Solar-Heated Water

How we proved the skeptics wrong.

Photography by Dan Bassak

Our quest to use solar energy started in 1996 when we decided to build a new home. In our area of Pennsylvania, the sun shines only about 50% of the time, on average, and the winters are cold. Contractors said that solar would not work, and the bank refused to lend us money for this type of home.

Fortunately, a good friend believed it could be done and financed our home so that we were able to build it as designed. Now that our heating bills are less than half those of our neighbors, we’ve proven the skeptics wrong.

For the past 12 years, our south-facing windows have saved us a lot on heating costs — but we still burned a fair amount of oil to make hot water. In spring 2008, when the price of heating oil was $4.50 a gallon, we searched for a way to use less oil. Our goal was to use none at all to heat our water during summer, while reducing consumption dramatically throughout the rest of the year.

Our system uses what I call the make-and-hoard method: it makes as much hot water as it can on sunny days, and stores it in well-insulated tanks for later use.

I started by purchasing two inexpensive 80-gallon stainless steel storage tanks and circulator pumps on eBay. These, along with our existing 40-gallon oil-fired tank, give us a total capacity of 200 gallons. Assuming the average person uses 20 gallons of hot water per day, the solar-heated system contributes sufficient hot water for my wife and myself for four days. And when it’s full to capacity, the system continues to preheat our well water, reducing the amount of fuel oil we use to heat water in the 40-gallon tank.

Since the temperature in our area drops well below freezing during the winter, I used a closed-loop system with food-grade antifreeze. The solar collector is located at ground level on the hill behind my house, to allow me to keep the snow off and to maintain it when necessary (Figures A and B). It uses 90 Thermomax pyrex-glass vacuum tubes with coated copper strips inside each (Figures C and D).

The vacuum insulates these collector tubes for a near-zero heat loss. The copper strips are attached to copper pipes that contain a small amount of antifreeze in a vacuum.

At 90°F, the antifreeze boils and the steam rises to the manifold, which heats water circulating through pipes that run underground between the solar collector and the heat exchangers in the tanks, located in our basement (Figure E).

A differential temperature-controller unit regulates the system. Sensors monitor water temperature in four locations: in the solar collector, in each of the two 80-gallon storage tanks, and in the common return line back to the collector (Figure F).

When the collector is warmer than the return line, the controller turns on the pump that circulates the heated water in the collector to the heat-exchanger coil in the first tank. If there’s enough sun, this circulation continues until the tank reaches 180°F, at which point the controller switches the flow to the second storage tank and heats the water in there.

If the second tank reaches 180°F, the controller will shut down flow to both tanks and turn on a small pump (Figure H, following page) to dump any extra heat to a radiator, which will safely dissipate the heat so that the system won’t make steam. I also added a small bronze circulator pump to refresh the oil-heated tank with warm water from the first solar tank before the oil burner will run.

If the power fails, the collector will stagnate in the full sun, and high temperatures will build. Since many plastics melt under these conditions, I needed to find the right type of pipe to run from the collector to the tanks and back, about 160 feet, round trip.

I was going to use PEX plastic pipe until I discovered EasyFlex, a newly approved, stainless steel corrugated pipe that’s light, flexible, and perfect for solar hot water, at half the cost of copper. I ordered it with an exterior plastic coating, so that its corrugations won’t act like a radiator and waste heat. The coating is rated to boiling temperature (100°C/212°F), and it made pulling 80 feet of pipe through a 4-inch PVC conduit much easier (Figures I and J). I recommend soldering (sweating) all the plumbing, because the temperature extremes can cause threaded pipe connections to fail.

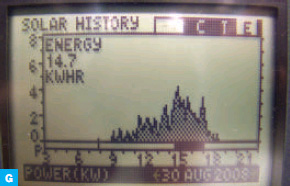

The day we installed the tubes in the collector, the sky was overcast, with not enough sun to cast a shadow. Yet after installing only three of the 90 tubes, the system started to make warm water (Figure G) and store it in the basement tanks.

With the system fully installed, we’ve been able to generate more hot water than we can use. And it works great in the winter; even at –10°F outside, the system is making 160°F water to store, eliminating most of our need for fuel oil to make hot water.

Our cost for materials was $12,000, which will be reduced 30% with a federal tax credit. I estimate the system will pay for itself in six to seven years.

Dan Bassak is an electronics technician specializing in biomedical equipment repair and modification. He also builds gadgets that assist his wife, Trina, a blind physical therapist. They enjoy roller-skating, organic gardening, solar living, and bread baking.