FEATURES MAKEOVER BUILDS

Extreme Makeovers

HOW MAKE OVERHAULS PROJECTS …

Flying Wing R/C Plane

The Towel airplane (MAKE Volume 30) is minimal: a broad wing made of blue foam, with exposed electronics on a Coroplast deck. Dan wanted to make his really pop while adding the durability to withstand Maker Faire demos for years to come. He hid the wiring between the electronics deck and the wing, used Coroplast for the whole wing to further stabilize the craft, and then extended the deck all the way to the nose. This overhaul compromises the reusablility of the deck and makes the nose just a tad more dangerous. But with his final coat of paint, he really likes the new sleek, modern look.

Dog Ball Launcher

The original Fetch-O-Matic (Volume 31) was housed in a drab plywood box with an unassuming hopper. Dan decided to add an injection of whimsy and a few colorful details to the design: protruding lips on top and bottom, rounded corners, a spiral arrow cutout and MAKE badge, a redesigned hopper, and extra vertical reinforcement. These details add strength and beauty; it may still be a box, but the last thing you’d call it is drab.

More resources we use in MAKE Labs:

» Working with plastics: tapplastics. com/product_info/videos

» Woodworking tricks: wood magazine.com/woodworking-tips

» Create detailed fiberglass shells: makezine.com/go/fshells

Brilliant!

Making laser-cut acrylic enclosures.

By Eric Chu and Dan Spangler

Acrylic looks great but it’s prone to cracking when worked by tools. Solution? Laser-cut acrylic cases. Just send a PDF or other vector image of your pattern to a laser cutter. Here are some tricks we like.

Finger joints, aka box joints Great-looking, simple, and strong. CAD up your own, or try boxmaker.rahulbotics.com.

For a sliding finger joint (like for T-slot constructions), use a single line to form the shared edges of a joint. Our laser has a 0.004" kerf (the total width of material the laser removes) so it gives the two adjacent edges a 0.002" cut.

T-slots These hold a machine screw and nut for fastening joints. When drawing a T-slot, use the nominal dimensions of your hardware for a sliding fit. Add extra space at the top (like a lowercase t) so you can tighten the screw a little more.

Slot thickness and tooth height should be the same as your material’s thickness; measure with calipers. For the width of slots/teeth, I use twice the thickness.

Living hinges Amazingly, you can cut a pattern into rigid acrylic to make flexible hinges, aka “sninges” (named for Rotterdam’s Snijlab). Learn how to make them at makeprojects.com/project/g/1683.

Cutting acrylic with hand or power tools OK, sometimes you must. Learn how at makezine.com/go/cutplastic.

… TO MAKE THEM SHINE

The Electronic Nag

When you walk by the Notification Alert Generator (Volume 30), it reminds you to do your chores. Eric took design inspiration from the elegant lines and restrained color of an old-fashioned refrigerator to give it this modern yet retro look. The parts are laser-cut from white acrylic and screwed together using T-slots (see above), with a speaker grille that spells out NAG. It seems right at home hanging in the kitchen.

... TO MAKE THEM SHINE

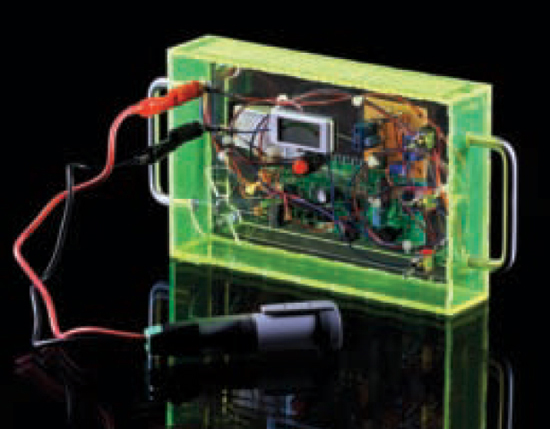

Geiger Counter

This gadget (Volume 29) began as a bare circuit board, which carried the risk of electric shock as well as damage to the circuit. Dan experimented with several styles before choosing this finger-jointed, transparent green box, with grilles to allow the entry of radiation, mounted controls, and handles that let you point the unit at a sample. The result protects the circuit board and evokes a sort of mad-atomic-scientist aesthetic.

Max Eliaser, Dan Spangler, Eric Chu, and Brian Melani are engineering interns in the MAKE Labs in Sebastopol, Calif.