READER INPUT

Punk science, loudspeaker breakdown, fun kid projects, and a father-and-son story.

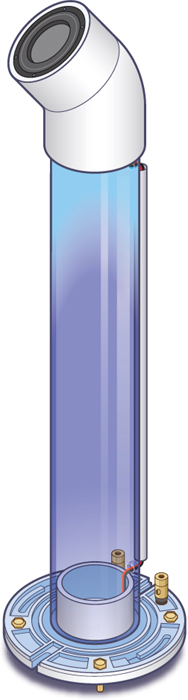

» In Volume 31’s “Sound-O-Light Speakers” project (makeprojects.com/project/s/2464), two diagrams on page 82 describe an acoustic suspension (sealed) alignment and a bass reflex (vented) alignment. Unfortunately, the description of the bass reflex design is based on a popular but incorrect theory — that the back wave of the driver is made available via a port or opening to augment the sound from the front of the driver.

In reality, the port is a Helmholtz resonator whose resonance is defined by its length and cross-sectional area. The port is typically tuned to a frequency that’s lower than that of the driver — it’s not a manifestation of the back wave of the driver.

The opening at the bottom of the Sound-O-Light speaker is not a port since the entire chamber would be the resonating column. It more closely resembles a transmission line speaker.

Vented designs are by their nature less forgiving and more difficult to work with. For a hobby-type speaker, a sealed design is far easier to build and get right.

I plugged the HiVi B3N driver’s parameters into a Thiele-Small calculator (you can find these online). In a sealed alignment, for a speaker box volume of 0.1ft3, the length of the 3" pipe is a manageable 24.49" and the max bump in low-end response is 0.98dB. This will add a little boominess to the sound and some false impact to the bass, and should be OK.

A vented alignment is not so easy. The optimum calculated volume is 0.59ft3, for a max low-end bump of 1.63dB. The vent (port) will be 1"×1.5" (or 1.5"×4.85" but that’s hard to fit in this design), tuned at 36.9Hz. Unfortunately, our 3" pipe would have to be over 12’ long! If we reduce the volume to 0.1ft3, the low-end bump rises unacceptably high, and the port tuning has to be moved up, so we lose the extended low end, and the port’s output can’t match the bump; the result is a really bad response curve.

In summary, a small speaker made from this driver works best in a sealed box. If we allow for significantly more volume (a bigger box or a 3" pipe that’s 12’ long), the vented alignment can be made to work and yield a much better low end than the sealed box. It’s a tradeoff.

Or, one could ignore the details and just build the thing and enjoy it. :)

—Louis Lung, lungster.com, Westborough, Mass.

Projects Editor Keith Hammond replies:

Louis, thanks for your excellent analysis. We thought we were clever to offer a vented option but it’s clearly trickier than we knew. Consider yourself an honorary member of the MAKE Technical Advisory Board, Loudspeaker Division.

» Just had to tell you how much I loved Gareth Branwyn’s Welcome in MAKE Volume 31 (“Three Test Tubes and the Truth”). You perfectly captured the intersection between DIY and punk. I feel like I have a new understanding of my relationship with both. One more reason to raise your kids punk!

—R. Mark Adams, Westport, Conn.

» We built the MAKE Compressed Air Rockets Kit (makeprojects.com/project/m/2235) from the MAKE School’s Out Summer Fun Guide (makershed.com/schoolsout) and it took about 2½ hours to complete the launcher. We came back to make the rockets another day. It was a total blast, kid safe, and the rockets shoot amazingly far. We lost a few to the trees, so we angled the launcher to shoot down our street — and easily shot 100 yards. Great project!

—Jack Lamb, Santa Clara, Calif.

» We had a ball making the “Marshmallow Shooters” project (makeprojects.com/project/m/2000) from the MAKE School’s Out Summer Fun Guide on the weekend — and they were so simple. Now we have 10 neighborhood kids wanting to build the same thing. We might have to run a workshop for them all. Cheers, MAKE.

—Earl Pilkington, Mandurah, Western Australia

» In January 2011, I read Len Cullum’s Japanese-style “Workhorses” project (makeprojects.com/project/w/572) and thought they were beautiful. At the time, I had taken on only simple projects that required no more than a miter saw and a cordless drill. Your sawhorses would introduce me to many new skills, so I decided to make them. They would also allow me to spend some quality time with my father, a very experienced woodworker who was declining in health rapidly due to pulmonary fibrosis.

After 17 months, I just finished my project! However, a few things happened along the way. Most importantly, my father received a lung transplant in May 2011 and has had a full recovery. Secondly, your beautiful sawhorses became the “ends” of a pretty good-looking table (see below). I probably spent 400 hours working on the table and about 30 hours talking to my father on the phone about it.

I turn 40 this year and this table represents a lot for me. My kids hated it because it took so much of my time, but now they love it. My 8-year-old son thinks this project had to be on my “bucket list”!

Thank you so much, Len, for contributing that article to MAKE.

—Walt Stewart, Decatur, Ala.

Author Len Cullum replies: Maybe this happens to MAKE contributors all the time, but I am blown away that someone would build my project and then take the time to share their story with me. I can’t find adequate words to describe what it means to me. All I can say is thanks to you, Walt, and to everyone at MAKE for giving me the opportunity. I am humbled.

MAKE AMENDS

In Volume 31’s “Sound-O-Light Speakers,” the vented build option is not a true bass reflex design (see reader Louis Lung’s letter, opposite). Also, author Bill Gurstelle’s Night Lighter 36 spud gun project (makeprojects.com/project/s/5) is from MAKE Volume 03, not 04.

In Volume 31’s “Mendocino Motor” project, the correct URL for downloading the 3D part files is makeprojects.com/v/31.

A caption in Volume 31’s “Drive-by Science” incorrectly identified Dr. Akira Sugiyama’s affiliation; he’s with Tokyo University.