BASICS Model: Implementation (I)

The I in our BASICS model stands for Implementation (see Figure 5.1). An important aspect for the team to realize is that some tasks are “just do it” in nature and can be implemented quickly, or at latest the next day. However, many improvements require the action of work done by an improvement team. Many times, this will be done with sub-projects and will take time and resources to complete.

Figure 5.1 The BASICS six-step model for Lean implementation—implement. (Source: BIG Archives.)

Implement the New Process, Use Pilots, and Test It out Using Scrum

We have been one of the first consulting firms to use the Scrum approach to Lean implementation. This was a challenge given to us by our Scrum sensei Nigel Thurlow, former internationally renowned consultant and now a V.P. at Toyota. This approach utilizes one-week sprints with the Lean team. The team includes a part-time product owner and full-time scrum master (one of our consultants) to do the scrum coaching for the team. Scrum has allowed us to implement the process much quicker, but it relies on having the right people on the team that can carry out all the stories. We use a simple board to keep track of our progress (see Figure 5.2). The board contains the backlog of stories for the entire implementation, a “To Do” column for the sprint week, “In Process” for the one or two stories being worked, and “Complete” for the stories that are finished.

Figure 5.2 Simple Scrum board to keep track of our progress. (Source: BIG Archives.)

The team meets in the morning to discuss their activities for the day and in the evening to debrief the day and suggest improvements (see new Figure 5.3). The board contains the stickies from a 10-minute meeting, with key learnings, accomplishments, to do’s, and challenges, which is where escalation may be necessary.

Figure 5.3 The team meets in the morning to discuss their activities for the day and in the evening to debrief the day and suggest improvements. (Source: BIG Archives.)

This process has almost doubled our implementation speed and keeps the team focused, and there is never a question about what they should be working on or what they have completed.

Once it is complete, the story must get added to the chrono file. This way we have a record, similar to an ongoing kaizen newspaper, of what has been accomplished and key bottom-line savings.

Parallel Implementation

Production is near and dear to all our hearts. We work diligently to keep this in mind whenever we implement a new line. As stated earlier, the best implementation is where one can execute pilots and still have the main line running. Many times, this option is viable.

What Is the Difference between Apparent and True Efficiency?

By reducing batching with its extra steps and complexity, we reduce the opportunity for defects in the process. This is extremely important. Behind this are the wastes of overproduction and overprocessing. While this may sound very simple, it is violated all the time.

Toyota differentiates this by highlighting the difference between apparent versus true efficiency. True efficiency occurs only when we increase efficiency without overproducing or overprocessing (see Figure 5.4).

Figure 5.4 Apparent versus true efficiency. (Source: Toyota Training Manual.)

Create Lean Line Package

Next, we create what we call the Lean line package. It is made up of several starting documents required to bring up the line. We have the supervisor own this document, which is a team collaboration. This package includes the following:

■ Role of the operator.

■ Guidelines for running the line.

■ Team leader duties (first level of supervision, working line leader, supervisor, etc.), group leader duties (manager)—this is the beginning of leader standard work and quality’s duties.

■ Pre- and post-shift checklists.

■ Guidelines for water spider and water-spider duties.

■ Guidelines for safety, TPM, and 5S.

■ Role of day-by-hour chart.

■ Standard job sheet (layout with walk pattern by number of operators).

Starting up the New Line

When implementing the line, we start with the Lean practitioner running the line. We then coach the team leader how to run the line and then hand it back to them. A team leader must not only understand the line but must also be able to perform all the processes (functions) on the line for which they are responsible.

As the name implies, they are leaders and a leader leads by example. The ability for the team leader to do all processes on the line helps develop respect as well.

When you first start up the line you must have discipline and make the operators or staff accountable to follow the standard work. If you just let the team members go at it, you will find that despite their training class on how to work in the new line, they revert to their old jobs and behaviors in the brand-new line. Some are naturally excited to start working and some of course are probably not as enthusiastic. They will start to create WIP everywhere because they want to keep busy and will think you want them to rush, even though you have repeatedly told them this is not the case.

We also suggest creating a quick-response team. This team should be at the line, prior to its starting, to ensure the line launch is smooth. We will discuss this more later.

The team leaders must stay on the line 100% of the time. This is one of the most difficult issues to resolve. Normally, the team leader is called to many meetings or has other tasks or sometimes other lines to run. In this system, the team leader needs to be available 100% of the time for cross-training, filling in on the line when a team member has to use the facilities or experiences some type of problem.

Prior to starting up the line, we always ask if everyone is cross-trained. “Oh yes,” is the normal response. Then the first problem we seem to run into is that they are not all cross-trained. It becomes obvious as soon as we ask each person to run the line by themselves.

This creates all kinds of problems bringing up the line. Suddenly, one operator can only do one job. Now they are at one station the entire time and then they want a chair! It also leads to some operators having to work around others. This then makes standard work impossible. One thing the Lean practitioner can do, starting immediately before the pilot even begins, is to promote cross-training on all lines, especially the pilot.

Quick-Response Team

Prior to implementing the line, we need to designate a quick-response team. This team should be composed of maintenance, process engineering (with design on call), quality materials, HS&E, and the Lean team members.

This team should be on hand initially for the first few hours the line is running to be able to immediately react to problems. After, the team should be on call so in the event of a problem, the team leader can call them. When first bringing up the line, have a flipchart and markers ready on the floor (or office) to capture any problems or ideas that are found. The LP should work with the team leader to assign actions and due dates to work on the problems or implement the ideas.

Create Standard Work—Why Are Standards Important?

Imagine a world without standards. How would one measure an inch or a cm? How could you make any recipe without a cup or liter? What if a dollar was worth 90 cents to one store and $1.10 to another?

Without standards, we have nothing to consistently measure our progress or our results. In effect, we have no quality. This leads us to standard work. Without standard work, there can be no real improvement, flexibility, or guarantee of quality. Standard work must be the foundation and definition of every process throughout the organization to create a continuous improvement environment.

Standard Work Definition

Standard work is defined by Ohno as three items:

1. Work sequence: Each operator must be trained and must execute the process steps in proper order for each operation the same way, every time. This does not mean that the operators are robots; however, it does mean that the operators will get into a rhythm as they perform standard work. Standard work is a very inflexible yet flexible system. It is inflexible in that we want everyone to always follow the standard and do the work the same way; yet, it is flexible in that we want everyone to constantly think about how to improve the process and then experiment with the improvements. This step includes capturing the key points and reasons for key points for each step. This foundation came from TWI Job Instruction (JI) training.

2. Cycle time: The next component of standard work is cycle time. Cycle time is the time it takes to do each step in the sequence of operations. It is important to differentiate cycle time from TT. Standard work must be based on cycle time because to run to TT may not always be feasible.

3. Standard work in process (SWIP): Inventory is the amount of inventory necessary to meet the cycle time and perform the job safely.

Job Breakdown for the Operator

In the BASICS approach, standard work comes from the job breakdown. We break down the job to the second, as part of the workflow analysis (WFA). Included in the analysis are minor steps, key points for each step (how you do the work), and reasons for key points (why you do the work). Key points include quality, safety, ergonomics, and sometimes PPE (personal protective equipment).

We combine this document with a video of the operation and use it to train the operator. We call the video depicting the operator standard, the golden unit video. This becomes the foundation for our cross-training program which then leads to creating a certification program for all the operators and staff in an office setting.

How to Create Standard Work

We wait until the line is up and running to create the formal standard work. This is because there are many improvements we normally find and implement once we get the line up and running. Once we have stabilized the line then we start to work on creating the standard work and standard work audits.

Standard Work Combination Sheet/Operations Routine Sheet*

This sheet combines the PFA (product steps) and WFA (operator steps) generally at higher-level time increments (see Figure 5.5). We tend to use it the most when humans are interacting with machines. It can be used for assembly operations, but we find assembly standard work sheets are better for this purpose.

Figure 5.5 Mr. Tadashi Mori, the senior consultant at the TPS training center, explains standard work combination sheet (SWCS). (Source: BIG Archives—used with permission—HIRAYAMA Corporation. February 2017.)

The SWCS is the primary sheet used by Toyota. The purpose of the sheet is to graphically depict the operator steps against the operational or physical machining steps that may be in a different sequence depending on how the work is split up between the operators. It is also used to highlight waste in the process.

In the left-hand column of the SWCS is the sequence of operator steps, manual time, machine time, and walking time. A straight line is shown for manual work, a dotted line for the machine work (to show how long the machine runs), and a squiggly line for walk time. A red line is drawn vertically on the page to show the takt time. Very quickly one can see waste and determine if the operator has more work than the overall cycle time (or takt time) or if a machine runs longer than the cycle time or TT.

Standard Work in Process (SWIP)

We can approximate the calculation of SWIP in the process using Little’s Law, which is:

|

|

When calculating SWIP, we need to include the piece the operator has in their hands and then any inventory necessary for the machines or equipment in the process. For machines which the operator can leave unattended, we would keep one piece in the machine all the time. If the machine is a manual machine, then the piece in the machine and the operator piece would be the same.

We then need to determine if the equipment is interruptible or uninterruptible. If it is interruptible, it means we can unload a piece and then load a piece and start the machine one-piece flow. If it is uninterruptible, then we consider it a batch machine, which means we can’t interrupt the machine cycle until it is completed.

Example: an interruptible oven would be a conveyor-type oven or oven where we can open the door each cycle. To calculate the quantity we need in an oven: take the oven time and divide it by the cycle time. If the oven takes 60 minutes and we are running 20-minute cycles, then we would have to have three pieces in the oven at all times (60 minutes per piece ÷ 20 minutes per piece = 3 pieces) (see Figure 5.6).

Figure 5.6 Standard WIP for interruptible = 3 pieces versus standard WIP for non-interruptible oven = 6 pieces. (Source: BIG Archives.)

An example of an oven that is uninterruptible or a batch oven is one where we cannot open the door for the entire 60 minutes until the thermal cycle is completed. This means we must have three pieces in the oven always. In addition, we must build up an extra three pieces while the three pieces are in the oven because we cannot open it. These three pieces are needed to replace the three that will be removed from the oven after the thermal cycle. So, we need a total of six pieces to manage the oven.

Wetting versus Drying up the Line

Wetting the line means we have all the SWIP in place prior to starting the line. Drying out the line means we have used up all the SWIP prior to leaving the line.

What happens if we dry out the line at the end of each day? Assuming we are running the same parts the next day, we are now going to have to wait to wet the line again and we will lose the output during the first hour.

True Standardized Work

Some make a distinction between true standardized work and standard work. You can only have true standardized work if the operation is repeatable without variation. True standardized work is visible only in the results and can initially be sustained through standard work audits. True standardized work can be very difficult to obtain in some processes owing to the variation that exists.

Work Standards

In almost all operations, we encounter substantial variation. Very seldom do we get a line where everyone has exactly, to the second, the same amount of work. Variation generally leads to overproduction, which is batching and excess inventory.

So, in many cases, we must first implement work standards (Figure 5.7) instead of, in addition to, or as part of standard work. Work standards are different from standard work and are designed around jobs that do not repeat or only repeat every so often. In some cases, the work standard may have no cycle times for each step or may have a range of times for each step because there is so much variation in the process.

Figure 5.7 Work standard template. (Source: BIG Archives.)

Advantages of Standardizing Work

As we standardize work and activities, we can now see opportunities to semi-automate or completely automate tasks. This concept, especially in the United States, is met with resistance. Yet, this is the nature of processes, equipment, and technology. Think about how fast technology is moving. Our experience is jobs can be semi-automated (i.e., in its simplest form by just using a power screwdriver vs. a manual screwdriver) and realize 80% of the improvement for about 20% of the cost. It normally takes the other 80% of the cost to get 20% remaining improvement by fully automating tasks.

Assembly Standard Work Form

The assembly standard work form is derived from the WFA we did earlier. After documenting the operator steps, key points, and reasons for key points, we go back and look for items to omit or items where we can save time through the improvements brainstormed during the omits process, that is, eliminate, rearrange, simplify, or combine. The steps not omitted are then rearranged into the proper sequence and become the basis for how to do the job. This becomes the basis for the operator standard work. Figure 5.8 shows a standard work form.

Figure 5.8 Standard work form. (Source: BIG Archives.)

The standard work form is primarily designed for the operators and supervisor or anyone else observing the line. It is constructed at a higher level than the WFA (job breakdown).

We have added columns for key points and reasons for key points, which were derived from TWI.

We have also merged the capacity by headcount and what is called a standard job sheet, which depicts a layout of the area. The standard job sheet is used to show the operator walk patterns and denote safety items, WIP storage, and number of operators, quality checks, and utility (electric, air, water, gas, etc.) locations.

This form can be adapted to any area. We normally create standard job sheets to cover running the line with plus or minus one or two operators, so the supervisor can run the process short or with additional staff (see Figure 5.9).

Figure 5.9 Standard job sheet. (Source: Courtesy of Ancon Gear.)

Separate Man from Machine

It is important, during analysis, when operators interact with machines, to separate the work performed by the machine from the person. We have run into several situations where people perform the work better than robots, and others where the robots perform better than people.

Robots and machines have their place, as they are good for repetitive tasks, dangerous tasks, and for total automation; however, if the robots continue to operate and batch up parts, they are not very useful for Lean. Robots should do one-piece flow, just like people.

There are many cases where we have removed robots to ensure one-piece flow. We apply all the same Lean tools to analyze robots and machines as we do with people. We break out machine time into value-added and non‒value-added. With the respect for humanity principle, human work should include the following:

■ Creativity: The joy of thinking

■ Physical activity: The joy of working with sweat on the forehead

■ Sociality: The joy of sharing pleasure and pain with colleagues

■ Leadership implementation of total company-wide quality management (TCWQM)

People need to be used wisely, have challenging work, and be taught to constantly identify problems and make improvements.

Determine the Capacity and Labor Requirements

Part Production Capacity Sheet (PPCS)

Lean has a tool we used called the part production capacity sheet (PPCS) (Figure 5.10). This form is easy to create and gives the supervisor or line leader most of the knowledge they need to know about capacity in order to staff their line properly to meet the required cycle time.

Figure 5.10 Part production capacity sheet (PPCS). (Source: BIG Archives—and with permission from Ancon Gear.)

How to Create the PPCS

The PFA is captured in the description of process boxes and listed in the proper sequence on the left-hand side and the labor times come from the sequence of operations on the WFA sheet. Setup times are also factored in the middle of the sheet and amortized based on the lot size across each part. The next two columns are for labor value-added and labor non‒value-added time. These two columns add up to TLT.

The next two columns are for machine value-added and machine non‒value-added time (a new column we created back in the mid-1990s). These two columns sum up to total machine time. This is where we separate operator (person) from machine.

The next column is complete time. This column adds the labor and machine columns together to get the total time necessary for each step for one piece.

The next column is called tool exchange time. This is where changeover information is entered if applicable.

There are different ways to use this form and it can be modified to suit the project application. The tool exchange time contains a column for the lot or batch size utilized and the setup time column has the amount of time required for the changeover.

The form then divides the setup time by the number of products run (lot size), which will amortize the runtime per piece. This is then added to the complete time for that step.

The next column is capacity. But before we get to that, let’s discuss the top lines.

On the top is customer demand and available time. Once these are filled out, the form calculates the TT. There is also a block for factory demand (or transactional area demand) and once we have this number, we can calculate the cycle time we need to use. The next block is TLT. This block is the total of value-added and non‒value-added labor time. If we divide it by the cycle time, it tells us how many operators we need based on the demand we are going to run through the process versus the customer demand.

Now, back to the capacity column. Once we have the available time, we can divide it by complete time to determine our capacity. The lowest capacity number represents the bottleneck. Again, a bottleneck should never be a person because we can always add people. The longest complete time driven by a machine is the bottleneck operation (but keep in mind it may not be a true bottleneck). If there is a machine, we need to SWIP the machine, which means that the machine always has a piece to work on while the operator is running the rest of the cell. The next step is to calculate headcount.

The cycle time with one person is always equal to the TLT with one person unless there is a machine with a longer run time. The cycle time with two people would be half the cycle time with one person and so on. This assumes that the work is or can be balanced.

The output per hour is determined by dividing the cycle time into one hour or 60 minutes; however, the output per day is determined by dividing the cycle time into the available time per day.

Remember that this form was originally designed for manufacturing but it is a powerful form. It can be used for any process from banking, insurance, emergency rooms, to landscaping.

This is a phenomenal tool for the supervisor of an area to have at their disposal. Now, they have data with which to answer any question thrown at them from upper management at their fingertips.

Staffing Analysis and Plan

To staff the line, we take the TLT that comes from the WFA and divide it by the TT or cycle time we wish to run. In a machining line, this same formula will work if there is not a machine that runs longer than the cycle time in which case the operator will be idle at that machine. The capacity is then determined by how many people run the line and the cycle time of the machines.

Every time there is a change in demand, a change in products or services offered, a change in process, or new machinery introduced, it necessitates updating the standard work and recalculating all the numbers on the PPCS. World-class companies see these changes as opportunities to improve and eliminate even more waste in the process.

Types of Improvement

The term process improvement can be misleading. When reading Ohno and Dr. Shingo’s books, one will find that their approach to improvement is prioritized in the order listed below.

Work Improvement

The improvement starts with the work itself first. The reason is if one starts with equipment improvement, we may find as we improve the work, the equipment is not needed, or it has too many features or the tooling needs to be modified.

Equipment/Machine Improvement

This is about improving the machines. The first step is to make sure your machines are back to “like new” condition. Then we work to speed up the machines, programs, or speeds and feeds.

You must have the ability to tinker and improve the machines you have. If you buy the latest high-tech machines and use unskilled workers who become slaves to the machines, then you lose the sight of what will keep costs down.

Process Improvement

Refers to improvement of processes. For this we utilize the BASICS tool we have been discussing throughout the book.

Facilities/Information Systems Improvement

This involves looking at the entire facility layout and potential improvements. This is normally the costliest. There is a hierarchical approach to doing improvement. It is important to do work improvement first, then equipment improvement, process improvement, facility improvement, and information system improvement. Following this order will save money in the long run as otherwise you can end up doing lots of rework or automating waste.

True Bottlenecks

A true bottleneck is defined as a machine that runs 24 hours a day and cannot meet TT. One has to manage a true bottleneck differently than an ordinary bottleneck. This means a true bottleneck should run over breaks, lunch, shift changes, etc. It should be optimized for setup times. It must be assigned an owner to manage it. If it runs on its own, it should be connected to a system that can text a message to someone before it goes down.

Make and Approve Recommendations

When you have completed the analysis, and new layout and workstation planning, we call a meeting to review it with management. Prior to this all the operators/workforce should have been either involved or updated in preparation of the new system. If management is far down the Lean maturity path then they will already be aware of the Lean progress, and approval is probably a formality.

Training

Prior to implementing the line, we must run all the operators through at a minimum two to eight hours’ Lean course. This includes a Lean overview, which they should already have had, and a batch versus flow exercise where we teach them baton-zone/bumping handoffs. This training is very important to gain buy-in and to prepare them for what is coming. We cover a simple overview of what Lean is and do a before-and-after Lean exercise. We all know that learning by doing is an effective learning methodology.

TWI Training

TWI stands for Training Within Industry and was a US government program launched during World War II. It was initially composed of three parts.

1. JI—Job instruction—taught how to break down the job into steps and add the key points and reasons for key points to each step. It is the foundation for standard work today.

2. JM—Job methods—taught how to continuously improve the job.

3. JR—Job relations—taught how the supervisor should react to various problems in the workplace. This became the foundation for respect for people.

Since then JS and PD—job safety and program development programs—have been added.

Roles and Responsibilities (R&R) Matrix

We use a roles and responsibilities sheet to define owners and accountabilities across functional lines. Some people call this a RACI chart. The R&R makes it very clear as to who owns what in the organization (Figure 5.11). The rule is there can only be one owner or person responsible for a decision. There can be shared owners, as well as people consulted, informed, or needed to approve, but only one owner. The format for this chart (see Figure 5.12) comes from a book called Designing Organizations by Jay Gailbraith.

Figure 5.11 Roles and responsibilities matrix. (Source: Designing Organizations, Jay Galbraith, 2002. John Wiley and Sons.)

Figure 5.12 Roles and responsibilities matrix example. (Source: BIG Archives.)

How to Construct a Cross-Training Matrix

A cross-training matrix (see Figure 5.13) is one of our tools that comes from the JI module of TWI. It provides the training status for each member of a work cell and lists the skills and associated training for each member. This matrix lists all the employees in the cell/area/company and the skills they have acquired to date.

Figure 5.13 Cross-training matrix example. 1 = in training, 2 = can follow standard work at 50% speed, 3 = can follow standard work at 100% speed, 4 = can train others/suggests improvement ideas. (Source: BIG Archives.)

The matrix should be posted in the work area for all members to review and should be used to help staff the cell as well as to develop the training plan for the cell.

The team lead should oversee and manage the matrix and ensure the maximum amount of team members are trained to offer both flexibility and to ensure staff is available as customer demand changes occur. Each staff member that works in the area is rated based on a set of objective measures one to four. These ratings should be continually monitored and revised. This requires the staff to be trained on the latest developments and standard work in the area. The levels vary by company but generally follow:

1. In training

2. Can follow the standard at 50% of the cycle time

3. Can follow the standard and hit the cycle times and suggest improvement ideas.

4. Qualified as a TWI trainer

The team leader is responsible to create and update the cross-training plan each year (see Figure 5.14).

Figure 5.14 TWI cross-training plan example. (Source: BIG Archives.)

Implementing Line Balancing—Bumping versus Station Balancing

If we have a process in which there are 30 minutes of total labor time per unit and six people working on the line, how much work should be done by each person?

|

|

This requires each person to be given exactly the same amount (five minutes of work) and each person, in turn, must do his or her fair share of the five minutes’ worth of work.

To accomplish this, we need to consider the skill-set of the operators or staff performing the tasks or activities. This works well if everyone in the line can do the same work at the same speed. It is important that each person has the appropriate cross-training to enable flexibility between tasks, processes, and equipment.

The true test of Lean is found by examining and looking for two items on your lines or in the office process. These are: excess inventory and idle time. If there is excess inventory, it means either the line is not balanced or there is a piece of equipment not functioning properly (downtime), has a lot of variation, or is not process capable.

People should never be the reason for imbalance if the line is set up with bumping/baton-zone balancing. Does anyone in the line have idle time? It is important to look closely and be objective. However, not all problems necessarily manifest themselves as excess inventory or idle time. Excess inventory always covers up some type of problem. This is an example of what we referred to earlier as hidden waste.

When balancing the line, the Lean layout should never change. Proper batons zone-balancing layouts can run with one person or ten people. This is the most difficult concept for people to get in Lean training. They always want to move the product steps around to balance the labor at each station.

Station Balancing

Most cellular models we see today date back to 1983 when Hewlett Packard created an instructional road-show video demonstrating stockless production or how to move from batch to small-lot flow to one-piece flow manufacturing. In the HP video, they showed how they could “pull 3 or pull 1.” This is a system with WIP caps or what we call the lazy-man’s balance (see Figure 5.15). In effect, the line is being balanced by the WIP present between the operators. Remember, excess inventory and idle time hide problems. With this kanban-square system in between each operator, we encounter both idle time (when we fill up the square to the WIP cap quantity) and the fact that the inventory in the kanban is and of itself by definition excess. The excess materials in the kanban squares hide the fact that the line is imbalanced (if you have not learned how to “read the WIP”).

Figure 5.15 Lazy-man’s balance. (Source: BIG Training Materials.)

The other problem we have witnessed is that even if the WIP caps are labeled with the maximum amount allowed in the squares (which in many cases are bins or trays), the operators that don’t have enough work will inevitably fill them with more than the maximum and in many cases as much as will physically fit in the area. Lines that utilize this model have the following characteristics:

■ They are sit-down lines.

■ They were originally balanced based on a station approach with the goal of equal work at each station.

■ There are spaces or kanban squares (WIP) in between each operator.

Station balancing consists of simply trying to divide [the total labor required to build one product produced by the cell] by [the number of operators in the cells] (see Figure 5.16). Ohno described the material handoffs in the pull 1 HP-type of assembly kanban system as swimming relay handoffs. In a swimming relay, the swimmer cannot leave the starting block until the prior swimmer has touched the wall. In a cell, the next operator cannot start an operation until the prior operator completes the work at their station and moves their part(s) into the kanban square. The kanban squares (see Figure 5.17) have rules:

Figure 5.16 Station balancing. (Source: BIG Training Materials.)

Figure 5.17 A pull 3—kanban squares have rules.

■ The rule is that you can’t start working on a part unless there is one in your kanban square.

■ You must stop working on it once you have filled your downstream kanban square.

Problems with Station Balancing

■ People are not robots and we all work and improve at different rates.

■ If the line needs to run more than one model or style of product, it is difficult to keep the labor balanced

■ Because station balancing was designed based on a set number of operators, if an operator is missing, it creates problems.

■ Most station-balanced lines are sit-down lines, where the product flow is normally lost, and are 10%–30% less efficient than stand-up and walking lines.

■ The operators tend to dry out the line (use up all the SWIP) going from one product to another.

■ If we have a fast worker in a station-balanced line, he/she will finish the work and sit idle. With a slower worker or worker that has too much labor assigned, the WIP will pile up before them.

■ Where a line is balanced to takt time (customer demand) instead of cycle time.

■ When the total labor changes due to a different product or even sometimes a slower operator.

Because of these problems, we end up with either idle time, excess WIP inventory between stations, or both. When we station-balance a line, we must allow enough time for the operators to perform each task. An industry standard taught in every Lean class is to create man-loading or station-loading charts (see Figure 5.18). The problem with operator load charts is that they are symptomatic of station-balanced lines and while they should, they seldom drive waste elimination. In addition, most practitioners will pad the labor times and allow a 5% or more variation in the cycle times for each operator in order to make them feel good. This immediately creates imbalance in the line.

Figure 5.18 Traditional man/station-loading chart. (Source: BIG Training Materials.)

Rabbit Chase

The rabbit-chase line-balancing methodology has each operator make their own parts by working around the entire cell every cycle. So instead of one operator bumping back to another, each operator is continuously circling the cell working on making a complete product from start to finish. The rabbit chase (see Figure 5.19) is generally less productive. You lose the time pressure that exists when working on a team and bumping.

However, there are times when this approach may be optimal. For example, we had a forced isolated island in a layout. The operators would open bags of material and dump them into a mixer. In order to speed up the process, while one operator was dumping the other was getting the next bag cut and ready to dump. It was faster to do rabbit chase than to try to hand off an open bag of material.

Figure 5.19 Rabbit chase. You can only go as fast as your slowest person or have the slower person stop while the other moves around them. Kind of like playing through in golf. (Source: BIG Archives.)

One-Piece Flow and Baton-Zone Line-Balancing (Bumping)

To facilitate work balancing, we utilize a concept Ohno referred to as baton zones, or flex zones, which are areas where handoffs occur between operators (Figure 5.20). In this system, the operators or assemblers are spread out on the line to work just like runners in a relay race. Like the baton handoff in the relay race, the operators hand off the product to the operator after them and then bump to the operator before them. This bumping process continues until the first operator is reached, who goes to the beginning of the line and starts a new part (see Figure 5.21).

Figure 5.20 Stations versus work zones with flexing (bumping). (Source: BIG Training Materials.)

Figure 5.21 Bumping versus station balancing. (Source: BIG Training Materials.)

Bumping eliminates the kanban squares, results in zero WIP between the operators, and automatically balances the operators across stations. We tell the operators: You no longer have stations, and the work zones are guidelines only! This would be equal to the pull 1 in the HP model that was said in the video to be impossible.

The bumping rule is you must continue to build until the operator at the station after yours pulls the part from you. When the last operator (closest to the end of the line, i.e., pack and ship) completes a unit, they then walk back to the operator before them and bump that operator by taking their part from them wherever they may be in the process. The bumped operator communicates where they are in the process and then goes and bumps the operator before them and so on until the first operator in line starts a new part.

This system requires the operators to flex. Some of the major differences with this approach are as follows:

■ The stations must be stand-up height and redesigned with the parts sequenced in the order of assembly (the basis for true standard work).

■ Everyone must be cross-trained.

■ Operators must stand, move, and bump as required to maintain continuous flow.

■ May have to duplicate some tools, fixtures or materials.

■ Operators should rotate several times a day.

■ Standard WIP must be labeled and maintained at all times.

■ The line works best when the fastest person is last, at the end, as they create the pull. However, this should not be an excuse for slow people not to have to speed up.

■ You cannot bump forward … only backward.

■ Do not bump to the standard WIP (SWIP); you must bump to the person.

■ Operators should never have to wait on a machine. SWIP the machine, and it takes the machine out of the equation.

■ On mixed-model lines, since several orders could be running down the line at the same time, one has to figure out how to handle the paperwork. Normally, the paperwork travels with the first unit.

■ When balancing the cell, start with the bottleneck. Assuming there is demand, the bottleneck should never be idle. You can only go as fast as your slowest machine. The bottleneck should never be a person, only a machine.

■ There should be a training progression path for the operators within each line and lines across the plant.

■ Don’t tie workers to a station (i.e., with a piece of test equipment).

■ Major variation should be removed wherever possible.

■ Day-by-hour charts must be in place so operators and team leaders catch problems in real time as they occur.

■ Operators must follow the guidelines for running the cell (see Figure 5.22).

Figure 5.22 Guidelines for running the cell. (Source: BIG Training Materials.)

■ First person only drops their piece of WIP and bumps if they can’t advance or if the other person will bump back on top of them. If rework is a big problem, some extra stations may have to be added to handle the repair or allow extra time to rework the units. Obviously, the goal is to eliminate the rework but in the real world this does not always happen. Someone must own the rework and fix it so it doesn’t come back.

The main difference from station balancing is all the operators in this type of line are not waiting for the person before them to hand them the product (or the baton) like in a push-type station-balanced system. Instead they are literally pulling the part from the operator before them, even if the operator before them are not finished their station’s work.

Once the operators see the bumping in action, they will be self-balancing and figuring out how and when to bump. Eventually with some experimenting you will learn how to introduce people to the line and remove them from the line and keep the line running. In some cases, if people must be added you may have to add stations. The goal is to have people moving and walking, not standing in one place on the line.

Bumping Results

By implementing bumping we increase the output and corresponding productivity by up to 60% and pieces per person per hour by 150% (see Figure 5.23).

Figure 5.23 Results from a finishing area in a foundry show implementing baton zone bumping increased the output 60%. (Source: BIG Archives.)

Line balancing is always controlled by the number of people or the SWIP. There are two types of bumping scenarios. One is as described above where the operators do the bumping. The other is where the operators remain at their stations and the SWIP moves to them. This means they must have all the tools and materials at every station necessary to complete the product.

Advantages of Bumping

Aside from the obvious elimination or reduction of some of the wastes mentioned earlier in this chapter, there are more obvious advantages of the baton handoff-style line. They are the following:

■ Maximizing team member’s efficiency.

■ Maximizing output of the line by using the fastest person to create the pull.

■ Minimizing the effect of absenteeism.

■ The line does not have to be U shaped.

■ Drive cross-training.

■ Ability to easily measure output.

■ Quality improvements and mistake-proofing opportunities surface from breaking the operations into small steps.

■ Incorporation of subassemblies or other operations being performed off-line.

■ Eliminates idle time (assuming SWIP is in place).

■ Line is not dried out each shift or after each product model change.

■ Variation with options or mixed model is easy to handle.

■ It is easy for operators to rotate in and out of the line.

■ It is easy for operators to rotate to a different position in the line.

Failure Modes of Baton Handoff Lines

■ Most people want to bump to the SWIP, not the person.

■ They are not cross-trained and cannot bump.

■ Equipment is off the line, requiring operators to leave the line, disrupting the flow.

■ Line is not stand-up and walking.

■ Team leader or supervisor doesn’t understand how to run the line.

■ SWIP is dried up or not maintained in the line.

■ All components for the product being built are not available when the order is released.

Line Operations/Pre-Assembly

One common mistake people make in implementing Lean is that people want to keep certain operations offline. We are not sure why this is but it is commonplace and widespread. Generally keeping off-line operations in a separate area results in batching and huge waste.

For instance, one must figure out how to link the area up to the line that it is feeding. This means that there needs to be an inventory buffer between the lines or, if not, the final line cannot start until all the subassemblies are available. Keep in mind pre-assembly is batching even if we are doing it one-piece flow. Any defects found are likely to be contained in the whole batch that is pre-assembled.

For some reason, as human beings, we are literally compelled to want to keep subassemblies offline, as if this gives them some type of advantage over the process. They still require labor; the labor is sporadic and inefficient and normally ends up holding up the line.

Job Rotation

Job rotating (see Figure 5.24) can be done each hour, after breaks, or after lunch, based on whatever makes sense for the business. Job rotation also gives the workers a sense of accomplishment, and by learning new skills, they become more marketable. Additionally, it can break down silos and provide a better understanding of the whole process.

Figure 5.24 Job rotation chart. (Source: Joe McNamara, president of Ttarp Industries, and BIG Training Materials.)

Implement Line Metrics

Day-by-Hour Chart

The day-by-hour chart (see Figure 5.25) displays the planned production for each hour, considering breaks, meetings or huddles, and exercise times. There are many variations of this chart depending on the line or area in which it is utilized. Each hour, the team lead or one of the operators enters the actual amount of product (or paperwork) produced.

Figure 5.25 Day-by-hour board. (Source: BIG Archives.)

If there is a variance for the hour, the team lead or operator enters in the variance and the explanation for the variance and whether any containment actions or countermeasures were required. The real value in the chart is twofold.

■ First, it shows the team members how they are doing against the plan (which originally comes from the workflow analysis [WFA] and subsequent standard work).

■ The second is to assess and fix the root cause(s) for the variance so it never comes back.

There should be some type of action taken by the team lead or supervisor to begin to root-cause and take countermeasures to correct the variance. If the problem can be corrected right away, that is noted on the sheet. If it cannot be corrected right away, it should go to the +QDIP board under the appropriate heading and then root-caused by the team or supervisor. The key is to flush out all the problems in the line. If the variance is positive we need to understand why? Maybe we can update the standard times?

The day-by-hour chart will also give the operators something to shoot for each hour since they know from sitting in the analysis sessions these times are more than achievable. When we first set up the line, we normally don’t require the supervisor to put in the plan, but we do get them used to recording the actuals each hour. The reason for this is, when we put the plan up immediately, the team members (operators) think we want them to rush to meet the numbers. Nothing could be farther from the truth. We let them get used to the line and work our way down the learning curve, and normally a week later, we will start entering the plan by hour.

Some plants will set the targets at 80% or less of what could be achieved. This is wrong. It is important to set the plan to align with the results supported by the video analysis. Making the plan numbers easy to achieve or to make the employees happy does not drive continuous improvement, and is not fair to the employees, as it allows supporting functions to slack off, but still hit the plan.

Takt Time Board and Line Counters

It helps to install line counters to support day-by-hour charts (see Figure 5.26). With standards in place and line counters, it is easy to determine if you are ahead or behind schedule.

Figure 5.26 Takt time versus actual real-time status.

Introduction to + QDIP

The acronym +QDIP stands for:

■ Plus (+) stands for 6S (safety + 5S)

■ Q = quality (typically first-pass yield but rolled throughput yield has been used also)

■ D = OTD

■ I = inventory

■ P = productivity

Companies use other acronyms, such as QCD, SQDP, and SQDIP, where QCD stands for quality, cost, and delivery; SQDP substitutes S for safety instead of + for 6S and does not include inventory; and SQDIP includes inventory as well (see Figure 5.27).

Figure 5.27 QDIP meeting being run by Tom Turton, focus factory manager Xylem Corp. Tom is also a Master BlackBelt and Master Lean Practitioner. (Source: Joe McNamara, president of Ttarp Industries, and BIG Archives.)

Plus (+) = Safety/5S*

Plus (+) stood for our 5S, plus safety metrics of severity and frequency were agreed to and the team focused on the metrics. A highly visual, daily 5S standard work board exists in each value stream, noting that any safety incidents that resulted in lost time had to be reported directly to the president of the division.

If all the 5S tasks were completed from the day before and there were no injuries or near misses, then the day was colored green. If there had been a near miss or a 5S task was not completed, then the frontline leader switched markers real time in the meeting and colored the day’s box red within the “+” month. The day would be colored blue when the cell or value stream was not working due to a planned shutdown. If the shutdown was not planned (i.e., equipment down or short components needed for an order), blue would not be used.

Q = Quality

Quality was the measure of the quality for the area. For a manufacturing cell, if there were no quality issues that day, the day would be colored green during the meeting. If there was a quality issue that was caused by a nonconforming component or an assembly/machining error in the cell/area, the day would be colored yellow if the commitments for the day were still met despite the issue, and red if commitments weren’t met. A shop floor nontraditional definition was used for quality for +QDIP boards in support areas or departments. If all drawings and bills of material engineering produced and delivered to the shop floor were correct without errors, then the day was colored green for the engineering board. If not, the day was colored in red.

D = Delivery

Delivery was a measure of the delivery from that area against their schedule. For example, the receiving inspection +QDIP board would be green only if their inspections were all completed correctly and on time for the day, which allowed parts to go to the cells on time.

Inventory

This metric changed from the number of inventory turns to a shop floor‒based metric if all parts that were supposed to be available were available. If a work order was found to be short while building an order, or short such that an order could not be started, the day would be colored red. If a part was not the right revision letter or had quality issues (missed by receiving inspection), it would be coded red. If a part was missing in the bill of material (BOM) list, it was coded red. If a component inventory level was below the expected level in the cell but no orders were required, and the parts were being built, the day would be colored yellow.

Productivity

The productivity definition evolved rapidly going from standard versus actual hours to a shop-floor metric of:

■ Any unplanned machine downtime

■ Issues that caused the machine to operate at a slower speed

■ Any missing tools

If any of these items impacted the cell the day prior it would be colored red. Daily counters and the day-by-hour charts also fed into this metric. The color code is as follows: If the plan on the day-by-hour chart was met with no problems, then the day was colored green; if the plan was met but we had any of the issues noted earlier, it was yellow; and if the targeted plan output was not met on the day-by-hour chart, then productivity on the +QDIP board for the day was colored red.

KPI (Key Performance Indicator) Board

The KPI board*—and other value stream‒related metrics (i.e., bookings, sales numbers, customer feedback) posted at the cell—is another template that can be used as an alternative to the +QDIP template. It emphasizes root-cause analysis through its Pareto sheets, which is advantageous from a Toyota Kata (coaching) standpoint when indoctrinating the concept of root-cause analysis (i.e., 5 Whys) into your culture.

In addition to the +QDIP letters and countermeasures sheets that are below the QDIP letters, we also include the daily orders, delinquent backlog, and backlog (see Figure 5.28), which, in some cases, we simply wrote on a whiteboard daily during the huddle. It is important to share a quick high-level view of the health of the business to every employee.

Figure 5.28 QDIP board and daily cell metrics and goals. (Source: BIG Archives.)

The equivalent KPI board modified for the focus-factory or value-stream level is shown in Figure 5.29 and 5.30. Sample cell metric calculations are shown in Figure 5.31, and should be adjusted to align with your businesses’ exact need and strategic goal deployment. The productivity and inventory turns are typically weekly or monthly at the focus-factory level. This is particularly applicable if it is an engineered-to-order or large-dollar build-to-order business model as day-to-day measurement is too variable and thus not meaningful. To the extent that productivity can be meaningfully measured daily at the focus-factory level, that is clearly preferred.

Figure 5.29 Alternative KPI metric board for focus-factory level. (Source: Joe McNamara, president of Ttarp Industries, and BIG Archives.)

Figure 5.30 Alternative KPI metric board for work-cell level. (Source: Joe McNamara, president of Ttarp Industries, and BIG Archives.)

Figure 5.31 Cell metric calculations. (Source: BIG Archives.)

+QDIP Boards/Meetings

The +QDIP board is generally created for each assembly and machining cell to record problems and to encourage root-cause analysis and corrective action to fix the problem. The team that is assigned to the board—to include supervisor, manufacturing engineer, quality engineer, buyer, and planner—would be responsible to check the board and assign their name as the owner of the issue for their functional area.

Support staffs, such as engineering, sales, and HR, are in attendance to provide needed support and feedback to ensure the operations run smoothly, providing quality, affordable products and services to customers. The employees from all the different cells in a focus factory may all attend the same huddle in the morning, but they may each have their own +QDIP board for their individual cells.

Metric development should be evolutionary and focus on what the business needs and must be measurable when the metric is introduced. The metrics must ultimately be tied to customers, such as customer demand, quality, delivery, and affordability.

This approach brings accountability into the organization at all levels. It also is the beginning of developing a Hoshin environment where everyone on the shop floor saw how they contributed to the strategic goals of the business.

Visual Management—Incorporate 5S, Visual Displays, and Controls

Visual management is made up of three activities: 5S, visual displays, and visual controls (see Figure 5.32). Visual management is a work area that is

Figure 5.32 Visual management pyramid. (Source: BIG Archives.)

1. Self-explaining

2. Self-regulating

3. Self-improving

where what is supposed to happen does happen, on time, every time.

5S—Housekeeping and Discipline

As we make changes to the layout and workstations, we implement 5S as we go. While some organizations add an S for safety and call this 6S, and others add a seventh S for Satisfaction (employee), many use 3S. It’s a simpler way to start. Safety is really a part of each of the 5Ss. The 5Ss are:

Seiri: Proper arrangement, sort, cleanup, clearing up, or organization. The first step is to separate and consolidate those items necessary for the proper functioning of the work area (i.e., tools, fixtures, work instructions, parts, or office supplies) from the unnecessary items. Get rid of those unnecessary items.

Seiton: Arrange, put in order, and store, set in order, order, orderliness, organize logical order, or neatness. Arrange items so they can be retrieved immediately in the order required. Make a place for all the necessary items and put them in their place. Identify their appropriate place by outlining the area and/or labeling the space.

Seiso: Neat, tidy, sweep, shine, cleanliness, cleaning, or pick up. Operators clean the work area daily, sweep the floors, wipe off the machines, and keep a sanitary work area. Make sure everything is neatly in its place. This concept is often misinterpreted and misunderstood.

Seiketsu: Cleanliness, standardize, neatness, or maintaining a spotless workplace. Find ways to keep the overall environment neat and clean. The white-glove test is very applicable here. Are there ways to reduce dust, dirt, and debris that make the cleanup easier? How are old documents purged from the area? Are minimums and maximums identified and visible in storage? This makes visual management easier to maintain. Can we eliminate safety hazards? Make sure standard procedures and work standards are created to document the 5S process, including how 5S tasks are to be completed and visual photographs of what the area should look like when it is completed.

Shitsuke: Discipline, sustain, conduct, changing work habits, or training. Discipline and training. The most important step of all is to maintain/sustain the area once it has been created. Everyone must follow and update the standardized procedures for cleaning and organizing. Continue to look at the whole area, not just your workspace.

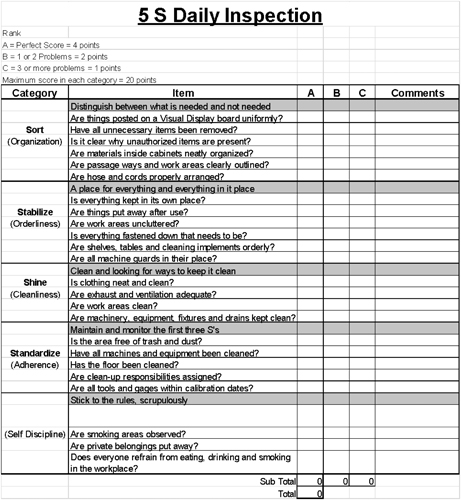

This is the most difficult S of all. To sustain, the 5S program must become part of the documented procedures of the company, monitored, and audited (see Figure 5.33).

Figure 5.33 5S audit sheet. We prefer to have non-scoring audits; otherwise, it becomes more about the score than 5S. (Source: BIG Archives.)

5S must be led by every executive, manager, group leader, and team leader. Management must provide the training and resources to ensure 5S succeeds.

If you walk by a piece of trash you should pick it up. Lead by example and let others see your back. If you see someone not put a tool back and don’t say anything, you have just rewarded that person’s behavior. Many area teams audit themselves regularly to track their improvement. The area team uses the audit results to focus their improvement efforts and increase their score on the next audit.

We prefer the 5S audit not have a score. This keeps the focus on improvement and takes the pressure away from “gaming the system” to just increase the 5S score.

Since the audits are conducted with the team leader, they get real-time feedback on the opportunities. In summary, 5S has two major components—housekeeping and discipline. Housekeeping is about the old saying, “a place for everything and everything in its place,” but it is also about discipline.

Discipline is putting things back in their place, which is the most difficult part of 5S. We all need to be part of setting the standard at the highest levels if we are to be considered world class.

Benefits of 5S

■ A cleaner workplace is a safer workplace.

■ Contributes to how we feel about, and the pride we take in, our product, process, our company, and ourselves.

■ Customers love it.

■ Product quality and especially contaminant levels will improve.

■ Cleaning typically reveals problems and areas that need repair.

■ Efficiency will increase.

■ Good program to get everyone in the organization involved.

■ Demonstrates an enterprise commitment to the Lean/5S program.

Red-Tag Strategy

Using red tags are helpful when establishing the 5Ss. Continuous improvement teams use red tags to mark unneeded items for removal. The red-tag strategy helps identify and separate out needed items from unneeded items. Items tagged are placed in a cordoned-off area to be dispositioned later. The red-tag strategy helps lay the foundation for improvement by making obvious which items are not needed for daily production activities.

The 5S Board

5S boards (see Figure 5.34) can have the employee name or picture at the top and the days (and sometimes week, month, or quarter) on the side. The boards can be set up several different ways. Every employee is assigned a short five-minutes-or-less task each day to complete.

Figure 5.34 5S board for engineering department—each person gets a daily five-minute 5S task. When it is complete, they turn the magnet over. (Source: Joe McNamara, president of Ttarp Industries, and BIG Archives.)

This can be expanded to include safety and TPM tasks as well. When the task is completed, its tag is turned over to show the complete side. These boards can be expanded to incorporate TPM and Lean audit-type tasks as well. The advantages of these boards are that they get all the employees in the area involved in the care and maintenance of the area and they are also useful to maintain audit compliance.

A 5S board, if it covers all the 5S points, becomes self-auditing. If the person does not do their task, everyone else knows in real time. A simple walk around the area to inspect the tasks provides the audit function.

Visual Displays

Visual displays communicate important information (see Figure 5.35) but do not necessarily control what people or machines do. Visual displays such as signs and bulletin boards do not suggest or enforce any action. They only communicate the name of an area, machine, or some other type of information.

Figure 5.35 Visual display example. (Source: BIG Archives.)

The 5/20 Rule

We use the 5/20 rule for visual boards. Within 5 ft of the board, you should only need 20 seconds to see the current state of the cell/process and determine if it is in control. It is also useful to use red/orange/green color coding to show the immediate status of an item. At Toyota they have a standard green circle, yellow triangle, and red box to show the immediate status on boards, electronic displays, and even on A3 actions.

If you can’t read the board from 5 ft away, then the information is too small and no one will read it.

Visual Controls

■ Communicate information in a way that helps everyone identify or prevent a problem.

■ Build in standards and make defects (abnormalities) obvious.

The analogy for visual controls is the human body. When the body has a problem, it lets you know. It may be in the form of a fever, pain, bleeding, blister, etc. Once your body signals a problem, it needs to be taken care of right away or it tends to get worse. The goal is to make every problem immediately visible, so it can be fixed right away. This sounds easy to do but is very difficult.

As you walk around an area, the factory or office should talk to you and communicate its condition as you walk around it. Think about an airport. Everything is visual, even the tarmac. Sign boards communicate the status of the flights; each gate is labeled and contains a signboard of which flights are leaving the gate and when. Restrooms, handicap areas, safety issues concerning strollers on escalators, and a speaker above saying “caution, the moving walkway is ending” are all visuals and talk to you as you walk through. You immediately know the status of your flight and what is going on around you. Does your factory communicate to you the same way the airport does (see Figure 5.36)?

Figure 5.36 Visual controls on the tarmac. (Source: BIG Archives.)

Visual controls are different than visual displays because they go a step further to suggest some action be taken or they help remind us to do something but usually can’t force certain actions to be taken. For instance, a red light, stop sign, and RR signal (see Figure 5.37) are visual controls versus displays because they tell the driver to stop, but can’t force the driver to stop. We can still go through the red light, RR crossing, or stop sign with some risk to ourselves and others. The driver stops because they know if they continue, there may be some negative consequence, like an accident or a ticket.

Figure 5.37 Visual controls—red light, stop sign, and RR signal. (Source: BIG Archives.)

Advantages of a Visual Factory (see Figure 5.38 and 5.39)

■ Surfaces problems quickly, indicates non-conformances and when help is needed, reduces search time by 50%

Figure 5.38 Visual workplace example. (Source: Five Pillars of the Visual Workplace, Hiroyuki Hirano © 1995, Taylor & Francis.)

Figure 5.39 Visual workplace description. (Source: Five Pillars of the Visual Workplace, Hiroyuki Hirano © 1995, Taylor & Francis.)

■ Improves safety, increases audit compliance for HS&E, and increases productivity

■ Management by sight

■ No technical knowledge of area is needed to assess the current condition

■ Can sometimes lower insurance rates

■ Enabler for high-performance work teams

■ Reduces meetings to discuss work issues

■ Shows if you are on target to meet requirements

■ Identifies flow, roadblocks, and controls inventory

■ Communicates real-time feedback to everyone

■ Can positively influence the behavior and attitude of team members

■ Customers love it

■ Shows everything has a place and everything is in its place

Gemba Walks

The term gemba walk has many meanings today. There are books written on them, but everyone has their own opinion. In our case if you go to the floor (or office) it is a walk to the gemba. Gemba is where the action is going on. The common three aspects are to see, to eliminate waste, and to learn.

We conduct different types of walks. These include waste walks where we look for waste, process walks where we look at each workstation along with the tools used to see what could go wrong and how to mistake-proof. There are daily management walks where the manager should be able to look at the visual board and know immediately if there is a problem. Depending on the severity of the problem, the manager may leave a note to be answered by the team leader or supervisor (to see if they are managing the board) or they may use an urgent problem/gap on the board as a coaching moment to further develop their team leader’s thinking.

Mike Rother suggests in addition to the three common aspects above that the gemba walk should focus on how people are working. This means “… focusing on their pattern of thinking or acting which they utilize as they improve and strive for their goals.” This involves four steps:

1. It should be used system-wide

2. It should be suitable for any goal or problem

3. It should be based on the scientific method

4. It should include structured practice routines for beginners

This approach is described in detail in his books and videos which can be found on his Kata website.

The bottom line on it all is the gemba walk should be focused on teaching and driving ongoing improvement toward your targets. This means you need to understand the gaps between where you are now and your target and then experiment using small PDSA cycles to overcome the gaps.

Typical gemba-walk questions encourage problem-solving. The first question we always ask is: what is the standard? If there is no standard then we have an immediate problem and it means we need to do a job breakdown and develop the standard work. If there is a standard then we should be looking to see the actual condition. Are we meeting the standard? Are we ahead or behind? Both are problems. If we are behind, we need to understand why and remember the problem is not the person. If we are ahead we need to understand if we are following the standard. If we are, and have figured out a way to better it, then we need to update the standard work to include the improvement.

Another question we can ask is what improvements the team is working on now. Then we need to understand how and where they are in the problem-solving process. We need to understand the target they are shooting for compared to the baseline and if they have identified the root cause. The most important thing is to make sure they are not just throwing solutions at the problem.

You can’t manage the floor or office area or fix a problem without going to the gemba, floor, or office, to determine what is really going on.

Ritsuo Shingo,* when he was president of Toyota in China, personally walked the entire property, prior to building their new facility, in order to root-cause a problem with a stream and related drainage that would have seriously impacted the plant. If he hadn’t walked the property he would have never discovered the problem. You cannot manage a plant from your office.

Dashboard

Some companies create a dashboard of commonly tracked metrics. These may appear electronically or via manual charts tracked at the cell or in the office each day.

Most companies will use electronic dashboards and they can be useful when managing multi-sites or remotely. We caution you against only using electronic systems though. We have found a great deal of value in using manual tracking systems. They force the first-line leaders to acknowledge abnormal conditions and thus react to them. It also requires leaders to understand the formulas for the metrics for which they are responsible.

Process- versus Results-Focused Metrics

We tell companies to focus on the process and the results will take care of themselves. This is a very difficult “leap” for most executives to take since there is so much pressure on short-term results. Seeing and eliminating waste becomes how everyone in the organization does business.

Lean and Productivity, Efficiency, and Effectiveness

What to Do When There Is Rework or Scrap?

One-piece flow will bring every problem that has ever existed immediately to the surface. Initially there will probably be scrap and rework issues. We must figure out how to deal with it. This is a difficult point in the project.

The Lean answer would be to shut down the line and fix the problem so it never comes back. However, we have never worked with an organization that is even remotely at the Lean maturity level to deal with this. If the stop-the-line strategy is employed at this stage, the line probably won’t run for a week, month, or even a year.

The initial answer is to develop a countermeasure and work to figure out the root cause. The obvious danger is that once you work around the problem, the pressure to determine the root cause and fix the problem is now gone. We call this drive-thru parking.

Implement the Lean Material System

Kanbans

Kanban literally means “watch over board for a period.” Kanbans facilitate inventory management by providing a trigger i.e., sign or signal for replenishment. According to Taiichi Ohno, kanban is a means through which JIT is achieved. Ohno believed the goal for kanbans should be no more than five pieces of inventory with a goal of zero inventory. This would mean the prior process would produce the parts needed for the next process JIT. The purpose of a kanban system is to control the flow of material by providing inventory as a buffer to synchronize two disconnected processes.

Kanban is a visual management tool to help curb overproduction—the number one waste—and for detecting delays in the process, or when processes are producing ahead of schedule (a pacemaker to prevent overproduction i.e., produce only what is ordered, when ordered, and quantity ordered).

Kanbans are inventory, which is waste, thus we must constantly work to minimize the amount of materials. A kanban trigger or signal can be an empty space, an empty bin, a piece of paper, an electronic signal (lights, EDI), or an icon (e.g., rolling golf balls down a tube). The term kanban can initially be very confusing because the term kanban itself is used in several ways.

Kanban Replenishment: Constant Time or Constant Quantity

Kanbans can be replenished in two ways:

■ Constant time means they are replenished the same time each day or several times a day. This is referred to as breadman-type replenishment, which is like grocery store shelves being restocked each night.

■ Constant quantity is like the two-bin system. It may empty out at any time, and we refill it with the same quantity every time.

There are several types of kanbans, as explained in the first six chapters of Monden’s book entitled The Toyota Production System. The two main types are:

■ Withdrawal: Toyota refers to this as retrieval

■ Production: Toyota refers to this as informative

Two-Bin Systems

The simplest type of kanban is called a two-bin system (see Figure 5.40). A two-bin system is a constant quantity system, which can be used for withdrawal or production kanbans. It is composed of two separate bins containing the same parts, with one bin placed behind the other. When the first bin empties, the next full bin slides down.

Figure 5.40 Two-bin system. (Source: BIG Archives.)

The empty bin becomes the kanban signal or trigger visually indicating that the bin needs to be replenished. The empty bins are then collected, taken to the stockroom (or sent back to the supplier), and refilled. The new bin of materials is then returned to the original location in the area. This is called a withdrawal-kanban system.

Kanban systems regulate the inventory in a production system as the volume or rate of the process changes. The kanban system can be a one-bin system as well if the parts are replenished every day. Normally in a one-bin system, the bins are refilled to the top, or a water level, as one might refill bread in a store.

In some areas, parts are scanned into a bar-code terminal as the quantity of supplies is taken. This information is passed immediately to the stockroom or supplier as data for replenishment. This is called a point-of-sale system.

Kanban systems can also utilize card systems. Kanban cards are normally paper-based cards in clear vinyl envelopes. They are used to disseminate three types of information.

1. Pickup information

2. Transfer directive information

3. Production directive information

This is the same when using bins. The back of the bins show the pickup information, the front of the bins show the production information.

In this system, the card is taken from the empty bin and placed in a holder (to be ordered). This is called a kanban post. At certain frequencies during the day, the team leader, material handler, or water spider comes and collects the cards in the post. The cards are used to reorder the parts from the supplier. Once the material is ordered, the card is placed back in the kanban post in the ordered slot (see Figure 5.41).

Figure 5.41 Kanban post. (Source: BIG Archives.)

When the new bin of materials arrives, the card from the reordered slot is placed on the arriving bin of materials. The new bin of materials is returned to the original location in the area. This is called a withdrawal-kanban system.

Some jobs have non-common parts. For these jobs, we must create a special-order kanban card. These cards are typically generated once for a work order.

Kanban systems have two major failure modes:

1. First, the kanban system was originally designed in the plan for every part (PFEP) to support a certain maximum volume or customer demand. If this volume is exceeded, there will be parts shortages.

2. Second, if kanban cards are lost, inventory will not be replaced. If there are too many cards in the system to begin with, it will create excess inventory.

Every book has a different formula for calculating the size and number of kanban (see Figure 5.42). The simplest way to consider sizing a kanban is to think about a two-bin system. When the first bin empties out, the second one slides down to replace it. How much material do we need in the second bin? The answer is as much material as it takes to replenish the first bin and place it back behind the second bin. In addition, we need a small buffer of material to cover us in the event something goes wrong and the bin does not get replenished right away, which we define as buffer stock.

Figure 5.42 Sizing kanbans—kanban calculations. (Source: BIG Archives.)

We also carry some extra parts just in case there are quality issues, which is called safety stock. It is normal to carry a small percentage of the overall quantity (up to 10%) to cover safety and buffer stock. The goal of initial kanban systems should be 12–20 inventory turns the first year and 40–60 by the third year.

How Do You Know If It Should Be a Kanban Part?

The simplest way is to consider any part for kanban which has a consistent demand over a user-defined period and will not be obsoleted. This may be daily, weekly, monthly, or sometimes even quarterly. Parts that are considered special orders or ordered only once a year are not good candidates. For parts that repeat frequently we use average daily demand to divide into the lead time plus safety/buffer stock and for parts used infrequently we use peak demand. While this is a broad generalization, in order to minimize inventory and reduce stock-outs, we look at the cost of each part and each part as a separate case to determine what and how much to keep in stock.

Transition to Lineside Materials

Lineside materials are generally in two-bin containers or in slotted sequence to the line. In an office, this includes any tools needed to do the job at that station, such as a stapler, a three-hole punch, or a two-bin stack of blank paper. Lineside inventory can be sized differently for different applications, but the normal rule of thumb is to start out with a day’s worth of product in each lineside bin. For large or bulky parts, this may require replenishing every hour or sometimes even every cycle (assuming longer cycle times). For mixed-model lines, we may have parts for each model on a different row of shelves, or we may have shelves that roll up to the line. The goal is to determine what will work best for your situation and to make the operator’s job easy.

The material warehouse or supermarket on the shop floor is composed of parts kept next to or near the line to feed the lineside materials. The end goal is to eliminate these parts and have the vendor supply right to the line (vendor-managed products). Ideally, these would be flow-thru racks like the lineside racks, but this is not always possible.

There are two main strategies for the warehouse. It can be next to the line or in a centralized area off the line. Each strategy has pros and cons.