When considering the difference between being efficient and being productive, I tend to go back to the rectangles. The ideal situation is to have an overall balance between what is produced and what is needed, which I’ll call demand. This is even true in constraint-based production such as when using constraint-based scheduling. The demand for each step should be designed around the needs of the constraints; hence, this demand may not be based and timed solely on the needs of a non-constraint resource. For instance, if I sign checks at 60 per hour and you can print them at 60 per minute, your demand may not be hourly based. Your demand may be determined to be 120 in two minutes so that you keep me busy for two hours and then move on to other needs.

When it comes to efficiency, I tend to look at it two ways. First, is the overall efficiency, comparing the output to input as discussed in Chapter 14. However, there is also a demand efficiency, comparing the demand to input. This allows you to do simple calculations and comparisons. First, you have actual efficiency, which is output/input (Equation B.1). Second, you can calculate the demand efficiency, or productivity, which I consider the ratio of demand to input. This is a modification of the efficiency equation (Equation B.2):

From these two ratios, you can begin to tell a lot from your production and capacity situations. First, you can look at the absolute difference between your overall efficiency and your demand efficiency by taking the difference between the two (Equation B.3). This number can tell you how much capacity you either used too much of, or not enough of (Exhibit B.1). For instance, let’s say you have eight hours, and in that eight hours, your employee, who manually puts return address labels on envelopes, should be able to process a maximum of 450 envelopes for an efficiency of 56.3 envelopes per hour. In one shift, she produces 400 envelopes. Her actual efficiency is 50 envelopes per hour. If demand is for 300 envelopes, the productivity level required for her is 37.5 envelopes per hour. From Equation B.3, she is 12.5 absolute efficiency points too high:

Exhibit B.1 Ideally, you will want to balance your output with demand. Being unbalanced creates less than ideal situations. If you find you always have more capacity than there is demand for, this creates an opportunity to reduce costC by reducing the amount of capacity you buy

If the absolute difference is positive, that means you were too efficient. Being too efficient is not always a good thing. Doing excess work can create waste and, in some cases, increase your costC. If it is negative, it means you were not efficient enough. For example, if she only processed 240 envelopes, she would be 7.5 points too low (30 envelopes/hour −37.5 envelopes/hour = −7.5 envelopes/hour, a deficit).

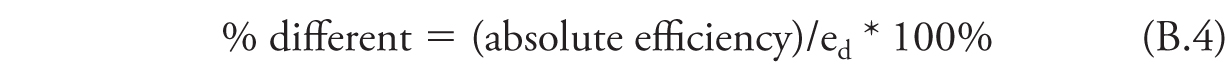

You can also translate this into percent too high and too low as well using Equation B.4:

This equation will tell you how different efficiency and productivity are on a percentage basis.

What is important about these analyses is that the numbers give you a feel of how much over or under the demand levels you are, and this gives you options to adjust capacity levels of the efficiency of the capacity to meet demand.