Chapter 9

Auto & Shop Information

IN THIS CHAPTER

Looking under the hood of vehicles

Knowing the tools of the trade

Checking out the many uses of fasteners

Driving up your test score

Ever wonder why automobile mechanics and carpenters charge you about a billion dollars an hour when you need to hire their services? Because if the jobs were easy, everyone would do them.

Fortunately, to do well on the Auto & Shop Information (AS) subtest of the ASVAB, you don’t have to get your hands greasy or chance hitting your thumb with a hammer. The questions on this subtest are pretty basic. Automotive questions usually ask about basic automotive systems and malfunctions. The shop questions generally ask you to identify a tool or fastener or the purpose of such.

The Auto & Shop Information subtest consists of 25 questions on the paper and pencil version. Happily, the ASVAB gurus give you 26.4 seconds to answer each question (11 minutes total). About half of the questions measure your basic knowledge of automotive principles and half query you about shop tools and basic shop principles. On the CAT-ASVAB, you have 7 minutes to answer 11 questions on Auto Information and 6 minutes to answer 11 questions on Shop Information. Your scores on these subtests are combined to give you a single Auto & Shop score.

Checking under the Hood

Contrary to what you may think, an automobile is much more than the mechanical monster you park in your driveway each night. It’s a complex machine that has undergone more than a century of evolution. Henry Ford would probably have a stroke if he could see what his simple horseless carriage has evolved into.

The modern car is divided into several primary and secondary systems. I cover these systems in the next few sections.

The engine: Different strokes

How does an engine work? You turn the key, and if it doesn’t start, you call your mechanic or your folks, right? Well, not quite. The internal combustion engine burns a mixture of gas and air. Burning the gas and air (the fuel mixture) makes it expand quickly (explode). The pressure from this explosion is transferred (via additional systems) to the wheels to make the car move.

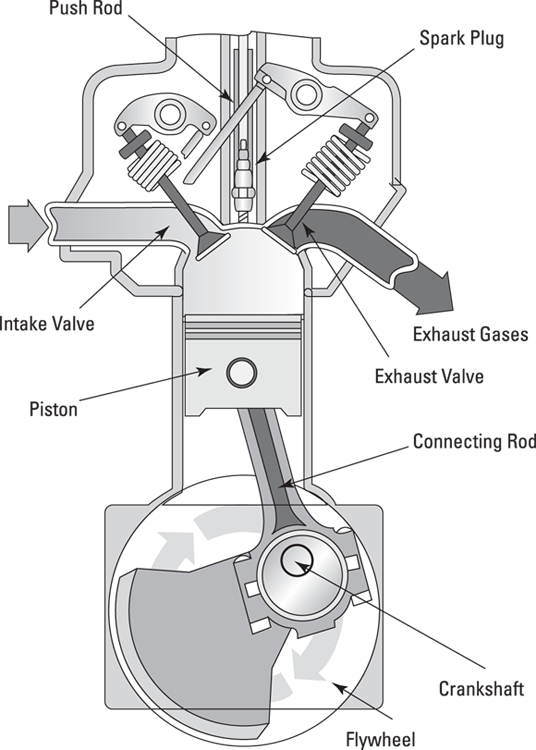

The movement is brought about by a cycle, which your car’s engine repeats a zillion-and-one times. Here are the four strokes that make up a cycle (Figure 9-1 illustrates how this process works):

- Intake: The intake valve opens as the connecting rod pulls the piston down, drawing the gas/air mix into the cylinder.

- Compression: The valves are closed. The connecting rod pushes the piston up, compressing the gas/air mix.

- Power: The spark plug ignites the gas/air mix, forcing the piston down. That pushes down on the connecting rod, turning the crankshaft; the crankshaft turns the flywheel, which keeps the engine going.

- Exhaust: The exhaust valve opens as the connecting rod moves the piston back up, pushing out the exploded gases. The valves are timed, of course, using push rods attached to the camshaft.

© John Wiley & Sons Inc.

FIGURE 9-1: A four-stroke engine.

In order for the cycle to happen at all, fuel must be properly mixed with air and transported within the cylinder at the proper time. Various components perform this function. Depending on how old a car is, it may use a carburetor or fuel injectors:

- Carburetors: Carburetors are used on most older cars (pre-1990) to mix the fuel and air mechanically. As air moves quickly through the carburetor, it creates a vacuum, which draws more and more fuel into the mixture.

-

Fuel injectors: Fuel injectors have replaced carburetors on newer cars to perform the air/fuel mixture function. (Actually, fuel injectors have been around since the late 1950s, but they weren’t widely introduced until the late ’80s and early ’90s.) The fuel injector acts as the fuel-dispensing nozzle. It injects liquid fuel directly into the engine’s air stream. In almost all cases, this requires an external pump.

A doodad called the EFI computer (electronic fuel injection computer) determines the amount of fuel entering the engine. The EFI computer receives information from the sensors in the fuel, air, and exhaust system, and from that information, it determines how much fuel the engine needs to operate at optimum levels.

A throttle is mechanically connected to the carburetor or electronically connected to the EFI computer. Advancing (opening) the throttle causes more fuel to be transferred to the carburetor or the fuel injectors. The accelerator (the gas pedal) is connected to the throttle by mechanical linkages. The harder you push on the gas pedal, the farther the throttle is advanced (opened). Thus, more fuel is transported to the carburetor or fuel injectors.

Cooling system: Acting cool, staying smooth

Because of the high temperature at which the fuel burns, the engine has a cooling system (otherwise, the engine would melt). In this system, water jackets surround the parts that reach the highest temperatures. A water pump circulates water through the jackets. While the water circulates, it absorbs heat from the engine and then passes through the radiator, where outside air cools the water.

The water in the system is usually mixed with coolant (antifreeze), which raises the boiling point of the water (which keeps the water from boiling away) and lowers its freezing point (which keeps the system from freezing up during cold weather).

In addition, the engine parts must be lubricated to prevent them from breaking down, which occurs if the metal parts are allowed to rub against each other. An oil pump circulates oil through the engine; oil flows through the crankshaft and connecting rods, lubricating as it goes. Lubrication reduces friction, which in turn reduces heat.

Electrical and ignition systems: Starting up

Your car requires more than just gasoline to operate. It also needs a supply of electricity. In the old days, automotive electrical systems operated on 6 volts. Shortly after World War II, as electrical accessories became more prevalent in automobiles, 12 volts became the standard.

An electric motor powered by the battery starts the engine when you turn the key or push the ignition button. This motor is called a starter (for obvious reasons). A gizmo called an alternator sends an electric current back to the battery to keep the battery charged and also powers the other electronic gadgets on your car when the engine is running.

The ignition system supplies a high-voltage current to the spark plugs to ignite the fuel mixture in the cylinders. (See the section “The engine: Different strokes” earlier in this chapter.) The system takes the 12-volt current from the battery, steps it up to about 20,000 volts, and then sends the current to the spark plugs.

In older cars, this increase of voltage is accomplished by means of a device called a coil, which uses electromagnetic induction to step up the voltage. The current then passes through an electrical/mechanical switching device called a distributor. A rotating shaft and a switch within the distributor, called breaker points, route the current through wires to the spark plugs. A condenser absorbs excess current and protects the breaker points from damage by the high-voltage surge. The distributor and other devices control the timing of the spark-plug discharges.

In the 1970s, the electronic ignition systems were introduced. In modern ignition systems, the distributor, coil, points, and condenser have been replaced by solid-state electronics controlled by a computer. A computer controls the ignition system and adjusts it to provide maximum efficiency in a variety of driving conditions.

Drive system: Taking it for a spin

Having a working engine is all fine and dandy, but the power of the engine still has to be transferred to the wheels to make them move. This is the job of the drive system. Cars have drive systems that run on axles. The axle is the shaft on which the wheels revolve. The universal joint allows the axle to move up and down without breaking the drive shaft. The drive shaft is the connecting component that carries torque and transmits rotation. Gears on the axle allow the vehicle to make turns. Axle shafts turn the wheels. The wheels on vehicles turn in three different ways:

- Rear-wheel drive: The rear wheels push the car. The drive shaft extends from the transmission to the rear axle.

- Front-wheel drive: The front wheels pull the car. The drive shaft extends from the transmission to the front axle.

- All-wheel drive (four-wheel drive): All wheels push and pull the car at the same time. The drive shaft extends from the transmission to both axles.

Cars also have transmissions. The transmission changes the speed of the engine in relation to the speed of the rear wheels (in rear-wheel drive), the front wheels (in front-wheel drive), or all the wheels (in four-wheel or all-wheel drive). Vehicles have two types of transmissions: automatic or manual (stick shift).

The transmission consists of gears in several combinations, so the amount of torque used can vary according to needs. When the terrain is difficult (as in snow), the wheels need more torque (the force that produces rotation) in order to move. The transmission increases torque as needed. In an automatic transmission, this variation is done automatically by the torque converter. In a manual transmission, the driver shifts the gears by hand. The clutch is used to facilitate this process by disconnecting the engine from the drive shaft. It’s necessary to temporarily disconnect the engine in order to change to a different gear (torque). The clutch also allows the engine to run when the car isn’t moving.

Brake system: Pulling out all the stops

When a vehicle is in motion, you apply brakes to stop the car from moving. Each wheel has a brake that applies friction to the wheel to stop its rotation.

A brake system consists of a master cylinder that has brake lines (filled with brake fluid) running from it. The brake pedal applies pressure to the master cylinder, which sends pressure (and brake fluid) through the lines. What happens next depends on the type of brakes:

- Drum brakes: In a drum brake, the lines are connected to a hydraulic cylinder on each wheel. This cylinder contains pistons that move outward and force two brake shoes against the metal drum that rotates the wheel.

- Disc brakes: In a disc-brake system, the master cylinder forces a caliper, containing a piston, with brake shoes on each side, to squeeze against a rotating disc in each wheel, thus stopping your car by using fluid and releasing hot air.

Emissions-control systems: In layman’s terms, filters

Think of the engine as a giant cigarette and the emissions-control system as a filter. The exhaust from automobiles emits pollutants, including carbon monoxide. These pollutants are a result of the combustion process (or they’re partially combusted or unburned fuel). To prevent these pollutants from poisoning the atmosphere, manufacturers place emissions-control systems on cars. These systems include the following:

- Positive-crankcase ventilation: An old method (still in use) that forces unburned or partially burned fuel back into the cylinder so the fuel can be burned

- Air-injection system: System that forces air into the engine’s exhaust system to burn unburned or partially burned fuel before the fuel comes out the exhaust pipe

- Catalytic converter: Oxidizes hydrocarbons and carbon monoxide into water vapor and carbon dioxide (the same thing people exhale); this system doesn’t control other types of pollutants such as nitrogen oxides

- Exhaust-gas-recirculation system: Helps control nitrogen-oxide emissions by forcing some of the gases back into the cylinders

Picking Up the Tools of the Trade

You’ve probably heard the phrase “Use the right tool for the job.” This statement is what Dad used to yell at you when you’d use a Phillips screwdriver to punch holes in oil cans (thereby getting oil on your shirt). The ASVAB folks also believe in using the right tool for the job, and many of the questions on the Auto & Shop Information subtest ask you to identify the best tool for certain tasks.

Tools are easiest to understand when you classify them by their function, so the following sections are divided by function. See Figure 9-2 for an illustration of the various types of tools covered.

© John Wiley & Sons Inc.

FIGURE 9-2: Various tools you need to know for the ASVAB.

Striking tools

Striking tools apply driving force to an object. (Watch your fingers!) These tools include hammers, sledges, and mallets. Here’s a brief explanation of the three:

- Hammer: A hammer is generally made of metal or plastic and consists of a handle, a head, a face (the part of the hammer that touches the nail or other fastener), a claw (to pull nails), and a wedge that attaches the head to the handle. The face of a hammer may be made of steel, brass, or lead.

- Mallet: A mallet is generally made of metal or plastic but may be made of wood, rubber, or rawhide. It’s used to strike another tool or to strike a surface without damaging it. A mallet doesn’t have a claw like its friend, the hammer.

- Sledge: A sledge is generally made of metal. People use it to drive bolts and chisels and to break rock. A sledge doesn’t have a claw, either.

Fastening tools

Fastening tools apply fasteners, such as screws, to objects. (For more info on fasteners, check out “Sticking Materials Together with Fasteners” later in this chapter.) Numerous tools make up the fastening category:

- Stapler: A stapler is a fastening tool. Heavy-duty staplers can staple roofing felt to a roof, for instance.

- Wrenches: Wrenches turn nuts and bolts. The bolt or nut fits between the jaws of the wrench, and the wrench turns the bolt. Some wrenches have adjustable jaws. Not only can wrenches be used to turn nuts and bolts, but they may also be used to keep nuts and bolts stationary.

- Open-end wrenches: These wrenches have open jaws.

- Box wrenches: Box wrenches are closed. Some wrenches have open-end jaws on one end and a box wrench on the other.

-

Socket wrenches: Socket wrenches have box-type sockets of varying sizes that can be attached to a handle, which in turn can be attached to an extension.

Note: Socket, box, and open-ended wrenches come in set, standard sizes — either in inches or in millimeters. They’re not interchangeable. (Selecting the wrong socket wrench is how mechanics learn to use cuss words.)

- Torque wrenches: These wrenches apply additional leverage to a fastener. A torque wrench looks much like a socket wrench but has additional internal mechanisms designed to measure and limit the amount of torque (force) being applied.

- Pipe wrenches: Pipe wrenches have serrated jaws and grip round objects.

- Screwdrivers: A screwdriver, in the shop world, turns screws. (In the civilian world, it’s a yummy drink!) Some special screwdrivers have different blades to fit different types of screws:

- Standard screwdriver: A standard screwdriver has a flat blade at one end of the shank (the other end of the shank goes into a handle).

- Phillips screwdriver: Phillips screwdrivers have a blade that is shaped like a cross; this blade fits into a cross-shaped Phillips screw head.

-

Allen wrench: An Allen wrench fits hexagonal screw heads. Nobody knows why this tool is called an Allen wrench instead of an Allen screwdriver; after all, it’s used on hexagonal screws. That’s just one of the mysteries of the shop world.

The Allen wrench, which was designed in 1943, gets its name from the Allen Manufacturing Company of Hartford, Connecticut.

The Allen wrench, which was designed in 1943, gets its name from the Allen Manufacturing Company of Hartford, Connecticut. - Offset screwdriver: Offset screwdrivers have the shank set at an angle to the blade to allow the tool to be used in cramped spaces. Offset screwdrivers can have a standard blade, Phillips blade, or any number of other blades.

- Pliers: Pliers can be used to fasten and unfasten fasteners, hold objects, and cut material. When you squeeze the handles, the jaws of the pliers come together.

- Long-nosed or needle-nosed: Long-nosed pliers, also called needle-nosed pliers, have tapered jaws that can hold small objects or fit into small spaces.

- Curved-nose: These pliers have curved jaws.

- Slip-joint: These pliers can be adjusted so the handles lock in a certain position.

- Wrench or vise-grip: Wrench pliers, or vise-grip pliers, have serrated jaws that clamp onto and hold objects of all shapes.

- Cutting: These pliers are used to cut wire.

Cutting tools

Cutting tools use sharp blades to cut through metal, wood, or other materials. Cutting tools have teeth. The number of teeth per inch (or points per inch) gives an indication of the type of work the saw can do. Because of the way points and teeth are counted, a saw always has one more point per inch than tooth per inch. A saw with fewer teeth is used for rough work, like cutting wood to size. A saw with more teeth cuts more finely and is used for more delicate work, like sawing joints and lightweight pieces of wood. Check out Table 9-1 for a breakdown of the different cutting tools that may be covered on the ASVAB.

Table 9-1 Cutting Tools

Cutting Tool |

Description/Function |

Bolt cutters |

Heavy-duty shears that produce enough force when the handles are closed to slice through metal bolts or rods |

Circle snips |

Used to cut curves |

Crosscut saw |

A type of handsaw that cuts against the grain of the wood; the shape of the teeth and the angle in which they’re set are the main differences in this type of saw |

Coping saw |

A type of handsaw that’s used to cut curved lines or shapes |

Hacksaw |

A type of handsaw that’s used to cut metal; a hacksaw has an adjustable frame that holds thin blades of varying length in place; a handle is set in one end |

Pipe cutters and tube cutters |

Used to score and cut metal pipes and tubes |

Ripsaw |

A type of handsaw that cuts with the grain of the wood; the shape of the teeth and the angle in which they’re set are the main differences in this type of saw |

Snips and shears |

Snips and shears have two cutting blades that scissor together when the handles close; the blades can be curved or straight |

Drilling, punching, and gouging tools

No, this section isn’t about hand-to-hand combat training from basic training. Masters in the art of shop often make holes in the material they’re working with in order to build that perfect birdhouse (or whatever they’re working on). These holes can be made with a variety of tools, which I cover in the following sections.

Drills and bits

Twist drills use drill bits, which are round pieces of steel shaped in a spiral, to create holes. Drill bits are attached to a drill (usually a power drill but sometimes a hand drill operated by manually turning a crank). The point of the drill bit is sharpened, and the shank is smooth and fits into the drill.

Auger bits bore larger holes. They’re shaped differently from drill bits. They have a long, deep spiral flute for easy chip removal. They’re also much larger. Auger bits are most commonly used with a brace for drilling holes in wood. Their length varies from 7 to 10 inches.

Punches

Punches have a sharp end that’s placed against the material to be punctured; the other end is struck with a hammer. A center punch is used to mark where a drilled hole is to be placed; this keeps the drill bit in position and prevents the drill from jumping to another part of the material.

Chisels

Chisels are made of steel and have a sharp cutting edge. They’re used to chip or cut metal or wood:

- Metal-cutting chisels: Chisels that cut metal are usually struck with a mallet to make the cut. These chisels have different shapes depending on how they’ll be used; cold chisels are flat, and they’re used for cutting metals without using heating torches or forges, whereas round chisels make circular cuts.

-

Wood-cutting chisels: Some wood chisels, called socket chisels, are also struck with a mallet. Other wood chisels require only the pressure of your hands.

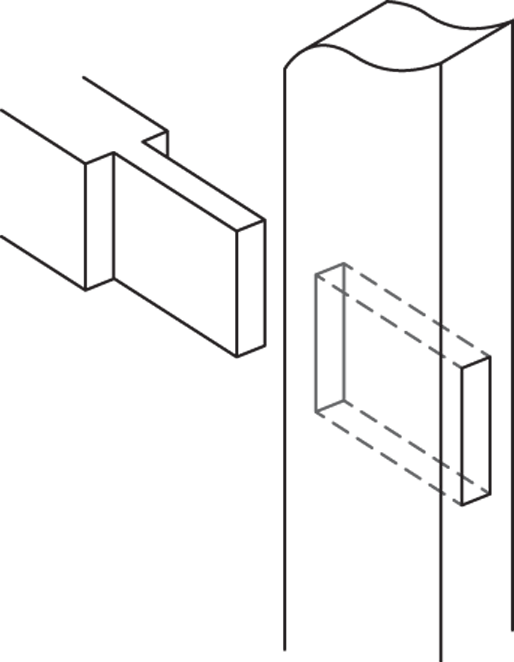

Wood chisels also come in different shapes, depending on what they’re used for. A butt chisel has a short blade and is used for in-close work. A mortising chisel has a narrow blade made for chiseling out the narrow mortises in joints. A framing chisel has a heavy, strong blade meant for rough work.

Finishing tools

Filing and finishing shop tools are used to sharpen the blades of other tools and to smooth the edges of cut metal objects. Files come in a range of fineness, and the blades can be cut in different patterns. Files also come in different shapes to finish different kinds of objects. Here are the different kinds of files:

- Single-cut: Single-cut files are used for finishing work and sharpening blades.

- Double-cut: Double-cut files are used for rough work.

- Flat files and half-round: These files are for general purposes.

- Square and round: These files fit square and round openings.

Planes are a type of finishing tool used to prepare wood for final finishing and to fit doors and trim. Planes consist of a handle to push with, a knob to guide with, a frame, a sole, and a mouth (where the blade is). Bench planes are used to smooth surfaces. Longer planes give a more uniform surface by shaving off a portion of the wood.

Clamping tools

A clamping tool is a device used to hold or fasten objects securely so they won’t move while you’re working on them. There are several types of clamping tools available for many different purposes:

- Pliers: Pliers (discussed in the “Fastening tools” section earlier in the chapter) can be used to hold objects while you’re working on them.

- Vises: Vises hold material while it’s being sawed, drilled, or glued. Here are some different types of vises:

- Bench vise: A bench vise has large, rough jaws that keep the material from slipping.

- Pipe vise: Pipe vises hold round trim or pipes.

- Handscrew vise: A handscrew vise has two hard, wooden jaws connected by two long screws. The screws are tightened to bring the jaws of the handscrew vise together.

- Clamps: Clamps are used when a vise won’t work. Vises generally attach to a workbench, while clamps generally connect only to the items being worked with. C-clamps consist of a stationary frame and a screw that moves back and forth to open and shut the clamp.

Measuring tools

As any shop enthusiast will tell you, the golden rule of shop is to “measure twice and cut once.” It’s frustrating to cut a piece of material only to find it’s just a little bit too short to fit in the place you intended. Using measuring tools helps you avoid this embarrassing situation.

Tape rules, rigid steel rules, steel (or fiberglass) tape rules, and folding rules are all used to measure material. Calipers are also used for very exact and small measurements. Calipers can be used with a rule to measure diameter; the legs of a set of calipers curve in to measure outside curves and curve out to measure inside curves. Slide calipers have the rule built in.

Depth gauges measure the depth of holes. Thickness gauges measure the thickness of small openings. Thread gauges measure the number of threads per inch in threaded fasteners. Wire gauges measure the thickness of wire.

Leveling and squaring tools

A square is used to check the trueness (accuracy) of an angle. Because most squares have a rule, they can also be used for measuring (see the preceding section). Squares have two arms, called the blade and the tongue, that meet at a right angle. A square can be set against any angle that is supposed to be a 90-degree angle. If a gap exists between the square and the material, the material isn’t true — that is, it’s not at the specified angle. A sliding T-bevel has an adjustable blade so different angles can be checked.

Levels show whether a surface is true. A basic level has one or more small tubes filled with a liquid (like alcohol) and an air bubble. If the level is placed on a surface and the bubble remains exactly in the center of the tube, the surface is level. (This method can’t be used to see if your recruiter is on the level. I tried it. Recruiters simply won’t hold still long enough.)

A plumb bob is a heavy weight that’s suspended from a line. It indicates vertical trueness.

Sticking Materials Together with Fasteners

Although wood and metal (and other materials) can be held together with glue, straps, duct tape, and other brilliant fastening methods, people usually fasten these types of materials with nails, screws, bolts, and rivets. These fasteners offer more strength and stability than the white glue that you used to fasten painted macaroni noodles onto construction paper in the first grade.

Nails

Nails are used to hold pieces of wood together. The nail head is flat, and the shank is usually round. Nail length is designated by the penny system, which is abbreviated with a d. A ten-penny nail is a 10d nail. Length and thickness generally correspond. Nails that are larger than 20-penny are called spikes and are measured in inches.

Other types of nails include the following:

- Brads and finishing nails: They have heads that are made to fit flush with or slightly below the surface of the wood.

- Common nails: These nails are the most commonly used nails. (How about that for a truly difficult vocab word?)

- Double-headed nails: These have two heads, one lower than the other, and a point on the other end. The nail is driven to the lower head but can be pulled out of the material because of the remaining higher head. These nails are used for temporary construction that will be taken apart.

Screws and bolts

Unlike nails, you can easily take screws and bolts out of the wood without causing additional damage to the wood (unless, of course, the threads are stripped). These fasteners also hold more tightly than nails. Screws have flat heads, round heads, or oval heads; and in addition to this classification, they also have standard heads (for standard slotted screwdrivers) or Phillips heads (with cross-shape slots). Screw sizes are based on length and the diameter of the unthreaded part of the screw.

Here’s the lowdown on these types of fasteners:

- Wood screws: Wood screws are used to fasten wood. (Hmm, ingenious!)

- Lag screws: Lag screws have square- or hexagon-shaped heads.

- Bolts: Bolts don’t thread into wood. They have flat ends (as opposed to the pointed ends of screws). They’re held in place by a nut (which is what actually screws into the threads) and washer. The body of the bolt may have few threads or many.

- Machine screws: Machine screws are used to fasten metal parts. Machine screws are sometimes used with nuts. They come in various lengths and widths and have a wide variety of heads.

Nuts and washers

Nuts can be square or hexagonal. Cap nuts are rounded and smooth; stop nuts prevent the screw or bolt from coming loose. Wing nuts have flanges on each side so they can be tightened by hand.

Washers prevent damage to the surface of material by preventing the bolt head from digging into the material. They also help keep the bolt (or screw) in place. Flat washers, a simple ring of flat metal, are the most common type of washer. Shake-proof washers have teeth to prevent them from skipping, while split-lock washers have two ends that dig into the nut and the material to keep the screw from slipping out.

Rivets

Rivets are commonly used to fasten metal parts together, especially when a weld is insufficient. Standard rivets are driven using a bucking bar. Rivets come in a wide variety of lengths, diameters, and head shapes. The rivet material should match the material being fastened. Pop rivets can be driven when only one side of a joint is accessible.

Building a Better Score

If you haven’t picked up auto and shop knowledge by this point in your life and want to do well on this subtest, one thing you can do is get an automotive manual and take your car apart (hoping that you can get it back together again). Then get a woodworking book and build some furniture for your mom. (Even if you mess it up, Mom always likes gifts from the heart.)

Or you can check out your local community college, which may be a more practical solution. Many community colleges offer basic auto and shop classes. You may also want to take a gander at the following books, all published by Wiley:

- Auto Repair For Dummies by Deanna Sclar

- Woodworking For Dummies by Jeff Strong

- Home Improvement All-in-One For Dummies by Roy Barnhart, James Carey, Morris Carey, Gene Hamilton, Katie Hamilton, Donald R. Prestly, and Jeff Strong

On this subtest, you usually either know the answer or you say, “Huh?” However, some questions you run into can be answered by using the common sense approach. For example, say you run into a question on the ASVAB that reads something like the following:

(A) wood screws

(B) nails

(C) wood glue

(D) both A and C

If you think about it, screws have threads, which are likely to “grab” wood more securely than a nail would. Glue would likely strengthen that bond even more. It’s obvious that the common sense answer would be Choice (D).

Try a variation of the same question:

(A) wood screws

(B) nails

(C) wood glue

(D) both A and C

In this case, the best answer would be Choice (B), because pounding a nail in with a hammer is generally faster than waiting for glue to dry or screwing a screw in with a screwdriver (even in these days of electric screwdrivers).

Auto & Shop Information Practice Questions

If you like to tinker with cars and your idea of a fun weekend is to rebuild the engine, you should do well on this subtest without too much additional study. If your idea of fixing your car involves calling that guy down the street, a little extra study may be in order.

1. A two-penny nail is

(A) thicker than a 10d nail.

(B) shorter than a 10d nail.

(C) the same thing as a 10d nail.

(D) harder than a 10d nail.

2. A carburetor has the same function as a/an

(A) distributor.

(B) fuel-injection system.

(C) alternator.

(D) exhaust system.

3. An engine’s rotational energy is stored by using which mechanical device?

(A) connecting rod

(B) rear axle

(C) flywheel

(D) cylinder

4. A hacksaw is used to cut

(A) with the grain of wood.

(B) against the grain of wood.

(C) round stock.

(D) metal.

5. To drive a cold chisel, the best object to use would be

(A) a frozen hammer.

(B) a warm sledge.

(C) a mallet.

(D) your foot.

6. Which of the following is NOT normally part of an automotive tune-up?

(A) Replace the air filter.

(B) Replace the spark plugs.

(C) Replace the CV axles.

(D) Check the fluids.

7. Antifreeze is used to

(A) prevent the engine from overheating.

(B) prevent water in the cooling system from freezing.

(C) prevent damage to the engine block.

(D) all of the above

8. The best tool for cutting curves or shapes in wood is a

(A) ripsaw.

(B) crosscut saw.

(C) coping saw.

(D) pliant saw.

9. What assembly is pictured?

© John Wiley & Sons Inc.

(A) exhaust

(B) compressor

(C) carburetor

(D) radiator

10. Why might you be hesitant to offer a jump start to another vehicle?

(A) The battery terminals are not corroded.

(B) One of the vehicles has a digital ignition system.

(C) One of the vehicles makes a clicking sound when attempting to start.

(D) The vehicle is really dirty.

11. What is the next step after filling in a hole with plastic filler and letting it dry?

(A) Clean the area with a glass-cleaning solution.

(B) Sand the area with medium-grain sandpaper.

(C) Coat the area with a layer of primer.

(D) None of the above.

12. What type of joint is pictured?

© John Wiley & Sons Inc.

(A) overlap joint

(B) butt joint

(C) dovetail joint

(D) mortise and tenon joint

13. What is most likely to occur if a spark plug’s gap is too wide?

(A) It could damage the motor.

(B) It could misfire.

(C) The car could swerve.

(D) A fire could start in the engine.

14. What is the primary purpose of an intake manifold?

(A) to burn fuel

(B) to distribute the air/fuel mixture

(C) to ignite the spark plugs

(D) to circulate coolant

15. Identify the vehicle part shown here.

© John Wiley & Sons Inc.

(A) water pump

(B) fuel filter

(C) oil pump

(D) air compressor

16. Why is a cross-shaft lug wrench better than a single-shaft wrench?

(A) It gives more leverage.

(B) It holds lug nuts better.

(C) It fits better in storage because it’s smaller.

(D) It doesn’t scratch the lug nuts.

17. Which term refers to the measure of thickness of a liquid?

(A) hydrometer

(B) viscosity

(C) fluidity

(D) frequency

18. What is the name of the tool shown here?

© John Wiley & Sons Inc.

(A) bench vise

(B) pipe vise

(C) pipe cutter

(D) ripsaw

Answers and Explanations

Use this answer key to score the Auto & Shop practice questions.

- B. Penny, abbreviated d (for the ancient Roman denarius coin), indicates length; a 2d nail is shorter than a 10d nail.

- B. The alternator, exhaust system, and distributor all have very different purposes from the carburetor, which combines the fuel and air mixture and sends it to the engine, just as the fuel-injection system does.

- C. The flywheel accelerates a rotor to a high speed and uses rotational energy to maintain and store the energy to keep the engine speed constant as the flywheel and rotor work together. As for the other devices, the drive shaft turns the rear axle. The cylinder contains the piston that moves the connecting rod that’s connected to the crankshaft, which turns the flywheel.

- D. The hacksaw has a blade specifically designed to cut metal, not wood.

- C. A hammer has a smaller, harder striking surface than a mallet. A mallet won’t damage the chisel (or the object being chiseled, should the mallet slip off the chisel). A sledge is exceptionally large and heavy and is therefore inappropriate for this use. Temperature of the striking object is irrelevant.

- C. A general automotive tune-up consists of checking/replacing the following: air and fuel filter, belts, spark plugs, distributor cap, battery, clutch (if it’s manual), engine timing, fluids, ignition timing, and valves. You can also change the positive crankcase ventilation valve and change the points and condenser if you have an older vehicle. Replacing the CV (constant velocity) axles is something that is accomplished when they become worn.

- D. Antifreeze raises the boiling point of water and lowers the freezing point. This process keeps the water in the cooling system from boiling away or freezing. Either condition can cause damage to the engine.

- C. Coping saws have thin blades with many teeth and are specifically designed to cut curves and shapes in wood.

- C. A carburetor is an assembly used in an engine (mostly used in older cars and machines) that mixes fuel and air to an appropriate amount in order for the engine to run properly.

- B. Capacitive discharge ignitions, like digital ignition systems, store charged energy for the spark in a capacitor within the vehicle, releasing it to the spark plug on demand. Because all the energy is stored in the capacitor for the vehicle to release the energy, using the battery doesn’t help give or receive power and could result in an overload.

- B. After the filler dries completely, the next step is to sand the area to create a smooth surface for painting.

- D. You use a mortise and tenon joint when you need it to withstand weight and movement, such as in a piece of furniture.

- B. A spark plug that has too wide of a gap may not fire at all, or it may misfire at high speeds.

- B. The primary purpose of an intake manifold is to evenly distribute the air/fuel mixture to the cylinders in an internal combustion engine.

- C. An oil pump is a small pump located in the crankcase that circulates the oil from the oil pan to the moving parts of the engine.

- A. A cross-shaft wrench (shaped like a cross) is better than the single-shaft wrench (one long handle) because you can push down and pull up at the same time, resulting in more leverage.

- B. The viscosity of a fluid is a measure of its thickness.

- B. Pipe vises hold round trim or pipes.

The military uses the Auto & Shop Information subtest only to determine your qualifications for certain jobs. It’s not used in the calculation of your AFQT score. Turn to

The military uses the Auto & Shop Information subtest only to determine your qualifications for certain jobs. It’s not used in the calculation of your AFQT score. Turn to  Using a Phillips screwdriver as a punch is bad form in the shop world because hitting the handle of a screwdriver with a hammer can damage it (and then you’ll get talked about in serious shop circles).

Using a Phillips screwdriver as a punch is bad form in the shop world because hitting the handle of a screwdriver with a hammer can damage it (and then you’ll get talked about in serious shop circles). When attaching two pieces of wood together, the most secure bond would be formed by using

When attaching two pieces of wood together, the most secure bond would be formed by using