Central processor complex hardware components

This chapter provides information about the new IBM z15™ and its hardware building blocks, and how these components physically interconnect. This information is useful for planning purposes and can help in defining configurations that fit your requirements.

|

Note: Throughout this chapter, z15 refers to IBM z15 Model T01 (Machine Type 8561), unless otherwise specified. The terms frame and rack refer to the same 19-inch packaging of the 1 - 4 units of the system.

|

This chapter includes the following topics:

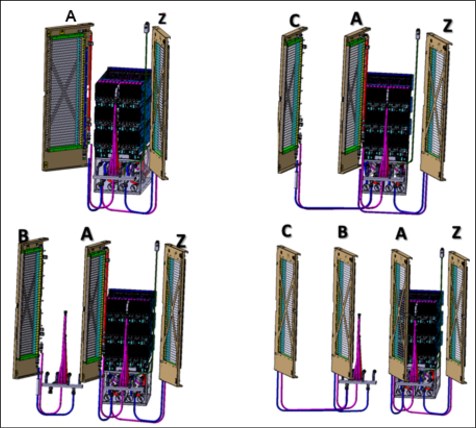

2.1 Frames and configurations

The z15 Model T01 system is designed in a 19-inch form factor with configuration of 1 - 4 frames that can be easily installed in any data center. The z15 Machine Type 8561 can include 1 - 4 42U EIA (19-inch) frames, which are bolted together. The configurations can include up to five central processor complex (CPC) drawers and up to 12 Peripheral Component Interconnect Express+ (PCIe+) I/O drawers.

The redesigned CPC drawer and I/O infrastructure also lowers power consumption, reduces the footprint, and allows installation in virtually any data center. The z15 server is rated for ASHRAE class A31 data center operating environment.

The z15 server differentiates itself from previous Z server generations through the following significant changes to the modular hardware:

•All external cabling (power, I/O, and management) is performed at the rear of the system

•Flexible configurations: Frame quantity is determined by the system configuration (1 - 4 frames)

•Choice of power Intelligent Power Distribution Unit (iPDU or PDU) or Bulk Power Assembly (BPA)

•Feature codes that reserve slots for plan-ahead CPC drawers

•Added internal water cooling plumbing for systems with more than three CPC drawers

•New PCIe+ Gen3 I/O drawers (19-inch format) supporting 16 PCIe adapters

The power options include PDU-based power or BPA-based power. The z15 server can be configured as a radiator (air) cooled or water cooled (that uses data center chilled water supply) system. Only BPA-based power system can be (optionally) configured for water cooling and with Internal Battery Feature (IBM), while a radiator (air) cooled system has PDU-based power (no Internal Battery Feature [IBF] available for PDU-based systems).

The z15 includes the following basic hardware building blocks:

•19-inch 42u frame (1 - 4)

•CPC (Processor) drawers (1 - 5)

•PCIe+ Gen3 I/O drawers (up to 12)

•CPC drawer Cooling Units: Radiator cooling assembly (RCA) or Water Cooling Unit (WCU)

•Power, with choice of:

– Intelligent Power Distribution Units (iPDU) pairs (2 - 4 per frame, depending on the configuration).

– Bulk Power Regulators (1 - 6 pairs, depending on the configuration)

•Support Elements (two):

– Single KMM2 device (USB-C connection)

– Optional extra hardware for IBM Hardware Management Appliance feature

•24-port 1GbE Switches (two or four, depending on the system configuration)

•Hardware for cable management at the rear of the system

An example of a fully configured system with PDU-based power, five CPC drawers, and maximum 12 PCIe+ I/O drawers is shown in Figure 2-1.

Figure 2-1 Maximum configuration, PDU-based powered system, rear view

An example of a BPA-based powered system with IBF, and a maximum of five CPC drawers and 11 PCIe+ I/O drawers is shown in Figure 2-2.

Figure 2-2 Maximum configuration, BPA-based powered system, rear view

The key features that are used to build the system are listed in Table 2-1 on page 38. For more information about the various configurations, see Appendix D, “Frame configurations” on page 509.

Table 2-1 Key features that influence the system configurations

|

Feature Code

|

Description

|

Comments

|

|

0503

|

Model T01

|

Supports CPs and specialty engines

|

|

0655

|

One CPC Drawer

|

Feature Max34

|

|

0656

|

Two CPC Drawers

|

Feature Max71

|

|

0657

|

Three CPC Drawers

|

Feature Max108

|

|

0658

|

Four CPC Drawers

|

Feature Max145

|

|

0659

|

Five CPC Drawers

|

Feature Max190

|

|

2271

|

CPC1 reserve

|

Reserve A15 location for future add CPC1

(Max34 to Max71 upgrade)

|

|

2272

|

CPC2 reserve

|

Reserve A20 location for future add CPC2

(Max71 to Max108 upgrade)

|

|

Frames and cooling

|

||

|

4033

|

A Frame

|

Radiator (air cooled)

|

|

4034

|

A Frame

|

Water cooled

|

|

4035

|

B Frame

|

Radiator (air cooled)

|

|

4036

|

B Frame

|

Water cooled

|

|

4037

|

Z Frame

|

I/O drawers only

|

|

4038

|

C Frame

|

I/O drawers only

|

|

PDU power

|

||

|

0629

|

200-208V 60A 3 Phase (Delta - “∆”)

|

North America and Japan

|

|

0630

|

380-415V 60A 3 Phase (Wye- ”Y”)

|

Worldwide (except North America and Japan)

|

|

BPA power

|

||

|

0640

|

Bulk Power Assembly (BPA)

|

Quantity 1 = 2 Bulk Power Enclosures

Quantity 2 = 4 Bulk Power Enclosures

|

|

3003

|

Balanced Power Plan ahead

|

Only available with BPA

|

|

3016

|

Bulk Power Regulator (BPR)

|

Quantity per BPA feature: Min. 2, max 6 (in pairs)

|

|

3217

|

Internal Battery Feature (IBF)

|

Quantity per BPA feature: Min. 2, max 6 (in pairs)

|

|

I/O

|

||

|

4021

|

PCIe+ I/O drawer

|

Max. 12 (PDU) or max. 11 (BPA)

|

|

7917

|

Top Exit Cabling

|

Includes cable management top hat

|

|

7919

|

Bottom Exit Cabling

|

Includes rear tailgate hardware at bottom of frame

|

|

7928

|

Top Exit Cabling without Tophat

|

Uses rear slide plates at top of frame

|

Considerations

Consider the following points:

•A-Frame is always present in every configuration

•1u Support Elements (x2) are always in A-Frame at locations A41 and A42

•1u 24-port internal Ethernet switches (x2) are always at locations A39 and A40

More Ethernet switches (x2) are available when necessary in Frame C or B

•I/O PCHID numbering starts with 0100 and increments depending on the number of features that is ordered. There is no PCHID number affinity to a fixed PCIe+ I/O drawer location as with previous systems.

2.1.1 z15 cover (door) design

The standard cover set for z15 model T01 is shown in Figure 2-3. Depending on the number of frames for the configuration, a Z and IBM accent top panel is installed on the outer frames. The single frame configuration combines the accents.

Figure 2-3 z15 Frames

The front doors of the z15 for systems with 1 - 4 frames also is shown in Figure 2-3.

2.1.2 Top exit I/O and cabling

For the z15 Model T01 server, the top exit of all cables for I/O or power is always an option with no feature codes required. Adjustable cover plates are available for the openings at the top rear of each frame.

The Top Exit feature code (FC 7917) provides an optional Top Exit cover enclosure. The optional Top Exit cover enclosure provides cable retention hardware and mounting locations to secure Fiber Quick Connector MPO3 brackets on the top of the frames.

All external cabling enters the system at the rear of the frames for all I/O adapters, management LAN, and power connections.

Feature code 7917 provides a top hat assembly to be installed at the top of each frame in the configuration. This assembly is designed to assist with fiber trunking management.

Overhead I/O cabling is contained within the frames. Extension “chimneys” that were featured with previous Z systems are no longer used.

A view of the top rear of the frame and the openings for top exit cables and power is shown in Figure 2-4. When FC 7917 is installed, the plated adjustable shields are removed and the top exit enclosure is installed.

Figure 2-4 Top exit without and with FC7917

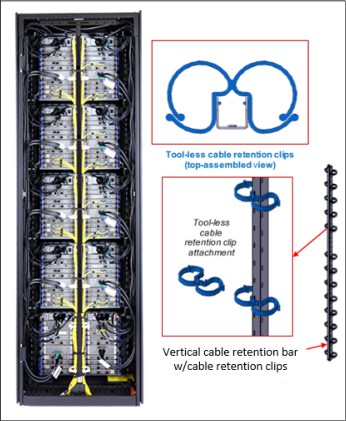

A newly designed vertical cable management guide (“spine”) can assist with proper cable management for fiber, copper, and coupling cables. Depending on the configuration, a spine is present from manufacturing with cable organizer clips installed.

The cable retention clips can be relocated for best usage. All external cabling to the system (from top or bottom) can use the spines to minimize interference with the PDUs that are mounted on the sides of the rack.

The rack with the spine mounted is shown in Figure 2-5. If necessary, the spine easily can be relocated for service procedures.

Figure 2-5 I/O cable management spine (Frame Z, rear view)

2.2 CPC drawer

The z15 Model T01 (machine type 8561) server continues the design of z14 by packaging processors in drawers. A z15 CPC drawer includes the following features:

•Five single chip modules (SCMs)

•Up to 20 Memory DIMMs

•Symmetric multiprocessor (SMP) connectivity

•Connectors to support PCIe+ Gen3 fanout cards for PCIe+ I/O drawers or coupling fanouts for coupling links to other CPCs

The z15 can include 1 - 5 CPC drawers (three in the A frame and two in the B frame). A CPC drawer and its components are shown in Figure 2-6 on page 42.

Figure 2-6 CPC drawer components (top view)

The z15 Model T01 5u CPC drawer always contains four Processor Unit (PU) SCMs, one System Controller (SC) SCM, and up to 20 memory DIMMs.

Depending on the feature, the z15 contains the following CPC components:

•The number of CPC drawers installed is driven by the following feature codes:

– FC 0655: One CPC drawer, Max34, up to 34 characterizable PUs

– FC 0656: Two CPC drawers, Max71, up to 71 characterizable PUs

– FC 0657: Three CPC drawers, Max108, up to 108 characterizable PUs

– FC 0658: Four CPC drawers, Max145, up to 145 characterizable PUs

– FC 0659: Five CPC drawers, Max190, up to 190 characterizable PUs

•The following SCMs are used:

– PU SCM uses 14nm SOI technology, 17 layers of metal, 9.2 billion transistors, core running at 5.2GHz: (with 12 cores design per PU SCM).

– SC SCM, 17 layers of metal, 9.7 billion transistors, 960 MB shared eDram L4 cache.

•Memory plugging:

– Four memory controllers per drawer (one per PU SCM)

– Each memory controller supports five DIMM slots

– Four or three memory controllers per drawer are populated (up to 20 DIMMs)

– Different memory controllers can have different size DIMMs

•Up to 12 PCIe+ Gen3 fanout slots that can host:

– 2-Port PCIe+ Gen3 I/O fanout for PCIe+ I/O drawers (always ordered and used in pairs for availability)

– ICA SR and ICA SR1.1 PCIe fanout for coupling (two ports per feature)

•Management elements: Two dual function flexible service processor (FSP) or oscillator cards (OSC) for system control and to provide system clock (N+1 redundancy).

•CPC drawer power infrastructure consists of the following components:

– Three or four Power Supply Units (PSUs) that provide power to the CPC drawer. The loss of one power supply leaves enough power to satisfy the drawer’s power requirements (N+1 redundancy). The power supplies can be concurrently removed and replaced (one at a time)

– 7x 12v distribution point-of-load (POL) that plug in slots that divide the memory banks

– 7x Voltage Regulator Modules that plug outside of the memory DIMMs

– Two Power Control cards to control the five CPC fans at the front of the CPC drawer

•Four SMP connectors that provide the CPC drawer to CPC drawer communication (NUMA).

The front view of the CPC drawer, which includes the cooling fans, FSP/OSC and bulk (power) distribution cards (BDC), is shown in Figure 2-7.

Figure 2-7 Front view of the CPC drawer

The rear view of a fully populated CPC Drawer is shown in Figure 2-8 on page 44. Dual port I/O fanouts and ICA SR adapters are plugged in specific slots for best performance and availability. Redundant power supplies and four SMP ports also are shown.

Figure 2-8 Rear view of the CPC drawer

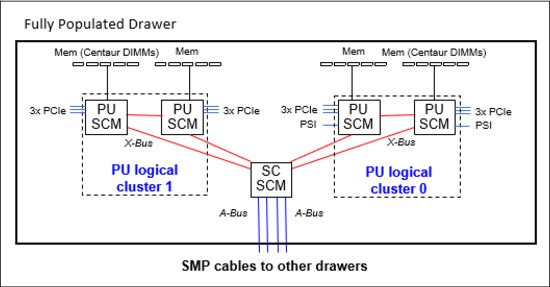

The CPC drawer logical structure, component connections (including the PU SCMs), and the storage control SCMs are shown in Figure 2-9.

Figure 2-9 CPC drawer logical structure

Memory is connected to the SCMs through memory control units (MCUs). Up to four MCUs are available in a CPC drawer (one per PU SCM) and provide the interface to the DIMM controller. A memory controller uses five DIMM slots.

The buses are organized in the following configurations:

•The PCIe I/O buses provide connectivity for PCIe fanouts and can sustain up to 16 GBps data traffic per port.

•The X-bus provides interconnects between SC chip and PUs chips to each other, in the same logical cluster.

•The A-bus provides interconnects between SC chips (L4 cache) in different drawers by using SMP cables.

•Processor support interfaces (PSIs) are used to communicate with FSP cards for system control.

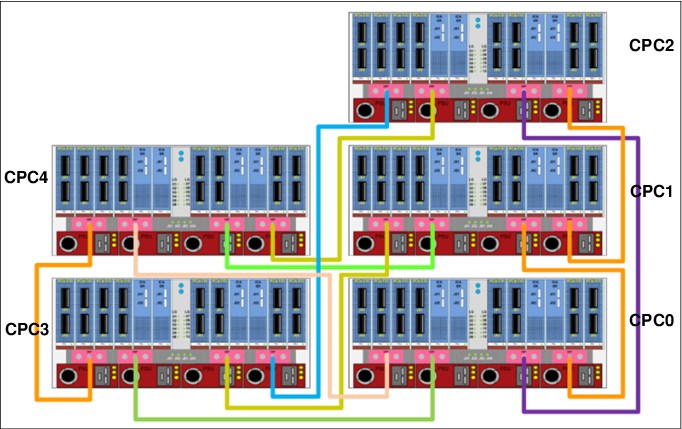

2.2.1 CPC drawer interconnect topology

The point-to-point SMP connection topology for CPC drawers is shown in Figure 2-10. Each CPC drawer communicates directly to all of the other CPC drawers SC SCM (L4 cache) by using point-to-point links.

Figure 2-10 Maximum CPC drawer SMP connections (rear view)

The CPC drawers that are installed in Frame A and Frame B are populated from bottom to top.

The order of CPC drawer installation is listed in Table 2-2.

Table 2-2 CPC drawer installation order and position

|

CPC drawer1

|

CPC0

|

CPC1

|

CPC2

|

CPC3

|

CPC4

|

|

Installation order

|

First

|

Second

|

Third

|

Fourth

|

Fifth

|

|

Position in Frame A

|

A10B

|

A15B

|

A20B

|

B10B

|

B15B

|

1 CPC3 and CPC4 are factory installed only (no field MES available)

CPC drawer installation in the A frame is concurrent. Non-disruptive addition of CPC1 or CPC2 drawers is possible in the field (MES upgrade) if the reserve feature (FC 2271 or FC 2272) is present. Concurrent drawer repair requires a minimum of two drawers.

2.2.2 Oscillator4

With z15 Model T01, the oscillator card design and signal distribution scheme is new; however, the RAS strategy for redundant clock signal and dynamic switchover is unchanged. One primary OSC card and one backup are used. If the primary OSC card fails, the secondary detects the failure, takes over transparently, and continues to provide the clock signal to the CPC.

Manage System Time

On z14, HMC 2.14.1 provided a significant user experience enhancement for timing controls with the new Manage System Time task.

For simplification, the z15 (2.15.0) removes the Support Element “Sysplex/System Timer” task panels. HMC level 2.15.0 (Driver 41) is required to manage system time for z15.

|

IEEE 1588 Precision Time Protocol (PTP)1: In the future, IBM plans to introduce PTP as an external time source for IBM Z Server Time Protocol (STP) for an IBM Z Coordinated Timing Network (CTN). The initial implementation is for PTP connectivity by using the IBM Z HMC/Support Element (SE).

At that time, the use of STP CTNs for time coordination will not be changed, other than the potential to use a PTP-based external time source. Future implementation is planned to include full connectivity of an external PTP time source directly to the IBM Z CPC, and the reintroduction of the concept of a mixed CTN, with support for traditional STP and native PTP implementations. Beyond that, the goal is to enhance the role of IBM Z machines in a PTP environment that addresses the many governmental regulations and security concerns that our clients are facing.

|

1 Statements by IBM regarding its plans, directions, and intent are subject to change or withdrawal without notice at the sole discretion of IBM. The development, release, and timing of any future features or functionality described for IBM products remain at the sole discretion of IBM.

The SEs provide the Simple Network Time Protocol (SNTP) client function. When Server Time Protocol (STP) is used, the time of an STP-only Coordinated Timing Network (CTN) can be synchronized to the time that is provided by a Network Time Protocol (NTP) server. This configuration allows time-of-day (TOD) synchronization in a heterogeneous platform environment and throughout the LPARs running on the CPC.

The accuracy of an STP-only CTN is improved by using an NTP server with the PPS output signal as the External Time Source (ETS). NTP server devices with PPS output are available from several vendors that offer network timing solutions.

Consider the following points:

•A new card combines the FSP and OSC was implemented with z15. The internal physical cards (FSP and OSC) are separate, but combined as a single FRU because of a packaging design.

•Two local redundant oscillator cards are available per CPC drawer each with one PPS port.

•An enhanced precision oscillator (20 PPM5 versus 50 PPM on previous systems) is used.

•The following PPS plugging rules apply (see Figure 2-11):

– Single CPC drawer plug left and right OSC PPS coaxial connectors.

– Multi-drawer plug CPC0 left OSC PPS and CPC1 left OSC PPS coaxial connectors.

– Cables are routed from rear to front by using a pass-through hole in the frame, and under the CPC bezel by using a right-angle Bayonet Neill-Concelman (BNC) connector that provides the pulse per second (PPS) input for synchronization to an external time source with PPS output.

Cables are supplied by the customer.

– Connected PPS ports must be assigned in the Manage System Time menus on the HMC.

Figure 2-11 Recommended PPS cabling

|

Tip: STP is available as FC 1021. It is implemented in the Licensed Internal Code (LIC), and allows multiple servers to maintain time synchronization with each other and synchronization to an ETS.

For more information, see the following publications:

•Server Time Protocol Planning Guide, SG24-7280

•Server Time Protocol Implementation Guide, SG24-7281

•Server Time Protocol Recovery Guide, SG24-7380

|

2.2.3 System control

The various system elements are managed through the FSPs. An FSP is based on the IBM PowerPC® microprocessor technology.

With z15, the CPC drawer FSP card is combined with the Oscillator card in a single Field Replaceable Unit (FRU). Two combined FSP/OSC cards are used per CPC drawer.

Also, the PCIe+ I/O drawer has a new FSP. Each FSP card has one Ethernet port that connects to the internal Ethernet LANs through the internal network switches (SW1, SW2, and SW3 and SW4, if configured). The FSPs communicate with the SEs and provide a subsystem interface (SSI) for controlling components.

An overview of the system control design is shown in Figure 2-12

Figure 2-12 Conceptual overview of system control element

|

Note: The maximum z15 system configuration features four GbE switches, five CPC drawers, and up to 12 PCIe I/O drawers.

|

A typical FSP operation is to control a power supply. An SE sends a command to the FSP to start the power supply. The FSP cycles the various components of the power supply, monitors the success of each step and the resulting voltages, and reports this status to the SE.

Most SEs are duplexed (N+1), and each element has at least one FSP. Two internal Ethernet LANs and two SEs, for redundancy, and crossover capability between the LANs, are available so that both SEs can operate on both LANs.

The Hardware Management Consoles (HMCs) and SEs are connected directly to one or two Ethernet Customer LANs. One or more HMCs can be used.

2.2.4 CPC drawer power

The power for the CPC drawer is a new design. It uses the following combinations of PSUs, POL6s, VRMs, and Bulk Distribution Cards:

•PSUs: Provide AC to 12V DC bulk/standby power and are installed at the rear of the CPC. The quantity that is installed depends on the following configurations:

– Three PSUs for configurations that use BPA power

– Four PSUs for configurations that use PDU power

•POLs: Seven Point of Load N+2 Redundant cards are installed next to the Memory DIMMs.

•VRMs: seven Voltage Regulator Modules (N+2 redundancy).

•Bulk distribution card (BDC): Redundant processor power and control cards connect to the CPC trail board. The control function is powered from 12V standby that is provided by the PSU. The BDC card also includes pressure, temperature, and humidity sensors.

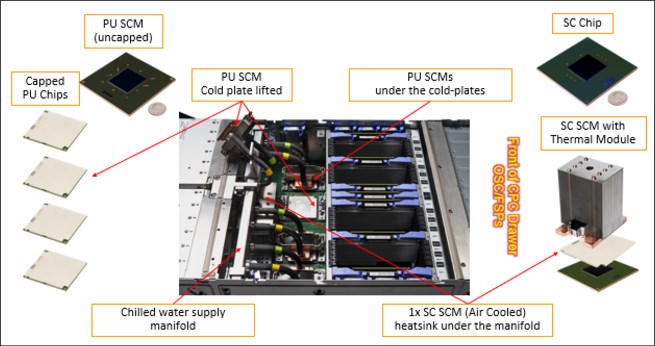

2.3 Single chip modules

The SCM is a multi-layer metal substrate module that holds one PU chip or an SC chip. Both PU and SC chip size is 696 mm2 (25.3 mm x 27.5 mm). Each CPC drawer has four PU SCMs (9.1 billion transistors each), and one SC SCM (9.7 billion transistors).

The two types of SCMs (PU and SC) are shown in Figure 2-13. For both SCMs, a thermal cap is placed over the chip. Each PU SCM is water cooled by way of a cold plate manifold assembly. The SC SCM is air cooled by using CPC drawer fans and heat sink.

Figure 2-13 Single chip modules (PU SCM and SC SCM)

PU and SC chips use CMOS 14 nm process, 17 layers of metal, and state-of-the-art Silicon-On-Insulator (SOI) technology.

The SCMs are plugged into a socket that is part of the CPC drawer packaging. The interconnectivity between the CPC drawers is accomplished through SMP connectors and cables. Four inter-drawer connections are available on each CPC drawer. This configuration allows a multidrawer system to act as an SMP system.

2.3.1 Processor unit chip

A schematic representation of the PU chip is shown in Figure 2-14.

Figure 2-14 PU SCM floor plan

The z15 PU chip (installed as a PU SCM) is an evolution of the z14 chip design. It includes the following features and improvements:

•CMOS 14nm SOI technology

•12 core design (versus 10 for z14) with increased on-chip cache sizes

•Three PCIe Gen4 interfaces (GX bus was dropped)

•DDR4 memory controller

•Two X-buses support cluster connectivity (PU SCM-to-PU SCM and PU SCM-to-SC SCM connectivity by way of X bus).

•New EDRAM macro design with 2x macro density. Compared to z14 PU:

– L3 was increased from 128 MB to 256 MB per chip

– L2-I was increased from 2 MB to 4 MB per core

– L2-L3 protocol was changed to reduce latency

•On-chip compression accelerator (Nest Acceleration Unit - NXU)

•Further optimization of the nest-core staging

2.3.2 Processor unit (core)

Each processor unit, or core, is a superscalar and out-of-order processor that supports 10 concurrent issues to execution units in a single CPU cycle. Figure 2-15 shows the core floor plan, which contains the following units:

Figure 2-15 Processor core floor plan

•Fixed-point unit (FXU): The FXU handles fixed-point arithmetic.

•Load-store unit (LSU): The LSU contains the data cache. It is responsible for handling all types of operand accesses of all lengths, modes, and formats as defined in the z/Architecture.

•Instruction fetch and branch (IFB) (prediction) and Instruction cache and merge (ICM). These two sub units (IFB and ICM) contain the instruction cache, branch prediction logic, instruction fetching controls, and buffers. Its relative size is the result of the elaborate branch prediction.

•Instruction decode unit (IDU): The IDU is fed from the IFU buffers, and is responsible for parsing and decoding of all z/Architecture operation codes

•Translation unit (XU): The XU has a large translation lookaside buffer (TLB) and the Dynamic Address Translation (DAT) function that handles the dynamic translation of logical to physical addresses.

•Instruction sequence unit (ISU): This unit enables the out-of-order (OoO) pipeline. It tracks register names, Out-of-Order instruction dependency, and handling of instruction resource dispatch.

•Instruction fetching unit (IFU) (prediction): These units contain the instruction cache, branch prediction logic, instruction fetching controls, and buffers. Its relative size is the result of the elaborate branch prediction design.

•Recovery unit (RU): The RU keeps a copy of the complete state of the system that includes all registers, collects hardware fault signals, and manages the hardware recovery actions.

•Dedicated Co-Processor (CoP): The dedicated coprocessor is responsible for data compression and encryption functions for each core.

•Core pervasive unit (PC) for instrumentation and error collection.

•Modulo arithmetic (MA) unit: Support for Elliptic Curve Cryptography:

– Vector and Floating point Units (VFU):

• BFU: Binary floating point unit

• DFU: Decimal floating point unit

• DFx: Decimal fixed-point unit

• FPd: Floating point divide unit

• VXx: Vector fixed-point unit

• VXs: Vector string unit

• VXp: Vector permute unit

• VXm: Vector multiply unit

– L2I/L2D – Level 2 instruction/data cache

2.3.3 PU characterization

The PUs are characterized for client use. The characterized PUs can be used in general to run supported operating systems, such as z/OS, z/VM, and Linux on Z. They also can run specific workloads, such as Java, XML services, IPSec, and some Db2 workloads, or clustering functions, such as the Coupling Facility Control Code (CFCC).

The maximum number of characterizable PUs depends on the z15 CPC drawer feature code. Some PUs are characterized for system use; some are characterized for client workload use.

By default, one spare PU is available to assume the function of a failed PU. The maximum number of PUs that can be characterized for client use are listed in Table 2-3.

Table 2-3 PU characterization

|

Feature

|

CPs

|

IFLs

|

Unassigned IFLs

|

zIIPs

|

ICFs

|

IFPs

|

Std

SAPs

|

Add’l

SAPs

|

Spare

PUs

|

|

Max34

|

0-34

|

0-34

|

0-33

|

0-22

|

0-34

|

1

|

4

|

0-8

|

2

|

|

Max71

|

0-71

|

0-71

|

0-70

|

0-46

|

0-71

|

1

|

8

|

0-8

|

2

|

|

Max108

|

0-108

|

0-108

|

0-107

|

0-70

|

0-108

|

1

|

12

|

0-8

|

2

|

|

Max145

|

0-145

|

0-145

|

0-144

|

0-96

|

0-145

|

1

|

16

|

0-8

|

2

|

|

Max190

|

0-190

|

0-190

|

0-189

|

0-126

|

0-190

|

1

|

22

|

0-8

|

2

|

The rule for the CP to zIIP purchase ratio is that for every CP purchased, up to two zIIPs can be purchased. Java and XML workloads can run on zIIPs.

However, an LPAR definition can go beyond the 1:2 ratio. For example, a maximum of four physical zIIPs can be installed on a system with two physical CPs.

Converting a PU from one type to any other type is possible by using the Dynamic Processor Unit Reassignment process. These conversions occur concurrently with the system operation.

|

Note: The addition of ICFs, IFLs, zIIPs, and SAP to the z15 does not change the system capacity setting or its million service units (MSU) rating.

|

2.3.4 System Controller chip

The System Controller (SC) chip uses the CMOS 14nm SOI technology, with 17 layers of metal. It measures 25.3 x 27.5 mm, and has 9.7 billion transistors. Each CPC drawer of the system has one SC chip.

A schematic representation of the SC chip is shown in Figure 2-16. Consider the following points:

•A Bus (SC-SC off drawer): Minor changes to reflect protocol improvements and new system topology

•960 MB shared eDRAM L4 Cache

•L4 Directory is built with eDRAM

•New L4 Cache Management: Ratio of L3 to L4 cache capacity is increasing

Figure 2-16 SC chip floor plan

2.3.5 Cache level structure

The cache structure comparison between CPC drawers on z14 and z15 is shown in Figure 2-17.

Figure 2-17 Cache structure comparison: z14 versus z15

2.4 PCIe+ I/O drawer

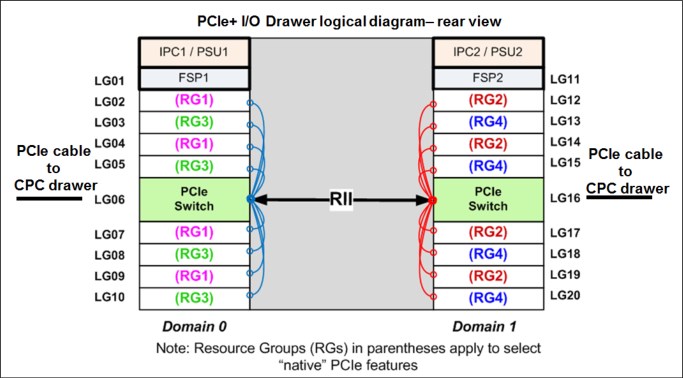

As shown in Figure 2-18 on page 55, each PCIe+ I/O drawer has 16 slots each to support the PCIe I/O infrastructure with a bandwidth of 16 GBps and includes the following features:

•A total of 16 I/O cards are spread over two I/O domains (0 and 1):

– Each I/O slot reserves four PCHIDs.

– Left side slots are numbered LG01-LG10 and right side slots are numbered LG11-LG20 from the rear of the rack. A location and LED identifier panel is at the center of the drawer.

– New with z15 Model T01, the numbering of the PCHIDs is not related to a fixed location in a frame as with previous generations of Z systems. Instead, the first configured I/O location starts with PCHID 100 and continues the incremental sequence to the next configured PCIe I/O drawer. For more information about examples of the various configurations, see Appendix D, “Frame configurations” on page 509.

•Two PCIe+ switch cards provide connectivity to the PCIe+ Gen3 fanouts that are installed in the CPC drawers.

•Each I/O drawer domain has four dedicated support partitions (two per domain) to manage the native PCIe cards.

•Two Flexible Support Processor (FSP) cards are used to control the drawer function.

•Redundant N+1 power supplies (two) are mounted on the rear and redundant blowers (six) are mounted on the front.

Figure 2-18 PCIe I/O drawer front and rear view

The following configuration examples and how the configurations are different with the power selection, number of CPC drawers and I/O features ordered, the layout of the PCIe+ I/O drawers, and PCHID numbering are shown in Figure 2-19:

Figure 2-19 Configuration examples with PCHID numbering

•The first, a single frame system, ordered with PDU power, radiator cooling, one CPC drawer, and greater than 32 I/O features to drive three I/O drawers.

PCHID numbering is consecutive from top to bottom.

•The second, a three frame system, ordered with PDU power, radiator cooling, four CPC drawers, and greater than 128 I/O features to drive nine I/O drawers.

PCHID numbering starts in the A-frame, resumes in the B-frame from top down, and continues to the Z-frame working from the bottom up.

•The third, a two frame system, ordered with BPA, IBF power options, radiator cooling, one CPC drawer, two reserved CPC drawer slots for future CPC drawer add MES, and greater than 64 I/O features to drive five I/O drawers

PCHID numbering starts in the Z-frame, from the bottom and working up.

Consideration for PCHID identification:

In previous PCIe I/O drawers (introduced with zEC12), the orientation of the I/O features were vertical. For z15, the orientation of the PCIe features is horizontal, and the top of the card is now closest to the center of the drawer for the left and right side of the drawer.

The vertical card collapsed horizontal and the awareness of the port and PCHID layout where the top of the adapter (port D1) is closest to the location panel on both sides of the drawer are shown in Figure 2-20.

Figure 2-20 I/O feature orientation in PCIe I/O drawer (rear view)

|

Note: The CHPID Mapping Tool (available on ResourceLink) can be used to print a CHPID Report that displays the drawer and PCHID/CHPID layout.

|

2.5 Memory

The maximum physical memory size is directly related to the number of CPC drawers in the system. Each CPC drawer can contain up to 8 TB of customer memory, for a total of 40 TB of memory per system.

The minimum and maximum memory sizes that you can order for each z15 feature are listed in Table 2-4.

Table 2-4 Purchased Memory (Memory available for assignment to LPARs)

|

Feature

|

# of CPC drawers

|

Customer memory GB

|

Flexible memory GB

|

|

Max34

|

1

|

512 - 7936

|

NA

|

|

Max71

|

2

|

512 - 16128

|

512 - 7936

|

|

Max108

|

3

|

512 - 24320

|

512 - 16128

|

|

Max145

|

4

|

512 - 32512

|

512 - 24320

|

|

Max190

|

5

|

512 - 40704

|

512 - 32512

|

The following memory types are available:

•Purchased: Memory that is available for assignment to LPARs.

•Hardware System Area (HSA): Standard 256 GB of addressable memory for system use outside of customer memory.

•Standard: Provides minimum physical memory that is required to hold customer purchase memory plus 256 GB HSA.

•Flexible: Provides more physical memory that is needed to support that activation of base customer memory and HSA on a multiple CPC drawer z15 with one drawer out of service (concurrent drawer replacement; not available on Max34 feature).

|

Note: The Plan Ahead Memory feature is not offered with a new order z15 system. The Plan Ahead Memory feature that is available on z13 or z14 can be carried forward to z15.

|

The memory granularity, which is based on the installed customer memory, is listed in Table 2-5.

Table 2-5 Customer offering memory increments

|

Memory increment (GB)

|

Offered memory sizes (GB)

|

|

64

|

512 - 768

|

|

128

|

896 - 2048

|

|

256

|

2304 - 3840

|

|

512

|

4352 - 17152

|

|

1024

|

18176 - 32512

|

|

2048

|

34560 - 40704

|

2.5.1 Memory subsystem topology

The z15 memory subsystem uses high-speed, differential-ended communications memory channels to link a host memory to the main memory storage devices.

The CPC drawer memory topology of a z15 server is shown in Figure 2-21.

Figure 2-21 CPC drawer memory topology at maximum configuration

Consider the following points regarding the topology:

•One MCU per processor chip with five memory channels, one DIMM per channel (no DIMM cascading) is used.

•The fifth channel in each MCU enables memory to be implemented as a Redundant Array of Independent Memory (RAIM). This technology features significant error detection and correction capabilities. Bit, lane, DRAM, DIMM, socket, and complete memory channel failures can be detected and corrected, including many types of multiple failures. Therefore, RAIM takes 20% of DIMM capacity. (No non-RAIM option is available.)

•DIMM sizes used are 32, 64, 128, 256 and 512 GB with five DIMMs of the same size included in a memory feature (160, 320, 640, 1280 and 2560 GB RAIM array size, respectively).

•Three or four features (15 or 20 DIMMs) are plugged in each drawer.

•Features with different DIMMs sizes can be mixed in the same drawer.

•The five DIMMs per MCU must be the same size.

•Addressable memory is required for partitions and HSA.

2.5.2 Redundant array of independent memory

The z15 server uses the RAIM technology. The RAIM design detects and recovers from failures of dynamic random access memory (DRAM), sockets, memory channels, or DIMMs.

The RAIM design requires the addition of one memory channel that is dedicated for reliability, availability, and serviceability (RAS).

The five channel RAIM Memory Controller overview is shown in Figure 2-22.

Figure 2-22 Five channel RAIM Memory Controller Overview

The fifth channel in each MCU enables memory to be implemented as a RAIM. This technology features significant error detection and correction capabilities. Bit, lane, DRAM, DIMM, socket, and complete memory channel failures can be detected and corrected, including many types of multiple failures. Therefore, RAIM takes 20% of DIMM capacity (a non-RAIM option is not available).

The RAIM design provides the following layers of memory recovery:

•ECC with 90B/64B Reed Solomon code.

•DRAM failure, with marking technology in which two DRAMs can be marked and no half sparing is needed. A call for replacement occurs on the third DRAM failure.

•Lane failure with CRC retry, data-lane sparing, and clock-RAIM with lane sparing.

•DIMM failure (discrete components and VTT Reg) with CRC retry, data-lane sparing, and clock-RAIM with lane sparing.

•DIMM controller ASIC failure.

•Channel failure started RAIM recovery.

2.5.3 Memory configurations

Memory sizes in each CPC drawer do not have to be similar. Different CPC drawers can contain different amounts of memory. The 10 (10-19) drawer memory configurations that are supported are listed in Table 2-6. Each CPC drawer is included from manufacturing with one of these memory configurations. Total physical memory includes RAIM (20%).

Table 2-6 Drawer memory plugging configurations

|

CFG #

|

Physical

memory

GB

|

32 GB

#DIMMs

|

64 GB

#DIMMs

|

128 GB

#DIMMs

|

256 GB

#DIMMs

|

512 GB

#DIMMs

|

-RAIM

GB

|

-HSA

GB

|

|

10

|

640

|

20

|

0

|

0

|

0

|

0

|

512

|

256

|

|

11

|

960

|

10

|

10

|

0

|

0

|

0

|

768

|

512

|

|

12

|

1280

|

0

|

20

|

0

|

0

|

0

|

1024

|

768

|

|

13

|

1600

|

0

|

10

|

10

|

0

|

0

|

1536

|

1280

|

|

14

|

1920

|

0

|

0

|

20

|

0

|

0

|

2048

|

1792

|

|

15

|

3840

|

0

|

0

|

10

|

10

|

0

|

3072

|

2816

|

|

16

|

5120

|

0

|

0

|

0

|

20

|

0

|

4096

|

3840

|

|

17

|

7680

|

0

|

0

|

0

|

10

|

10

|

6144

|

5888

|

|

18

|

10240

|

0

|

0

|

0

|

0

|

20

|

8192

|

7936

|

|

19

|

480

|

15

|

0

|

0

|

0

|

0

|

384

|

128

|

Consider the following points:

•A CPC drawer always contains a minimum of 15 32GB DIMMs as listed in drawer configuration number 19 in Table 2-6 on page 59.

•A CPC drawer can have more memory installed than is enabled. The amount of memory that can be enabled by the client is the total physically installed memory minus the RAIM amount (20%) and minus the 256 GB of HSA memory.

•A CPC drawer can have available unused memory, which can be ordered as a memory upgrade and enabled by LIC-CC without DIMM changes.

•DIMM changes require a disruptive power-on reset (POR) on z15 with a single CPC drawer. DIMM changes can be done concurrently on z15 models with multiple CPC drawers using Enhanced Drawer Availability (EDA).

DIMM plugging for the configurations in each CPC drawer do not have to be similar. Each memory 5 slot DIMM bank must have the same DIMM size; however, a drawer can have a mix of DIMM banks. Table 2-7 lists the memory population by DIMM bank for the 15 configurations that are listed in Table 2-6 on page 59.

As an example, for configuration #14, memory positions MD06-MD10 are populated with five 128 GB DIMMS.

Table 2-7 Memory Population by DIMM Bank

|

CFG #

|

MD01-MD05

|

MD06-MD10

|

MD11-MD15

|

MD16-MD20

|

Physical

|

Total -RAIM

|

Total- RAIM+HSA

|

|

10

|

32

|

32

|

32

|

32

|

640

|

512

|

256

|

|

11

|

64

|

32

|

32

|

64

|

960

|

768

|

512

|

|

12

|

64

|

64

|

64

|

64

|

1280

|

1024

|

768

|

|

13

|

128

|

64

|

64

|

128

|

1920

|

1536

|

1280

|

|

14

|

128

|

128

|

128

|

128

|

2560

|

2048

|

1792

|

|

15

|

256

|

128

|

128

|

256

|

3840

|

3072

|

2816

|

|

16

|

256

|

256

|

256

|

256

|

5120

|

4096

|

3840

|

|

17

|

512

|

256

|

256

|

512

|

7680

|

6144

|

5888

|

|

18

|

512

|

512

|

512

|

512

|

10240

|

8192

|

7936

|

|

19

|

32

|

32

|

32

|

|

480

|

384

|

128

|

The support element View Hardware Configuration task can be used to determine the size and quantity of the memory plugged in each drawer. Figure 2-23 shows an example of configuration number 16 from the previous tables, and displays the location and description of the installed memory modules.

Figure 2-23 View Hardware Configuration task on the Support Element

Figure 2-24 shows the CPC drawer and DIMM locations for a z15.

Figure 2-24 CPC drawer and DIMM locations for a z15

Table 2-8 lists the physical memory plugging configurations by feature code from manufacturing when the system is ordered. Consider the following points:

•The CPC drawer columns for the specific feature contain the Memory Plug Drawer Configuration number that us referenced in Table 2-6 on page 59 and the Population by DIMM Bank that is listed in Table 2-7 on page 60.

•Dial Max indicates the maximum memory that can be enabled by way of the LICC concurrent upgrade.

If more storage is ordered by using other feature codes, such as Virtual Flash Memory, or Flexible Memory, the extra storage is installed and plugged as necessary.

For example, a customer orders FC 1528 that features 1920 GB memory and Max145 (4 CPC drawers). The drawer configurations include the following components:

•CPC0 (768GB), CPC3 (768GB) - Configuration #11 (from Table 2-6 on page 59)

•CPC1 (384GB), CPC2 (384GB) - Configuration #19

•Total 768 + 768 + 384 + 384 - 256 HSA= 2048GB (Dial Max)

Table 2-8 Memory features and physical plugging

|

Feature

Code

|

Increments

|

Customer

Memory

Increments

|

Max34

|

Max71

|

Max108

|

Max145

|

Max190

|

|||||||||||||||

|

Drawer CPC0

|

Dial Max

|

Drawer CPC0

|

Drawer CPC1

|

Dial Max

|

Drawer CPC0

|

Drawer CPC1

|

Drawer CPC2

|

Dial Max

|

Drawer CPC0

|

Drawer CPC1

|

Drawer CPC2

|

Drawer CPC3

|

Dial Max

|

Drawer CPC0

|

Drawer CPC1

|

Drawer CPC2

|

Drawer CPC3

|

Drawer CPC4

|

Dial Max

|

|||

|

1515

|

64

|

512

|

12

|

768

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

1516

|

576

|

12

|

768

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1517

|

640

|

12

|

768

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1518

|

704

|

12

|

768

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1519

|

768

|

12

|

768

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1520

|

128

|

896

|

13

|

1280

|

11

|

19

|

896

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

1521

|

1024

|

13

|

1280

|

12

|

19

|

1152

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1522

|

1152

|

13

|

1280

|

12

|

19

|

1152

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1523

|

1280

|

13

|

1280

|

12

|

11

|

1536

|

11

|

19

|

19

|

1280

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1524

|

1408

|

14

|

1792

|

12

|

11

|

1536

|

11

|

19

|

11

|

1664

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1525

|

1536

|

14

|

1792

|

12

|

11

|

1536

|

11

|

19

|

11

|

1664

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1526

|

1664

|

14

|

1792

|

12

|

12

|

1792

|

11

|

19

|

11

|

1664

|

11

|

19

|

19

|

19

|

1664

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1527

|

1792

|

14

|

1792

|

12

|

12

|

1792

|

11

|

11

|

11

|

2048

|

11

|

19

|

19

|

11

|

2048

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1528

|

1920

|

15

|

2816

|

13

|

13

|

2816

|

11

|

11

|

11

|

2048

|

11

|

19

|

19

|

11

|

2048

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1529

|

2048

|

15

|

2816

|

13

|

13

|

2816

|

11

|

11

|

11

|

2048

|

11

|

19

|

19

|

11

|

2048

|

11

|

19

|

19

|

19

|

19

|

2048

|

|

|

1530

|

256

|

2304

|

15

|

2816

|

13

|

13

|

2816

|

12

|

11

|

12

|

2560

|

11

|

11

|

11

|

11

|

2816

|

11

|

11

|

19

|

19

|

11

|

2816

|

|

1531

|

2560

|

15

|

2816

|

13

|

13

|

2816

|

12

|

11

|

12

|

2560

|

11

|

11

|

11

|

11

|

2816

|

11

|

11

|

19

|

19

|

11

|

2816

|

|

|

1532

|

2816

|

15

|

2816

|

13

|

13

|

2816

|

12

|

12

|

12

|

2816

|

11

|

11

|

11

|

11

|

2816

|

11

|

11

|

19

|

19

|

11

|

2816

|

|

|

1533

|

3072

|

16

|

3840

|

14

|

14

|

3840

|

13

|

12

|

13

|

3840

|

12

|

11

|

11

|

12

|

3328

|

11

|

11

|

11

|

11

|

11

|

3584

|

|

|

1534

|

3328

|

16

|

3840

|

14

|

14

|

3840

|

13

|

12

|

13

|

3840

|

12

|

11

|

11

|

12

|

3328

|

11

|

11

|

11

|

11

|

11

|

3584

|

|

|

1535

|

3584

|

16

|

3840

|

14

|

14

|

3840

|

13

|

12

|

13

|

3840

|

12

|

12

|

12

|

12

|

3840

|

11

|

11

|

11

|

11

|

11

|

3584

|

|

|

1536

|

3840

|

16

|

3840

|

14

|

14

|

3840

|

13

|

12

|

13

|

3840

|

12

|

12

|

12

|

12

|

3840

|

12

|

12

|

11

|

11

|

12

|

4352

|

|

|

1537

|

512

|

4352

|

17

|

5888

|

15

|

15

|

5888

|

13

|

13

|

13

|

4352

|

13

|

12

|

12

|

13

|

4864

|

12

|

12

|

11

|

11

|

12

|

4352

|

|

1538

|

4864

|

17

|

5888

|

15

|

15

|

5888

|

14

|

13

|

14

|

5376

|

13

|

12

|

12

|

13

|

4864

|

12

|

12

|

12

|

12

|

12

|

4864

|

|

|

1539

|

5376

|

17

|

5888

|

15

|

15

|

5888

|

14

|

13

|

14

|

5376

|

13

|

13

|

13

|

13

|

5888

|

13

|

12

|

12

|

12

|

13

|

5888

|

|

|

1540

|

5888

|

17

|

5888

|

15

|

15

|

5888

|

14

|

14

|

14

|

5888

|

13

|

13

|

13

|

13

|

5888

|

13

|

12

|

12

|

12

|

13

|

5888

|

|

|

1541

|

6400

|

18

|

7936

|

16

|

16

|

7936

|

15

|

14

|

15

|

7936

|

14

|

13

|

13

|

14

|

6912

|

13

|

13

|

12

|

13

|

13

|

6912

|

|

|

1542

|

6912

|

18

|

7936

|

16

|

16

|

7936

|

15

|

14

|

15

|

7936

|

14

|

13

|

13

|

14

|

6912

|

13

|

13

|

12

|

13

|

13

|

6912

|

|

|

1543

|

7424

|

18

|

7936

|

16

|

16

|

7936

|

15

|

14

|

15

|

7936

|

14

|

14

|

14

|

14

|

7936

|

13

|

13

|

13

|

13

|

13

|

7424

|

|

|

1544

|

7936

|

18

|

7936

|

16

|

16

|

7936

|

15

|

14

|

15

|

7936

|

14

|

14

|

14

|

14

|

7936

|

14

|

13

|

13

|

13

|

14

|

8448

|

|

|

1545

|

8448

|

|

|

17

|

17

|

12032

|

15

|

15

|

15

|

8960

|

15

|

14

|

14

|

15

|

9984

|

14

|

13

|

13

|

13

|

14

|

8448

|

|

|

1546

|

8960

|

|

|

17

|

17

|

12032

|

15

|

15

|

15

|

8960

|

15

|

14

|

14

|

15

|

9984

|

14

|

14

|

13

|

14

|

14

|

9472

|

|

|

1547

|

9472

|

|

|

17

|

17

|

12032

|

16

|

15

|

16

|

11008

|

15

|

14

|

14

|

15

|

9984

|

14

|

14

|

13

|

14

|

14

|

9472

|

|

|

1548

|

9984

|

|

|

17

|

17

|

12032

|

16

|

15

|

16

|

11008

|

15

|

14

|

14

|

15

|

9984

|

14

|

14

|

14

|

14

|

14

|

9984

|

|

|

1549

|

10496

|

|

|

17

|

17

|

12032

|

16

|

15

|

16

|

11008

|

15

|

15

|

15

|

15

|

12032

|

15

|

14

|

14

|

14

|

15

|

12032

|

|

|

1550

|

11008

|

|

|

17

|

17

|

12032

|

16

|

15

|

16

|

11008

|

15

|

15

|

15

|

15

|

12032

|

15

|

14

|

14

|

14

|

15

|

12032

|

|

|

1551

|

11520

|

|

|

17

|

17

|

12032

|

16

|

16

|

16

|

12032

|

15

|

15

|

15

|

15

|

12032

|

15

|

14

|

14

|

14

|

15

|

12032

|

|

|

1552

|

12032

|

|

|

17

|

17

|

12032

|

16

|

16

|

16

|

12032

|

15

|

15

|

15

|

15

|

12032

|

15

|

14

|

14

|

14

|

15

|

12032

|

|

|

1553

|

12544

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

15

|

15

|

16

|

14080

|

15

|

14

|

14

|

15

|

15

|

13056

|

|

|

1554

|

13056

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

15

|

15

|

16

|

14080

|

15

|

14

|

14

|

15

|

15

|

13056

|

|

|

1555

|

13568

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

15

|

15

|

16

|

14080

|

15

|

15

|

15

|

15

|

15

|

15104

|

|

|

1556

|

14080

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

15

|

15

|

16

|

14080

|

15

|

15

|

15

|

15

|

15

|

15104

|

|

|

1557

|

14592

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

16

|

16

|

16

|

16128

|

15

|

15

|

15

|

15

|

15

|

15104

|

|

|

1558

|

15104

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

16

|

16

|

16

|

16128

|

15

|

15

|

15

|

15

|

15

|

15104

|

|

|

1559

|

15616

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

16

|

16

|

16

|

16128

|

16

|

15

|

15

|

15

|

16

|

17152

|

|

|

1560

|

16128

|

|

|

18

|

18

|

16128

|

17

|

16

|

17

|

16128

|

16

|

16

|

16

|

16

|

16128

|

16

|

15

|

15

|

15

|

16

|

17152

|

|

|

1561

|

16640

|

|

|

|

|

|

17

|

17

|

17

|

18176

|

17

|

16

|

16

|

17

|

20224

|

16

|

15

|

15

|

15

|

16

|

17152

|

|

|

1562

|

17152

|

|

|

|

|

|

17

|

17

|

17

|

18176

|

17

|

16

|

16

|

17

|

20224

|

16

|

15

|

15

|

15

|

16

|

17152

|

|

|

1563

|

1024

|

18176

|

|

|

|

|

|

17

|

17

|

17

|

18176

|

17

|

16

|

16

|

17

|

20224

|

16

|

16

|

16

|

15

|

16

|

19200

|

|

1564

|

19200

|

|

|

|

|

|

18

|

17

|

18

|

22272

|

17

|

16

|

16

|

17

|

20224

|

16

|

16

|

16

|

15

|

16

|

19200

|

|

|

1565

|

20224

|

|

|

|

|

|

18

|

17

|

18

|

22272

|

17

|

16

|

16

|

17

|

20224

|

16

|

16

|

16

|

16

|

16

|

20224

|

|

|

1566

|

21248

|

|

|

|

|

|

18

|

17

|

18

|

22272

|

17

|

17

|

17

|

17

|

24320

|

17

|

16

|

16

|

16

|

17

|

24320

|

|

|

1567

|

22272

|

|

|

|

|

|

18

|

17

|

18

|

22272

|

17

|

17

|

17

|

17

|

24320

|

17

|

16

|

16

|

16

|

17

|

24320

|

|

|

1568

|

23296

|

|

|

|

|

|

18

|

18

|

18

|

24320

|

17

|

17

|

17

|

17

|

24320

|

17

|

16

|

16

|

16

|

17

|

24320

|

|

|

1569

|

24320

|

|

|

|

|

|

18

|

18

|

18

|

24320

|

17

|

17

|

17

|

17

|

24320

|

17

|

16

|

16

|

16

|

17

|

24320

|

|

|

1570

|

25344

|

|

|

|

|

|

|

|

|

|

18

|

17

|

17

|

18

|

28416

|

17

|

17

|

16

|

16

|

17

|

26368

|

|

|

1571

|

26368

|

|

|

|

|

|

|

|

|

|

18

|

17

|

17

|

18

|

28416

|

17

|

17

|

16

|

16

|

17

|

26368

|

|

|

1572

|

27392

|

|

|

|

|

|

|

|

|

|

18

|

17

|

17

|

18

|

28416

|

17

|

17

|

17

|

16

|

17

|

28416

|

|

|

1573

|

28416

|

|

|

|

|

|

|

|

|

|

18

|

17

|

17

|

18

|

28416

|

17

|

17

|

17

|

16

|

17

|

28416

|

|

|

1574

|

29440

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

18

|

32512

|

17

|

17

|

17

|

17

|

17

|

30464

|

|

|

1575

|

30464

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

18

|

32512

|

17

|

17

|

17

|

17

|

17

|

30464

|

|

|

1576

|

31488

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

18

|

32512

|

18

|

17

|

17

|

17

|

18

|

34560

|

|

|

1577

|

32512

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

18

|

32512

|

18

|

17

|

17

|

17

|

18

|

34560

|

|

|

1578

|

2048

|

34560

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18

|

17

|

17

|

17

|

18

|

34560

|

|

1579

|

36608

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18

|

18

|

17

|

17

|

18

|

36608

|

|

|

1580

|

38656

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

17

|

18

|

38656

|

|

|

1581

|

40704

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18

|

18

|

18

|

18

|

18

|

40704

|

|

2.5.4 Memory upgrades

Memory upgrades can be ordered and enabled by LIC, upgrading the DIMM cards, adding DIMM cards, or adding a CPC drawer.

For a model upgrade that results in the addition of a CPC drawer, the minimum memory increment is added to the system. Each CPC drawer has a minimum physical memory size of 480 GB.

During a model upgrade, adding a CPC drawer is a concurrent operation. Adding physical memory to the added drawer is also concurrent. If all or part of the added memory is enabled for use, it might become available to an active LPAR if the partition includes defined reserved storage. (For more information, see 3.7.3, “Reserved storage” on page 141.) Alternatively, the added memory can be used by a defined LPAR that is activated after the memory is added.

|

Note: Memory downgrades within a z15 are not supported. Feature downgrades (removal of a CPC quantity feature) are not supported.

|

2.5.5 Drawer replacement and memory

With Enhanced Drawer Availability (EDA), which is supported for z15, sufficient resources must be available to accommodate resources that are rendered unavailable when a CPC drawer is removed for upgrade or repair. For more information, see 2.7.1, “Redundant I/O interconnect” on page 70.

Removing a CPC drawer often results in removing active memory. With the flexible memory option, removing the affected memory and reallocating its use elsewhere in the system is possible. For more information, see 2.5.7, “Flexible Memory Option”. This process requires more available memory to compensate for the memory that is lost with the removal of the drawer.

2.5.6 Virtual Flash Memory

IBM Virtual Flash Memory (VFM) FC 0643 replaces the Flash Express features (0402 and 0403) that were available on the IBM z13s. It offers up to 6.0 TB of virtual flash memory in 512 GB (0.5 TB) increments for improved application availability and to handle paging workload spikes.

No application changes are required to change from IBM Flash Express to VFM. Consider the following points:

•Dialed memory + VFM = total hardware plugged

•Dialed memory + VFM + Flex memory option = total hardware plugged

•VFM is offered in 0.5 TB increment size; VFM for z15 is FC 0643 - Min=0, Max=12

VFM is designed to help improve availability and handling of paging workload spikes when z/OS V2.1, V2.2, V2.3, or V2.4 is run. With this support, z/OS is designed to help improve system availability and responsiveness by using VFM across transitional workload events, such as market openings and diagnostic data collection. z/OS is also designed to help improve processor performance by supporting middleware use of pageable large (1 MB) pages.

VFM can also be used by coupling facility images to provide extended capacity and availability for workloads that are use IBM WebSphere MQ Shared Queues structures. The use of VFM can improve availability by reducing latency from paging delays that can occur at the start of the workday or during other transitional periods. It is also designed to help eliminate delays that can occur when collecting diagnostic data.

VFM can help organizations meet their most demanding service level agreements and compete more effectively. VFM is easy to configure in the LPAR Image Profile and provides rapid time to value.

2.5.7 Flexible Memory Option

With the Flexible Memory Option, more physical memory is supplied to support the activation of the actual purchased memory entitlement in a single CPC drawer that is out of service during activation (POR), or in a scheduled concurrent drawer upgrade (memory add) or drawer maintenance (n+1 repair) with the use of enhanced drawer availability.

When you order memory, you can request extra flexible memory. The extra physical memory, if required, is calculated by the configuration and priced accordingly.

The hardware required is pre-plugged based on a target capacity specified by the customer. This pre-plugged hardware is enabled by using an LICCC order that is placed by the customer when they determine more memory capacity is needed.

The flexible memory sizes that are available for the z15 are listed in Table 2-9.

Table 2-9 Flexible memory offering

|

Feature Code

|

Increment

|

Minimum

|

Maximum

|

|

1951

|

32GB Flex Memory

|

0

|

250

|

|

1952

|

64GB Flex Memory

|

0

|

250

|

|

1953

|

256GB Flex Memory

|

0

|

250

|

|

1954

|

64GB Virtual Flash Memory Flex Memory

|

0

|

1

|

2.6 Reliability, availability, and serviceability

IBM Z servers continue to deliver enterprise class RAS with IBM z15. The main philosophy behind RAS is about preventing or tolerating (masking) outages. It is also about providing the necessary instrumentation (in hardware, LIC and microcode, and software) to capture or collect the relevant failure information to help identify an issue without requiring a reproduction of the event. These outages can be planned or unplanned. Planned and unplanned outages can include the following situations (examples are not related to the RAS features of IBM Z servers):

•A planned outage because of the addition of physical processor capacity or memory

•A planned outage because of the addition of I/O cards

•An unplanned outage because of a failure of a power supply