Chapter 7. Numerical Methods

7.1 Introduction

This chapter is subdivided into two parts. The finite difference method is treated briefly first. Then, the most commonly employed numerical technique, the finite element method, is discussed. We will apply both of these approaches to the solution of problems in elasticity and the mechanics of materials. The use of these numerical methods enables the engineer to expand his or her ability to solve practical design problems. The engineer may now treat real shapes as distinct from the somewhat limited variety of shapes amenable to simple analytic solution. Similarly, the engineer no longer needs to force a complex loading system to fit a more regular load configuration so as to conform to the dictates of a purely academic situation. Instead, numerical analysis provides a tool with which the engineer may feel freer to undertake the solution of problems as they are found in practice.

Analytical solutions of the type discussed in earlier chapters of this text have much to offer beyond the specific cases for which they have been derived. For example, they enable us to gain insights into the variation of stress and deformation with basic shape and property changes. In addition, they provide the basis for rough approximations in preliminary design, even though there is only crude similarity between the analytical model and the actual case. In other situations, analytical methods provide a starting point or guide in numerical solutions.

Numerical analyses often lead to a system of linear algebraic equations. The most appropriate method of solution then depends on the nature and the number of such equations, as well as the type of computing equipment available. The techniques introduced in this chapter and applied in subsequent chapters have clear application to computation by means of electronic digital computers. Formulating and solving a problem (Appendix A) and using tools for computations (Section 7.16) are important in such cases. In these types of computations, fundamentals of matrix algebra—a subset of the finite element method—are extensively used.

Part A: Finite Difference Analysis

7.2 Finite Differences

The numerical solution of a differential equation is essentially a table in which values of the required function are listed next to corresponding values of the independent variable(s). In the case of an ordinary differential equation, the unknown function (y) is listed at specific pivot or nodal points spaced along the x axis. For a two-dimensional partial differential equation, the nodal points will be in the xy plane.

The basic finite difference expressions follow logically from the fundamental rules of calculus. Consider the definition of the first derivative with respect to x of a continuous function y = f (x) (Fig. 7.1):

(dydx)n=limΔ x→ 0y(xn+Δ x)Δ x=limΔ x→ 0yn+1−ynΔ x

Figure 7.1. Finite difference approximation of f(x).

where the subscript n denotes any point on the curve. If the increment in the independent variable does not become vanishingly small but instead assumes a finite Δx=h, the preceding expression represents an approximation to the derivative:

(dydx)n≈Δynh=yn+1−ynh

where Δyn is termed the first difference of y at point xn:

Δyn=yn+1−yn≈h(dydx)n(7.1)

Because the relationship (Fig. 7.1) is expressed in terms of the numerical value of the function at the point in question (n) and a point ahead of it (n + 1), the difference is termed a forward difference. The backward difference at n, denoted ∇yn, is given by

∇yn=yn−yn−1(7.2)

7.2.1 Central Differences

Various central difference expressions involve pivot points symmetrically located with respect to xn and often result in more accurate approximations than are possible with forward or backward differences. The latter are especially useful where, because of geometric limitations (as near boundaries), central differences cannot be employed. In terms of symmetrical pivot points, the derivative of y at xn is

(dydx)n≈y(xn+h)−y(xn−h)2h=12h(yn+1−yn−1)(7.3)

The first central difference δy, then, is

δy=12(yn+1−yn−1)≈h(dydx)n(7.4)

A procedure similar to that just used will yield the higher-order derivatives. The second forward difference at xn is expressed in the form

Δ2yn=yn+2−2yn+1+yn≈h2(d2ydx2)n(7.5)

The second backward difference is found in the same way:

∇2yn=∇(∇yn)=∇(yn−yn−1)=∇yn−∇yn−1 =(yn−yn−1)−(yn−1−yn−2)∇2yn=yn−2yn−1+yn−2≈h2(d2ydx2)n(7.6)

It is a simple matter to verify that the coefficients of the pivot values in the mth forward and backward differences are the same as the coefficients of the binomial expansion (a-b)m. Using this scheme, higher-order forward and backward differences are easily written.

The second central difference at xn is the difference of the first central differences. Therefore,

δ2yn=Δ(∇yn)=Δ(yn−yn−1)=Δyn−Δyn−1 =(yn+1−yn)−(yn−yn−1) =yn+1−2yn+yn−1≈h2(d2ydx2)n(7.7)

In a like manner, the third and fourth central differences are readily determined:

δ3yn=δ(δ2yn)=δ(yn+1−2yn+yn−1)=δyn+1−2δyn+δyn−1 =12(yn+2−yn)−(yn+1−yn−1)+12(yn−yn−2) =12(yn+2−2yn+1+2yn−1−yn−2)≈h3(d3ydx3)n(7.8)

δ4yn=yn+2−4yn+1−6yn−4yn−1+yn−2≈h4(d4ydx4)n(7.9)

Examination of Eqs. (7.7) and (7.9) reveals that for even-order derivatives, the coefficients of yn, yn+1 are equal to the coefficients in the binomial expansion (a-b)m

Unless otherwise specified, we use the term finite differences to refer to central differences.

We now discuss a continuous function w(x, y) of two variables. The partial derivatives may be approximated by the following procedures, similar to those discussed in Chapter 6.

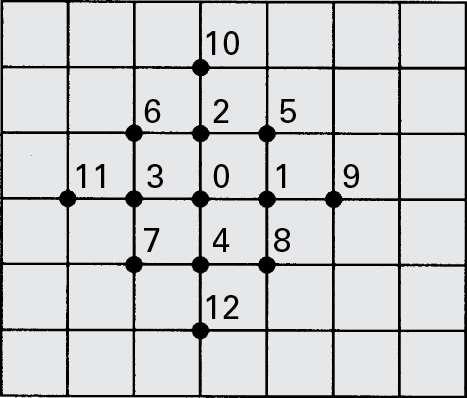

For purposes of illustration, consider a rectangular boundary as shown in Fig. 7.2. By taking Δx =Δy =h, a square mesh or net is formed by the horizontal and vertical lines. The intersection points of these lines are the nodal points. Equation (7.7) yields

∂w∂x≈1hδxw,∂w∂y≈1hδyw(7.10)

∂2w∂x2≈1h2δ2xw,∂2w∂x2≈1h2δ2yw,∂2w∂x∂y≈1h2δx(∂w∂y)(7.11)

Figure 7.2. Rectangular boundary divided into a square mesh.

where the subscripts x and y applied to the δ values indicate the coordinate direction appropriate to the difference being formed. The preceding expressions written for the point 0 are

∂w∂x≈12h[w(x+h,y)−w(x−h,y)]=12h(w1−w3)∂w∂y≈12h[w(x,y+h)−w(x,y−h)]=12h(w2−w4)(7.12)

and

∂2w∂x2≈1h2[w(x+h,y)−2w(x,y)+w(x−h,y)] =1h2(w1−2w0+w3)(7.13)

∂2w∂y2≈1h2(w2−2w0+w4)∂2w∂x∂y≈12h2(δxw2−δxw4)=14h2(w5−w6+w7−w8)(7.14)

Similarly, Eqs. (7.8) and (7.9) lead to expressions for approximating the third- and fourth-order partial derivatives.

7.3 Finite Difference Equations

We are now in a position to transform a differential equation into an algebraic equation. This is accomplished by substituting the appropriate finite difference expressions into the differential equation. At the same time, the boundary conditions must be converted to finite difference form. Through this approach, the solution of a differential equation is reduced to the simultaneous solution of a set of linear, algebraic equations, written for every nodal point within the boundary.

Example 7.1 Torsion Bar with Square Cross Section

Analyze the torsion of a bar of square section using finite difference techniques.

Solution The governing partial differential equation is (see Section 6.3)

∂2Φ∂x2+∂2Φ∂y2=−2Gθ(7.15)

where Φ may be assigned the value of zero at the boundary. Referring to Fig. 7.2, the finite difference equation about the point 0, corresponding to Eq. (7.15), is

Φ1+Φ2+Φ3+Φ4−4Φ0=−2Gθh2(7.16)

A similar expression can be written for every other nodal point within the section. The solution of the problem then requires the determination of those values of Φ that satisfy the system of algebraic equations.

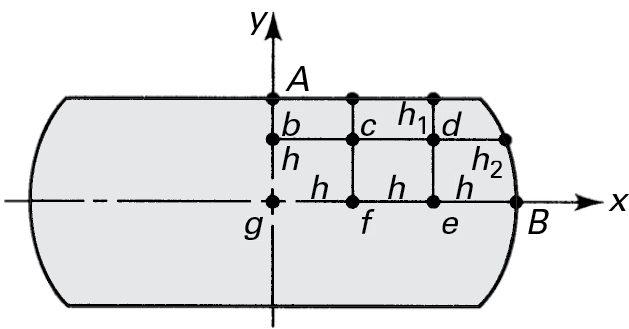

The domain is now divided into a number of small squares—16, for example. In labeling nodal points, it is important to take into account any conditions of symmetry that may exist, as has been done in Fig. 7.3. Note that Φ = 0 has been substituted at the boundary. Equation (7.16) is now applied to nodal points b, c, and d, resulting in the following set of expressions:

4Φd−4Φb=−2Gθh22Φd−4Φc=−2Gθh22Φc+Φb−4Φd=−2Gθh2

Figure 7.3. Example 7.1. A square cross section of a torsion bar.

Simultaneous solution yields

Φb=2.25Gθh2,Φc=1.375Gθh2,Φd=1.75Gθh2(a)

The results for points b and d are tabulated in the second column of Table 7.1.

Table 7.1. Values of the Forward Differences for Given Φ's

x |

Φ/Gθh2 |

Δ/Gθh2 |

Δ2/Gθh2 |

Δ3/Gθh2 |

Δ4/Gθh2 |

|---|---|---|---|---|---|

0 |

0 |

1.75 |

-1.25 |

0.25 |

-0.5 |

H |

1.75 |

0.5 |

-1.0 |

-0.25 |

|

2h |

2.25 |

-0.5 |

-1.25 |

||

3h |

1.75 |

-1.75 |

|||

4h |

0 |

To determine the partial derivatives of the stress function, we will assume a smooth curve containing the values in Eq. (a) to represent the function Φ known as Newton's interpolation formula [Ref. 7.1]. This function, which is used for fitting such a curve, is

Φ(x)= Φ0+xhΔΦ0+x(x−h)2! h2Δ2Φ0=x(x−h)(x−2h)3! h3Δ3Φ0+x(x−h)(x−2h)(x−3h)4! h4Δ4Φ0+⋯+x(x−h)⋯(x−nh+h)n! hnΔnΦ0(7.17)

Here the ΔΦ0 values are the forward differences calculated at x = 0 as follows:

ΔΦ0=Φd−Φ0=(1.75−0)Gθh2=1.75Gθh2Δ2Φ0=Φb−2Φd+Φ=1.25Gθh2Δ3Φ0=Φd−3Φb+3Φd−Φ0=0.25Gθh2Δ4Φ0=Φ0−4Φd+6Φb−4Φd+Φ0=0.5Gθh2(b)

The differences are also calculated at x = h, x = 2h, and so on, and are listed in Table 7.1. We can readily obtain the values given in Table 7.1 for the given Φ by starting at node x = 4h: 0 – 1.75 = – 1.75, 1.75 – 2.25 = – 0.5, – 1.75 – (– 0.5) = – 1.25 and so on.

The maximum shear stress, which occurs at x = 0, is obtained from (∂Φ/∂x)0 Thus, after differentiating Eq. (7.17) with respect to x and then setting x = 0, the result is

(∂Φ∂x)0=1h(ΔΦ0−12Δ2Φ+13Δ3Φ−14Δ4Φ0+⋯)(c)

Substituting the values in the first row of Table 7.1 into Eq. (c), we obtain

(∂Φ∂x)0=τmax=3112Gθh=0.646Gθa

The exact value, given in Table 6.2 as τmax =0.678Gθa, differs from this approximation by only 4.7%.

Comments By using a finer network, we can improve the result. For example, if we select h = a/6, we obtain six nodal equations. The maximum stress in this case, 0.661Gθa, is within 2.5% of the exact solution. On the basis of results for h = a/4 and h = a/6, a still better approximation can be found by applying extrapolation techniques.

7.4 Curved Boundaries

As mentioned earlier, one important strength of numerical analysis is its adaptability to irregular geometries. In this section, we turn from the straight and parallel boundaries of previous problems to situations involving curved or irregular boundaries. Examination of one segment of such a boundary (Fig. 7.4) reveals that the standard five-point operator, in which all arms are of equal length, is not appropriate because of the unequal lengths of arms bc, bd, be, and bf. When at least one arm is of nonstandard length, the pattern is referred to as an irregular star. One method for constructing irregular star operators is discussed next.

Figure 7.4. Curved boundary and irregular star operator.

Assume that, in the vicinity of point b, w(x, y) can be approximated by the second-degree polynomial

w(x,y)=wb+a1x+a2y+a3x2+a4y2+a5xy(7.18)

Referring to Fig. 7.4, this expression leads to approximations of the function w at points c, d, e, and f:

wc=wb+a1h1+a3h21wd=wb+a2h2+a4h22we=wb+a1h+a3h2wf=wb+a2h+a4h2(a)

At nodal point b(x = y = 0), Eq. (7.18) yields

(∂2w∂x2)b=2a3,(∂2w∂y2)b=2a4(b)

Combining Eqs. (a) and (b), we have

(∂2w∂x2)b=2h(wc−wb)+h1(we−wb)hh1(h+h1)(∂2w∂y2)b=2h(wd−wb)+h2(wf−wb)hh2(h+h2)

Introducing this expression into the Laplace operator, we obtain

h2(∂2w∂x2)b= 2wcα1(1+α1)+2wdα2(1+α2) +2we1+α1+2wf1+α2−(2α1+2α2)wb(7.19)

where α1 = h1/h and α2 = h2/h. It is clear that for irregular stars, 0≤αi≤1(i=1,2).

This result may readily be reduced for one-dimensional problems with irregularly spaced nodal points. For example, in the case of a beam, Eq. (7.19), with reference to Fig. 7.4, simplifies to

h2(∂2w∂x2)b=2wcα1(1+α1)+2we1+α1−2wbα1(7.20)

where x represents the longitudinal direction. After setting α = α1, this expression may be written as

h2d2wdx2=2α(α+1)[αwn−1−(1+α)wn+wn+1](7.21)

Example 7.2 Elliptical Bar Under Torsion

Find the shearing stresses at the points A and B of the torsional member of the elliptical section shown in Fig. 7.5. Let a = 15 mm, b = 10 mm, and h = 5 mm.

Figure 7.5. Example 7.2. Elliptical cross section of a torsion member.

Solution Because of symmetry, only a quarter of the section need be considered. From the equation of the ellipse with the given values of a, b, and h, it is found that h1 = 4.4 mm, h2 = 2.45 mm, and h3 = 3 mm. At points b, e, f, and g, the standard finite difference equation (7.18) applies, while at c and d, we use a modified equation found from Eq. (7.15) with reference to Eq. (7.19). We can therefore write six equations, which are presented in the following matrix form:

[2000 2−4 0201−41 002−410 −420001 1−4.27101.060 01.25−7.411.3400]{ΦbΦcΦdΦeΦfΦg}={−2h2Gθ−2h2Gθ−2h2Gθ−2h2Gθ−2h2Gθ−2h2Gθ}

These equations are solved to yield

Φb=2.075Gθh2,Φc=1.767Gθh2,Φd=0.843Gθh2Φe=1.536Gθh2,Φf=2.459Gθh2,Φg=2.767Gθh2

The solution then proceeds as in Example 7.1. The following forward differences at point B are first evaluated:

ΔΦB=2.075Gθh2,Δ3ΦB=−0.001Gθh2Δ2ΦB=−1.383Gθh2,Δ4ΦB=0.002Gθh2

Similarly, for point A, we obtain

ΔΦA=1.53Gθh2,Δ4ΦA=0.001Gθh2Δ2ΦA=−0.613Gθh2,Δ5ΦA=0.001Gθh2,Δ3ΦA=−0.002Gθh2,Δ6ΦA=−0.002Gθh2,

Thus,

τB=(∂Φ∂y)B=(2.075+1.3832−0.0013+0.0024)Gθh =2.766Gθh=1.383Gθb=0.01383GθτA=(∂Φ∂x)A=(1.536+0.6132−0.0023−0.0014+0.0015+0.0026)Gθh =1.842Gθh=0.614Gθa=0.00921Gθ

Comment Note that, according to the exact theory, the maximum stress occurs at y = b and is equal to 1.384Gθb (see Example 6.4), indicating excellent agreement with τB.

7.5 Boundary Conditions

Our concern has thus far been limited to problems in which the boundaries have been assumed to be free of constraints. In the real world, many practical situations involve boundary conditions related to the deformation, force, or moment at one or more points. Application of numerical methods under these circumstances may become more complex.

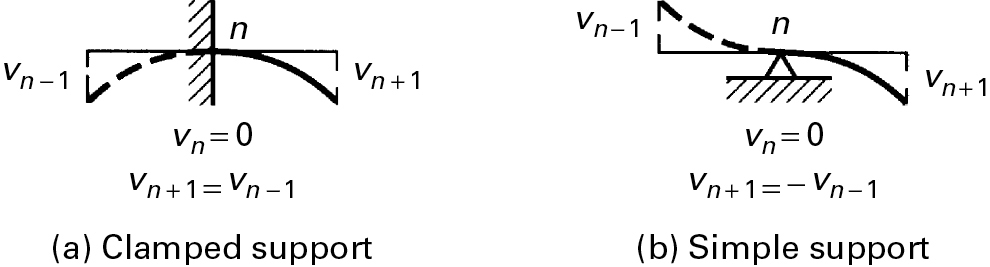

To solve beam deflection problems, the boundary conditions as well as the differential equations must be transformed into central differences. Two types of homogeneous boundary conditions, obtained from υ = 0,dυ/dx = 0, and υ = 0,d2υ/dx2 = 0, at a support (n), are depicted in Fig. 7.6a and b, respectively. At a free edge (n), the finite difference boundary conditions are similarly written from d2υ/dx2 = 0 and d3υ/dx3 = 0 as follows:

υn+1−2υn+υn−1=0υn+2−2υn+1+2υn−1−υn−2=0(a)

Figure 7.6. Boundary conditions in finite differences: (a) clamped or fixed support; (b) simple support.

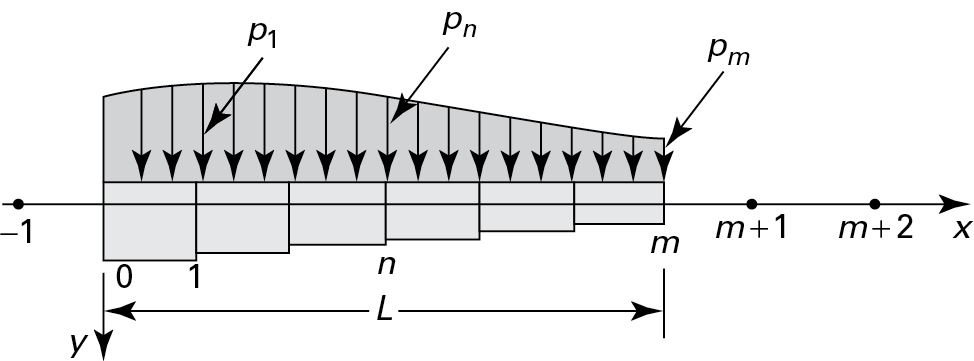

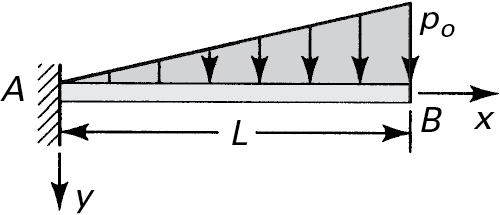

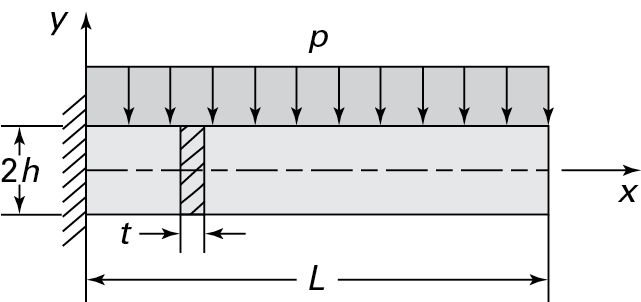

Let us consider the deflection of a nonprismatic cantilever beam with depth varying arbitrarily and of constant width. We divide the beam into m segments of length h = L/m and replace the variable loading by a load that changes linearly between nodes (Fig. 7.7). The finite difference equations at a nodal point n may now be written. Referring to Eq. (7.7), we find the difference equation corresponding to EI(d2υ/dx2) = M to be of the form

υn+1−2υn+υn−1=h2(MEI)n(7.22)

Figure 7.7. Finite difference representation of a nonprismatic cantilever beam with varying load.

where the quantities Mn and (IE)n represent the moment and the flexural rigidity, respectively, of the beam at n. In a like manner, the equation EI(d4υ/dx4) is expressed as

υn+2−4υn+1+6υn−4υn−1+υn−2=h4(pEI)n(7.23)

where pn is the load intensity at n. Equations identical to Eq. (7.23) can be established at each remaining point in the beam. There will be m such expressions; the problem involves the solution of m unknowns, υ1,..., υm.

Applying Eq. (7.4), the slope at any point along the beam is

θn=(∂υ∂x)n=υn+1−υn−12h(7.24)

The following simple examples further illustrate this method of solution.

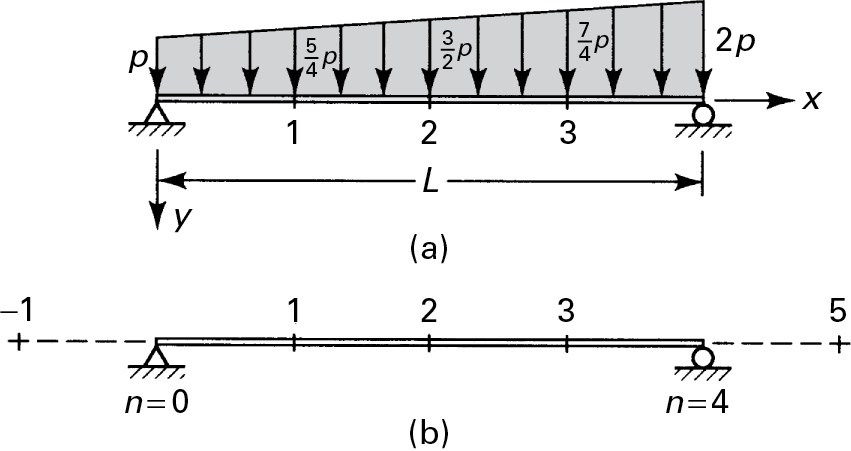

Example 7.3 Displacements of a Simple Beam

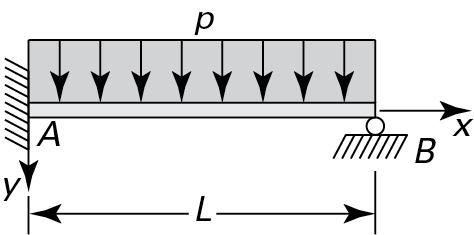

Use a finite difference approach to determine the deflection and the slope at the midspan of the beam shown in Fig. 7.8a.

Figure 7.8. Example 7.3. Simply supported beam with varying load.

Solution For simplicity, take h = L/4 (Fig. 7.8b). The boundary conditions υ(0) = υ(L) = 0 and υ"(0) = υ″ = υ″(L) = 0 are replaced by finite difference conditions by setting υ(0) = υ0 and υ(L)=υ4, and then applying Eq. (7.7):

υ0=0,υ1=−υ−1,υ4=0υ3=−υ5(b)

When Eq. (7.23) is used at points 1, 2, and 3, the following expressions are obtained:

υ3−4υ2+6υ1−4υ0+υ−1=L42565p4EIυ4−4υ2+6υ2−4υ1+υ0=L42563p2EIυ4−4υ3+6υ2−4υ1+υ0=L42567p4EI(c)

Simultaneous solution of Eqs. (b) and (c) yields

υ1=0.0139pL4EI, υ2=0.0198pL4EI, υ3=0.0144pL4EI

Then, from Eq. (7.24), we obtain

θ2=υ3−υ12h=0.001pL3EI

Note that, by successive integration of EId4υ/dx4 = p(x), the result υ2 = 0.0185 PL4/EI is obtained. Thus, even a coarse segmentation leads to a satisfactory solution in this case.

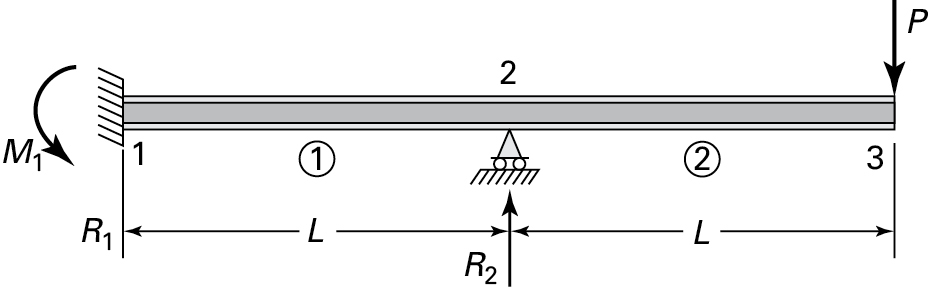

Example 7.4 Reactions of a Continuous Beam

Determine the redundant reaction R for the beam depicted in Fig. 7.9a.

Figure 7.9. Example 7.4. Statically indeterminate beam: (a) load diagram; (b) and (c) moment diagrams.

Solution The bending diagrams associated with the applied loads 2P and the redundant reaction R are given in Figs. 7.9b and c, respectively.

For h = L/2, Eq. (7.22) results in the following expressions at points 1, 2, and 3:

υ0−2υ1+υ2=L24EI(−PL+RL4)υ1−2υ2+υ3=L24EI(−PL+RL2)υ2−2υ3+υ4=L24EI(−PL+RL4)(d)

The number of unknowns in this set of equations is reduced from five to three through application of the conditions of symmetry, υ1 = υ3 and the support conditions, υ0 = υ2 = υ4 = 0. Solution of Eq. (d) now yields R = 8P/3.

Example 7.5 Stepped Cantilever Beam

Determine the deflection of the free end of the stepped cantilever beam loaded as depicted in Fig. 7.10a. Take h = a/2 (Fig. 7.10b).

Figure 7.10. Example 7.5. Nonprismatic cantilever beam under concentrated loads.

Solution The boundary conditions υ(0) = 0 and υ'(0) = 0, referring to Fig. 7.6a, lead to

υ0=0,υ1=υ−1(e)

The moments are M0 = 3pa, M1 = 2pa, M2 = pa, and M3 = pa/2. Applying Eq. (7.22) at nodes 0, 1, 2, and 3, we obtain

υ1−2υ0+υ−1=3Pa2EIh2υ2−2υ1+υ0=PaEIh2υ3−2υ2+υ1=Pa1.5EIh2υ4−2υ3+υ2=Pa2EIh2(f)

Observe that at point 2, the average flexural rigidity is used. Solving Eqs. (e) and (f) gives υ1 = 3C/4, υ2 = 5C/2, υ3 = 47C/12, and υ4 = 47C/6, in which C = (pa/EI)h2. Therefore, after setting h = a/2, we have

υB=υ4=47Pa324EI

Comment The preceding deflection is approximately 2.2% larger than the exact value.

Part B: Finite Element Analysis

7.6 Fundamentals

Structural analysis involves the determination of the forces and deflections within a structure or its members. The earliest demands for structural analysis led to a host of so-called classical methods. Over time, the specialization of these classical methods was replaced by generalities of the modern matrix methods. The presentation of such methods in this chapter is limited to the most widely used of these techniques: the finite element stiffness or displacement method. Unless otherwise specified, we will refer to this approach as the finite element method (FEM). Finite element analysis (FEA) is a numerical approach that is well suited to digital computers. It relies on the formulations of a simultaneous set of algebraic equations relating forces to corresponding displacements at discrete preselected points (called nodes) on the structure. These governing algebraic equations, also called the force-displacement relations, are expressed in matrix notations.

The powerful finite element method had its beginnings in the 1980s. Since then, with the advent of high-speed, large-storage-capacity digital computers, it has gained great prominence throughout industry for the solution of practical analysis and design problems of high complexity. FEA offers many advantages. The system's structural geometry can be readily described, and combined load conditions can be easily handled. This technique also offers the ability to treat discontinuities, to handle composite and anisotropic materials, to handle unlimited numbers and kinds of boundary conditions, to handle dynamic and thermal loadings, and to treat nonlinear structural problems. In addition, it has the capacity for complete automation. The literature related to FEA is extensive (see, for example, Refs. 7.2 through 7.9). Numerous commercial FEA software programs are available, as described in Section 7.16, including some directed at the learning process.

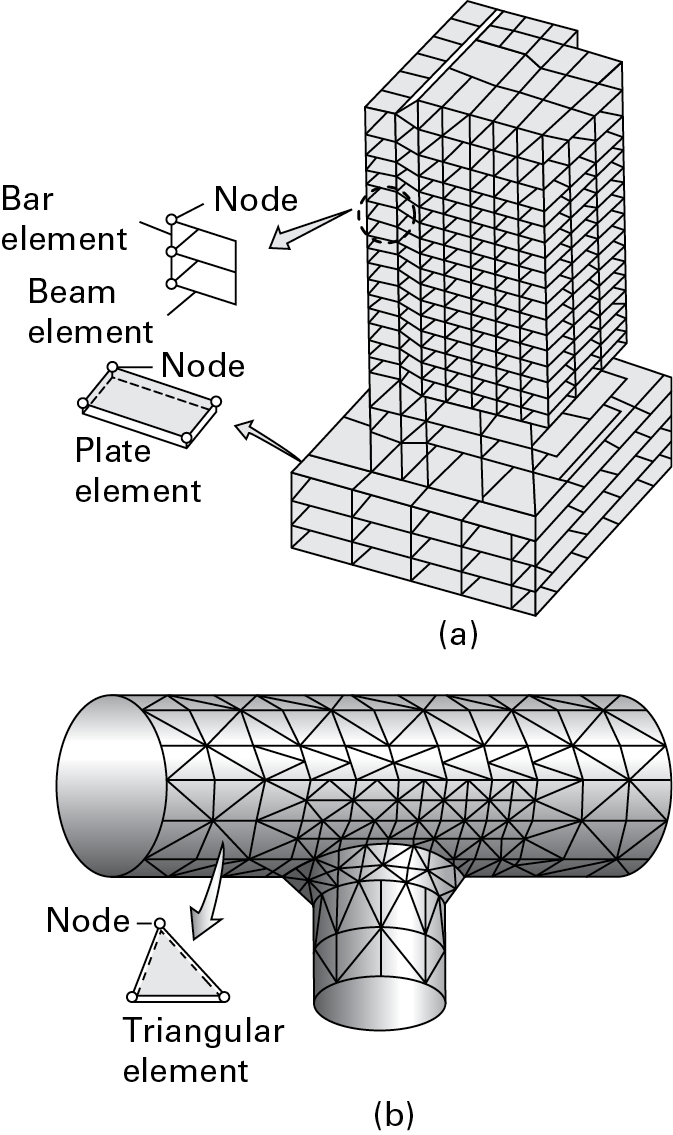

The basic concept of the finite element approach is that the real structure can be divided or discretized by a finite number of elements, connected not only at their nodes but also along the interelement boundaries. Triangular, rectangular, tetrahedral, quadrilateral, and hexagonal forms of elements are often employed in the finite element method. The types of elements that are commonly used in structural idealization are the truss, beam, two-dimensional elements, shell and plate bending, and three-dimensional elements. Figure 7.11a depicts how a multistory hotel building is modeled using bar, beam, column, and plate elements, which can be employed for static, free vibration, earthquake response, and wind response analysis [Ref. 7.2, page 6].

Figure 7.11. Finite element models of two structures: (a) multistory building; (b) pipe connection.

A model of a nozzle in a thin-walled cylinder, created using triangular shell elements, is shown in Fig. 7.11b [Ref. 7.3]. Similarly, large structural systems, such as aircraft or ships, are usually analyzed by dividing the structure into smaller units or substructures (e.g., the wing of an airplane). When the stiffness of each unit has been determined, the analysis of the system follows the familiar procedure established by the matrix methods used in structural mechanics.

The network of elements and nodes that discretize the region is called a mesh. The density of a mesh increases as more elements are placed within a given region. In mesh refinement, the mesh is modified through an analysis of a model to give improved solutions. Mesh density is increased in areas of high stress concentrations and when geometric transition zones are meshed smoothly (Fig. 7.11b). Usually, the FEA results converge toward the exact results as the mesh is continuously refined.

To discuss FEA adequately would require a far lengthier presentation than can be justified here. However, the subject is sufficiently important that engineers concerned with the analysis and design of members should have at least an understanding of FEA. The fundamentals presented in this chapter clearly show both the potential of FEA and its complexities. The material provided here can be covered as an option, used as a “teaser” for a student's advanced study of the topic, or used as a professional reference.

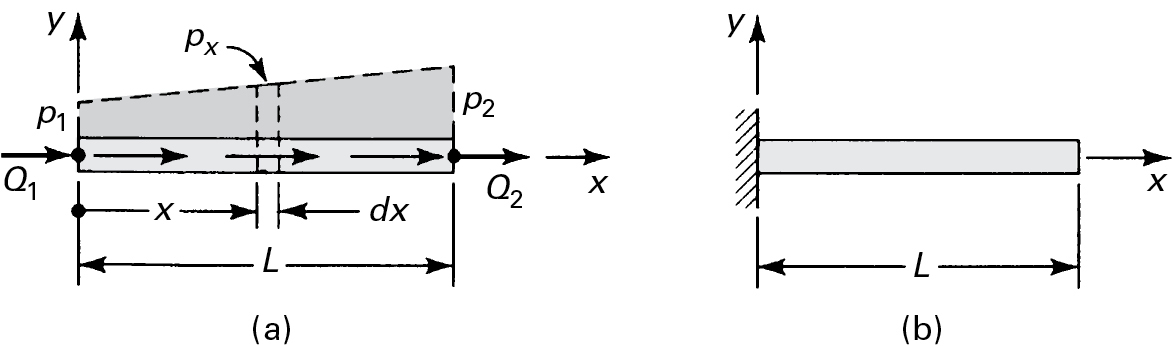

7.7 The Bar Element

A bar element, also called a truss bar element or axial element, represents the simplest form of structural finite element. An element of this type of length L, modulus of elasticity E, and cross-sectional area A, is denoted by e (Fig. 7.12). The two ends or joints or nodes are numbered 1 and 2, respectively. A set of two equations in matrix form are required to relate the nodal forces (ˉF1 and ˉF2) to the nodal displacements (ˉu1 and ˉu2).

Figure 7.12. The one-dimensional axial element (e).

7.7.1 Equilibrium Method

The direct equilibrium approach is simple and physically clear, but it is practically well suited only for truss, beam, and frame elements. The equilibrium of the x-directed forces requires that ˉF1=−ˉF2 (Fig. 7.12). In terms of the spring rate AE/L of the element, we have

ˉF1=AEL(ˉu1−ˉu2)ˉF2=AEL(ˉu2−ˉu1)

This may be written in matrix form,

{ˉF1ˉF2}=AEL[1−1−11]{ˉu1ˉu2}(7.25a)

or symbolically,

{ˉF}=[ˉk]e{ˉu}e(7.25b)

The quantity [ˉk]e is called the element stiffness matrix and has dimensions of force per unit displacement. It relates the nodal displacements {ˉu}e to the nodal forces {ˉF}e on the element.

7.7.2 Energy Method

The energy approach is more general, easier to apply, and more powerful than the direct method just discussed, particularly for complex kinds of finite elements [Ref. 7.2]. Using this technique, it is necessary to first define a displacement function for the element (Fig. 7.12):

ˉu=a1+a2ˉx(7.26)

where a1 and a2 are constants. Clearly, Eq. (7.26) represents a continuous linear displacement variation along the x axis of the element that corresponds to that of engineering formulation for a bar under axial loading. The axial displacements of joints 1 (at x = 0) and 2 (at ˉx=L), respectively, are

ˉu1=a1 ˉu2=a1+a2L

Solving these equations, we have a1=ˉu1 and a2=−(ˉu1−ˉu2)/L. Carrying these results into Eq. (7.26), we obtain

ˉu=(1−ˉxL) ˉu1+ˉxLˉu2(7.27)

Using Eq. (7.27), we write

εx=dˉudx=1L(−ˉu1+ˉu2)(7.28)

Thus, the axial force in the element is

ˉF=(Eεx)A=AEL(−ˉu1+ˉu2)(7.29)

Substituting Eq. (7.29) into Eq. (2.58), the strain energy in the element may be expressed as follows:

U=∫L0F2dx2AE=AE2L(ˉu21−2ˉu1ˉu2+ˉu22)(7.30)

Then, Castigliano's first theorem, Eq. (10.22), gives

ˉF1=∂U∂ˉu1=AEL(ˉu1−ˉu2)ˉF2=∂U∂ˉu2=AEL(−ˉu1+ˉu2)

The matrix form of these equations is the same as that given by Eqs. (7.25).

7.8 Arbitrarily Oriented Bar Element

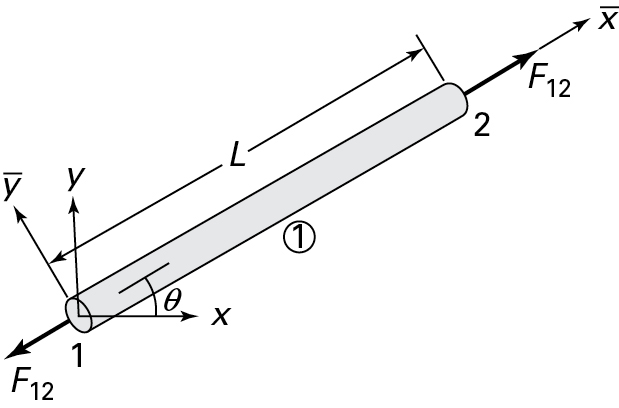

In this section, we develop the global stiffness matrix for an element oriented arbitrarily in a two-dimensional plane. On the one hand, the local coordinates are chosen to conveniently represent the individual element. On the other hand, the reference or global coordinates are chosen to be convenient for the entire structure (Fig. 7.13). The local and global coordinates systems for an axial element are designated by ˉx, ˉy and x, y, respectively.

Figure 7.13. Global coordinates (x,y) for plane truss and local coordinates (ˉx,ˉy) for a bar element 1–2.

7.8.1 Coordinate Transformation

Figure 7.14 depicts a typical axial element e lying along the x axis, which is oriented at an angle θ, measured counterclockwise from the reference axis x. In the local coordinate system, each joint has an axial force ˉFx, a transverse force , an axial displacement , and a transverse displacement . Referring to the figure, Eq. (7.25a) may be expanded as follows:

Figure 7.14. Local and global (x,y) coordinates for a twodimensional bar element (e).

or concisely,

Here the quantities and are the stiffness and nodal displacement matrices, respectively, in the local coordinate system.

7.8.2 Force Transformation

From Fig. 7.14, we can see that the two local and global forces at joint 1 may be related by the following expressions:

Similar equations apply at joint 2. For brevity, let

Hence, the local and global forces are related in the matrix form as

or symbolically,

In Eq. (7.32b), [T] represents the coordinate transformation matrix:

{F}e is the global nodal force matrix:

We note that the coordinate transformation matrix satisfies the following conditions of orthogonality: c2 + s2 = 1, (–s)2 + c2 = 1, and (–s)(c) + (c)(s) = 0. Thus, [T] is an orthogonal matrix.

7.8.3 Displacement Transformation

Inasmuch as the displacement transforms in an identical way as forces, we can write

The concise form of this matrix is

where {δ} is the global nodal displacements. Carrying Eqs. (7.35b) and (7.32b) into Eq. (7.31b) results in

from which

The inverse of the orthogonal matrix [T] is the same as its transpose: [T]–1 = [T]T. Here the superscript T denotes the transpose. Recall that the transpose of a matrix is found by interchanging the rows and columns of the matrix.

7.8.4 Governing Equations

The global force-displacement relations or the governing equations for an element e can be expressed in the form

where

The global stiffness matrix for the element, substituting Eq. (7.33) and from Eq. (7.31a) into Eq. (7.37), may be written as

This result indicates that the element stiffness matrix depends on its dimensions, orientation, and material property.

7.9 Axial Force Equation

Reconsider the general case of a truss element 1- 2 oriented arbitrarily in a two-dimensional plane, shown in Fig. 7.14. We multiply the third and fourth expressions in Eq. (7.36) to obtain the global forces at node 2 as

The axial tensile force in the element with nodes 1 and 2, designated by F12, is then F12 = F2xc+F2ys, in which cos = c and sin = s. This force is equivalent to the nodal force or associated with the local coordinates .

Combining the preceding relationships leads to

or

F12 = (spring rate)(total axial elongation)

Here, the quantities (u2-u1) and (υ2-υ1) are, respectively, the horizontal and vertical components of the axial elongation. Equation (a) may be expressed in the matrix form

Thus, the axial force in the bar element with nodes ij is

A positive (negative) value obtained for Fij indicates that the element is in tension (compression). The axial stress, in the element of cross-sectional area A, then is σij = Fij/A.

Example 7.6 Properties of a Truss Bar Element

The element 1- 2 of the steel truss shown in Fig. 7.13 with a length L, cross-sectional area A, and modulus of elasticity E, is oriented at angle counterclockwise from the x axis.

Given:

Figure 7.15. Example 7.6. An axially loaded bar.

Find: (a) The global stiffness matrix for the element; (b) the local displacements of the element; (c) the axial stress in the element.

Solution The free-body diagram of the element 1- 2 is shown in Fig. 7.15. The spring rate of the element is

and

Element Stiffness Matrix. Applying Eq. (7.38),

or

- Element Displacements. Equation (7.35b), , results in

Axial Force. Substituting the given numerical values into Eq. (7.39) with i= 1 and j = 2, we find

It follows that axial stress in the element is equal to σ1 = F1/A = - 244 MPa.

Comment The negative sign indicates a compression.

7.10 Force-Displacement Relations for a Truss

We now develop the finite element method by considering a plane truss. A truss is a structure composed of differently oriented straight bars connected at their joints (or nodes) by means of pins, such as that shown in Fig. 7.13. It is easier to understand the basic procedures of treatment by referring to this simple system. The general derivation of the FEM is discussed in Section 7.13. To derive the truss equations, the global element relations for the axial element given by Eq. (7.36) will be assembled. This gives the following force-displacement relations for the entire truss or the system equations:

The global nodal matrix {F} and the global stiffness matrix [K] are expressed as

and

where the quantity e designates an element and n is the number of elements found within the truss. Observe that [K] relates the global nodal force {F} to the global displacement {δ} for the entire truss.

7.10.1 The Assembly Process

The element stiffness matrices [k]e in Eq. (7.38) must be properly added together or superimposed. To perform direct addition, a convenient method is to label the columns and rows of each element stiffness matrix in accordance with the displacement components related with it. The truss stiffness matrix [K] is then found simply by summing terms from the individual element stiffness matrix into their corresponding locations in [K]. Alternatively, we can expand [k]e for each element to the order of the truss stiffness matrix by adding rows and columns of zeros. We will employ this process of assemblage of the element stiffness matrices. It is obvious that, for those problems involving a large number of elements, implementing the assembly of [K] requires a digital computer.

The use of the fundamental equations developed are illustrated in the solution of the following example numerical problems.

Example 7.7 Stepped Axially Loaded Bar

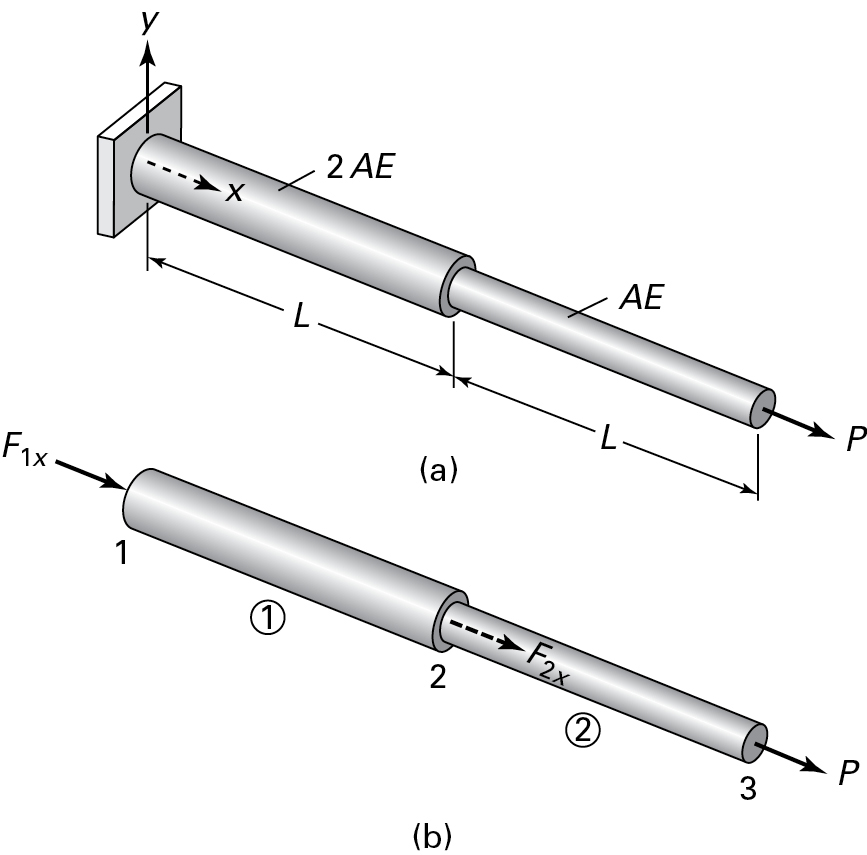

A bar consists of two prismatic parts, fixed at the left end, and supports a load P at the right end, as illustrated in Fig. 7.16a. Determine the nodal displacements and nodal forces in the bar.

Figure 7.16. Example 7.7. (a) A stepped bar under an axial load; (b) twoelement model.

Solution In this case, the global coordinates (x, y) coincide with local coordinates. The bar is discretized into elements with nodes 1, 2, and 3 (Fig. 7.16b). The axial rigidities of the elements 1 and 2 are 2AE and AE, respectively. Therefore, (AE/L)1 = 2AE/L and (AE/L)2 = AE/L.

Element Stiffness Matrices. Through the use of Eq. (7.25), the stiffness for the elements 1 and 2 is expressed as

The column and row of each stiffness matrix are labeled according to the nodal displacements associated with them. There are three displacement components (u1,u2,u3), so the order of the system matrix must be 3×3. In terms of the bar displacements, we write

In these matrices, the last row and the first column of zeros are added, respectively (boxed in the dashed lines).

Stiffness Matrix System. The superposition of the terms of each stiffness matrix leads to

Force-Displacement Relations. Equations (7.40) are expressed as

The displacement and force boundary conditions are u1 = 0,F2x = 0, and F3x = P. Then, Eqs. (a), referring to Fig. 7.16b, become

Displacements. To determine u2 and u3, only part of this equation is considered:

Solution of this equation yields

With the displacements available, the axial force and stress in element 1 (or 2) can readily be found as described in Example 7.6.

Nodal Forces. Equations (a) give

Comment The results indicate that the reaction F1x = -p is equal in magnitude but opposite in direction to the applied force at node 3, F3x = P. Also, F2x = 0 shows that no force is applied at node 2. Equilibrium of the bar assembly is thus satisfied.

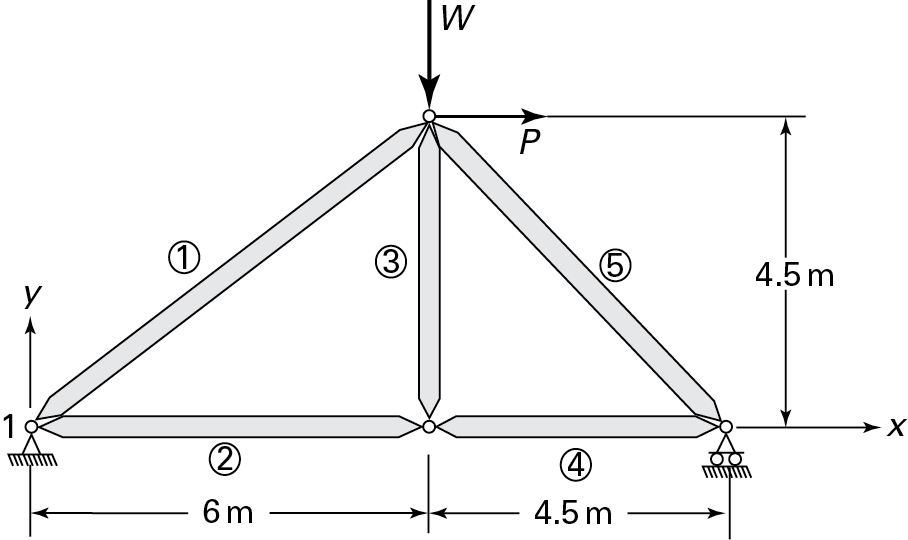

Case Study 7.1 Analysis of a Three-Bar Truss

A steel plane truss in which all members have the same axial rigidity AE supports a horizontal force P and a load W acting at joint 2, as shown in Fig. 7.17a. Find the nodal displacements, reactions, and stresses in each member.

Figure 7.17. Case Study 7.1. (a) Basic plane truss; (b) finite element model.

Given:

Solution The reactions are marked and the nodes numbered arbitrarily for elements in Fig. 7.17a.

Input Data. At each node, there are two displacements and two nodal force components (Fig. 7.17b). Recall that θ is measured counterclockwise from the positive x axis to each element (Table 7.2).

Table 7.2. Data for the Truss of Fig. 7.17

Element |

θ |

c |

s |

c2 |

cs |

s2 |

AE/L |

|---|---|---|---|---|---|---|---|

1 |

0 |

1 |

0 |

1 |

0 |

0 |

4(107) |

2 |

270° |

0 |

-1 |

0 |

0 |

1 |

4(107) |

3 |

225° |

0.5 |

0.5 |

0.5 |

Element Stiffness Matrix. Applying Eq. (7.38) and Table 7.2, we have for the bars 1, 2, and 3, respectively:

The column and row of each of these stiffness matrices are labeled according to the nodal displacements associated with them. Notice that displacements u3 and υ3 are not involved in element 1; u2 and υ2 are not involved in element 2; and u1 and υ1 are not involved in element 3. Thus, prior to adding [k]1, [k]2, and [k]3 to obtain the system matrix, two rows and columns of zeros must be added (boxed in by the dashed lines) to each of the element matrices to account for the absence of these displacements. Using a common factor 107, the element stiffness matrices then take the following forms:

System Stiffness Matrix. There are a total of six components of displacement for the truss before boundary constraints are imposed. Hence, the order of the truss stiffness matrix must be 6 × 6. After adding the terms from each element stiffness matrix into their corresponding locations in [K], we readily determine the global stiffness matrix for the truss:

System Force-Displacement Relationship. With reference to Fig. 7.11, the boundary conditions are u1 = 0, υ1 = 0, and u3 = 0. In addition, we have F3y = 0.

Then, Eq. (7.40) becomes

where [K] is given by Eq. (b).

Displacements. To find u2, υ2, and υ3, only the part of Eq. (c) associated with these displacements is considered. Thus, we have

Inversion of this matrix gives

Reactions. Carrying these values of u2, υ2, and υ3 into Eq. (c) results in the following reactional forces:

These results may be verified by applying the equilibrium equations to the free-body diagram of the entire truss (Fig. 7.17a).

Axial Forces in Elements. From Eqs. (7.39) and (d) and Table 7.2, we obtain

Stresses in Elements. By dividing the preceding element forces by the cross-sectional area of each bar, we obtain

The negative sign indicates a compressive stress.

Comments The results found in this case study indicate that member axial stresses are well below the yield strength for the material considered. As seen here, FEA permits the calculation of displacements, forces, and stresses in the truss with unprecedented ease and precision. Even in the simplest cases, however, this analysis requires considerable algebra. For any significant problem, an electronic digital computer must be used to find the solution.

7.11 Beam Element

This section provides only a brief discussion of the development of a stiffness matrix for beam elements. Let us consider an initially straight beam element of uniform flexural rigidity EI and length L (Fig. 7.18a). The element has a transverse deflection υ and a slope θ = dυ/dx at each end or node. Corresponding to these displacements, a transverse shear force F and a bending moment M act at each node. The deflected configuration of the beam element is depicted in Fig. 7.18b.

Figure 7.18. The beam element with nodal forces and displacements: (a) before deformation; (b) after deformation.

The linearly elastic behavior of a beam element is governed by Eq. (5.32) as d4υ/dx4 = 0.

Observe that the right-hand side of this equation is zero because in the formulation of the stiffness matrix equations, we assume no loading between nodes. In the elements with a distributed load (see Example 7.9) or a concentrated load between the nodes, the equivalent nodal load components listed in Table D.5 are employed. These equivalent nodal loads correspond to the (oppositely directed) reactions provided by a beam subject to the distributed or concentrated loading under fixed-fixed boundary conditions. For further details, see Ref. 7.4.

The solution of the governing equation is a cubic polynomial function of x:

The number of terms in this expression is the same as the number of nodal displacements of the element. Equation (a) satisfies the basic beam equation, the conditions of displacement, and the continuity of interelement nodes. The coefficients a1, a2, a3, and a4 are obtained from the conditions at both nodes:

Introducing Eq. (a) into (b) leads to

The inverse of these equations is

Substituting the foregoing expressions into Eq. (a) yields the displacement function in the following form:

The bending moment M and shear force V in an elastic beam with a cross section that is symmetrical about the plane of loading are related to the displacement function by Eqs. (5.32). Therefore,

in which the minus signs in the second and third expressions are due to opposite to the sign conventions adopted for V and M in Figs. 5.7b and 7.18.

It can be verified [Ref. 7.2] that inserting Eq. (7.43) into Eqs. (7.44) gives the nodal force (moment)-deflection (slope) relations in the matrix form as

or symbolically,

where the matrix [ke] represents the force and moment components. Likewise, {de} represents both deflections and slopes. The element stiffness matrix lying along a coordinate x is then

With development of the stiffness matrix, formulation and solution of problems involving beam elements proceeds like that of bar elements, as demonstrated in the next few examples.

Example 7.8 Displacements of a Uniformly Loaded Cantilever Beam

A cantilever beam of length L and flexural rigidity EI carries a uniformly distributed load of intensity p, as illustrated in Fig. 7.19a. Find the vertical deflection and rotation at the free end.

Figure 7.19. Example 7.8. (a) Beam with distributed load; (b) the equivalent nodal forces.

Solution Only one finite element is used to represent the entire beam. The distributed load is replaced by the equivalent forces and moments, as shown in Fig. 7.19b (see case 3 in Table D.4). The boundary conditions are given by

Since

the force-displacement relations, Eqs. (7.45a), simplify to

Solving for the displacements,

Subsequent to the multiplication, we obtain

Comment The minus sign indicates a downward deflection and a clockwise rotation at the right end, node 2.

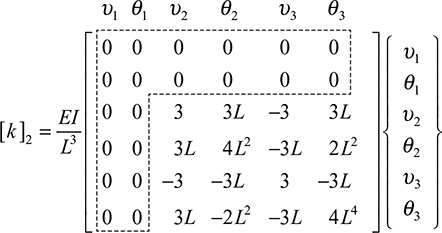

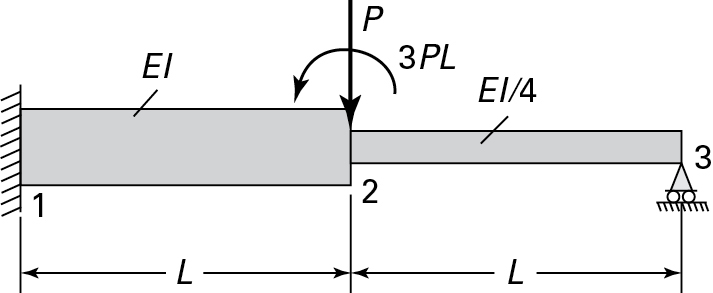

Example 7.9 Analysis of a Statically Indeterminate Stepped Beam

A propped cantilever beam of flexural rigidity EI and 2EI for the parts 1- 2 and 2- 3, respectively, supports a concentrated load P at point 2 (Fig. 7.20a). Calculate (a) the nodal displacements and (b) the nodal forces and moments.

Solution The beam is discretized into elements 1 and 2 with nodes 1, 2, and 3, as illustrated in Fig. 7.20a. There are a total of six displacement components for the beam before the boundary conditions are applied. The order of the system stiffness matrix must therefore be 6 × 6. Applying Eq. (7.46), the stiffness matrix for element 1, with (EI/L3)1 = EI/L3 and L1 = L, may be written as

Figure 7.20. Example 7.9. (a) Stepped beam with a load; (b) shear diagram; (c) bending moment diagram.

Likewise, with (EI/L3)2 = EI/4L3 and L2 = 2L, the stiffness matrix for element 2, after rearrangement, is

In these matrices, the nodal displacements are shown to indicate the associativity of the rows and columns of the member stiffness matrices. Hence, rows and columns of zeros are added (boxed in by the dashed lines).

The system stiffness matrix of the beam can now be superimposed [K] = [k]1+ [k]2. The beam governing equations, with F2y = -P (Fig. 7.20b), are therefore

The boundary conditions are υ1 = 0,θ1 = 0, and υ3 = 0. After multiplying these equations with the corresponding unknown displacements, we obtain

and

Solving Eqs. (d), we find the deflection and slopes as follows:

The minus sign means a downward deflection at node 2 and clockwise rotation of the left end 1; the positive sign means a counterclockwise rotation at the right end 3 (Fig. 7.20), as appreciated intuitively.

Substituting the displacements found into Eq. (e), and then multiplying and simplifying, we find the nodal forces and moments to be

Comments Usually, it is necessary to obtain the nodal forces and moments associated with each element to analyze the whole structure. For the case considered in this example, it may readily be seen from a free-body diagram of element 2 that M2 = R3 (2L) = 8PL/23. So, we have the shear and moment diagrams for the beam, as shown in Figs. 7.20b and c, respectively.

7.12 Properties of Two-Dimensional Elements

Now we define a number of basic quantities relevant to an individual finite element of an isotropic elastic body. In the interest of simple presentation, in this section the relationships are written only for the two-dimensional case. Section 7.13 provides the general formulation of the finite element method applicable to any structure. Solutions of plane stress and plane strain problems are then illustrated in detail in Section 7.14. The analyses of axisymmetric structures and thin plates employing the finite element are given in Chapters 8 and 13, respectively.

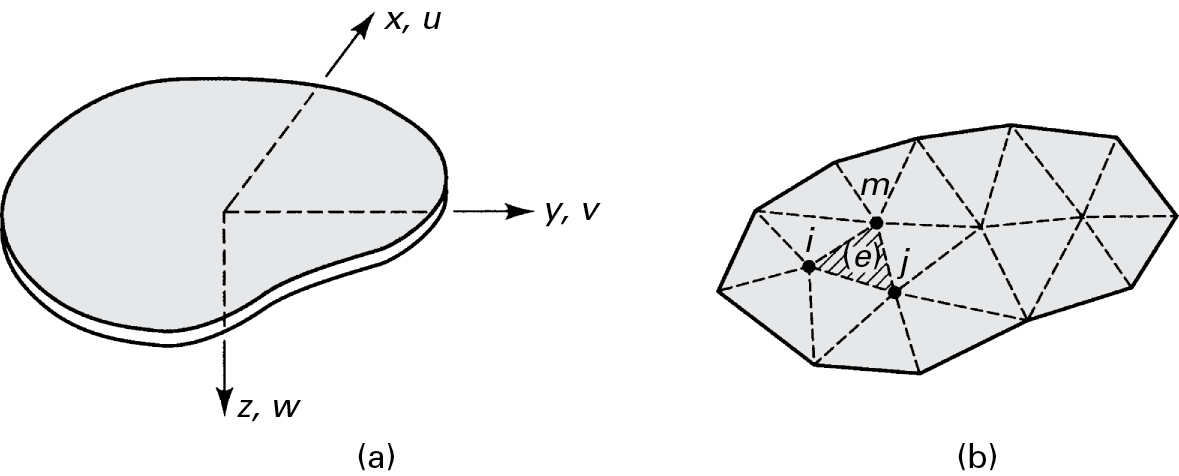

To begin, the relatively thin, continuous body shown in Fig. 7.21a is replaced or discretized by an assembly of finite elements (triangles, for example) indicated by the dashed lines (Fig. 7.21b). These elements are connected not only at their corners or nodes, but also along the interelement boundaries. The basic unknowns are the nodal displacements.

Figure 7.21. Plane stress region (a) before and (b) after division into finite elements.

7.12.1 Displacement Matrix

The nodal displacements are related to the internal displacements throughout the entire element by means of a displacement function. Consider the typical element e in Fig. 7.21b, shown isolated in Fig. 7.22a. Designating the nodes as i, j, and m, the element nodal displacement matrix is

Figure 7.22. Triangular finite element.

or, for convenience, expressed in terms of submatrices δu and δυ,

where the braces indicate a column matrix. The displacement function defining the displacement at any point within the element, {ƒ}e, is given by

which may also be expressed as

Here the matrix [N] is a function of position, to be obtained later for a specific element. Ideally, the displacement function {ƒ}e will be selected such that the true displacement field is represented as closely as possible. The approximation should result in a finite element solution that converges to the exact solution as the element size is progressively decreased.

7.12.2 Strain, Stress, and Elasticity Matrices

The strain, and hence the stress, are defined uniquely in terms of displacement functions (see Chapter 2). The strain matrix is of the form

or

where [B] is also yet to be defined.

Similarly, the state of stress throughout the element is, from Hooke's law,

Put succinctly,

where [D], an elasticity matrix, contains material properties. If the element is subjected to thermal or initial strain, the stress matrix becomes

The thermal strain matrix, for the case of plane stress, is given by {ε0} = {αT,αT,0} (Section 3.8). Comparing Eqs. (a) and (7.52), it is clear that

In general, the elasticity matrix may be represented in the form

Recall from Section 3.5 that two-dimensional problems are of two classes: plane stress and plane strain. The constants λ,D12, and D33 for a two-dimensional problem are given in Table 7.3.

Table 7.3. Elastic Constants for Two-Dimensional Problems

Quantity |

Plane Strain |

Plane Stress |

|---|---|---|

λ |

||

D12 |

ν |

|

D33 |

7.13 General Formulation of the Finite Element Method

A convenient method for executing the finite element procedure relies on the minimization of the total potential energy of the system, expressed in terms of displacement functions. To see how this method works, consider again an elastic body (Fig. 7.21). The principle of potential energy, from Eq. (10.21), is expressed for the entire body as follows:

Note that variation notation δ has been replaced by Δ to avoid confusing it with nodal displacement. In Eq. (7.56),

n = number of elements comprising the body

V = volume of a discrete element

s = portion of the boundary surface area over which forces are prescribed

F = body forces per unit volume

p = prescribed boundary force or surface traction per unit area

Through the use of Eq. (7.49), Eq. (7.56) may be expressed in the following matrix form:

where superscript T denotes the transpose of a matrix. Now, using Eqs. (7.50), (7.51), and (7.53), Eq. (a) becomes

The element stiffness matrix [k]e and element nodal force matrix {Q}e (due to body force, initial strain, and surface traction) are

It is clear that the variations in {δ}e are independent and arbitrary. Thus, Eq. (b) we may write

We next derive the governing equations appropriate to the entire continuous body. The assembled form of Eq. (b) is

This expression must be satisfied for arbitrary variations of all nodal displacements {Δδ}.

This leads to the following equations of equilibrium for nodal forces for the entire structure—that is, the system equations:

where

Note that structural matrix [K] and the total or equivalent nodal force matrix [Q] are found by proper superposition of all element stiffness and nodal force matrices, respectively, as discussed in Section 7.10 for trusses.

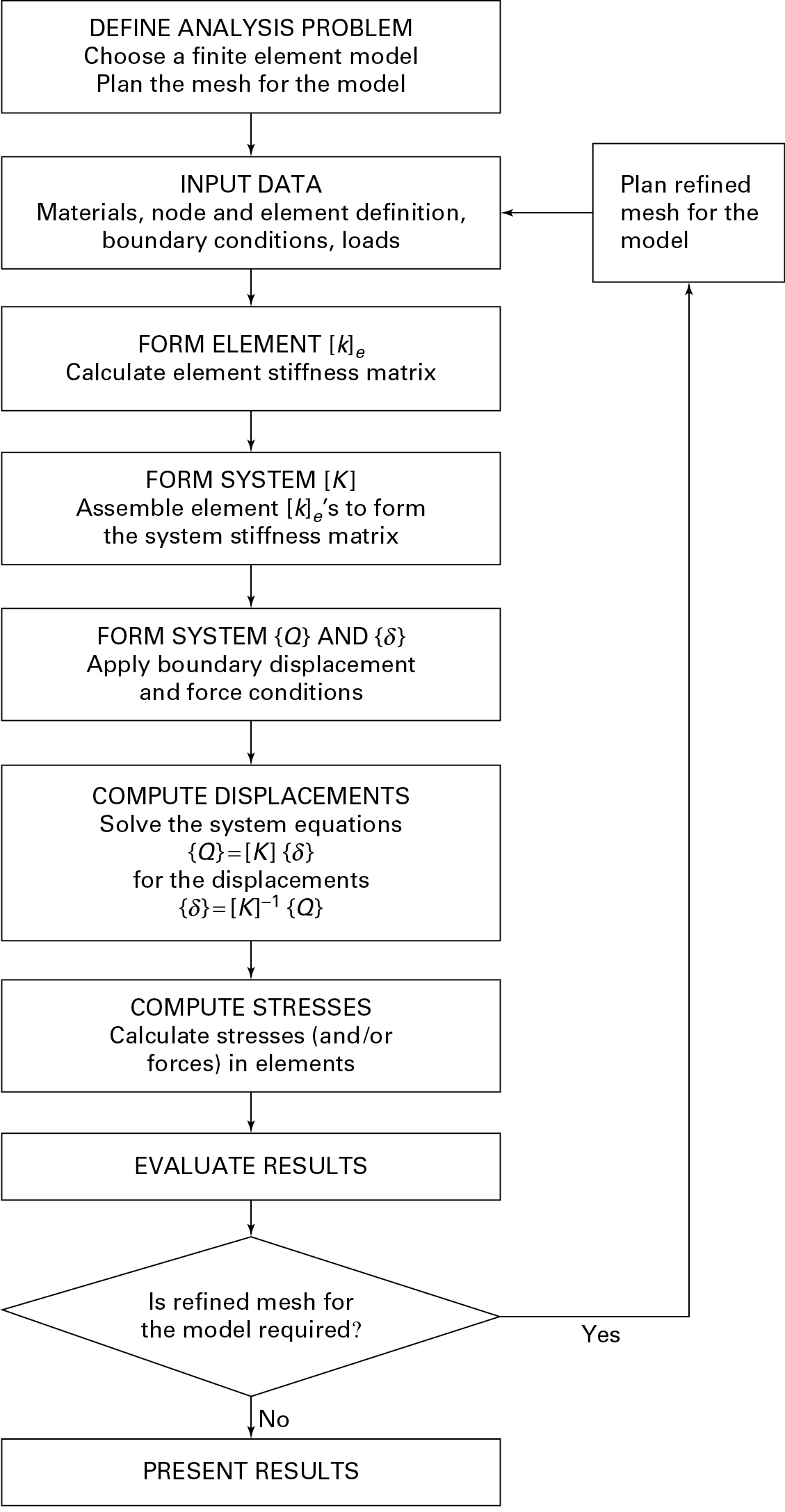

7.13.1 Outline of General Finite Element Analysis

We can now summarize the general procedure for solving a problem by application of the finite element method as follows:

Calculate [K]e from Eq. (7.57) in terms of the given element properties. Generate [K]=Σke.

Calculate [Q]e from Eq. (7.58) in terms of the applied loading. Generate [Q]=ΣQe.

Calculate the nodal displacements from Eq. (7.60) by satisfying the boundary conditions: {δ}=[K]–1{Q}

Calculate the element strain using Eq. (7.51): {ε}e = [B]{δ}e

Calculate the element stress using Eq. (7.53): {σ}e=[D]({ε}-{ε0})e

A simple block diagram of finite element analysis is shown in Fig. 7.23 [Ref. 7.3, page 632].

Figure 7.23. The finite element analysis block diagram.

When the stress found is uniform throughout each element, this result is usually interpreted two ways: (1) The stress obtained for an element is assigned to its centroid; and (2) if the material properties of the elements connected at a node are the same, the average of the stresses in the elements is assigned to the common node.

The outline of the finite element method will be better understood when it is applied to a triangular element in the next section. Formulation of the properties of a simple one-dimensional element, using relations developed in this section, is illustrated in the following example.

Example 7.10 Deflection of a Bar Under Combined Loading

A bar element of constant cross-sectional area A, length L, and modulus of elasticity E is subjected to a distributed load px per unit length and a uniform temperature change T (Fig. 7.24a). Determine (a) the stiffness matrix, (b) the total nodal force matrix, and (c) the deflection of the right end u2 for a fixed left end and px=0 (Fig. 7.24b).

Figure 7.24. Example 7.10. (a) Bar element subjected to an axial load px and uniform temperature change T; (b) fixed end bar.

Solution

a. As before (see Section 7.7), we will assume that the displacement u at any point within the element varies linearly with x:

where a1 and a2 are constants. The axial displacements of nodes 1 and 2 are u1=a1 and u2=a1+a2L, from which a2 = -(u1-u2)/L. Substituting this into Eq. (d),

Applying Eq. (7.51a), the strain in the element is

or, in matrix form,

For a one-dimensional element, we have D = E and the stress from Eq. (7.52) equals

The element stiffness matrix is obtained by introducing [B] from Eq. (f) into Eq. (7.57):

b. Referring to Fig. 7.24a,

where p1 and p2 are the intensities of the load per unit length at nodes 1 and 2, respectively. Substitution of [N] from Eq. (e) together with Eq. (7.63) into Eq. (7.58) yields

The distributed load effects are obtained by integrating the preceding equations:

The strain due to the temperature change is ε0 =αT, where α is the coefficient of thermal expansion. Inserting [B] from Eq. (f) into Eq. (7.58),

The thermal strain effects are then

The total element nodal matrix is obtained by adding Eqs. (g) and (h):

c. The nodal force-displacement relations (7.60) now take the form

from which the elongation of the bar equals u2=α(T)L a predictable result.

7.14 Triangular Finite Element

Because of the relative ease with which the region within an arbitrary boundary can be approximated, the triangle is used extensively in finite element assemblies. Before deriving the properties of the triangular element, we describe area or triangular coordinates, which are very useful for the simplification of the displacement functions.

In this section, we derive the basic constant strain triangular (CST) plane stress and strain element. Note that several two-dimensional finite element types can lead to better solutions, including linear strain triangular (LST) elements, triangular elements having additional side and interior nodes, rectangular elements with corner nodes, and rectangular elements having additional side nodes [Ref. 7.4]. The LST element has six nodes: the usual corner nodes plus three additional nodes located at the midpoints of the sides. The procedures for the development of the LST element equations follow the same steps as those for the CST element.

Consider the triangular finite element 1 2 3 (where i = 1, j = 2, and m = 3) shown in Fig. 7.22b, in which the counterclockwise numbering convention of nodes and sides is indicated. A point P located within the element, by connection with the corners of the element, forms three subareas denoted as A1, A2, and A3. The ratios of these areas to the total area A of the triangle locate P and represent the area coordinates:

It follows that

Consequently, only two of the three coordinates are independent. A useful property of area coordinates is observed through reference to Fig. 7.22b and Eq. (7.65):

and

The area A of the triangle may be expressed in terms of the coordinates of two sides—for example, 2 and 3:

or

Here i, j, and k are the unit vectors in the x, y, and z directions, respectively. Two additional expressions are similarly found. In general, we have

where

Note that aj, am, bj and bm can be found from the definitions of ai and bi with the permutation of the subscripts in the order ijmijm, and so on.

Similar equations are derivable for subareas A1, A2, and A3 The resulting expressions, together with Eq. (7.65), lead to the following relationship between area and Cartesian coordinates:

in which

Note again that, given any of these expressions for cij, the others may be obtained by permutation of the subscripts.

Now we explore the properties of an ordinary triangular element of a continuous body in a state of plane stress or plane strain (Fig. 7.22). The nodal displacements are

The displacement throughout the element is provided by

Matrices [N] and [B] of Eqs. (7.50) and (7.51b) are next evaluated, beginning with

We observe that Eqs. (7.71) and (b) are equal, provided that

The strain matrix is obtained by substituting Eqs. (7.71) and (7.69) into Eq. (7.51a):

Here A, ai, and bi are defined by Eqs. (7.67) and (7.68). The strain (stress) is constant throughout, so that the element of Fig. 7.22 is referred to as a CST. Comparing Eqs. (c) and (d), we have

The stiffness of the element can now be obtained through the use of Eq. (7.57):

Let us now define

where [D] is given by Eq. (7.54) for plane stress. Combining Eq. (e) ith Eqs. (7.73) and (7.74) and expanding, we can express the stiffness matrix in the following partitioned form of order 6 × 6:

in which the submatrices are

7.14.1 Element Nodal Forces

Finally, we consider the determination of the element nodal force matrices. The nodal force owing to a constant body force per unit volume is, from Eqs. (7.58) and (7.72),

For an element of constant thickness, this expression is readily integrated to yield*

*For a general function , defined in area coordinates, the integral off over any triangular area A is given by

where α, β, and γ are constants.

The nodal forces associated with the weight of an element are observed to be equally distributed at the nodes.

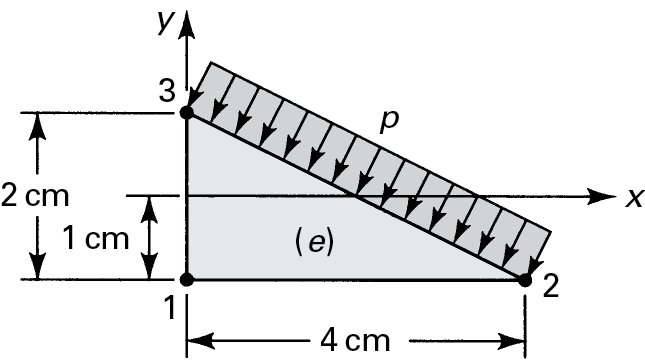

The element nodal forces attributable to applied external loading may be determined either by evaluating the static resultants or by applying Eq. (7.58). Nodal force expressions for arbitrary nodes j and m are given next for a number of common cases (Prob. 7.41).

Linear load, p(y) per unit area, Fig. 7.25a:

Figure 7.25. Nodal forces due to (a) linearly distributed load and (b) shear load.

where t is the thickness of the element.

Uniform load is a special case of the linear load with pj=pm=p:

End shear load, P, is the result of a parabolic shear stress distribution defined by

Eq. (3.24) (see Fig. 7.25b):

Equation (7.75), together with those expressions given for the nodal forces, characterizes the constant strain element. These are substituted first into Eq. (7.61) and subsequently into Eq. (7.60) to evaluate the nodal displacements by satisfying the boundary conditions.

The basic procedure employed in the finite element method is illustrated in the following simple problems.

Example 7.11 Nodal Forces of a Plate Segment Under Combined Loading

The element e shown in Fig. 7.26 represents a segment of a thin elastic plate having side 2–3 adjacent to its boundary. The plate is subjected to several loads as well as a uniform temperature rise of 50°C. Determine (a) the stiffness matrix and (b) the equivalent (or total) nodal force matrix for the element if a pressure of p = 14 MPa acts on side 2–3. Let t = 0.3 cm, E = 200 GPa, v = 0.3, specific weight γ=77kN/m3, and α=12×10–6/°c.

Figure 7.26. Example 7.11. A triangular plate.

Solution The origin of the coordinates is located at midlength of side 1–3, for convenience. However, it may be placed at any point in the x, y plane. Applying Eq. (7.74), we have (in N/cm3)

Stiffness matrix: The nodal points are located at

Using Eq. (7.68) and referring to Fig. 7.26, we obtain

Next, the first equation of Eqs. (7.76), together with Eqs. (g) and (i), yields

The submatrix kuu is thus

Similarly, from the second and third equations of Eqs. (7.76), we obtain the following matrices:

Assembling the preceding equations, the stiffness matrix of the element (in newtons per centimeter) is

We next determine the nodal forces of the element owing to various loadings. The components of body force are Fx=0 and y=0.077 N/cm3.

Body Force Effects. Through the application of Eq. (7.77), it is found that

Surface Traction Effects. The total load, , is equally divided between nodes 2 and 3. The nodal forces can therefore be expressed as

Thermal Strain Effects. The initial strain associated with the 50°C temperature rise is ε 0 = αT = 0.0006 0. From Eq. (7.59),

Substituting matrix [B], given by Eq. (7.73), into this equation, and with the values of the other constants already determined, the nodal force is calculated as follows:

or

Equivalent Nodal Force Matrix. Summation of the nodal matrices due to the several effects yields the total element nodal force matrix:

If there are any actual node forces, they must also be added to the value obtained.

7.15 Case Studies in Plane Stress

A good engineering case study includes all data necessary to analyze a problem in detail and may come in many varieties [Refs. 7.5 and 7.6]. Obviously, in solid mechanics, it deals with stress and deformation in load-carrying members or structures. In this section, we briefly present four case studies limited to plane stress situations and CST finite elements: a cantilever beam supporting a concentrated load, a deep beam or plate in pure bending, a plate with a hole subjected to an axial loading, and a disk carrying concentrated diametral compression.

Recall from Chapter 3 that very few elasticity or “exact” solutions to two-dimensional problems exist, especially for any but the simplest shapes. As will become evident in the following discussion, the stress analyst and designer can reach a very accurate solution by employing proper techniques and modeling. Accuracy is often limited by the willingness to model all the significant features of the problem and to pursue the FEA until convergence is reached.

Case Study 7.2 Stresses in a Cantilever Beam Under a Concentrated Load

A 0.3-cm-thick cantilever beam is subjected to a parabolically varying end shearing stress resulting in a total load of 5000 N (Fig. 7.27a). Divide the beam into two constant-strain triangles and calculate the deflections. Let E = 200 GPa and v = 0.3.

Solution The discretized beam is shown in Fig. 7.27b.

Figure 7.27. Case Study 7.2. Cantilever beam (a) before and (b) after being discretized.

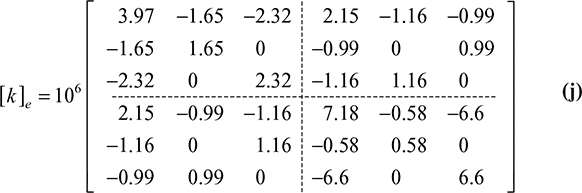

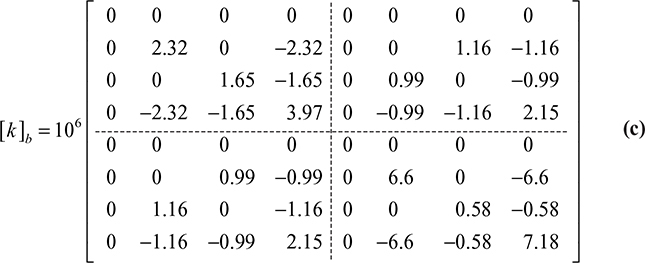

Stiffness Matrix. Inasmuch as the dimensions and material properties of element a are the same as those given in Example 7.11, [k]a is defined by Eq. (j) of that example. For element b, assignment of i = 2, j = 4, and m = 3 [Eq. (7.68)] leads to

Substitution of these and Eq. (g) of Example 7.11 into Eqs. (7.76) yields

Thus,

Similarly, we obtain

The stiffness matrix of element b is therefore

The displacements u4, υ4 and u1, υ1 are not involved in elements a and b, respectively. Therefore, prior to the addition of [k]a and [k]b to form the system stiffness matrix, rows and columns of zeros must be added to each element matrix to account for the absence of these displacements. In doing so, Eqs. (j) of Example 7.11 and (a) become

and

Then, addition of Eqs. (b) and (c) yields the system matrix (in newtons per centimeter):

Nodal Forces. Referring to Fig. 7.27b and applying Eq. (7.79), we obtain

Because no other external force exists, the system nodal force matrix is

Nodal Displacements. The boundary conditions are

The force-displacement relationship of the system is therefore

Equation (e) is readily reduced to the form

From this, we obtain

The strains {ε}a may now be found by introducing Eq. (i) of Example 7.11 and Eq. (g) into Eq. (d) of Section 7.14 as follows:

Finally, the stress is determined by multiplying [D] by {ε}a:

Element b is treated similarly.

Note that the model employed in this solution is quite crude. The effect of element size on solution accuracy is illustrated in the next case study.

Case Study 7.3 Analysis of a Deep Beam by the Theory of Elasticity and FEM

By means of (a) exact and (b) finite element approaches, investigate the stresses and displacements in a thin beam subjected to end moments applied about the centroidal axis (Fig. 7.28a). Let L = 76.2 mm, h = 50.8 mm, thickness t = 25.4 mm, p = 6895 kPa, E = 207 GPa, and v = 0.15. Neglect the weight of the member.

Figure 7.28. Case Study 7.3. (a) Beam in pure bending; (b) moment is replaced by a statically equivalent load.

Solution

Exact Solution. Replacing the end moments with the statically equivalent load per unit area p = Mh/I (Fig. 7.28b), the stress distribution from Eq. (5.5) is

From Hooke’s law and Eq. (2.4), we have

By now following a procedure similar to that described in Section 5.4, and satisfying the conditions u(0,0)=υ (0,0)=0 and u(L,0)=0, we obtain

Substituting the data into Eqs. (h) and (i), the results are

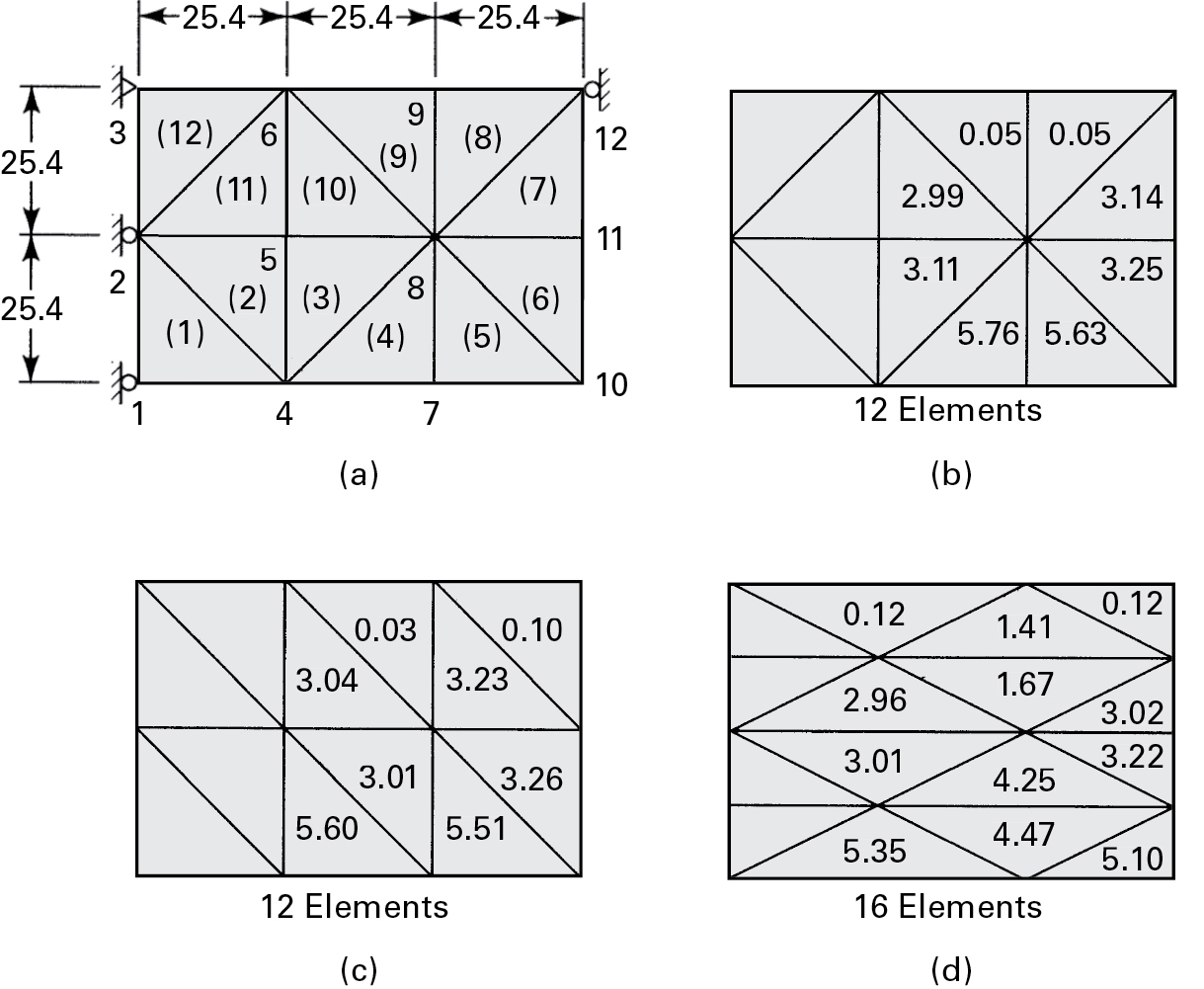

Finite Element Solution. Considerations of symmetry and antisymmetry indicate that only any one-quarter (shown as shaded portion in the figure) of the beam needs to be analyzed.

Displacement Boundary Conditions. Figure 7.29a shows the quarter-plate discretized to contain 12 triangular elements. The origin of coordinates is located at node 3. As no axial deformation occurs along the x and y axes, nodes 1, 2, 6, 9, and 12 are restrained against u deformation; node 3 is restrained against both u and υ deformation. The boundary conditions are thus

Figure 7.29. Case Study 7.3. Influence of element size and orientation on the stress (MPa) in the beam shown in Fig. 7.28.

Nodal Forces. For the loading system of Fig. 7.28b, Eq. (7.78a) applies. After substituting numerical values,

The remaining Q’s are zero.

Results. The nodal displacements are determined by following a procedure similar to that used in Case Study 7.2. The stresses are then evaluated, with representative values (in megapascals) being given in Fig. 7.29b. Note that the stress obtained for an element is assigned to the centroid. Moreover, there is a considerable difference between the exact solution, Eq. (j), and that resulting from the coarse mesh arrangement employed. To demonstrate the influence of element size and orientation, calculations have also been carried out for the grid configurations shown in Figs. 7.29c and d. For purposes of comparison, the deflections corresponding to Figs.7.29b through d are presented in Table 7.4.

Table 7.4. Comparison of Deflections Obtained by FEM and the Elasticity Theory

Deflection (m) |

||||||

|---|---|---|---|---|---|---|

Case |

Number of Nodes |

υ 12(106) |

u 10(106) |

|||

12 |

1.547 |

2.133 |

||||

12 |

1.745 |

2.062 |

||||

15 |

1.572 |

1.976 |

||||

Exact solution |

— |

1.905 |

2.540 |

|||

Comments The effect of element orientation is shown in Figs. 7.29b and c for an equal number of elements and node locations. Figure 7.29d reveals that elements characterized by large differences between their side lengths, weak elements, lead to unfavorable results, even though the number of nodes is larger than those shown in Figs. 7.29b and c. Using equilateral or nearly equilateral well-formed elements of finer mesh leads to solutions approaching the exact values.

Owing to the approximate nature of the finite element method, nonzero values are found for σy and τxy, though these are not listed in the figures. As the mesh becomes finer, these stresses do essentially vanish.

It is clear that we cannot reduce element size to extremely small values, as this would tend to increase to significant magnitudes the computer error incurred. Since an “exact” solution is unattainable, we seek instead an acceptable solution. The goal is then to find a finite element that ensures convergence to the exact solution in the absence of round-off error. The literature provides many comparisons between the various basic elements. The efficiency of a finite element solution can, in certain situations, be enhanced through the use of a “mix” of elements. For example, using a denser mesh within a region of severely changing or localized stress may save much time and effort.

Case Study 7.4 Stress Concentration in a Plate with a Hole in Uniaxial Tension

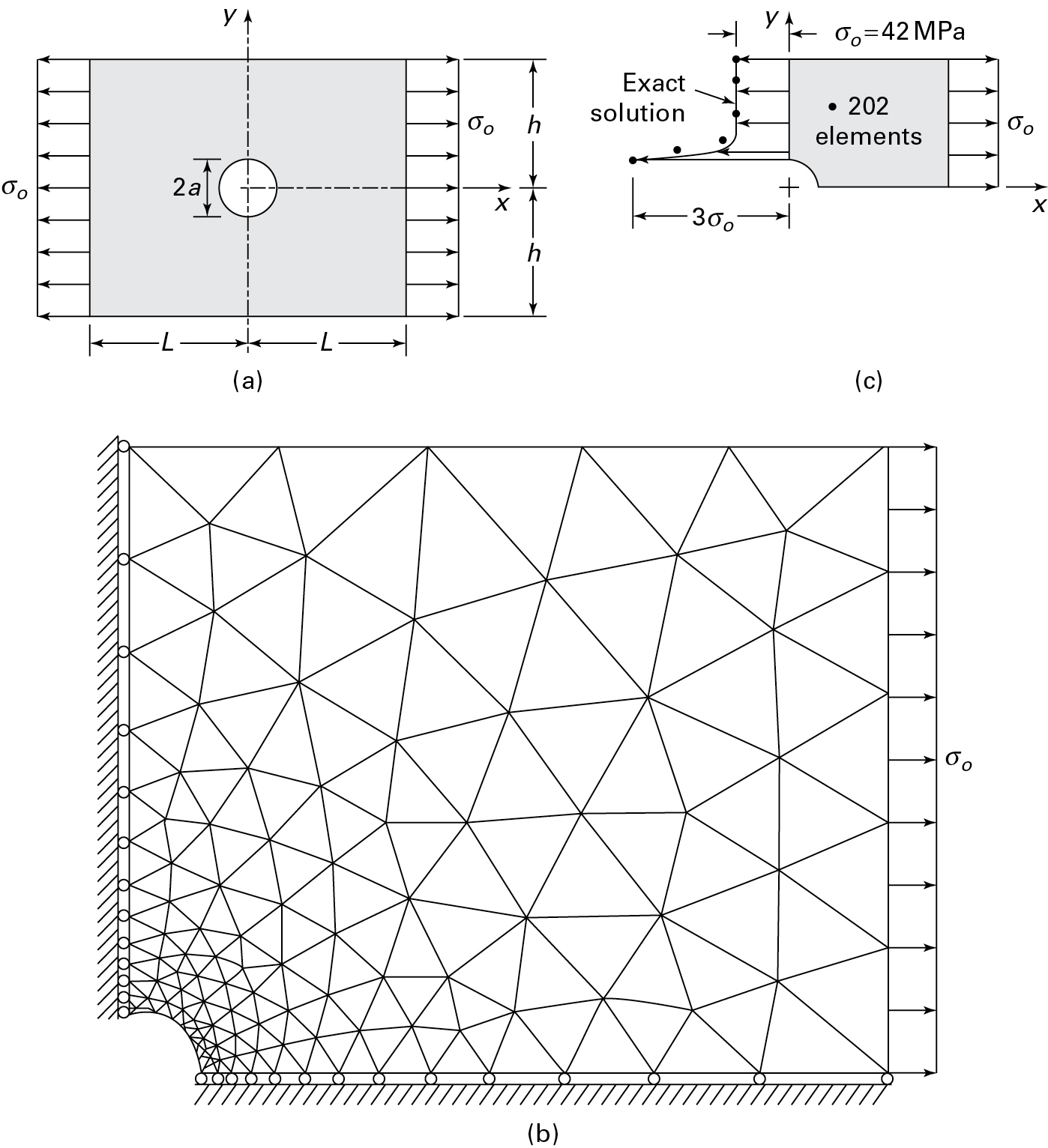

A thin aluminum alloy 6061-T6 plate containing a small circular hole of radius a is under uniform tensile stress σ0 at its edges (Fig. 7.30a). Using finite element analysis, outline the determination of the stress concentration factor K. Compare the result with that obtained by applying the theory of elasticity in Section 3.12.

Given: L = 600 mm, a = 50 mm, h = 500 mm,σ0 = 42 MPa, v = 0.3. Also, from Table D.1, E = 70 GPa.

Figure 7.30. Case Study 7.4. (a) Circular hole in a plate under uniaxial tension; (b) one-quadrant plate model; (c) uniaxial stress (ó x) distribution.

Solution Due to symmetry, only any one-quarter of the plate needs to be analyzed, as illustrated in Fig. 7.30b. In this case, the quarter plate is discretized into 202 CST elements [Ref. 7.2]. The roller boundary conditions are also shown in the figure.

The values of the edge stress σx, calculated by the FEM and the theory of elasticity are plotted in Fig. 7.30c for comparison [Ref. 7.7]. Observe that the agreement is reasonably good. The stress concentration factor for σx is equal to K ≈ 3σ0/3σ0=3.

7.16 Computational Tools

Various computational tools can be employed to carry out analysis calculations. A quality scientific calculator may be the best tool for solving most of the problems in this text. General-purpose analysis tools such as spreadsheets and equation solvers are very useful for certain computational tasks. Mathematical software packages of these types include MATLAB, TK Solver, and MathCAD. Such tools offer a key advantage: The user can both document and save the detailed completed work

As noted earlier and in Appendix E, the website for this text contains MATLAB simulations for advanced mechanics of materials and applied elasticity. Computer-aided drafting or design (CAD) software packages can also produce realistic three-dimensional representations of a member. Most CAD software provides an interface to one or more FEA programs. Such an interface permits direct transfer of the member’s geometry to an FEA package for analysis of stress and vibration as well as fluid and thermal analysis. Computer programs (e.g., NASTRAN, ANSYS, ABAQUS, GT-STRUDL) are used widely for performing the numerical computations required in the analysis and design of structural and mechanical systems.

With the proper use of computer-aided engineering (CAE) software, problems can be solved more quickly and more accurately. Clearly, the results are subject to the accuracy of the various assumptions that must necessarily be made in the analysis and design. This kind of computer-based software may be used as a tool to assist students with lengthy homework assignments. At the same time, it is important to thoroughly understand the basics, and analysts must check the computer solutions for accuracy and feasibility.

References

7.1. KREYSZIG, E. Advanced Engineering Mathematics, 10th ed. Hoboken, NJ: Wiley, 2011.

7.2. YANG, T. Y. Finite Element Structural Analysis. Upper Saddle River, NJ: Prentice Hall, 1986.

7.3. UGURAL, A. C. Mechanics of Materials. Hoboken, NJ: Wiley, 2008.

7.4. LOGAN, D. L. A First Course in the Finite Element Method. Boston: PWS-Kent, 1986.

7.5. KNIGHT, E. The Finite Element Method in Mechanical Design. Boston: PWS-Kent, 1993.

7.6. UGURAL, A. C. Mechanical Design of Machine Components, 2nd ed. Boca Raton, FL: CRC Press, Taylor & Francis Group, 2016.

7.7. BORESI, A. P., and SCHMIDT, R. J. Advanced Mechanics of Materials, 6th ed. New York: Wiley, 2003.

7.8. ZIENKIEWICZ, O. C., and Taylor, R. I. The Finite Element Method, 4th ed., Vol. 2 (Solid and Fluid Mechanics, Dynamics and Nonlinearity). London: McGraw-Hill, 1991.

7.9. BATHE, K. I. Finite Element Procedures in Engineering Analysis. Upper Saddle River, NJ: Prentice Hall, 1996.

Problems

Sections 7.1 through 7.4

7.1. Referring to Fig. 7.2, demonstrate that the biharmonic equation

takes the following finite difference form:

7.2. Consider a torsional bar having rectangular cross section of width 4a and depth 2a. Divide the cross section into equal nets with h = a/2. Assume that the origin of coordinates is located at the centroid. Find the shear stresses at points x = ±2a and y = ±a by using the direct finite difference approach. Note that the exact value of stress at y = ±a is, from Table 6.2, τmax = 1.860Gθa.

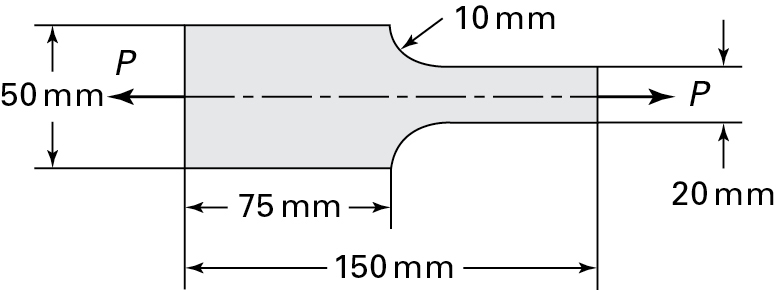

7.3. For the torsional member whose cross section is shown in Fig. P7.3, find the shear stresses at point B. Given: h = 5 mm and h1 = h2 = 3.5 mm.

Figure P7.3.

7.4. Re-sole Prob. 7.3 to find the shear stress at point A. Let h = 4.25 mm; then h1 = h and h2 = 2.25 mm.

7.5. Calculate the maximum shear stress in a torsional member of rectangular cross section of sides a and b (a = 1.5b). Employ the finite difference method, taking h = a/4. Compare the results with that given in Table 6.2.

Section 7.5

7.6. A force P is applied at the free end of a stepped cantilever beam of length L (Fig. P7.6). Determine the deflection of the free end using the finite difference method, taking n = 3. Compare the result with the exact solution υ(L)= 3PL3/16EI.

Figure P7.6.

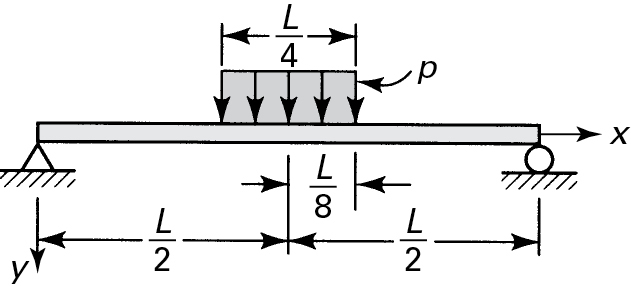

7.7. A stepped simple beam is loaded as shown in Fig. P7.7. Apply the finite difference approach, with h = L/4, to determine (a) the slope at point C and (b) the deflection at point C.

Figure P7.7.

7.8. A stepped simple beam carries a uniform loading of intensity p, as shown in Fig. P7.8. Use the finite difference method to calculate the deflection at point C. Let h = a/2.

Figure P7.8.

7.9. Cantilever beam AB carries a distributed load that varies linearly as shown in Fig. P7.9. Determine the deflection at the free end by applying the finite difference method. Use n = 4. Compare the result with the “exact” solution, w(L) = 11P0L4/120EI.

Figure P7.9.

7.10. Applying Eq. (7.22), determine the deflection at points 1 through 5 for the beam and loading shown in Fig. P7.10.

Figure P7.10.

7.11. Employ the finite difference method to obtain the maximum deflection and the slope of the simply supported beam loaded as shown in Fig. P7.11. Let h = L/4.

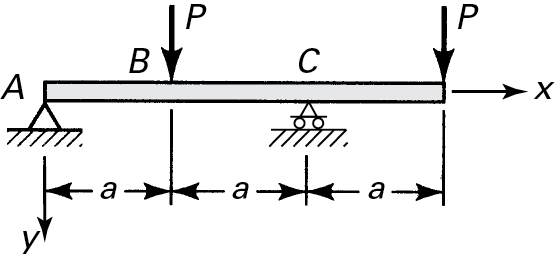

Figure P7.11.

7.12. Determine the deflection at a point B and the slope at point A of the overhanging beam loaded as shown in Fig. P7.12. Use the finite difference approach, with n = 6. Compare the deflection with its “exact” value, υB = Pa3/12EI.

Figure P7.12.

7.13. Re-solve Prob. 7.6 with the beam subjected to a uniform load p per unit length and P = 0. The exact solution is υ(L) = 3PL4/32EI.

7.14. A beam is supported and loaded as depicted in Fig. P7.14. Use the finite difference approach, with h = L/4, to compute the maximum deflection and slope.

Figure P7.14.

7.15. A fixed-ended beam supports a concentrated load P at its midspan, as shown in Fig. P7.15. Apply the finite difference method to determine the reactions. Let h = L/4.

Figure P7.15.

7.16. Use the finite difference method to calculate the maximum deflection and the slope of a fixed-ended beam of length L carrying a uniform load of intensity p (Fig. P7.16). Let h = L/4.

Figure P7.16.

Sections 7.6 through 7.16

7.17. The bar element 4–1 of length L and cross-sectional area A is oriented at an angle a clockwise from the x axis (Fig. P7.17). Calculate (a) the global stiffness matrix of the bar, (b) the axial force in the bar, and (c) the local displacements at the ends of the bar. Given: A = 1350 mm2, L = 1.7 m, α = 30°, E = 96 GPa, u4 = 21.1 mm, υ4 = 21.2 mm, u1 = 2 mm, and υ1 = 1.5 mm.

Figure P7.17.

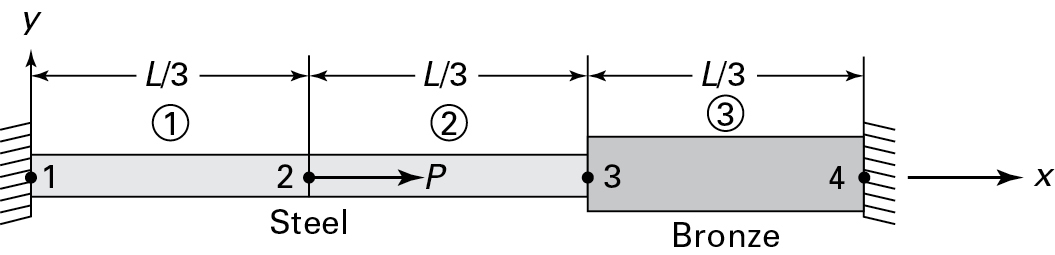

7.18. The axially loaded bar 1–4 of constant axial rigidity AE is held between two rigid supports and under a concentrated load P at node 3, as illustrated in Fig. P7.18. Find (a) the system stiffness matrix, (b) the displacements at nodes 2 and 3, and (c) the nodal forces and reactions at the supports.

Figure P7.18.

7.19. The axially loaded composite bar 1–4 is held between two rigid supports and subjected to a concentrated load P at node 2, as depicted in Fig. P7.19. The steel bar 1–3 has cross-sectional area A and modulus of elasticity E. The brass bar 3–4 has cross-sectional area 2A and elastic modulus E/2. Determine (a) the system stiffness matrix, (b) the displacements of nodes 2 and 3, and (c) the nodal forces and reactions at the supports.

Figure P7.19.

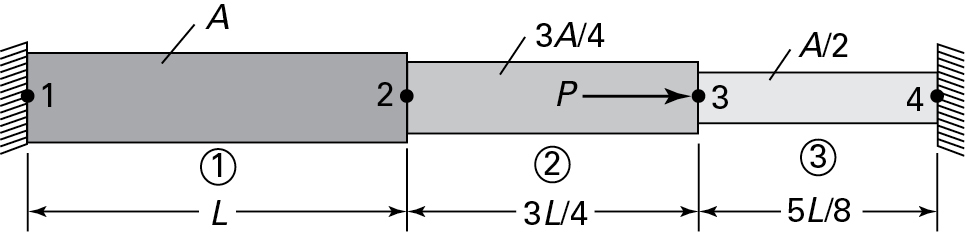

7.20. A stepped bar 1–4 is held between rigid supports and carries a concentrated load P at node 3, as illustrated in Fig. P7.20. Find (a) the system stiffness matrix, (b) the displacements of nodes 2 and 3, and (c) the nodal forces and reactions at the supports.

Figure P7.20.

7.21. A planar truss containing five members with axial rigidity AE is supported at joints 1 and 4, as shown in Fig. P7.21. What is the global stiffness matrix for each element?

Figure P7.21.

7.22. A plane truss is loaded and supported as illustrated in Fig. P7.22. Each element has an axial rigidity AE. Find (a) the global stiffness matrix for each element, (b) the system stiffness matrix, and (c) the system force-displacement relations.

Figure P7.22.

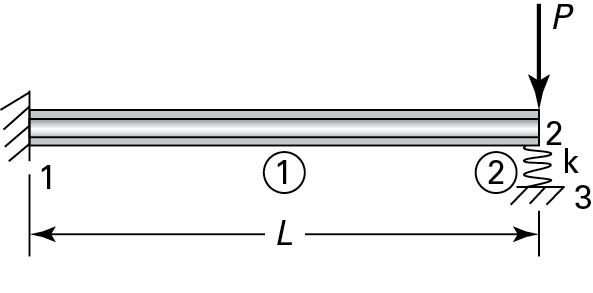

7.23. A two-bar planar truss is supported by a spring of stiffness k at joint 1, as depicted in Fig. P7.23. Each element has an axial rigidity AE. Calculate (a) the stiffness matrix for bars 1 and 2, and spring 3; (b) the system stiffness matrix; and (c) the force-displacement equations. Given: L2 = L, (AE)2 = AE, , .

Figure P7.23.

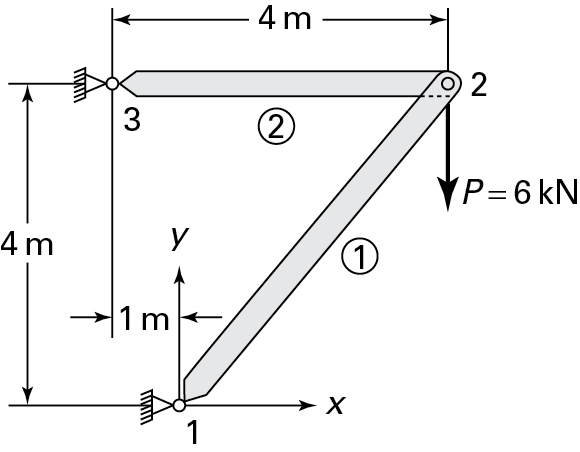

7.24. A vertical concentrated load P = 6 kN is applied at joint 2 of the two-bar plane truss supported as shown in Fig. P7.24. Take AE = 20 MN for each member. Find (a) the global stiffness matrix of each bar, (b) the system stiffness matrix, (c) the nodal displacements, (d) the support reactions, and (e) the axial forces in each bar.

Figure P7.24.

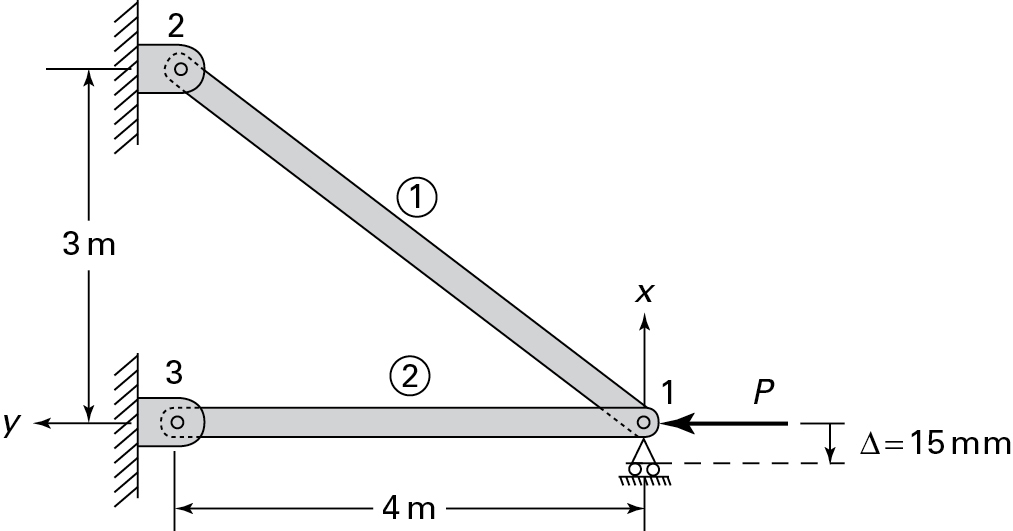

7.25. In a two-bar plane truss, its support at joint 1 settles vertically by an amount of u = 15 mm downward when loaded by a horizontal concentrated load P (Fig. P7.25). Calculate (a) the global stiffness matrix of each element, (b) the system stiffness matrix, (c) the nodal displacements, and (d) the support reactions. Given: E = 105 GPa, A = 10 × 10–4m2, P = 10 KN.

Figure P7.25.

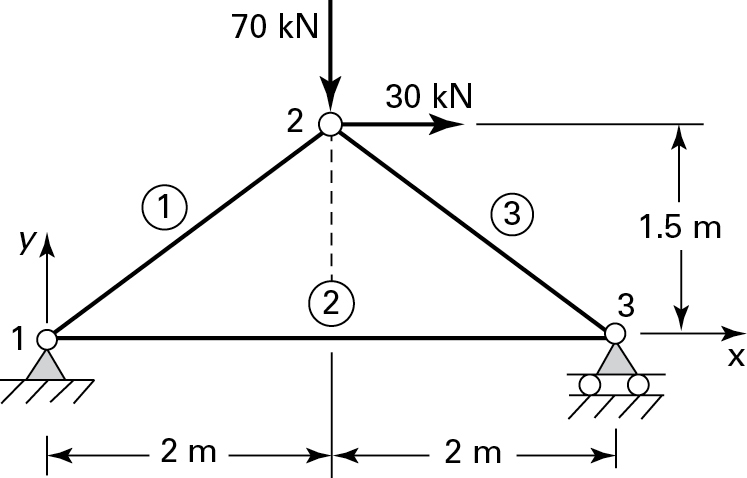

7.26. A plane truss is loaded and supported as shown in Fig. P17.26. Find (a) the global stiffness matrix for each member, (b) the system stiffness matrix, (c) the nodal displacements, (d) the reactions, and (e) the axial forces in each member. Given: The axial rigidity AE = 20 MN is the same for each bar.

7.27. A cantilever of constant flexural rigidity EI carries a concentrated load P at its free end, as shown in Fig. P7.27. Find (a) the deflection υ 1 and angle of rotation u1 at the free end, and (b) the reactions R2 and M2 at the fixed end.

Figure P7.26.

Figure P7.27.

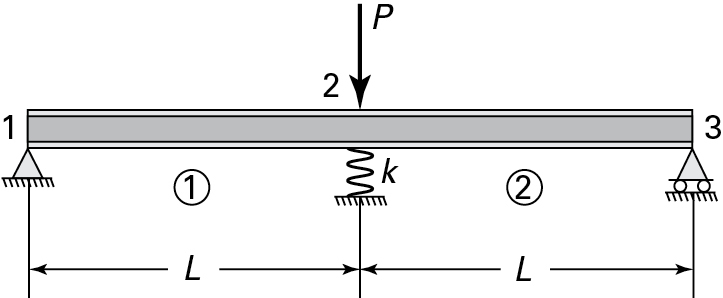

7.28. A simple beam 1–3 of length L and flexural rigidity EI is supports a uniformly distributed load of intensity p, as illustrated in Fig. P7.28. Determine the deflection of the beam at midpoint 2 by replacing the applied load with the equivalent nodal loads (see Table D.5).

Figure P7.28.

7.29. A beam supported by a pin, a spring of stiffness k, and a roller at points 1, 2, and 3, respectively, is under a concentrated load P at point 2 (Fig. P7.29). Calculate (a) the nodal displacements and (b) the nodal forces and spring force. Given: L = 4 m, P = 12 KN, EI = 14 MN · m2, and k = 200 KN/m.

Figure P7.29.

7.30. A cantilever beam 1–2 of length L and constant flexural rigidity EI is subjected to a concentrated load P at the midspan, as shown in Fig. P7.30. Find the vertical deflection v2 and angle of rotation θ 2 at the free end by replacing the applied load with the equivalent nodal loads acting at each end of the beam (see Table D.5).

Figure P7.30.

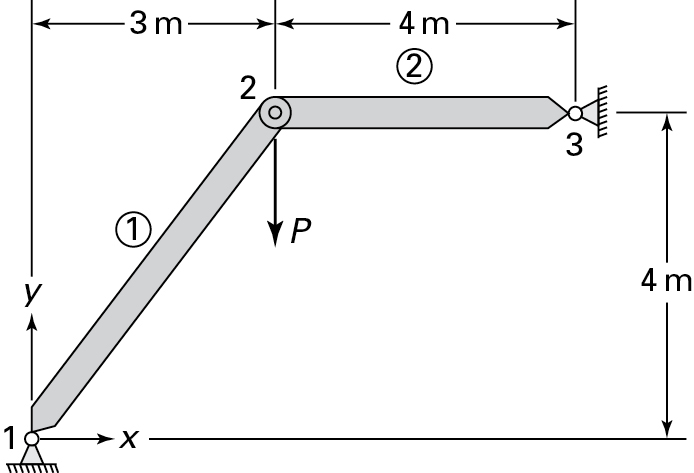

7.31. A propped cantilever beam with flexural rigidities EI and EI/2 for the parts 1–2 and 2–3, respectively, carries concentrated load P and moment 3PL at point 2 (Fig. P7.31). Calculate the displacements υ2, θ 2, and θ 3. Given: L = 1.2 m, P = 30 KN, E = 207 GPa, and I = 15×106 mm4.

Figure P7.31.