Chapter 1. The Chemical Engineering Profession

Engineering is the art of organizing forces of technological change.

—Gordon Stanley Brown1

1. Former Dean of Engineering at the Massachusetts Institute of Technology; an accomplished teacher, researcher, and administrator who influenced engineering education post World War II. Quotation source: Scalzo et al, Database Benchmarking: Practical Methods for Oracle and SQL Server, Rampant Techpress, Kittrell, NC, 2006.

Engineering, with its attractive salary and continued projected demand growth, is consistently ranked among the most desirable professions in various surveys and reports, such as the ones published by the U.S. News & World Report. Yet, only a little more than half of the students entering the engineering programs as freshman actually end up with a degree in engineering [1]. One of the reasons contributing to this student attrition is that a typical high school senior/college freshman entering an engineering program has only a limited understanding of the engineering profession, and this lack of understanding is compounded by the inability of engineers to answer the simple question, What do engineers really do? [2]. Answers often heard include the following:

• “An engineer solves problems.”

• “An engineer builds and creates machines, processes, structures, and so on.”

• “An engineer makes things.”

All of these answers are true and yet add little to the student’s conception of the engineering profession. In particular, such answers do not help distinguish an engineer from a scientist, a confusion that is only enhanced by the fact that almost all engineering degrees are designated as bachelor of science. If an individual is to succeed in an engineering course and profession, he/she must understand the basic nature of engineering [3]. This is particularly true of chemical engineering, the most recent of the four main engineering disciplines. This chapter attempts to explain the chemical engineering profession, starting with a brief discussion of what the profession of engineering means and what roles engineers—the individuals practicing the engineering profession—play.

1.1 Engineering and Engineers

Engineering has been considered as the practical application of science for over two centuries. ABET, Inc., formerly the Accreditation Board of Engineering and Technology (www.abet.org), the organization that evaluates and accredits college and university programs in applied science, computing, engineering, and technology in the United States and many other countries, defines engineering as follows:

Engineering is the profession in which a knowledge of mathematical and natural sciences, gained by study, experience and practice, is applied with judgment to develop ways to utilize economically the materials and forces of nature for the benefit of mankind.

This is an all-encompassing definition that makes it clear that engineering is based on science and harnesses resources for the benefit of mankind. Any activity practiced today as engineering would certainly be covered by this definition, and yet, the definition suffers from the disadvantage of being too general. Practically any commercial venture can be construed as an engineering activity according to this definition. Further, this definition does not help distinguish between science and engineering. Landis [4] has compiled 21 different definitions of engineering by various individuals over the last two centuries, and the recurring theme in these definitions is that engineering is the application of science for the benefit of humanity. As with the ABET definition, any engineering activity practiced today would conform to any one of these definitions, and yet, the definition would not be exclusive to engineering activities.

Obviously, defining engineering is not an easy task (we would have already had a more than adequate definition if it were so), and it would be better to describe characteristic attributes of engineering before attempting to develop a new definition for it:

• An engineering activity has an economic impact associated with it: An organization engages in engineering activity in order to derive immediate commercial or other benefit from it. The commercial benefit is primarily through generating revenue and profit through the manufacture of products, provision of service, supply of energy, and so on. The commercial benefit may also take the form of cost-aversion, such as avoiding penalties and taxes through the treatment of waste streams prior to releasing them in the environment. Certain engineering activities, particularly those conducted by governmental or quasi-governmental entities, may not have immediate or direct commercial benefit. For example, public works such as bridges, roads and dams, or weapons development and other military engineering activities may not generate revenue/profits but have implicit economic value to the society and the nation. These activities build infrastructure that makes economic growth possible and protect the people from external dangers that, among other impacts, threaten the economy of the nation. Similarly, engineering clean-up of polluted waterways and air and soils also has positive economic impact on the society through aversion of healthcare spending and other costs and increasing the resource availability for economic activities.

• An engineering activity is conducted for the benefit of society at large: Engineering activities are undertaken to satisfy the demand for products, services, and energy by the society. In other words, the public at large is the direct beneficiary of engineering activities, be those in the form of power plants, automobiles, machines, or clean environment. Some of these activities, particularly public works activities, benefit each and every member of the society. Other activities that are purely commercial in nature are targeted at the customers of the products and services of such activities. For example, an automobile manufacturer produces cars to satisfy the market demand for them. The customer for the product is any member of the society, any individual who has the need and resources to afford the product. This aspect of engineering activities contrasts with scientific activities, which while adding to our knowledge, are of direct benefit only to a more specialized group of people, namely other scientists, engineers, and technical professionals in that specific field.

• Engineering involves application of scientific knowledge: As the ABET definition states, engineering utilizes science for practical purposes. Science is essentially a field of discovery where fundamental understanding of processes and phenomena is the objective. Scientists seek to produce knowledge that enables us to explain observed phenomena and elucidate underlying laws of nature. Engineers apply this knowledge to create products, processes, and services to improve the quality of life of people. A scientist is typically driven by the desire to derive a global understanding of the phenomena; in other words, the knowledge is not complete until each and every factor affecting the phenomena is identified and a theoretical explanation proposed and validated for every observed effect. Such knowledge is obviously beneficial to the engineer; however, an engineering activity can proceed without necessarily having the complete theoretical scientific understanding and framework for the process. As it is often said, the steam engine was developed before the science (thermodynamics) behind it was fully understood.

• Engineering activities are conducted on a large scale: A key significant characteristic that distinguishes engineering from science is the scale of activities. Science involves discovery of new products, principles, and processes in a laboratory or research setting. Engineering involves taking this novel discovery and scaling up to make it accessible and affordable to the entire society. A chemist may synthesize a new chemical with promising properties in the laboratory in milligram quantities, starting with high-purity substances. An engineer develops, on the basis of the reaction discovered in the laboratory, a commercial process producing the same chemical in bulk quantities (kilograms or tons, a scale-up factor of a million or more) starting with the cheapest substances possible. Scientists discovered radioactivity and nuclear fission; engineers utilized this knowledge to build nuclear power plants for electricity generation. The key challenge in engineering is to ensure that the outputs of industrial commercial ventures have the same properties (including purity) and functionality as the laboratory products while minimizing the energy and resource consumptions, and realizing economic benefit.

It should be noted that scale can refer to either the size or the number of the products of the engineering activity. Figure 1.1 shows the massive Hoover Dam on the Colorado River in the United States, a structure that required more than 5 million barrels of cement. Weighing in excess of 6.6 million tons, the Hoover Dam was the largest dam of its time when completed (www.usbr.gov/lc/hooverdam/faqs/damfaqs.html).

Source: Photo courtesy of the U.S. Bureau of Reclamation, www.usbr.gov/lc/hooverdam/images/D001a.jpg.

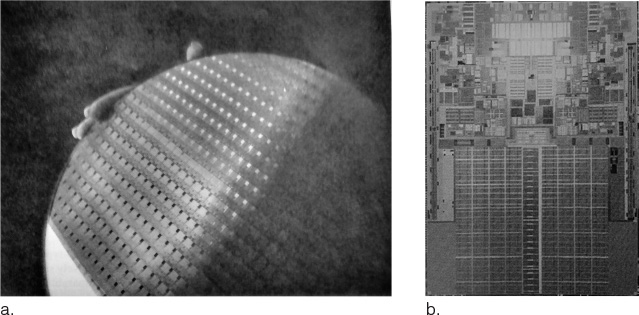

Not every product of engineering activities has such large dimensions. Figure 1.2(a) shows a 300-mm diameter silicon wafer containing a large number of microchips, each containing an integrated circuit similar to one shown in Figure 1.2(b) with the interconnections having a width of only a few nanometers [5]. Figures 1.1 and 1.2 both show manifestations of remarkable engineering endeavors.

Source: Shackelford, J. F., Introduction to Materials Science for Engineers, Seventh Edition, Prentice Hall, Upper Saddle River, New Jersey, 2009.

These characteristics point out engineering as the activity that makes science a reality for the common man. It transforms the knowledge from the realm of a select few to an entity that can serve a consumer for betterment of the quality of life. The basic laws of mathematics, physics, and chemistry are harnessed through engineering to manufacture automobiles, planes, and other machines; build dams, highways, and other structures; construct power plants to supply electricity and refineries to provide gasoline; and countless such endeavors. A consumer, the beneficiary of these undertakings, does not need to have even a rudimentary understanding of the fundamental scientific laws to enjoy the resultant product or service, thanks to engineering.

An alternative way of expressing the same idea is to say that engineering is the process of transforming science into technology. This definition introduces an additional concept—that of technology. Technology is variously defined as (1) the application of science for practical purposes, (2) a branch of knowledge dealing with engineering or applied science as a machine, and (3) a piece of equipment developed from scientific knowledge. The first definition makes technology virtually indistinguishable from engineering, and the second definition lacks clarity. The third definition is the closest to the meaning intended in this book, as elaborated in the discussion that follows.

Science comprises the natural laws that govern the behavior and interaction of inanimate and animate objects. Technology is the manifestation or implementation of this knowledge in the form of a manufacturing, treatment, or other process that yields a machine, an object, or a service that is used by a consumer. For example, an automobile is the product of a manufacturing technology developed on the basis of laws of physics. Similarly, principles of chemistry are harnessed in another type of manufacturing technology to obtain a chemical product, such as sulfuric acid.

Not all technologies yield tangible objects such as sulfuric acid or an automobile as their end products. The products of information technology, based on mathematics and computer science, are frequently services in the form of software packages and programs used by consumers. Technology is essentially science-based process (or technique) that yields an object or a service that is used by the consumer, who need not have any understanding of the fundamental scientific principles on which it is based.

Once science is understood to be the foundation of the structure that is technology, engineering can be easily understood as the process of developing and building the structure. Engineering thus differs from both science and technology in being an action rather than a concept or an object. The initial starting point of engineering activities is science, and the end result is technology. Science and technology can be viewed as the initial and final states, and engineering, the process of traversing the path between them. Engineering also includes the actions that result in improvement of technology. This dynamic nature of engineering distinguishes it from both science and technology.

With this concept of engineering, an engineer can be conveniently defined as an individual engaged in the practice of engineering. An engineer must possess the scientific knowledge, but the overarching goal of the engineer is to apply this knowledge to create useful things—technology—for everyone. Discovering new knowledge is not an engineer’s principal function, although some engineers may indeed add to the knowledge base while devising practical applications of science.

This scheme of things also allows us to define the role of a technologist with greater clarity. A technologist is the individual who has the responsibility to operate and ensure that the technology functions as designed and intended.2 The technologist must understand how the technology operates; however, a technologist is not required to know how the technology was developed. A technologist may use his/her experience and empirical knowledge to effect improvements in the technology, but those activities would not qualify as engineering activities in the rigorous sense of engineering.

2. Despite the nature of responsibilities, these positions are most often termed as engineering positions.

In the past, it was possible for an individual to acquire the necessary knowledge to practice the engineering profession through experience; however, at the present time a degree from an ABET-accredited program is indispensable for one to be qualified and licensed as a professional engineer.3 These engineering programs feature rigorous science, engineering science, and engineering courses to prepare the individual for an engineering career.

3. Each state in the United States has its own board of licensed engineers that administers the necessary examinations to certify an individual as a professional engineer who can then legally engage in engineering practice.

Many universities also offer degree programs in engineering technology that prepare individuals for a career as a technologist. These programs are typically characterized by lower mathematical and scientific rigor and absence of the design component as compared to the engineering programs [3]. The emphasis is on understanding the operation of the process and maintenance of machinery. The actual operation of the machinery and the process is done by technicians skilled in the particular trade. The technical skills and knowledge necessary for such duty are typically acquired in a vocational school that offers an associate’s degree or a certificate course or are learned on the job. The associate’s degree or certificate programs are of shorter duration and feature less rigorous science and mathematics courses.

Based on the nature of engineering practice, the engineering field is divided into several disciplines. These disciplines are described briefly in the next section.

1.2 Engineering Disciplines

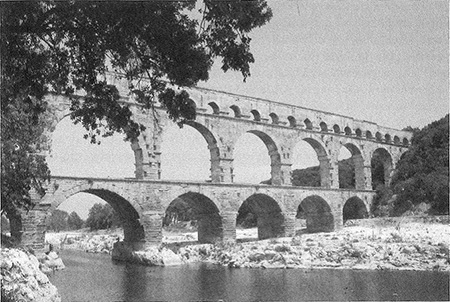

The evolution of engineering is essentially a history of civilization. As early humans transitioned from a nomadic existence into settlements, there arose a need for permanent structures and systems for handling water and wastewater demands. Civil engineering developed in response to these needs, and even today one can marvel at the systems developed by engineers of ancient civilizations in Egypt, Mesopotamia, Indus Valley, and Ancient Rome. Figure 1.3 shows Pont du Gard—a bridge over the river Gard in France built by the Roman engineers nearly 2000 years ago [6]. The third tier of this impressive structure, 160 feet above the river, is an aqueduct supplying water to the cities [6, 7].

Source: Hanser, D. A., Architecture of France, Greenwood Press, Westport, Connecticut, 2006.

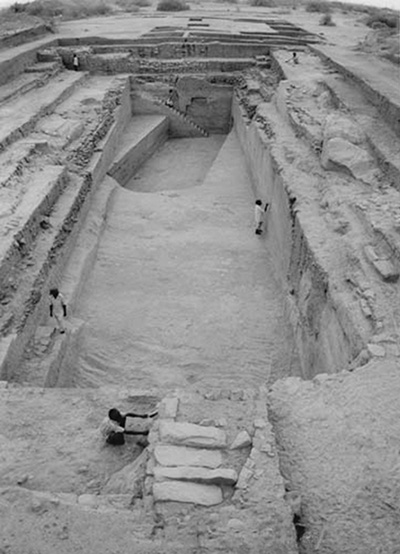

Figure 1.4 shows the ruins of a sophisticated water reservoir from the city of Dholavira belonging to the Indus Valley Civilization dating several millennia further back. The cities and even smaller towns and villages of the Indus Valley Civilization feature a water and waste management system that can simply be described as outstanding [8].

Source: Archaeological Survey of India, http://asi.nic.in/images/exec_dholavira/pages/015.html.

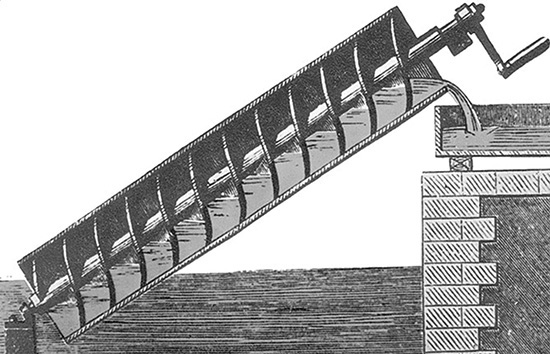

The second driving force for engineering development was the need for accomplishing things beyond what was possible through simple manual labor, leading to simple machines such as the Archimedes screw (Figure 1.5), a simple yet elegant machine for pumping water and transferring material. This simple machine is capable of lifting the fluid, even if it contains a small amount of debris [9]. These machines progressively increased in complexity with time, driven in no small measure by the need for advanced weapons and means of movement, leading to the discipline of mechanical engineering. This evolution has continued with new disciplines appearing over time in response to societal needs based on advances in sciences and new discoveries.

Source: Chondros, T. G., “Archimedes Life Works and Machines,” Mechanism and Machine Theory, Vol. 45, No. 11, 2010, pp. 1766–1775.

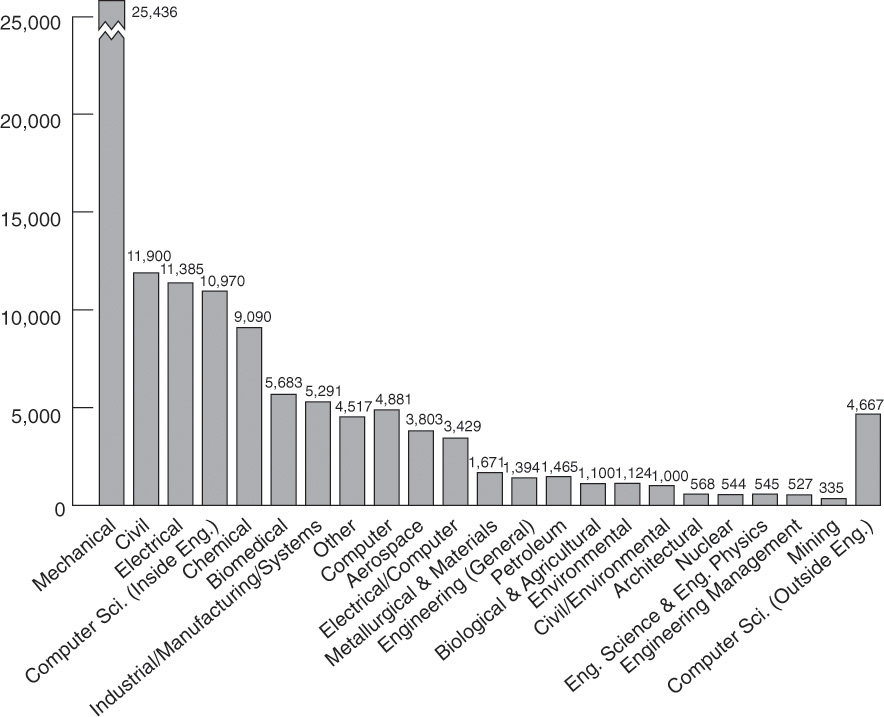

The American Society of Engineering Education (ASEE, www.asee.org), as a part of its activities, compiles statistical data on engineering graduates by disciplines, degree levels (bachelor, master, doctorate), demographics, and various other criteria. Figure 1.6 shows the breakdown by discipline of more than 106,000 bachelor’s degrees in engineering awarded in 2014–15 [10]. Mechanical engineers form the largest group of engineering graduates, followed by civil, electrical, and chemical. These four disciplines are traditionally recognized as the big four of engineering, and any comprehensive school of engineering offers, at the minimum, degree programs in these four disciplines.

Source: Yoder, B. L., “Engineering by the Numbers,” https://www.asee.org/papers-and-publications/publications/college-profiles/15EngineeringbytheNumbersPart1.pdf.

The emerging disciplines of engineering can also be identified from the figure. Computer science has the fourth-largest number of graduates, reflecting the explosive growth of information technology in recent times. However, it was not too long ago that most computer science programs were housed in colleges of science, typically as a part of the mathematics department. The last two decades have seen these programs migrating to the college of engineering, with their own department that does not include the word engineering in its name. Computer science is distinct from computer engineering, which is often associated with electrical engineering programs. The other emerging engineering field is biomedical engineering, which has evolved out of advances in biotechnology and biomedical sciences.

The following briefly describes the big four engineering disciplines—mechanical, civil, electrical, and chemical:

• Mechanical engineering, as the name indicates, deals with development, design, and operation of all types of machines and systems for human convenience and comfort. This is the broadest of the engineering disciplines, with mechanical engineers serving fields ranging from machine design, manufacturing, energy, transportation machines and materials, materials handling, refrigeration and heating systems, maintenance and biomechanics, and many others. Mechanical engineers are a ubiquitous presence in all industries.

• Civil engineering is the earliest discipline of engineering dealing with the development, design, construction, and operation of the facilities and structures for the society. These facilities range from buildings, dams, highways, and canals to all types of systems and infrastructures for mass transit, water supply, waste disposition, and so on. Civil engineering can be further subdivided into specializations such as construction engineering, transportation engineering, geotechnical engineering, water resources engineering, and so on [4].

• Electrical engineering is the discipline dealing with machines and systems associated with electrical energy. Electrical engineers are concerned with the generation and transmission of electricity and with electrical machines. With electricity replacing all other types of energy for practically all consumer applications with the exception of automobiles and cooking, electrical engineers are as ubiquitous as mechanical engineers. Within electrical engineering, one can find specializations such as electronics, controls and power engineering, and so on.

• Chemical engineering as a discipline grew out of industrial chemistry and the need to produce large quantities of chemicals economically. Detailed discussion of chemical engineering is presented in the following section.

The identification of these four as distinct and major branches of engineering is not based on numbers alone but also on the fact that subjects studied during undergraduate studies for each are distinct enough to warrant a separate curriculum. There is an inevitable content overlap between disciplines, particularly between mechanical and civil engineering related to fluid and solid mechanics [11]. However, even for the overlapping content, the approach and treatment of topics and educational objectives generally differ for different disciplines. An individual obtaining a bachelor’s degree in one of these disciplines will not be easily able to go on for graduate study in the other three disciplines without spending a substantial amount of time, perhaps equivalent to junior and senior years of a 4-year undergraduate degree program, completing prerequisite courses to address deficiencies. This is in contrast to the rest of the engineering disciplines seen in Figure 1.6.

With the possible exception of material and metallurgical engineering, an individual with a bachelor’s degree in one of the big four disciplines can successfully go on to pursue graduate studies in many of the other engineering disciplines without needing substantial additional coursework to satisfy prerequisites. A civil, mechanical, or chemical engineer can go on to study and practice environmental engineering. A mechanical engineer can become an industrial, manufacturing, aerospace, or nuclear engineer. Similarly, a chemical engineer can pursue nuclear, biological/agricultural, or petroleum engineering graduate degrees. Many engineers, particularly over last two decades, have changed their fields to computer science at the graduate level. Many biomedical engineering programs operate only at the graduate level, admitting students with undergraduate degrees in mechanical or chemical engineering.

1.3 Defining Chemical Engineering

As with engineering, a clear and concise definition that captures the essence of chemical engineering is not readily available. The American Institute of Chemical Engineers (AIChE), the professional society of chemical engineers in the United States, defines chemical engineers as follows:

Individuals who use science and mathematics, especially chemistry, biochemistry, applied mathematics, and engineering principles, to take laboratory or conceptual ideas and turn them into value added products in a cost effective, safe (including environmental) and cutting-edge processes.

This definition is clearly broad enough to cover all the activities that a chemical engineer engages in and yet not specific enough to distinguish it from other engineering disciplines. By specifically mentioning biochemistry, the definition also tends to show a bias toward biological or life sciences, which is not reflective of the occupation of a vast majority of chemical engineers.

An alternative, more concise definition of chemical engineering is presented by Morton M. Denn [12]:

Chemical engineering is the field of applied science that employs chemical, physical and biochemical rate processes for the betterment of humanity.

The term applied science carries the meaning of taking laboratory or conceptual ideas to a larger scale. Chemical engineering differs from other engineering in having the scientific basis in chemistry in addition to physics and mathematical sciences. The concept of rate processes is at the heart of the previous definition. Chemical engineering, according to this definition, is the field dealing with the rates of physicochemical processes involving transformations of molecular species. The definition places emphasis on processes and the rates thereof. Although the process or the rate of transformation is of critical importance, affecting the economics of the engineering endeavor, it is ultimately the result of the transformation that is usually the desired outcome. In other words, the consumer or the society is interested in the product that can provide a needed service and not in the specifics of how that product is obtained.

The benefit or betterment of humanity is a common theme in most of the definitions of engineering. As previously mentioned, the term is too general, and engineering is not the only occupation working for the betterment of humanity. Despite the shortcomings, a combination of both definitions does convey the essence of chemical engineering as a profession. An individual can be identified as a chemical engineer, if the following descriptors can adequately describe his/her activities:

• The individual is engaged in an engineering enterprise; that is, he/she is working to apply scientific knowledge to make products, both tangible and intangible, commercially available to the general society.

• The engineering enterprise is based on the transformation of species, involving restructuring of bonds (forces) between them. This restructuring is typically at the atomic level, that is, involving chemical reactions yielding products that are distinct from initial species. However, the transformation may simply involve separations, or restructuring of physical bonds between different species. No new molecular species are generated in such transformations. In other words, the transformations involve altering the affinities between elemental and/or molecular species.

Chemical engineering thus deals generally with systems where chemical reactions take place. These chemical reactions are invariably accompanied by physical separations. These physical separations, as explained in subsequent chapters, often play the dominant role in determining the economics of the process. Chemical engineers use their knowledge of science and mathematics to ensure that laboratory reactions and separations are scaled up to the industrial level.

Historically, one can argue that individuals who fermented various brews were the earliest chemical engineers, predating even civil engineers. However, chemical engineering came into being as a distinct profession toward the end of the 19th century and beginning of the 20th century [12]. The development of the discipline resulted from increased demand for chemicals and fuels for both peacetime (fertilizers, consumer goods) and wartime (explosives) activities. Many of the technologies and products developed during the world wars led to additional industrial chemicals. Subsequent developments and societal needs have seen chemical engineering encompass myriad industries ranging from semiconductor, textile, pharmaceutical, agriculture, and food to energy, biotechnology, and medicine [13]. Chemical engineering is a highly versatile field full of challenges and opportunities in practically all facets of human activity.

1.4 Roles and Responsibilities of a Chemical Engineer

A chemical engineer performs a number of different tasks in the chemical industry or an organization engaged in chemical business. The tasks and responsibilities of the chemical engineer that are described in this section are based on the concept of engineering as the transformation process from science to technology.

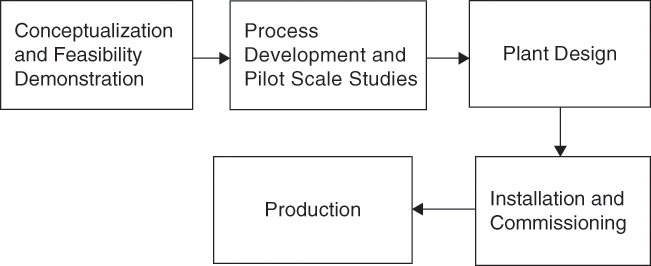

Consider the case of manufacturing a new chemical product or a new manufacturing process for an existing chemical product. Going from conceptualization to commercial operation is an extremely complex and involved process, and any such undertaking typically moves through the following stages [14]:

1. Conceptualization and inception

2. Preliminary economic evaluation

3. Development of data needed for final design

4. Final economic evaluation

5. Detailed design

6. Procurement and construction

7. Start-up and trial runs

8. Production

A simplified flowchart for the various stages of a typical project are shown in Figure 1.7.

The first stage in this development consists of conceptualization of the idea for the new product or process, based on existing technical literature. Before an organization commits financial and other resources to any new venture, it conducts a preliminary economic analysis to gauge the economic viability of the venture. If the venture is judged to be economically attractive, the organization proceeds to the next stage: gathering the necessary information. Extensive laboratory experimentation is generally conducted to demonstrate the feasibility of the idea on the bench scale. Subsequent investigations are conducted over larger scales to ensure repeatable and reproducible results. An integrated process is developed for commercialization identifying the raw materials and processing steps, including those necessary for the treatment of effluents.

The key step, or possibly the entire process, is operated at pilot level to confirm the feasibility. The organization typically conducts a refined, accurate economic analysis using the gathered data. If the project is still commercially attractive, a full-scale plant is designed using scientific and engineering principles and experimental data. The necessary equipment is fabricated and procured from vendors and installed, and the plant is commissioned. Modifications and fine-tuning of processes and operations is invariably required before the plant starts operating consistently, producing the desired product commercially.

A chemical engineer is involved in all of these activities. Depending on his/her responsibilities, the role of the engineer may include one or a combination of the following:

• Research and development engineer: An engineer who is involved in the initial stages of the diagram shown in Figure 1.7 is called a research and development (R&D) engineer. The research component of the position typically involves working with a chemist to investigate the key concept at the bench scale. The development component involves conceptualization of the process based on the key step. The engineer is responsible for identifying the sequence of upstream and downstream processing steps, evaluating alternatives, and conducting investigations on larger scales. Depending on the organization and the complexity of the process, an engineer may be engaged only in research, may conduct only developmental work, or may do both. The R&D engineer designs and executes experimental work, supervises staff, coordinates the data collection and analysis, and handles knowledge interchange among the members of the project team, including the chemist and engineering team. The R&D engineer is essentially the subject matter expert in the team, developing solutions to various challenges. A graduate degree (preferably Ph.D.) is highly desirable for an individual functioning as an R&D engineer.

• Pilot plant engineer: The laboratory investigations typically yield only a few grams of product, while the commercial process may be required to produce thousands of tons of product per day. The laboratory process thus has to be scaled by several orders of magnitude. Before the construction of a full-scale plant is initiated, requiring substantial financial investment, the entire process is inevitably tested in pilot plants having a capacity one or two orders of magnitude lower than that of the full-scale plant. These pilot plants serve two primary purposes: first, they provide validation of the plant design and confirmation of the ability of the organization to successfully operate the process on a large scale; second, they help identify the challenges that arise with the scale-up of the process. For example, heating or cooling of material is generally not an issue on bench scale, but effective energy transfer can become a challenge on a larger scale. Similarly, whereas separation of solids by filtration can be a straightforward matter in the laboratory, it can limit the process efficiency and prove to be a bottleneck when scaled up. The pilot plant operation provides information about such potential technical problems and provides an opportunity to devise and test workable solutions to these problems. Pilot plant engineers run these plants, discovering potential problems, and devising, testing, and perfecting solutions to these problems before they manifest in the production plant.

• Design engineer: Sizing of the process equipment and specifying the operational conditions for the process are among the responsibilities of the design engineer. A design engineer, in the chemical engineering field, is mostly a process design engineer4 who performs detailed calculations of energy and material flows, specifies equipment capacities, and determines the layout of the plant. The design engineer interfaces with the R&D and pilot plant engineers to obtain data and information and interfaces with vendors and fabricators to finalize process equipment specifications. He/she also typically develops cost estimates for the process. The tasks of fabrication of equipment, infrastructure development, and installations are typically executed by mechanical, civil, and electrical engineers. The design engineer interacts with these engineers and suppliers to ensure that the installed plant conforms to the design specifications.

4. In other fields, a design engineer may be a product design engineer, one who creates different product designs, such as a new phone or an app.

• Start-up, or commissioning, engineer: The engineer involved in the initial start-up of a new plant is the start-up/commissioning engineer. He/she has the responsibility to ensure that various process units function as designed and the plant is able to deliver the product having the specified purity and quality at the rated design capacity. Once the initial problems are sorted out and the plant is operating smoothly, the commissioning engineer hands over the responsibility to the production operating personnel.

• Manufacturing/production engineer: A manufacturing/production engineer provides support to the manufacturing operation, monitoring daily operations to ensure that operations conform to the process design. He/she investigates process deviations, troubleshoots problems, and continually explores opportunities to increase profitability through capacity enhancement, efficiency improvements, and cost minimizations. The manufacturing/production engineer is responsible for plant safety, product quality and reliability, and costs for operations under his/her charge. Additionally, the manufacturing/production engineer works collaboratively with operations, engineering, maintenance, quality, and other departments to ensure plant reliability and production goals are met. Some plants may employ individuals other than chemical engineers to oversee the operation of the plant and its production. In this case, they may have a chemical engineer associated with the plant; such plant engineers are responsible for improving the productivity of the process, optimizing operations, and troubleshooting any problems that affect the operation of the plant. A facility may have a number of engineers who respond to such issues, and they may be called technical services engineers. All process plants also employ maintenance engineers, who ensure continuity of operation of various pieces of equipment through routine maintenance and repair of broken equipment. These engineers are typically mechanical or electrical engineers, and the production, plant, and technical services engineers interact closely with them.

Smaller organizations or simple processes may not require distinct personnel to perform the different jobs described. The same individual may perform multiple tasks, bearing the responsibility from laboratory investigations through commissioning. Conversely, larger organizations or complex processes may have separate and multiple individuals for each step. Commercialization of the process is always a team task, with the R&D engineer, pilot plant engineer, design engineer, and commissioning engineer exchanging information and refining/optimizing the process. An organization may also outsource many of the activities, contracting R&D with one entity, getting designs from specialist firms, and having plants commissioned by yet another entity.

Apart from these process- and plant-related jobs, many chemical engineers may work as sales or marketing engineers. Many companies need services of an individual to market their products, services, and equipment to other industries. This individual must have a thorough engineering understanding of the particular product/service being offered and is typically called a sales engineer, technical sales engineer, marketing engineer, or a variation thereof. A sales engineer must possess the necessary technical competence and must have excellent communication skills, a desire to interact with people, an ability to understand the client needs, and the ability to work closely with the team to develop products and services in response to these needs. Ability to cultivate relationships is an absolutely essential skill for such positions. A sales engineer invariably spends a considerable amount of time traveling, visiting clients in a territory typically assigned to him/her, and developing a customer base for the company.

Despite the different nature of responsibilities, all the engineering positions may be designated simply as process engineers, which is the most common title for the jobs advertised across the chemical industry. The next section describes briefly the various industries and other sectors of the economy that employ chemical engineers.

1.5 Employment of Chemical Engineers

The U.S. Department of Labor maintains an extensive database of labor and economic statistics through its Bureau of Labor Statistics (www.bls.gov). The career information about duties, education, training, pay, and current and future prospects for practically any occupation can be found in the Occupational Outlook Handbook (www.bls.gov/ooh) published by the Bureau. The handbook lists the myriad industries—chemicals, fuels, energy, food, drugs, electronics, clothing, life sciences, biotechnology, and many others—where chemical engineers find employment. It lists the median pay for the chemical engineering jobs to be $96,400 (for 2014) and projects a 2% annual growth in the number of jobs. The handbook very likely underestimates the actual number of chemical engineering jobs, with a more realistic number estimated by summing up the number of graduates over an average of 40 years [15]. A National Science Foundation (www.nsf.gov) estimate put the total number of working chemical engineers in 2002 across all occupations at closer to 200,000 [15].

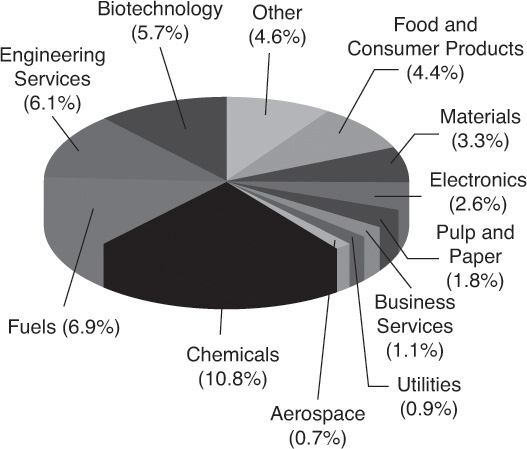

Chemical process industries, composed of chemical and fuels manufacturing and associated R&D, engineering, and environmental services, are the biggest employers of chemical engineers [15]. The initial placement of new chemical engineering graduates conforms to this distribution as well. According to the 2015 initial placement survey of college graduates, conducted by the AIChE [16], nearly half of the graduates opted for industrial careers, and nearly a quarter of the bachelor’s degree graduates chose to continue their education. Although a majority of those going to graduate study were continuing in the chemical engineering field, many chose different engineering fields or even medicine for further studies. For those opting for industrial careers, the chemicals sector was the dominant choice, followed by fuels, engineering services, and biotechnology, as shown in Figure 1.8.

Source: CEP News Update, “AIChE’s Initial Placement Survey: Where Is the Class of 2015?” Chemical Engineering Progress, Vol. 111, No. 12, 2015, pp. 5–6.

This distribution was slightly different from the choices of 2014 graduates, of whom half still opted for industrial careers with chemicals as the dominant choice, but a significantly larger fraction opted for jobs in the fuels sector, and the biotechnology sector was not as dominant, lagging behind the food sector [17].

Traditionally, chemical engineers have pursued careers in the chemicals and fuels sectors of the industry. However, over the past two decades, increasingly greater numbers are being attracted by the pharmaceutical, biomedical, and microelectronics industries [18]. From a historical perspective, we can look back at chemical engineering since the beginning of the 20th century and recognize a few “golden ages” of the disciplines—times of unprecedented discoveries, developments, and industrial growth [19]. The 10 years from 1915 to 1925 and the decades of the 1950s and 1960s are time periods that exhibit such characteristics. It is, of course, impossible to predict the future; however, the current environment is characterized by possibly unlimited opportunities for chemical engineering due to developments in molecular biological sciences and computing and information technology. Chemical engineers, due to the breadth and depth of their preparation, are ideally positioned to enter this new golden age and find solutions to challenges in the areas of environment, resources, energy, food, health, and many other fields.

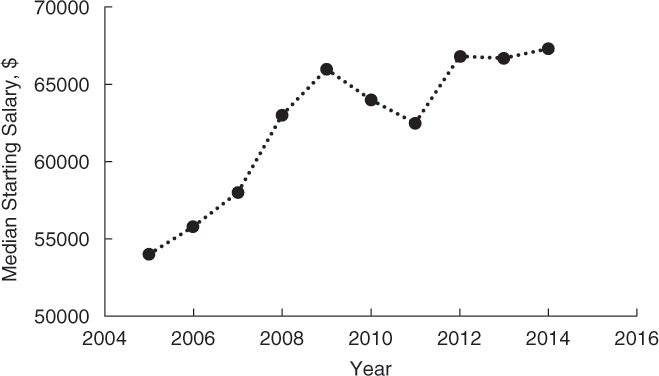

Salary and benefits data for chemical engineers are regularly collected by the professional societies of individuals associated with chemistry-related fields—the AIChE as well as the American Chemical Society (ACS, www.acs.org). Figure 1.9 shows the median initial starting salaries of inexperienced chemical engineers holding a bachelor’s degree over the last 10 years [20]. These salaries have slightly outpaced inflation. As expected, the salaries also exhibit a slight dip coinciding with the overall downturn in the economy around 2009 to 2011.

Source: Marchant, S., and C. Marchant, Starting Salaries of Chemists and Chemical Engineers: 2014 Analysis of the American Chemical Society’s Survey of New Graduates in Chemistry and Chemical Engineering, American Chemical Society, Washington, D.C., 2015.

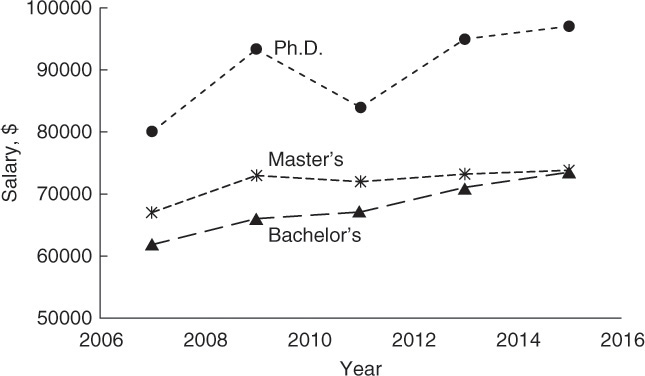

The average starting salaries of chemical engineers are second only to those of petroleum engineers at the bachelor’s level. However, chemical engineers command the highest salaries at the master’s level [21]. The median salaries of chemical engineers having less than 6 years of experience, shown in Figure 1.10, are based on the data collected by AIChE through its biennial salary survey [22].

Figure 1.10 Median salaries of chemical engineers with less than 6 years of experience [22].

Source: Chemical Engineering Progress, “2007 AIChE Salary Survey,” Vol. 103, No. 8, 2007, pp. 25–30; “2009 AIChE Salary Survey,” Vol. 105, No. 8, 2009, pp. 26–32; “2011 AIChE Salary Survey,” Vol. 107, No. 6, 2011, pp. S1–S13; “2013 AIChE Salary Survey,” Vol. 109, No. 6, 2013, pp. S1–S17; “2015 AIChE Salary Survey,” Vol. 111, No. 6, 2015, pp. S1–S20.

It can be seen that a graduate degree generally translates into higher salary for a chemical engineer, though this effect is not as pronounced for master’s-level graduates as it is for those holding a doctorate. The differences in the salaries of bachelor’s and master’s degree holders were insignificant in 2015. Further, the economic downturn clearly impacted those holding advanced degrees more than those holding only a bachelor’s degree, whose salaries did not show any decrease. In contrast, the salaries of those holding a Ph.D. were impacted significantly. The biennial surveys provide a valuable and extensive database, where additional information based on regions, industry sectors, experience, and many other factors is available.

1.6 Summary

Engineering, as a profession, involves transforming science into technology for the benefit of humanity. Mechanical, electrical, civil, and chemical engineering are the big four engineering disciplines, accounting for over half of the bachelor’s-level engineering degrees granted in the United States. Chemical engineering is the branch of engineering dealing with the transformation of species at the molecular level. A chemical engineer is a versatile individual who can serve in different capacities in an organization, with responsibilities ranging from research to technical sales. Over half of the chemical engineering graduates enter the workforce in the industrial sector, with the chemical sector offering predominant employment opportunities. Recent developments indicate a continual growth in opportunities for engineers in biological science–related fields. A chemical engineer, due to the breadth and depth of education and training, is ideally positioned to take advantage of these opportunities to play a major role in addressing challenges facing the society.

References

1. Besterfield-Sacre, M., C. J. Altman, and L. J. Shuman, “Characteristics of Freshman Engineering Students: Models for Determining Student Attrition in Engineering,” Journal of Engineering Education, John Wiley and Sons, Vol. 86, No. 2, 1997, pp. 139–149.

2. Kemper, J. D., and B. R. Sanders, Engineers and Their Profession, Fifth Edition, Oxford University Press, New York, 2001.

3. Burghardt, M. D., Introduction to the Engineering Profession, Second Edition, Prentice Hall, Upper Saddle River, New Jersey, 1997.

4. Landis, R. B., Studying Engineering: A Road Map to a Rewarding Career, Fourth Edition, Discovery Press, Los Angeles, 2013.

5. Shackelford, J. F., Introduction to Materials Science for Engineers, Seventh Edition, Prentice Hall, Upper Saddle River, New Jersey, 2009.

6. Smith, H. S., The World’s Great Bridges, Harper and Row, New York, 1965.

7. Hauck, G. F. W., “The Structural Design of the Pont du Gard,” Journal of Structural Engineering, Vol. 112, No. 1, 1986, pp. 105–120.

8. Kenoyer, J. M., Ancient Cities of the Indus Valley Civilization, Oxford University Press, Oxford, U.K., 1998.

9. Chondros, T. G., “Archimedes life works and machines,” Mechanism and Machine Theory, Vol. 45, No. 11, 2010, pp. 1766–1775.

10. Yoder, B. L., “Engineering by the Numbers,” https://www.asee.org/papers-and-publications/publications/college-profiles/15EngineeringbytheNumbersPart1.pdf.

11. Muslih, I., D. B. Meredith, and A. S. Kuzmar, “Overlap Between Mechanical and Civil Engineering Undergraduate Education,” American Society of Engineering Education, 2005 IL/IN Sectional Meeting, April 2005, Dekalb, Illinois, Paper D-T1–2.

12. Denn, M. M., Chemical Engineering: An Introduction, Cambridge University Press, Cambridge, U.K., 2012.

13. Solen, K. A., and J. N. Harb, Introduction to Chemical Engineering: Tools for Today and Tomorrow, Fifth Edition, John Wiley and Sons, New York, 2011.

14. Peters, M., K. Timmerhaus, and R. West, Plant Design and Economics for Chemical Engineers, Fifth Edition, McGraw-Hill, New York, 2012.

15. Self, F., and E. Eckholm, “Employment of Chemical Engineers,” Chemical Engineering Progress, Vol. 99, No. 1, 2002, pp. 22S–25S.

16. CEP News Update, “AIChE’s Initial Placement Survey: Where Is the Class of 2015?” Chemical Engineering Progress, Vol. 111, No. 12, 2015, pp. 5–6.

17. CEP News Update, “AIChE’s Initial Placement Survey: Where Is the Class of 2014?” Chemical Engineering Progress, Vol. 110, No. 11, 2014, pp. 5–6.

18. Himmelblau, D. M., and J. B. Riggs, Basic Principles and Calculations in Chemical Engineering, Eighth Edition, Prentice Hall, Upper Saddle River, New Jersey, 2012.

19. Westmoreland, P. R., “Opportunities and Challenges for a Golden Age of Chemical Engineering,” Frontiers of Chemical Engineering Science, Vol. 8, No. 1, 2014, pp. 1–7.

20. Marchant, S., and C. Marchant, Starting Salaries of Chemists and Chemical Engineers: 2014 Analysis of the American Chemical Society's Survey of New Graduates in Chemistry and Chemical Engineering, American Chemical Society, Washington, D.C., 2015.

21. National Association of Colleges and Employers, “Top-Paid Engineering Majors at the Bachelor’s and Master’s Levels,” 2015, http://naceweb.org/s03182015/top-paid-engineering-majors.aspx.

22. Chemical Engineering Progress, “2007 AIChE Salary Survey,” Vol. 103, No. 8, 2007, pp. 25–30; “2009 AIChE Salary Survey,” Vol. 105, No. 8, 2009, pp. 26–32; “2011 AIChE Salary Survey,” Vol. 107, No. 6, 2011, pp. S1–S13; “2013 AIChE Salary Survey,” Vol. 109, No. 6, 2013, pp. S1-S17; “2015 AIChE Salary Survey,” Vol. 111, No. 6, 2015, pp. S1–S20.

Problems

1.1 Discuss the similarities and differences between engineering and technology.

1.2 Search the literature and list 10 different definitions of engineering. Use any source, including those (websites, books) mentioned in the “References” section. Discuss comparative features of three alternative definitions. Which one do you prefer? Why?

1.3 How many engineers have graduated with a bachelor’s degree over the last 5 years in the United States? Which disciplines exhibit the highest and lowest rates of growth? How do these compare to trends for chemical engineering?

1.4 Use the data available from the Bureau of Labor Statistics to compare projected growth in jobs for the four major engineering disciplines.

1.5 What are the trends in the placement of recent chemical engineering graduates over the past 5 years? Which sectors show higher growth rates? Which sectors show negative growth rates?

1.6 Which of the responsibilities of a chemical engineering position is more appealing to you? Why?

1.7 What were the two golden ages of chemical engineering according to reference 19?

1.8 Which of the emerging new applications of chemical engineering are attractive to you? What features make the opportunities in these fields desirable for you?