20. Organovo: Leaving 3D Bioprints for Others to Follow

It all began in 2003, when Dr. Thomas Boland patented ink-jet printing of viable cells at Clemson University. Drawing inspiration from this, Prof. Gabor Forgacs and his multi-institution team began work on organ (bio) printing technology at the University of Missouri the very next year. The subsequent year, the founders of Organovo had discussions regarding the formation of a bioprinting company around the Forgacs organ printing technology. Through bioprinting, printing equipments could be devised to deposit biological material and create tissues that mirror key traits of the native tissues. With this vision in mind, Organovo, Inc. was formally incorporated in Delaware, in 2007.

Under the leadership of Keith Murphy, CEO, Organovo, Inc. began raising start-up funds and receiving $3 million in angel financing in 2008. In 2009, Organovo opened its laboratory in San Diego and completed work on the delivery of NovoGen MMX Bioprinter. It created bioprinted blood vessels and received its first National Institutes of Health (NIH) grant. Organovo, Inc. has had exponential progress since then.

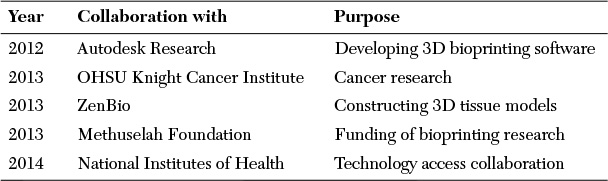

The main focus of Organovo Inc. was on launching 3D bioprinting. Using this technology, the company designs and creates functional human tissues, which are built to function just like native tissues. After it demonstrated the ability to create novel tissues in 3D using primary human cells, it began corporate partnerships (see Table 20.1).

In February 2012, the company went public through a $15.2 million financing round. The same year, Organovo received its company patent and key founder patent. It closed $46.6 million in secondary public offering and stock listed on NYSE MKT in 2013. The same year, it developed its own 3D human liver model and in 2014, it delivered the first 3D liver tissue to Key Opinion Leader. Not surprisingly, Organovo featured in MIT Technology Review’s 2012 list of the world’s 50 most innovative technology companies and will be honored as the 2015 Technology Pioneer by the World Economic Forum (WEF).

WOW: Digitally Printed Organs on Demand, or Bioprinting Tissues in Their Own Image

Organovo is a pioneer in 3D bioprinting. Basically, the 3D printing process involves taking particular cells and putting them into a 3D matrix. The cells are internally programmed (by nature) to help create the final tissue. The final tissues are then layered architecturally in the right positions. The tissues formed thus represent the true human biology better than its polymer-based counterparts.

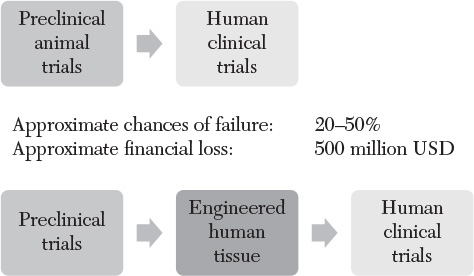

Organovo partners with biopharmaceutical companies (e.g., Pfizer, Janssen Research & Development, L.L.C.), and university medical centers to fashion “preclinical discovery,” i.e., to create and authenticate predictive tissues for disease modeling, toxicology, metabolism, and transport studies. This ensures that the preclinical models are safe and efficient, when compared to the 2D animal and cellular (cells in petri dish) models. Sometimes, clinical tests which might work in the 2D models might not work in real human tissues. The failure rate is 20 to 50 percent. This causes a loss of close to 500 million USD yearly. With bioprinting, Organovo solves this problem and ensures the testing and production of more, quicker, safer, and effective drugs. This bridges the gap between preclinical testing and clinical trials by allowing for the testing of drugs in functional human tissues, even before administering them to a human being (see Figure 20.1). The 3D printed liver tissues made commercially available by Organovo in November 2014 is a step in this direction.

SO WHAT Makes Organovo the Fittest?

Organovo When Compared to Human Donors

Another area where Organovo tissues can be useful is in surgery. Organovo aspires to produce small, purely cellular, functional replacement tissues that go through clinical trial pathways like heart muscle patches, nerve graphs, blood vessels, etc. These 3D tissues in turn would repair or replace the diseased or damaged tissues. This not only enhances the chances of availability of tissues for recipients, but also ensures the quality of donors. With human donors, it is difficult to determine the quality of donated tissues or to ascertain whether they carry any traces of chronic diseases. Organovo would be able to ensure that the recipient gets high-quality tissues harnessed from his own cells, thus guaranteeing its safety and suitability. By using the recipient’s own cells, organ rejection during transplantation could also be checked. Furthermore, this would solve the problem of the mismatch between the numbers of willing, healthy organ donors and worthy recipients. Likewise, recipients usually have to be in long transplant waiting lists till a suitable donor is identified. With Organovo bioprinting technology, transplant waiting lists would soon be things of past. After all, it would take only less than 30 minutes to create a 5-centimeter section of artery.

Organovo When Compared to Traditional Models

Organovo moves 3D printing beyond building plastic prototypes and metal end products (e.g., work done by companies like Stratasys, 3D Systems) and into cardiovascular medicine, medical research, and transplant medicine. It revolutionizes Pharma drug discovery and toxicology testing by enhancing the effectiveness and longevity of testing models. When compared to animal tissues, Organovo tissues are human, as well as have a longer life (more than 40 days).

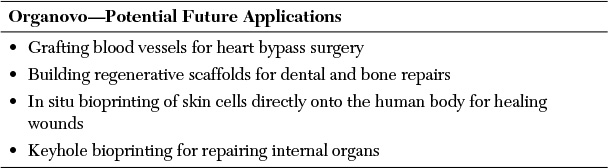

Organovo as the Future

Organovo’s ultimate aim is to harness new organs from the patients’ own cells. Even though Gabour Forgacs is uncertain about 3D printing being able to create body parts identical to the ones provided by nature, he is quite sure that creating body parts functionally equivalent to the natural ones would be possible in the future. Science today cannot fix an upper limit on longevity. If Organovo does indeed succeed in this attempt, we could look forward to a future where tissue-on-demand and organs-on-demand would be technologically possible. Shedding defective organs and replacing them with new, functional ones would be a reality (see Table 20.2).

Table 20.2 Potential Future Applications of Organovo’s Bioprinting Technology, Compiled from Published Sources and Company Website

Challenges

Not many 3D printing companies work with live tissues. Nevertheless, Organovo does have one strong competitor at this point. Envisiontec, the 3D rapid manufacturing solutions company, launched its 3D-Bioplotter in April 2014. According to Envisiontec, this Bioplotter is a “rapid prototyping tool for processing a great variety of biomaterials within the process of Computer-Aided Tissue Engineering from 3D CAD models and patient CT data to the physical 3D scaffold with a designed and defined outer form and an open inner structure.” It comes in two series—the Developer Series (for educational institutions) and the Manufacturer Series (for advanced tissue engineering research and production). Apart from printing bio-ink “tissue spheroids” and supportive scaffold materials (like Organovo), Envisiontec also prints a variety of biomaterials like biodegradable polymers and ceramics for supporting and actuating the formation of artificial organs, and bone substitutes. However, Envisiontec Bioplotter is not capable of bioprinting with high concentrations of living cells. It can work only with biomaterials of very dilute cell mixtures in hydrogels. This process would not be able to yield a “tissue” with the cellular density that approaches native human tissue, the way Organovo does.

Apart from industry adjacents like Envisiontec, academic institutions like Columbia, Cornell, and Wake Forest also have researchers working on bioprinting. Wake Forest research team members, under the directorship of Surgeon Anthony Athala, have already lab-grown their first organ (a bladder) which could be implanted into a human being. They are also working on experimental fabrication technology that can print human tissue on demand, just like Organovo envisions.

Apart from the competition in the field, another challenge Organovo faces is its stock fluctuations. In 2013, the company’s stock rose 345 percent based on the potential of its tissue engineering technology. Yet, in 2014, its stock crashed by 40 percent. This can be attributed to the wearing off of the awe-factor and the ambiguity regarding the company breaking even and making profits. The company’s full-year profitability is at least 3 to 5 years off. Likewise, another factor contributing to this challenge is the cash burn out rate of the company. According to investment experts, the company might have 3 years of cash viability unless it turns to open market and sells some of its shares. However, selling shares this way would dilute the existing investors. Another way out would be for Organovo to enter into a licensing deal with a larger company.

Outlook

Bioprinting might one day prove to be a potent tool for people pursuing life extension and longevity. Doctors and scientists would be able to manipulate a living tissue at its cellular level itself. As a result, we could anticipate developments in medical fields and pharmacology, which might even lead to bioprinters becoming mandatory in every hospital emergency units. Bioprinting could also cause ripples in fields like nanotechnology, genetic engineering, and plastic surgery. Who knows, in a future not far away, people might be able to use bioprinting to achieve their desired looks and perpetual youth. Maybe the elixir of life is not just a legend after all.

From the Perspective of Michael Renard, Executive Vice President of Commercial Operations, Organovo

The following answers were provided to the questions presented in an e-mail exchange:

1. The purpose on which the company was founded; what is your passion?

The company is driven by the potential for “Changing the shape of medical research and practice”—our brand essence and purpose.

2. Its difference relative to incumbents; why is it strategically novel in your view?

We are the only company able to produce human tissues with the density, composition, and architecture that closely resemble native tissue, and consequently achieve behavior that is representative of native biology. This gives our tissues unique and differentiate performance for a variety of uses.

3. A quick tour of history; how did you and your colleagues in the company get here in terms of doing something differently? (What rules did you break?)

I am not a founder, but the founders saw the opportunity to combine the disciplines of biology and engineering in a way that had never been done before.

4. Future intent; what is the next opportunity and related challenges?

To prove the utility of this new technology with value-added products and services that fulfill our purpose.

5. Looking back from the future; why did what you have done matter more broadly speaking (even beyond this particular company surviving or not)?

We are a leader in this area, and the promise of this is in the creation of a new industry, an industry based on where biology can be engineered—and built by design.

6. How have you amplified the change, which the company stands for? Or how did you punch above your weight to make impact?

We work to leverage our technology with capable and reputable partners, and we remain the first mover, market leader in innovation, allowing us to set the rules for this new and burgeoning industry.