288 289

how operations and production work

Management

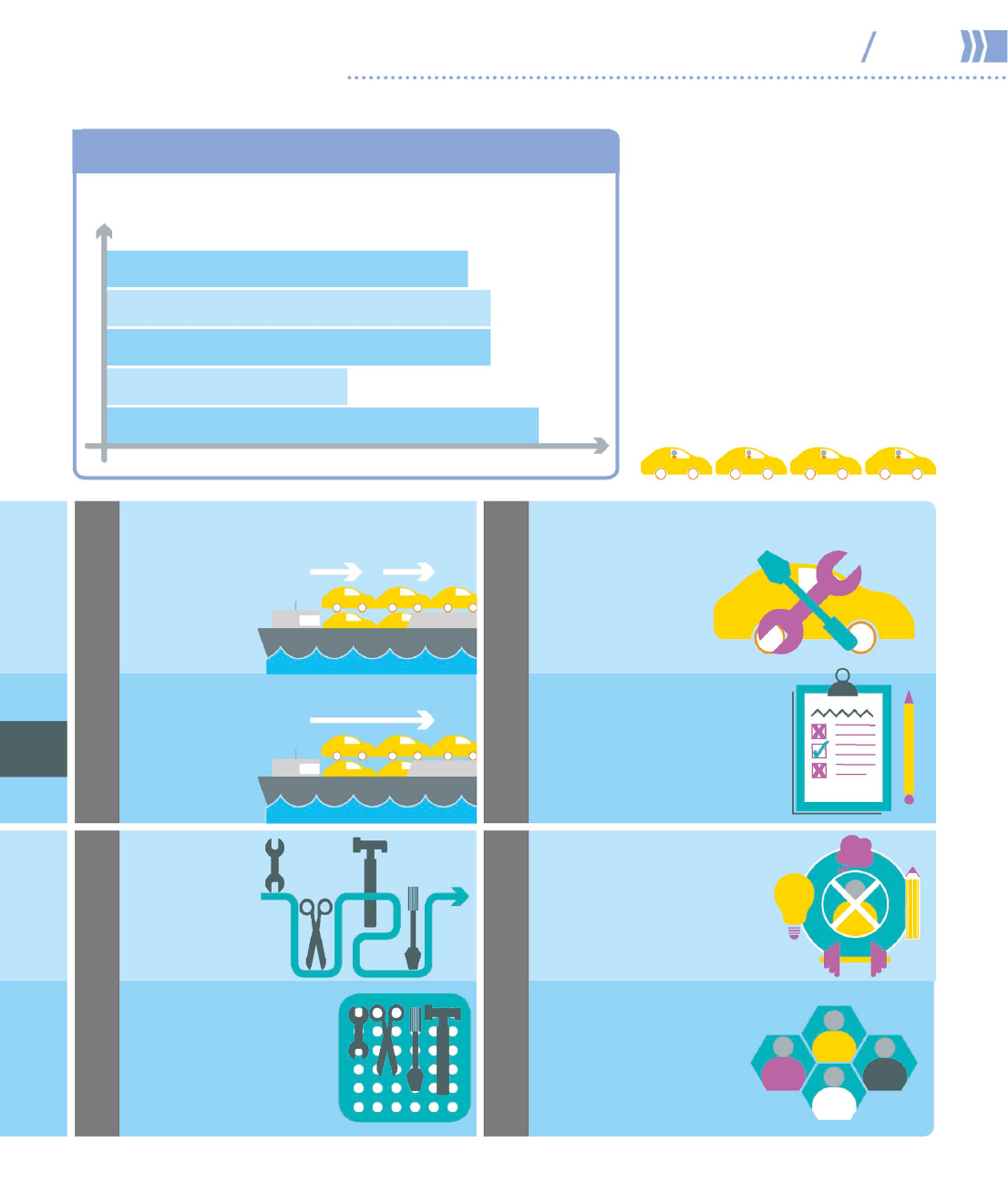

According to a US National Institute of Standards and Technology survey,

40 firms implementing lean production reported these benefits:

BENEFITS OF LEAN PRODUCTION

Waste

Superfluous

stages in the

transportation

process

Lean solution

Material shipped

directly from the

vendor to the

assembly line

Waste

Poor workflow,

poor layout,

and inconsistent

working methods

Lean solution

Workplace Organization,

a systematic method

for standardizing the

workplace

Waste

Underutilization of

employees’ mental,

creative, and physical skills

and abilities

Lean solution Work

cells replace assembly line;

better use of labor and

employee involvement

and communication

Waste

Unprofitable stages

in the production

or reworking of

a product

Lean solution

Map the value stream to

identify non-value-added

steps in the process; get it

right the first time

10

million

the number of cars

Toyota expected

to sell in 2014

Lead time (taking product from start to finish) reduced by 90%

Productivity increased by 50%

Work-in-process inventory reduced by 80%

Quality improved by 80%

Amount of space required reduced by 75%

A CB

Transportation in stages

Non-value-added processing

Excess motion

Underused people

A B

BENEFIT

PERCENTAGE

US_288-289_Lean_Production.indd 289 21/11/2014 16:28

How it works

Also called demand-pull production,

just-in-time means that stock levels

of raw materials, components, work

in progress, and finished goods are

kept as low as possible, reducing

costs. The system requires detailed

planning, scheduling, and flow

of resources throughout the

production process, now assisted

by sophisticated production-

scheduling software. Supplies

have to be delivered directly to

the production line when they

are needed, requiring strong

relationships and interconnected

systems with suppliers. The

benefits of reduced inventory

are balanced against the cost

Just-in-time

of frequent deliveries and loss of

purchasing economies of scale

(discounts for bulk buying). The

system dates back to 1953, the

year Toyota brought in just-in-time

manufacturing. The phrase is

sometimes used in a more general

sense today to mean eliminating

waste of resources.

The system of production in which an actual order is the trigger for

an item to be manufactured is called just-in-time. It enables a firm to

produce only the items required, in the right amount, at the right time.

just-in-time

pros and cons

Pros

Lower stock so less storage space

and less working capital needed

Demand-pull avoids obsolete,

out-of-date stock

Staff spend less time checking

and moving items

Cons

No room for error—for instance,

if there are any faults in the

stock delivered, the whole

day’s production is halted

Operation is reliant on suppliers

No cushion for sudden upsurge

in demand

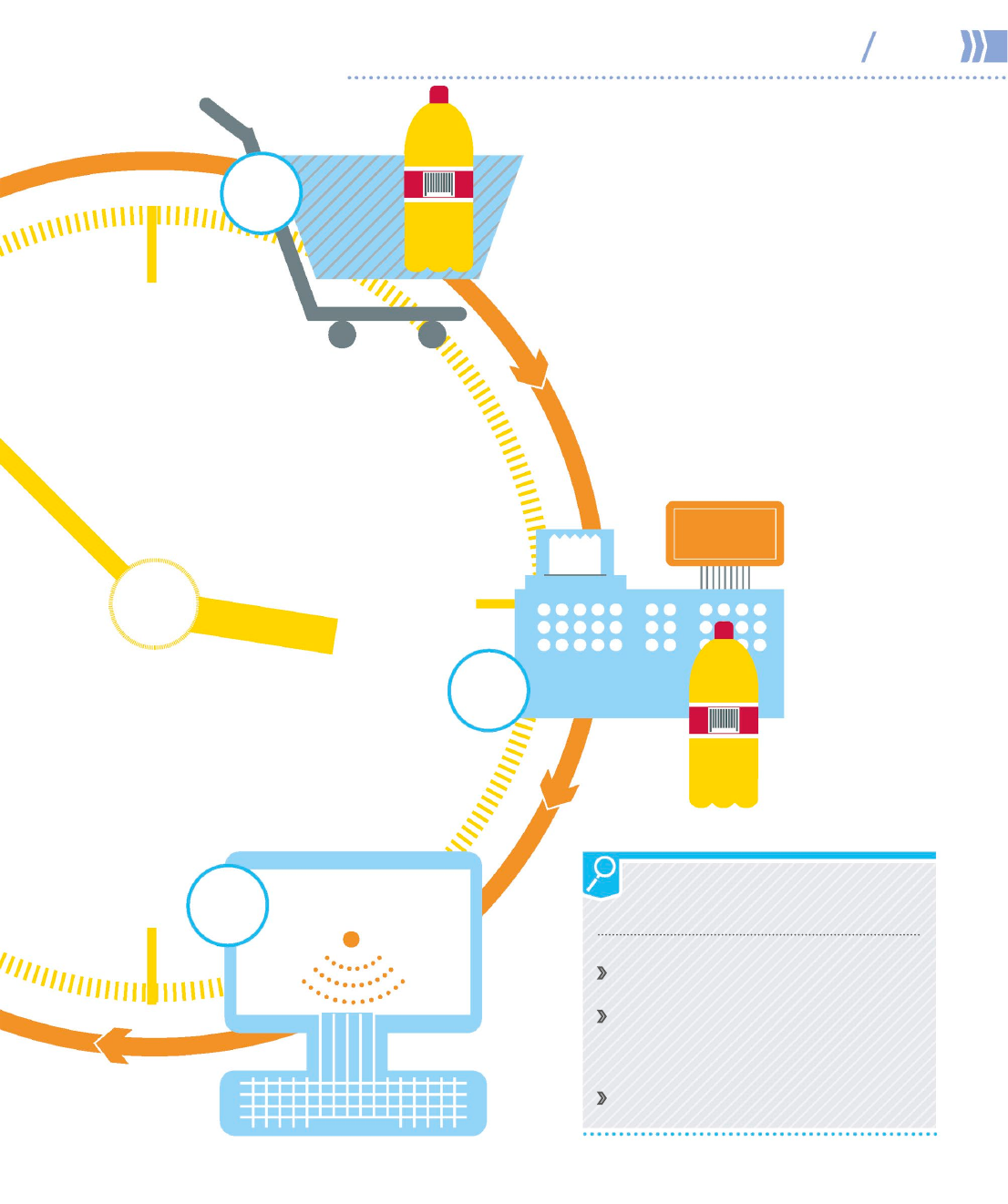

SYSTEM

TRIGGERS

DELIVERY FROM

SUPPLIER WHEN

MINIMUM STOCK

LEVEL REACHED

NEW STOCK IS DELIVERED TO

STORE TO REFILL SHELVES

4

5

US_290-291_Just_in_time.indd 290 21/11/2014 16:28

290 291

HOW OPERATIONS AND PRODUCTION WORK

Management

$62

billion

the value of

Dell computers

sold in 2012

CUSTOMER

SELECTS

ITEM FROM

SHELF

COMPUTER SYSTEM

SIGNALS WAREHOUSE

Just-in-time in retail

To reduce stock levels, many supermarkets

now use just-in-time deliveries, relying on

computer data systems. In manufacturing,

systems are often based on Kanban cards—

dockets for withdrawing and ordering items at

each workstation of the production process.

CASHIER SCANS

BARCODE

1

2

3

Dell’s just-in-time computers

Computer produced when customer orders it:

Customer’s individual specification is sent

straight to factory floor.

Just in time manufacturing sees deliveries

of supplier parts arriving at one side of the

factory and unloaded directly into bins to

build customer order.

Inventory and costs are reduced.

Case study

US_290-291_Just_in_time.indd 291 21/11/2014 16:28

290 291

HOW OPERATIONS AND PRODUCTION WORK

Management

$62

billion

the value of

Dell computers

sold in 2012

CUSTOMER

SELECTS

ITEM FROM

SHELF

COMPUTER SYSTEM

SIGNALS WAREHOUSE

Just-in-time in retail

To reduce stock levels, many supermarkets

now use just-in-time deliveries, relying on

computer data systems. In manufacturing,

systems are often based on Kanban cards—

dockets for withdrawing and ordering items at

each workstation of the production process.

CASHIER SCANS

BARCODE

1

2

3

Dell’s just-in-time computers

Computer produced when customer orders it:

Customer’s individual specification is sent

straight to factory floor.

Just in time manufacturing sees deliveries

of supplier parts arriving at one side of the

factory and unloaded directly into bins to

build customer order.

Inventory and costs are reduced.

Case study

US_290-291_Just_in_time.indd 291 21/11/2014 16:28

WHAT TQM MEANS

How it works

Companies use TQM to create a

customer-focused organization

that involves all employees in

continuous improvement. It is a

strategic and systematic approach

that puts quality at the heart of the

organization’s activities and culture.

Customers determine the level of

quality, measured through their

satisfaction. The organization is

viewed as a series of horizontal

processes that take inputs from

suppliers through to the outputs

that are delivered to the customer.

Recording and measuring

performance data is critical, as

is effective communication to

maintain momentum.

Total Involves everyone and all

activities in the company

Quality Conformity to meeting

customer requirements

Management Quality can and

must be managed

Total quality

management

Case study: The Walt

Disney Company

Manufacturing companies, in which

the focus is on meeting or exceeding

customer expectations by making

products within certain specifications,

are often used as TQM examples. TQM

can also be applied in service industries,

of which Disney is a very good example.

“TQM is a

philosophy for

managing an

organization to

meet stakeholder

needs without

compromising

ethical values.”

Chartered Quality Institute

Success though customer satisfaction is the ethos of total quality

management (TQM). Everything a company does is relevant, and the

focus is on managing and improving processes rather than outcomes.

The Walt Disney

Company

Disney’s goal is to maximize

long-term shareholder value,

and part of this involves

delivering a magical customer

experience at its theme parks.

Involve everyone

in quality

Founder Walt Disney firmly

believed in quality and saw it

as everyone’s job, something

that could not be delegated.

Focus on the customer

Disney incorporated the

TQM concept of quality into

its approach to customer

service. Its visitors are seen

as

guests and treated as VIPs

and individuals.

Perfect processes

Walt Disney viewed the theme

parks as factories producing

delight. He built quality by

designing processes and

repeating them.

US_292-293_Total_Quality_Management.indd 292 21/11/2014 16:41

292 293

how operations and production work

Management

NEED TO KNOW

Suppliers

Disney collaborates with

suppliers—for example, it has

partnerships with McDonald’s

and Coca-Cola—to ensure

consistent quality.

Employees

Disney calls its employees

“cast members.” They are

trained in every aspect of

delivery, including posture,

gestures, facial expressions,

and tone of voice.

“When does the Three

O’Clock Parade start?”

Cast members are trained to

answer this common question

by responding with the time

the parade will be passing a

particular point in the park.

Continuous

improvement

Walt Disney saw the theme

parks as an incomplete

product; today, improvements

come from the bottom up.

Exceptional service

Cast members (employees)

are focused on delighting

the customer—their sole job

is to make visitors happy.

Shared purpose

Walt Disney started by

defining a company culture

based entirely on creating

a genuine shared purpose

that people would be proud

to support.

Integrated systems

Technology supports the

experience: for example, the

volume of ambient music is

the same in all theme parks,

delivered through thousands

of perfectly placed speakers.

American customer

satisfaction index (ACSI)

Cross-industry benchmarks for

customer satisfaction in the US;

NCSI is the UK equivalent

Net Promoter Score (NPS®)

Metric for company performance

from the perspective of customers,

who are divided into promoters,

passives, and detractors

12,000

Disneyland “cast members” are

employed to make guests happy

US_292-293_Total_Quality_Management.indd 293 21/11/2014 16:41

292 293

how operations and production work

Management

NEED TO KNOW

Suppliers

Disney collaborates with

suppliers—for example, it has

partnerships with McDonald’s

and Coca-Cola—to ensure

consistent quality.

Employees

Disney calls its employees

“cast members.” They are

trained in every aspect of

delivery, including posture,

gestures, facial expressions,

and tone of voice.

“When does the Three

O’Clock Parade start?”

Cast members are trained to

answer this common question

by responding with the time

the parade will be passing a

particular point in the park.

Continuous

improvement

Walt Disney saw the theme

parks as an incomplete

product; today, improvements

come from the bottom up.

Exceptional service

Cast members (employees)

are focused on delighting

the customer—their sole job

is to make visitors happy.

Shared purpose

Walt Disney started by

defining a company culture

based entirely on creating

a genuine shared purpose

that people would be proud

to support.

Integrated systems

Technology supports the

experience: for example, the

volume of ambient music is

the same in all theme parks,

delivered through thousands

of perfectly placed speakers.

American customer

satisfaction index (ACSI)

Cross-industry benchmarks for

customer satisfaction in the US;

NCSI is the UK equivalent

Net Promoter Score (NPS®)

Metric for company performance

from the perspective of customers,

who are divided into promoters,

passives, and detractors

12,000

Disneyland “cast members” are

employed to make guests happy

US_292-293_Total_Quality_Management.indd 293 21/11/2014 16:41

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.