5.1

NATURAL GAS TRANSPORTATION

Because of cost considerations, natural gas is typically transported by pipeline. Natural gas needs to be kept in airtight containers to prevent it from dispersing. If gas is transported in a container, the weight of the container affects transportation costs. Pipelines eliminate the problem of moving heavy containers, and, as a result, have become the most common method of transporting natural gas.

Once they are built, pipelines are cost-effective. They have relatively few moving parts and can operate around the clock. This has effectively eliminated interest in building alternative distribution networks. The downside is that natural gas transportation is generally restricted to areas connected by pipelines. These pipelines form an interconnected network that allows natural gas to flow from production areas to consumption areas. However, when an area is not connected into the pipeline network, it is very difficult to get gas in or out. When natural gas can’t be placed onto a pipeline network, it is said to be “stranded.”

Natural gas pipelines also have substantial operating constraints. The largest constraint is that they need to operate continuously. Unless there is continuous movement of gas over a pipeline, it won’t work. Pipelines must maintain areas of high and low pressure to keep gas moving. If the pressure in the pipeline fully equalizes, the gas will stop flowing and it can take a very long time to get moving again.

As their name would suggest, pipelines are long pipes that use compressors to move gas from one end of the pipe to the other. A compressor (like a fan) at the start of the pipe creates a high pressure area, and a compressor at the end of the pipe pulls gas out of the pipeline by suction (a low pressure area). Gas is drawn through the pipe by the pressure differential between the high pressure injection point and the low pressure suction point.

Pipeline Terminology

Pipelines are often separated into categories based on how far they transport gas. Transportation pipelines involve the long-distance transportation of natural gas. Distribution pipelines are concerned with delivering gas to end-users. Of the two, distribution pipelines tend to be much more complex. With a distribution pipeline, gas is delivered to a large number of consumers. This creates a complex branching structure. In contrast, a long-distance transportation pipeline might only have one or two branches. The complexity of local delivery pipelines is expensive. It often costs as much to deliver gas the last mile from a citygate to a consumer as it costs to move the gas across the country.

Special terms are given to the locations where pipelines connect with one another. The intersection of two or more long-distance pipelines is called a hub. The connection between transportation pipelines and a distribution pipeline is called a citygate. Both hubs and citygates are common delivery locations for natural gas contracts. Consumers of natural gas are often called the burner tip.

Adding gas to a pipeline is called injection. Removing gas from a pipeline is called withdrawal. Pipelines typically have a variety of locations where gas can be injected or withdrawn from the system. An injection point is called a receipt point since it is where the pipeline receives the gas. A point where gas is removed is called a delivery point. The names are based on the pipeline’s obligation, rather than the obligations of the purchaser of the transportation contract.

Pipeline Operations

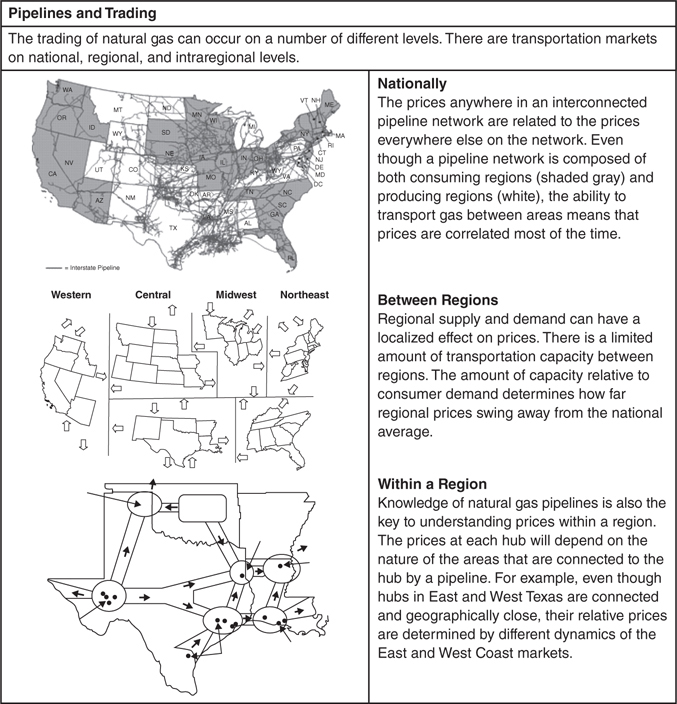

There are many different types of pipelines (Figure 5.1.1). Some pipelines connect wells to refineries. Others are transcontinental in nature, moving the gas from producing regions to consuming regions. Still other pipelines are used to deliver gas to consumers. All pipelines work in a similar manner—gas moves along a pipe from an area of high pressure to an area of low pressure. By manipulating the pressure in different areas of the pipe (through compressors), pipeline companies can control the flow of gas through their networks.

Figure 5.1.1 Pipeline networks

(Source: Maps courtesy of U.S. Energy Information Agency)

It is important that a pipeline maintains the proper ratio of pressures throughout its length. If the pressure at the discharge end of the pipe were to be higher than the pressure at the well head, gas would flow back into the well. In practical terms, this means that if a pipeline is to remain operational, gas must be continually injected at one side and removed at the other. If gas isn’t added continuously at the injection point (to create a high pressure zone) and removed at the consumer end (to create a low pressure zone), gas won’t flow in the proper direction, and the pipeline won’t operate. This is a very important concept—for a pipeline to operate, neither injections nor removals can stop because they are uneconomical. Because of the time required to restart pipelines, it might be necessary to run a pipeline even if no consumers are using gas and there isn’t any storage available.

Compressor Stations

Compressor stations form the heart of the pipeline network. Similar to how a heart pumps blood throughout a human body, compressor stations push natural gas through the pipeline network. When liquid or gas is compressed, it moves toward an area of lower pressure. By controlling the location of high and low pressure areas, compressor stations are used to control the flow of gas through pipelines. The simplest way to think of a compressor is a household fan. On one side of the fan, gas is being pulled in and a low pressure zone exists. On the other side of the fan, air is being pushed out to create a high pressure zone.

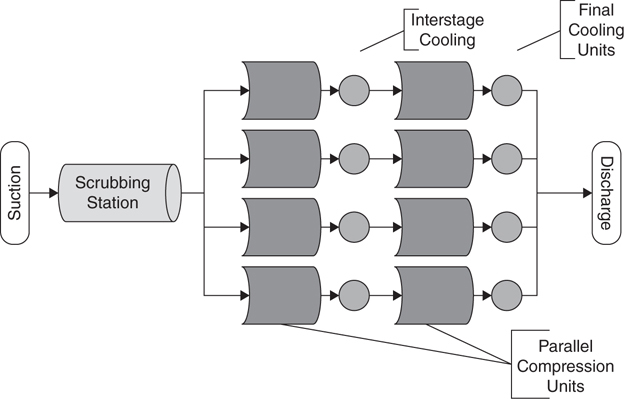

One key issue with compression is that it will increase the temperature of the gas being compressed. Cold gas is denser than hot gas. If the pipeline is operated at a constant pressure, a greater quantity of gas can be transported if the gas is kept cool. As a result, most compressing stations include several cooling stages as part of the compression process. Cooler gas also causes less corrosion. Natural gas is never perfectly pure methane. It almost always contains trace amounts of other gases. Some of these trace gases can be highly corrosive and cause mechanical breakdowns if they are allowed to accumulate. As a result, compression stations also provide scrubbing systems to remove trace impurities.

A modern compression station will usually contain several compressor units running in parallel (Figure 5.1.2). Gas enters the station through a suction header, and then moves through the scrubber system. The scrubber system removes particulate matter and most liquids from the gas. Then the gas goes through a series of compression and cooling stages before being discharged into the next segment of the pipeline.

Figure 5.1.2 A multistage compression station

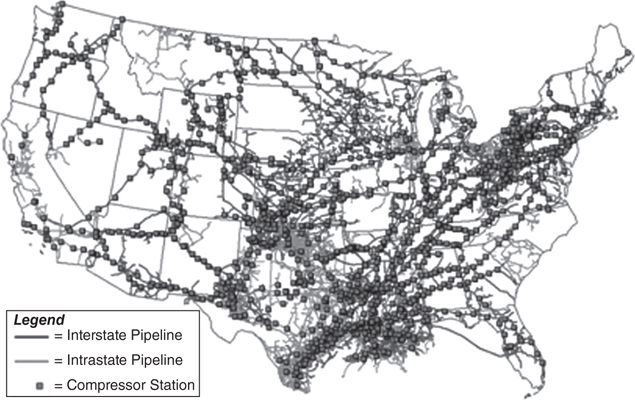

Compression stations are located along the entire length of a pipeline. These compression stations divide the pipeline into small segments. Gas moves between pipeline segments by traveling from the high pressure discharge point of one station to the low pressure suction point of the next station. Chaining these sections together allows a steady flow of gas through the pipeline. It is very important that all of the stations on a pipeline work together or else the pipeline will stop operating. Most compressor stations are fully automated and coordination between stations is handled by a computer at a central location. On most pipelines, compression stations are located approximately every 50 miles (Figure 5.1.3).

Figure 5.1.3 Interstate pipelines and compressor stations

(Source: Map courtesy of U.S. Energy Information Administration)

Transportation Contracts

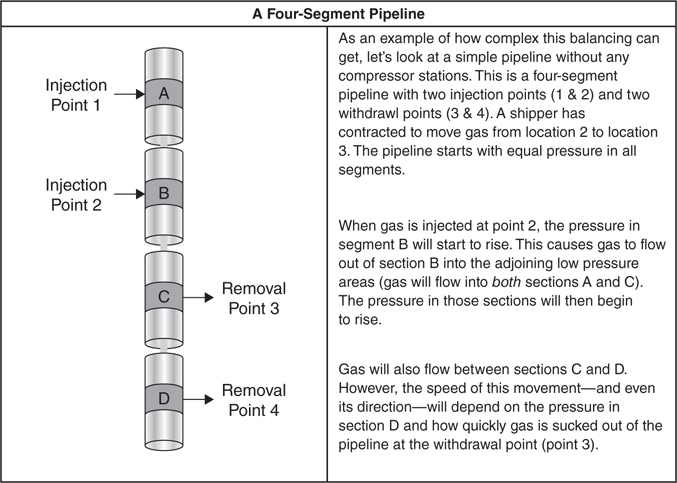

When arranging transportation on a pipeline, there are two major levels of service—firm service and interruptible service. Firm service is offered with a guaranteed availability except when prevented by act of force majeure.1 Firm service is highly reliable but also relatively expensive compared to interruptible service. Interruptible service is offered on a “best efforts” basis and is relatively cheap. However, it can be interrupted for any reason and may not be available at all. There are a number of valid reasons why interruptible service might be disrupted. The most common reason is to balance the flow of gas on a pipeline. Because of the nature of gas, its movement can never be precisely controlled—it always moves from areas of high pressure to low pressure. Even optimizing a relatively simple pipeline can get very complicated (Figure 5.1.4).

Figure 5.1.4 A four-segment pipeline

Even in this simple case, gas is being spread all around the pipeline. It would be practically impossible to get all of the gas injected at Point 2 out of the pipeline at Point 3. If the pipeline were mostly full of gas, it would be possible to get approximately the same amount of gas out of the pipeline as was injected, but it wouldn’t be the same gas. This has some advantages. For example, if the pipeline was nearly full, and the amount of gas being transported was relatively small, gas could be simultaneously injected and removed from the pipeline. It would take some time for the pipeline to reach equilibrium again, but the so-called “transportation” would occur very quickly.

The rate at which gas flows depends on the pressure difference between areas. High pressure gas moves more quickly than low pressure gas. In the previous example, injecting gas into a nearly empty pipeline and injecting gas into a nearly full pipeline give two very different operational results. Starting empty, since the gas will spread throughout the entire pipeline, it would probably be impossible to fully remove the full quantity of the gas from the pipeline at Location 3.

Pipeline operators have a vested interest in keeping the pipeline as full as possible. While they can’t keep the pipeline at maximum capacity since it would be impossible to inject additional gas, neither can pipelines be operated at very low pressure.

The firm shipper pays a large premium (a reservation charge) in order to guarantee that enough capacity is available at all times for its use. However, the shipper doesn’t actually have to put its gas into the pipeline—perhaps it is a warmer than expected winter, and residential demand is much lower than expected. The pipeline operator still needs gas in the pipeline—the pressure in the pipeline can’t be allowed to drop too far—so it will offer much lower cost interruptible service to other clients. When the firm shipper wants to make a delivery, the interruptible clients will get shut off.

There are valid business reasons for using either type of contract. It is important that a public service company provide gas heat to residences without interruption. A power plant or industrial facility might also want to guarantee its supply of gas as well. On the other hand, a gas storage facility might opt to use interruptible service for buying gas. A storage facility wants to buy gas cheaply (during periods of low demand) and sell high (during periods of high demand). There is no need to pay a high premium to buy during periods of minimal usage—minimal usage indicates that interruptible service contracts are operating.

For regulated pipelines in the United States (this covers pretty much every pipeline that is available for public use), the fee structure charged by the pipeline will be listed in a public document, called a tariff, which can be obtained from either the pipeline company or the regulating agency (Figure 5.1.5).

Figure 5.1.5 Pipeline map and tariff schedule

Transportation Contracts Between Buyers and Sellers

As opposed to transportation contracts with pipelines, there are three common levels of contracts between buyers and sellers of gas—short term interruptible contracts, baseload contracts, and firm contracts. These use similar terminology to the transportation contracts, but mean slightly different things.

Short term interruptible contracts are short-term contracts between buyers and sellers utilizing interruptible service. Usually these are only for a couple of days or the balance of a month. If the seller has supply, and the buyer wants it, and there is available transportation, then the trade gets made. If any of those things does not happen, there is no obligation on anyone’s part.

Baseload contracts are another type of interruptible contract between buyers and sellers. They are generally made with the understanding that both parties will make a “best effort” to meet the terms of the contract every day. They may or may not use firm pipeline transportation, or they might use a combination of firm and interruptible transportation. These contracts are based on trust that each side will hold up its end of the deal.

Firm contracts between buyers and sellers are binding agreements obligating both parties to the transportation—the seller is obligated to deliver, and the buyer is obligated to receive gas. There is legal recourse if either side fails on its side of the agreement. In these cases, the pipeline also needs to be obligated to reserve delivery capacity—these types of contracts will almost always utilize firm transportation contracts.

Trading Example—Pipelines as Insurance Providers

A pipeline offers capacity on its pipeline at two levels of service—guaranteed service and nonguaranteed service. The pipeline wants to offer as much guaranteed service as possible to earn a higher margin. It is considering whether to buy backup compressors along the pipeline.

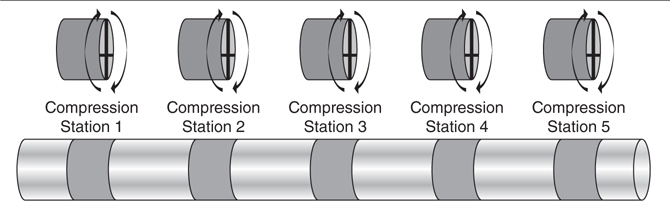

1. The Opportunity. A pipeline consists of five compressor stations located in a row. Each compressor is active 85 percent of the time and has a scheduled maintenance of one week a year. The pipeline can continue to operate unless adjacent compressing stations are down simultaneously. However, every compressor that is offline the pipeline loses 20 percent of its capacity. A graphic of the pipeline is shown in Figure 5.1.6.

Figure 5.1.6 A pipeline with five compressors

A large portion of the pipeline’s profit comes from guaranteed contracts. The pipeline offers annual contracts to deliver gas at two levels, firm contracts and interruptible contracts. The pipeline faces a steep penalty for failing to deliver on a firm contract. For each MMBtu of firm transportation that the pipeline successfully delivers, it receives $1. For each undelivered MMBtu of firm transportation, the pipeline must pay $12.50. For each MMBtu of interruptible transportation, the pipeline receives $0.15. If the pipeline fails to deliver the gas, it costs no money.

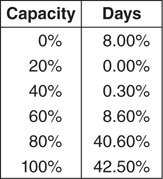

2. The Intuition. The pipeline is losing a lot of money when it fails to deliver on a firm contract. For the past five years, it has been unable to operate on 8 percent of the days. It is only able to operate at full capacity 42.5 percent of the time (Figure 5.1.7). The pipeline has offered 60 percent of its capacity in firm contracts. Although it has delivered 91.7 percent of its firm contract successfully, the penalty for nondelivery of the remainder has eaten up all of those profits.

Figure 5.1.7 Operating availability

3. The Strategy. The pipeline operator plans to increase its profits by improving the reliability of the pipeline. It plans to add a second compressor to each compression station. Even though the second compressor will be idle most of the time, by increasing the reliability of the pipeline, more firm capacity can be sold, cutting down on penalties for nondelivery of firm contracts.

4. The Results. The pipeline goes from making 15 cents on 40 percent of its capacity, to making $1 on 80 percent of its capacity. The pipeline starts making 100 times the profit it made previously. Even with doubled maintenance costs, this is a tremendous improvement in profitability.

Trading Example—Short Term Interruptible Trades

A chemical processor can produce methanol from either agricultural waste or natural gas. When natural gas is expensive, the manufacturer will use the discarded stalks and leaves of corn plants (corn stover). When natural gas is cheap, the manufacturer will use natural gas.

1. The Opportunity. One way to think about the natural gas markets is as an auction. The people willing to pay the highest amount for natural gas at that moment win the available supply. Everyone else has to wait for a later time to buy natural gas. Around the country, each area has a different amount of supply arriving at any given point and a different pool of people demanding fuel. The natural gas marketer would like to buy natural gas at a bargain price whenever there is no one else interested in using it.

2. The Intuition. The chemical processor would like to buy natural gas when it is cheap. However, the processor finds natural gas uneconomical to use as a feedstock when prices are high. For this type of strategy, it doesn’t make sense to reserve firm transportation on a pipeline. If the chemical processor is only going to buy natural gas when prices are low, this coincides with the times when the demand for pipeline transportation is also low.

3. The Strategy. The chemical processor agrees to buy natural gas from a natural gas processor using a swing contract. This contract is a nonbinding contract to purchase gas on an as-available basis using nonguaranteed transportation. In other words, the chemical processor agrees to buy gas when no one else wants it.

4. The Risks. The chemical processor has little risk in this trade. It is getting a product at low cost when almost no one else is buying natural gas. The chemical processor can then convert that gas into a more valuable product, methanol.

5. The Results. Arranging for gas to be purchased with swing contracts and interruptible transportation is the lowest cost way to purchase physical gas. The main downside is that the supply of gas isn’t guaranteed and during periods of high demand, almost no supply will be available. The chemical processor will have to rely on its other feedstock, corn stover, in those periods.

1 Force majeure is French for “greater force.” This is a common clause in contracts that frees both parties from liability in cases of wars, natural disasters, and other extraordinary events. Typically these events are outside the control of either party, which would prevent one or both of the parties from fulfilling their obligations under the terms of the contract.