18. ZenRobotics: Riveting Robots to Reduce and Recycle

Q: What happens when two academics and an ex-pop star get together?

A: They do something cool and “trashy” with robots.

When Harri Volpola (PhD, Physics, Mathematics, Neural networks), Tuomas Lukka (PhD, Quantum Chemistry), and Jufo Peltomaa (ex-pop star, serial entrepreneur) got together, that was exactly what they did. After Tuomas and Jufo had sold off their hybrid graphics to Nvidia, they were contemplating what to do next. Their only business plan at that time was that their new venture would involve robots.

To better figure out what it was that they wanted to do with robots, they conducted interviews with potential customers. The interviews helped them understand on what area the customers would like to save money on and need assistance with, simultaneously. The typical interview questions included inquiries about the areas where the companies faced difficulty, areas where they lost money the most, etc. After looking at 200 to 300 companies from a variety of industries, the founders were convinced that recognition and manipulation of odd-form objects in trash was a potential area to focus upon. ZenRobotics estimates that a client would normally pay €100 to dispose of a ton of waste. The metal from the waste however, could earn as much as €250 per ton. Thus they realized that, of the six identified business fields where robotics is most important, the most promising one was recycling. The idea of “robotic recycling” was thus born. Data showed that in European Union alone, 3 billion tons of waste is produced every year, of which construction and demolition waste contributes to 900 million ton. The related recycling and disposal issues could be solved through introducing a new robotic system. With this concept in mind, ZenRobotics was conceived in 2007.

WOW: Robots Sorting Our Trash

ZenRobotics uses artificial intelligence technology to solve the age-old dilemma associated with recycling and waste disposal. It uses a robotic system for identifying the recyclable materials (metal, wood, stone), irrespective of the shape or size, while the trash passes through a conveyor belt. This is quite noteworthy as the differentiation and management of odd-shaped objects were impossible with automation systems before ZenRobotics. In ZenRobotics, the system is equipped with infrared scanners, metal detectors, and load sensors for doing this. The latter detects the surface area and weight of the trash materials. The robot systems weigh the trash while they lift items and calculate the associated price. The adaptive picking motions of the industrial robots are also controlled. The robots used in ZenRobotics are reliable, standard industrial robots (“similar to the ones used in Volkswagen factories”). They are backed up by artificial intelligence software. The systems are monitored so as to check for wear and tear.

In its first funding round ZenRobotics received $17 million from the international equity investor, Invus and the Vigo accelerator, Lifeline ventures. ZenRobotics hired Juho Malmberg (Accenture, Finland), as its CEO and Jorma Eloranta (Metso), as the Board chairman. The initial product launch was in 2012. Within a year, ZenRobotics was able to sell five units, with an approximate per unit price of $1 million.1

1It could also process a minimum of 12,000 tons of waste in a year (and a maximum of 60,000 tons), making sure that the cost of a unit purchased can be recovered by the buyer company in a year.

ZenRobotics contacted 16 waste processing companies in Finland, for its first installation. All the companies were interested in the technology and concept. SITA Finland Ltd., a part of SUEZ Environment, was the keenest one. SITA is Europe’s largest environmental company handling waste. Through the collaboration, ZenRobotics launched its product pilot and worked on streamlining the processes. By 2011 February, ZenRobotics had 20 agents in 47 countries, handling the sales. The robotics systems are assembled locally in Finland and then delivered to customers. Then they are installed through a global reseller network. In May 2014, ZenRobotics opened the world’s very first robotic waste processing plant in Finland. They estimate their overall global sales potential to be 8000 units.

Apart from the novelty of the approach, ZenRobotics is also a frontrunner in robotics-based recycling. It is the original robotic waste sorting system in the whole world. Currently, the technology is still a newfangled concept in the Environmental Services Industry. ZenRobotics is working toward making this technology conventional. By adding on to, and creating new applications for existing sensors, ZenRobotics is striving to expand its arena to include more recyclables and a wider array of potential customers.

SO WHAT: Robotics to the Rescue? How Does ZenRobotics Operate?

ZenRobotics systems can handle a maximum of 20 kilograms of recyclable material in one pick (gathering motion). The picking cycle is 3 seconds and a machine can do 1400 picks per hour, 5000 hours per year. By doing the math, quite evidently ZenRobotics can recover more than 10,000 tons of recyclable material per year.

How Is ZenRobotics a Positive Outlier?

Unlike companies that bring a new idea into an existing business, ZenRobotics created a new business with their idea. The idea was born after numerous interviews with potential customers, thus ensuring its relevance and applicability in the contemporary setting. Through robotics recycling, the customer could save on the disposal costs and at the same time, make money on the recyclable material. ZenRobotics identified a market and a business opportunity in the field of Environmental Services and Waste Management. It adapts itself to the present trend toward higher recycling rates. ZenRobotics works along the lines of the model of “Circular economy”—the processes are designed from the start itself to ensure that the waste from one process acts as input to another process. The products are reused and upgraded instead of being discarded.

Compared to manual waste sorting plants, ZenRobotics is a safer option as it prevents exposure of humans to hazardous material (asbestos, mold, toxins, sharp and heavy objects, etc.). The associated labor costs are also reduced as the robots are designed to replace a high number of manual work hours per year. The machines are very durable, capital efficient, and require very less maintenance cost. They also come in different models. For instance, ZenRobotics Recycler comes in three models (with one, two, or three arms). The installation options include retrofit (to be integrated into existing processes), and stand-alone (all in one compact semi-mobile package).

As it is unnecessary to transport the waste material to centralized plants, the transportation cost is much lesser than in conventional models. By eliminating the need to source-separate the customer can increase the profits by single stream collection of waste materials. To top it all, being the company with a “robot waste sorter” attracts media attention and the interest of clients, thereby boosting up business.

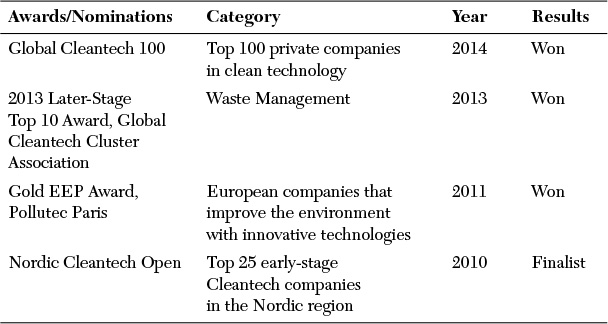

ZenRobotics’ innovative idea, systematic implementation, and product enhancement attempts have won it many awards and accolades (see Table 18.1).

Table 18.1 Awards and Nominations Received by ZenRobotics, Compiled from Published Sources and Company Website

Challenges

In any field, one of the challenges that frontrunners face is from incumbents and competitors. The incumbents in this context are the manual waste sorting plants. Other recycling facilities designing recycling sorting systems like Machinex are also potential competitors to ZenRobotics. However, Machinex is yet to develop a robotic recycling system that could become a potential contender to ZenRobotics Recycler.

Another significant challenge is the fact that the field of environmental services is a conservative one. The technologies used are conventional and mechanical. Introducing and successfully integrating Robotic systems into this field would require some preparation. Customers might need time and information about the technology to make the transition. On the other hand, ZenRobotics counts on the concept of Best Available Technology (BAT), promoted by the European Union and the United States as an element which would encourage this transition. Juho Malberg (CEO) envisions that in an immediate future, when manual sorting becomes obsolete and illegal, the BAT principle would drive both local and international regulation to the usage of the most efficient technology available, i.e., the one of ZenRobotics (Source: cleantech.com). What is more, he believes that the good results of the technology would be enough to convince even the most conservative people to make the switch.

Outlook

ZenRobotics entered a market which is booming, socially sensitive, and yet facing a lag in efficiency and effectiveness. Waste disposal and recycling is an area which is too complicated and disorganized for standard robot control systems. It is in this field that ZenRobotics entered and created a disruption. By combining sensory fusion, data-mining, machine learning, and real-time robotics, ZenRobotics made the outmoded recycling industry automatic, modern, scalable, and effective. The change which the founders envision through this is quite similar to the one which happened in auto industry, with the advent of robots.

Besides, ZenRobotics is still evolving. It aspires to be able to process new waste streams like Municipal Solid Waste (MSW), End of Life Vehicles (ELV), Waste Electrical & Electronic Equipment (WEEE), hazardous materials, and radioactive waste, among others, in the near future. MSW includes everyday waste items that are discarded by the public, usually disposed of by landfilling. ELV, or motor vehicles which have reached the end of their productive lives, usually constitute about 8 to 9 million tons in the European Union only. Managing them the correct way would involve dismantling and recycling them. ZenRobotics could prove to be extremely prolific in both of these areas. Another line of work ZenRobotics could involve itself is in the promotion and implementation of facilities for the reuse, recycling, and recovery of electrical and electronic equipment waste (WEEE). Disposal of radioactive waste in a safe and suitable way is another grave matter of concern. Spent nuclear fuel from nuclear reactors, high-level radioactive waste from the reprocessing of spent nuclear fuel, transuranic radioactive waste from nuclear weapon manufacturing, uranium mill tailings from the mining, and milling of uranium ore, low-level radioactive waste (contaminated industrial or research waste), and naturally occurring radioactive material constitute different kinds of nuclear waste. The final category on the check list is hazardous waste. It is a big category and includes subcategories such as household hazardous waste, some agricultural wastes, drilling wastes, or cement kiln wastes. ZenRobotics plans to expand to this domain too.

It looks like ZenRobotics has set its aims high. In a distant future, ZenRobotics might even be able to move robots from factory settings to the real-life environment. In short, as the founders rightly say, “what you buy is just the beginning.” It looks like the ultimate aim of ZenRobotics is indeed, world (of trash) domination.

From the Perspective of Tomi Laamanen, Professor of Strategic Management, University of St. Gallen

ZenRobotics is an innovative start-up that was established by three founders through a careful thought process where the founders were systematically analyzing alternative industries in which they could enter. The founding of ZenRobotics resembles the thought processes that Jeff Bezos, the founder of Amazon, and Austin Ligon, the founder of Carmax, went through before choosing the product areas they wanted to focus on. Similarly to Jeff Bezos that was convinced of the opportunities offered by the Internet and Austin Ligon that wanted to benefit from the trend toward specialized superstores, the founders of ZenRobotics were convinced of the opportunities offered by robotics.

The waste recycling business is an interesting, in many respects attractive business since one has the in-bound and out-bound customers that both provide cash flows for the waste recycling firm. On the one hand, one is serving the in-bound customers in helping them dispose their waste and, on the other hand, one is using the valuable materials or energy retrieved from the waste recycling process and selling them onward to the out-bound customers that can use them as raw materials in their own processes. Furthermore, as the amount of waste is continuously increasing and the pressures for recycling and environmental consciousness are getting higher, there are without a doubt major global growth opportunities in waste recycling.

ZenRobotics is tapping onto this global trend in helping the waste recycling companies to optimize their processes through robotized waste handling systems. The use of advanced sensor technology combined with artificial intelligence and robots capable of handling odd-shaped objects represents a major innovation for waste recycling that enables the waste recycling firms to further automate and optimize their processes. The major potential associated with the firm was also recognized by investors and, as a consequence, ZenRobotics was able to raise 17 MUSD from a syndicate of reputed early-stage venture capital investors.

While the investment provides ZenRobotics a great opportunity to start expanding its business with the help of its newly recruited CEO, Mr. Juho Malmberg (former CEO of Accenture Finland and former management team member of Kone Corporation), it also puts major pressure on it to be able to sell major customer projects internationally due to its relatively narrow sectoral focus. Moreover, starting to sell internationally an innovative concept that requires major capital expenditures from its customers is not easy, because, in addition to developing a relationship with the potential customers, one has to be able to convince them that the new automated concept works and provides a solid pay-back time for the investment. Moreover, developing an international sales force often tends to take more time than one would have originally anticipated and cost more than initially expected.

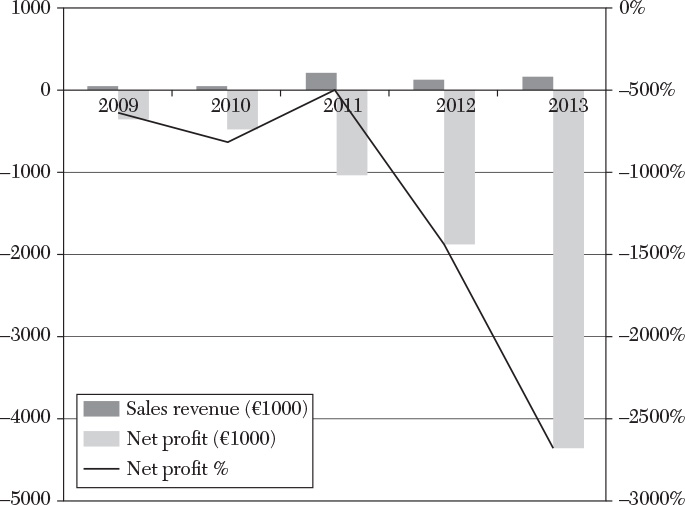

This difficulty is clearly visible in the financials of ZenRobotics (see Figure 18.1) where the investments into the international expansion and the further development of the product concept have not yet paid off in terms of higher sales revenue. With the help of the relatively generous initial venture capital funding, the balance sheet of ZenRobotics continues to be strong, but the present burn-rate cannot continue for many more years without an additional funding round if the sales do not dramatically increase. This struggle can also be seen in resignation of the CEO of ZenRobotics at the end of 2014.

One of the further reasons for the challenges of ZenRobotics has been that even though already the initial system worked well, the robotic arms were too slow for industrial scale automated waste recycling. Thus, the ZenRobotics team had to go back to the drawing board in 2014, halt the sales efforts, and redesign the system to make it faster. A pilot version of the new robot is now already in operation in Finland in SITA’s waste plant and the sales efforts of the new product concept were restarted in the RoboBusiness Exhibition in Boston in the Fall 2014. The future will show how the 10 meters long and 4 meters wide system costing roughly €500,000 will sell and how long it will take for ZenRobotics to return back to profitability.

Going beyond the early lessons learned regarding customer requirements, ZenRobotics continues to be well-positioned with an innovative product in a growing industry. A further important consideration for the company will be the business model of the future. A central question for ZenRobotics in this respect will be whether to become a vendor of automated systems or whether to retain the ownership of the systems and rather start selling waste handling as a service with a monthly or yearly service fee.