% of green house gas emissions . However, controlling or reducing these figures is not easy. Even with a three-pronged strategy, such as improving building insulation and energy efficiency and providing better building control systems, progress has been painfully slow. Typically, this is due to the results of several conditions. The first of these strategies—improving insulation—is a major cost saving incentive for any building as it reduced heating or cooling costs to the inhabitants. Furthermore, it reduces energy costs and reduces CO2 emissions and is easy to implement into the design and installation of new buildings, but very expensive and difficult to deploy into existing buildings. The reason for this is that most older buildings were simply not designed to be energy efficient.

The second strategy for improving the building’s energy efficiency , for example, by changing light bulbs and strip lighting for LED lights, is gaining some traction but is still under exploited. This may be due to a failure to get the message across to property owners and businesses. However, the third strategy, improving building management through automation control systems, can provide the potential to improve building energy efficiency and reduce green house emissions.

Unfortunately, like installing insulation into existing buildings, especially older ones, deploying a building control management system is a painful task, both in financial costs and in business disruption. Previously, installing sensors and actuators (such as on radiators or on AC units) required major refit work. However, with the recent advances in technology and the IoT in particular, sensors and actuators are now “smart” and can use wireless communications, which greatly reduces the disruption and much of the cost.

The integration and development of sensors, devices, and protocols based on the IoT are important enablers of applications, for both industries and the general population, by helping to make smart buildings a reality. IoT technology allows for the interaction between smart things and the real world, providing a method for harvesting data from the analogue world and producing information and knowledge in the digital world.

For example, a smartphone has built-in sensing and communication capabilities, such as sensors for acceleration, location, along with communication protocols that support Wi-Fi, SMS, and cellular. They also have NFC (near field communication ) and RFID (radio frequency identification ), both of which can be used for identification. Consequently, the smartphone provides the means to capture data and communicate information. Also, the ubiquity and user acceptance of the smartphone makes them an ideal HMI (human machine interface ) for smart buildings, where users need to control their own environmental conditions.

Nevertheless, the IoT comes with its own set of problems, such as the management of huge amount of data provided in real time by a large number of IoT devices deployed throughout the building. Additionally, there is the problem related to the interoperability of devices, and furthermore the integration of many proprietary protocols and communication standards that coexist in the marketplace. The protocols that are applicable to buildings (such as heating, cooling, and air conditioning machines) may not be available on devices presently available off-the-shelf. This needs addressing before wide-scale adoption is achievable.

One of the main problems with installing traditional building management systems (BMS) into existing and especially older buildings is that the traditional methods are often based on specialized protocols, which we will discuss later, such as BACnet, KNX, and LON. In addition, the alternative WSN (wireless sensor networks ) solutions are based on specific protocol stacks typically used in building control systems, such as ZigBee, Z-Wave, or EnOcean. The deployment is much easier than with the BACnet wired bus, but they still have issues with integration into other systems.

To this end, in 2014, IoT6 (a European Union working group) set up a testbed for a smart office to research the potential of IPv6 and related standards in support of a conceptual IIoT design. The aims were to research and test IPv6 to see whether it could alleviate many of the interconnectivity and fragmentation that currently bedevils IoT implementation projects. The methods the IOT6 group decided on was to build a test office using standard off-the-shelf sensors, devices, and protocols. IPv6 was preferable but not always an option due to lack of availability. The devices were connected via a service-orientated architecture (SOA) to provide Internet services, interoperability, cloud integration, mobility, and intelligence distribution.

The original concept of the IOT6 Smart Office was to investigate the potential of IPv6 as a common protocol, which could provide the necessary integration required between people and information services, including the Internet and cloud-based services, the building, and the building systems.

The IOT6 team hoped to demonstrate that by better control of traditional building automation techniques, they could reduce energy consumption by at least 25%. In addition, they hoped to ease the deployment and integration of building automation systems, something that is typically costly and requires refits and expensive installation. They also looked to improve the management of access control and security by utilizing smartphones as an HMI .

With regard to the integration of people and the building information services, the testbed would provide a location, a smart office that was fully equipped and operational. It would provide a meeting and conference rooms, and they would also provide for innovative interfaces within the building (virtual assistant, etc.) that would enable users to interface with their environment and customize the actions of sensors controlling things like the temperature, lights, and blinds. Furthermore, the office would have full information and services, such as computers for Internet access and displays to provide real-time information on the state of the world. In addition, the smart office would provide a professional coffee machine—a machine that provides hot water 24/7.

One of the goals of the IOT6 testbed was to provide a platform for testing and validating the interoperability among the various of-the-shelf sensors and protocols and the conceptual architecture of the Industrial Internet of Things. They were determined to interconnect and test wherever possible multi-protocol interoperability with real devices through all the possible different couplings of protocols (among the selected standards). Also, they wanted to test and demonstrate various innovative Internet-based application scenarios related to the Internet of Things, including business processes related scenarios. In addition, they planned to test and demonstrate the potential of the multi-protocol card, IPv6 proxy’s for non-IP devices, and estimate the potential scalability of the system. Furthermore, they would deploy and validate the system in a real testbed environment with real end users in order to test the various scenarios.

The four scenarios tested were:

The first scenario involved the building maintenance process, which is the process of integrating IPv6 with standard IoT building control devices, mobile phones, cloud services, and building management applications.

The second scenario addressed user comfort in the smart office and this is really where the office does become intelligent or “smart”. In this scenario, a user is identified by his mobile phones, NFC, or RFID, and the control management system will adjust the environment to the user’s pre-set or machine learned preferences, such as temperature or light levels that provide the user with a welcoming ambience. When a visitor arrives, detected again by RFID on their mobile phone, the CMS can turn on the lights in the reception area and play music and video, again to provide a welcoming atmosphere. When the last person leaves the smart office, detected by presence detectors, the CMS will turn off the lights and reduce the HVAC to the standby condition.

The third scenario related to energy saving and awareness. In this scenario, the intention was to demonstrate the use of IPv6, with a focus on energy management and user awareness. The intention was to allow a user, when entering an office, to adjust the environment using their mobile phone app. The mobile app will display current settings and when the user selects to change the setting the mobile app will display the energy consumption implications of such modifications. Once the user leaves the room, the system returns the settings to the most economical energy configuration.

The fourth scenario entailed safety and security and focused on intrusion detection and fire-detection. In this scenario, the system learns of a security issue due to presence detectors, which notify the system of someone being in a room that is supposedly empty, or magnetic switches on windows or doors trigger the alarm. Similarly, temperature sensors or smoke detectors can trigger fire-detectors. In both cases, the system looks up the IP addresses of the closest security server and possible backups. The system contacts the local data server by sending the data by anycast with QoS and priority routing. If it does not receive a reply, it sends duplicate data to another group of security servers. The system also contacts the closest duty security agent, who can then access the location via remote video using their mobile phone app.

The IOT6 group discovered through their technical analysis of the Smart Office that there were many significant improvements when deploying a building control management system using IoT devices based on an IPv6 -aware protocols such as 6LoWPAN and CoAP on a native IPv6 network (discusses later in the technical chapters). They reported improvements in ease of deployment, scalability, flexibility/modularity, security, reliability, and the total cost of deployment. The technical reports key performance indicators focused on energy savings and improvements in energy efficiency.

Logistics and the Industrial Internet

Logistics has always been at the forefront of the IIoT, as so much of the opportunities and techniques are a perfect match for the logistics industry. Therefore, it is no surprise that the logistics industry has been using many of the sensors and related technologies associated with the IIoT for years. For example, logistics have been using barcode technology in packaging, pallets, and containers for many years as a way to monitor inbound deliveries and outgoing dispatches from warehouses. This was a huge advance from the previous method of opening each attached delivery note and physically checking the items. However, using manual barcode scanners was still labor intensive and although accurate if performed diligently there were still pallets overlooked or products going undetected. In order to address these inventory control processes, logistic companies sought an automated solution using IIoT techniques and wireless technologies.

The solution is to use embedded RFID tags and the associated RFID readers, which can scan entire rows or stacks of pallets queued at the inbound gate simultaneously. This is something a barcode reader had to perform one at a time, which is an improvement in speed and accuracy as every RFID tag in radio range on every pallet, whether visible or not, is read by the system. The RFID reader automatically records the RFID tag’s information such as the order ID, the manufacturer, product model, type, and quantity, as well as the condition of the items before automatically recording the delivery in the ERP system.

Once the inbound delivery has been recorded and the items moved to the correct stock location, the tags can be updated to show the relevant stock details, such as part numbers and location. They can also communicate other information using temperature and humidity sensors and send information regarding the environmental storage conditions. This allows warehouse staff to take action before the stock becomes damaged.

Another major benefit of using RFID tags is that they allow for fast and accurate audits of stock. Stock level is managed through an ERP application interfacing with the RFID readers, so changes in stock levels are updated automatically and stock levels are continuously updated and discrepancies are immediately alerted.

Similarly, for outgoing stock control when an order is dispatched, an RFID tag reader can read all of the pallet tags as they pass through the outbound gates and automatically adjust the stock holding for every item simultaneously, while also updating each order’s ERP delivery ticket as being complete and in good condition.

Automating stock control task such as delivery and dispatch has improved operation efficiency and stock control accuracy because booking in and out products to warehouses is now a trivial process.

Such is the competitive advantage gained by adopting sensor technologies in improved operational efficiency, for example faster, accurate, and cost-effective warehouse management, logistic companies are always keen to explore new IIoT initiatives. The areas that are proving appetizing to logistic companies are with optimized asset utilization, whereby a centralized system can monitor the condition, status, and utilization of machinery and vehicles. This is important for warehouse managers as they often unintentionally overutilize some assets while underutilizing others. For example, a forklift truck may sit idle in another area of the warehouse, when other forklifts and drivers are working continuously.

Another operational issue is that in large warehouses, forklift productivity can be problematic. This issue arises as the result of drivers needing to find the stock locations and navigate the aisles and rows trying to locate the correct products. Using a combination of location sensors, barcodes, RFID tags, and ERP stock data, it is possible to instruct the driver to the location of the stock items and provide directions of how to get there from the driver’s current location. This is a method adopted by Swisslog’s SmartLIFT technology , which uses directional barcodes on the ceilings and aisles, in addition to forklift sensors and warehouse stock location data to create a visualization of each stock location in relation to the forklift’s current position. By working similar to GPS, the system informs the driver as to the best route to the stock. SmartLIFT technology improves forklift utilization and reduces stock-handling errors considerably.

Forklifts are the cause of over 100,000 accidents each year in the United States alone, with almost 80% involving pedestrians. Therefore, the logistics industry is keen to utilize IIoT to prevent many of these accidents. There are several ways that IIoT can help, for example, by using sensors, cameras and radar on forklifts to warn the driver of the presence of pedestrians and another forklift. Ideally, a forklift would communicate with other forklifts, ensuring they were aware of one another to take avoiding action, such as slowing or stopping at blind intersections if another forklift is detected in the immediate vicinity.

However, in the developed world it is still far more common to pick-by-paper , which is the term applied to the manual human picking of goods from a shelf. Forklifts, autonomous vehicles, and robots are great for heavy lifting of large pallets, but not much use for picking small intricate articles out of a stock bin. This is where human workers are in their element. Remember all those pedestrians being injured in the warehouse by forklifts? Well those pedestrians are most likely to be the pick-by-paper workforce. These are workers employed to collect individual stock items from a list. It is not very efficient and they have the same problems as the forklift drivers, finding their way around the warehouse and locating the stock.

However, help is at hand through augmented reality. The most commonly known augmented reality device is Google Glass ; however, other manufacturers produce products with AR capabilities. Where augmented reality or, for the sake of explanation, Google Glass, comes into logistics is that it is extremely beneficial for human stock pickers. Google Glass can show on the heads up and hand free display the pick list, but can also show additional information such as location of the item and give directions on how to get there. Furthermore, it can capture an image of the item to verify it is the correct stock item. Where items are practically identical to the eye, for example a computer chip, or integrated circuit, hands-free, automatic barcode scan ensures correct item identification. Furthermore, augmented reality accelerates training, and since the stock pickers are often seasonal temporary workers, this is very important. The technology also allows for hands-free use, which leads to greater productivity, as workers can find the items far more quickly, which greatly increases efficiency while eliminating pick errors.

Augmented reality glasses are similarly suited to freight loading whereby forklift drivers can do away with the fright load sheet, which tells them the order each pallet has to be loaded onto the truck. In the same manner as with the stock picker, the forklift driver will see displayed on the glasses the relevant information, which increases load times as the driver has hands-free information so does not have to keep stopping to refer to a printed list.

Another very promising use-case for IoT and augmented reality is using document scanning and verification . In its most simple use-case delivery drivers can check that a load is complete with every package or pallet accounted for and loaded. In a more advanced use-case, the glasses could be used to scan foreign documentation, the type used in international trade for compliance with import export laws. The augmented reality device’s IoT integration could enable a driver to scan the document while the software looked for keywords, phrases, and codes required for the document to be valid. This could save many wasted hours at ports and borders correcting incomplete or inaccurate paperwork.

The potential IIoT use-case for logistics goes beyond the warehouse and has interesting applications in freight transportation. Currently, logistics companies perform track and trace and they can monitor the location of pallets on an aircraft mid-flight or a container on a ship in the middle of the ocean. Despite these capabilities, the industry is looking forward to a new generation of track and trace , which would bring improvements in speed, safety, accuracy, and security. For example, theft of freight goods is still a major issue and with more robust IIoT solutions deployed it would enable freight goods to be tracked meter by meter from dispatch to arrival. Advanced telemetric sensors in trucks and RFID tags on goods will allow for accurate and predictive location and condition monitoring. Multiple sensors in freight goods will monitor conditions such as temperature, humidity, shock, or even if a package has been opened, which might indicate potential theft.

The trucks themselves can use advanced telemetric sensors to predict when and how the vehicle will require maintenance and to automatically alert the driver and maintenance crews and even schedule a window for the required service. However, it is not just the trucks that require monitoring; drivers have to work long hours, sometimes in hazardous conditions, and fatigue can be a health and safety issue for themselves and other road users. There are already technologies in use that help detect driver fatigue. For example, Caterpillar uses infrared cameras to monitor the driver’s eyes, and a computer monitors blink rate and pupil size. Should it detect the drivers are sleepy, it will alert them using audio alarms and seat vibrations.

Another possible use-case is in supply chain management where the predictive analysis techniques of Big Data can come into play. The world’s largest logistic companies need to know the latest current events on a global scale, such as the political climate as well as the local weather conditions that affect traditional trade routes. They need to know of impending strike action by traffic controllers or crane drivers in a shipping port, as these could cause massive disruption and have a knock-on effect to a customer’s stock inventory levels. However, with trucks and goods bristling with sensors, it is now possible to harvest this data on a global level. When combined with data on current affairs, natural disaster, socioeconomic unrest, and similar threats to traditional trade lanes. It will be possible to manage threats proactively by moving cargo from air to sea or vice versa to mitigate the threats of strike action.

Similarly, urgent cargo routes can be altered in real-time if predicative analysis of all the global data shows a high risk of civil unrest or bad weather on route, which could seriously delay delivery. Predictive analysis through Big Data is becoming a required tool for business intelligence analysis; it is believed that over 80% of businesses will adopt it in one form or another in 2016. The promise that predictive analysis holds for global logistics is that they will be able to take proactive action to mitigate potential threats to their operations and keep their freight moving to the destination.

Retail

Retailers, like most businesses, suffer IT costs and overheads, which directly affects their profits, as they must pass these costs onto the customer as part of the cost of goods. Therefore, it is in the retailers’ interest to reduce, manage, or at least leverage value out of these IT costs.

IT costs incurred by a retailer typically come in the form of IT systems required to run the business and the follow-on costs of supporting those systems. In order to reduce their IT costs , the retailer must find a way to meet their requirements using a cheaper, more efficient technology. The high IT costs in retail are generated by replication of hardware and software licenses, IT support such as site maintenance, and break-fix callouts. Any solution that reduces those variable high overheads and transforms them into a lower fixed cost is a favorable alternative.

Retailers require a means of collecting payments, temporarily securing cash and credit receipts, recording sales transactions, refunds, partial payments, the running cash balance, and importantly produce an end-of-day sales report. All this information is required for the retailer to reconcile the end-of-day sales reports with the cash in hand. This might not seem much but for a retailer with say 1,000 stores reconciling the total sales at the end of day, both individually and collectively can become an onerous task.

Traditionally, the retailer accomplished end-of-day sales reconciliation by using cash registers overseen by store managers. Cash registers evolved into point of sales (POS) machines , based on PC technology with specialist peripherals, such as a cash box and a barcode scanner. Therefore, as this is at the technology level simply a computer with POS software replicated in every store, we can optimize this by shifting the intelligence and the majority of the IT burden from the individual store into a central location—the cloud.

By shifting the IT burden out of the stores to a networked environment, the head office, and into the cloud, we greatly reduce the capital (Capex) and operating (Opex) costs. We reduce equipment costs for the stores as now the POS device simply needs to run a web browser as the POS application runs in the cloud. Therefore, sales assistants can use mobile devices such as tablets or smartphones, freeing them from the fixed sales point, and this can reduce the burden of staffing a busy store. These savings alone can turn a borderline store into a viable one.

However, running the POS application has greater operational value, such as central administration and management. Previously with legacy POS solutions each store completed its own end-of-day report and sent it to the retail head office, which had to collate all the reports into one unified report. This could take until late the next day before the manager/owner had a clear picture of the overall sales performance. However, with a cloud POS application, the individual and collective reports are available at any time and from anywhere—and they are accurate.

Having an immediate view of the individual and overall sales performance optimizes other areas of the business, such as stock control (inventory). After all, every sale requires a stock replenishment or at least set the process in motion. By storing all the individual stores data in a central multi-tenant database, which segregates each stores sales and stock, the cloud application can automatically handle sales and stock management both at an individual and collective perspective, and do it in real time, not late the next day.

Central management is a very important feature of a cloud POS as it allows management to apply a central policy to every store and POS device with the click of a button. It also enables the automation of processes, procedures, and workflows, which manage stock replenishment.

Real-time reporting and visibility is also a major cloud service that shortens the decision-making process. Having immediate access to reports and live status reports enables greater control and more timely management. For example, during sales promotions the performance at individual stores are tracked as they happen, tactics altered, and decisions made to immediately replenish dwindling stock, as events unfold and not on yesterday’s stale data.

As we have seen, retailers can reduce costs by taking a cloud POS strategy to IT and the remaining costs managed and leveraged to provide value to the business. Direct IT cost savings come about through reduced hardware/software and support/maintenance. A cloud POS solution removes these costs replacing them with one fixed monthly fee. This alone reduces the cost of goods and increases profit. Additionally, cloud POS provides the services to create value through efficiency and control, and the ability to manage the business in real time.

IOT Innovations in Retail

Innovations in the retail industry have gone well beyond just operational efficiency; the retail industry has positively embraced the IIoT. Here are some examples of the change in mindset.

The IIoT will provide a means for innovation for retailers previously unimaginable, for example, it facilitates, a means to communicate directly to customers through omni-channels, such as in-store interactive advertising, web promotions, social media, video, and augmented reality. Let’s not leave the traditional media, such as newspaper, magazines, and TV/radio behind, as they still have massive consumer reach. However, in order to stay relevant, retailers have to deliver the right message via the popular channels that focus on their customers’ preferences, and importantly look forward to getting their message across to the next generation of customer.

This approach requires a transformation in how retailers adopt the IoT as it is at the heart of this transformation. The potential of the omni-channel reach of the IoT is that it connects people, machines, items, and services, well beyond any single communication channel, such as TV. Therefore, retailers, in order to streamline the flow of information, must ensure that their advertising strategies are delivered over omni-channels. It’s also important that retailers target customer real-time decisions and heighten consumer experiences, as this is paramount in the Internet age.

Leading fashionable retailers that target young fashion-conscious consumers are already investing billions in the IoT—think about mobile phone shops and high street fashion stores. Their adoption of high-tech advertising and providing in-store virtual customer experience provided by the adoption of the IoT has realized the financial returns beyond expectations. The operational and financial benefit that retailers have reaped range from efficient inventory management to real-time customer targeted promotions, and in-store entertainment that increase footfall, develops the brand and ultimately increase sales. These pioneers of IoT have identified early that it was necessary to evolve and transform their business practices to conform with the shift in their customers’ lifestyles. They also identified that, in time, the IoT will touch nearly every area of retail operations and customer engagement.

Retailers that have managed to successfully navigate this transformation, from traditional to state-of-the-art, have not only embraced innovation but have realized the potential of IIoT.

Retailers may well understand the concepts of the IIoT, as well as the business and marketing potential. Unfortunately, they find there is rarely concrete evidence of the specific competitive advantage. More often than not, the IIoT is portrayed as deploying high technology, such as augmented reality, RFID customer tracking with personalized advertising, and similar marketing concepts that would not fit easily with most retailers’ current or even future customers.

The advantages of IoT are not delivered just through enhanced customer experience—many of the benefits come in the back store, in stock control, inventory management, perishable and cold chain management, and for larger operations, digital signage, fleet management, and smart fulfillment centers. As an example, three of the largest supermarkets in the UK reported savings of 50% after the adoption of the IIoT.

For some retailers deploying IIoT solutions, it has meant installing a vast range of bewildering technologies, including hardware, sensors, devices, apps, telematics, data, and connectivity to the cloud. Even so, the operational benefits are clear, and in addition, there are further gains that can be reaped from interactive advertising. This innovative form of advertising works by embedding NFC or RFID tags to products, which provide customers with additional information when they are in close proximity. An example, of this is when a potential customer stops in front of a product on a supermarket shelf, a digital sign located below the product is activated to provide further information, such as nutritional data or in the case of clothing, social-media ratings and perhaps a current discount. These may sway the customer’s purchasing decision.

The trouble is though, is that all of this can be a big turnoff to the customer. Not everyone wants to have such intrusive marketing thrust upon them. As a result, retailers are attempting to design the customer experience, which they now realize can become as important as advertising the products. With the shopping experience becoming increasingly more valued than material items to the customer, it makes sense to begin planning for new products and services with the customer’s experience in mind.

What retailers that operate in a business-to-consumer or a business-to-business model have realized is that adopting IoT concept and technologies will simplify life for the target audience and offer a fulfilling customer experience. The intent is that the IoT initiatives and technologies deployed will not just push products, marketing, and services, but will contribute to the overall enhanced customer experience, which results in higher individual sales and greater gross profits.

Of course, not all customers are the same. Some absolutely revel in high technology as can be seen though the success of stores deploying augmented reality. In these stores, retailers have gone a step beyond inventory control and NFC card payment retailers and have provided a virtual magic mirror.

Augmented reality is a new trend in retail as it provides a way for customers to evaluate products interactively and compare them to other similar products or consider their suitability to the environment they would be situated. Examples of augmented reality are the latest IKEA catalogue, a mobile app that enables customers to virtually simulate having the items of furniture in their real living room. The customer can arrange the virtual furniture in different location checking for dimensions, color schemes, and alter their choices to suit. Similarly, an LA-based fashion company, Uniquo’s magic mirror, has created a stir, as it allows customers to try on one item of clothing, then the AV mirror recognizing the size, style, and product can change colors to show available alternatives, without the customer having to change each time.

However, IoT and augmented reality do not stop there. Virtual interfaces can go even further as demonstrated by Yihaodian, the largest food e-retailer in China. The company recently announced that it was going to open the first AR supermarket chain in the world. Each of these virtual supermarkets has a completely empty floor space and situated near high footfall areas (e.g., train or subway stations, parks, and universities). The interesting thing is that while the naked eye will just see empty floors and walls, people using an AR-capable device, for example Google Glass, will see shelves filled with vegetables, fruit, meat, fish, beer, and all sorts of real-world products. To buy these virtual products, the customer scans each virtual product with their own mobile devices, adding it to their online shopping carts. They subsequently receive delivery of the products to their homes.

https://www.rti.com/whitepapers/5_Ways_Oil_Gas.pdf

iot6.eu/sites/default/files/IoT6%20-%20D7.3.pdf