WITH THE GRAIN: Mike LaVecchia, president and founder of Grain Surfboards, stands outside his shop next to a book-matched beauty he built.

Photography by Mark Marchesi

Locally Grown

Carving boards and waves with the maker of all-wood Grain Surfboards.

Mike LaVecchia and Brad Anderson own Grain Surfboards, a small company on the coast of Maine making wooden surfboards and DIY surfboard kits from sustainably cut, locally milled northern white cedar. Born in LaVecchia’s basement in 2005, the company now employs seven people.

The handmade boards are computer-designed to maximize the efficient use of the wood — to “save some trees but also save some money,” LaVecchia says — and constructed in a modern rib-and-keel style with roots in traditional boatbuilding. Grain also offers weeklong surfboard-building classes whose pupils each go home with a beautiful wave vehicle they’ve made with their own hands. I spoke with LaVecchia from his workshop in York, Maine.

Peter Smith: What goes into building an all-wood board?

Mike LaVecchia: Our boards are hollow and are built around an internal frame, which a lot of people equate with an airplane wing. So you’ve got an internal structure that gives the board the shape, then cedar planks and these specially milled strips that you build up around the frame.

PS: Why did you choose hand craftsmanship?

ML: I’ve been around wooden boats most of my life. Love the feeling of them. Love the fact that no matter where you are, you can repair it. You can fix it with common materials. There’s no real mystery technology there. If you can build it by hand, then you can fix it by hand.

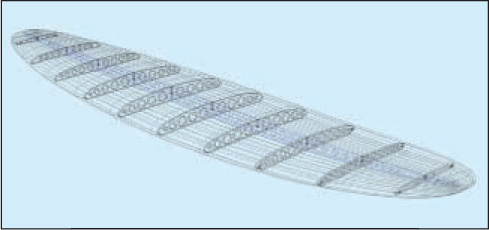

A student in a surfboard building class shapes his rails with a hand planer; a Grain employee teaches a lesson on board building; CAD drawings, like this one showing the “airplane wing” structure of a funboard, let the makers refine their designs based on customer feedback.

Our boards are designed in AutoCAD, so we can get it really dialed in. We send designs back and forth to a customer and get feedback and tweak things. Then, the idea is to build it as accurately as possible. We don’t quite have the freedom that somebody shaping a foam blank does.

PS: But you don’t wear dust masks either.

ML: Exactly. We do all of our work with edge tools. Never wear a dust mask. You’re not worried about breathing dust, fumes, and all that kind of stuff. We do have to sand, but compared to what you’re doing with a foam board — power planers and sanding screens — it’s just such a nicer process.

PS: Why did you create kits and classes for people?

ML: Once we really dialed it in, we thought, “This is easy and fun.” We can’t get the prices down to where most foam boards are, so we thought, “Why not offer them as a kit?” We still think of it as selling a surfboard, it’s just they have to put it together. We’ve put a ton of time into our manual. We get a lot of satisfaction that people are out there doing it.

PS: What tools would I need to build one at home?

ML: Everything that goes into the board comes with the kit. All the planking, the rail strips, the frame, all the glues, the fiberglass, the epoxy, fin boxes, all the hardware. You need clamps, and some edge tools — like a hand plane and a spokeshave. You could spend 75 bucks and have everything you need.

The clamps can add up [but] if you take a 4-inch PVC pipe and cut pieces off it and open the pipe up, it’s got tension in it. It’s a real inexpensive way to make your own clamps.

PS: Is it ever too cold to surf?

ML: Rarely. Wetsuits have come a long way. There’s some cold days, though. Luckily, we all live close by, so it’s nice to run home and jump in the hot shower.

Peter Smith lives in Maine and has covered food, culture, and technology for Good, Gastronomica, and The Atlantic Online. peterandreysmith.com