CASE 4

JSW’s Sajjan Jindal: Steel King Racing to the Top

This case study is based on our video interview of Sajjan Jindal, Chairman and Managing Director, JSW Steel

SYNOPSIS

Steel and the extent of its consumption has become one of the main indicators of the socio-economic development of a country. In the Global Steel Industry, China occupies the top spot with 716.5 mtpa followed by Japan with 107 mtpa, USA with 89 mtpa and Russia with 71 mtpa. India currently lies in the 4th spot with 77.6 mtpa.i

(Source: World Steel Association Report)

The Steel Industry in India consists of the Public Sector and the Private Sector. The main producer in the Public Sector is SAIL (Steel Authority of India Limited) having 9 plants including the most recent plant RINL (Rashtriya Ispat Nigam Ltd).

In the Private Sector, the leading producers are Tata Steel and JSW including Ispat Industries, which it has recently acquired. There are other private sector plants like Essar Steel etc. In addition, there are a host of small steel producers.

JSW Steel started with two small plants in 1982 at Vasind and Tarapur, which were given to Sajjan Jindal by his father to nurture and develop. Sajjan Jindal’s first goal was to be as big in production capacity as SAIL and Tata Steel. He therefore, set up a major venture in Vijayanagar in Karnataka—a 3 mtpa plant. Unlike other plants which used blast furnace technology, Jindal decided to use Corex technology. Despite various problems including a natural disaster, he successfully got the plant in operation. Thereafter, he never looked back.

In 2010, he acquired Ispat Industries from the Mittals, despite it being in deep financial trouble. Using great strategic insights, Jindal saw a number of synergies between Ispat and JSW Steel, which would work for the benefit of both companies. With this acquisition, JSW Steel had now become the largest private sector company with 14.3 mtpa thereby, edging out Tata Steel. Now it has its sights on SAIL along-with RINL.

Under Sajjan Jindal’s leadership, the Company took steps to develop its markets. However, in 2007-08 the Western world was deeply affected by recession. This would have adversely affected the Company had it not been for Sajjan Jindal looking at Bharat rather than India. The rural market had a lot of unsatisfied demand which was met satisfactorily by JSW Steel by increasing its distribution centres from 50 to 174 during 2008 to 2010 respectively. On the international front, JSW turned its attention to the emerging economies and started selling to regions like South America, CIS, Africa and Asia.

JSW’s history has shown a steady growth from a turnover of ₹3,419 crore in 2003/04 to ₹48527 crore in 2013-14. Profits after tax had also increased from ₹529 crore in 2003-04 to ₹1335 crore in 2013-14. This was a fantastic feat, as what Jindal has been able to do in 20 years, Tata’s and SAIL took more than 60 years to achieve!!

Much of JSW’s success has to be attributed to the leadership of Sajjan Jindal. However, his employees have also contributed to his success. JSW Steel through its HR policies has also been able to attract technically qualified individuals and has been able to motivate them through payment of attractive salaries and providing of good benefits. Moreover, the employees were given opportunities to be exposed to new technology as well as to multi-tasking. Thus, JSW Steel can boast of a higher per capita steel production as well as the lowest labour cost per ton of steel, globally.

The Company also participates actively in CSR activities. Total spending on CSR as percentage of PAT is 2.03 % in FY 13-14. It conducts the activities in and around its various plants and covers areas of Education, Health, Environment, Livelihood, Sports and Arts, Culture and Heritage.

Today, the Company is facing serious problems on a variety of fronts, which are threatening to prevent it from achieving its grandiose plans. The second bout of recession in the developed economies is hurting the Company. It has to renew its efforts in making deeper inroads into Rural India as well as the expansion of its activities into emerging economies. Moreover, Sajjan Jindal has to contend with the problems of iron-ore and coal shortages. Furthermore, he has the task to put the recently acquired Ispat Industries on its feet as soon as possible so that JSW Steel as a whole can proceed along the growth path it has set for itself.

CMD’s Message

It is the broader definition of KnowHow, that has governed our actions. It enables us to innovate every day and redefine the way we operate. It gives us the ability to adapt to changing market dynamics with precision and speed. As an organisation, it is part of our very strategic and operational DNA.

Sajjan Jindal*

PROFILE OF THE STEEL INDUSTRY IN INDIA

Steel is crucial to the development of any modern economy and is considered to be the backbone of human civilization. The level of per capita consumption of steel is treated as an important index of the level of socio-economic development and living standards of the people in any country. All the major industrial economies are characterized by the existence of a strong steel industry and the growth of many of these economies has been largely shaped by the strength of their steel industries in their initial stages of development.

Steel industry in India was in the vanguard of the liberalization process of the Industrial Sector and has made rapid strides since then. The real test of the steel industry will be to surmount the various difficulties it is facing and remain globally competitive.

Steel Market size in India

India has become the world’s fourth-largest producer of crude steel. The country is slated to become the second-largest steel producer by 2015 as large public and private sector players strengthen steel production capacity for meeting the rising demand for steel.

Presently, steel contributes to nearly two per cent of the gross domestic product (GDP) and employs over 500,000 people. The total market value of the Indian steel sector stood at US$ 57.8 billion in 2011 and is expected to touch US$ 95.3 billion by 2016.

India’s per capita steel consumption stood at 57.8 kilograms in 2013, according to a World Steel Association report. This is well below the world average (at about 200 kg per annum) and much below that of the developed world (around 350 kg per annum).

The total employment in the industry is more than two million (including direct and indirect employment). However, it is expected to rise with increased industrialization throughout the country. India’s real consumption of total finished steel grew by 0.6 per cent year-on-year in April-March 2013-14 to 73.93 MT, according to the Joint Plant Committee (JPC), Ministry of Steel.ii

Although China is the dominant player in the steel sector, India is increasing its presence in the global steel market because of domestic steel consumption. The Government of India’s role in the industry’s growth is significant. It has relaxed foreign direct investment (FDI) norms, allowed private ownership and reduced customs duty. As a result, FDI has increased and the value of merger and acquisition (MandA) deals in the industry rose at a CAGR of 138 per cent over 2008–11.

Strong long-term demand from the steel industry is expected to further boost the iron ore industry, and increasing power production is likely to catapult demand for coal. The rising middle class population coupled with increased urbanization will grow the steel requirement in the economy. India has seen a rapid rise in production over the past few years, which has resulted in India becoming the fourth largest producer of crude steel and the largest producer of sponge iron in the world.

INTRODUCTION TO THE COMPANY: HISTORY AND DEVELOPMENT

The Jindal Group set up its first steel plant in 1982 at Vasind near Mumbai. Soon after, it acquired Piramal Steel Ltd., which operated a mini steel mill at Tarapur in Maharashtra. The Jindals, who had wide experience in the steel industry, renamed it as Jindal Iron and Steel Co. Ltd. (JISCO). Sajjan Jindal got from his father these two small steel plants. However, he was not satisfied with them and wanted to compete with the biggies SAIL and Tata Steel. However, these two companies were miles ahead in terms of size, technology and experience but that did not deter the young Jindal.

In 1994, in order to achieve his vision of moving up the value chain and building a strong, resilient company. Mr. Sajjan Jindal saw a great potential for a large steel plant and accepted the invitation from the Govt. of Karnataka. Vijayanagar Steel Ltd. (JVSL) was setup with its plant located at Toranagallu in the Bellary-Hospet area of Karnataka. This was in the heart of the high-grade iron ore belt and spread over 3,700 acres of land. It is just 340 kms from Bangalore, and is well connected with both the Goa and Chennai ports. Sajjan Jindal also selected COREX technology, which generated enough gases to fuel a captive power plant and consumed less water as compared to the traditional Blast Furnace technology. This was a bold and visionary selection of technology for the first time in India and not commercially proven. Today,it is hailed as a great innovative step in the history of steel making in India.

However, after setting up of the plant, Sajjan Jindal had to contend with a natural disaster that crippled the plant. With great courage and doggedness and by involving himself in the effort of salvaging the plant, Sajjan Jindal brought the plant back to full capacity and made a success of the venture. JSW Steel Ltd is today a fully integrated steel plant producing from pellets to colour coated steel. JSW Steel, the flagship company of US$ 11 billion JSW Group, is spread over six locations in India and has a footprint that extends to the US, South America and Africa.

The registered office of JSW Steel is at BKC, Mumbai. JSW Steel has coated product division in Maharashtra at Vasind, Tarapur, Kalmeshwar and manufacturing facilities at Torangallu in Karnataka and Dolvi in Maharashtra. JSW Steel has upstream facilities like the Raw material handling plant, coke oven, Corex plant, pellet plant, continuous casting plant and a hot strip mill. On the other hand, hot and cold rolling divisions are major downstream set-ups.

JSW Steel Ltd. upstream was the first Greenfield project to have Corex technology for manufacturing. JSW Steel’s sensitive approach had also lead to the development of Vijayanagar into a modern township, enveloped by acres of green, planted and maintained by Company Vijayanagar is prospering by leaps and bounds. Today, it produces 10 mtpa of crude steel at its Vijayanagar Works making it the leading largest integrated steel plant in southern India. Be it education, career opportunities for women empowerment, JSW Steel’s initiatives have gone a long way in making Vijayanagar the success that it is today.

Just when the organization was getting ready to start the steel project and was organizing the financial resources, the Asian Currency Crisis followed by a stock market crash in the mid 1990’s sent shock waves across the economy. These were indeed dark days for the upcoming organization as delays in project implementation were leading to huge cost over-runs.

As JSW Steel Ltd. grew phenomenally, it also steered Tarapur and Vasind towards newer horizons of prosperity. Apart from providing more jobs, JSW actively participated and organized various social and cultural activities to make lives richer. The region is now cleaner, happier and even more beautiful. Better health facilities, promotion of sports and education are few areas, which have gained through JSW’s Steel presence.

The story of JSW Steel is really the story of Sajjan Jindal who is the son of O.P. Jindal. The father was a son of a farmer and built the Jindal Empire from scratch. Sajjan Jindal is a technology savvy person and he takes all technological decisions. Every year he visits various fairs and exhibitions abroad and examines the best technology for his plants. If convinced he would import and install that technology.

Besides introduction of new technology, Sajjan Jindal had his sights on becoming the largest producer of steel in the country.JSW has produced 12.17 mpta when compared to SAIL and Tata Steel whose outputs were 13.58 Mtpa and 9.155 mtpa respectively in FY-13-14. However, what Sajjan Jindal has done is unbelievable, as he has bridged the capacity gap between his plants and those of SAIL and Tata Steel. What took them over 50 or 60 years to build; he plans to do in 20 years. Sajjan Jindal is a man in a hurry and he is going full speed to overtake these giants and be one of the leading producers of steel in the world.

One of the boldest decisions taken by Sajjan Jindal was the acquiring of Ispat Industries. This was a company running in losses, yet Sajjan Jindal acquired it for ₹2157 crore. He said that he would put Ispat back or track and make it profitable in three years. Behind this acquisition, was a deep-seated strategy, which saw a tremendous synergy between JSW Steel and Ispat Industries. He would utilize these synergies to bring Ispat back to health and provide JSW Steel the necessary inputs for further growth. Acquiring of Ispat also contributed to the faster expansion of JSW steel enabling it to reach its targeted turnover. The milestones in the history of the company are detailed in Annexure - I

THE PRODUCTS

JSW Steel offers the entire gamut of steel products – Hot Rolled, Cold Rolled, Galvanized, Galvalume, Pre-painted Galvanised, Pre-painted Galvalume, TMT Rebars, Wire Rods and Special Steel Bars, and Rounds and Blooms. JSW Steel has manufacturing facilities at Toranagallu in Karnataka, Salem in Tamil Nadu and Dolvi in Maharashtra. The coated product division are at Vasind, Tarapur and Kalmeshwar

The details of the variety of products of JSW Steel are given in Annexure – II

JSW Steel is one of the lowest cost steel producers in the world. It has established a strong presence in the global value-added steel segment with the acquisition of a steel mill in US and a service center in UK. JSW Steel has also formed a joint venture for setting up a steel plant in Georgia. The Company has also tied up with JFE Steel Corp, Japan for manufacturing the high grade automotive steel. JSW Steel has recently acquired a majority stake in Ispat Industries Ltd. This will make JSW Steel India’s largest private steel producer with a combined capacity of 14.3 mtpa by March 2011. The Company has also acquired mining assets in Chile, USA and Mozambique.

By 2025, the Company aims to produce 40 million tons of steel annually with Greenfield integrated steel plants coming up in West Bengal and Jharkhand.

THE COMPANY: VISION AND MISSION

The Vision and Mission and Core Values as detailed above, serve as important guidelines for all the stakeholders of the Company and particularly its employees and the Board of Directors.

The Board of Directors who gives direction to the Company is enclosed in Annexure – III.

Figure 4.1

DOMESTIC / EXPORTS MARKETS

- Activities relate to the development of new export markets for products and services. Exports has always been a strategic move of the Company with a clear focus on Value-Addition, Customization and expanded geographical reach. Despite demand contraction in international market during fiscal 2013-14, the company exported 8.3 million tonnes and expanding its reach to five continents.

- Total Foreign Exchange earned and used

- Revenue Analysis

STRATEGY

Domestic Markets

- Focus -Value Addition: By increasing the sales of Value added Products as well as by developing new products conforming to higher end specifications and grades.

- Enhancing Global Competitiveness of Value-Chain partners: By making steel available at globally competitive prices.

- Expanding distribution network: To capitalize on the spread-out demand opportunities as well as for the betterment of timely delivery concept. JSW Shoppe continues to expand from 50 in 2008-09 to 450 as on March’14 with an increase of 8 times over the last 5 years. Additionally, JSW has been expanding its Distribution Points on a Pan-India basis as well.

- Efforts of Brand Building: Focus on leveraging brand-recall and brand-value adopting multi-fold brand-building techniques viz. Introduced innovative concept of ‘Shoppe-On-Wheel’ in the Rural India, Wall- Paintings, Pro-Active participation in relevant exhibitions, Print-Media Advertisements, etc., leveraged sales of branded products by 5% of domestic sales.

International Markets

The Company has been maintaining a strategic presence in the international market. The year 2009-10 proved to be a boon in disguise, which led to exploring and partial shift in the focus from the conventional advanced markets, adversely impacted by the global economic crisis, to other promising economies.

- Shift of Focus by exploring the world: While the demand in conventional coated export markets of North America and Europe suffocated, JSW strategically shifted and consolidated its presence in other promising geographies including South America, CIS, Africa and Asia and capitalized on the demand potential, especially for the Coated products.

- Expand into Logistics-Advantage zone: Increased its presence for other Semis, Flats and Wire Rods into the economies having logistics advantage including South and Far East Asia, Rest of Asia, Middle East and Africa, especially, while the prices were touching the bottom.

- Increasing orders from customers that are more regular: Focused on increasing orders from customers that are more regular by entering into MOUs that shielded the Company and allowed it to have a continuous off-take. The year saw an addition of almost 50% more customers through MoU route, which led to increase in the sales volume.

- Focus on retail market: Increased focus on retail market, through first of-its-kind distribution network (JSW Shoppes), accounted for 25% of the total domestic sales. The number of JSW Shoppes increased to 400 as on 31 March 2013 from 350 as on 31 March 2012.

- Enhance Customer base: In order to maximize tonnages coupled with Price Advantage, JSW judiciously expanded its customer base, meeting the challenges of small order lots with high degree of customization, demanding fast-track delivery schedules. For the coated products, 96 new customers were added accounting for approx. 13% of export sales.

The Company successfully paved its way through the trying times of 2009-10 and further sharpened its focus and efficiency across the domestic and international markets, harnessing and nurturing its relationship with its valued business partners (customers) which would enable its more effective journey ahead and also taking the challenges of expanding its product range with greater tonnage intensity.

COMPETITORS—COMPARATIVE ANALYSIS

The above figures make interesting reading. Without doubt, there are four big players in the Indian steel industry viz. SAIL, Tata Steel, JSW Steel and Essar Steel.

JSW Steel has overtaken Tata Steel in capacity and is fast catching up with the leader SAIL. Essar steel is the fourth. There are a host of small producers whose individual capacities are much lower.

FINANCIAL PERFORMANCE OF THE COMPANY

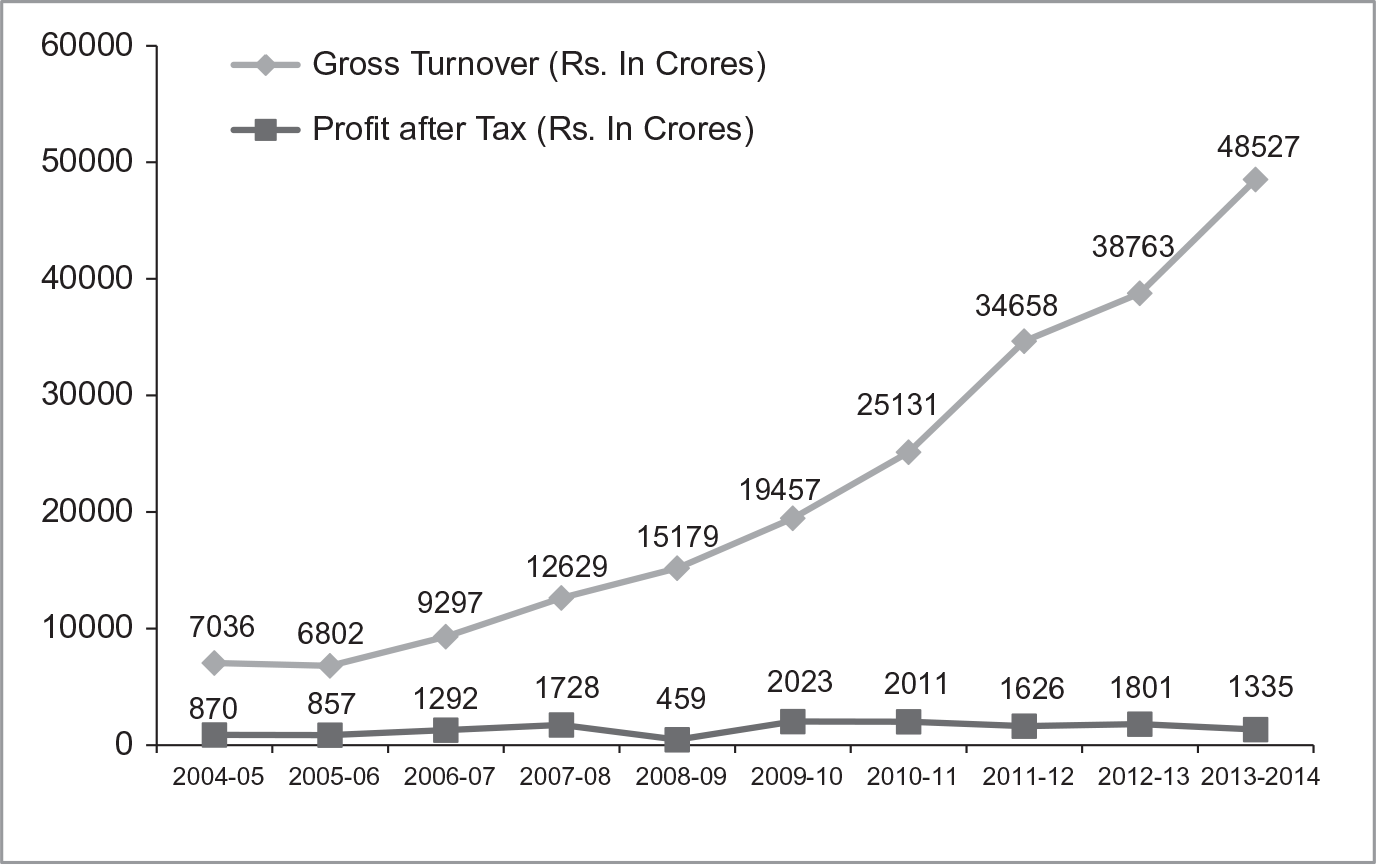

Figure 4.2

JSW Steel have been steadily growing over the last six to seven years. From turnover of ₹12,629 crore and a profit of ₹1728 crore in the year 2007-09 it has increased to ₹48527 crore and ₹1335 crore in the year 2013-14. The turnover has increased by 284% while the profit has come down by 22%.

It must be noted that from the above graph that the profits have not been increasing in line with the company’s turnover. This could be because of increase in raw material costs and rise in costs of power, fuel as well as interest costs.

Contribution towards Government and Society

JSW Steel has been contributing to wealth generation in the country and its contribution to Government and Society has increased by 18% as compared to 2012-13

ACQUISITIONS AND COLLABORATIONS

JSW Steel has bought assets including land, buildings and branded machinery of Bellary Steel for ₹210 crore in the year 2011.

In December 2010, JSW Steel and Ispat Industries wrote a new chapter of Indian Corporate history, when JSW Steel acquired a major stake in Ispat Industries Ltd to form JSW Ispat. JSW Steel had acquired 41 percent stake in debt-ridden Ispat Industries by investing ₹2157 crore in the deal and becoming the largest shareholder.

Sajjan Jindal was able to convince Mittal to sell Ispat to him. Jindal has foreseen some synergy between Ispat and JSW Steel, which would benefit both companies.

The above deal would lead to a saving of at least ₹2500 per ton of steel for Ispat as under:

To quote Sajjan Jindal: ‘Both companies compete in the same market—we supply to Maharashtra and they to the South. We have decided that Ispat will move its steel only within a 200 km (radius) which will help it cut freight to ₹325 per ton from ₹1400 per ton- a straight saving of ₹1100 per ton.’

On June 1st 2013, the two companies strengthened their coalition by merging JSW Ispat with JSW Steel thus enabling the full realization of strategic benefits resulting from the amalgamation. Both the Boards agreed upon the exchange ratio of one equity share of JSW Steel for every 72 equity shares of JSW Ispat.

Because of strategic and operational initiatives, JSW Ispat had made considerable progress in its turnaround journey since the acquisition. JSW Ispat has started making profits since April-June quarter of 2012.

With the completion of merger, JSW Steel has become the second largest steel producer in the country after state-owned Steel Authority of India (SAIL) with 14.3 million tonnes capacity.

The merger would also help JSW Steel in laying claim on deferred tax benefits available to JSW Ispat of over ₹2,088 crore as Ispat has started making profits.

The merger will result in a lot of synergy in operation and economies of scale for JSW Steel. Post merger, JSW Steel plans to leverage the infrastructure of Dolvi unit to add another 3–4 mtpa of capacity through brownfield expansion.

Besides the above acquisition, Sajjan Jindal was keen to acquire the best technology in the world. He had signed a deal with JFE Steel of Japan, one of the largest steel producers in the world to invest ₹4800 crore in JSW Steel in July 2010. This was necessary for funding the acquiring of Ispat Industries for 12,106 crores. This investment and the agreement provided for beefing up JSW’s financial position on the one hand and providing sharing of the best technology on the other. JFE would provide the best technology particularly for the Japanese Automobile sector in India. Thus the high standards of Japanese auto companies could be provided by JSW Steel in collaboration with JFE Japan.

JFE Japan has also shown keen interest to pick up a stake in JSW Steel’s Bengal unit at Salboni. JSW Steel plans to set up an integrated steel plant and acquired the land measuring 4334 acres from the State Government.

With the JSW Ispat merger with JSW Steel, JSW promoters hold 35.12% stake in the company. The second largest shareholder JFE Steel holding has now come down to 14.92% from 15%.

Thus Sajjan Jindal has been able to weather the various storms coming his way and making a success of the merger of JSW Ispat with JSW Steel by exploiting the synergies of both companies. JSW Steel integrated with Ispat is now back on track as per its long term plans.

Era of Consolidation

To become one of the fastest growing steel plants in the world the Company now went for the largest Blast Furnace in India with the capacity to produce 2.8 MTPA of hot metal. This created a huge stir in the Indian steel industry prompting others to follow suit. Mr. Jindal now unfolded his mega plan to produce 40 mtpa of steel in India by 2025 with a mix of green field as well as brown field expansion.

This was also the time when the Indian lenders like ICICI bank invited Sajjan Jindal to take over other sick steel plants. JSW acquired the Southern Iron and Steel Company (SISCOL) in Salem in the year 2004. Today the Salem plant has witnessed a dramatic turnaround in its fortunes and has become a 1 mtpa profitable integrated steel plant.

JSW Steel has been ranked in 7th position among the world class steel makers as per World Steel Dynamics in June-2014. Right from project stage, JSW Steel’s focus has been on innovation, continual improvement, quality products and highest level of health and safety standards for its employees and the community around its plants.

Growth and Diversification

Early turbulence taught Mr. Jindal a very important lesson. To be a stable company one has to have strong forward and backward linkages in its area of core competency.

With this in mind, the company’s diversification strategy was formulated and it was decided that leadership position would have to be achieved in related areas of steel making like Power, Cement, Ports, and Mining etc.

The company has acquired coal mines in Mozambique; iron ore mines in Chile to have assured raw material supply. The company has also acquired a plate mill at Houston, USA, and a service center in UK to serve the mature markets by being nearer to the customer.

HUMAN CAPITAL–NUMBER AND BREAKUP

Employee Strength–Breakup into Categories

The Company represents a compelling story of courage, perseverance, counter-convention and stretch achievements. JSW Steel has a team size of 9,522 members which is responsible for the manufacture and marketing of 11 mtpa of crude steel predictably the smallest team size per ton manufactured in India’s growing steel sector. Interestingly, at JSW, the labour cost per ton of steel is the lowest globally!

Qualifications profile of JSW Steel’s Employees

Composition and Qualification

The employees comprise a rich pool of MBAs, CAs, CSs, ICWAs, ITIs, Engineers, Graduates, Postgraduates and Diploma holders as on 31 March 2014

Besides, the average experience of the senior management is over 20 years. Moreover, the Company’s average employee age is about 36.5 years. The result is a prudent mix of youth and experience.

Figure 4.3

People Management

- The team comprises only 8,893 members in the works area, which translates into 2.124 tons of steel per person–amongst the world’s highest; and

- The Company achieved the unique recognition of having one of the lowest conversion cost per ton of steel globally, and the lowest employee cost per ton of steel among global peers.

HUMAN CAPITAL DEVELOPMENT

The slogan of the company regarding Human Capital Development is ‘Of the people, by the people, for the people’ JSW‘s Human Resource policies are created in a bottom-up approach, i.e. it is first rolled out at a Company level and then integrated at a Group level. These policies address the changing needs of people in a dynamic business environment. Credible, transparent and uniform people management practices are benchmarked against industry best practices to acquire and retain the best talent, while nurturing and developing the skill set of each employee.

The human capital development strategy consisted of certain pillars which are as under:

- Developing the mindset of employees towards domain expertise and multi tasking

- Being a part of the team for adopting state of art technologies with a mix of engineering and management graduates along with experienced professionals

- Implementing various measures for effective two way communication to facilitate involvement and participation

- Introducing an effective Performance Management System and Reward system for the motivation of employees.

From the above, it is evident that a large amount of emphasis is given to the Human Factor not only to attract but also to motivate, develop and involve them in the business of the Company. The HR policy has contributed to a high retention of employees which is necessary to cope with the fast pace of expansion and introduction of new technology.

CSR INITIATIVE

JSW Foundation, an independent Trust, administers the social development initiatives of the JSW Group and is chaired by Mrs. Sangita Jindal. Management is committed to allocate 1.5% of profit after tax for CSR operational expenses since 2011-12. Total spending on CSR activities for the year 2013-14 was ₹27.03 crores.

CSR Policy: JSW cherishes people and believes in inclusive growth to facilitate creation of a value based and empowered society through continuous and purposeful engagement of all partners in the development process.

CSR Vision: ‘Empowered communities with sustainable livelihoods’

CSR activities are provided at JSW Steel plants located at Vijayanagar, Vasind, Tarapur, Salem, Salbori in West Bengal and at Jharkhand.

JSW strives to achieve sustainable development in all spheres of life including Education, Health and Livelihood, Promotion of Arts and Culture, Environment Protection, and Sports as under:

- Education

The Foundation′s endeavour is to sensitize people to the need for education among regular and contract employees′ children by establishing schools in the Company′s vicinity. It also ensures creation of an exciting and attractive learning process for the children in the surrounding village schools. The Foundation also takes care to build and infuse confidence among school dropouts by encouraging them to join back It also plays a pivotal ‘parental role’ through individual monitoring of the first generation learners. Besides exploring and nurturing local rural talents, it regularly demonstrates innovative teaching methods at neighbouring government-run schools with the aim of improving learning standards.

- Health

The Foundation provides door-to-door medical care by conducting regular general health check-ups. It also conducts specialized healthcare for the elderly by conducting cataract screening and performing free surgeries. This apart, it holds routine STI/RTI check-up camps to identify potential HIV cases to prevent the spread of HIV/AIDS cases and at the same time enhancing rural awareness of the dreaded scourge.

- Environment

To create an environmental friendly environ, the Foundation builds model villages by developing rural infrastructure complete with roads and drainage system. To improve living standards, it creates sanitary facilities for providing effective disposal of solid waste. The Foundation also sensitizes rural eco- friendliness through enhanced tree planting.

- Livelihood

To create livelihood for rural women the Foundation provides a revolving fund, skill training and other linkage services to empower rural women to reduce gender-based discrimination.

- Sports

To encourage rural sports, the JSW Foundation has formed the Jindal Academies for Squash, Badminton Swimming and Table Tennis. These academies provide necessary training for students to attain national- level success in many events.

- Arts, Culture and Heritage

Heritage conservation

JSW Foundation is involved in preservation, conservation and restoration of Heritage buildings. In 2004, JSW Foundation facilitated the creation of the Friends of Sir J. J. School of Arts Trust that restored the exterior of the Fine Arts building.

HOW THE GLOBAL SLOWDOWN HAS AFFECTED THE COMPANY AND THE STRATEGIES IMPLEMENTED

The World Economy was down by 0.6% with Reduced Liquidity, Investments, Industrial Production, and Trade and with job losses running into millions and economic-dynamics almost coming to a standstill. The strategies involved an integrated approach to develop all aspects of the Company including the following:

Capitalizing on Domestic Demand

- India had the inherent advantage of High Domestic Dependency with unfolding Investments and Consumption opportunities derived out of its strong demographic dividend, strong savings and leveraging rising potential of Industrialization and Urbanization. Indian economic growth in 2009-10 was 7.4%

- Steel Demand = Socio-Economic potential…. A derivative of Infrastructure, Construction, Industrial Production and Consumer Durables… accordingly seems to be at its take-off stage with Steel Demand to accelerate out of Direct Investments as well as Derived Dividends from these investments.

- JSW has always had immense trust and faith in the country’s economic potential and growth prospects

Moreover, India continues to remain in deficit across every economic facet be it energy, capital goods, infrastructure, housing, food grains or metals including steel. With Import Dependency at approximately 14% or 7.7 million tons over a demand of 56 million tons revealed a direct Substitution opportunity

Expansion and collaborating with the Best

JSW’s strategic collaboration with JFE Steel Corp in the area of technological expertise has opened up new avenues of growth particularly in the manufacture of high end auto steel in India. This was also relevant in a country recognized as the global small car hub where more than 65% of national requirements of steel were imported. This partnership is an important milestone for JSW to move up the value chain in steel products and to become a one-stop solution for all steel grades required by global and Indian customers.

Great and Global

Through technical and process innovation, JSW Steel has emerged as an aspiration for global steel manufacturers and has put India on the global map. This is because of out-of-the-box thinking, in laying a 2 km railway track and commissioning India’s largest blast furnace in only 20 days - a national record.

JSW Steel’s conviction that ‘there is always room at the top’ leads to lateral out-of-the-box initiatives in its journey from a ‘good company to a great organization’

Employment Transformation

- Employed and Employable

JSW Steel transforms employees into entrepreneurs through a combination of authority, decision- making and risk-taking. Inspiring each individual to place the Company before self and align the personal with the professional.

- Growing the workforce within

The Company’s growth from 3.8 mtpa in 2007-08 to 14.3 mtpa in 2013-14 catalysed employment from 7060 members (April 1, 2008) to 11408 employees (March 31, 2014) and team of its indirect employment associates concurrently expanded.

The Company’s plan of more than ₹10000 crore investments in next three years will reinforce its position among the largest employment opportunity generator.

JSW Shoppe Network: JSW Steel created and grew India’s first-of-its-kind retail chain dedicated to market steel in 350 non-metro outlets across India thereby generating employment.

- Growing the Community around:

- More than 26000 employment generated around JSW Steel plants

- More than 4900 Employable Indians through vocational programs in last five years including adopting of 16 ITIs and proposing to develop these into centers of excellence in different trades.

- More than 2000 employable women through various initiatives in last five years

BIG CHALLENGES BEFORE JSW STEEL

Over its short history, JSW Steel has had a steady rise in terms of increased turnover and profits. However, there have been serious problems to contend with, particularly the technical problems encountered at the Vijaynagar Steel plant. The other major problem was the global slowdown that affected all parts of the world including India. However, JSW Steel was quick to devise a strategy to counter falling demand from abroad by surveying rural India and finding out that there lay an outstanding opportunity. By setting up distribution centres all over India, the company tapped this huge market very successfully and made good the loss from international demand for steel products.

But in 2011, the company was faced with very serious problems in terms of shortage of two of its most critical raw materials viz. Iron-ore and Coal.

Regarding iron ore, one of the biggest sources is in Karnataka State especially in the Bellary region. There was a lot of illegal mining happening in this region, which forced the Supreme Court to step in and ban the illegal mining, which was also causing environmental degradation.

With the sudden banning of illegal mining from iron ore mines, JSW and other steel plants were starved of iron ore and a situation arose that the plants were operating at only 30% of capacity. JSW, which is one of the largest producers of steel products, was the worst hit but the two other large producers viz. SAIL and Tata Steel were not affected much because both have their own captive iron-ore mines. JSW on the other hand, does not have its own iron ore mines but had entered into long-term contracts with companies for supply of iron-ore. By way of relief, however, the Supreme Court had asked NMDC a major supplier of iron ore to float auctions and sell the iron ore.

Besides iron ore, there was also an acute shortage of coal all over the country. Coal India, one of the largest producers of coal and coke, essential for steel and other plants, had a long strike by its employees, which affected the supply of coal and coke. Steel plants including JSW Steel were badly hit.

Thus, in view of shortage of both iron ore and coal there was a steep fall in turnover and profits and the company was in the dumps. This was perhaps one of the most difficult problems for both Sajjan Jindal and his JSW steel team.

The basic issue was what strategies are to be implemented to bring the company out of the serious situation it had found itself in. What happens to its grandiose plans and how and when can the company be brought back on track? Sajjan Jindal had his hands full and the resilience of Sajjan Jindal and his team was going to be tested to the utmost limit.

FUTURE PLANS

The company has very ambitious future plans and intends to get into other core areas like Power Generation, Cement and Infrastructure besides Steel. As far as steel is concerned; the Company wants to produce 40 mtpa by 2025. Regarding Power Generation, it plans to produce 11,000 MW by 2015. Again, it plans to set up cement plants and get into Infrastructure.

When Mr. Sajjan Jindal was asked about why his Company is concentrating on core areas and not other areas, he replied that India requires development of the core areas which could make a greater impact on the economy. Moreover, Sajjan Jindal is one who looks for challenges and the core areas require major investment with long gestation periods and offer the toughest challenges.

Besides challenges, the core areas require technological innovation. Sajjan Jindal has always been looking out for the best technology. Using the most modern technology gives the company a competitive edge. He is in close collaboration with JFE, Japan for getting the best technology so that his products could become world-class.

There are also serious problems that Sajjan Jindal has to cope with in the near future. The key issue is how to secure the raw materials of coal and iron ore for his plants. However, in the globalized environment, Jindal could access suppliers from abroad and make good the short fall, of course at a price.

The expansion on the steel front is planned to be done by setting up Greenfield steel plants in Jharkhand and in West Bengal. This would result in expansion of steel production three times from the current 11 mtpa in 2011-12 within the next decade.

The other issue was whether there is only expansion all the way without consolidation and restructuring. Sajjan Jindal was of the view that the Indian economy is in its growth phase and if the Company has to take advantage of the opportunities thrown up by the growth phase, then it has to first expand capacities and produce higher output. Consolidation and restructuring can be done later. But he believes that for the next decade it would have to be mainly expansion and consolidation and restructuring to a lesser degree running parallel.

Thus, despite the second global slowdown, Sajjan Jindal is optimistic that there is enough scope for growth and profits in the next decade with growing demand from India and Bharat as well as from the emerging economies. As and when the developed countries come out of recession their demand would be the icing on the cake.

JSW GROUP—FORGING AHEAD

JSW Steel commissioned country’s largest Blast Furnace thereby increasing the total steelmaking capacity by 60%. This propelled the company to becoming the 2nd largest steel producer in India and the largest among the private steel producers. The company is further expanding its brown-field capacity at Dolvi from current 3.3 mtpa to 4.8 Mtpa by 2015 and at Vijaynagar from 10 mtpa to 16 mtpa. Subsequently JSW has plans to further increase its production to 40 mtpa by 2025.

JSW Infrastructure Ltd. has developed a port at Jaigad in Maharashtra with total handling capacity of 10 million tons per annum, which will be increased to 20 million tons by deploying additional small environmental friendly mechanized bulk cargo handling systems.

To make use of the slag generated from the Blast Furnace of the steel plant, , the Group currently has a cement manufacturing capacity of 5.4 mtpa with expansion plans at Dolvi works..

While on this growth trajectory, the group is aware of the need for integration with raw materials especially iron and coal for which the company has acquired iron ore mines in Chile, mining rights of coal mines in Mozambique and Jharkhand, thermal coalmine in Indonesia and many more yet to come…

FINANCIAL PERFORMANCE

Global Impact

The Group has excellent credit standing in the domestic as well as international debt market which enabled JSW Steel Ltd. to raise about US$ 2 billion during its span of existence.

JSW Steel started with a vision to put India on the international steel map. This has been ably demonstrated in the recent survey conducted by leading US based global Steel Research Company World Steel Dynamics (WSD). They compared top 32 world-class steel companies on 23 parameters and ranked JSW Steel Limited as 7th best steel company in the world (ranking as on June 2014)

This propelled the company to being 2nd largest steel producer in India and the largest among the private steel producers. JSW Steel commissioned its largest blast furnace in the country well ahead of time, demonstrating its strong project implementation capabilities.

The group adopts latest technologies and synergies in its global operations and expects to achieve a turnover in excess of US$ 20 billion.

CASE UPDATE

JSW Steel, the flagship Company of the JSW Group and one of India’s largest steel producers has been facing a number of problems during the last five years, but has always been able to fight back, and surmount them.

As per the last update, JSW was facing problems on all fronts. There was shortage of iron ore and coal - the basic raw materials for the making of steel. Again, the USA and European markets were hit by recession. This resulted in sales dipping.

Industry analysts had predicted a dismal performance of JSW Steel during 2013-14. The Company was hit by softening of steel prices particularly with a slowdown in China, the largest producer and consumer of steel. The issue of rising debt, which was in foreign currency because of the falling rupee, was the other issue. But JSW steel recorded a good turnover of ₹48527 crore with a profit of ₹1335 crore displaying great resilience and fortitude during 2013-14.

JSW Steel continued to concentrate its efforts on the export market. Despite demand contraction in international markets during fiscal 2013-14, the Company exported 8.30 million tones.

The above is despite the fact that the Company does not have its own mines for iron ore or coal. In fact, JSW Steel has encashed upon its strengths, which lie in technology, productivity and services. Moreover, its collaboration with JFE of Japan has enabled it to produce steel from the lowest grade of iron ore and with higher operating margins.

Thus, JSW Steel’s performance is one of best amongst the 25 steel producers in the world.

It is said that when the going gets tough, the tough get going. The last 5 years were very difficult but JSW showed its resilience by facing the challenges bravely. To quote Mr. Sheshagri Rao(Joint MD), ‘Right from the beginning, we were aware that we don’t have iron ore and coal. We didn’t complain, but worked on our strengths and weakness for greater competitiveness. In all other areas, other than raw material, we have become No. 1 in the world. Our technology is the best, our yield is the best, our geographies are the best and our services are the best’.

In addition to the improved performance detailed above, the report of ET-500 was another heartwarming feature. JSW stood at the 29th position with a turnover of ₹38,279 crores and a Profit After Tax (PAT) of ₹963 crores.

As Mr. Seshagiri Rao, Joint Managing Director explained, the company introduced an innovative step of serving the rural demand for steel to offset the fall in demand from the US and European markets. The JSW Shoppe increased from 2 shops in FY 10 to 450 shoppes in FY14.

Another strategy was to use a combination of technologies including Corex technology. Moreover, by collaborating with JFE of Japan, JSW Steel was able to use technology for converting output from both lower grade iron ore and coal.

The use of technology as mentioned above and through improvement in products, JSW Steel was able to achieve highest operating margins amongst the top 25 steel companies in the world. Thus, JSW Steel is now back on track in its pursuit of becoming the highest producer of steel in the country.

If one were to summarize the integrated approach or success mantra of JSW Steel it can be explained by the following diagram:

JSW Group - Success Mantra

Figure 4.4

QUESTIONS FOR DISCUSSION

- Describe the position of the Indian Steel Industry and its prospects.

- Will JSW be able to sustain its pace of growth and catch up with SAIL?

- What are the synergies between JSW Steel and Ispat Industries? Do you think Ispat Industries can be turned around in three years and how?

- What has been the role of the Human Factor in JSW’s progress?

- Is CSR obligatory and what are its returns to the company?

- Do you agree with the strategy of JSW to expand, all the way? What about consolidation?

- Will JSW be able to achieve its future plans? What are the obstacles it will have to surmount?

- What is your opinion about Sajjan Jindal’s leadership?

- Should there be a change in JSW’s marketing strategy?