Qualitative and Semiquantitative Methods for Natech Risk Assessment

Abstract

Risk assessment is a prerequisite for understanding the Natech risk and for determining if and which prevention and preparedness measures should be implemented to reduce the risk. The analysis of multihazard risks is a highly complex task and there is no consolidated methodology for assessing the Natech risk. This chapter introduces selected qualitative and semiquantitative Natech risk-analysis methodologies, approaches, and tools of varying levels of resolution. The outcome of these methodologies can be used for evaluating the risk in accordance with the risk-acceptability criteria in place.

Keywords

8.1. RAPID-N

8.1.1. Scientific Module

8.1.2. Industrial Plants and Units Module

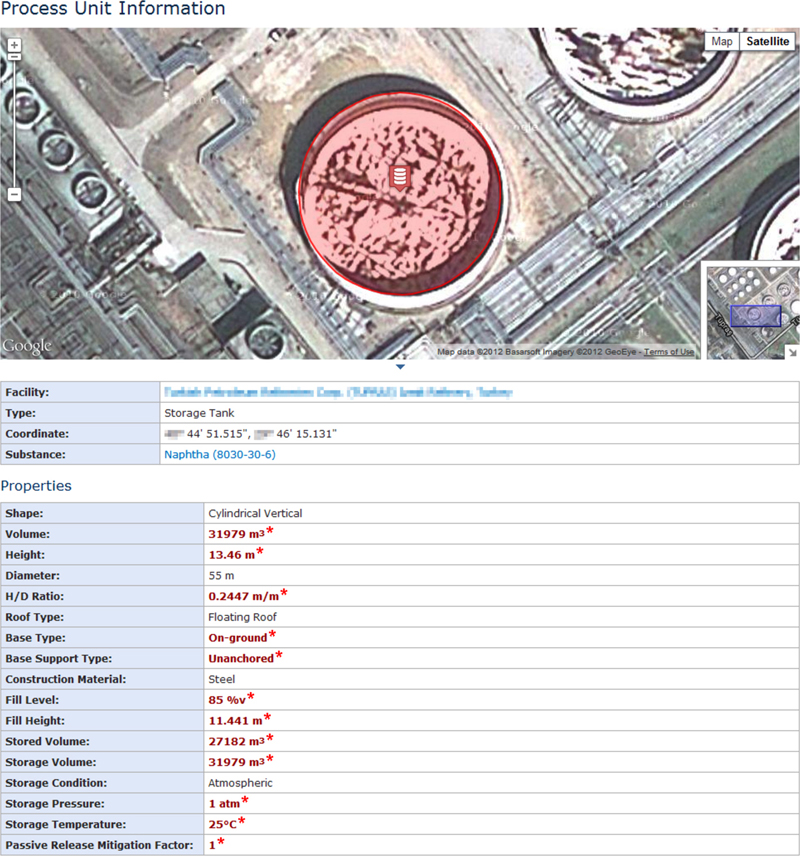

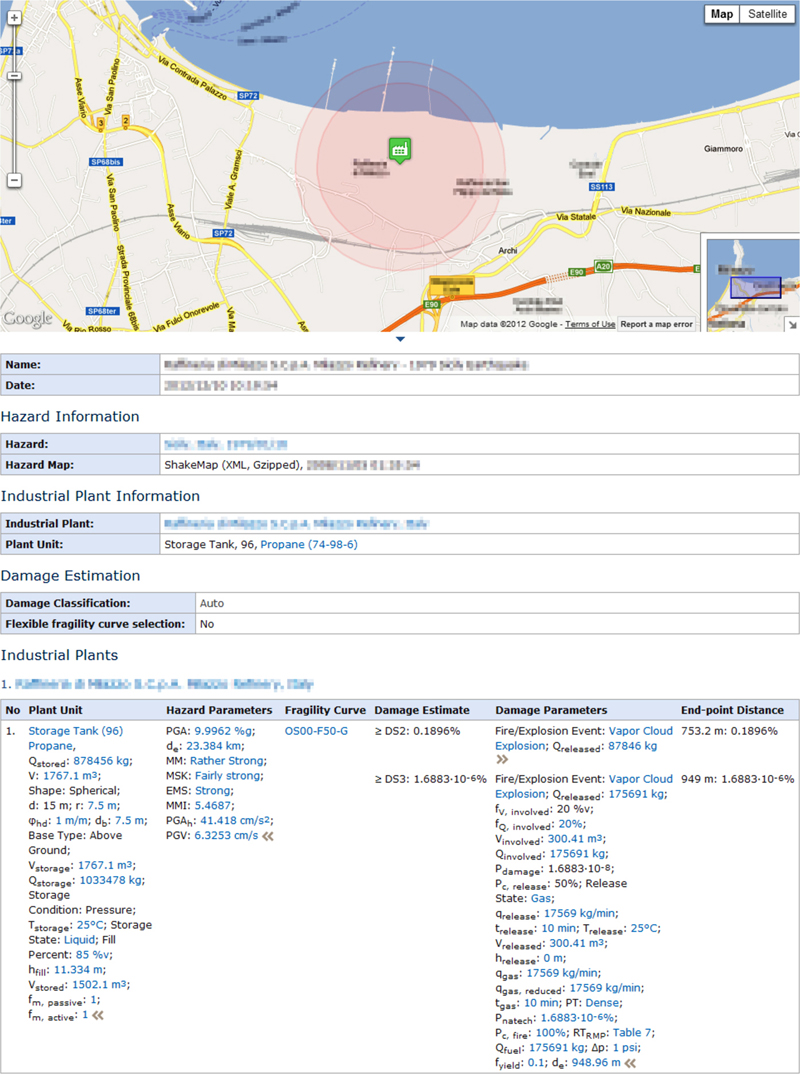

The asterisk designates data estimated or assigned as default values by RAPID-N in the absence of user-defined information.

8.1.3. Natural-Hazards Module

8.1.4. Natech Risk-Analysis Module

8.1.5. Outlook

8.2. PANR

8.3. TRAS 310 and TRAS 320

8.3.1. TRAS 310 “Precautions and Measures Against the Hazard Sources Precipitation and Flooding”

8.3.1.1. Scope of Application

8.3.1.2. Methodological Approach of TRAS 310

*If required pursuant to Art. 10 of the Major Accidents Ordinance only.

8.3.1.3. Hazard Source Analysis

8.3.1.3.1. Simplified hazard source analysis

Table 8.1

Criteria for Selected Natural-Hazard Sources

| Hazard Source | Criterion | Necessity and Extent of Hazard Source Analysis | |

| River or coastal high water flooding combined with flow, dynamic pressure, flotsam, and ice run | Designated flood plain or area mapped on (flood) hazard or risk maps under Art. 74 of the Federal Water Act | On the designated flood plain or within the mapped (flood) risk area | Detailed hazard source analysis required |

| Mapped, but outside (flood) risk areas | No further examination required | ||

| Rising groundwater | Underground parts of installations where hazardous substances are present (tanks, pipes) | Releases due to buoyancy possible | Detailed hazard source analysis required |

| Releases due to buoyancy not possible | No further examination required | ||

8.3.1.3.2. Detailed hazard source analysis

8.3.1.3.3. Consideration of climate change

8.3.1.4. Determination of Threatened Safety-Relevant Parts of Establishments and Installations

8.3.1.5. Determination of Possible Causes of Major Accidents

8.3.1.6. Specification of Scenarios and Protection Aims

8.3.1.7. Elaboration of Protection Concepts for Scenarios

8.3.1.8. Review of Protection Concepts

8.3.1.9. Determination of Accident Scenarios

8.3.1.10. Specification of Measures to Mitigate the Effects of Major Accidents

8.3.1.11. Planning for Emergencies

8.3.1.12. Design Criteria for the Consideration of Climate Change

Table 8.2

Requirements for Adaptation to Climate Change

| Hazard Source | Intensity to Be Estimated as of 2010 | Intensity to Be Estimated for 2050 |

| River flooding | Flood runoff (m3/s) | 1.2 × flood runoff (m3/s) |

| Flash flood events | Flood runoff (m3/s) | 1.2 × flood runoff (m3/s) |

| Storm surge events | Nominal height of levees, etc. pursuant to designation | May subsequently be raised by up to 1 ma |

| Heavy precipitation | Peak heavy precipitationb for t = 100 a | 1.2 × peak heavy precipitation for t = 100 a |

| Rising groundwater | Surface of terrain | Surface of terrain (climate change adaptation factor not relevant) |

a General coastal defense plans, for example, the measures taken by the Lower Saxony Water, Coastal Defense and Nature Conservation Agency, http://www.nlwkn.niedersachsen.de