You put a computer in a bad operation and you get a worse operation quicker.

—Unknown

When technology works it enables good things, like quality, productivity, and efficiency. When you program around how work flows, the success rate is dramatically higher: Customers get their orders and life is good. Conversely, if technology is used without understanding where a business is going and how it actually works, it can be an unmitigated disaster.

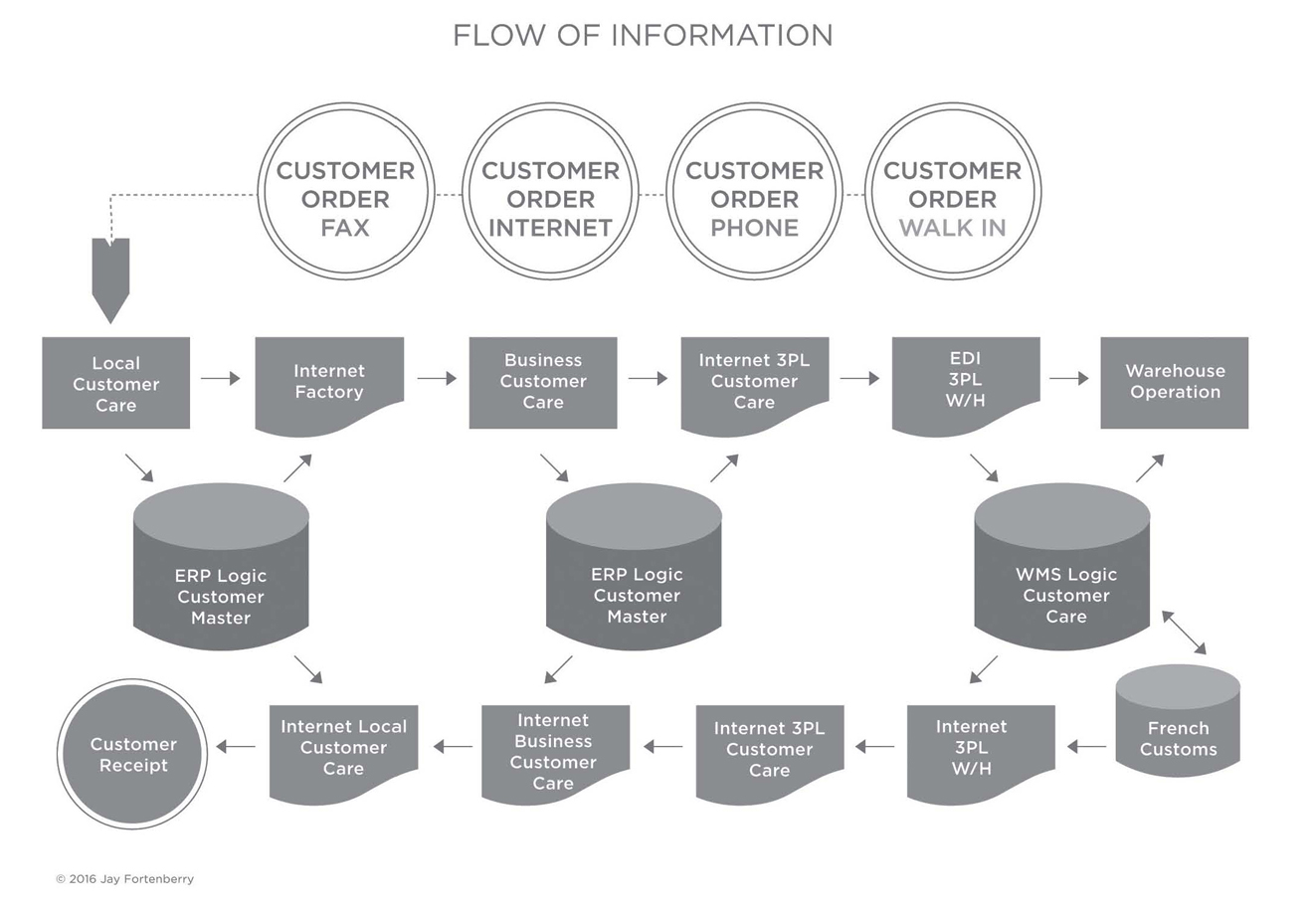

It’s all about employing the right technology for the right situation rather than using an overprescribed or basic version. There are no silver bullets to replace rolling up your sleeves, mapping the processes, and walking in the workers’ shoes. It may seem like a puzzle, but it is really an integrated and fully connected system (Figure 15.1).

Figure 15.1 Fully integrated systems

Mistakes Are the Ultimate Teacher

Everyone has horror stories of instances where this lesson was not applied. In my first experience with an enterprise resource planning (ERP*) program, we lost a full year of financial data as soon as it went live. As a $100 million P&L owner, I mistakenly turned a blind eye to what was happening around me—it was a kind of ostrich head-in-the-ground thing where I hadn’t taken the time to understand what was happening to me and my department. Then, on Memorial Day in 1998, I had to manually piece it back together on my kitchen table. That’s how I learned not to be a victim and to proactively take these monsters on.

After that bad experience there was an SAP implementation where we spent 3 years and $850 million (not a typo) developing a pilot that didn’t work. The switch was flipped on and nothing happened.

After that, there was the time we had over 100 ERP systems: Business Planning and Control Systems (BPCS), Manufacturing, Accounting, and Production Information Control Systems (MAPICS)—every version of Oracle you can think of, and we changed to SAP. Lord knows what that actually cost.

My ultimate failure involved two failed Warehouse Management System (WMS)* implementations—one in the United States and one in Germany.

The debacle in the United States was where the “smart” people decided to program the software without talking to anyone who actually did the work. At the same time, they decided that these workers needed a whole new vocabulary to go along with their jobs (because the workers “didn’t really know what they were doing”).

Confusion reigned. Processes stopped. Trucks couldn’t be unloaded and product ceased moving out the door. It was a total, 100 percent disaster that was completely preventable. This was the cultural thing I often refer to and was one of the most arrogant displays by management that I’ve witnessed over my 40 years of working in a supply chain. The implementation team actually never bothered to walk in the workers’ shoes and, therefore, failed to understand what happened.

Germany was a different story, but it had the same outcome: It was the first implementation in the company of a specific type of software. There was a huge amount of change from the previous situation: going from paper to radio frequency technology (RF), order-based picking to zone picking, new freight forwarder integration, and so on. Productivity plummeted with peak (or high) season just around the corner. This was a case of too much change for the body to take.

Both cases ended with the same outcome: There were abundant hidden factors, skyrocketing costs, missed deliveries, and a degradation of quality with no Plan B, C, or D for the extra labor needed to be successful. Also, in both cases, the people aspect was totally forgotten.

Technology and the Supply Chain

As stated throughout this field guide, optimizing supply chain design is about positioning resources in ways that enhance profitability, cash, and working capital, all while producing tangible shareholder value. Customer, supplier, and IT strategies all play into how well a company responds to changes in the marketplace. It’s called the cash-to-cash cycle.

Furthermore, the dynamics of a supply chain are continually changing. The supply chain is increasingly central to the management of cash and information.

Employing a technology into a business should be treated in the same way as any other basic improvement practices. Unfortunately, these powerful systems are often rolled out without a true understanding of processes, and with tentacles reaching deeply throughout the company. Old inferior processes are simply adapted or translated into the new system without regard to how they’ll operate in the fresh environment. It’s equally bad to just implement a standard basic package without understanding how the operations are run. Both result in the same kind of losses: massive overtime, exploding inventories, past due deliveries, and missed financial results.

ERP

The noble cause of employing an Enterprise Resource Planning (ERP)* system is stated as a way for the business to reduce cost, improve its processes, and be more responsive to customers. An ERP reaches into every process, throughout the whole company, which we will now examine:

Customer Service and Care

Customer care begins the entire process, from when a customer first enquires about a product through the time the product is delivered and cash is rendered, as illustrated above. Order management strategies are driven by how a business wants to present itself in the marketplace and who is the company’s main contact point for customers.

Information (or technology) flows from customers follow a completely different path from the product’s physical flow. It is common for a mature company to have layers of systems that feed each other back and forth. These systems are often batch-driven and can take up to a week to transfer information. In these cases, inventory is required to protect the goods that have been reserved in the queue.

Some of customer care’s critical responsibilities in their systems are:

•Maintaining customer and item masters

•Determining how orders are defined

•Quoting pricing and lead times

•Providing technical support

•Managing return goods

•Working with “checkout abandonment” in the process.

Tools for Forecasting and Business Planning

The goal of a business is to have one number: one demand plan, one supply plan, and one financial plan.

A demand forecast is an electronically generated projection into the future of expected demand for a business’s products and services given a stated set of environmental assumptions. It is an unconstrained forecast and one that draws from the entire business.

A demand plan is the main business process that anticipates and acts on a changing business outlook:

•Review of product portfolio, understanding lifecycle and its implications

•Planning demand, considering risks and opportunities

•Developing a supply response and the ability to react to changes

•Reconciling all plans with financial assessment of risk and trade-offs

•Team decisions presented to executives for review and agreement.

The outputs of a business’s demand planning process are the actions that result from the balancing of demand and supply, as seen above. They include:

•Supply or operational plan

•Demand plan

•Revenue plan.

Materials Resource Planning (MRP)

As we discussed earlier, materials management is a coordinated effort between planning, sourcing, and suppliers. It is aimed at developing replenishment methods that provide the highest availability at the lowest cost by addressing these questions: How much is needed? When is it needed? How is it triggered? And how will it come in?

An MRP system is software that assists in doing the calculations needed to plan manufacturing based on inputs from a forecast. It aids in the execution of inventory control and production planning.

MRP has evolved over time to be able to group demands together, calculate start from need dates, and integrate business planning and operations. Used properly, it plans production so that the right materials are at the right place at the right time. Ideally, MRP should:

•Reduce inventory levels and component shortages

•Increase shipping performance and customer service

•Simplify and provide accurate scheduling

•Improve productivity while reducing scrap and rework

•Decrease purchasing costs and lead times

•Enhance production scheduling and manufacturing cost while producing higher quality.

Data Integrity Is the Key to MRP System Accuracy

MRP does not think or foresee events: It only provides calculations from the data it is fed. It can be a classic case of “garbage in/garbage out” if not installed and maintained properly. In addition, as multiple people maintain data streams, MRP can quickly get out-of-sync unless planners stay vigilant in its maintenance. While bills of materials (BOM) are generally maintained well, variations in inventory record accuracy, lead time adjustments, capacity changes, missed processes, new product introductions (NPI), or supplier performance can produce profoundly different results.

Data accuracy is essential for:

•Accurate routings

•Accurate standards

An example of how data integrity affects accuracy is illustrated in the following figure.

The illustration above shows that if you are 98 percent accurate with your BOM while not maintaining inventory and lead times properly, it will drive you to meet only 75 percent of production schedules.

The benefits of MRP should be:

•Realistic promising, which provides for better customer service

•Controlled reduction of inventories, which reduces the use of working capital

•Improved responsiveness and flexibility through better forward planning

•Enhanced employee involvement through availability of information

•Stronger relationships with suppliers

•Integrated financial management.

The following two case studies illustrate how not maintaining data in MRP can lead to unpredictable and often bad things happening.

Case Study 15.1

German Manufacturing and a Global Customer

In this case, the customer care department was making promises to customers based on data that were loaded from the system’s forecasting software. This information had no relationship to the reality on the ground.

We learned that regardless of the function or position, no one should be able to approve or promise customers due dates that have not been agreed to by the factory (and are impossible to deliver). This example raised inventory levels, caused missed deliveries, and negatively impacted financial performance. See the 5 Why technique used.

Corrective action: load correct data into the forecasting system.

Raw Material Purchases

This study involved raw material purchases by a multinational manufacturer from a German supplier with a global customer that had inaccurate lead times loaded into MRP.

Again the 5 Why system was employed.

MRP stated that the process took 180 days, but when mapped it took over 210 days. No one knew how long it actually took to manufacture the product (see figure).

Specifically, in this case, when the system was installed it was loaded with dummy data; therefore, no one actually understood how long the manufacturing process took. As a result, as erroneous information flowed out, deliveries were missed, inventory exploded, and financial results for the year were missed.

Trade

The administration of trade requires tools for the ever-changing world of global regulations. As governments around the world implement new automated tools to detect violations, businesses without proper systems in place will find that their exposure grows exponentially. Benefits of automating trade are as follows:

•Strengthening of compliance while redirecting focus to training and prevention

•Reduction of the risk of disclosures/penalties to Customs agencies

•Allows the ability to extend global compliance within the current headcount constraints

•Increases duty savings through expanded use of global free trade agreements (FTA)

•Reduces brokerage fees through electronic feeds of import and export data

•Increases the accuracy and responsiveness to customer requests.

Business Continuity

Business continuity1 literally covers every aspect of a company. The initial step for building a business continuity process is to do a self-assessment starting with an examination of the company’s tolerance for risk through its people, processes, and tools.2

•Are the systems agile and scalable to support changes in operations, or would a disruption put the business back in manual mode?

•How does the team communicate and to whom do they report the details of their activities?

•If a disaster occurred would the company be resilient and continue operations or would it limit its losses via insurance and/or just pick up and move?

Having agile and scalable systems is the only way to prevent catastrophe and to keep the business running.

Final Thoughts on the Technologies

For success in applying technological advances, senior executives and all team members have to be engaged in implementing an enterprise-wide system. There can be no victims or people left behind. These systems touch every aspect of a business and can drive devastating results if not implemented properly, as they touch every aspect of a business’s life.

My parting words to the wise come from learning how to fail:

•The process implementation has to be led by the business leader

•The leadership team has to be educated on the integrated nature of the system

•Management must see and be held accountable to achieve the forecasted benefits

•Accountability must be built into each step

•Locate all of the hidden factors

•Build the loss of productivity into the model and have Contingency Plans B, C, and D

•IT is busy programming and providing security for the system; therefore, each function must own its own data

•No victims allowed.

The keys here are accountability, and it starts at the top.

________________

1J. Fortenberry. 2017. “Anticipating and Planning Business Interruptions to Ensure Continuity.” Fortenberry Group, January 24, 2017. https://www.fortenberrygroup.com/anticipating-and-planning-business-interruptions-to-ensure-continuity

2J. Fortenberry. 2017. “Keeping ‘People’ Front and Center in People, Process and Tools.” Fortenberry Group, January 10, 2017. https://www.fortenberrygroup.com/keeping-people-front-and-center-in-people-process-and-tools