Chapter 8

Solid Wastes and Agricultural Refuse

KEY CONCEPTS

- Waste is wealth

- Incinerators, pyrolysis, anaerobic digestion, and recycling methods of wastes disposal

- Waste recovery management systems

- Sources and types of wastes

- Advantages and disadvantages of wastes recycling

- Tips on reducing waste and conserving resources (the three R’s—reduce, reuse, and recycle)

- Plastic recycling and plastic resin identification codes (RID)

Waste has always been the negative side of the economy. In production and consumption, it is wasteful matter always available in energy activity system that is rejected as useless, harmful things that damage the environment. Waste is also known as the garbage waste, rubbish, refuse, etc. The social task of waste management has been to either minimize or to completely get rid of it. Traditional way of waste removal is to carry away them through sewers and dustbins, dispatched in the air through burning, dumped in disused quarries or the oceans, or fly-tipped in gutters or behind hedges.

The availability of free places for dumping waste in near future and associated environmental problems have created the need to find some new ways for efficient waste utilization and environmental protection. For example, landfill sites are a significant cause of global warming and a source of groundwater pollution, because of their methane emissions. However, incinerators also produce hazards. Their emissions of acid gases, mercury, dioxins, and furans have very harmful effects.

8.1 WASTE IS WEALTH

All the wastes and waste management concepts are, therefore, now changing. Globally, the focus is to modify all resources from waste to wealth or from trash to cash; both are as good as having the better of two words. Three basic drivers of change are turning waste and waste management into a dynamic, fast changing, and international economic sector. This transformation presents new choices and opportunities and provides lessons and pointers for industrial, social, and environmental policy in the new post-industrial landscape. The following are some of the driving forces of change:

- Growing concern about the hazards of waste disposal

- Broad environmental concerns, especially global warming and resource depletion

- Economic opportunities created by new waste regulations and technological innovation

- Since the fuel shortage today is widely recognized not only as a political problem but also as agricultural problems as they are also consuming the great proportions of fuels and hence they have started thinking that fuels can be produced as an agricultural crop.

The following are the three main concepts have been introduced for converting waste materials to usable fuel and energy with main concern of minimizing the environmental damage.

- Heat energy generation: Waste is used as supplemental boiler fuel and heat energy is obtained by the direct combustion of the waste to heat energy.

- Bioenergy generation: It is a modern method of hazards control of waste disposal and for the recovery of fuels and energy (such as methane). Biological methane generation have commercially potential for energy resource recovery.

- Eco-modification through recycling: Improved and efficient design of process and products reduces the health hazards and increases the resource productivity. Recycling conserve material, fuel, and energy by lengthening their life span.

- Fuel and energy generation from forest and agricultural and municipal wastes: In order to cope up with fuel and energy shortages, all such wastes are considered as raw resources for converting them into improved fuels and energy.

8.1.1 Incinerators

Incinerator is precisely a furnace where waste is burnt to produce energy. Burning waste in incinerators only reduces the volume of solid waste, but it does not dispose the toxic substances contained in the waste and creates the largest source of dioxins.

The burning of waste produces heat that boils the water. Thus, the steam obtained is used to convert heat energy into electrical energy by thermo electromechanical converters. As already stated, the flue gases coming out of simple incinerator contain toxic gases (hazardous gases such as furans and dioxins).

Modern incinerators are equipped with pollution improvement systems to remove health hazardous gases. Incinerator combustion temperature of about 1000°C is maintained for complete combustion of wastes to reduce chlorine-enriched organic substances. Flue gases are sent through scrubbers for the removal of dangerous chemicals. A high chimney having cooling systems is installed as it removes the hazardous gases. Cost and efficiency are considered as the main parameters for selecting incinerator as a method of waste disposal. However, they can be thought of as a sustainable energy production system.

Incineration with recovery of energy is considered the best method of waste management and dominates over plain incineration and landfill. Incineration converts solid waste into ash, flue gas, and heat. Still with the incineration, some quantity of about 10% waste is produced that of original wastes.

8.1.1.1 Process of Incineration

Electricity generation is the most important useful energy obtained from incinerators. Incinerators have the common mode of operation even there are many variations in the incineration process.

- Auditing of wastes: Understanding the quality, quantity, and composition of wastes is the important step in selecting the appropriate disposal options.

- Proper incinerator selection: It is essential to assess the suitability of existing incinerators capability to disposal of newly added wastes and improving and replacing by new (modern) incinerator. Building and equipment design is appropriate. The recommended configuration is a dual-chamber controlled air incinerator.

- Proper operation of incinerator: Operating the incinerator correctly ensures optimum combustion conditions. It includes separation and sorting of wastes, weighing and mixing it for specific calorific value, and closing and opening of incinerator doors for complete combustion of wastes. Personnel safety is very important.

- Removal of dangerous chemicals and toxic gases: Combustions of wastes at high temperature reduce chlorine-enriched organic substances. The installation of high chimney with cooling system and scrubbers removes chlorine compounds and dangerous toxic gases contained in flue gases.

- Safe handling and disposal of incinerator residues: Ash (or residues) obtained from bottom of chamber of the incinerator containing materials that health hazardous and environmental polluting materials and disposed of as per standard norms (in batch production). Incinerated waste is finally disposed in landfills.

8.1.1.2 Advantages of Incineration

- Incineration is a practical method of disposal that minimizes high transport costs of wastes to landfills.

- It largely reduces the carbon footprint during the transportation of wastes.

- Large reduction in the amount of waste volume after incineration requires less space for landfills, thus saving money.

- Gases and leachates produce in landfills by waste are completely eliminated.

- Incinerated wastes are totally free of any environmental risk.

- It is used for hazardous and clinical (containing pathogenic bacteria) waste treatments.

- It is used for generation of electricity.

- It can be operated under any weather conditions.

- Incineration is cheaper in the long term and has long life span.

8.1.1.3 Disadvantages of Incineration

- Incineration can generate hazardous gases such as furans and dioxins (an unwanted by-product of chlorine), which causes cancer, affects the functioning of hormones, and damages the immune system.

- It can generate CO2 and odour sometimes.

- Expensive to build and operate and requires high energy.

8.1.2 Pyrolysis

Pyrolysis provides an alternative to methods of municipal waste disposal (such as anaerobic digestion, landfill storage, and more specifically incineration). In this technology, organic waste is burnt at relatively low temperatures to produce char (like charcoal), oils, and combustible gases. The oils can be used as a chemical feedstock and as fuel. Feedstock includes mixed waste, plastics, tires, and sewage sludge. Essentially, it involves chemically mining (a form of treatment that chemically decomposes organic waste materials by heat in the absence of oxygen under pressure and at operating temperatures above 430°C) the waste to produce elements that can be used for energy generation or chemical inputs.

In practice, it is not possible to achieve a completely oxygen-free atmosphere. Because some oxygen is present in any pyrolysis system, a small amount of oxidation occurs. If volatile or semi-volatile materials are present in the waste, thermal desorption will also occur. Organic materials are transformed into gases, small quantities of liquid, and a solid residue containing carbon and ash. The off-gases may also be treated in a secondary thermal oxidation unit (secondary combustion chamber), flared, and partially condensed. Particulate removal (such as fabric filters or wet scrubbers) is also required. Several types of pyrolysis units are available, including the rotary kiln, rotary hearth furnace, and fluidized bed furnace. These units are similar to incinerators except that they operate at low temperatures and with less air supply.

Pyrolysis transforms hazardous organic materials into gaseous components, small quantities of liquid, and a solid residue (coke) containing fixed carbon and ash. Pyrolysis of organic materials produces combustible gases, including carbon monoxide, hydrogen and methane, and other hydrocarbons. If the off-gases are cooled, liquids condense producing an oil or tar residue and contaminated water.

Pyrolysis liquids can be used directly (e.g., as boiler fuel and in some stationary engines) or refined for high quality uses such as motor fuels, chemicals, adhesives, and other products.

Direct pyrolysis liquids may be toxic or corrosive.

8.1.2.1 Advantages of Pyrolysis

- Volume of the waste is significantly reduced.

- Produces useful products for multiple applications. Solid, liquid, and gaseous fuel can be produced from the waste.

- Storable or transportable fuel or chemical feedstock is obtained.

- It is safer and more environment friendly than incineration, land filling, and many other gasification processes.

- Environmental problem is reduced. Produces few air emissions due to limited use of oxygen.

- Contamination of air emissions is easy to control because syngas is cleaned after production to get rid of any contaminants.

- Desirable process as energy is obtained from renewable sources such as municipal solid waste or sewage sludge.

- Replaces coal and natural gas as viable fuel sources, causing a reduction in climate change,

- Can be easily implemented in CHP systems. More efficient than incineration.

- It is sustainable process by reusing thrown away products that can be recycled again and again.

- Pyrolysis plants are flexible and easy to operate because they are modular. They are made up of small units that can be added to or taken away when the mass or volume of organic matter changes.

8.1.2.2 Disadvantages of Pyrolysis

- Generates possible toxic residues such as inert mineral ash, inorganic compounds, and unreformed carbon.

- Potential to produce a number of possible toxic air emission such as acid gases, dioxins and furans, nitrogen oxides, sulphur dioxide, and particulates.

- Pyrolysis plants require a certain amount of materials to work effectively.

8.1.2.3 Pyrolysis Versus Incineration

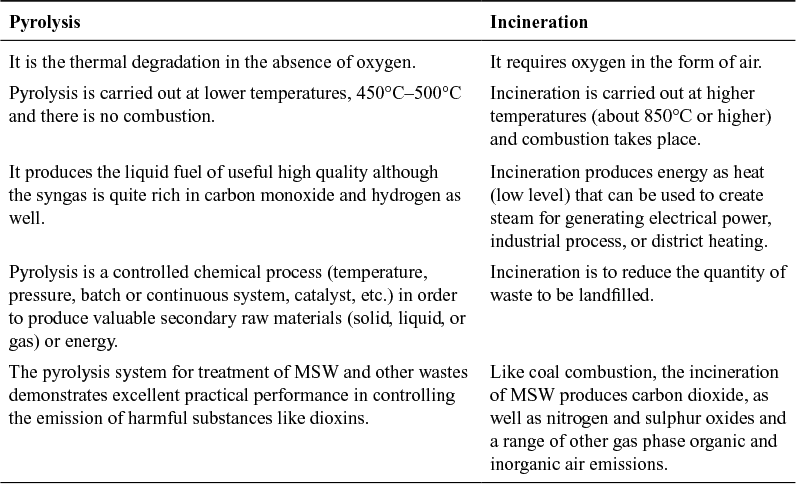

They are fundamentally different as given in Table 8.1:

Table 8.1 Differences between Pyrolysis and Incineration

8.1.3 Anaerobic Digestion

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. Anaerobic digester is an airtight chamber in which organic waste is decomposed and transformed into biogas by a biological process called anaerobic digestion.

One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels.

A range of anaerobic digestion technologies are converting livestock manure, municipal wastewater solids, food waste, high strength industrial wastewater and residuals, fats, oils and grease (FOG), and various other organic waste streams into biogas for 24 × 7.

Separated digested solids can be composted, utilized for dairy bedding, directly applied to cropland, or converted into other products. Nutrients in the liquid stream are used in agriculture as fertilizer.

8.1.4 Recycling

Waste control and reduction depends on complex flows and simple or specialist treatment. It is organized around material streams and creates a circular flow of separate materials as an alternative to the linear flow of mass waste. Its central concept is the ‘closed loop’. As a result, the innovations of eco-modified recycling are in collection systems rather than high tech plants. The cost of collection and sorting has been one of the main barriers for increasing recycling among households and small traders.

It involves the collection of used and discarded materials in order to process these materials and make them into new products. It reduces the amount of waste that is thrown into the community dustbins, thereby making the environment clean and the air fresh to breathe. Recycling is an economic development as well as an environmental tool. Reuse, recycling, and waste reduction offer direct development opportunities for communities. When collected with skill and care, and upgraded with quality in mind, discarded materials are local resources that can contribute to local revenue, job creation, business expansion, and the local economic base.

Recycling-based economic development has been the heart of Waste to Wealth program of national economy. Recycling and reusing reduce the pressure on primary resources. In some sectors, such as machinery, cars, and household appliances, there has been a long-term practice of scrap recycling; however, substantial amounts are still landfilled along with precious metals and other materials in electronic goods. Alongside its potential for the environment, economy, and local regeneration, recycling also offers many social benefits.

8.1.5 Bioenergy Conversion

Bioenergy conversion seems to be the most promising energy conversion techniques, specifically for India in near future probably because of the following points:

- Absence of or the difficulties related to the installation of centralized power supply systems.

- Increasing energy demand for energy even in remote rural areas or isolated parts of the country.

- Basic need for large amounts of protein for food and feeding purpose.

- Inexpensive methods available for collecting and storing of energy.

Energy schemes utilizing plant (biomass) as source of liquid fuel (such as ethanol or methanol) are therefore worth attempting in addition to electrical power generation. The production of usable energy through algal and similar crops includes the following three important conversion steps.

- Photosynthesis production of organic matters.

- Collection and processing of plant materials.

- Fermentation of the organic matters, leading to liquid and gaseous fuels and storage.

Sugar crops, trees, grains, and grasses are various aquatic fuel sources and have relative potentials on each other utilized in any biomass production schemes. Sugar crops and algal crops seem to be the most promising crops of importance suitable for bioenergy conversion in India.

8.2 KEY ISSUES

The following are the key issues that must be investigated before the economic viability of a refuse-derived fuel (RDF) scheme:

- Collection of waste from doorsteps, commercial places, community dump, and final disposal sites.

- The volume and nature of refuse to be processed.

- The type of efficient RFD process required and market for fuel products.

- The required potential users and the revenue obtainable.

- The economy of the alternative method of disposal of the refuse.

- The utilization of solar thermal energy for increasing the temperatures of digesters.

8.3 WASTE RECOVERY MANAGEMENT SCHEME

A simple waste, refuse resource recovery scheme can be understood from Figure 8.1, which represents the various important scheme components as energy use and solid waste generation, transportation, storage, energy recovery, treatment, and final disposal of the waste.

Figure 8.1 Schematic representation of waste refuse energy management

The major part of waste obtained after the energy utilization are non-organic that have diversified nature and characteristics, and thus, their identification and separation from the main waste stream by improved techniques are an essential parameter of any energy recovery scheme. On-site processing of waste for the reduction of in-home compactors and industrial shredders through improved technology should be employed, which may be environmentally acceptable. Collection and transportation components of the waste energy conversion scheme are the most expensive components owing to many varying social, technical, and other reasons. A careful cost analysis and implementation of this vital component will minimize the running cost of the scheme. The storage of waste for resource recovery and final disposal after suitable treatment is another component of scheme and selection of storage station and other associated problems invite careful attention. Normally, two types of energy recovery systems are used:

- Separation of metals, paper, and glass from the remaining waste through the process such as size reduction, screening, vibrating sorting, and electronic scanning; however, a truly homogeneous, inexpensive separation system will provide competitive input to waste energy utilization.

- Conversion of the remaining waste product to usable form of energy and energy conversion may include the following:

- Generation of methane gas (biogas conversion) or other fuels (biological conversion)

- Generation of electricity either from (a) or through thermo-mechanical process

- Composting of fertilizers

8.3.1 Treatment

Here, the treatment means that those process designed to reduce waste to innocuous forms without or after energy recovery. The most familiar techniques are the burning of waste at high temperatures in the presence of oxygen (known as incineration) and the breaking down of the complex compounds using heat in the absence of oxygen (known as pyrolysis). However, treatment techniques should be selected so as to be accepted socially, environmentally, and economically. The cheapest method for final disposal of waste before or after energy recovery is a systematic burial in ground.

8.4 ADVANTAGES AND DISADVANTAGES OF WASTE RECYCLING

Significant advantages and disadvantage of waste recycling are discussed in this section.

8.4.1 Advantages of Waste Recycling

Recycling is a process of using old or waste products into new products; this is an important step towards energy conservation (to reduce energy usage and reduce the consumption of fresh raw materials) and reduction in pollution (to reduce air, water, land pollution, and greenhouse emissions).

- Reduced damage to environment: This is the foremost advantage of recycling and this promotes environmental protection in a balanced manner. For instance, let us consider the case of cutting down trees for paper production; here, individuals can create balance by recycling old used papers and new paper products made from trees. In such a way, deforestation and felling is reduced. Natural resources are conserved this way.

- Reduced consumption of energy: Large amount of energy is consumed when raw materials are processed during manufacturing. Therefore, recycling helps reduce energy consumption making production process beneficial and cost effective. It leads to reduced utilization of raw materials. It ensures additional energy availability and saving money. It reduces the creation of waste at source.

- Reduced environmental impact and pollution: At present, industrial waste is major source of pollution. Recycling industrial products such as plastics and cans help a lot in cutting down levels of pollution for the reason that these materials are being reused instead of being thrown away irresponsibly. It saves on requirement of open landfill spaces, the surroundings clean and healthy. It also reduces environmental impact of traditional methods of waste treatment and disposal.

- Mitigate global warming: Recycling aids in alleviating or lessening global warming and its harsh effects. Today, massive waste is being burned producing large amount of greenhouse gas emissions. Therefore, recycling is an effective way of ensuring that the process of burning is reduced and waste are regenerated and converted to useful and eco-friendly products without creating harmful impact to the environment.

- Promotes sustainable utilization of resources: Recycling promotes sustainable and wise use of resources. This activity helps ensure that there is no discriminate use of materials and resources saving them for possible use in the future.

8.4.2 Disadvantages of Waste Recycling

- High cost of recycling: The establishment of separate facilities in order to process products and make them reusable is cost effective. This might somehow trigger pollution in terms of transporting the materials and cleaning activities.

- Durability and small life span of recycled items: The durability and efficiency of recycled products does not guarantee 100%. Recycled products are sometimes taken from cheap and overused materials; therefore, there is no assurance that it can last for long.

- Unsafe and unhygienic process: Recycling sites and processes are often unhygienic and unsafe and this might pose dangers to your health.

8.4.3 Status of Municipal Solid Wastes Management in India

Municipalities in India spend hardly between 10% and 50% of their budget on solid waste management (SWM), but most of this is consumed in the salaries of sanitation workers and transport of waste, while a minute proportion is spent on its scientific disposal. The abysmal state of affairs with regard to the collection and transport of waste is all too well known. However, the implications of the negligence in waste treatment and disposal, such as untreated and unprocessed garbage left in open dumpsites, and its grave consequences for public health and the environment are not fully understood. They are the main cause of river water, land, and air pollutions.

8.4.4 Tips on Reducing Waste and Conserving Resources (the Three R’s—Reduce, Reuse, and Recycle)

The three R’s (reduce, reuse, and recycle) help approaching system acceptability index to unity, and thus, to cut down on the amount of dissipated energy (waste). They conserve natural resources, landfill space, and energy.

The three R’s save land and money as waste to dispose of waste in landfills. Identifying a new landfill has become difficult and more expensive due to environmental regulations and public opposition.

8.4.4.1 Reduce

Reduce means using fewer resources in the first place. This is the most effective of the three R’s and the place to begin. The best way to manage waste is to not produce it. This can be done by shopping carefully and being aware of a few guidelines:

- Use of disposable goods (such as paper and plastic plates, cups, napkins, razors, and lighters.) must be avoided. Throwaways of disposable goods contribute to the waste disposal problem and cost more because they must be replaced again and again.

- Well-built durable goods or that carry good warranties should be purchased. They will last longer, save money in the long run, and save landfill space.

- Electronic mail, online railway reservation, banking services, etc., minimize the wastage of paper.

- Use of cloth napkins, jute bags, and dish cloth towels should be encouraged in place of paper and plastic made products.

- Avoid overly packaged goods. The packaging is a total throw-away materials.

- Things made with toxic materials must be avoided.

- Use of water and electricity must be minimized. Highly energy efficient electrical and electronic goods should be purchased.

8.4.4.2 Reuse

It makes economic and environmental sense to reuse products. Sometimes, it takes creativity. Reusing keeps new resources from being used for a while longer, and old resources from entering the waste stream.

Before recycling or disposing of anything, it must be considered that whether it has life left in it or not?

- Reusing an item means that it continues to be a valuable, useful, productive item, and replaces new items that would utilize more water, energy, timber, petroleum, and other limited natural resources in their manufacture.

- Lumber, tools, windows, doors, light fixtures, paint, plumbing supplies and fixtures, architectural pieces, fencing, hardware, and many other items needed for constructing or refurbishing a building can be used from available waste building materials.

- Desks, tables, chairs, filing cabinets, credenzas, shelving units, stacking trays, tape dispensers, notebook binders and other equipment and supplies can be reused in offices, schools, hospitals, non-profit organizations, and others.

- Reuse products for the same purpose. Save paper and plastic bags, and repair broken appliances, furniture, and toys.

- A product that can be used repeatedly instead of a version that is only used once and thrown away should be purchased.

8.4.4.3 Recycle

The third R in the hierarchy is for recycle, which in terms of waste is the reprocessing of disposed materials into new and useful products. Items that are commonly recycled include glass, plastic, paper, and metal. When recycled, some of these materials are used to create more of the same original product, while other materials are used to create entirely different products after recycling.

Recycling is a series of steps that takes a used material and processes, remanufactures, and sells it as a new product. Begin recycling at home and at work.

- A recycled plastic soda bottle is chipped, melted, and made into fibre, which becomes a jacket or sleeping bag stuffing.

- Recycling household waste is a relatively simple and inexpensive way to contribute to a better global environment.

8.5 SOURCES AND TYPES OF WASTES

The following are some of the wastes:

- Residential wastes: These are single family or multifamily dwellings. They constitute kitchen wastes, paper and cardboards, clothes and leather materials, plastics and rubber materials, glass, wood and metal crockery and furniture, electrical and electronics appliances and gadgets, etc.

- Municipal services wastes: They include general wastes collected from street sweeping, park, recreational places, sludge, landscaping, and tree trimming.

- Industrial and commercial wastes: They are housekeeping and food wastes, packaging and demolition material wastes, scraps, hazardous wastes, wood, cardboard paper, plastics, etc.

- Building construction and demolition: They constitute various types of wastes such as wood, concrete, steel, and dust.

- Agriculture: It consists of dairy and agriculture farm crop wastes, hazardous pesticides, etc.

8.6 RECYCLING OF PLASTICS

Plastics play an important role in almost every aspect of our lives. Plastics are durable; their toughness and inertness are what make them so useful. Unfortunately, they are so durable that they break down very slowly in a landfill. Plastics are used to manufacture everyday products such as beverage containers, toys, and furniture. The widespread use of plastics demands proper end of plastic life management. The largest amount of plastics is found in containers and packaging (e.g., soft drink bottles, lids, shampoo bottles), but they also are found in durable (e.g., appliances, furniture) and nondurable goods (e.g., diapers, trash bags, cups and utensils, medical devices). The recycling rate for different types of plastic varies greatly. Plastics are a versatile material that can be a valuable asset to recycling program.

Plastics can be divided into two major categories:

- Thermosets: A thermoset solidifies or ‘sets’ irreversibly when heated. They are useful for their durability and strength and are, therefore, used primarily in automobiles and construction applications. Other uses are adhesives, inks, and coatings.

- Thermoplastics: A thermoplastic softens when exposed to heat and returns to original condition at room temperature. Thermoplastics can easily be shaped and moulded into products such as milk jugs, floor coverings, credit cards, and carpet fibres.

According to most estimates, 80% of post-consumer plastic waste is sent to landfill, 8% is incinerated, and only 7% is recycled.

Since the production of plastics uses 8% of the world’s oil production, it is in the best interests to recycle plastics. In addition to reducing the amount of plastics waste requiring disposal, recycling plastic will reduce the consumption of non-renewable fossil fuels, energy, the amount of solid waste going to landfill, and the amount of carbon emissions.

8.6.1 Recycling of Plastics

Recycling plastic material is one of the important environmental agenda defined in the three R’s. Instead of simply reusing the material as it is, successful chemical reusing is a more effective way for reducing the use of natural resources and environmental damage incurred thereof. An effective process and a pertinent effective plant that successfully converts plastic wastes into wax-free hydrocarbon such as naphtha and diesel oil is an important plastic recycling system.

Plastics from Municipal Solid Wastes (MSW) are usually collected from curbside recycling bins or drop-off sites. Then, they go to a material recovery facility, where the materials are sorted by plastic type, baled, and sent to a reclaiming facility. At the facility, any trash or dirt is sorted out, then the plastics are washed and ground into small flakes. A flotation tank may be used to further separate contaminants based on their different densities. Flakes are then dried, melted, filtered, and formed into pellets. The pellets are shipped to product manufacturing plants, where they are made into new plastic products.

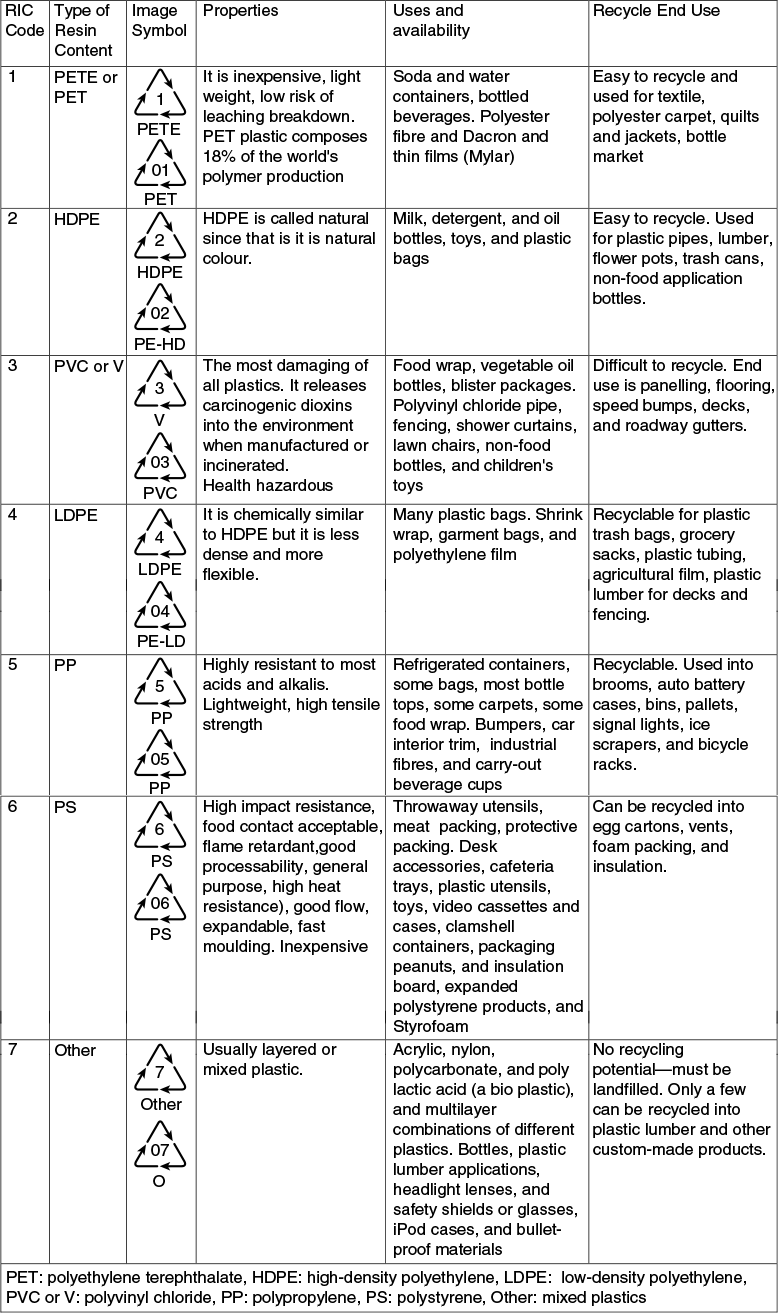

8.6.2 Plastic Resin Identification Code

Plastics come in a variety of colours and chemical formulations, all with different recycling needs. Turn the product over and look for the recycling symbol, a triangle with a number from 1 to 7 inside, as shown in Figure 8.2. The plastic resin identification code is a set of symbols placed on plastics to identify the polymer type. It was developed by the Society of the Plastic Industry (SPI) in 1988 and is used internationally. It was transferred to ASTM International in 2010. The primary purpose of the codes is to allow efficient separation of different polymer types for recycling. Separation must be efficient because the plastics must be recycled separately. Even one item of the wrong type of resin can ruin a mix.

Figure 8.2 Resin identification code

There are seven different types of plastic resins that are commonly used to package household products. The identification codes listed in Figure 8.2 can be found on the bottom of most plastic packaging. It (RIC system) offered a way to identify the resin content of bottles and containers commonly found in the residential waste stream. Plastic household containers are usually marked with a number that indicates the type of plastic. Consumers can then use this information to determine whether or not certain plastic types are collected for recycling in their area. Contrary to common belief, just because a plastic product has the resin number in a triangle, which looks very similar to the recycling symbol, it does not mean it is collected for recycling.

8.6.3 Benefits of Plastic Recycling

The following are the benefits of plastic recycling:

- Energy and natural resource conservation: The first and foremost benefit of recycling of plastics is the conservation of petroleum products (oil and natural gas) and water used for making new plastic products. A large amount of petroleum and natural gas can be saved by recycling plastics. Oil and natural gas are two of the main components used for the production of the raw materials used to make plastic. These natural resources are not only in limited supply, but also in high demand for other important uses such as powering automobiles and producing electricity. Because plastic materials are already in such abundance, recycling these existing materials means that fewer natural resources are used for production of new plastic materials.

- Environmental protection: The benefits of recycling of plastics include reduction in emission of greenhouse gases in its manufacturing by burning petroleum and natural gases. As the use of petroleum products are reduced in manufacturing of new plastics, the greenhouse gas emission will also reduce. Factories that produce plastic products from raw materials also produce a great deal of harmful greenhouse gases. By using recycled plastic materials, production time is greatly reduced, which means that less greenhouse emissions are making their way into the atmosphere.

Plastics being a major contributor to the worldwide waste can cause serious environmental concerns because of their non-degradable nature that keeps them intact for a very long time.

One of the important benefits of recycling of plastics is that it saves life of animals, birds, and aquatic creatures from fatal due to ingestion of plastics. Pollution of air, soil, and water is greatly reduced by recycling of plastics.

- Reducing the dumping (landfill) spaces: Plastics are not a biodegradable material, which means that it can sit in a landfill for hundreds or thousands of years. Recycling plastic products also keeps them out of landfills and allows the plastics to be reused in manufacturing new products. Best of all, plastics can be indefinitely recycled, which means they could potentially be eradicated from landfills altogether. Landfill space is largely reduced by recycling of plastic.

- Energy conservation: By using recyclable plastic materials, factories can produce new plastic products using approximately 2/3 less energy than with raw material production.

8.6.4 Thermal Depolymerization

While interest in combusting and gasifying plastics appears to be growing, there is another route to making practical use of all the waste plastics modern society produces. A catalytic pyrolysis system has been developed to convert waste plastics into liquid hydrocarbons, coke and gas, which can then be used as boiler fuel for power generation. Power generation of approximately 5 kW is possible at 1l of mixed oil.

Thermal depolymerization (TDP) is a depolymerization process using hydrous pyrolysis for the reduction of complex organic materials (usually waste products of various sorts, such as biomass and plastics) into light crude oil. It mimics the natural geological processes that are involved in the production of fossil fuels. Under pressure and heat, long chain polymers of hydrogen, oxygen, and carbon decompose into short-chain petroleum hydrocarbons with a maximum length of around 18 carbons.

Pyrolysis is a process of thermal degradation of a material in the absence of oxygen. Plastic is fed into a cylindrical chamber. The pyrolytic gases are condensed in a specially designed condenser system to yield a hydrocarbon distillate comprising straight and branched chain aliphatic, cyclic aliphatic, and aromatic hydrocarbons, and liquid is separated using fractional distillation to produce the liquid fuel products. The plastic is pyrolysed at 370°C–420°C.

The following are the essential steps involved in the pyrolysis of plastics:

- Evenly heating the plastic to a narrow temperature range without excessive temperature variations.

- Purging oxygen from pyrolysis chamber.

- Managing the carbonaceous char by-product before it acts as a thermal insulator and lowers the heat transfer to the plastics.

- Careful condensation and fractionation of the pyrolysis vapours to produce distillate of good quality and consistency.

8.6.4.1 Catalytic Pyrolysis of Waste Plastics

In this method, a suitable catalyst is used to carry out the cracking reaction. The presence of catalyst lowers the reaction temperature and time. The process results in much narrower product distribution of carbon atom number and peak at lighter hydrocarbons that occurs at lower temperatures. The cost should be further reduced to make the process more attractive from an economic perspective. Reuse of catalysts and the use of effective catalysts in lesser quantities can optimize this option. This process can be developed into a cost-effective commercial polymer recycling process for solving the acute environmental problem of disposal of plastic waste. It also offers the higher cracking ability of plastics and the lower concentration of solid residue in the product.

8.6.5 Plastic Waste to Oil Production in India

If all goes well, in India, Surat will be the first in the state of Gujarat to convert its plastic waste into crude oil and pellets, which could be further used as fuel substitute to power industrial units, vehicles, power plants, boilers, and generators.

Process claimed to be relatively simple. Forced air, heated by a gas burner, is used to indirectly heat the feedstock inside the process vessel. The air is continually recycled in a loop to minimize heat loss.

The process vessel is isolated from oxygen and is exposed to a negative pressure (vacuum) environment. The energy transferred to the plastic feedstock from the burner is used to depolymerize, or ‘crack’ the plastic into synthetic crude oil.

Oil is chromatographically removed from the waste plastic and aggregated from several vessels for on-site micro-refinement or sent to existing commercial refinement facilities.

Waste products are recycled for energy usage (gases), treated, and reused or disposed (liquids), or made available for commercial use (solids).

8.6.6 Waste Plastic to Electricity Generation

Non-biodegradable plastics break down in a waste combustor to create an alternative source of fuel to generate electricity. Self-sustainability is the key to the double-tank combustor design. Plastic waste is first processed in an upper tank through pyrolysis, which converts solid plastic into gas. Next, the gas flows to a lower tank, where it is burned with oxidants to generate heat and steam. The heat sustains the combustor while the steam can be used to generate electric energy. Self-sustainability is the key to the double-tank combustor design. Plastic waste is first processed in an upper tank through pyrolysis, which converts solid plastic into gas. Next, the gas flows to a lower tank, where it is burned with oxidants to generate heat and steam. The heat sustains the combustor while the steam can be used to generate electric energy.

8.6.7 Advantages of Recycling of Plastics

- It is good for the environment.

- It is good for practicing green living.

- It saves the energy, resource, and some money.

8.6.8 Disadvantages of Recycling of Plastics

- Plastics are bad for the environment because it takes hundreds of years to biodegrade.

- It takes money, time, and energy to recycle plastics itself. Plastics are made from petroleum and thus have high significant heating value than coal. The recycled plastics can recover energy and can produce enough electricity to meet power requirements.

SUMMARY

- Waste is any material that is unwanted, discarded, or useless. These wastes causes dangerous environmental damage and other problems related with their dumping and disposal throughout the entire world.

- Efforts are, therefore, directed to make all these wastes as wealth to the extent possible, and the methods are designed to protect the environment

- Incineration is a waste treatment technology that involves burning commercial, residential, and hazardous waste. It converts discarded materials, including paper, plastics, metals, and food scraps into bottom ash, fly ash, combustion gases, air pollutants, wastewater, wastewater treatment sludge, and heat.

- Incineration is a practical method of disposal that saves a lot of money on transport of waste to landfills. It also reduces the carbon footprint that such transport leaves behind.

- Incinerator can be understood more precisely as a furnace where waste is burnt.

- Pyrolysis is a controlled chemical process (temperature, pressure, batch or continuous system, catalyst, etc.) in order to produce valuable secondary raw materials (solid, liquid, or gas) or energy.

- Pyrolysis is the process of thermal degradation of wastes in the absence of oxygen.

- Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen.

- The three R’s (reduce, reuse, and recycle) help approaching the system acceptability index to unity, and thus, they help to cut down on the amount of dissipated energy (waste).

REVIEW QUESTIONS

- What are solid wastes? Explain their effects on environment. Also discuss main sources of solid wastes.

- What are the major classifications of solid wastes

- State and explain the methods of municipal solid wastes management.

- Define wastes source reduction and its necessity and benefits. Also explain practical methods of source reduction.

- Define and explain recycling of wastes and its benefits.

- Define the following terms: Incineration, Pyrolysis, and Gasification. What is the difference among these processes?

- What is the advantage and disadvantage of the following solid treatment technique?

- Incineration

- Composting

- Land filling

- RDF (Refused Derived Fuel)

- Explain the role of incineration, Pyrolysis and composting in solid waste management.