![]()

Getting a 3D Printer

The 3D printing world is rapidly expanding with new printer vendors, models, and features being added almost daily. This is especially true given how fast printer designs change. Part of this is because there is a very large (also growing) community of developers, engineers, artists, and laymen who are building, contributing, or providing ideas for new features. Knowing when to jump in or even how to jump in can be a challenge.

That is, how do you know which printer to buy, or even whether one printer design is a better choice than another? Even if you already have a 3D printer, chances are you will either discover features you would like to have or eventually decide you need a different model with certain features. For example, if you have been printing with PLA and discover you need to print with ABS; your existing PLA-optimized printer may not have either a heated print bed or a sealed heated build chamber (required for high-quality ABS printing).

Sometimes when you reach a stage of wanting or needing a certain feature, you can upgrade your existing printer, but this depends entirely on the platform (hardware design). For example, adding a heated build platform to a RepRap variant is very easy, but adding a heated build platform to a commercial, prebuilt printer may require specialized parts or even additional external electronics. It may also void your warranty!

Whether you are looking to buy your first 3D printer or looking to move on to a newer model with more features, this chapter will guide you in the right direction. I will discuss the options for getting a 3D printer (including some specific hardware designs) and present advice on whether to buy or build a printer. I will also present some advice for those considering building their own printer. Let’s get started with a discussion of the options for getting a 3D printer.

Classes of 3D Printers

Unlike conventional ink-on-paper printers, there are few 3D printers that have become available in retail stores. While there are some available from major retail chains such as Microsoft (MakerBot) and Staples (Cube), you won’t find a 3D printer at your local big-box home electronics store (but you may soon).

So where do you go to find a 3D printer if not in a store1? Why, the Internet of course! A quick Google search for “3D printer” will result in many different printers—from ones that resemble a mash-up of random parts, to the loveable animated sanitation robot Wall-E, to early versions of the replicators on Star Trek. But how do you know which one is right for you?

I will answer these questions by first discussing the options available. I have classified the various 3D printers and vendors into three categories. While there are certainly other options available (like inventing your own 3D printer, as well as other types of 3D printers, like a UV-cured resin printer), the vast majority of the FFF printers fall into one of these categories. I describe each of these in more detail in the following sections.

- Professional grade: Closed source options with advanced features and paid support

- Consumer grade: Commercial offerings available as a kit or preassembled

- Hobbyist grade: Pure open source designs for DIY enthusiasts

PROSUMER, PROFESSIONAL, OR INDUSTRIAL?

I use the label professional grade to describe a range of printers that are purpose-built, require little setup, and are backed by warranties and accessible technical support. However, some may disagree with this label because there are other printers of even greater sophistication that are designed for use in industrial design and manufacturing. That is, what I call professional grade is too broad and blurs the line between what is available to the consumer and what must be purchased through industry channels.2

Thus, some people would say the top consumer 3D printers are “prosumer”—meaning they are meant for consumers who need higher-grade printers than, say, a hobbyist or home user. However, since this book is written for 3D printer enthusiasts who may range from novices to professionals, I feel the professional-grade label is fitting.

To complete the discussion on the range of printers available, I refer to the level above professional grade as industrial grade because the price, features, and sophistication of these printers are targeted at industries.

A case in point is the new Z18 printer from MakerBot. The features, size, and price of this printer exceed the budget of all but the most fortunate. Few 3D printing enthusiasts would need all of the capabilities of this new printer. With the Z18, MakerBot is entering the world of its parent company by offering an industrial-grade option in its portfolio of excellent 3D printers.

The first category contains those vendors who offer 3D printers that have been manufactured for commercial sale to consumers. That is, they offer printers of their own design with mass-produced parts (from minor parts to the entire unit) that arrive with a warranty and support options. Such vendors have elaborate, professional web sites where you can not only buy their products, but also purchase parts and even get help using the products.

While these qualities may (and often do) apply to other 3D printer options, these printers are typically built with a higher level of quality and precision. Vendors typically do not offer a full parts catalog; rather, they typically offer only those parts that are considered wear-and-maintenance items. As you can expect, they are typically more expensive. What you get for the extra cost is directly reflected in the quality and ease of use of the product.

For example, a professional-grade 3D printer normally does not need much in the way of setup and configuration. You won’t eagerly unbox your new purchase and find “some assembly required” stamped on the inner packaging. In fact, some printers arrive so well packed that it takes longer to get it out of the box than it does to get it to print!

That doesn’t mean commercial printers are ready-to-print out of the box. You can assume any printer you buy will require some amount of setup to use it the first time. You can also expect to have to adjust the printer periodically.

WHAT IS READY-TO-PRINT?

Some vendors market their printers as “just click print”—meaning the printer requires little or no setup once it is unboxed. There has been mixed success with these claims. This is because a 3D printer is a very specialized machine that requires a great deal of precision to print properly. However, the setup is typically much less than one you’ve assembled yourself. Even the MakerBot Replicator 2, arguably one of the best professional-grade offerings, requires no more than about 10 to 15 minutes to set up. I think we are a year or so away from having offerings that can truly print right out of the box without any calibration or setup procedure.

The “higher quality” that I mentioned refers to how well the printer is constructed rather than how well it prints, but in general the two go hand in hand. Despite being well made, some professional-grade printers are more finicky to get good quality prints than others. That doesn’t mean you won’t get a good quality print. Rather, it means you may need to spend some time to properly adjust or calibrate the printer in order to get a good quality print. Unfortunately, you may not always find this information without experiencing it yourself.

Before buying a printer, I recommend searching for reviews first. You do this with everything you buy online, right? When you read a review, pay attention to the relative experience of the reviewer. If the reviewer is a professional and has experience with 3D printers, her outlook on what is easy to set up will be quite different than someone who knows little about 3D printing. I have read and dismissed a few negative reviews by inexperienced reviewers because I recognized the skipped step (or more) in setting up their printers.

It is also a good idea to visit the vendor’s web site and carefully examine the manuals, paying attention to the procedure for unboxing and setting up the printer. If the manual discusses a lengthy setup procedure, you may want to spend extra time going over it carefully.

In general,3 you will find a commercial 3D printer to be a rewarding buying and owning experience. They do cost more, but the higher cost may be worth considering if you need to get started printing objects quickly. Whether for your organization or for personal enjoyment, a professional-grade 3D printer is by far your best investment.

Vendors

There are several vendors who offer professional-grade 3D printers. Table 2-1 lists some of the more popular choices, along with some specifics about their services and products. Before buying a professional-grade 3D printer, I recommend visiting each of these vendors and reading the product descriptions thoroughly. You should also check out the support portal for the type of information the vendor makes available to customers. I think you will find that there is a lot more information than you expect.

Table 2-1. Commercial 3D Printer Vendors

![]() Tip You can find complete reviews and more about each of these vendors in Make: Ultimate Guide to 3D Printing (Maker Media, 2012). Despite the name, it is a condensed overview of 3D printing technologies and vendors, and reviews of popular 3D printers. But you won’t find much about DIY kits or RepRap. For that, read on!

Tip You can find complete reviews and more about each of these vendors in Make: Ultimate Guide to 3D Printing (Maker Media, 2012). Despite the name, it is a condensed overview of 3D printing technologies and vendors, and reviews of popular 3D printers. But you won’t find much about DIY kits or RepRap. For that, read on!

Vendor Spotlight

Rather than describing each of the printers in Table 2-1, I will spotlight one of the printers from MakerBot. Arguably the top dog in professional-grade 3D printers, the MakerBot Replicator Desktop 3D Printer and its predecessors have consistently won “best of” categories when compared to other 3D printers. Figure 2-1 shows the latest MakerBot Replicator Desktop 3D Printer.

Figure 2-1. The MakerBot Replicator Desktop 3D Printer (Fifth Generation)

This new model is a step-wise improvement over the previous model. It offers more features, including an onboard camera, network-capable printing, a graphical LCD panel, easier to access mechanicals, and more. It also features a build platform that extends for easier removal of prints. In typical MakerBot fashion, they’ve taken a superb printer and kicked it up a notch with more features, while retaining print-quality superiority.

MakerBot launched a lower-priced entry-level printer, the MakerBot Replicator Mini. It has a smaller build volume but incorporates many of the newer features. MakerBot also has a larger form-factor model, the MakerBot Replicator Z18. It has a huge build volume (and a price tag to match). Clearly, the larger model is aimed at the growing application of 3D printing in manufacturing and engineering.

While the new models are sure to become as popular as the previous models, fortunately, much of the knowledge in this book is applicable to the new versions, with minor differences in mechanical procedures only. For example, the extruder is mounted differently but the need to clean the drive gear and how to do that is the same. The current models—the Replicator 2 and Replicator 2X—are the MakerBot 3D printers that I will use to demonstrate when I discuss troubleshooting and maintenance. Figure 2-2 shows the MakerBot Replicator 2.

Figure 2-2. MakerBot Replicator 2

In summary, professional-grade 3D printers are a wise choice for those seeking a product that they can use without any assembly or lengthy configuration. Professional-grade 3D printers also provide ample documentation and software for using the printer, are covered by a warranty, and vendors offer access (paid or free) to experienced technical support personnel.

The next category contains those 3D printers that are available as partial kits (some parts preassembled), full kits (requires you to do all of the assembly work), or fully assembled. They aren’t full, professional offerings since vendors typically don’t offer the same level of services and support (although some come close).

This category is also larger than the professional-grade 3D printer category. One reason for this is that many of these vendors either gather their components from suppliers and assemble the kits for you (while offering an assembly option) or are smaller organizations that do not yet have the capital to implement and produce their own designs. That doesn’t mean these aren’t excellent choices! In fact, many of the printers that fall into this category are considered on par with professional-grade 3D printers, having the same print quality and attention to detail in their components.

So don’t be tempted to think an assembled option of one of these 3D printers is something you must settle for if your budget doesn’t permit a more expensive professional-grade 3D printer. Furthermore, some of the printers in this category are priced competitively with some of the printers in the professional-grade category. However, it is the kit format that permits vendors in this category to offer some of their 3D printers at lower prices.

If you purchase a 3D printer that comes as a kit, you can expect it to be fairly easy to assemble, requiring a small number of tools and a moderate level of skill. These printers aren’t quite as simple as assembling a tricycle, but can sometimes require the same level of patience required for assembling furniture from Scandinavia.4 The time it takes to assemble varies, but in general you can expect assembly to vary from a few hours to an afternoon or three. Of course, your own skills, patience, and time constraints will play a factor in how long it takes you to assemble the kit. I like to double the vendor’s estimate, and then add 50% more for those “oh, drat” moments.

One of the motivations for requiring the buyer to assemble part of the components is to reduce shipping cost. A portion of the shipping cost is calculated by weight, but it is also based on the size of the box. The smaller the box, the cheaper it is to ship (well, sort of). One extreme case of this is the Printrbot Simple. In kit form, it packs down to a box that is surprisingly small. While the assembled printer itself is small, the shipping box is quite a bit smaller yet. Shipping a product partially assembled also reduces the need for sophisticated packaging, and therefore reduces the risk of being damaged during shipment.

THE EFFECT OF SIZE ON SHIPPING COSTS

I once shipped a guitar to someone, and despite it weighing no more than about 20 pounds, the size of the box made it many times more expensive than if I had shipped a 20-pound lead weight in a shoe box!

Another reason the kit form is cheaper is because it saves the cost of labor required for an assembly line. This is likely to be the case for small (and growing) companies. The kit form therefore offers you a price break in exchange for a few hours of your time.

So what do 3D printers in this category have in common besides the fact that they require some assembly? As you may surmise, it has to do with how the product is offered and the level of support available. Some vendors offer the same level of services as professional-grade vendors, but more often, vendors in this category have limited support on their web sites and either do not offer any paid support or do not offer any phone support. While this may not be an issue for some, if you are concerned about getting help with your printer, you may want to examine a vendor’s web site carefully, and before buying one of their 3D printers, ask them if they provide any level of support.

Another aspect of 3D printers in this category is the material used in construction. While most use commodity components (e.g., stepper motors, bolts, etc.), the material used for the major frame components can range from laser-cut wooden platforms, like the Printrbot line of printers, to the professionally manufactured components found in the SeeMeCNC Delta printers.

None of this should affect or prevent you from buying a consumer-grade 3D printer. If you have some mechanical and electronics skills, as well as the desire to tinker, and you don’t mind having to spend a little time putting the printer together yourself, you can save some money and have some fun at the same time!

Vendors

There are simply too many 3D printer vendors in this category to form any reasonable coverage. Rather than attempt to describe all of the available options (and fail), in Table 2-2 I include a list of some of the more widely known vendors, along with a summary of their products and services. All of these vendors offer assembly of their 3D printer kits for a fee.

Table 2-2. Assembly-Required 3D Printer Vendors

Vendor Spotlight

Since the assembly requirements and type of components used in this category can be quite diverse, I will spotlight two extremes. The first is a simple kit made from laser-cut plywood that can be assembled with a small set of tools—those found in a typical kitchen junk/fix-it drawer. The other is an example of a high-quality printer that requires more skill and time to assemble.

Let’s start by examining a printer from Printrbot. Printrbot offers a complete range of 3D printers that are sure to meet the needs of enthusiasts and professionals alike (see printrbot.com for more details). Figure 2-2 shows the Printrbot Simple.

Figure 2-3. Printrbot Simple (courtesy of printrbot.com)

The Printrbot Simple is a very special DIY kit. It was conceived as an inexpensive, entry-level 3D printer. It is a minimalist’s machine—with as few moving parts as possible, while still retaining many of the features of larger, more complex, and more expensive 3D printers. One of the side effects of being a minimalist’s design is the build volume is rather small at approximately 4"×4"×4".

The Printrbot Simple uses a unique Y-axis arm that doubles as a gantry for the Z axis. Thus, the entire Y axis is raised up and down. The print bed moves left-to-right for the X axis. It also uses a peculiar string-and-drum mechanism to move the X and Y axes. A traditional threaded rod is used for the Z axis.

Another interesting feature of the Printrbot Simple is that it is open source. That means you can find the designs on the vendor’s web site and make any part of the frame and related parts yourself. As such, it uses only commodity hardware that is readily available (you don’t have to buy specially made parts from the vendor). About the only thing on the printer that you would have to buy from Printrbot is the electronics board, the hot end, and the extruder. Interestingly, the electronics board is open source, so other electronics boards can be used—you aren’t tied to using the Printrboard.

The next examples from SeeMeCNC are delta printers (http://reprap.org/wiki/Rostock). Their Rostock Max line of 3D printers is sold in kit form and their higher-end fast-printing Orion Delta 3D printer is sold preassembled. The major components of all of their 3D printers are a combination of laser-cut melamine and extruded aluminum. The build volume is about average but can typically print objects taller than other printers can due to the vertical configuration of the delta mechanism. Figure 2-4 shows the Orion 3D printer from SeeMeCNC.

Figure 2-4. SeeMeCNC’s Orion Delta printer (courtesy of seemecnc.com)

Aside from the fact that they look odd, they are fully featured 3D printers. They have LCD panels and a heated print bed, and the quick-release extruder makes maintenance a breeze. The delta mechanism allows the Orion printer to achieve higher speeds than most 3D printers, while also achieving a very high resolution.

If you are looking for a fast, accurate 3D printer that can print tall objects, you should consider the SeeMeCNC delta printers. I should note that SeeMeCNC offers more than printer kits for sale. Indeed, SeeMeCNC offers many high-quality parts for RepRap and similar 3D printers, as well as filament. SeeMeCNC is one of the best examples of this category because they offer a full portfolio of products, making them a one-stop shopping experience. I have used a number of their RepRap components myself with great satisfaction.

WHAT IS A DELTA PRINTER?

A delta printer is a special design that uses three vertical tracks or rods to control each of the axes. Each axis is moved up and down in its tracks (or on the rods) using a special link that ties the axis to a print head. The print head is moved by a combination of the movement of all three axes. Needless to say, delta printers look quite different from most 3D printers.

In summary, consumer-grade 3D printers are a good option for those who want or can handle a 3D printer that requires some assembly, for those who don’t mind working on the printer, and for those who don’t need technical support (free or otherwise). These 3D printers are a mix of customized designs with some open source derivations. The quality of the printers ranges from a bit below (but still considered good) to comparable with professional-grade 3D printers. They are sometimes cheaper than professional-grade 3D printers and parts are more readily available. Some vendors offer warranties, but those that do, have shorter warranty periods than professional-grade vendors. Lastly, consumer-grade 3D printers require more time and skill to operate and maintain.

The vendors in this category offer 3D printers that are implementations of one or more RepRap designs. They are open source and almost entirely DIY. That is, the printers are in kit form, requiring assembly from scratch. As a result, they are not designed for those who want to open the box and start printing. This is one of the tenets or perhaps rules of the RepRap world—you are expected to have the technical skills to put it together. Those with less skill can assemble some kits, but most kits require some mechanical skills, soldering, and a zeal for tinkering.

If you do not have these skills and you don’t want to learn them, or if you don’t have the time to devote to assembling your own 3D printer, you may want to consider a consumer-grade printer kit or an assembled 3D printer. You should also consider the fact that RepRap 3D printers require a fair bit of maintenance and tinkering to get working well. Thus, you may still need to repair and maintain it.5 If this isn’t for you, you may want to consider a professional-grade 3D printer.

Most of the vendors in this category do not offer much in the way of services, but most at least make their manuals and assembly guides available for download. While a few offer phone support, most will answer your questions via e-mail within a day or so.

REPRAP FAMILY TREE

There have been a number of variants of the RepRap 3D printer movement since its inception in 2005. If you would like to know more about the RepRap project, and especially the timeline for when certain variants came to be or were updated (like the Prusa Mendel), you can visit http://reprap.org/wiki/RepRap_Family_Tree for a chronological map of designs.

The main reason for this is that the vendors are striving to make RepRap printers more widely available. They’ve done all of the hard work for you by sourcing the various parts and ensuring that the parts will work together. Consequently, most vendors will allow you to pick and choose options when ordering their kits.

For example, if you decide to use a different electronics board, you can usually specify that when you order the kit. Similarly, you can often find kits that have part of the components omitted, permitting you to buy only what you need. I find this very convenient because it allows me to upgrade a RepRap printer from one iteration to another, reusing the motors, electronics, and extruder. If you are thinking about getting another printer because your old one is a bit dated or it doesn’t have some of the latest features, look for vendors that offer partial kits so that you can save some money and get a new printer in the bargain.

![]() Tip If you go with the partial kit to upgrade you printer, you can often recover a portion of the cost by selling your old parts.

Tip If you go with the partial kit to upgrade you printer, you can often recover a portion of the cost by selling your old parts.

You can find RepRap vendors—such as MakerFarm (makerfarm.com) or NextDayRepRap (nextdayreprap.co.uk)—that offer printers in kit form, as well as a vast array of parts and options to keep even the most enthusiastic tinkerers among us happy. You can also find vendors that offer assembled or partially assembled RepRap printers, such as IC3D Printers (www.ic3dprinters.com).6

The RepRap designs are considered to be the largest segment of the 3D printer market. Whether this is true or not (I cannot substantiate or refute), it is easy to see why some would consider this to be true. That is, the Internet is chock full of blogs, articles, forums, and wikis dedicated to discussing and promoting RepRap printers.

You can see this trend on a popular online auction site. Searching for RepRap generates thousands of hits, whereas searching for Ultimaker, MakerBot, Printrbot, and other commercial printers generates only a few hundred hits each. That doesn’t necessarily mean RepRaps are everywhere, but it is a good indication that the RepRap world is alive and prospering.

In fact, one survey7 of 3D printer owners—both commercial and consumer—suggests that the RepRap community is the largest segment of the 3D printing universe. Figure 2-5 shows a pie chart from this survey. Clearly, RepRap holds a large percentage of the market share.

Figure 2-5. Survey of 3D printer owners (courtesy of Stephen Murphey, http://stephenmurphey.com)

This rising popularity has a downside. RepRap designs are rapidly evolving. New features, designs, redesigns, and even revolutionary designs appear almost daily.8 Part of this is due to how much data there is available for anyone wanting to build a RepRap printer. However, they are popular for a more profound reason: RepRap printers are open source.

The hardware and software is freely shared under various open source licenses. For example, you can freely download, print, and build any variant of a RepRap printer you wish. You can also modify the various printer components, provided you share them with others.

![]() Note Never modify and attempt to sell a component unless you have verified with the owner that the license governing the component permits you to do so. To do otherwise isn’t playing nice in open source land and could get you flamed (at the very least) or result in legal action.

Note Never modify and attempt to sell a component unless you have verified with the owner that the license governing the component permits you to do so. To do otherwise isn’t playing nice in open source land and could get you flamed (at the very least) or result in legal action.

If you are wondering why I keep saying “RepRap variant,” it is because RepRap designs have changed rapidly over a relatively short time. In fact, there are over a dozen evolutionary (and some not so evolutionary) designs to choose from—and that’s limiting your choices to popular designs. If you include all of the minor variants and abandoned designs, it probably totals several dozen.

For the purposes of this book, and to try to keep as current as possible and avoid killing every tree in the Northern hemisphere,9 let us consider only the RepRap variants based on Josef Prusa’s designs (http://josefprusa.cz/). They represent the largest and most popular RepRap designs.

Consequently, the designs are a family of RepRap printers called simply Prusa or Prusa Mendel. The latest iteration of the Prusa design is named iteration 3, meaning it is the third version of Prusa’s original Mendel design. However, since the iteration 2 is still very much in demand (I have several myself) and parts are readily available—more so than the Prusa iteration 3, I will include both iteration 2 and iteration 3 design details in the following sections.

Prusa Mendel i2

The Prusa Mendel iteration 2, hence Prusa i2, is most notable for its triangular frame assembled from threaded rods bolted to printed plastic components. Figure 2-2 shows a highly modified Prusa i2 printer. It has one motor for each X and Y axis, and two motors mounted on top of the frame for the Z axis. The X and Y axes are moved using toothed belts, and the Z axis by two 8mm or 5/16-inch threaded rods.

As you can see in Figure 2-2, there are a number of printed parts. In the base version (without all of the modifications), there are over 36 parts. If you plan on printing a set of plastic parts using your existing (or a friend’s) printer, it is likely it will take a while. Some of the parts are quite large and each could take several hours to print.

The frame itself is very sturdy, and despite all of the plastic, it does not wiggle, shake, or bounce around on the table. Some people have cited breakage or loose joints, but careful inspection and preventive maintenance can help you avoid those rare cases.

MY PRUSA I2 IS A GRANDPARENT— IS YOURS?

There is a certain satisfaction one gets when the last part of a new Prusa 3D printer has finished printing. This is amplified when you pass on the plastic kit to a friend or start your own build. In this way, you are demonstrating the original intent of the RepRap—to self-replicate. Thus, the printer you build using a set of printed parts is called the child and the original printer is the parent. Using this terminology means one of my Prusa i2 printers is a grandparent. I used its child to print a Prusa i3.

Most Prusa i2 kits are complete printers, but lack some of the nice-to-have or advanced features. What that means is that it has all of the basic components for you to assemble and start printing. Most even come with heated print beds and high-temperature hot ends. What most kits lack most are adjustable build platforms, belt tensioners, and a fine-adjustment Z endstop. I would consider all of these features essential for sustaining good-quality prints (nearly) every print.

Figure 2-6. A Prusa i2

MY PRUSA I2 MODIFICATIONS

The Prusa i2 in Figure 2-6 includes the following modifications. I describe many of these in later chapters.

- Adjustable feet for keeping the printer stable on uneven surfaces

- Adjustable print bed

- Fine-adjustment Z-height (endstop)

- LED light

- Filament filter/cleaner

- Nozzle fan

- Y-belt tensioner

- Relocated RAMPS (electronics)

- Onboard power supply (most are external like a ball and chain)

- LCD panel with SD card reader

- Spool holder

Many of these modifications improve print quality, but some (like the onboard power supply and filament holder) are designed to make the printer self-contained. This allows you to move the printer more easily and makes it easier to maintain since you don’t have to disconnect a bunch of things to move it.

The Prusa i2 improved greatly on previous designs by providing a more stable Y and Z axis, as well as far more freely moving axes due to the use of linear bearings. The bearings alone improved the quality over the previous version. But the Prusa i2 is not without its drawbacks.

One of the drawbacks of this design is the use of threaded rods for the Z axis. If your threaded rods are not perfectly straight and wound correctly, and both ends of the Z axis are bolted or fixed to the frame, you may experience Z wobble, which manifests as slightly offset layers. If you are fortunate, the offsets are very minor, and noticeable only upon close inspection. However, perusing the various things on Thingiverse will reveal the norm to be more noticeable. There are a number of treatments for Z wobble, but the best way to eliminate it is to use flexible shaft couplers that permit either the motor or the rods to move slightly, such as a flexible shaft coupler or stepper motor mounts that permit the motor to move freely horizontally. For an excellent in-depth analysis of Z wobble, see the article by Richard Cameron titled “Taxonomy of Z Axis Artifacts in Extrusion-Based 3d Printing” in RepRap Magazine (http://reprapmagazine.com/issues/1/index.html).

While it may seem like the Prusa i2 isn’t a good choice, that isn’t exactly true. Given how long this variant has been around (longer than most), there are a great number of upgrades and options you can install. Aside from those mentioned in the preceding sidebar, other examples include tool holders, accessory drawers, and dual extruders. If you want to build your own printer, and you enjoy tinkering and refining, the Prusa i2 may be a good choice.

Prusa i3

The Prusa iteration 3, hence Prusa i3, is most notable for its fewer and smaller plastic parts and a distinctive frame. There are three different frame designs for the Prusa i3. You can opt for a single-sheet aluminum frame (“single sheet” as in cut from a single sheet), wood or composite braced frame, and a boxed frame. The boxed frame is become less used and it is rare to see it as a kit.

![]() Note Some vendors refer to the braced wood or composite frame as the “boxed” version, but that is not correct. The distinction is important because the plastic parts for the Z axis are slightly different. Be sure to check if you are buying your plastic parts separately.

Note Some vendors refer to the braced wood or composite frame as the “boxed” version, but that is not correct. The distinction is important because the plastic parts for the Z axis are slightly different. Be sure to check if you are buying your plastic parts separately.

The new frame design accomplishes another important function. It improves access to the print bed. I find working with parts on the Prusa i3 to be much easier than the Prusa i2. For example, when I have a part that is stuck really well to the print bed (perhaps stuck too well), on the Prusa i3 I am free to attack the part from multiple angles, whereas on the Prusa i2 the frame can sometimes get in the way.

No matter which frame material/version you choose, the design includes a compact horizontal sub frame made from several threaded rods. These rods are shorter, and the ones that run parallel with the Y-axis smooth rods are larger in diameter. Once bolted together, it makes for a very strong platform. Figure 2-7 shows a modified Prusa i3 3D printer.

Figure 2-7. A Prusa i3, single-sheet aluminum frame

Like the Prusa i2 example, this Prusa i3 has many of the same features—onboard power supply, adjustable Z-height, adjustable print bed, filament filter/cleaner, and more.

Perhaps the most significant improvement over the Prusa i2 is the use of smaller-diameter threaded rods for the Z axis. Unlike the Prusa i2, where the stepper motors are mounted on top, the Prusa i3 Z-axis stepper motors are mounted on the bottom with the threaded rods mounted to the stepper motor side only.

Since the Prusa i3 is a fairly new design, there hasn’t been as much stabilization on revisions to the printed parts. Many people use Prusa’s original designs (as shown in Figure 2-7), but others use a slightly different design. The main difference is how the X axis mounts to the Z-axis rods. The original Prusa design mounts the rods behind the X-axis mounts, whereas recent revisions mount them in front of the X-axis mounts. Another difference concerns the addition or omission of belt tensioners (and how they work). Lastly, the designs differ on how the extruder mounts to the X axis. Most use a Greg’s Wade extruder (also shown in Figure 2-7), whereas newer revisions use either a modified Greg’s Wade extruder or a version of a compact extruder. Again, be sure you know which plastic kit you are buying if you are not buying a full kit.

Vendors

The vendors in this category offer more than just kits. They often include a full range of parts, and even filament choices. After all, many of the vendors are people who have turned their passion and hobby into a business designed to support others with the same passions. Table 2-3 lists some of the more popular RepRap 3D printer vendors.

Table 2-3. RepRap 3D Printer Vendors

![]() Tip The NextDayRepRap site contains one of the richest repositories for help on RepRap printers. If you own or plan to build a RepRap, you should consider this site a valuable resource.

Tip The NextDayRepRap site contains one of the richest repositories for help on RepRap printers. If you own or plan to build a RepRap, you should consider this site a valuable resource.

Vendor Spotlight

RepRap 3D printer vendors are more plentiful than the other categories. Some offer kits and a few of the parts needed. Others offer only parts and no kits. In fact, it can be a challenge to find a single vendor that has all of the components you need to put together your own kit. One notable exception (among the several listed) is MakerFarm, which is a one-stop shopping site for those who want either a kit or to buy all of the components for their own kit.

They offer two Prusa i3 kits—a normal-size 6" build plate and a larger 8" build plate. Their kits are unique wood laser-cut frames. In fact, the printer doesn’t use the normal Prusa i3 printed parts. Indeed, only the extruder and extruder gears are printed plastic. Figure 2-8 shows an 8" MakerFarm Prusa i3 3D printer.

Figure 2-8. A Prusa i3, wooden frame (courtesy of makerfarm.com)

MakerFarm has taken the same tactic as Printrbot with using wood for all of the major components. All of the mounting points for the stepper motors, the Y axis, and even the X-axis mounts are wood. This makes assembly of the kit much quicker than a kit like the one used to build the printer in Figure 2-7.

The kits still retain the Prusa i3 design, but are priced a bit lower than an aluminum single-sheet frame version. The absence of the plastic parts, fewer threaded rods, and the wood frame components contribute to this price break. This makes choosing a MakerFarm kit a good choice for those who want to build their own 3D printer but may not have the skills or time needed for a more complex kit.

In summary, RepRap printers are pure and simply DIY. The vendors that support RepRap 3D printers typically offer kits or parts only, and little or no online technical support. Most provide excellent documentation for their kits, but seldom include any help for assembly. Did I mention that they’re DIY?

A RepRap kit is a good choice for someone who wants to learn how a 3D printer works and those who want to tinker. Due to the lower cost of the kits, a RepRap kit can be a good way for someone to enter the 3D printing world, but success or failure lies in the hands of the buyer. You can find a lot of help on the Internet, including the RepRap wiki (reprap.org), but you should not expect to be able to pick up the phone and ask your vendor for help. Did I mention it’s DIY only?

Now that we’ve had a merry jaunt down DIY lane, let’s go a bit further and discuss how you can go about putting together your own RepRap 3D printer from scratch.

Sourcing Your Own Printer Kit

If you are reading this, then you are considering building your own 3D printer from scratch. This option is for those of us who enjoy a challenge.10 Instead of buying a kit of matched or at least compatible components, you will need to spend the necessary research time to discover sources for each of the components needed. This often means buying pieces and parts from multiple vendors.

The biggest benefit of doing it this way is that you can end up saving a bit more money than if you bought a complete DIY kit. Of course, you will also gain considerable knowledge about the components and how they fit together. This is because, unlike the DIY kit, you will have to ensure that you are buying parts that can work with other parts. However, there is the risk of incurring unforeseen costs if you do not plan your build carefully. More specifically, if you make multiple orders of parts, you could incur more shipping costs than if you purchased a complete kit. Furthermore, if you purchase incompatible (or the wrong) parts, you could end up with more parts than you need and thus have paid more in the long run.11

Another advantage of this option is that it allows you to pick and choose the best components for your new printer. Most DIY kits come with whatever the vendor decides to include, and you do not normally have a choice of manufacturers or even which extruder or hot end is used. The sky is the limit as to what you can achieve with proper planning and a well-thought-out source list.

Make a Plan

Like all successful endeavors, you need to make a plan for how you will gather your components. Begin by making a list of the major components of a RepRap printer. Then use my vendor list or your own Google searches to find vendors. Beside each component, list the vendors that have the component in stock. You may also want to note the cost of the component so that you can plan your budget accordingly.

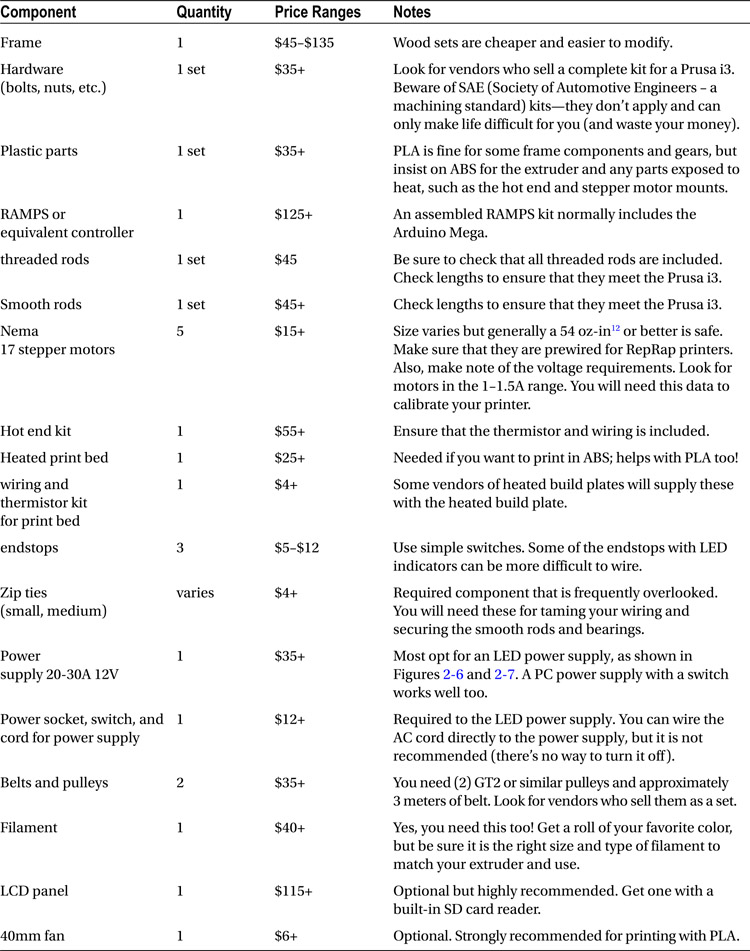

We call this a bill of materials. Table 2-4 shows an example bill of materials for a Prusa i3. You can copy this and make a new column for vendors.

Table 2-4. Prusa i3 Bill of Materials

![]() Tip RAMPS kits can come assembled or unassembled. If you do not know how to solder or have little experience in soldering small components, you may want to get a preassembled RAMPS kit. On the other hand, if you do solder, you can save as much as 50% on the cost if you assemble it yourself.

Tip RAMPS kits can come assembled or unassembled. If you do not know how to solder or have little experience in soldering small components, you may want to get a preassembled RAMPS kit. On the other hand, if you do solder, you can save as much as 50% on the cost if you assemble it yourself.

Once you have your list completed, you can begin acquiring your components. I like to start with the most expensive ones first, making it easier to complete the list if you cannot buy the components all at once.

Another strategy is to first buy the components for the frame and then assemble it. This can help you focus on achieving your goal. I’ve tried this myself and it does indeed help to see your project come to life early rather than waiting for your parts bin to fill up.

Whichever method you choose, this is also part of the plan that you should decide early on. Knowing where you are going to get the parts and the order you plan to acquire them can help a lot when sourcing your own printer kit. It also helps avoid getting almost entirely through the build only to discover that you don’t have any endstops or that you’re missing a thermistor. Hey, it happens!

Rules of Acquisition12

Yes, there are some unofficial rules out there in the RepRap world. While some may be of my own imagination, it has been my experience there are limits to what you can expect from a vendor and the RepRap community in general.

Vendors who supply RepRap components vary—ranging from those who have an online presence to sell components in large quantities to those with a higher purpose of fulfilling the needs of RepRap owners. The best way to tell the difference is by what the vendor offers on its web site in the form of documentation. If you see detailed descriptions, manuals, specification sheets, or technical forums, chances are you have a winner. Beware of those that don’t specify the features of their components or offer vague descriptions. You simply must do your homework and buy from vendors that have good reviews in the community and that will answer your questions.

Assuming you are buying from a respectful vendor, you can and should ask them questions about their products. Most are very patient with buyers who may be new to building a RepRap 3D printer. But there are limits. Don’t expect the vendor to tutor you on how to assemble your printer with their components. You can ask them about how best to assemble, or even what other parts they recommend, but it is not OK to ask them how to adjust your axes when leveling the print bed.

If you use the RepRap forums (and you will), you should expect those who monitor the forums and participate (answer questions) to be no different than other forums. That is, you must keep your topics on track and not meander in thought or try to ask a host of questions in the same or the wrong forum. All of these are likely to get you a stern, negative response.

You can also expect to encounter responses that may not apply to your postings. With so many people commenting on the forums, it is easy for someone to offer advice for fixing various problems, but confuse the situation or circumstances. For example, if you are having trouble getting your endstops mounted, be sure you are looking at forum posts that match your choice of design; the mounting of the endstops for a Prusa i3, while in the same general location, use different mounting tabs than other Prusa variants.

Similarly, when asking for advice, make sure to provide as much information as you can so people can help you zero in on the problem. Don’t write a book about it, but do make a list of your pertinent hardware. Sometimes knowing which stepper motor you are using will help immensely in solving a calibration problem (discussed shortly). Again, ask questions about your problems, but one at a time, and provide all of the symptoms.

As far as etiquette goes, be courteous, and similar courtesies will be returned. You will likely see some instances of where this doesn’t happen, but do not let this hamper you in any way. Like most hobbies, the RepRap world has its share of opinions, including some that come close to an obsession. For example, there are those who would stake their reputation on one hot end over another, and there are others who would argue the opposite. Another example is the question of which filament to use, as I discussed in Chapter 1. Until you have experience with a component yourself, you should not take commentary too seriously beyond the advice and reviews presented.

Finally, there are two more pieces of advice when it comes to sourcing your own kit. First, visit and read every forum and technical blog or discussion about RepRap that you can find the time to read. While you may not understand all of what you read at first, the more you read, the more it will become clear. Second, if you happen to be in a city that has a Maker group—or better, a 3D printer user group—join it! Go meet other RepRap enthusiasts and talk with them! You will gain considerable knowledge very quickly if you are fortunate enough to make a friend or two who shares your passion. You will find all types—from beginners to experienced RepRap-ers—who will take the time to help you (but you have to take the initiative).

Danger Ahead

The RepRap world can be very rewarding and educational. You will encounter people who are very helpful and will gladly offer advice. You will also find vendors who are very responsive and supply customers with quality RepRap components. All you need to succeed is a desire to learn and a little patience. Your reward at the end of your journey is a printer, but it is often the journey itself that is most enjoyable.

Sadly, this isn’t always the case. There are downsides to sourcing your own kit. I’ve already mentioned the lack of guidance by vendors (generally—there are exceptions) and I’ve warned you about making sure the components are designed for RepRap use. What I haven’t discussed yet are some of the bad things that you may encounter.

What I mean are the things that can go wrong unexpectedly, which can lead to a host of problems. In other words, the downsides and pitfalls to building a RepRap 3D printer from scratch. While I cannot cover them all (I’m sure I’ll encounter more myself), I can give you some examples to help illustrate what you can expect.

The biggest drawback is that it simply takes a while to gather the parts for a RepRap before you can start assembling it. This could be because you need time to research vendors or because some of the parts are not currently available (there was a drought of stepper motors for a while in 2012). More likely, it will take time to pay for the parts—especially if you are doing so on a limited budget or with discretionary funds set aside for hobbies.13

There can also be long build times if you encounter incompatibilities. For example, I bought a RAMPS board from what I was led to believe was a respectable vendor, but the result was a maddening calibration session concerning the motors I chose. It turned out that the stepper driver boards I purchased would not output the current needed for the motors, despite the documentation and the vendor’s claim to the contrary. The result was that my axis movement was jerky and the motors would fail (seemingly) at random. Once I discovered the problem, I purchased better stepper driver boards and all was well.

Another example concerns buying bargain components. Early in my immersion into the RepRap world, I ordered a set of stepper motors in “like new” condition (I was OK with that) in order to save some money. The vendor specifications listed respectable performance characteristics and 5mm shafts (the standard). Furthermore, the supplied specification sheet (a PDF document that describes all of the details) met the minimum specifications for a RepRap (see http://reprap.org/wiki/Stepper_motor).

When the motors were delivered, they had been clearly used in a very dirty environment (probably a CNC machine), had 4mm shafts with pressed-on pulleys, and were not wired correctly for use with a RepRap. Despite my arguments, the vendor told me “no returns,” so I was stuck with the motors. I had to either try to make them work or toss them away as an expensive lesson learned. Whereas the motors were easily cleaned and the wiring easily resolved, the 4mm shafts and pulleys proved to be quite a challenge. Even once I had the pulleys removed (I had to destroy the pulleys to remove them),14 it took me a long time to find a source for 4mm pulleys. Once I had acquired the pulleys, I later discovered the stepper motors would not hold torque.15

The end result was that one of my early built-from-scratch RepRap 3D printers took about three months to complete—far from typical. I managed to build two other printers while waiting to get the problem child sorted out. I am wiser now and won’t make those mistakes again!

![]() Caution You really must do your homework on each and every component you buy. Don’t take the vendor’s word that the product is compatible. Ask other customers or do a search on the Web to see if others have had problems with the components. You will be glad you did!

Caution You really must do your homework on each and every component you buy. Don’t take the vendor’s word that the product is compatible. Ask other customers or do a search on the Web to see if others have had problems with the components. You will be glad you did!

Please don’t think I am suggesting that building a RepRap 3D printer is a bad idea—it isn’t. But as I demonstrated in examples from my own experience, it isn’t always going to be smooth sailing. That being said, sourcing your own kit and building it from scratch can be extremely rewarding. This is especially so if your results yield a higher print quality. The first time I did this, I went a bit overboard and included about a dozen minor upgrades in the process. While some ultimately didn’t work, the end result was a printer that exceeded the print quality of my last DIY kit and it cost about $200.00 USD less! Of course, it took about eight months to complete.

3D Printer Features

Let us now discover the features and some common options of 3D printers. While not all vendors or printers have all of these features, it is important to be familiar with them when considering your first (or next) 3D printer. The more common options and their benefits are included in the following list and subsections. Some of these will be discussed in greater detail in the maintenance and troubleshooting part of the book.

- Build volume

- Filament

- Hot end

- LCD panel

- SD card reader

- Filament cartridge system

- Network connection

- Wireless support

- Adjustable print bed

- Filament cleaner

- Filament spool holder

- Heated print bed

- Cooling fans for print bed

- Electronics cooling fan

- Auto bed leveling

The size of the object you can create with a 3D printer may be something you want to consider carefully when evaluating which printer to buy. If you want to print large objects, you will want to look at 3D printers that are designed with a large print area (build volume). For example, if you want to print tall objects, you may want to consider a delta 3D printer—their design is best for tall objects. Most RepRap printers have a rather limited build volume compared to professional- or consumer-grade printers. Some of the lower-cost 3D printers have a smaller build volume.

REALISTIC BUILD VOLUME OF REPRAP 3D PRINTERS

While some RepRap designs are billed as having a certain build volume, the actual build volume is often smaller. For example, a combination of the Prusa i2 frame components, the size of the extruder, and the clips used to hold the glass build plate to the heated bed can reduce the size of the build volume considerably.

If you have chosen a filament type you want to use (e.g., ABS or PLA), make sure that the printer you are evaluating for purchase or to build from a kit is optimized for your choice. Keep in mind that most 3D printers that can print with ABS can also print with PLA provided they have a print bed cooling fan (or you can add one). Similarly, if you want to print with ABS, the printer must have a heated print bed.

Hot End Types

There are dozens of hot end designs available for 3D printers. This may seem like an exaggeration, but it isn’t. My research revealed several sites listing 10 or even 20 designs. The site that seems most complete, but incomplete, is at https://sites.google.com/site/3dprinterlist/home/hot-ends. You will find links to details about each of the more than 50 hot ends listed.

With so many hot end designs, how do you know which one to choose or even which one is best for your printer, filament, and object design choices? Fortunately, most hot end designs can be loosely categorized by their construction into two types: all-metal and PEEK body with PTFE (polytetrafluoroethylene) liner. There are some exceptions, like an all-metal design with a PTFE liner, but in general they either are all one material or use a liner of some sort. I will discuss some of the characteristics of each in the following sections.

All-metal hot ends are made from one or more metal types. Typically, this includes a stainless steel core, aluminum, or brass heater block, and a brass or stainless steel nozzle. They are relatively maintenance-free since they do not contain any parts that wear out from normal use. A stainless steel core permits filament to glide with little friction. In some cases, the hot end can be certified for use with food, which could come in handy if you want to print with chocolate.

Some all-metal hot ends have a body with fins so that the body can be cooled with a fan. This is necessary because all-metal designs need a sharp heat transition to keep the filament from jamming. However, it is possible the entire hot end could reach the temperature of the heater block (or nearly so). If you use the hot end without a fan and the body isn’t long enough to dissipate enough heat, it is possible these hot ends can transfer heat to your extruder body or mount. This could make the plastic parts soft and they could deform. Thus, most all-metal hot ends are used with a fan.

These hot ends have one distinct advantage: they can handle much higher temperatures and thus can be used to print higher-temperature filament. As I mentioned, all-metal hotends are lower maintenance because there are no internal parts that must be replaced when they wear out.

Examples of all-metal hot ends include the proprietary MakerBot Mk8 (makerbot.com), the Prusa Nozzle (http://prusanozzle.org/), and the E3D (http://e3d-online.com/E3D-v5). Figures 2-9 and 2-10 show the MakerBot Mk8 extruder and hot end.

Figure 2-9. MakerBot Mk8 extruder (upgraded with aluminum body)

Figure 2-10. MakerBot Mk8 hot end

This construction type uses a metal heater block with a brass, aluminum, or stainless steel nozzle connected to a special plastic body made from polyether ether ketone,16 a.k.a. PEEK (http://en.wikipedia.org/wiki/PEEK), which has a PTFE liner. There are a lot of hot ends in this category, so consequently, they are more widely available.

The peek, or body, of the hot end has low thermal conductivity and normally does not need a fan to cool it. Some versions of this type of hot end may add fins or slots in the peek to further aid in dissipating heat.

One advantage that some manufacturers provide is the ability to change the PTFE liner for use with 1.75mm or 3mm filament. However, the PTFE liner has a couple of limitations. It can deform over time and will need to be replaced periodically. The liner also limits the heat range to a maximum of about 240 degrees Celsius. Any more than that and the PTFE liner will fail and the material may degrade. Regardless of these limitations, this type of hot end is very popular and can be found on a lot of printer designs.

Examples of this type of hot end include the J-head (http://hot-ends.com), Budaschnozzle (www.lulzbot.com/products/budaschnozzle-20c-w-035mm-nozzle), and Merlin (www.reprapdiscount.com/hotends/59-merlin-hotend-set.html). Figure 2-11 shows the J-head hot end from MakerFarm.

Figure 2-11. J-head hot end

Hot ends can also be designed expressly for direct drive, Bowden drive, or both. Hot ends designed for direct drive extruders mount close to or in the same body as the extruder. Examples of these are the J-head and MakerBot MK8 hot ends. There are a few hot ends that can be used only with Bowden extruders, but these require a special mount or come with their own mount.

![]() Note The J-head is commonly used for Bowden extruders, particularly on deltabots. In some cases, the hollow-set screw used to lock the PTFE tube in place can be replaced with a push-to-connect fitting, which allows you to attach the Bowden tube in a secure manner.

Note The J-head is commonly used for Bowden extruders, particularly on deltabots. In some cases, the hollow-set screw used to lock the PTFE tube in place can be replaced with a push-to-connect fitting, which allows you to attach the Bowden tube in a secure manner.

Most hot ends can be used with either a direct or Bowden drive extruder. Only the mount (extruder body) and installation differs, where the direct drive is mounted together with the hot end and the Bowden drive mounts the hot end and extruder separately.

Choosing a Hot End

If you are building your own printer or upgrading, you can change the hot end easily. Those printers build with vendor-specific extruders and hot ends may not be so easily upgraded.

So which one should you use? That depends on what you want to do with it. If you want to print higher-temperature filament, you should choose an all-metal hot end. If you want a hot end made for PLA or ABS that is reliable and doesn’t need a fan to operate, choose a peek body hot end.

This may seem noncommittal since I don’t list specific hot ends that you should use. The reason is also simple: I think there are so many hot ends (well, variants on a theme) because each one is designed to perform to the needs driving that particular design. In fact, you will encounter some people who feel one particular hot end is superior to all others. It seems there are as many different opinions as there are hot ends!

If you decide on the construction type and make a list of the features or capabilities, such as range of filament, mounting type, and so forth, you should be able to narrow down your selection.

Your criteria should also consider whether a vendor is the original designer or manufacturer—that is, make sure to buy a hot end from someone who manufactures it. For example, the J-head hot end is very widely used in RepRap printers; so much so that there are many vendors who make copies or clones of the design. Some are very well made, others not so much. Before buying a new hot end, do some research and read reviews from previous buyers.

Thus, you should buy the hot end that best meets your needs, is designed to fit your printer (or the one you are building), is well made, and has a reputation for reliability.

Most commonly a text-based multiline display, an LCD panel allows for computerless operation of the printer. Since most LCD panels include either a rotary selector or buttons, the firmware provides menus that you can use to select options, such as moving the axes, turning on the heaters, and more. Having features like this on the printer itself helps with routine adjustments and maintenance, without the need for connecting to a computer. Now that I’ve converted all of my older 3D printers (except one) to have an LCD panel (and software to use it), I cannot imagine having a printer without it. In fact, I have plans to add one to my Printrbot Simple so that even my entry-level example can be used without a computer.

If you don’t want to tie up your computer or dedicate a computer to printing, you should consider buying a printer that has an SD card reader. Not only will this permit you to disconnect your printer from your computer, if the printer has an LCD interface, it allows you to print without ever having to turn on your computer. Which means you can take your printer anywhere and amaze your friends.

A few 3D printers incorporate a filament loading system that uses a cartridge or similar enclosure to confine the filament. This promotes easy filament loading and unloading, and can also eliminate the need for a filter or cleaner to ensure that the filament is clean.

A network connection would permit you to print over the network and share your printer with others on your network. The newest 3D printers from MakerBot include this feature.

Wireless support is the same as having a network connection, but without the wires!

I consider this feature another must-have for any 3D printer. It permits you to tram the print bed quickly, thereby making routine maintenance a bit easier. Some mechanisms (like the MakerBot 3D printers and the one I designed for my Prusa i2) can be adjusted without tools.

If your 3D printer doesn’t have a hood or some covering for the spool of filament, you should consider opting for a 3D printer with a filament cleaner. Even if the printer you want doesn’t have this option, it can be added to just about any 3D printer. A quick search on Thingiverse reveals a number of options. For example, I use thingiverse.com/thing:16483 for my RepRap printers and thingiverse.com/thing:52203 for my MakerBot printers. The major benefit of filament cleaner is that it prevents small pieces of lint, dust, and other contaminates from entering the extruder, and eventually the nozzle. If you are having frequent filament extrusion failures, try adding a filament cleaner.

A lot of printers have this feature. Not only does it keep the area around the printer tidy, it also helps reduce extrusion failures by relieving tension on the extruder motor. That is, the filament spool holder allows the spool to unwind filament by rolling on some form of roller or other low-friction device. This is another item I feel is essential to a good printing experience. If you are having extrusion failures and don’t have a spool holder, it is likely there is too much tension on the filament, causing the extruder to strip the filament.

If the printer you are considering doesn’t have a heated print bed, it is not optimized for printing ABS and other high-temperature material. If you want to (perhaps in the future) print with ABS, insist on having a heated print bed. Not only does it ensure that the printed object retains heat, it also helps the object stick to the build plate. It can also help with PLA adhesion, so you really cannot go wrong here.

Cooling Fans for the Print Bed

If you want to print with PLA, you simply must have a print bed fan. Blowing air over the printed object helps keep the PLA stable by making it cool faster.

This option isn’t normally something you find on professional-grade and most consumer-grade options. Indeed, the need for cooling the electronics should have been solved by the manufacturer. Thus, this applies mainly to RepRap 3D printers. In this case, it can help keep things working properly, such as avoiding skipped steps when the stepper drivers get too hot. I had this happen once on a really big print. Sadly, it happened at about 90% complete, ruining the part entirely. If you build your own RepRap, consider carefully how you will house and cool the electronics.

One of the hottest new features is called auto bed leveling. This feature permits the printer to discover its Z-height (how far the nozzle is from the print bed) and detect and correct for bed misalignment. In fact, vendors are starting to equip their printers with this feature. It is becoming a popular option for RepRap printers too (see thingiverse.com/thing:182889). It is likely that this technology or something similar will become more prevalent in the coming year. I will talk more about this particular feature in Chapter 11 as I demonstrate some of the ways you can upgrade your RepRap printer.

LEVELING VS. TRAMMING: IS THERE A DIFFERENCE?

Like any industry, the 3D printing world has its share of misused, mangled, and otherwise misspelled words, terms, and acronyms.17 One case that has a lot of experts baffled is the misuse of the terms level or leveling when referring to adjusting the print bed. For better or worse, the industry as a whole seems to be accepting of the term leveling to describe the process of making the print bed parallel to the X axis. Indeed, several well-known vendors use level in this manner.

The goal is to make sure the nozzle is the same distance from the print bed throughout the range of movement of both the X and Y axes, while the Z axis remains fixed. This process is called tramming. It has nothing to do with leveling as in the process of making an object parallel to the horizon (perpendicular to gravity)18 nor does it involve a bubble, line, or plane level or any such device.19

In fact, you should avoid and ignore any description of a similar process that uses these devices to adjust the print bed. Similarly, don’t bother buying or printing any device that is designed to make the print bed level with the horizon. However well intended, these processes and devices are likely to make your print bed issues worse. Unless, of course, you are lucky enough to have a printer whose X axis is actually level with the horizon.

Personally, I am OK with the use of the word leveling when referring to adjusting the print bed, but some experts are not so accepting. So long as you understand the goal of the process, it should not matter that it is technically misnamed. Furthermore, if you encounter a process that is described as “tramming the print bed,” you know it has the same goal as the process presented here and should be interchangeable.

Build or Buy?

The answer to the question of whether to build your own printer or buy a ready-to-go printer lies in your assessment of your skills and your desire to learn. If you are confident you can handle any electrical or mechanical task needed to build a 3D printer, and you have the time necessary to devote to the task and learn new skills, then a 3D printer kit is an option you will want to consider. On the other hand, if you don’t have the skills or you don’t have the time to learn those skills, much less the time to build the printer, you may want to consider buying a printer that is ready-to-print.

In this section, I provide advice for choosing whether to build or buy a 3D printer. I also present a condensed summary of the list of the characteristics for each category of 3D printer option. While you are ultimately the one who needs to make the choice, the information in this section should help you make your choice a bit easier.

Reasons for Building Your Own 3D Printer

Let us set some expectations about a 3D printer build. Building your own 3D printer encompasses all of the RepRap class of printers, as well as any of the consumer-grade class 3D printers that require some form of assembly.

There are two main reasons why you would want to opt to build your own printer. First, you enjoy working on a project that requires you to spend a lot of time during construction and configuration. Second, you want to save some money. Other reasons include wanting to build a 3D printer with specific unique features or you want to be able to upgrade the printer in the future.

If you want to embark on a build option, you should plan to spend anywhere from a single afternoon (for some assembly-required kits) to about 40 to 60 hours for a built-from-scratch RepRap 3D printer. While this estimate may seem very high (and some would say it is), realistically you should anticipate it taking more than a long weekend to complete—and that’s if you have all of the parts and they all work! In addition, you should plan to spend some time configuring and calibrating your new printer. The next chapters will help you to prepare so that you spend less time than if you had to do it without help.

However, you should not try to rush through the build, but take your time to get things right. You will be glad you did. Once you have your printer whirring away, laying down plastic to make a whistle or another small gewgaw, you will be glad you took the time to get it right. So if you want a challenge and time isn’t an issue, building your own printer is a good option.

Reasons for Buying a Ready-to-Print 3D Printer

Ready-to-print 3D printers encompass all of the professional-grade class of 3D printers and any 3D printer in the consumer-grade class that comes assembled or can be ordered assembled.

There are several reasons for choosing a professional-grade 3D printer. One reason is time. If you need to get started printing objects quickly and do not have time to learn how to build (and then build) your own 3D printer, either from a kit or from scratch, you will want to choose a professional-grade option.

Another reason you may want to buy a printer that is ready-to-go concerns quality. The print quality is generally better than what you may achieve if you built your own 3D printer. This isn’t always the case, however, and it is more often applicable to professional-grade options. Regardless, if quality is a concern, you may want to buy a printer with a good reputation for high-quality prints.

Additionally, a ready-to-print option is easier to use and more reliable. That is, a ready-to-print option means all of the hard work of configuration and calibration has been done for you. Although you may need to spend some time to get the printer set up properly once you’ve unboxed it, this is typically a small fraction of the time required to build your own 3D printer. That is, you don’t have to invest the time required to get everything fit together and working. This goes far beyond the mundane mechanics of the assembly.

Perhaps the most important factor in buying a ready-to-go printer is technical support. If you do not have or do not want to learn the skills required to diagnose or fix problems with your 3D printer, you should buy your printer from a vendor who offers a support option.

How Do I Decide?

So how do you decide which to choose if none of these reasons apply to you or perhaps aren’t that big of a deal to you? To help you decide, Table 2-5 is a list of the more important characteristics of each class of 3D printer offerings. It includes a rating in each class of printer for each characteristic.

Table 2-5. Considerations for 3D Printer Categories

You can use this table to circle the ratings that best apply to you, and then sum up which class aligns with your own assessment. For example, if you consider a difficult setup as something that you want to avoid, you would circle the cell marked “Low” for that characteristic. Try it now.

I think you will find that one class stands out for you. If it happens to be the professional-grade class, you can conclude that you should buy a 3D printer. Similarly, if the RepRap class stands out, you can conclude that building your own 3D printer is a good option.

However, if your assessment isn’t definitive, focus on those characteristics that matter most to you, and base your decision on that. For those of us who are truly ambivalent, a 3D printer kit from the consumer-grade class can be a good choice. You will have a bit of fun putting it together and can expect very little additional work to ensure a good quality print.

Buying a Used 3D Printer

If your budget limits your buying power or you are looking for a bargain, a used printer may be a good choice. You can often get a slightly used 3D printer for about 75% of the price of a new one. However, like all used purchases, you need to do your homework to ensure that you are getting a well-maintained and reliable printer. The following lists several considerations and some advice on how to buy a used 3D printer. If you follow this advice, you should be able to find a good printer to fit your budget.

- Online auction sites are an excellent place to look for a 3D printer. If you apply a little patience and avoid the temptation to join a bidding frenzy, you will find the printer you want at the price you are willing to pay.

- Set your expectations based on your budget. Remember, real bargains are hard to come by. If the price is too good to be true, chances are there is something wrong with it.

- Find the printer with the lowest usage. I’ve seen cases where used printers have no more than a few hours of use. Avoid printers with hundreds of hours of use.

- Beware of highly modified printers. Buying a well-tuned printer is a good idea, but don’t pay extra for all of the add-ons and upgrades. It is possible those upgrades could be useless or even detrimental to your print quality.

- If you are seeking a professional-grade printer, check to see if there is an extended warranty and that it can be transferred to you (most cannot).

- Ask if the seller is the original owner. If the printer has passed among several owners, you may want to pass on it as well.

- Check for the original accessories. Look for printers that come with the original manuals and accessories. Consumables may not be included, but the original tools and whatnot should.

- Be very careful if buying from a seller who doesn’t have the original shipping box. This shouldn’t be a deal breaker, but you should insist on shipping insurance and ask the seller to explain how they plan to prepare the printer for shipping. You should also ensure that they secure the axes for shipping.

- Ask to see hi-res photos of printed objects. Check the quality carefully. If you see any anomalies or quality issues (described in Chapters 7 and 8), don’t buy the printer.

- Good communication is the key to a good sale. If the seller is willing to exchange e-mails and answer questions promptly, it is a good sign. Don’t buy from a seller who won’t return your e-mails, dodges questions, or takes a long time to respond.

- Lastly, ask the seller whether he will take the printer back for a full refund if there is something wrong with it. You may have to pay return shipping.

I’d like to present two examples from my own experience of buying a used 3D printer. In fact, both printers are MakerBot printers. The first one is a Replicator 2 and the second a Replicator 1 Dual.

The Replicator 2 was listed with less than 20 hours of use. The seller described it as being in excellent condition. The price was also very good. Aside from missing the original box, the printer met all of my criteria (as listed earlier). The printer was packed well and the axes secured. In fact, it took me almost 10 minutes to free it from its cocoon of packing material.

However, when I unpacked the printer, I found that it was very dirty and in need of a full maintenance overhaul. Fortunately, a few hours of cleaning and partial disassembly proved that the printer was still a good buy. Had I known the printer needed so much work, however, I would have negotiated a lower price.

The lesson here is that another person’s idea of “excellent” may not meet your own. The only way to avoid this mistake is to ask for hi-res photos taken from every angle. Specifically, ask for photos of the axes and look for dust, dirt, and other signs of neglect. While my purchase turned out OK in the end, I was a bit disappointed.

The Replicator 1 Dual was a different story. It had only four hours of use. The seller was very understanding and answered all of my questions, including requests for additional photos. I could tell from the photos that the printer was in excellent like-new condition. The seller had the original box, all accessories, and even the consumables were included. It arrived packed exactly as MakerBot originally shipped it. Best of all, the sale price was less than half of the original sale price. I saved so much money that I was able to upgrade this printer with some top-of-the-line options. In fact, it is now one of my most reliable and best-quality printers.

Summary

Getting a 3D printer isn’t at all like buying a toaster. There are so many 3D printers to choose from that a random choice may be out of the question (it’s far too risky that you’ll end up hating your purchase). Furthermore, deciding whether to buy a 3D printer or to build your own can be a difficult decision process.

In this chapter, I presented three classifications of 3D printer options for you to consider, ranging from sourcing your own printer kit piece by piece, to acquiring a commercial printer with very high quality, paid support, and a warranty. I also presented some advice for those considering a RepRap printer.