Case Study Application III: RISKCURVES

Abstract

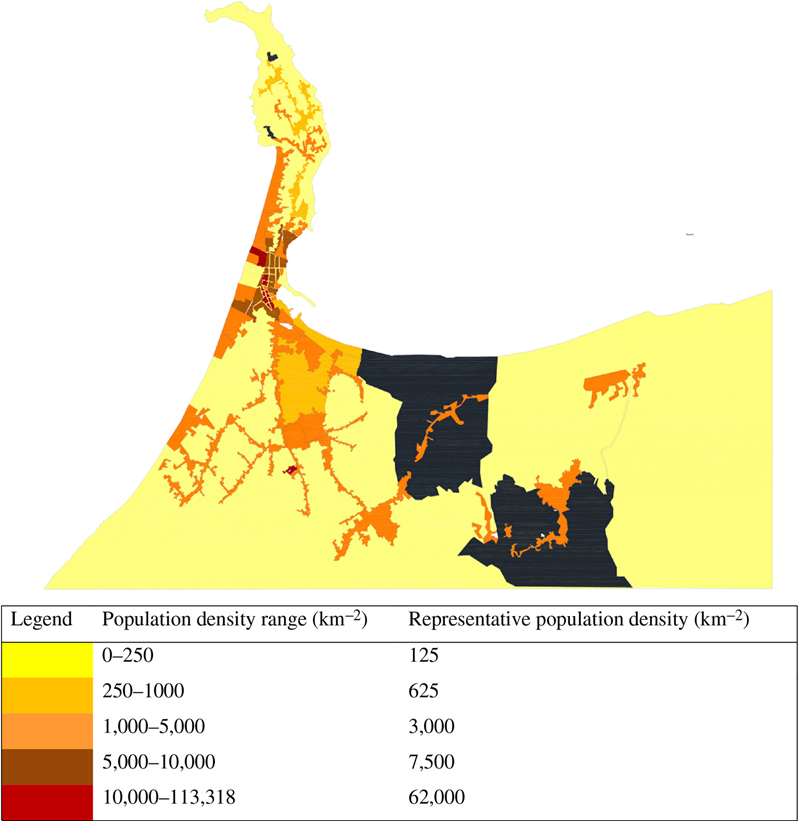

This chapter discusses the application of TNO’s software packages RISKCURVES and EFFECTS in the quantitative Natech risk analysis of a refinery located on the Mediterranean coast. In addition to conventional industrial accident scenarios that could lead to a release of dangerous substances, the impact of two natural hazards (earthquake and tsunami) on the overall risk level was also considered and the priority risk contributors identified.

Keywords

12.1. Introduction

12.2. Methodology

12.3. Description of the Case Study

Table 12.1

Standard Scenarios and Associated Frequencies for Industrial Accidents

| Scenario | Frequency (Year−1) | |

| Atmospheric Vessels (Single Containment) | Pressurized Vessels | |

| Instantaneous release of the complete inventory | 5 × 10−6 | 5 × 10−7 |

| Continuous release of the complete inventory in 10 min at a constant rate of release | 5 × 10−6 | 5 × 10−7 |

| Continuous release from a hole with an effective diameter of 10 mm | 10−4 | 10−5 |

Table 12.2

Standard Scenario and Frequencies for Above-Ground Pipes With Diameter D

| Scenario | Frequency (Year−1) | ||

| D < 75 mm | 75 mm < D < 150 mm | D > 150 mm | |

| Full-bore rupture | 10−6 | 3 × 10−7 | 10−7 |

Table 12.3

Pool Surface Areas

| Scenario | Pool Surface Area Considered |

| Instantaneous release tank | 1.5 × main basin |

| 10-min release tank | Main basin |

| 10-mm leak tank | Subbasin |

Table 12.4

Accident Scenarios and Frequencies for Stationary Vessels due to Natural-Hazard Impacts (Salzano et al., 2003; Fabbrocino et al., 2005; Campedel et al., 2008; Lanzano et al., 2013; 2014; 2015)

| Scenario | Frequency (Year−1) | ||

| Earthquake | Atmospheric Vessels (Single Containment) | Pressurized Vessels | Pipes |

| Instantaneous release of the complete inventory | 3.70 × 10−3 | 1.16 × 10−9 | — |

| Continuous release of the complete inventory in 10 min at a constant rate of release | 3.70 × 10−3 | 1.16 × 10−9 | — |

| Continuous release from a hole with an effective diameter of 10 mm | 7.33 × 10−2 | 0 | — |

| Full-bore rupture | — | — | 5.56 × 10−2 |

| Tsunami | Atmospheric Vessels (Single Containment) | Pressurized Vessels | Pipes |

| Instantaneous release of the complete inventory | 1.85 × 10−5 to 3.47 × 10−4 | 0 | — |

| Continuous release of the complete inventory in 10 min at a constant rate of release | 1.85 × 10−5 to 3.47 × 10−4 | 0 | — |

| Continuous release from a hole with an effective diameter of 10 mm | 0 | 0 | — |

| Full-bore rupture | — | — | 0 |

| Earthquake + Tsunami | Atmospheric Vessels (Single Containment) | Pressurized Vessels | Pipes |

| Instantaneous release of the complete inventory | 3.7 × 10−3 to 4.05 × 10−3 | 1.16 × 10−9 | — |

| Continuous release of the complete inventory in 10 min at a constant rate of release | 3.7 × 10−3 to 4.05 × 10−3 | 1.16 × 10−9 | — |

| Continuous release from a hole with an effective diameter of 10 mm | 7.33 × 10−2 | 0 | — |

| Full-bore rupture | — | — | 5.56 × 10−2 |

Table 12.5

Representative Substances

| Product | Representative Substance |

| Atmospheric residue | NA |

| Crude oil | Pentane |

| Fuel oil | Nonane |

| Gasoil | Nonane |

| Gasoline | Pentane |

| HVGO | NA |

| Jet fuel/kerosine | Nonane |

| LPG | Propane |

| Naphtha | Pentane |

| Others | Pentane |

| VAC residue | NA |

12.4. Results and Discussion