The Planning Cycle

The Idea Behind SIOP: Demand and Supply Integration

Sales, Inventory, and Operations Planning

Methodology Based on the People, Process, and Tools

The ideal supply chain maintains no unnecessary inventory, responds to changes in the marketplace, and supplies the required products in a timely manner. However, in most businesses that’s not what happens. Instead, manufacturing complains that sales overstates the demand forecasts and/or doesn’t sell the product, and the supply chain gets blamed for having too much inventory.

At the same time, the sales team complains that manufacturing can’t deliver on its production commitments and therefore hurts sales. This ends up creating unplanned demand spikes used to meet financial targets, coupled with a constant struggle for new product launches that strain the sales and operations teams.

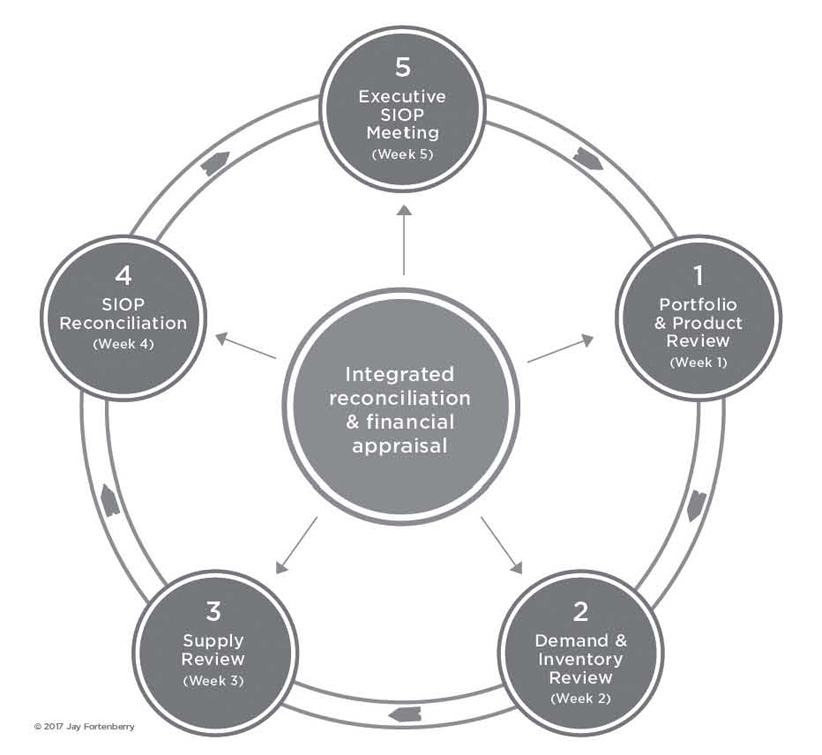

To address and correct this problem, we use what is known as SIOP, or sales inventory and operations planning* (or plain S&OP). SIOP is the single process that brings a business together to create a forward-looking 12- to 18-month plan that aligns functions and makes decisions on how to optimize resources, as well as how to achieve the goals of the business (see Figure 3.1).

Figure 3.1 Sales, inventory, and operations planning

The SIOP process is designed to be:

•A disciplined process to balance supply and demand

•A process that grasps the differences between forecasts and plans

•A tool to overcome the cultural differences of a business, including:

oThe demand side of the business trying to maximize revenue and be responsive to customers

oThe supply side of the business trying to maximize operational efficiency and keep costs low

oThe finance side of the business trying to make sense of it all in terms of how it relates to the P&L.

SIOP provides the opportunity to understand all sides’ issues and constraints. It does not set strategies for channels, customers, products, or supply. It does, however, identify trends in delivery, product revenue, inventory, and reliability. From a tactical perspective, SIOP doesn’t manage the day-to-day execution of a sales plan, customer order fulfillment, production scheduling, or sourcing, but it does allow a business the ability to understand its revenue versus plan, schedule attainment, and inventory levels.

SIOP is a continuous cycle of events occurring over a month (Figure 3.2).

Figure 3.2 SIOP: a consistent cycle of events

SIOP is based on the people, process, and tools methodology. Many companies buy into the idea but fail to drive the process throughout their culture, leading to spending time, money, and manpower without gaining value from their investment. Success comes from strong leadership, education of the participants, and a desire to drive these key elements:

•A process that produces a single number to run the business

•A comprehensive set of forward-looking plans matched with a financial summary

•Reviews of alternatives and their impact on objectives

•Decision-making to improve the business outlook.

SIOP also requires an engaged leadership and business team that utilizes standard processes and world-class tools to help manage through the upswings and downturns of a business cycle as well as shifts in the economic environment. SIOP is a forward-looking, continual monthly loop used to anticipate and act on the changing business outlook by:

•Reviewing the product portfolio, understanding lifecycles and implications

•Planning future demand, considering risks and opportunities

•Developing supply response and the ability to react to changes

•Reconciling all plans with a financial assessment of risk

•Creating a forum for executive review and agreement on team decisions.

This is where everyone commits to a single number for the business. Executed properly, a business can manage good times as well as bad with a consensus built from all parties. Successful planning processes:

•Have a formalized process

•Focus on people, process, and tools

•Create a burning platform

•Manage with discipline

•Communicate extensively and continuously

•Train continuously

•Sustain the process over years.

Likewise, planning implementations typically fail to achieve their desired results due to human and organizational issues, process, or technical reasons. These revolve around:

•Scope creep

•Inadequate resources

•Lack of sponsorship and leadership

•Poor project management skills

•Change management failure.

Case Study 3.1

The Impact of Demand Changes on Supply

The following case study was based on an analysis of the demand signals for a Canadian nutraceutical manufacturing and distribution company. There were four identified paths for how demand changed the supply plan on a daily basis:

•Forecast adjustments—where the sales team changed the date of a promotion with a Big Box retailer without first getting the agreement of the business or the supply chain leadership. To accomplish their goal, they adjusted the forecast to pull the order in early. This resulted in a failure that worked its way through the entire company. Pulling the order ahead led to several outcomes, including:

oMissed delivery to customers, resulting in delays and fines/penalties

oLack of availability of products for other customers

oRaw material shortages that resulted in increased expediting costs

oManufacturing overtime

oDeferred maintenance on manufacturing equipment.

•Forecast timing—the monthly process is beyond the capacity of the people performing the job.

•Smoothing a forecast—the software used to smooth orders out through the course of a month failed to identify how demand actually hits the business.

•Simulating in a “live” environment—these geniuses were simulating in a “live” environment sending out false and erroneous signals throughout the entire global supply chain.

Case Study 3.2

Production Planning

Background

The following case study involves an analysis of the supply planning process of a family-owned and operated retail paint manufacturer. This was an artistic company that was focused on product availability, marketing, and new product introductions (NPIs): They wanted to please their customers, who were artists. Two years into this company’s SIOP journey, I was asked to assess their supply planning process.

These were my initial observations:

•Prior to SIOP, production was planned the day before

•Planners struggled with gaps in software and were forced to use offline spreadsheets

•Customer service changes to order dates required workarounds for “Must Ships”

•Purchasing’s reports had a 99 percent exception rate; therefore, they were routinely ignored

•Kanban* (inventory) levels were set by purchasing with erroneous data

•Lead times were inaccurate

•A lack of defined flow of material into manufacturing caused unleveled results (see Figure 3.3)

•Ownership of finished goods inventory was unclear, but blamed on supply planners.

Figure 3.3 How inventory is created

The following were my recommended corrective actions:

•Establish performance management metrics immediately. Metrics needed to include:

oPurchases as a percentage of revenue

oDays of supply (DOS) of raw material

oSupplier on-time performance

oCycle time.

•Implement root-cause analysis with corrective actions for all material shortages focused on economic order quantities (EOQ), safety stocks, and Kanban calculations

•Assign a Kaizen engineer to create orderly flows of material into/out of manufacturing.

Final Thoughts on Planning

As a new hire, I once inherited an NPI and SIOP process because no one else wanted it. Knowing new product and end of life from my Toyota days, I unwittingly accepted the additional workload from the intern returning to school (yes, they had an intern running it all). At that point, I didn’t realize that there was no process and that the data were corrupt. In addition, after years of engineers building new product where there was no market, inactive, obsolete, and surplus inventories proliferated and financial targets were routinely missed.

Being a supply chain guy, I set a course to:

•Ground myself with the academics of the process

•Stick to my mantra of people, process, and tools

•Develop a very rudimentary process to get us moving forward.

SIOP is a tool to help manage a business. It is led by a business leader who is accountable for each of the process steps and who reports directly to the executive in charge. Implementation is aggressive—it starts early and is ugly at the beginning, eventually evolving into the process used to run the business.

SIOP requires behavior changes with new values, starting most importantly with honesty, meaning openness rather than hiding problems, and including:

•Forward planning versus a short-term focus

•Cross-functional participation versus silo mentality

•Balanced business goals versus individual targets

•Empowerment to develop solutions versus mandates.

SIOP is not an annual plan or the latest forecast. Rather, it’s a process that requires honesty in demand planning. Real focus is required to develop a crisp supply plan. Areas like preseason builds, material shortages, supplier failure, manufacturing maintenance, and safety can yield immediate benefits for both working capital and operating expense.

When the SIOP plan is translated into cash, it generates a realistic estimate of likely company performance, which potentially shows a gap with the budget. An honest process will result in an honest gap identification, which can then be managed.

The maturity path that most businesses can expect to experience is illustrated as follows (Figure 3.4).

Figure 3.4 The maturity stages versus time