CHAPTER 9

How to Choose the Right Wind Turbine for the Job

The word “energy” incidentally equates with the Greek word for “challenge.” I think there is much to learn in thinking of our federal energy problem in that light. Further, it is important for us to think of energy in terms of a gift of life.

–THOMAS CARR, TESTIMONY TO U.S. SENATE COMMERCE COMMITTEE, SEPTEMBER 1974

We’re getting closer to arguably the most exciting decision of the whole process: which wind turbine will you spend your hard-earned money on, and hopefully enjoy watching spin for years to come?

But everything else being in place, it’s also true that shopping for a wind generator can be a lot of fun. We’re as smitten by the “cool factor” of the technology as much as anyone (Figure 9-1). But before we get too carried away, let’s take a look at a brief bucket list.

FIGURE 9-1 Building and owning a small wind system can be a blast. Just ask Hugh Piggott (center), who leads small wind workshops in his native Scotland, in America, and beyond. Hugh Piggott.

When considering a wind turbine, there are five main things you need to know:

1. Swept area is the single most important factor in determining energy output.

2. It’s a good idea to go with a turbine certified by an independent agency.

3. Hype, testimonials, and slick YouTube video demonstrations do not validate turbine performance claims; field tests do, especially third-party tests.

4. Durability is more important than performance when selecting a turbine.

5. Choose the turbine with the highest net capacity factor.

So, bringing together what we learned in previous chapters, a simplified process for deciding on a wind-electric system looks like this:

• Determine your energy need in kWh per day, month, and year (Chapter 3).

• Downsize your energy need (Chapter 4).

• Estimate your average wind speed and decide on your tower location and height (Chapter 5).

What’s covered in this chapter:

• Determine rotor diameter based on predicted kWh at your site’s average wind speed.

• Compare all of the products in the rotor diameter range you have selected.

One note: If you are merely looking to get a micro-turbine that only needs to produce a very small amount of energy, you will have more flexibility. However, there are still useful parts of this chapter that can help inform even that decision.

Fortunately, there have been significant improvements in small wind turbines over the past few years, so some of the things that were written just a few years ago are no longer required. It’s not unlike the personal computer industry. Not long ago, owning a computer required a learning curve to install programs, ensure compatibility of a monitor with an operating system, and so on. Yet today, computers are much more intuitive to use and “plug and play.”

Small wind turbines used to require more specialized, technical knowledge and skills, often borrowed from the agricultural, marine, and automotive sectors. Today, the small wind industry has become more commercialized and accessible. It is still rather immature and underdeveloped compared to large wind, but it has come a long way since the 1970s, when heightened interest first blossomed. Today, there are a number of offerings for durable small wind turbines, many of which have good track records of providing 20 to 30 years of relatively trouble-free service.

What was once primarily the domain of garage tinkerers and research engineers has developed into a consumer-facing industry that is willing to back up their products with five-year warranties and develop international standards. Established manufacturers test their equipment for many months in various climate conditions. Largely gone are the memories of controller meltdowns and rotor failures; instead, the industry focuses on boosting efficiency and reliability and lowering costs. The fact that numerous governments support small wind turbines with tax credits, grants, loans, and feed-in tariffs should provide a measure of confidence in our ability to empower ourselves.

With more than 250 manufacturers and more than 500 models of small wind turbines available worldwide, you’ll discover considerable choice, on both rotors and kits. By the end of this chapter, you will be better prepared to make the tough decision—the right decision. We begin with the basics, and then we examine the types of wind turbines on the market today.

Small wind author and consultant Paul Gipe has argued that “small wind turbines should be designed for simplicity, ruggedness, and low maintenance.”1 We think that’s sound advice. To help you begin to sort out which system will bring you many years of energy production, we include tables of comparison data, websites for field-tested data, and some easy calculations to evaluate some good candidates. Since cost is likely on your mind, let’s begin with a rough guide.

Average turbine cost: Approximately 10 to 40 percent of total system cost

In other words, you should expect to spend roughly 10 to 40 percent of your system’s budget on the star, the actual turbine. Let’s take a closer look at the decision process.

Important Questions to Ask When Shopping for a Small Wind Turbine

If you aren’t interested in understanding all the workings of your turbine and what makes one different from the other, that’s okay, because you can have a dealer or installer do the legwork for you. We recognize that some people don’t really want to know how their car works, for instance, preferring instead to trust their ride in the care of a mechanic. Others want a computer or cell phone that works smoothly, yet they don’t want to ever have to open the case. If that’s true for you when it comes to small wind turbines (Figure 9-2), you may choose to skip over some of this chapter. Even so, we still think it’s a good idea to become an informed consumer. While the vast majority of small wind installers we’ve heard of seem to be honest, every industry has its share of shady characters, and knowledge is the best defense.

FIGURE 9-2 Choose the right turbine for the job. If you have a boat or small cabin, you may only need a micro-turbine, like this Southwest Windpower Air 403. Southwest Windpower/DOE/NREL.

So, to become an informed consumer, here is a list of questions you can ask a manufacturer or dealer of a small wind turbine, as adapted from the June/July 2009 issue of Home Power magazine.2 We will explain the concepts in more detail in this chapter. Please use our easy downloadable chart (see the link on the following page) to fill out the evaluation. We hope this process will at least help you rule out models that won’t be a good fit for you.

1. Has your turbine(s) been certified for performance and safety standards by an authorized agency, such as the Small Wind Certification Council (SWCC)?

2. What is the annual energy output (AEO), measured in kilowatt-hours, in average wind speeds of 8 to 14 mph (see Chapter 3)? Is AEO calculated using real-life (“field”) data (preferred) or laboratory/wind tunnel testing? (Remember, this is not the same as the rated power, which is given in kilowatts, and is not particularly useful.)

3. What is the warranty length and coverage? (The industry standard is five years, although see Chapter 6 for more details.)

4. Has the turbine and/or tower ever gone through a reliability test? By whom and for how long? What were the findings?

5. For how long was the prototype tested? By whom? In the field or in a wind tunnel?

6. How many turbines of this model have been sold, and for how long? How many are still running?

7. How frequently has the model been redesigned? What were the changes and why?

8. What problems have other customers had, and how have you dealt with them?

9. Can you provide references from other customers?

Questions to Ask About the Wind Turbine

bit.ly/MyWindquestions

What to Look For When Buying a Wind Turbine

Although manufacturer marketing materials may suggest the opposite, there are no additional silver bullets when it comes to evaluating a turbine. None of the bells and whistles touted by manufacturers on blade shapes, vibration isolators, or low wind cut-in speed are as important as the basics already covered. Still, in this section, we take a closer look at some other features, in order of decreasing priority:

1. Swept area

2. Durability

3. Annual energy output

4. Cost

6. Governing mechanism

7. Shutdown mechanism

8. Sound

The following comparison matrix (Table 9-1) provides a sample of some of the more popular small wind turbines and what to look for. We’ll go over this in some detail, and then cover some of the finer points of the turbine that might affect your design, or at least give you a better understanding of why designs are the way they are today.

TABLE 9-1 Sample Wind Turbine Comparison

Swept Area (Rotor Diameter)

When determining your rotor diameter (Figure 9-3), it’s worth remembering that you may consider a larger turbine if you expect your needs to grow over time, or a smaller turbine if you expect to be downsizing your consumption later on. That said, nearly every turbine owner we’ve talked to has said they wished they would have gone bigger, not smaller. The only exception we can think of is Rosalie Bay Resort in Dominica, which has a sizable 225 kW turbine. The owners told us they wanted something a bit smaller, but couldn’t get an installer to commit to their remote location for anything else. But for everyone else we can think of, they wish they could be producing more clean kilowatt-hours, not fewer.

FIGURE 9-3 Participants in a workshop held by “The Dans” Fink and Bartmann show off the wooden rotor they made to maximize swept area. Dan Fink.

Of course, in most net-metering agreements, you primarily benefit by using the electricity that you produce, not so much by selling excess. Still, in our experience, most people tend to underestimate how much electricity they use. If you produce too little with your wind generator, you will be paying retail for the difference. With a battery-based system, it is more than an inconvenience when you can’t run a heater or use any of the tools in your new workshop, because the turbine takes days or even weeks to recharge the batteries after you constructed your kid’s new bunk bed. Either way, it is better to be a little bigger than too small.

Note: Grid-tied systems without battery backup are often package systems sold with the turbine, controller, inverter, and frequently a tower matched and specified by the manufacturer. So once you choose the turbine, the system comes along as a package deal, unless you have some special situation that can’t be easily accommodated. A package arrangement is certainly convenient, and it can reduce compatibility issues, although it might limit your choice of options.

Swept area, the size of your wind collector in square feet or meters, is the single largest factor influencing turbine output—besides your average wind speed, which we have already discussed at length. It is the rotor that collects the wind energy, and depending on the efficiency of the blades and generator, a certain amount (up to 59.3 percent, the Betz limit; see Chapter 3) of the available wind energy is converted to electrical power.

If you aren’t immediately told the swept area of a wind turbine, the rotor diameter permits you to calculate it, using the basic formula for the area of the circle (πr2). Divide the diameter in half to get the radius, square this number, then multiply it by pi (roughly 3.14159265).

From that geometric formula, we see that

• As the length of the blade is doubled, this quadruples the swept area.

• As the swept area is doubled, it doubles the power output.

• A larger rotor will give you more energy, all other things being equal.

As you fine-tune your turbine selection, you should pay attention to how small change can have a big impact (Figure 9-4). The difference between a turbine with an eight-foot diameter and one with a ten-foot diameter might not seem large, but the 25 percent increase in diameter represents a 56 percent increase in collector size, with a proportional increase in energy output.

FIGURE 9-4 Students of The Dans carefully measure a new rotor. Dan Fink.

We will provide an extensive list of turbines, but it is recommended that you gain the tools to assess power available for any turbine size. Not only will this help you determine what size might work for you, it will simultaneously verify suspect claims of performance.

![]()

For the formula provided here, first determine if you are going to use either the imperial or metric system, and then follow these instructions.

1. Air density (rho) Air density is affected by the air pressure (altitude), temperature, and humidity. To simplify the calculation, plug in 1.225 kg/m3 (0.0764 lb/ft3) if your site is at sea level and with an average temperature of 14 degrees Celsius (57 degrees Fahrenheit). Otherwise, you’ll have to determine your air density based on temperature and elevation. Charts are widely available. We include a link to do an online calculation as well.

Resources

Simple Air Density Calculator bit.ly/calcRho (Fahrenheit)

Comprehensive Air Density Calculator (includes humidity and pressure) bit.ly/calcairdensityCnF

2. Swept area (A) Input the turbine’s swept area in cubic meters.

3. Velocity (V) Input the average wind speed in meters per second, multiplied to the third power. If you have yet to assess your site, no worries. Insert the global average of 5 m/s (11.2 mph), just for comparison purposes.

We have also provided a link for an online wind turbine power calculator. Later in this chapter, we will give you the know-how to accurately calculate your turbine’s energy output, factoring overall turbine efficiency and the capacity factor that provides a more realistic estimate for your turbine. But first, the most important part is how big is your potential.

Resources

Simple Power Calculator bit.ly/calc_wtpower

Comprehensive Power Calculator bit.ly/calc_windturbinepower mywindpowersystem.com/wind-power-calculator/

Durability

After swept area, the next important question you should be asking yourself is, “Will the turbine last long enough to provide a return on investment, or will it become an expensive kinetic sculpture?” Your turbine is outside 24/7, often in inclement weather. High winds don’t pack a punch; they pack a sledgehammer. Salty air will wreak havoc on internal circuitry and make Swiss cheese of iron-based metals. Extreme temperatures and any form of precipitation penetrating into the nacelle can have a negative effect on mechanical equipment and electronics.

Wind writer Paul Gipe wisely notes that efficiency, price, and peak power are meaningless without durability. A machine can be “engineered,” “an advance in technology,” and “spectacular” in the advertisements, but when it dies on the tower or falls off the tower, all “advancements” are about as useful as a turbine made of brick.

It’s important to remember that the total cost of the turbine depends on how long it lasts (Figure 9-5). Before you even take into account the savings from the annual energy output of your turbine, the price tag for a $10,000 robust system that lasts 20 years (10,000 / 20 = $500 annually) is a better deal than a $5,000 lightweight toy that fails after only five years ($5,000 / 5 = $1,000 annually). A manufacturer may tout that their product has a lifetime expectancy of 20 years, but unless they tested it on your site, you may have to give that claim some qualifications.

FIGURE 9-5 Wooden blades are relatively durable, although they do require maintenance, as students of The Dans know. Dan Fink.

Turbine Weight

Do I look heavy to you? Discussing turbine weight might seem a little odd, yet weight plays a part in controlling vibrations, which can be made worse by blade imbalances, extreme weather, or even worn bearings.7 A heavy turbine does not guarantee durability, yet more mass does help buffer vibration, which stresses internal components. The weight comes in the form of a full metal jacket, beefier alternators, and heavier bearing assemblies.

Start-Up Speed

Makers of rooftop and micro-turbines frequently boast that their products have extremely low “start-up” speeds. Some small, lightweight rotors are designed to start spinning in as low as two miles per hour. With less powerful alternators, they may even be able to start producing electricity at that speed. But you should know by now that there is very little energy available in winds of two miles per hour. Does it matter if you start producing when it’s only a trickle?

In truth, it depends on your application. If you only need enough juice to charge a cell phone, that might be fine. Maybe a gentle breeze or a sneeze is enough for you. Be aware that effective turbines have a limited range of wind speeds for which they can collect energy without sacrificing efficiency. So a micro-turbine that works in very low wind speeds is not going to work well in higher winds. It is going to have to shut down to avoid spinning too fast and getting damaged. So you’ll miss out on the opportunity to harvest energy when the winds are strong. At worst, the turbine can overheat and fail.

Cut-Out Speed

At very high wind speeds, typically above 45 mph, most wind turbines cease power generation and shut down. The wind speed at which shutdown occurs is called the cut-out speed. Having a cut-out speed is a safety feature that protects the wind turbine from damage during excessive gusts. Normal operation usually resumes when the wind drops back to a safe level. If you are considering a micro-turbine that doesn’t have a cut-out speed, it better be either extremely well armored or come with a free turbine-disposal bag.

Survival (Maximum Design) Wind Speed

All wind turbines are designed for a maximum wind speed, at least “on paper.” This is usually within the range of 90 mph (40 m/s) to 160 mph (72 m/s). Few manufacturers willingly sacrifice expensive equipment by scheduling field tests in hurricane zones. Sure, they can do tests in wind tunnels, but those only go so far when it comes to real-world conditions. In the field, it is essentially impossible to reliably and repeatedly test for survival wind speed by factoring out wind shear, wind chill, and wind-borne debris. It would be difficult to prove that it was the 150 mph gust that blew your turbine apart and not a wind-blown projectile. This means the maximum wind speed is a somewhat theoretical number, and leads to varied ratings.

What tends to kill wind turbines with more certainty than wind speed is turbulence, which can come even at lower wind speeds. Manufacturers issue warnings to tilt down, lock up, or remove the turbine entirely during episodes of wind approaching the survival wind speed. However, in the event that you find a turbine that has a low survival speed, or none at all, it is best to avoid it even if it is in the small-scale range.

Warranty

Most manufacturers currently provide a warranty on their turbines for at least 5 years, although good-quality systems are often expected to last up to 20 years, based on the lifetime expectancy of the composite blades, which withstand the brunt of harsh conditions. If the product warranty is less than five years, covers less than comprehensive coverage, or warns the installer to keep it out of winds approaching 30 mph—a speed most people would assume is an ideal wind condition—the turbine is a toy, and should have an Adult Safety Hazard label like “Blade debris swallowing hazard.”

INTERCONNECT

Turning Household Junk into a Wind Turbine

Sometimes, handy folks ask if they can rig up a small wind turbine out of spare parts they have lying around the garage. The short answer is yes, that is certainly possible. As we have pointed out, a determined 14-year-old brought electricity to his family for the first time by scavenging parts and dreaming big in his native Malawi in 2002. In fact, mechanically minded folks have been building and servicing their own homebrew turbines for a century.

These days, one can download plans from the Internet or order a kit that can make it easier to get started. However, there are a number of limitations to this approach.

For one thing, these kinds of hand-built devices tend to produce very small amounts of power. If you live in rural Africa without access to the grid, a little juice to run a light bulb, radio, or pump could make a big difference in your life, and might justify your efforts. However, if you live in a typical home in the developed world, you’re likely to be disappointed by seeing only a few watt-hours after all your hard work. Still, if you treat it like a hobby, educational exercise, or demonstration project, more power to you.

It’s also worth noting that turbines built from parts that weren’t specifically manufactured for that purpose often require more maintenance than commercial units. They tend to be fussy and prone to breakdowns, and they are often a bit noisy. Few offer the polished, sleek look of a professional install, and some, frankly, are downright ugly.

A functioning example of a small homebrew system is the six-foot turbine built by the team behind Windstuffnow.com (Figure 9-6). Although our e-mails seeking comment weren’t returned, the website claims the downwind turbine is “a very small but quite efficient little unit.” The turbine was built with a mix of custom-milled and off-the-shelf, nonwind parts, including a car alternator and chain drive. The controller unit was designed and built by Robert Nance Dee of Design Specialties. The six blades were cut from wood and painted yellow, making the finished product look like a sunflower. The leading edges of the blades were covered with durable tape in order to decrease damage from hitting raindrops.

FIGURE 9-6 This small homebrew turbine was originally made with a car alternator (not recommended) and chain drive, although it was eventually upgraded with better parts. Windstuffnow.com.

According to the website, the chain drive was “quite noisy,” due to the modified car alternator. However, the team is working on fitting it with a more powerful alternator. With everything working properly, the turbine will reportedly start spinning in about a 5 mph wind and start charging at around 7 mph.

In a test, the small turbine started producing 19 watts in 11.6 mph winds, according to Windstuffnow.com, and up to 320 watts in rare 32 mph winds. In 12.5 mph winds, it produced 38 watts, and at 15.6 mph it produced 76.2 watts, roughly enough to light one conventional incandescent bulb. Clearly, that’s not a lot of power, but it’s an interesting experiment.

Windstuffnow.com also sells micro-turbine rotor kits for $375.

Predicted Annual Energy Output (AEO)

Once you have a size range in mind for your new turbine and are assured that it is durable, how much energy will it actually produce (Figure 9-7)? You’ll want to ask the manufacturer for a chart of predicted annual energy output (Chapter 3) in kilowatt-hours, at a range of 8 through 14 mph (3 to 6 m/s). This won’t be for your specific site, of course, but it gives you some idea of how much energy the wind turbine will produce for a given average wind speed. Remember, wind speeds are listed at hub height. Since such production numbers are taken from manufacturer’s data, they should be regarded with a large grain of wind-borne sand. Not surprisingly perhaps, manufacturers do tend to overstate their performance.

FIGURE 9-7 Bergey turbines have a long track record of durability and excellent energy production. Warren Gretz/DOE/NREL.

Actual production will depend a great deal on the specific situation a turbine finds itself in, and remember that turbulence kills production. Some turbines perform better at certain wind speed ranges than others. In addition, AEOs are usually determined at sea level, at temperatures of 15 degrees C (59 degrees F). If your site is different, you should make adjustments.

To be conservatively cautious, if you live in an “average” location, you could simply multiply the AEO listed by about 75 percent (AEO × 0.75). It’s better to underpredict AEO and be pleasantly surprised. Even better, once you have a list of turbines in your range, choose the next larger model.

Power Curves = Meh, Energy Curves = Helpful

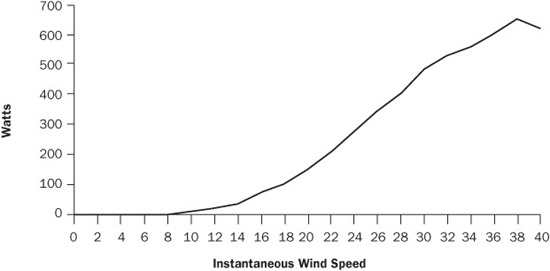

Graphing the generator output against the varying levels of wind speed yields a power curve. Figure 9-8 is a graph indicating how much power in watts (not watt-hours) the Air-X small wind turbine will produce at any given wind speed.8

FIGURE 9-8 A typical small wind turbine power curve, in this case for an Air-X turbine. Kevin Shea, based on data published by Brent Summerville in “Small Wind Turbine Performance in Western North Carolina.”

Like a roller coaster, we are drawn to look up at the peak power, believing that this is what we should expect. But these are just points on a curve, with no indication of how frequent your site will ever get this speed. At most sites, the wind speed at which a turbine generates its peak power occurs only a very small percentage of the time.

Many sites, particularly home sites, have annual average wind speeds more in the 7 mph range. As you can see from the sample power curve, that means an Air-X turbine installed there is going to be generating very little energy most of the time. Once again, we see why it is so critical to have access to a strong wind resource.

We avoid spending much time on power curves because they are, at best, misleading, though they are a central feature in manufacturer marketing materials and on their websites. But you really can’t compare turbines by the peaks, unless you happen to live on the top of Mt. Washington (Chapter 1). Instead, it is best to compare wind turbines on the area swept by their rotors (or by simply using rotor diameter).

You’ll also want to compare energy curves of turbines (Figure 9-9), which are often available on manufacturer websites and literature, though not as prominently touted as power curves.

FIGURE 9-9 Better than power curves are energy curves, which show monthly energy output, not just instantaneous power. Kevin Shea, based on data published by Brent Summerville in “Small Wind Turbine Performance in Western North Carolina.”

The first thing you should notice on an energy curve is that it will have the monthly energy output, which is what you are looking for. With an estimated average wind speed at your site, the energy curves can help you project the estimated energy production (in kilowatt-hours) from a particular turbine. Then you can determine how that projection matches up with your energy needs, determine which wind generator is right for your site, and get on with the job of designing and installing your wind-electric system.

If you have the average wind speed of your site and the power curve graph of the turbines, we have provided you a quick tool to quickly estimate the production of your unit.

Resource

Energy curve calculator bit.ly/energycurve

But a generalized formula is a generalization—it cannot take into account all factors for an individual turbine. It does, however, take into account the two most important factors—swept area and wind resource. Beyond that, we can next apply factors that tell us that a specific estimate is probable, unlikely, possible, and impossible.

Overall Turbine Efficiency

Like most things, a turbine is the sum of its parts. In Chapter 3, we introduced the concept of the Betz limit, which states that only as much as 59 percent of the energy in the wind is available to be converted to electrical energy. Actually attaining the Betz limit would require perfect conditions, including ideal temperature, pressure and air density, and perfectly smooth airflow. However, in the real world, we have turbulence, wind shear, elevation, changing weather, and other factors that interplay to reduce the usable energy.

Further, as we move along the chain from mechanical to electrical components—generator, shaft, bearings, sensor circuitry—we shall see that some of that energy is being used by the system components or is converted into waste heat. The overall turbine efficiency can range as wide as 10 percent up to just shy of the Betz limit. For most small wind turbines on the market, it is commonly 15 to 25 percent of the potential or rated power output.9 If any turbine reports less than 10 percent efficiency, it is advisable to look for another turbine.

Large utility-scale turbines tend to have higher efficiency, and many are approaching the Betz limit. But they have the advantage of sophisticated, computer-managed active controls, which make many small adjustments to blade pitch in real time. Some are even using lasers to gauge incoming wind speed and direction.

Capacity Factor

Besides the efficiency of the turbine system, you would like to get a realistic idea of the actual output capacity of your turbine (Figure 9-10). Naturally, no two wind sites are exactly the same. Some are dominated by occasional powerful gusts, while others have longer periods of more steady winds, plus everything in between. Each turbine design performs differently at different wind speeds and wind behavior.

The capacity factor, or the turbine performance at the rated power, compares the turbine’s actual production over a given period with the amount of power the turbine would have produced if it had run at full capacity (100 percent). The rated capacity is the full-load output in kilowatt-hours if the wind was pushing steadily at the manufacturer’s rated power.

FIGURE 9-10 Participants in a workshop led by The Dans test a hand-built turbine rotor. Note the alternator magnets embedded in the rotor. Dan Fink.

The net capacity takes into account most of the unused capacity due to the nature of wind’s intermittency, although some portion could be the result of shutdowns, equipment failures, and routine maintenance. It also includes the offset energy needed for control, monitoring, display, or maintaining operation.

To estimate the actual output, you can match up the data for annual wind history for the site with the performance (power) curves of the proposed turbine.

Researchers at Colorado State University did just that for a site in Stonington, Colorado.10 The Governor’s Energy Office installed and monitored a 50-meter anemometer tower there in 2007 and 2008. Scientists took the observation data on the wind and matched it to performance curves of some common turbines of various sizes and various heights. For the larger turbines, the researchers extrapolated the wind data to higher tower heights in order to allow enough clearance for the big blades.

Let’s consider the example of Northern Power’s NW 100/20 turbine, with a rotor diameter of 20 meters and rated power of 100 kW. Research suggested a hub height of 50 meters, which is also the top of the anemometer tower, so it wouldn’t require extrapolation. At that location, the wind speed at this site was a brisk 17.28 mph. Even with such a strong resource, the turbine would have zero output 16.7 percent of the time, and rated output none of the time. The average net energy output for this turbine was estimated at 234,900 kWh per year.

To find the annual capacity factor for this turbine, take the energy generated during the year (kWh) and divide by wind generator–rated power multiplied by the number of hours in the year.

You can use the capacity factor data to help you choose a turbine that would be best suited to your wind resource. A higher percentage number is better—it means the turbine is running closer to its full capacity. A capacity factor of 25 to 40 percent is common, although higher capacity factors may be achieved during windy weeks or months.11, 12

Power Up! Figure 9-11 suggests that larger turbines tend to have higher capacity factors, which isn’t surprising, since we have already mentioned that large turbines tend to be “more efficient” than smaller ones. However, even among the smaller turbines listed, there are some that show higher capacity factors than others for the test site. That’s because all turbines do not perform equally at different speeds and wind distributions, based on their design tolerances. This shows that it can pay to optimize your turbine choice for your particular site to maximize your ROI. If there are no turbines with at least a 10 percent capacity factor, you may want to reconsider whether wind is a good choice for your site.

FIGURE 9-11 Comparison of popular wind turbines, showing energy outputs and capacity factor. Mike Kostrzewa/Colorado State University 2008 Mechanical Engineering.

If you haven’t assessed your site yet but want a survey of turbine performance, there are test fields around the world you can use to see the average performance at the rated power of various turbines. Access to those sites is provided at the end of this chapter.

How to Calculate Net Energy Output for Any Wind Turbine

Tech Stuff We have been showing you how to estimate actual energy output, but each time we seem to share one more item that will reduce the ideal rated output. Now that you are developing an understanding of the parts of your wind collector and how each part factors in to how much energy will be produced, let’s bring it down to a more complete picture. How does the collection of selected parts—environment, blades, alternator, electronics, and so on—work together to get your juice blender the wattage it needs to make your morning margarita?

Each of the elements of the performance formula has its own distinct contribution to total wind turbine power output and resulting yearly energy yield. If there is any single equation that the beginning wind enthusiast should memorize, this is it.

Wind Turbine Power:

P = [1/2 × ρ × A × V3] × Cp × Ng × Nb

You can hopefully recognize the formula in the brackets as the power availability formula, discussed earlier in this chapter and in Chapters 3 and 5. To briefly review, ρ (rho), is the air density (about 1.225 kg/m3 at sea level, less higher up). A is the swept area of the rotor, typically calculated in meters squared. V is the wind speed, let’s say in meters per second.

The rest of the formula factors in the losses that affect the system, which are worth considering so you can better size your unit.

• Cp = Coefficient of performance, the aerodynamic efficiency of conversion of wind power into mechanical power, often called the power coefficient. This value has a theoretical maximum of 59 percent (0.59), the Betz limit (Chapter 3). Utility-scale turbines are approaching the Betz, while a “good” design for small wind turbines is around 35 percent (0.35).

• Ng = Generator efficiency, the conversion efficiency of the turbine generator (alternator). Typically, this will be 80 percent or more for a permanent magnet generator. With a car alternator it would be around 50 percent.

• Nb = Bearings/gearbox efficiency, the conversion efficiency of the bearings and gearbox, if one is present. In a well-made system, this could be as high as 95 percent.

We weren’t able to find any premade online tools for these calculations, so we decided to create one. Check out the second worksheet of the spreadsheet titled “online calculator.”

Resource

Turbine Power and AEO Online Worksheet bit.ly/AEO_xl

Cost

Prices in the chart are the manufacturer’s suggested retail price and generally include the turbine, controls, adapter for the towers, and the inverter. Battery-based systems might also include the batteries, charge controller, and divert load.

The versions field in the comparison chart is to let you know what system types are available and their price differences. As we have mentioned, batteryless grid-tied is normally the most cost-effective choice. Most such systems are configured to be connected to a standard 120 or 240 VAC single-phase utility service connection. Some turbine kits, such as Skystream 3.7 and the newer model Skystream 600 (tentative name), are also available for connection to a three-phase utility service. You might need a dedicated transformer if one is not nearby, but the installation and cost are generally the responsibility of the power authority with which you have a net-metering or feed-in tariff agreement. In addition, if you’re determined to have backup for utility outages, some battery-charging turbines can be grid-tied via a battery-based inverter that also synchronizes its output with the utility grid. Check with the manufacturer.

Battery voltages are listed for battery-charging turbines so you can choose the right turbine voltage for your battery bank. Most modern, whole-house, battery-based renewable energy systems use a 48 V battery bank with an inverter to supply the house with 120 or 240 VAC.

BOS included lists what components of the balance of system you receive when you buy an off-grid turbine—components such as a controller, batteries, dump load, and metering. If they are not included, don’t forget to add them into your cost estimates—these components can be expensive. Most grid-tied wind systems are usually sold as a package, with the wind turbine, controls, and inverter.

Tower or installation included. For smaller systems, the price of the tower and its foundation can easily eclipse that of the turbine. Therefore, it’s not surprising that more and more manufacturers are offering full-package deals that include the tower (Figure 9-12).

FIGURE 9-12 Byers Auto recently installed a 100 kW Northwind wind turbine at its car dealership in Columbus, Ohio, with the help of a $200,000 grant from the state. Byers and Renier Construction/DOE/NREL.

The all-in-one package option has various advantages for the consumer. It takes out the process of subcontracting the construction or locating the appropriate tower. The added cost of transporting a tower from the manufacturer or distant distributor is compensated by the fact that the warranty now includes the tower and foundation, assuming it is installed by a crew certified by the manufacturer. In fact, several manufacturers are now insisting on selling the whole package and using certified installers in order to avoid tower-related problems. Otherwise, less experienced installers frequently underestimate the lateral thrust of the wind. Some people put turbines on the darndest things (telephone posts, trees, plastic plumbing pipes).

Warranty is not only an indication of the manufacturer’s confidence in the machine; it tells you what is covered—usually it’s equipment only and not the costs of replacement shipping or labor, which can be significant. If the manufacturer provides less than five years of warranty coverage, it might be possible to extend the warranty for an additional cost. See Chapter 6 for more on warranties.

Speed (RPM and TSR)

RPM (revolutions per minute) gives the turbine’s blade speed at rated power output.13 Since most manufactured small turbines are direct-drive, it is also the alternator/generator rpm. Although we stated early in this chapter that you want a turbine with blade speeds (driven by lift) faster than the oncoming wind speed, it’s also not necessarily true that faster is always better. For one thing, the RPM rate relates to two other important characteristics of wind generators: durability and noise.

Just as you wouldn’t drive your car down the interstate in first gear because of the increased engine wear and poor fuel economy, you don’t want a wind turbine that spins at an excessively high RPM. The faster that rotor turns, the quicker the parts will wear out. That’s because higher RPMs mean more vibration, friction, centrifugal forces, and noise. As if wind shear weren’t enough, as a machine wears and the blades get nicked and abraded, imbalances will become more pronounced at higher speeds. This will naturally put more stress on the turbine and tower, which can lead to early failure in any of these components.

A faster turning engine will produce more friction, which means more of your precious wind energy will be lost to waste heat. And heat affects other parts. Bearings are one of the few moving parts that can fail on a direct-drive wind turbine. Several factors affect the life of a bearing, with heat, dirt contamination, and inadequate lubrication as the major culprits. Another side effect is the centrifugal force that constantly tries to tear the rotor apart. Finally, a slower rotor speed in a given class of turbines will generally mean a quieter turbine.14

Lower RPM does not necessarily mean lower energy production, just as higher RPM doesn’t always mean higher production. What you want is a good design that matches the alternator RPM and rotor speed to get as much energy out of the wind as possible, without sacrificing integrity of its components (Figure 9-13).

FIGURE 9-13 National Wind Technology Center researcher Dave Corbus outfits a 10 kW Bergey turbine for testing. Warren Gretz/DOE/NREL.

Tip Speed Ratio

A concept closely related to RPM is tip speed ratio (TSR). Browse through a glossy wind turbine catalog, and you’ll likely encounter numerous references to it, because it is important to the efficiency and longevity of your machine.15 The tip speed ratio describes how fast a turbine’s blade tips are moving compared to the oncoming wind speed. For example, if a 20 mph (9 m/s) wind is blowing on a wind turbine and the tips of its blades are rotating at 80 mph (36 m/s), then the tip speed ratio is 80/20 = 4. This means that the tip of the blade is moving four times faster than the wind driving the airfoil.

For a drag-based design like an anemometer, the TSR will always be 1 or less, because drag machines can never go faster than the wind. With the added push of lift, however, a turbine could see TSRs of 11 or higher.

Some engineers say a TSR of 8 would be the optimal balance of lift over drag. As tip speed ratios get smaller, drag tends to increase, since each blade encounters more of the wake of the previous blade. As TSR gets higher, blades get louder, and more stresses are placed on the equipment. As it turns out, most engineers decide that TSRs of 5 or 6 are optimal in the wind turbine industry, since that range is viewed to give the highest efficiency of energy extraction, balanced with longevity and avoidance of excessive noise.

It’s also worth pointing out that the fewer the blades, the faster the rotor has to rotate to cover its swept area in order to extract the maximum amount of energy (Figure 9-14). That means the fewer blades a turbine has, the higher its TSR tends to be.

FIGURE 9-14 The fewer the blades, the faster the rotor spins, and the higher the TSR tends to be. Higher TSR means more noise and stresses, while lower TSR means more drag. Kevin Shea.

Tech Stuff If you are considering a turbine with a number of blades not shown in Figure 9-14 and would like to calculate what the optimal TSR should be to achieve maximum power extraction, use this formula. The variable n is the number of blades:

![]()

In Figure 9-15, we can see how the number of blades affects the coefficient of performance, also called the power coefficient.

FIGURE 9-15 A comparison of power coefficient (coefficient of performance) and tip speed ratio for optimal wind turbines with one, two, or three blades. Most people choose three blades as a compromise of performance, stability, and durability. Kevin Shea.

Imagine that the lines in Figure 9-15 are like cargo nets, and anything underneath each net has been captured, while anything above has been lost. The maximum theoretical power extraction is 59.26 percent of the windstream—the Betz limit. Small turbines at their optimal tip speed ratio can achieve a range of 35 to 45 percent conversion efficiency due to losses and inefficiencies. Furthermore, in general, a one blade-turbine performs 10 percent less than a two-blade turbine (Figure 9-16), which in turn performs 5 percent less than a three-blade turbine for the same swept area.16

If a turbine frequently exceeds its optimum TSR, it can wear out faster and cause noise and excess vibrations, which can make for angry neighbors.17 If a turbine is below its optimum TSR, much of the wind will pass undisturbed through the gap between the rotor blades. In addition, the blades will tend to stall, a term borrowed from aviation that means the drag force is overpowering the lift force. This happens if the angle of attack of the airfoil is too big. It cuts into the power extraction and can disable grid-connection with the power authority.

So, your takeaway with regard to tip speed ratio is to ensure that your turbine’s optimal value approximates the numbers in Figure 9-15.

Power Up! Manufacturers sometimes tout higher TSRs as an attractive “feature.” We think this is because as rotor RPM increases due to increased TSR, alternator size can decrease and still get the same output at a given wind speed. Faster spinning machines allow for smaller, cheaper alternators for a given output power level. For the manufacturer, this means less cost to fabricate their particular product, which translates to a more competitive spot in the marketplace.

FIGURE 9-16 Two-bladed turbines like this model from Gaia Wind at the National Wind Technology Center tend to spin fast, though they introduce powerful cyclic forces on the hardware. Lee Jay Fingersh/DOE/NREL.

Calculating Tip Speed Ratio

Tech Stuff In the event that the turbine manufacturer doesn’t provide the tip speed ratio, or you want to know how this number has been calculated, there is a simple process to extract this information.

The tip speed as blades make a revolution is expressed in “meters per second,” and is calculated by multiplying the diameter (in meters) by π, and then multiplying this product by the RPMs divided by 60 (seconds), to get meters per second. For example, if we had a four-meter-diameter rotor that had 300 RPM at the rated output speed,

Tip Speed = (Dπ) (RPM / 60)

= 4π × (300/60)

= 63

With the tip speed, you can now get the TSR if you divide it by its rated wind speed:

TSR = Tip Speed of Blade / Rated Wind Speed

= 63/12 (m/s) = 5.25

The tip speed ratio is chosen carefully so that the blades do not pass through too much turbulent air left by the previous blade, yet they also do not allow too much air to pass between the blades without being “harvested.”

Resources

TSR discovery activity bit.ly/tsrdiscover

Technical Article bit.ly/tsrRagheb

Governing Mechanism

As you know, high wind speeds carry a lot of kinetic energy. However, turbines are built to operate only up to a specific speed (Figure 9-17). Anything from mechanical damage to catastrophic failure can occur when this limit is exceeded. Therefore, all turbines have some manual and/or electronic controls that allow the rotor to be slowed down or stopped (stalled). In fact, there are several reasons for having such a governing mechanism:

• Optimizing aerodynamic efficiency

• Enabling maintenance

• Reducing noise

• Keeping the generator within its speed and torque limits

• Keeping turbine and tower within their strength limits

FIGURE 9-17 Students and staff from Appalachian State University install a new 2.5 kW ARE 110 turbine with Robert Preus from the manufacturer, Abundant Renewable Energy. Appalachian State University/DOE/NREL.

The governing wind speed is the average point at which the turbine starts the mechanism(s) that deflects some of the wind. A lower governing speed suggests that the turbine designers were conservative, preferring a turbine to last through the rare times of excessive winds. A higher governing wind speed indicates that it was designed to spin a bit fast and furious, eking out a bit more yield, possibly at risk of reducing longevity.

In general, there are three main types of governing systems: stalling the blades, reducing the area of the rotor facing the wind, or changing the pitch angle of the blades. Let’s take a closer look.

Furling System Designs

There are several furling system designs, and not all are equal in their performance.

Tilt-Back The wind generator is hinged just behind the nacelle. When wind speed gets too high, the entire nacelle, hub, and blade assembly tilts back out of the wind, to nearly vertical, while the tail and vane follow the wind direction (Figure 9-18). As the wind slows down, it returns to normal horizontal operating position by springs, wind action on a tilted tail, or a counterweight. If you want to see what it looks like, follow the link to the YouTube video.

bit.ly/tiltback

• Advantages:

– It is time-tested, works effectively, and deflects large wind forces.

• Disadvantages:

– It cannot be used for very large turbines.

• Models: Many micro-, residential, and commercial wind generators use this method.

FIGURE 9-18 This Whisper H40 demonstrates tilt-back furling to mitigate high winds. Dean Davis/DOE/NREL.

Flexible/Coning Blades The blades flex or pivot on a hinge back from the wind like an umbrella with a big wind gust (Figure 9-19).

bit.ly/coning

• Advantages:

– They can be inexpensive to make.

– They can relieve stress on the tower during high or gusty winds.

• Disadvantage:

– The flexing may fatigue the blades.

FIGURE 9-19 Proven Energy wind turbines are among those with flexible blades, which are inexpensive and relieve stress in high winds. Proven Energy.

– With downwind machines (see later), tower shadow is a problem, since the rotor blade actually passes behind the tower. This can cause turbulence and increased fatigue on the unit.

– Increased noise as blade shears wind.

• Models: Proven Energy’s 2.5 kW, Southwest Windpower’s Skystream 3.7 and Skystream 600

Side Furling or Furling Tail The generator is mounted off-center horizontally from the yaw. The tail and/or vane is hinged and set angled back and to one side. The weight of the tail will want to turn it down. Figure 9-20 shows a small wind turbine that uses both side furling and tilt back.

bit.ly/av_furlingtail

A common misconception is that the tail folds. Actually, when the wind on the rotor is strong enough to overcome the weight of the generator, making it want to yaw, the angled tail stays aligned with the wind and the nacelle yaws sideways, turning the rotor away from the wind direction. When wind speeds drop, the nacelle is returned to normal operating position by gravity or additional springs.

• Advantages:

– It requires less stress on the system than tilt-back control.

FIGURE 9-20 Invented in 1927 by two brothers in Iowa, the Wincharger was popular on farms before grid electricity. Note the air brakes perpendicular to the blades. The Tin Box, www.thetinbox.com.

– The vane gets the brunt of the gale winds and can eventually lose integrity.

• Models: Residential and commercial-size turbines utilize this system, including many homemade designs. Examples include Bergey’s Excel and XL.1 and Fortis Energy’s Montana.

Air Brakes Early small wind turbines included metal “cups” that extended from the hub from centripetal force during high winds to slow the machine down; they retract back into the hub when the wind slows.

bit.ly/wincharger

• Advantages:

– Simple and accessible parts for DIY kits.

• Disadvantages:

– Many components to maintain.

– Noisy and full of vibration.

• Models: Air brakes are sometimes found in homemade designs, and were common in older models, like the classic Wincharger from the 1930s (Figure 9-20). Invented by brothers John and Gerhard Albers in Iowa in 1927, the Wincharger could charge a six-volt battery. The Albers started a company, and their design caught on across rural America. In 1935, they sold the firm to Zenith, which packaged the small turbine with a radio for $10. They also added 12, 32, and 110 volt versions. Vintage Winchargers can still be seen on farms across the Americas.

Shutdown Mechanism

Shutdown mechanism refers to the method used to completely stop the turbine, such as for service, in an emergency, or when you just don’t need or want it to run—like before a trip or an approaching storm. After shutdown, it is not allowed to spin at all, and should be able to survive extremely violent winds in this condition. Generally, larger, more expensive wind turbines have more reliability and redundancy built into their shutdown mechanisms, and may use more than one braking method.

Sound

We discussed the issue of noise and wind turbines at length in Chapter 2. As we pointed out, to try to get a handle on the often-subjective nature of noise annoyance, many ordinances specify the level of allowable sound from a wind turbine at the adjacent property line, the nearest dwelling, or at a certain distance. Typically, 50 to 60 decibels is considered the maximum allowable, with some exceptions for short-term events.

One variable you might see advertised for a turbine is sound power level, which is defined as the sound level at a distance of 1 m (3.3 ft) from the source, which for turbines we take as the center of the rotor, or in other words, hub height.19 Remember, as a person gets farther and farther away from the source, the intensity of the sound they hear reduces as the square of the distance.

The Small Wind Certification Council defines AWEA’s Rated Sound Level as such:

The sound level that will not exceed 95% of the time, assuming an average wind speed of 5 m/s (11.2 mph), a Rayleigh wind speed distribution, 100% availability, and an observer location 60 m (~200 ft.) from the rotor center. The final decision as to what is appropriate sound levels is between you and your local ordinances.

So, what used to be purely dependent on marketing pitches or anecdotes is becoming more transparent and quantifiable. (It’s also true that turbines have been designed to be quieter.) Now, turbine manufacturers can shout about how quiet their machines are, and you in turn can show noise level certifications to your angry neighbors.

That said, it’s worth pointing out that if noise is critical to you, there are small wind turbines that are quieter than others. Ask manufacturers for their noise ratings, and visit some examples of their turbines installed in the field during different wind conditions.

If you don’t need a lot of juice, you might consider the small Swift turbine, which is said to operate at less than 35 decibels, compared to a more typical range of 40 to 55 decibels for small turbines. According to the inventor, Scotland-based Renewable Devices, the lower noise is partly due to what they call a ring diffuser, the outer ring that goes around the tips of the five blades (Figure 9-21). This reportedly decreases turbulence, which is often the source of blade noise.

FIGURE 9-21 Swift turbines are said to be especially quiet because of the ring around the blades, called a “ring diffuser,” which is supposed to decrease turbulence. However, rooftop installations usually don’t produce much energy. Judith/Wikimedia Commons.

Swift turbines are made and sold for the North American market by Michigan-based Cascade Engineering, and they are priced aggressively low (around $8,500). The company says the grid-connected Swift has a peak production of “over 1.5 kW,” or 1.0 kW at 24.6 mph (11 m/s) winds. However, you should know by now that wind speeds that high are quite rare on almost all sites, especially in urban and suburban areas, where the turbine is marketed toward. Cascade says the Swift can produce 1,200 kWh a year on a site with 11.2 mph (5 m/s) annual average winds, which is still quite high. It isn’t that common to find such good annual average wind speeds even with a 200-foot tower, although the Swift is marketed primarily for rooftops.

According to Cascade’s website: “A structure-mounted SWIFT turbine is mounted on an aluminum mast with a minimum blade-roof clearance of approximately two feet. It is optimally mounted at the highest point of a roof, in a position which benefits from maximum prevailing wind, but it will work effectively in almost any location …; Now you can have clean, quiet energy generated right from your rooftop.”

This marketing makes the Swift controversial in the eyes of some, who fear that it won’t be able to produce enough energy to be worthwhile. But if you have enough wind and a small load, it might be worth a look.

Time to Select Your Wind Turbine

To help you get started on your comparison of small wind turbines on the market, we put together the matrix chart in Table 9-2. We tried to include a helpful list of variables to compare, as well as the most popular models from major manufacturers. Please note that all machines that are registered for certification are highlighted. Happy browsing!

To make selection easier, consider some guidelines:

1. Start by selecting a table based on your (estimated) energy requirements now and in the future.

2. Select your better matches based upon the monthly energy output (MEO) and your ultimate goal (savings and/or earnings).

3. Grid or Off-Grid is your next choice. There might be turbines that are not designed for grid connection.

4. Utilize the rotor diameter or swept area for calculations at your site and the hub height chosen.

5. Blade numbers and noise emission levels should be considered if at least one of your stakeholders is concerned.

6. Cost is always important. Note if the price tag includes the wind-in-a-box kit or just the turbine.

TABLE 9-2 Representative Small Wind Turbines

*Standard Power Rating: 200W/m2

The Variables

• MEO (monthly energy output) is how much energy your turbine might produce in a month in kilowatt-hours. The data was tabulated from the reported AWEA Rated Monthly (or Annual) Energy at the mean wind speed of 5 m/s. Otherwise, it was tabulated data from the manufacturer’s annual energy production (AEP) curve at sea level air density at a standard tower height of 10 meters (33 feet) with the Raleigh Wind Distribution factor of 2, and with the site roughness set at a grassy field. In both cases we divided the results by 12 months to get the turbine’s monthly output.

• Rated Power: When the manufacturer didn’t provide an official rated power, we provide the AWEA Rated Power at 7.5 m/s. This is to your advantage, because many manufacturers tend to overrate their turbines.

• Tower Clearance: We take the standard tower height to be at least 30 feet above obstacles. This would make the minimum tower hub height around 10 meters (33 feet) (knowing that, for those who are doing a boat, cell tower, or roof mount, this doesn’t necessarily apply).

• AWEA Rated Sound Level: The sound level at 60 m (197 ft) that the wind turbine will not exceed 95 percent of the time at a 5 m/s (11 mph) average wind speed site.

• BOS: Balance of system, in this case meaning the manufacturer sells the turbine in a package that also includes the inverter, charge controller, stop switch, wiring, and perhaps disconnects and meters.

• Cost: Generally the starting cost includes the turbine only. If the balance of the system is included (excluding the tower, battery bank, and installation) the price will be followed by an asterisk. If the tower is included, it will have 2 asterisks. If it includes installation, 3 asterisks.

Notes:

1. Please note that due to time constraints and constant subsidy changes, we cannot include a feature for financial incentives for each turbine. It is advisable for you to locate the turbine of your choice and check for it in your local and national government programs.

2. If the manufacturer failed to provide the information for any variable for whatever reason, we simply place a dash in that cell. This is not to suggest that it is not important or that it doesn’t apply to that turbine. If it doesn’t apply, it would have a “n/a” in the cell.

3. For those that want that extra assurance, we have highlighted the rows of wind turbines that have achieved either or both the MCS or SWCC (temporary) certification.

A regenerative brake slows a machine by converting its kinetic energy into another form, which can be either used immediately or stored until needed.

Resource

For more information on how to select your wind turbine, check out this Home Power magazine article by Ian Woofenden and Mick Sagrillo:

2010 Homepower’s Wind Generator Buyer’s Guide bit.ly/2010windbuyersguide

Summary

In this chapter, we tried to give you the tools to critically compare one wind turbine with another. The turbine, of course, is a central part of a wind system, and that choice often dictates much of the balance of system. As we pointed out, some of the key specifications to consider are swept area, durability, annual energy output, cost, speed, governing mechanism, shutdown mechanism, and sound.

We introduced the concepts of tip speed ratio and RPM, and explained the ways in which turbines dissipate excess energy during high winds. Going forward, you should be well armed to critically examine manufacturer claims, to make sure you get all your questions answered, and to focus on what’s really important. Otherwise, it’s easy to get distracted by nifty videos and slick brochures.