Now that orders have been taken, how do they get to their destinations and, once there, how are they paid for? Other questions to answer are these:

- What is being shipped?

- When will it ship?

- To and from where is it shipped?

- What is the current status of the shipment?

- What inventory receipts and issuances occurred during what times at what locations?

- What is the volume and nature of incoming and outgoing shipments?

- Was the entire order shipped or only part of it?

- What shipping documents have been completed and maintained?

- What carrier was used in the shipment and what routes did the shipment take?

This chapter will deal with the shipment of items that are scheduled to be or have been delivered. As will be shown, the information to support these functions does not, at first glance, seem very complex; however, the data interrelationships in a real-world environment can be complicated.

Models discussed in this chapter are the following:

- Shipments

- Shipping detail

- Shipment-to-order relationship

- Shipment receipt for incoming shipments

- Item issuance for outgoing shipments

- Shipping documents

- Shipment method

The basic data model for shipments is shown in Figure 5.1. There is the SHIPMENT entity, which can have many types. The relationships from SHIPMENT to PARTY are to record the shipped-from PARTY and the shipped-to PARTY. The relationship from SHIPMENT to POSTAL ADDRESS is to track where the shipment began and where the shipment was delivered. The model also shows that additional CONTACT MECHANISMs can be maintained to record where queries can be made to inquire about the shipment from the sender as well as a contact number for the receiver to facilitate delivery just in case the carrier cannot easily access or find the postal address.

Figure 5.1 Shipment definition.

An enterprise may need to know many things about a shipment. Some are critical; some are not so critical. The first thing to record in the SHIPMENT entity is the estimated ship date, which indicates when the shipment is expected to begin its journey to the client. This will be critical to customer service personnel when an irate client calls to see what happened to his or her order. The estimated ready date documents when the item is expected to be ready for shipment (perhaps packaging or other preparation is needed for the item). Other bits of information to know include estimated arrival date, estimated ship cost, actual ship cost (may be important for billing), and any special handling instructions (i.e., “fragile,” “requires signature upon delivery,” etc.). In the case of a cancellation, there is a need to know the latest date the shipment could be canceled. The last updated attribute provides a way to determine when this information was last changed because the estimated dates may change frequently, although the enterprise would hope not. The actual dates of all these events are recorded in SHIPMENT STATUS, which is discussed in a later section.

As can be seen in Figure 5.1, several subtypes on the SHIPMENT entity are included in the model to distinguish between some basic types of shipments. These types could be inferred based on the organizations involved in the shipment, but they have been included for clarity. If the shipment is from an internal organization to an external organization, then it is an OUTGOING SHIPMENT, which may be either a CUSTOMER SHIPMENT or a PURCHASE RETURN. A CUSTOMER SHIPMENT defines shipments sent out to customers. A PURCHASE RETURN defines shipments that were returned to the supplier. If it is an external organization shipping to an internal organization, then it is referred to as an INCOMING SHIPMENT and may be a PURCHASE SHIPMENT or a CUSTOMER RETURN. A PURCHASE SHIPMENT is an incoming shipment of purchased items from a supplier. A CUSTOMER RETURN is an incoming shipment from a customer that has returned the products bought from the enterprise. A shipment from an internal organization to another internal organization (e.g., from department A to department B) is called a TRANSFER. If the shipment moves from an external organization to a different external organization, then it is a DROP SHIPMENT. Typically, a drop shipment is a mechanism for a distributor to ship products directly from its supplier to its customer.

Shipments Parties and Contact Mechanisms

The shipment would not be a shipment if the enterprise wasn't sending something somewhere—but where? Shipments must be delivered to and from a location. Therefore, there are two relationships to POSTAL ADDRESS. One shows the location that is the ultimate destination of the shipment; the other shows the source or starting point of the shipment. A shipment, once scheduled, will need to show both shipped to and shipped from even prior to actual shipment.

The shipment is related to parties in addition to contact mechanisms. The shipped to party is needed as well as the shipped from party. The shipped to party will most likely be the same as the designated to be shipped to PARTY of the ORDER, and similarly the shipped to CONTACT MECHANISM relationship will likely be the designated to be shipped to relationship from ORDER to CONTACT MECHANISM. Therefore, it is possible to use these pieces of information as a default in order to determine the shipped to party and shipped to contact mechanism.

This may appear to be a duplication of data (PARTY and CONTACT MECHANISM information tied to both SHIPMENT and ORDER), but the information needs to appear in both places because the shipment record may not be created until much later than the order. If the shipment record was created during order entry, then the information could be stored only in the shipment record. This, of course, could also be controlled through business rules and processes. It is also possible that the shipment information may change and be overridden during the shipment process.

The model shows additional relationships from SHIPMENT to CONTACT MECHANISM to provide information about how to trace the shipment. There may be a receiving contact number for the receiver of the SHIPMENT, which would be a TELECOMMUNICATIONS NUMBER such as a phone number. This could be used to contact the receiver should the postal address of the shipment be in question. The used to inquire about relationship from CONTACT MECHANISM to SHIPMENT provides a way for any party to inquire about the shipment.

Table 5.1 shows some sample data regarding SHIPMENT and related CONTACT MECHANISM information. The first three rows show customer shipments that are shipped to the customer, ACME Corporation, from the internal organization, ABC Subsidiary. Shipments #1146 and #1149 represent incoming shipments, specifically purchase shipments from the supplier, General Goods Corporation. Shipment #1578 represents the return of a purchase, specifically, the return of goods to the supplier, General Goods Corporation. Shipment #3485 represents a transfer of goods from ABC Subsidiary to ABC Corporation. Finally, shipment #4800 represents a drop shipment from ABC's sales agent, Sellers Assistant Corporation, to its customer, ACME Corporation.

Table 5.1 Shipment Data and Contact Mechanisms

What items are being shipped, and what is the status of the shipment? This is what is reflected in the data model in Figure 5.2. Each SHIPMENT may be detailed by many SHIPMENT ITEMs. This provides a mechanism to track what was shipped or received and how many of each item was shipped via the quantity attribute.

Figure 5.2 Shipping detail.

Now that one can tell where a shipment is going to and coming from, and when it is being shipped, it is necessary to know what is being shipped and how many items are being shipped. The SHIPMENT ITEM entity will provide information on how many items will be shipped or are scheduled to be shipped. Details about what was shipped may be found in either the GOOD entity if it is a standard product or in the shipment contents description, if the item is not a standard item that is kept on file. For example, there could be a one-time incoming shipment from a supplier that is not maintained in the GOOD entity because it is not a standard product. Because shipments may change state during their life cycle (i.e., from “in transit” to “delivered”), the SHIPMENT STATUS entity is needed to describe the state of the shipment at various points in time. The recursive relationship around the SHIPMENT ITEMs accounts for the fact that shipment items may be in response to other shipment items, for example, when an organization receives the item, determines that the item is defective, and sends it back (which is another shipment item that is related to the original shipment item).

Why is a SHIPMENT ITEM related to GOOD and not INVENTORY ITEM? After all, the shipment item is involved in the process of taking something out of inventory and/or receiving into inventory. One reason is that the particular inventory item(s) may not be known when scheduling the shipment. Another reason is that the inventory items are related indirectly to the SHIPMENT ITEM through other entities such as SHIPMENT RECEIPT and ITEM ISSUANCE of inventory items that will be shown later in this chapter.

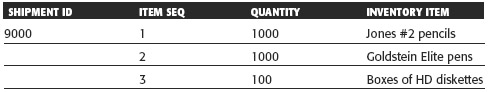

Table 5.2 highlights possible data for SHIPMENT ITEM. Shipment #9000 details the previously described customer shipment to ACME Corporation, and Table 5.2 shows that three items are being shipped.

Table 5.2 Shipment Items

The entity SHIPMENT STATUS in Figure 5.2 allows for the accurate tracking of the status of the shipment over its life. The status (from SHIPMENT STATUS TYPE) identifies the state of the shipment at a point in time. Possible statuses include “scheduled,” “shipped,” “in route,” “delivered,” and “canceled.” This model will allow the storage of any and all statuses of interest to the enterprise.

Table 5.3 shows sample data that could be stored with this entity. While the estimated ship date and estimated arrival date are stored as attributes in the SHIPMENT entity, the SHIPMENT STATUS stores the dates (and times, if needed) that activities actually occurred on the shipment. Customer shipment #9000 was scheduled for shipment March 4 (meaning that the shipment was first recorded) and actually shipped out on Mar 7 and received on Mar 7. Drop shipment #4800 was scheduled for shipment on July 9 and then canceled on July 10.

Table 5.3 Shipment Status Data

| SHIPMENT ID | SHIPMENT STATUS | STATUS DATE |

| 9000 | Scheduled | Mar 4, 2001 |

| Shipped | Mar 7, 2001 | |

| Received | Mar 7, 2001 | |

| 4800 | Scheduled | July 9, 2002 |

| Canceled | July 10, 2002 |

Shipment-to-Order Relationship

For the data model to be truly integrated and functional, there is a need to link orders taken to the shipments made. This will be handled through the entity ORDER SHIPMENT in Figure 5.3. This entity is the resolution of a many-to-many relationship between SHIPMENT ITEM and ORDER ITEM. The many-to-many relationship is required to handle partial shipments and combined shipments.

Figure 5.3 Shipment-to-order relationship.

Each SHIPMENT ITEM may be a shipment of one and only one GOOD and/or one or more SHIPMENT ITEM FEATUREs; alternatively it may be described only via a shipment contents description for non-standard items. Why is it necessary to record the goods and product features for a shipment if they are already included in the order? First of all, shipments and shipment items may exist independently of an order—for instance, with transfers of inventory. Second, it is possible that the good shipped is different from the ordered item. For example, perhaps a substitution occurred.

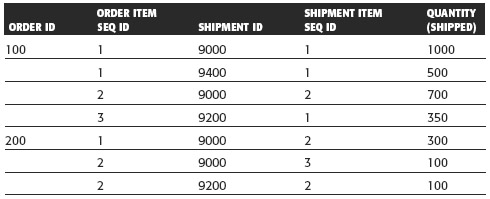

Tables 5.4, 5.5, and 5.6 give some sample data to demonstrate the many-to-many relationship from ORDER ITEMs to SHIPMENT ITEMs. For simplicity purposes, the data represents customer orders #100 and #200 and customer shipments #9000, #9200, and #9400. The data in these tables may seem complex, but there is a very good explanation behind this: In the real world, the relationship between orders and shipments is a complex one.

Table 5.4 Order Item Data

Table 5.5 Shipment Item Data

Table 5.6 Order Shipment Cross-Reference Data

Table 5.4 shows that there are two orders, #100 and #200. Table 5.5 shows that there are three shipments, #9000, #9200, and #9400. Table 5.6 illustrates how one order item could be distributed across multiple shipments. The first two lines of Table 5.6 show the relationship of one order item to two shipment items. Order ID #100, item #1 (from Table 5.4) was partially delivered by shipment #9000, item #1, then completed in a later delivery of shipment #9400, item #1, with a quantity of 1,000 to the first and 500 to the second. In this way, the entire order of 1,500 Jones #2 pencils was delivered.

Conversely, one shipment item could be used to deliver items from more than one order. The third and fifth rows of Table 5.6 illustrate this point. Shipment ID #9000, seq id #2, shown in Table, 5.5, is a shipment to deliver 1000 Goldstein Elite pens. It combines a partial shipment of order #100, item #2 (700 out of 2,500 Elite pens ordered), with order #200, item #1 (300 Elite pens). The partial shipment could be due to a lack of inventory at the time the shipment was made. This scenario assumes that business rules and processes are in place to ensure that both orders (i.e., #100 and #200) are intended to go to the same location and are for the same product. Note that the relationship is not between ORDER (as opposed to ORDER ITEM) and SHIPMENT because it is usually necessary to track the actual items being ordered and shipped.

Is it possible to ship an item with different features than were ordered? Certainly it is possible to do this by mistake. Another possibility is that the customer agreed to accept a different feature than what was ordered. In this case, the order could be changed, or the enterprise may want to reflect that the customer ordered an item with a specific feature, but he or she agreed to accept something else in the delivery.

To handle these cases, one can relate the PRODUCT FEATUREs to SHIPMENT ITEMs using the associative entity, SHIPMENT ITEM FEATURE to show which features the shipments had or were scheduled to have. The relationship from SHIPMENT ITEM through the associative entity SHIPMENT ITEM FEATURE to PRODUCT FEATURE in Figure 5.3 allows the enterprise to maintain SHIPMENT ITEMs as well as the PRODUCT FEATUREs that are to be shipped.

An alternative to the model shown is to store which ordered features are being shipped in the associative entity between order item and shipment item, ORDER SHIPMENT. When there is a difference in what is being shipped versus what is being ordered, this can be derived because each SHIPMENT ITEM is ultimately tied to an INVENTORY ITEM (this will be shown in later sections of this chapter), which is an actual instance of the good and has a configuration that includes the features included on it. The issue with this alternative is that there is still no mechanism for storing the features for a scheduled shipment (specific inventory is not yet tied to it) when the shipment features are different from the ordered features.

Table 5.7 provides an example whereby blue pens were ordered and then black pens were delivered in response to the orders. The shipment combines 700 pens from one order and 300 pens from another order, as in the previous example. This table also shows that the order item feature was blue; however, the shipment item feature was black. This could mean that either there was a mistake or the shipment was intentionally shipped with a different feature, perhaps because there were no blue pens in stock and the customer indicated that he or she would accept the color black as a substitute.

Table 5.7 Order Shipment Cross-Reference of Product Features

This example has involved only customer shipments to simplify the explanation of the data model. The data structures in these data models will also support the many-to-many relationships that occur with all types of shipments, including purchase shipment, drop shipments, and transfers. All of these types of shipments may combine the need to move items and involve partial shipments, which is why many-to-many relationships are necessary in any type of shipment.

Incoming shipments may be received at a formal dock or informally at a desk. Either way, information about the receipt of these items needs to be recorded. There is a need for information about how many items of what types were accepted or rejected; this information includes the contents of packages, the roles involved in the receipt, the date and time of the receipt, and where it was accepted into inventory.

Figure 5.4 provides a data model for shipment receipts. Each SHIPMENT ITEM may be packaged within one or more SHIPMENT PACKAGEs and vice versa, hence the associative entity, PACKAGING CONTENT with a quantity attribute to determine how many items are in which package. The shipment package id could very well be a bar-coded number in order to track shipment packages more easily. Each SHIPMENT PACKAGE may be received via one or more SHIPMENT RECEIPTs that store the details of the receipt. However, the SHIPMENT PACKAGE may exist without having a SHIPMENT RECEIPT, for instance on outgoing shipments when the organization assembles something into a package. So there is only a mandatory relationship from SHIPMENT RECEIPT to SHIPMENT PACKAGE and not vice versa. There could be many SHIPMENT RECEIPT ROLEs involved in each receipt, such as the person signing for the receipt, the inspector of the goods, the person responsible for storing the receipt within inventory, the receiving manager, and the organization that is receiving the item. Each SHIPMENT RECEIPT may be verified against and applied to an ORDER ITEM to record if the receipt was what was expected. Each SHIPMENT RECEIPT may be stored in an INVENTORY ITEM, allowing these received goods' physical storage place to be recorded.

Figure 5.4 Shipment receipt for incoming shipments.

The SHIPMENT RECEIPT maintains the record of each item and how many items are actually within a received package. The SHIPMENT RECEIPT will store the datetime received, which indicates exactly when the receipt occurred. The item description maintains what was received for non-standard items that would not be maintained as goods within the data model-for instance, for one-time purchases. The relationship to GOOD maintains what was received for standard goods. The quantity accepted represents the quantity of that item that the organization determined to be acceptable to receive. The quantity rejected represents the quantity of the item that the organization determined to be unacceptable to receive. The REJECTION REASON stores an explanation of why certain items may not be accepted. The recursion around the SHIPMENT ITEM handles related shipment items to each other, allowing the enterprise to track shipments that were sent back.

The model assumes that all SHIPMENT ITEMs are packaged in one form or another. Therefore, the SHIPMENT RECEIPT is always within a SHIPMENT PACKAGE, even if there is a single SHIPMENT ITEM that is in the SHIPMENT PACKAGE. There does not necessarily have to be packaging for the shipment, although usually items have some form of packaging such as a box, carton, or container.

Should the shipment receipt be related to the SHIPMENT PACKAGE or the SHIPMENT ITEM? In other words, is it a receipt for a shipment item or for a package? Suppose you received a package that had many different shipment items and some of them represented only partial amounts of the shipment items because perhaps the shipment box wasn't big enough for the full quantities. The model relates the receipt to the package because that is what was physically received. A reconciliation from the SHIPMENT RECEIPT to the SHIPMENT ITEM is needed, and this can be accomplished by traversing the data model through SHIPMENT PACKAGE to PACKAGING CONTENT to SHIPMENT ITEM in order to compare received items against what was expected.

Table 5.8 provides examples of receipts for shipments that are being received. These could represent the stocking of inventory items from suppliers so that ABC Corporation can sell them to its customers. Purchase shipment #1146 illustrates that a single shipment item could have multiple packages. The first two rows show that the first item of Jones #2 pencils was shipped using two packages. Package #52000 stored 1,000 pencils in its package, and shipment package #52001 stored the other 1,000 pencils. These may have been received at the same time, or the receipts may have occurred at different times because the boxes could have been separated. Shipment items seq id 2 and 3 each fit neatly into their own respective packages.

Table 5.8 Shipment Receipts

Multiple shipment items may also be delivered in the same package. All three shipment items within shipment #1149 were delivered in a single shipment package #53100. All the items were accepted. This shows that a single SHIPMENT PACKAGE could contain many SHIPMENT ITEMS.

The transfer shipment #4800 shipped one item in one package; however, only 300 of the 500 items were accepted. A rejection reason, such as ”damaged goods,” “wrong amount,” and so on, could have been recorded, depending on the reason for rejecting the other 200 items.

Item Issuance for Outgoing Shipments

Outgoing items being shipped need to issued, or in other words pulled, from inventory. A process takes place that may involve generating a pick list to determine which items need to be extracted from inventory, based on the current shipment needs. Different people are involved in the issuance of inventory in various roles to pick the items and quality assure the process.

Figure 5.5 provides a data model to handle the information requirements of the item issuance process. Based on the shipment needs, which could be obtained by reviewing the outstanding SHIPMENTs and SHIPMENT ITEMs, a PICKLIST is generated, identifying the plan for picking from inventory. Each PICKLIST will have a PICKLIST ITEM that stores the quantity of goods needed and are to be picked from each INVENTORY ITEM in order to meet the shipment needs. Various algorithms may have been used to generate this picklist, and once it is generated it is important to record because it represents the plan of action for issuing items out of inventory. Each SHIPMENT ITEM may be obtained via one or more ITEM ISSUANCEs, which are each issued from an INVENTORY ITEM. Each ITEM ISSUANCE may have many people involved in this process and therefore may have many ITEM ISSUANCE ROLEs for each PARTY involved; each role is described by the ITEM ISSUANCE ROLE TYPE.

Figure 5.5 Item issuance for outgoing shipments.

Notice that the relationship between ITEM ISSUANCE and SHIPMENT ITEM is optional because items may be issued from inventory for other reasons other than from shipments. For instance, an item may be issued for use within the enterprise at the same location that the inventory is stored.

Table 5.9 provides examples of item issuances. Shipment ID #9000 represents a customer shipment of three items. A thousand Jones #2 pencils are needed, and item issuance #12900 issues these 1,000 items out of inventory. For the second item, 1,000 Goldstein Elite pens, only 800 were available in the inventory location. A replenishment was expected soon, so the other 200 were issued out of inventory shortly afterward to accommodate the shipment item. This illustrates that multiple ITEM ISSUANCEs may be associated with a SHIPMENT ITEM. The last two rows in the table show a similar circumstance of two item issuances for the same shipment item, only in this case the items are packaged in separate packages.

Table 5.9 Item Issuances

Shipments often are required to carry shipment documents for various reasons. Some reasons are practical in nature, such as to easily identify the contents of packages with a packing slip or bills of lading to identify the contents of shipments. Some reasons are regulated, such as tax, tariff, or export documentation.

To which shipment entity are shipping documents related? The SHIPMENT? SHIPMENT ITEM? SHIPMENT PACKAGE? Depending on the shipment document, the document may be related to either the entire shipment or a specific package.

Figure 5.6 provides a data model for the information requirements of shipment documents. SHIPMENT DOCUMENT is a subtype of DOCUMENT since there may be many other documents that the enterprise maintains. Each SHIPMENT DOCUMENT may be for a SHIPMENT ITEM, a SHIPMENT PACKAGE, and/or a SHIPMENT, depending on the type and nature of the document. For instance, a PACKAGING SLIP generally describes the contents of a package while a MANIFEST describes the contents of a SHIPMENT. A HAZARDOUS MATERIALS DOCUMENT may describe the contents of a SHIPMENT ITEM or possibly a whole SHIPMENT.

Figure 5.6 Shipping documents.

The shipment documents used may vary based on the type of business; however, some standard subtypes are provided in this model. SHIPMENT DOCUMENTs are subtyped into BILL OF LADING, PACKAGING SLIP, EXPORT DOCUMENT, MANIFEST, PORT CHARGES DOCUMENT, TAX AND TARIFF DOCUMENT, HAZARDOUS MATERIALS DOCUMENT, or OTHER SHIPPING DOCUMENT. The DOCUMENT TYPE entity provides for other types of documents that the enterprise may want to maintain.

There is often a need to track the routes that the shipments and their items and packages travel in order to ensure that items are delivered according to needs and expectations. Enterprises need information about the various paths or shipment route segments to determine the status of the shipment and possibly expedite it. Some packages may have only one path that is tracked, for example, from a warehouse to a customer address. Some packages may have several shipment route segments, such as from a warehouse to a distribution center to an airline route, then to a local truck route, and finally to the customer's receiving dock. Depending on the nature of the enterprise, it may be important to track the progress of the shipment package as it moves along the delivery route. There is a need to track incoming as well as outgoing shipment packages.

Figure 5.7 provides a data model to track the packages along their routes in order to deliver them to their desired destination. Each SHIPMENT ROUTE SEGMENT maintains information about each leg of the journey for a SHIPMENT. In other words, it identifies the particular portions of the journey along which a shipment travels. The SHIPMENT ROUTE SEGMENT must be shipped via a particular SHIPMENT METHOD TYPE, such as by ground, cargo ship, or air. It must be shipped by a particular CARRIER, even if that carrier is part of the enterprise itself. Optionally, the enterprise may want to track the particular VEHICLE involved used in the segment as well as the from and to FACILITYs that maintain each location through which the shipment route segment travels.

Figure 5.7 Shipment route segments.

The relationship to VEHICLE would usually be tracked in circumstances where the enterprise maintains its own fleet. If the enterprise uses external carriers, the enterprise would probably not need this relationship within its data model. Could more than one vehicle be used in a particular SHIPMENT ROUTE SEGMENT? For instance, could truck #100 be used and then truck #120 take over the route at midpoint? This data model will define this circumstance as two shipment route segments; therefore, each route would have one and only one vehicle.

The relationships to FACILITY are optional because the enterprise may not have the will and means to track each physical location to and from which the shipment travels. This relationship would probably not be needed for enterprises that always use external carriers to ship their goods.

One question that arises is whether a SHIPMENT ROUTE SEGMENT should be related to a SHIPMENT, SHIPMENT ITEM, and/or a SHIPMENT PACKAGE. Does the organization need to trace the routes of entire shipments, individual items within the shipments, or the path of each package within a shipment? The routes of each shipment item would probably not need to be traced separately because these items will be stored together as part of a shipment. Packages are also maintained as part of a shipment (through their relationships to SHIPMENT ITEM). Could the packages within a shipment be combined and intermixed with packages from different shipments to provide optimal routings of goods? Another question is whether different packages within the same shipment can take two different routes, and would this actually constitute the same shipment? For instance, could the shipment of an office desk and some supplies, which are packaged separately, be shipped through two different shipment methods and still be considered the same shipment? For the purposes of the data model presented, these would be considered two different shipments, and therefore it would probably be wise to track and monitor these as two separate shipment transactions, even though they may be applicable to the same order.

Another scenario is that one of the shipment packages got lost along the way and there was a need to track the routes of the shipment packages separately. If the enterprise had the will and means to track the routes for each package, then instead of a relationship from SHIPMENT ROUTE SEGMENT to SHIPMENT, there could be a many-to-many relationship set up from SHIPMENT ROUTE SEGMENT to SHIPMENT PACKAGE (with an associative entity in between these entities).

The SHIPMENT METHOD TYPE entity contains information about the way the item or items were shipped. The various types of shipment methods described in SHIPMENT METHOD TYPE may include records such as “ground,” “rail,” “first class air,” or “cargo ship.” These values may differ depending on the enterprise's needs. Each SHIPMENT may be shipped via one or more SHIPMENT METHODS. For example, a shipment may require transportation by train, then by truck.

Table 5.10 contains examples of what might be stored in the SHIPMENT ROUTE SEGMENT entity. Notice that shipment #9000 is shipped in two shipment route segments that are all controlled by ABC Subsidiary. The first segment is by one truck, and then the shipment to the final destination is completed by a second truck. The other shipments are more straightforward and involve only one shipment route segment. Shipment #9200 is outsourced to the organization Very Reliable Parcel Service, and only one segment of the shipment journey is tracked because they pick up the shipment and delivery it straight to the customer. Shipment 1146 represents an incoming shipment whose route may also need to be tracked in order to know when to expect the goods.

Table 5.10 Shipment Route Segment

If an enterprise does its own shipping and owns the method of shipment, then it may need to track the actual vehicle being used. Thus, the entity VEHICLE is needed to record this information. The entity VEHICLE is a subtype of FIXED ASSET (further explained in Chapter 8, Figure 8.5). There is a one-to-many relationship from VEHICLE to SHIPMENT ROUTE SEGMENT because one truck could be used to deliver many shipments. Notice in Table 5.10 that shipment #9000, which had two segments within the shipment, is now broken down further into the actual trucks being used

Information that enterprises may want to keep about the VEHICLE would be the statistics behind the use of the vehicle, such as the start mileage and end mileage (if appropriate) and amount of fuel used. For detailed tracking one may also want to track the date and time a particular vehicle picked up a shipment and when it unloaded it. With this information it can easily be determined in what order multiple vehicles were used to deliver a single shipment and how long it took, including transfers. See Table 5.11 for examples.

Table 5.11 Shipment Vehicle Data

In the example given, one shipment (#9000) is delivered using two vehicles (Truck #1 and Truck #25). Looking at the appropriate start and end times, it is possible to determine that there was a 30-minute delay in the delivery of shipment #9000 while it was being transferred from the first vehicle to the second. Also, notice in the data that the vehicle “Truck #1” was used to deliver a second shipment (#9002). The reason the start time is the same as that of the previous shipment is that the truck contained two shipments that were loaded at the same time.

The data shown also provides information for calculating the real cost of the delivery. It shows the mileage and amount of fuel used. Knowing the cost of fuel, it would be possible to determine this part of the cost of delivery for each shipment. Additionally, mileage could be used to determine wear and tear on the vehicles used.

An enterprise may also need to track estimated and actual dates and times for each shipment route segment and for each vehicle to determine if the shipment is running behind schedule. The estimated start datetime and estimated arrival datetime attributes as well as the actual start datetime and actual arrival datetime on SHIPMENT ROUTE SEGMENT provide this additional functionality, if it is needed.

In this chapter there has been discussion of the details of shipments and how they relate to orders and to each other. The chapter provided models for shipments, shipment items, relationships of shipment items to order items, shipment receipts, item issuances, shipping documents, and shipment route segments. The key entities and relationships are shown in an overall model in Figure 5.8. These data structures, combined with the interrelationships with other aspects of the models, will allow for the development of robust, integrated systems. These models should, once implemented, minimize the occurrence of redundant data and make the maintenance of referential integrity simpler.

Figure 5.8 Overall shipments model.

Please refer to Appendix A for a listing of entities and attributes. SQL scripts to build tables and columns derived from the logical models in this book can be found on the full-blown CD-ROM, which is licensed separately. Note that there are some differences in the way service is delivered versus items. Inventory items are things that can be shipped. Service cannot really be shipped by any conventional means; instead, it is delivered to a customer through an entity called WORK EFFORT, which will be explained in the next chapter.