Toyota Production System and Lean

Toyota Motor Corporation Executives: Left to right, Kiichiro Toyoda (1894–1952), Eiji Toyoda (1913–2013), Taiichi Ohno (1912–1990), Dr. Edwards Deming (1900–1993)

Source: Jay Fortenberry

Keep Cars Moving, Maintain Quality, and Promote Efficiency

Kiichiro Toyoda established the company that would later become Toyota Motor Corporation. During his tenure he nurtured the processes of Just in Time (JIT)* that would become one of the main pillars of the Toyota Production System (TPS). In the early 1950s, E. Toyoda visited Ford Motor. He decided to adopt the American method of mass automobile production, but with a qualitative difference.

E. Toyoda collaborated with Taiichi Ohno, a veteran loom machinist, and during one of Ohno’s visits to the United States he had discovered the American supermarket. He admired the way that customers could choose exactly what they wanted, in the quantity they wanted, and when they wanted. He studied the simple, efficient, and repeatable manner in which stores replenished their inventories. These firsthand experiences would assist in the development of the core concepts of Kanban*, and other processes to cut costs while improving overall quality.

During this same period, Dr. Edwards Deming was brought to Japan to work on improving quality. Deming trained hundreds of engineers, managers, and scholars in statistical process control (SPC)* and other core concepts of quality. The following observations became Deming’s 14 Points, as outlined in his book Out of the Crisis.1

1.Create constancy of purpose for improving products and services

2.Adopt the new philosophy

3.Cease dependence on mass inspection to achieve quality

4.End the practice of awarding business on price alone

5.Improve constantly every process for planning, production, and service

6.Institute training

7.Institute leadership

8.Drive out fear

9.Break down barriers between staff areas

10.Eliminate slogans, exhortations, and targets for the workforce

11.Eliminate numerical quotas

12.Remove barriers to pride of workmanship

13.Institute a vigorous program of education and self-improvement for everyone

14.Put everybody in the company to work accomplishing the transformation.

The 14 Points became the bedrock of what we know today as the TPS.

The basis of the TPS hinges on people.

On the first day of work at Toyota we learned as a business enterprise, it is important for Toyota to keep a good balance among the company’s values and consistently apply those values in all its systems and policies. We also learned the following:

•Customer first

•Competition and cooperation within the industry

•Respect for the value of people

•Mutual trust between employees and management

•Challenge and courage

•Applied creativity

•Cost-consciousness.

Furthermore, we were taught that our fundamental principles were to consider the mid- and long-term needs and inputs, along with the following:

•Genchi Genbutsu, or seeing is believing

•Seek the most rational way

•Strive for cost efficiencies

•Promote teamwork

•Develop your people.

For a new employee, this was fascinating to see that everyone from the boardroom to the assembly line understood and applied these principles. This message was stressed and reinforced daily along with the importance of keeping a proper balance so that these standards were equally applied in all circumstances.

Fundamental to Toyota is the elimination of waste. TPS is about the complete elimination of Muda. Muda is unnecessary waste that adds no value, increases cost and lead times, and leads to deterioration in quality. There are seven kinds of waste:

1.Waste from overproducing

2.Waste from waiting

3.Waste from conveyance

4.Waste from improper processing

5.Waste from inventory

6.Waste from nonproductive motion

7.Waste from producing defective product.

If you understand that selling price is dictated by the market, then in order to increase profitability Muda must be minimized and eliminated. It is from this premise that all of the key success factors of the TPS originated.

More TPS Fundamentals

Just in Time (JIT) Production

If you produce only the necessary products at the necessary time and in the necessary quantity, waste, irregularity and the unreasonable disappear and the improvement of productivity becomes possible.

—Logistics Administration Division, Toyota Motor Corporation, January 1998

The primary goal of JIT production is to translate each order into the delivery of a finished vehicle as quickly and efficiently as possible with factory-fresh quality. This is accomplished through the following basic principles:

•Pull systems—withdrawing parts when they are needed, in the necessary quantity

•Continuous flow—or an orderly flow in the operations

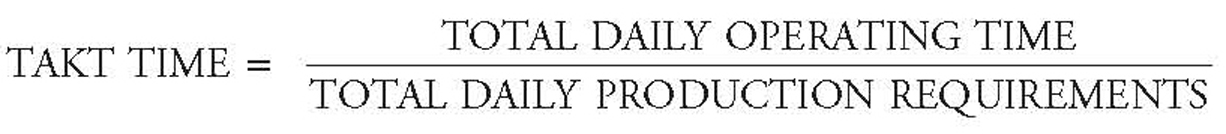

•Takt Time*—determining the pace of work by the required output in a certain working time (see the following discussion).

A basic precondition of JIT is Heijunka. Heijunka equals level production and level flow, which is based on a well-planned schedule. The objective of Heijunka is to minimize lot size in order to increase the frequency to achieve level production—a mathematical equation.

Kanban

Kanban is the cornerstone of TPS and the manifestation of on-the-job know-how. As shown earlier, it is a signaling system used to control the flow of materials, components, or products from one operation to the next. It is also a system in which the following production process withdraws only the parts it needs, in the necessary quantity, and when it needs them. Therefore, the preceding process only produces parts that will be consumed by the following process: This keeps a minimum inventory (or working capital).

The role of Kanban is to instruct the frequency and timing of delivery by providing the following:

•Instructions of production and conveyance

•A visual control to detect irregular process speed

•A tool to perform Kaizen (or continuous improvement).

When working a pull system, each process responds autonomously to hour-by-hour/minute-by-minute fluctuations so that the preceding process does not overproduce inventory. In addition, when a problem occurs, the entire process stops, thus making the problem apparent to all.

Continuous Flow

Continuous flow processing is a system of production—now referred to as “one-piece flow”—in which only one part is processed, then sent along the production line to the following process. This is based on a well-planned production schedule with the objective of minimizing lot size in order to attain the desired state.

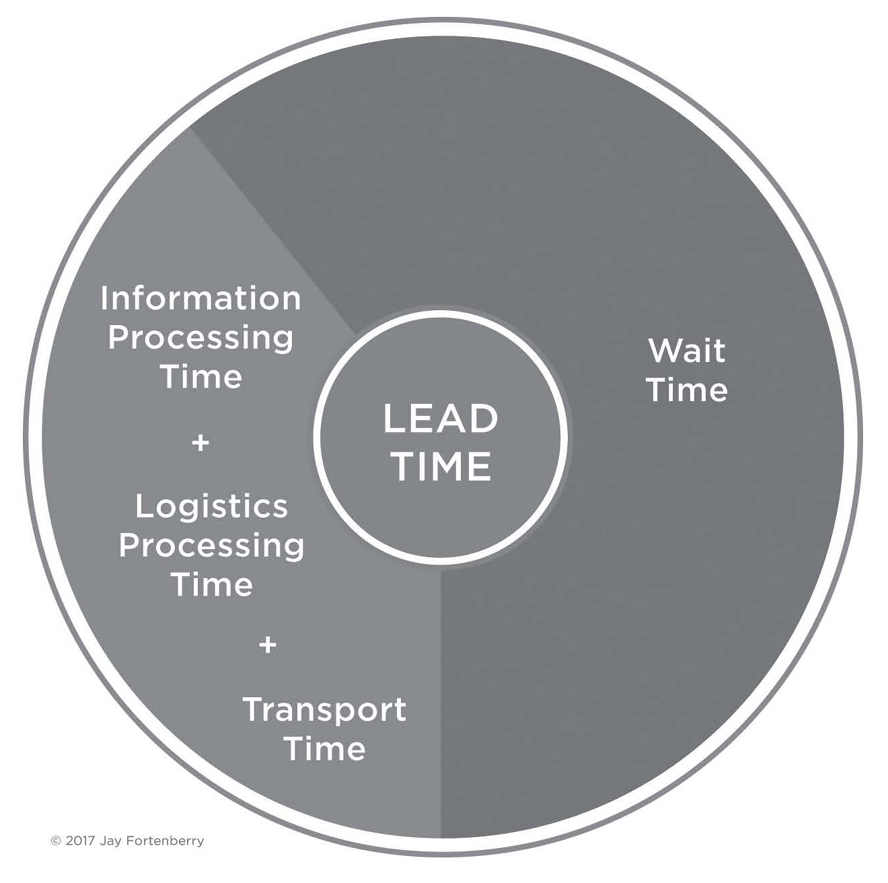

Heijunka eliminates stagnation between processes in order to carry out one-piece flows. In production, stagnation makes up over 50 percent of the time; therefore, managing continuous flows aids in managing the time that materials sit and sleep, as illustrated below.

Takt Time* is the time that should be taken to produce a product. This is based on total operating time, with all machinery operating at 100 percent of working time.

2017 Jay Fortenberry

Takt Time is achieved by performing standardized work for all processes. A standard work chart displayed at each workstation outlines the end product of the operation for each worker. In addition, this chart shows the essential work sequence, quality checks, and in-process stock for the task to be performed without Muda. Finally, standardized work shows the manual (as well as automatic) working and walking time at each location. This in turn is used to study the range in which one worker can operate within the Takt Time to determine the most efficient way of executing the process.

Visual Control

Visual control is a method for supervisors to grasp at a glance whether the production activities are proceeding normally or not. If there are problems, the supervisor must take action to remedy the problem immediately.

Andon is an electrical board that shows the current status of work to a supervisor: It enables countermeasures to be adopted quickly. A whiteboard at the workstation is also used to record the goals and actual production numbers, with problems recorded. A supervisor checks this board hourly to absorb the current status of their operation.

Jidoka

One of the basic premises of TPS is that defects are never to be passed on to the next workstation. Jidoka equals humanized automation, which builds quality into the process. When a machine detects an abnormality, it immediately stops and sends a warning to the person in charge. This prevents defective production, facilitates control of defects, promotes a safe working place, and prevents overproduction.

Kaizen

Determining where a process starts and where it stops is critical to understanding how a process works. Once identified, improvements for each of these areas can be translated into action plans, and from there the business can determine its best path forward for making improvements. Additional points to keep in mind include the following:

•Safety and quality are always preconditions

•Kaizen only comes from necessity

•The ideal condition is always pursued

•Genchi Gembets, Gemba, or Go and See are the watchwords of the day

•Find the root cause by using The 5 Whys*

•Concept follows actions

•Kaizen requires speed rather than perfection

•Do work Kaizen rather than machine Kaizen,

Seeing the problem first-hand allows the team to identify situations requiring improvement and to create a problem statement that describes the Who, What, When, Where, and Why of a problem. With this grounding, problem-solving becomes like forensic science, or a game.

Final Thoughts on the Toyota Production System

Thousands of pages have been written on the TPS, with a whole cottage industry built to teach it. Having been a witness to it, I’ve typically felt that many of these books, magazines, speeches, and websites lacked the soul to provide a true understanding of how the TPS philosophy infused the organization: You really have to live the life.

Perfection is an interesting topic that means little until you actually have to do it. You have to live it relentlessly—there’s a motion about it that is simply impossible to describe. Still, the tools that make up the TPS are simple; in fact, a part of its genius is that there is nothing too complicated so that everyone can “get it.”

TPS is all about managing inventory while taking care of your employees and suppliers, and it works. Our Toyota suppliers would do things for us that they wouldn’t do for anyone else, all because we took care of them. It’s a lesson that I learned the right way, and that I’m teaching my students today.

TPS was designed to make full use of all of a business’s resources, from its facilities and machines to the capabilities of its workers. It teaches that customer service is the mission and that the results are both a collective contribution to society and higher profits for the company. By ensuring that the processes and tools are in place and motivating and training people, you are able to achieve remarkable things.

________________

1 W. E. Deming. 2000. Out of the Crisis (Cambridge, MA and London, England: The MIT Press).