Toning

Several years ago an extraordinary experience confirmed for me the range of pure sensual pleasure photographs can offer. The event was the viewing of a large group exhibition from the Museum of Modern Art in New York called “The Photo Eye of the Twenties.” I found most striking the contrast between my experience of many of the images through halftone black-and-white reproductions in books and catalogs, and the presence of the beautiful prints on the exhibition walls. Although products of a variety of black-and-white processes, the prints displayed a rich range of colors characteristic of the unique papers or toning baths used. Clearly color, along with size and surface, helped translate the artists’ intent into substance.

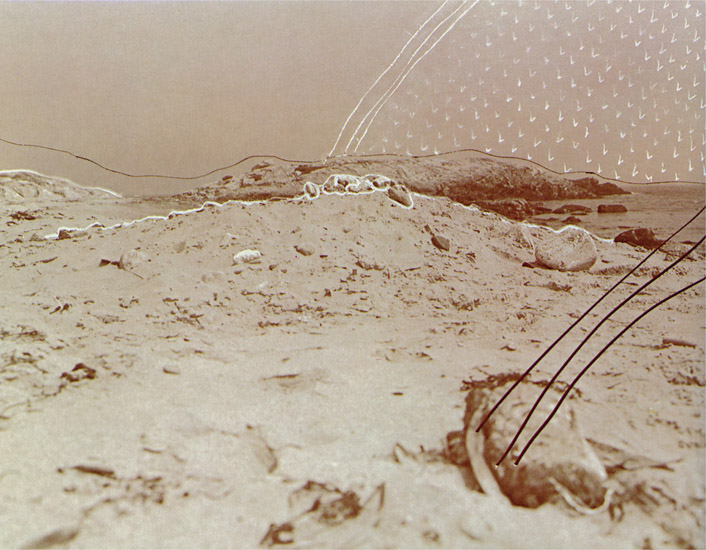

My own work over the last several years has incorporated large-scale prints and the use of various toning processes. I’ve printed on sheets of paper up to 30x40, and used toners and bleaches, both to warm the image and to call attention to the flatness of the photograph. This process expands the expressive range of the photograph and plays off the dimensional illusion of the photograph against the very real two-dimensional surface of the paper. These visual attributes, along with my not quite knowing the final result until the very end of the process, have been consistent factors in my work.

Print Color With Toning

Photographers using black-and-white materials have at their disposal three methods of color control through chemical manipulation of the emulsion. The first of these is independent of any toning: simply the combination of printing paper and paper developer used. This is a subtle control, but quite important if one or a combination of the other two methods is also used. The remaining two methods of color control comprise the subject of this chapter: the two main divisions of chemical toners.

Chemical Toners

Replacement toners work directly on the silver in the emulsion by replacing or partially replacing it with inorganic salts. These toners are characteristically stable, but provide only very subtle and muted colors.

Mordanted dye toners contain a dye base that is affixed to the silver in the emulsion through the action of a mordanting chemical. Mordants, such as potassium ferricyanide, act as anchors or catalysts to allow the use of dyes that otherwise would not combine with silver. This gives the dye toners the advantage of providing a broad range of vivid colors. On the other hand, the dyes are often lacking in long-term stability, particularly on prolonged exposure to light, and they tend to be more soluble than do other toners in the final wash. Often the paper base retains traces of the dye color even after a thorough washing.

With a sensitive scale, a formulary, and an assortment of chemicals, the spectrum of print hues available by toning is broadened considerably.

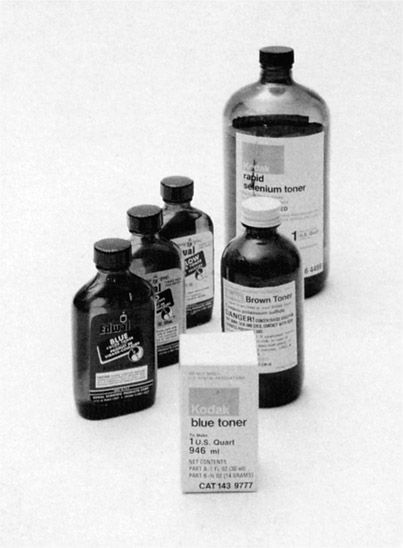

These are some of the readily available packaged toners.

Your selection of paper and print developer will have a significant effect on the final color of your toned print.

Some of the products mentioned have been discontinued; others have sprung up to take their place. As suggested, you should experiment to find the ones that work for you.

Papers

The results of any toner on your prints will be very much influenced by your choice of paper. The innate tone of photographic print materials can vary considerably over a range of browns and blacks. Also, the image tone of a paper is greatly influenced by your choice of developer and its dilution, age, and temperature.

Toners will respond to different papers in markedly different ways. A toner that is particularly satisfactory on one paper may be ineffective on another. Agfa Portriga-Rapid paper develops to a warm-black image tone in Kodak Dektol developer, and to brown in Kodak Selectol. Developed in either, prints on Portriga-Rapid respond noticeably to selenium toner. Agfa Brovira or Kodak Kodabromide, papers with cool image tones, show less color difference when processed in the same two developers, and barely respond to the selenium toner.

Toners of commercial manufacture are normally accompanied by recommendations for use, but experimentation on your own is the only satisfactory way to become proficient in using them. Most paper emulsions, even contrary to the recommendations of manufacturers, will respond in some way to most toners.

The procedures discussed in this chapter apply to the use of both replacement toners using inorganic salts and mordant dye toners. Some of the more commonly used toners are listed. Several of these are available in prepack-aged form, liquid or powder. You can formulate others from published information with available chemicals and an accurate scale.

Toner Chart

The chart of toners on the opposite page suggests an impressive range of colors. Inherent within this system of coloring photographs, unfortunately, is one major limitation. Each toner–paper combination yields a relatively fixed color. Thus, the color becomes a predetermined consequence of those chemicals and materials you have chosen to combine. If your initial results are not satisfactory, change your choices of paper, dilution of toner and developer, print exposure time, or print development time, until a new combination of adjustment produces a better tone.

Final toning results can be adequately evaluated only after the toner has had time to react fully with the emulsion silver. Many toners have a residual toning effect and will continue to work well beyond their removal from the toning bath. Even very low concentrations of Kodak Polytoner, for example, can continue to act for up to an hour after the print is removed from the toning bath. As you become familiar with the materials, you will learn to anticipate the color you want in advance of the effects of final washing and drying steps.

A Few Precautions

It is essential that any photographic darkroom be well ventilated. Gases or fumes released from photographic processes, including toning, not only are foul smelling and annoying, but in an unventilated darkroom become serious lung irritants. Sulfur dioxide gas released from Kodak Polytoner, some sepia toners, and some fixing solutions should be exhausted. A particularly effective green toner, GAF #251, mixed from formula, must be used only in a well-ventilated space. This toner contains hydrochloric acid in a solution of sodium sulfide, which releases toxic hydrogen sulfide gas.

Not all darkroom chemicals constitute extreme health hazards, but all should be treated as such until proven otherwise. Selenium toner contains poisonous selenium metal ions, and the package warns against ingestion. Although there remains some question whether the toner is adsorbed through the skin, it is certainly transmitted through any cuts or breaks in the skin. This risk is eliminated by wearing rubber gloves when handling prints in selenium toner. In fact, it is advisable to wear gloves when handling prints in any toner.

Formulating Your Own Toners

A practical piece of equipment for any photographer is a gram scale or balance. With a scale and a selection of chemicals, you have a wide variety of toners readily available. Aside from the convenience, mixing your own toners allows you to explore possibilities unavailable in packaged form, guarantees absolutely fresh solutions, and removes some of the mystery behind photographic chemistry. The scale can be useful for mixing any of your photographic solutions, from developers and fixers to non-silver emulsions.

As a final precaution, when formulating your own toners incorporating acids, always add the acid to water, never water to acid. Carelessness can result in surface boiling, which spatters the acid.

Preparing Your Prints

Printing and Developing

Before printing or toning any final prints, make a series of tests with the paper and chemistry you expect to use. Many toners affect density or contrast on the print as they act. Determine in advance whether your particular paper-chemistry system will require an adjustment of either printing or development time in preparation for toning. For example, Kodak Rapid Selenium Toner has an intensifying effect on some papers, making well-printed photographs look better. In the iron blue toners containing ferric ammonium citrate, prints darken slightly from the toning; they should be given less exposure to compensate for the increased density of the final toned print. Sepia toners, including the hypo alum sepia toners, reduce the print slightly and require a somewhat dark print. Only testing in your own darkroom will allow you to predict accurately the results of your toning.

Stop Bath

After development, prints to be toned should be placed in a standard acid stop bath according to manufacturers’ recommendations; 30 seconds with continuous agitation should be sufficient.

Fixing

Proper fixing is essential. Underfixed prints, or prints fixed in an exhausted fixing bath, will often stain in toning because of unremoved silver halides or silver thiosulfide compounds in the emulsion. Although much less troublesome, overfixing eventually leads to bleaching of the prints, and offers no advantages. Kodak Rapid Selenium Toner diluted 1:9 is useful as a test solution for residual silver compounds. Squeegee the print you wish to test, and place a drop of the toner solution on a section of white print margin. Any trace of color more than a barely visible cream tint after 2 or 3 minutes indicates the presence of residual silver compounds in the print, the result of inadequate fixing or washing or both. Stains will occur randomly on any inadequately fixed print during toning. The use of two fixing baths, standard procedure for many careful photographers, helps guarantee well-fixed prints that will tone evenly and wash to archival standards more readily. The two fixing baths are used in succession on each print, half the total time in each. The first bath will exhaust first. When it is exhausted, discard it, replace it with the second bath, and mix a fresh second bath. Hardeners in the fixing baths can also affect the result of later toning. Again, only tests with your own materials can adequately guide you.

Washing

After fixing, rinse the prints for a few minutes in running water and transfer them to a washing aid or fixer remover. Agitate them for 5 minutes; then follow with a 10-minute running water wash. They should then be free enough of residual silver compounds to tone.

Selenium toner can be used in a solution of a standard washing aid and Kodalk or sodium metaborate, immediately following the second fix bath. The addition of Kodalk to your fixer remover formula, 20g per liter, helps neutralize the fixer absorbed by the paper. This solution should be used only if the print is transferred to it immediately after the fixing bath, without a rinse. Used any other way, the Kodalk can cause a pH imbalance in the paper, generating small amounts of gas in the paper that can cause blistering of the emulsion. If this method produces stains, return to separate toning after the wash steps.

I find the printing and toning processes easier if divided into two separate operations. After fixing, rinse the prints; then transfer them to a holding bath for the duration of the printing session. The holding bath should be a tray of regularly changed or running water. After printing is completed, turn your complete attention to washing and toning.

If desired, prints accumulated in the collecting tray may be given a 5-minute wash and stored in a tray of water overnight for completion of the toning process the following day. If you wish to tone prints that have been dried, they should be immersed in water for at least 5 minutes before being placed in the toner. If the prints are not thoroughly wet, the toner will be absorbed unevenly, giving mottled results.

Temperature and Agitation

With the exception of a very few toners that must be used at high temperatures, most toners are recommended for use at 20° C. Temperature is not usually a critical factor, and toners can be used at room temperature. Temperature affects little beyond rapidity, higher temperatures causing faster toning. Continuous agitation, as normally given prints in development, is appropriate for toning. As controls, concentration and duration of the toning bath are most significant.

Toning Your Prints

Toning for Permanence

Part of the difficulty in protecting black-and-white photographs for longevity is the susceptibility of the image-forming silver itself to atmospheric pollutants. Just as any piece of silver jewelry or flatware will eventually tarnish, a photograph will stain or degrade, particularly in the presence of airborne sulfur compounds.

Certain metal-replacement toners, particularly selenium and gold, replace or coat the silver in the emulsion with a more stable, less reactive metal. A gold toner will protect a silver photographic image in the same way a gold-plated silver chain is protected from tarnish.

Gold compounds for toning are quite expensive, and aside from use with silver chloride printing-out papers that require a gold toning bath before fixing, they produce little or no visible effect.

Selenium, however, widely used as a protective toner, has the additional advantage of slightly increasing the tonal range of the print. By bonding with the silver in the image, it slightly increases density, more in the shadows than the highlights, giving the print a richer, darker black tone.

Used in a dilution of 1:30 for 3 to 5 minutes, Kodak Rapid Selenium Toner will protect and very slightly increase the print contrast without a significant color change. Used in higher concentrations, selenium toner will add a range of purple shades to your toner palette, in addition to its normal effects on contrast and permanence.

Toning for Color

After your prints are thoroughly washed, they are ready to be toned. The process of toning is a very easy one. Packaged toners and published formulas are all accompanied by specific suggestions and instructions on their use. Therefore, with the exception of some specific toners and dilutions, the following discussion can be applied generally to all toners.

A minimum of three trays is required for a single-bath toning solution. One is a holding tray for prints to be toned, one contains the toner, and one serves as a collecting tray for toned prints. If you are doing more than a few prints, an extra tray or two of rinse water after the toning tray will reduce the amount of toner successive prints will transfer with them into the final collecting tray. Remember that any amount of toner remaining in contact with the emulsion, including toner absorbed by the paper fibers and accumulating in the collecting tray, will continue to act upon the silver in the emulsion.

Take care not to splash or spill any toner onto prints in the holding trays. Even if the effect is not immediately apparent, the toners will begin working, possibly leaving you with noticeably overtoned spots on your prints.

When working for subtle tones with some toners, such as highly diluted selenium, the natural adaptation process of your eyes presents a major problem. As you watch the print in the slow-acting toner, one moment the color seems totally unchanged, and the next, it seems grossly overtoned. The only way to detect the minute changes in a gradual toning is to provide yourself with an identical untoned print, in a tray of plain water, as direct comparison with the progress of the print in the toner.

Manipulating Toners

If you are interested in localized toning, or multiple colors on a single print, toners can be selectively applied to specific areas. Squeegee a well-washed print onto a piece of Plexiglas or glass or the cleaned back of a flat plastic tray. The face of the print should be well squeegeed and free of droplets. You can then apply concentrated toners with cotton swabs, brushes, or small pieces of sponge. A few drops of Photo-Flo added to the toners will help prevent beading on the print surface. Apply one toner at a time. Rinse and squeegee again before reapplying the toner for richer effect, or adding a second color. It is difficult to achieve an even tone with hand-applied toner. More dilute solutions will help but will require multiple applications.

Ordinary rubber cement or Maskoid can be applied as an emulsion mask directly to any areas of the damp print you do not wish toned. The masking will prevent, for a short time, any toner from reaching the covered area. Prolonged immersion will allow toner to seep under the edges, or through the back. By peeling or rubbing off the mask, and then reapplying it, prints can accurately be polychromed.

Finishing Up

Washing

After toning, prints require thorough washing. Wash times vary for different paper–toner–washing aid combinations. The most reliable method of determining wash times for permanence is to test your washed prints with the Kodak ST-1 test for residual silver (Photo Lab Index, Morgan and Morgan) and HT-2 for residual hypo (Procedures for Permanence, East Street Gallery, Grinnell, Iowa).

For toned prints on double-weight paper, I recommend a 5-minute water wash, then a washing aid for 2 minutes, followed by a final wash for approximately 40 minutes. Warmer water washes better, but the fragile emulsion can be damaged by heat. Wash water at about 24° C is the most effective without presenting a potential hazard.

If you mistakenly place untoned prints in a washing aid once used for toned prints, they can be visibly affected by residual toner in the bath. To be certain of having no color bleeding or carryover, prepare a separate washing-aid solution for each different toner, as well as for untoned prints.

With experience, you will find that toners work in a predictable fashion. Some charac teristic difficulties to watch for include excessive solubility of some toners in the wash, and reactions of some toners and washing aids on one another. Most mordant dye toners are susceptible to long washes; a degree of overtoning will help compensate for color loss during the wash. When transferred to a washing-aid bath, prints toned in sepia toners may be slightly intensified or shifted in tone, and those toned in blue toners may be reduced in intensity. A quick test will tell you to what extent, if any, the solution you are using may affect these toners. Iron blue toners are also susceptible to fading during wash in water of neutral pH; most formularies suggest the addition of a few drops of acetic acid to each change of wash water, lowering the pH to maintain the intensity of the blue tones.

Storage

With the exception of hypo alum sepia toner, which improves with age, most toning solutions, once diluted and used, cannot be reliably stored. Rather than take chances, mix enough fresh solution for the number of prints to be toned each session and discard after use.

Summary of Processing Steps

| 1. Develop | Select paper and developer for match with toner | 1 ½ to 5 minutes |

| 2. Stop | Standard acetic acid bath | 30 seconds |

| 3. Fix(1) | Use fresh fixer, hardening or nonhardening. Do not overfix. | 3 to 5 minutes |

| 4. Fix (2) | 3 to 5 minutes | |

| 5. Rinse | Plain water | 2 to 5 minutes |

| 6. Washing aid | Perma Wash, Orbit Bath, Kodak Hypo-Clearing Agent, etc. | 2 to 5 minutes |

| 7. Wash | Running water | 10 to 40 minutes |

| 8. Toner | Three trays minimum, for one-bath toner | as necessary |

| Tray 1 | Fresh-water holding tray | |

| Tray 2 | Toner. Normal agitation | |

| Tray 3 | Collecting tray. Change water frequently or use running water. | |

| 9. Washing aid | Separate solution for toned prints. Pretest for intensifying or bleaching. | 2 to 5 minutes |

| 10. Wash | Running water | 20 to 40 minutes |

| 11. Dry | Air dry on plastic window screen |