FOUR

Optimize Work

What Does the Right Human-Automation Combination Look Like?

We’ve described how to deconstruct work into its elements (chapter 1), how to apply the concept of ROIP of deconstructed work elements (chapter 2), and understand how work-automation applications combine work element characteristics (repetitiveness, independence, and physicality) with the role of automation (replace, augment, or create) and the type of automation (RPA, cognitive, social) (chapter 3).

Here, we combine those threads to understand how ROIP and the characteristics of work elements help you determine the optimum role of automation (does automation substitute, augment, or create new work?), the optimum type of automation, and the nature of the payoff to work automation.

Let’s go back to the ATM.

Beyond ATMs Replacing Tellers: Optimal Solutions to Bank Work Automation

When you begin thinking about ATMs, your initial question, “How many humans can we replace with automation?” is naive. Your technology analysts’ calculations of the cost savings from replacing human bank tellers with ATMs is well intentioned but actually misdirected. That original question can only lead to the conclusion that the answer is neither yes nor no, and your debate could go on forever, illuminating very little.

You may think that replacing tellers with machines is the question, but when you deconstruct and add ROIP, you realize that some tasks have very different payoffs from changes in work performance or automation and that a teller machine is not the answer to all of them. For some tasks, the payoff comes from reducing mistakes, while for others, it is from reducing variation where it doesn’t add value to the customer experience. For yet others, the payoff comes from incrementally adding to productivity and, in yet others, exponentially creating new work or enhancing performance. Then, when you look at the work characteristics, you realize that tellers’ work can be rated as more or less repetitive (the more repetitive, suggesting that RPA or simple algorithms might work), more or less independent (more independent, suggesting that you don’t need sensors or social robotics to enhance human interactions), and more or less physical (more physical, suggesting the answer will include physical automation like social robotics versus cognitive automation). After you have mapped the work characteristics along these lines, you realize that it would be silly to use teller machines to counsel customers but logical to use them to receive or give cash and count it (i.e., automate repetitive work). You realize that a lot of the payoff of teller machines is in reducing mistakes or just standardizing ways of doing things, which have a certain payoff but will not revolutionize the work or services.

You also realize that some elements of tellers’ work, things that are more cognitive and contribute to greater performance value (high ROIP), could be automated, but you need something different from an ATM. You need cognitive automation that enhances the quality of interactions between teller and customer. You also realize that applying automation to some work elements (counting, receiving, and giving cash) will fully substitute automation for human tellers, while for other work elements, automation will create new work that could not be done without automation (accessing the complete customer record of bank services and history).

Fast forward now to today’s reality in the ATM story. The actual path of bank-teller work automation can only be seen clearly with the four-step framework that can examine the cost, risk, and quality implications of different types of automation, applied to different work tasks, each with a different ROIP and cost profile.

Bank tellers and their leaders now have immensely more sophisticated automation options than the simple ATMs of the 1970s, and those options are evolving quickly. Some of the cognitive tasks are now done by algorithms or AI that informs and supports the human worker. Still other tasks (such as collaborating with designers and process leaders) are likely to remain in the domain of humans for a long time. The introduction of automation creates new work for humans. We now see the prospect for automation of even more routine processes (e.g., ATMs now use optical sensors and AI to accept deposits of checks and to pay property tax bills) and human tellers providing a much higher-touch service. Yes, this is more complex than simply tabulating how many human workers automation will replace, but it is also much more precise and actionable.

Putting It All Together

We introduced the ROIP curves for the pilot and flight attendant roles in chapter 2. Let’s return to those two roles and add our three types of automation to ROIP to show how automation and ROIP combine to reveal new insights. We pose the question, “Can RPA, cognitive automation, and social robotics replace or augment the work of the human being, and what is the payoff?”

Let’s take a look at the right side (the steep, upward-sloping portion) of a flight attendant’s ROIP curve (see figure 2-3). How might cognitive automation augment human capabilities in delivering the optimal customer experience to shift performance to the far right and up the steep part of the curve? Augmented reality powered by cognitive computing can deliver an unprecedented level of insight into the unique needs of individual passengers. Such automation would augment the customer-care work elements of flight attendants and enable them to unleash their discretionary effort to deliver delivering highly personalized service.

Now, consider how social robotics can affect the left side of the curve (negative-value ROIP) for a pilot. Without automation, the way to reduce mistakes and get performance to be “at standard” involved investing in things like long careers to build proficiency through intensive simulation-driven training to prepare human pilots for any eventuality. Social robotics (the combination of AI with sensors and existing cockpit hardware) can substitute for pilots in all tasks involving routine navigation and even takeoffs and landings, significantly reducing the likelihood of error.

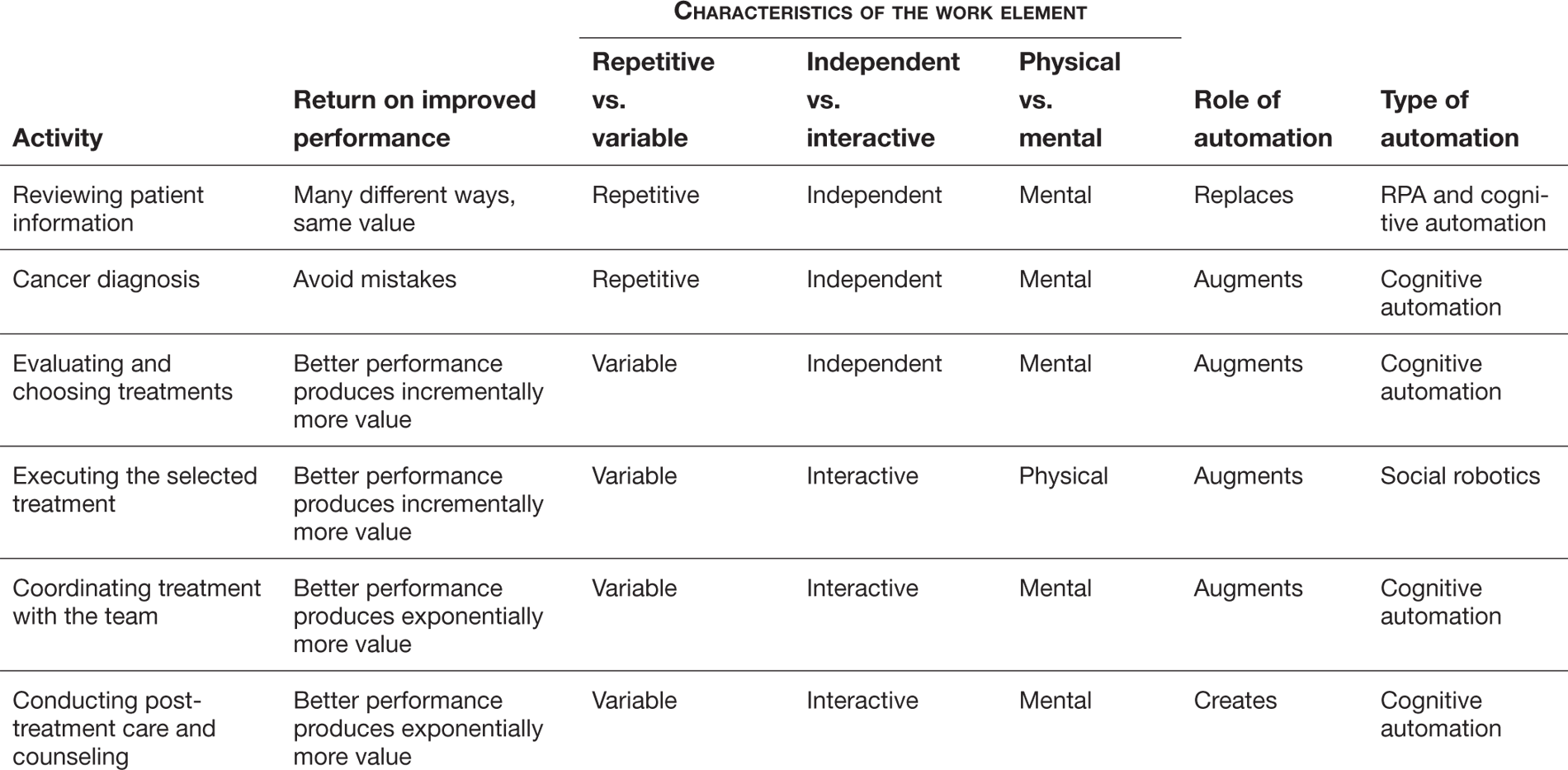

Also consider our example of cancer treatment. Table 4-1 shows how all of the elements of our framework are reflected in the work-automation opportunities for oncologists.

In summary, the first three steps, deconstructing jobs, describing the ROIP of work tasks, and identifying automation options, come together in the fourth step: optimizing the combination of work and automation.

Another way to see this process is through a series of questions:

- What are the elemental tasks within the jobs?

- What are the characteristics of the work?

- Repetitive versus variable

- Independent versus interactive

- Physical versus mental

- What is the ROIP of the work?

- Reduce mistakes (negative ROIP)

- Reduce variance (constant ROIP)

- Incrementally improve value (incremental ROIP)

- Exponentially improve value (exponential ROIP)

- Does automation substitute for the human, augment the human, or create new work?

- What are the available types of automation (RPA, cognitive automation, or social or collaborative robotics)?

- What is the optimal way to combine human and automated work across jobs and processes?

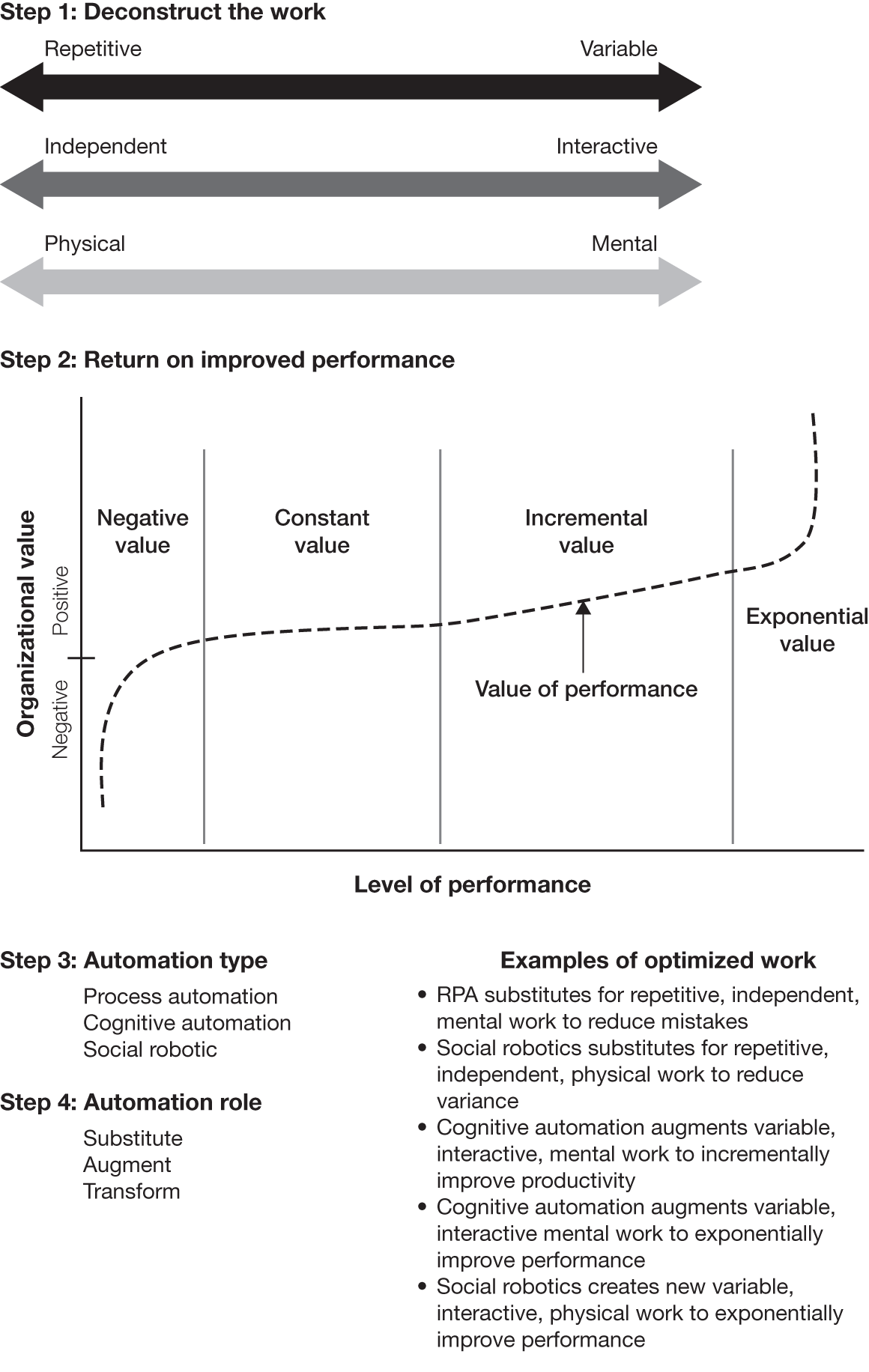

Figure 4-1 shows our four-step framework graphically. This framework can help you navigate the often-daunting tasks of taking high-level strategic automation goals and more clearly identifying how to reinvent jobs and reconfigure work and your organization to meet those goals. One of the best ways to see the framework in action is through examples.

Step 4: A framework to optimize work: The right combination of deconstruction, ROIP, and automation

In the next sections, we describe prominent examples that show how the elements of our framework come together to explain work-automation optimization. These examples are not comprehensive, and they do not imply that any one solution always works best. Rather, they show how to use the framework to explain and understand evolving work-automation solutions.

Obviously, when you combine the different elements of each of the four steps of our framework, you can envision many potential work-automation options. In the appendix, we provide a grid describing a comprehensive list of the feasible combinations and show how each example fits that list.

Repetitive, Independent, Physical Work with Negative-Value ROIP: Substitution with Social Robotics

Manufacturers once would have had a whole department of humans to perform inspections of manufactured parts. Here’s how Compass Automation, a maker of inspection robots, describes the process:

This machining center includes an out-feed conveyor, which delivers completed parts to the automated system. Once a completed part enters the system an in-feed nest accepts parts from the conveyor, utilizing a proximity sensor to alert the robot of part presence in the nest. The LR Mate 200iC robot moves the part to a blow-off station, where excess cutting fluid is removed from the part. The robot then moves the part to the New Vista Thread Verification Unit for inspection; this unit tests the pitch and depth of the part’s internal threads.

Next, the LR Mate 200iC robot moves the part to the vision inspection station, where a custom-designed inspection system measures several geometric features on the part, including the part’s height and diameter.

Finally, the robot moves the part to an out-feed conveyor for post-processing and packaging. This Compass Automation system, along with the FANUC LR Mate 200iC made it possible for the end user to meet the standards set by their customer for complete inspection of the part at the required production rate. Compass Automation fully models all custom-designed systems prior to beginning the build process.1

Inspecting parts has a classic negative-value ROIP. The value is in catching below-standard parts. There is no incremental value from exceeding that standard (e.g., looking for anomalies beyond the standard defects), but there is substantial cost in missing a part that is below standard. Substituting human inspectors with a combination of visual sensors, AI, and precision gauges allows a social robot to move around the factory floor to inspect parts with greater efficiency and fewer errors. The automated solution reduces negative ROIP because it works at the same pace as a human inspector, but with far fewer errors.

This example also applies to work with a significant risk of worker injury or environmental harm. Substituting automation for human workers can both reduce errors and avoid human injuries or death. These are perhaps the most extreme versions of negative-value ROIP. For example, Rio Tinto has deployed automated haul trucks and drilling machines at its mines in Pilbara, Australia. This achieved lower energy consumption and better employee safety.

Repetitive, Interactive, Physical Work with Incremental-Value ROIP: Substitution with Social Robotics

On oil rigs, traditionally the work of “pipe running” (i.e., attaching sequential sections of piping to extend the drill bit to reach oil reservoirs deep underground) is a manual process involving interactions between several workers, with a driller supervising from a control room. Today, automated rigs (e.g., iRig by Nabors Industries) feature automated tubular running services and equipment that eliminate the need for manual labor on the rig floor. The driller in the control room now directs and supervises the iRig.

This automation improves performance (moving upward and to the right on the incremental-value ROIP curve), as a result of faster work and reduced accidents.

Variable, Independent, Physical Work with Exponential-Value ROIP: Augmentation with Social Robotics

How do you quickly detect methane leaks around gas and oil production sites? Human workers usually carry infrared cameras into potentially contaminated fields, walking through the field until they see the infrared image of a leak. It’s a slow, arduous process. Even the best human worker can identify only the presence or absence of a leak, but not its size or extent.

Pacific Gas & Electric (PG&E) is testing aerial drone robots to augment the human workers.2 These drones were first used to detect methane on Mars. Now, they can cruise neighborhoods on Earth, searching for potentially dangerous methane leaks. PG&E worked with engineers at NASA’s Jet Propulsion Laboratory and mounted an open path laser spectrometer sensor on a simple off-the-shelf drone. The technology detects leaks faster and more accurately. That creates a payoff, moving up and to the right on the incremental-ROIP curve. In addition, the drone can scan hard-to-reach places where humans cannot go and is thousands of times more sensitive than the handheld technology that humans use. As one manager said, “A cow will generate more methane than the leaks that we are testing here today.” The job of inspection is reinvented. Now one worker pilots the drone, while another monitors the readings on a laptop.

Here, social robotics (drones flying among humans) augments the work of the human. First, it improves performance along the incremental-ROIP curve (detecting the existence of leaks faster and more accurately). Second, it makes the human workers exponentially more valuable than they ever could be without automation. This achieves exponential ROIP, shifting performance onto a new steeper ROIP curve (measuring formerly undetectable leaks in places humans cannot access, and measuring both the presence and severity of the leak).

Many related jobs have been reinvented. The drone now does the tasks of gaining access and doing the measurement. The new task of piloting the drone is created. Human inspectors still do the tasks of choosing the site and interpreting the readings. Humans do the tasks of analysis, but now with immensely more precise and complete data. The drone substitutes for humans in some tasks, augments the human in others, and creates yet other tasks, generally shifting human engineers to focus on those with exponential ROIP.

Variable, Interactive, Physical Work with Exponential-Value ROIP: Augmentation with Social Robotics

The Smart Tissue Autonomous Robot (STAR) is an example of this combination (see chapter 3). A social robot with precise sensors and AI takes on the physical tasks of surgery, interacting with the surgeon and the patient, and tackling situations that can vary across patients and surgical conditions. This exponentially increases the value of the human surgeon’s performance. Human surgeons can now assign STAR to the more routine or tedious tasks that a robot does better. Every surgeon becomes safer and less risk-prone in these tasks. In addition, STAR augments the surgeon in more complex and judgmental tasks, allowing formerly average surgeons to achieve results comparable to the best surgeons. This creates a new exponential performance ROIP curve.

Repetitive, Independent, Mental Work with Negative-Value ROIP and Incremental-Value ROIP: Substitution with RPA

Financial services companies face increasing costs for compliance. According to the Institute for International Finance, compliance activity can cost about $1 billion a year for a financial institution. Much of this cost is attributable to labor with significant responsibility falling to a credit analyst. That job includes tasks that improve compliance with requirements such as “know your customer.” This regulatory requirement dictates that banks demonstrate that they know who borrows money from them or buys their products. The bank must show that they know how the customer uses those funds, for example, to avoid lending to a drug dealer or money launderer. When someone applies for a mortgage, the tasks of the analyst include gathering data from the bank’s databases, pulling a credit history from rating agencies, analyzing the borrower’s tax records, and scanning social media for indications of borrower risk. This work is extremely time consuming and error prone, resulting in both incorrect decisions and potential violations of state and federal laws.

Now, RPA can perform many of these tasks. RPA gathers data from various sources, integrates the data, and presents a complete picture of the customer with far fewer errors at a fraction of the cost and time. McKinsey & Company estimates that such automation will generate a return on investment of between 30 percent and 200 percent in just the first year.3 Moreover, reduced errors means fewer defaults, higher customer satisfaction, and lower dropout rates from things like loan applications. These strategic goals can only be accomplished by reinventing the credit analyst job and transforming the approval process. As RPA substitutes for certain human tasks, credit analysts can devote more time to client support (e.g., explaining why a mortgage was denied and offering suggestions for clients to improve their credit rating, and handling unusual exceptions. Here, the job has been reinvented by deconstructing it to separate the tasks of gathering data and evaluating client risk using fixed rules from the tasks of supporting clients and handling exceptions. Automation substitutes for human workers on the former tasks, freeing human workers to create greater value on the latter tasks.

RPA also improves scalability. A spike in mortgage applications due to a cut in interest rates might traditionally require finding forty extra workers on the weekend. With RPA, you can add robots to do the work and then decommission them on Monday.

Optimizing work automation by substituting RPA for human workers improves negative-value ROIP by reducing errors. Shifting human workers to client contact and analyzing unusual cases moves them to tasks that have incremental-value ROIP, where their performance improvements add more value.

Repetitive, Independent, Mental Work with Incremental-Value ROIP: Substitution or Augmentation with Cognitive Automation

Recruiting is an extremely time-consuming activity for every organization. Recruiters expend significant time advertising positions, sifting through candidate profiles, assessing their skills and fit, and then scheduling interviews. This type of work automation has the same work characteristics: as the prior two (repetitive, independent, and mental), but here we shift performance to the right on an incremental-ROIP curve; the automation-work optimization augments human workers versus substituting their work. This example also uses cognitive automation, not RPA.

Cognitive automation can augment some of the recruiter’s work tasks. Unilever uses AI to source candidates by placing ads on online platforms like Facebook, WayUp, and Muse. Applicants click on the ads and apply through their LinkedIn profile. Unilever receives hundreds of thousands of such applicants. Traditionally, human recruiters would read these applications, sorting them by whether they were clearly qualified or unqualified. Unilever dealt with this vastly increased volume of applicants by building an algorithm that sifts through applicant qualifications, separating unqualified from qualified applicants. Those qualified complete an automated series of online games, tests, and video recordings. Finally, the AI system organizes the resulting data and scores each applicant using programmed rules, identifying who should receive an in-person interview. Unilever says that it gives an offer to 80 percent of applicants granted an in-person interview using this approach, up from 63 percent before using AI.4

Unilever’s method for using AI is similar to how the financial services industry uses it for credit analysts, as a sort of “audit” of applicants. AI filtration systems like this eliminate humans from doing repetitive recruitment tasks, which reduces labor costs and human error.

The automation also deconstructs the recruiter’s job so that the repetitive tasks are separate from the more human work of actual applicant interviews. Humans now focus on these more high-value tasks, after applicant skills have been assessed quickly and without bias. In addition, humans can now focus on delivering concierge-level service for their highest-profile candidates, eliminating many of the stresses associated with changing jobs. In short, by substituting automation for humans in the repetitive tasks, recruiters are available for the nonrepetitive and interactive tasks of helping candidates navigate their way through the recruiting and on-boarding process, serving as a one-stop shop for all their cares and concerns.

Sometimes, cognitive automation augments human workers by interacting with them. Kensho Technologies’ investment analytics system allows financial investment managers to ask questions in plain English and get answers in seconds. They might ask, “What sectors and industries perform best three months before and after a rate hike?” AI becomes their natural-language conversational adviser. Every human analyst doing the tasks of exploring different future scenarios now produces far greater value more quickly.

Both examples focus on tasks that include repetitive, independent, mental work with incremental ROIP. Cognitive automation substitutes or augments human work, moving performance to the right and up the slope of the incremental-ROIP curve by enhancing performance in assessing a candidate or investment. Automation analyzes more information faster and with higher quality and less bias. As we have seen, this substitution also allows the organization to shift human workers to higher-value-added tasks.

Repetitive, Interactive, Mental Work with Exponential-Value ROIP: Augmentation with Cognitive Automation

How do you maintain fleets of aircraft, vehicles, and windmills? Traditionally, an army of GE’s skilled and experienced technicians would visit customers’ locations to do maintenance. The job included the task of deciding what maintenance was needed, using rules of thumb based on factors like how long the machine had been running, the load and environmental conditions, and so on. The technicians’ job also included the task of sharing their experiences (or the best practices they discovered) by sending messages to electronic bulletin boards or processing centers, accessible to other technician teams. The work is repetitive because they execute the same tasks in a specific sequence. It is interactive because technicians on each on-site team must collaborate, and separate teams collaborate on the common learning platform. It is mental because it involves deciding what information to gather and then analyzing the information to choose the best maintenance approach. Of course, the job of a maintenance technician also includes physical tasks to execute the activity, but here we focus on the data-gathering, analysis, and diagnosis tasks. The traditional approach using human technicians produced significant equipment downtime, because customers waited for technician teams to be scheduled or teams faced new situations that required learning time, or because the central information platform waited for updated information on best practices from the field teams.

GE’s strategic goals were to drastically reduce downtime, perform maintenance only when needed, and offer more complete and customized data and best practices to human technicians in the field. GE did this by reinventing the technician job using AI, specifically machine learning, to leverage the power of sensors, big data, and IoT.5 GE created a “digital twin,” a digital replica of equipment such as a jet engine, gas turbine, or windmill. Sensors in the actual equipment gather data on the machine’s attributes and operating environment (heat, vibration, noise, etc.), and the data is organized into the simulated digital twin that now replicates the physical machine’s performance. GE can then program the digital twin to simulate different scenarios (loads, durations, environmental conditions, etc.). Using the data from the simulation, AI can diagnose faults and predict maintenance needs. AI can then create maintenance schedules and send alerts and recommended best practices to GE’s human technicians in the field. Multiple digital twins can even be linked to mimic aggregations of actual equipment (i.e., an entire factory) or vehicles (fleets of aircraft or trucks), allowing analysis of not only the performance of each individual machine, but the collective and integrated behavior of the network of machines.

Data from thousands of actual machines flows perpetually and constantly into the digital-twin models. Because the variables affecting machine performance and optimum maintenance change with time and circumstances, optimal maintenance is not simply a matter of finding one formula and following it consistently. With human technicians, the best available solution was often to take one consistent approach, because it was not possible to customize the approach to each situation. With automation, the optimization algorithms and approaches can be constantly updated with the flow of additional data. This machine learning allows the technology to learn from new data and modify predictive models over time, identifying anomalies and trends and understanding patterns. Machine learning can identify efficiencies in one machine or situation and apply it as a best practice for others. In 2017, GE had about 750,000 digital twins and was adding more.

In this situation, machine learning requires a combination of sensors, IoT, big data, and Web 2.0. A system without machine learning must rely on what a single customer can observe, or what individual technician teams can learn and convey to other teams. Optimizing the combination of humans and machine learning allows GE to leverage vastly more data, analytics, and learning across all the organizations that use its products. There is also a network effect, because the more GE learns, the more customers benefit by choosing GE engines, which grows the network, enhances the learning, and so on.

This has enhanced the performance of technicians on maintenance teams by shifting them to the right along the incremental-value ROIP curve, but it also creates an exponential-value ROIP curve for their performance. That’s because machine learning augments the technicians’ performance on tasks like choosing maintenance schedules and approaches. Now, when a technical team arrives at the equipment location, they are pre-briefed on the best maintenance approaches for that particular equipment. Those approaches are based not only on the team’s experience, but on all the data from all the other similar equipment and on the information from that particular machine’s twin. Every technician team is now exponentially more valuable because technicians now are assigned in exponentially more efficient ways, arriving only and always when most needed. They also execute the maintenance activities that are exponentially more correct.

Variable, Independent, Mental Work with Exponential-Value ROIP: Augmentation with Cognitive Automation

Product design and development is variable, independent, mental work. Cognitive automation accelerates product development by augmenting the work of procurement planners, improving their insights.

Coca-Cola Company’s Black Book model supports its strategic goal of producing its Simply Orange juice with a consistent taste profile, even as its sources of juice change due to weather and other crop factors.6 The Black Book model is cognitive automation that uses algorithms to predict weather patterns and expected crop yields. Those results inform the company’s ingredient procurement for Simply Orange juice, achieving similar juice taste even with wide variation in the quality and quantity of crops. The automated model supports minute-by-minute updates to procurement plans if weather conditions threaten to damage crops. In the past, the process relied on human planners who simply could not gather and analyze the necessary data quickly enough. There was significant variation in both product quality and quantity due to slow or inappropriate reactions to unforeseen weather conditions. Now, the Black Book model provides human planners with far more precise and rapid recommendations, increasing the value of their performance exponentially.

Stitch Fix, an online fashion retailer, sells fashions that customers don’t even know they want. How does it predict customer desires even before they know them? It does this by blending machine intelligence with human intelligence. It reinvented the job of its 3,400 fashion stylists who interact with customers, mostly while working from their homes. Stitch Fix’s customers begin shopping by filling out a lengthy, interactive questionnaire, powered by AI. If a customer says she wears medium-sized blouses, the interactive questionnaire is programmed to ask whether they typically fit loosely or tightly. Other questions include: “Does your office require business attire or casual?” “Do you take wardrobe risks?” “Which of these fifteen colors would you wear?” “Do you wear your jeans skinny, straight, or both?” The questionnaire data is fed to a database, along with data gathered from the web, such as social media profiles, Pinterest style boards, and so on.

Customers receive periodic orders of clothing chosen for them. They do not see the clothing until they receive it; they pay a $20 “styling fee” to receive each box of clothes, but they can send anything back for free. The boxes of clothes—called a “Fix shipment”—are assembled through the work of human stylists augmented by AI. The AI styling algorithm selects items it calculates that the customer will like. Those selections are sent to the human stylist. The stylist has been matched with a compatible customer, again by an AI algorithm. The human stylist then adjusts and streamlines the computer’s choices to produce the assortment that is ultimately delivered to the customer.

This combination of AI and human fashion selectors reveals nuanced ways to combine human and automated work. Stitch Fix’s chief algorithms officer, Eric Colson, says, “It turns out there are things humans can do much better,” like curation, seeing things as a cohesive set, improvising, and relating to other human beings.7

The job of stylist has been reinvented as an integrated collaboration with cognitive automation. Human stylists do tasks where their performance can add value, like curation, improvising, and relating to others. Cognitive technology takes on tasks that humans do less well, such as gathering and analyzing data, and producing decision guidelines. More important, the results of the cognitive automation make the value of every stylist’s performance incrementally better, because they can use the decision rules and results of cognitive automation as their starting point.

Variable, Interactive, Mental Work with Exponential-Value ROIP: Augmentation with Cognitive Automation

The earlier examples focused on independent work. Here, we discuss examples that are similar in that they are also mental and variable, but instead are interactive. Again, cognitive automation augments the human worker, but the interactive nature of the work means this happens very differently.

Call-center jobs are very interactive, and not always in a pleasant way. Traditionally, human call-center workers learn whether a customer is angry only after they answer the call. Or, they cannot even tell if a customer is angry because they interact only through text or chat. This means that the initial response to an angry or frustrated customer is often very generic or unemotional. Also, the particular call-center representative who receives the call might not be the best at handling irate or frustrated customers.

Ocado Group, a UK-based grocery delivery service, uses Google’s AI tools to analyze language and convert speech into text.8 These tools identify the irate customers by spotting language patterns in emails and phone calls that Google’s research shows are associated with anger, frustration, and irritation. Now, customer-care specialists are notified that the customer is angry before they answer the call. They can respond with the appropriate empathy and emotion, defuse the tension, and perhaps even turn a detractor into a promoter.

Like the GE technicians who have the benefit of the digital-twin analysis, here automation augments the human worker by providing otherwise unavailable data-based insights. In this example of very interactive work, the cognitive automation also improves the interaction between customer and service provider. This makes all customer representatives immediately incrementally more valuable than when they had to guess if customers are angry.

This kind of work-automation optimization also applies to jobs that use research knowledge to deliver creative solutions. A good example is the job of a trial lawyer, which used to involve the task of reading relevant court cases for precedents and judgment patterns. The job can now be reinvented to include asking the AI of IBM’s Watson about relevant court cases before developing a defense strategy. Or the job of an architect can now be reinvented to design buildings with the help of AI systems that analyze weather, traffic, demographic and social preferences, and location topography to suggest combinations of building orientation, location of amenities, and so on.

In every example, the reinvented job shifts some tasks to the automation, keeps other tasks with the human, but also augments the human worker to create performance or new work that would not be possible by either automation or the human alone.

Transforming Insurance by Reinventing Entire Job Families or Processes

Our previous examples looked at single jobs or closely related jobs to provide clear illustrations. In reality, optimizing work automation typically transforms many jobs involved in complete processes. Automation simultaneously substitutes, augments, and creates new human work. We will describe the implications for leadership and organization design in later chapters, but now we’ll discuss this process transformation using the insurance industry.

The insurance sector is ripe for work-automation optimization. Its global and statewide patchwork of regulation creates extreme inefficiency. Its convoluted distribution models and obscured data insights have long limited its product pricing. For example, auto insurance premiums are mostly determined by a driver’s credit score, but that score predicts less than 30 percent of differences in driver risk.

RPA, cognitive automation, and social robotics have converged to transform property and casualty (P&C) insurance to address these broad strategic challenges. Strategic execution requires deep work analysis and clear decisions about how to optimize combinations of human and automated work, and reinvent entire groups of jobs to support that optimization.

Claims Process before Automation

When you are involved in an auto accident, the traditional claims process involves many steps and human workers.9 First, you call your insurance company. You talk to a customer service representative, who enters details of your accident into a database. That triggers a notification to either send a claims appraiser to your location or give you an address to take your car to. The appraiser evaluates the damage, assesses the cost of parts and labor, and then tells you the insurer’s estimated payment to you to repair the damage. You choose from among the approved repair shops and inform the claims appraiser, who notifies the repair shop. The appraiser enters your choice into the system, which triggers the system to send the damage assessment and estimated price to your chosen repair shop. Once repairs begin, the repair technicians might discover additional damage that was overlooked by the field appraiser. That triggers more notifications, a visit or call for the appraiser to reconcile the damage estimates, and more negotiations. Finally, after reaching agreement, the repair shop can complete the repairs and be reimbursed by you or your insurance company. This process can take several days or weeks. It is prone to errors. Moreover, it has little memory, because very little intelligence is generated, even though there are hundreds of these transactions each day.

Claims Process after Optimizing Work Automation

Obviously, there are many ways that automation could enhance this process. It is tempting to concoct new approaches that substitute technology for human workers, insert technology in every transaction to reduce costs and errors, and so on. However, these ideas require precise and careful work design that optimizes the human-automation combinations. That means using automation where it makes sense, avoiding it where it doesn’t, and reinventing jobs to reflect the optimal combinations.

What is the new optimized process? The first work-automation step doesn’t even involve insurance company jobs. Virtually everyone has a cellphone with a camera, so you can optimize the combination of insurance customers and their cellphones. The policyholders can use their phones to take a picture of the damage. They upload that picture to their insurance company’s database. If the damaged vehicle is in a remote or dangerous location, or if the customer is hurt or unable to take a picture, a drone controlled by an insurance company operator can be dispatched to take pictures of the damage.

Once the pictures are in the company’s databases, the images are linked with the company’s records of the make and model of the vehicle. Cognitive automation then goes to work. These algorithms perpetually learn from the thousands of images of damaged cars uploaded every day and from millions more images already stored in the company’s databases. It can analyze the image to determine the damage location, such as the bumper and right rear fender. In fact, it is even possible for your phone to recognize the type and nature of the damage before the images are sent to the insurance company. This doesn’t require insurance companies to build image-recognition AI. In 2017, camera chip makers were already adding “smarts” to cameras, allowing the camera to extract information such as the movement of packages or recognizing a person’s face.10 Such technology can actually create automated image-recognition technology that assesses damage more completely and precisely than a human appraiser. The technology can recognize when a damage assessment is unusual or obscure, and forward its assessment to a human appraiser for verification or further analysis. This technology creates new work as human appraisers train the technology.

The next step uses RPA. It finds and connects data on all previous claims involving similar vehicles with similar damage, and related data on parts and labor costs from approved body shops in the area. With no human intervention, RPA and AI can create a detailed appraisal that determines the specific cost of repair, time to completion, and the likelihood of additional repairs being required.

The jobs of appraisers are reinvented. Cellphone cameras and drones substitute for the routine tasks of field appraisal. Cognitive automation now substitutes for the routine tasks of damage estimation. The job of appraiser doesn’t go away, but it is reinvented. Now, the appraisers’ tasks emphasize reviewing the automated analysis. They can also concentrate more on providing the “human touch” to the involved stakeholders (the policyholder, body shop, other involved drivers, etc.). The appraiser job evolves from executing routine individual transactions to reviewing the output from automation, overseeing multiple stakeholder interactions, and providing concierge-level service.

This process now takes hours, rather than days. The damage analysis from the optimal combination of human and automated work is more precise, and the claim preparation is already based on thousands of similar cases. So, the quote presented to the repair shop is more complete and precise, reducing the chance that overlooked damage will be discovered, or that the quote will omit important parts or labor. However, these attractive strategic outcomes were not achieved by simply substituting algorithms for analysts. They required reinventing several jobs and processes.

So far, our example has focused on making the process more efficient and precise. However, this new optimized process produces an even larger and more strategic benefit by changing the very nature of insurance pricing.

Recall that traditionally insurance was priced by using the policyholder’s financial credit score as a proxy for their accident and payment risk. Now, the information from the improved claims process transforms insurance pricing. Insurance companies can price their products to account for the historical riskiness of the region where the policyholder typically drives, such as the number of accidents that historically occur on preferred driving routes. It can account for the precise historical cost of parts and labor for the policyholder’s particular vehicle and even the policyholder’s driving style. Again, this is a game-changing strategic benefit, but it is only possible if companies get the work optimization correct.

The disruptive strategic change doesn’t stop there. At the same time that automation improves things like cameras, drones, and algorithms, the very nature of the automobile itself is changing. Driverless vehicles are increasingly widespread. When you combine driverless vehicles with enhanced claims and risk estimation, the very focus of insurance pricing changes. Traditionally, the human driver is the focus of risk estimation (where you drive, how you drive, whether you maintain your vehicle, etc.), and insurance is priced based on the individual.

With driverless technology and enhanced claims and repair analysis, the vehicle becomes the risk factor. Now, your insurance company can “microprice,” adjusting your premium minute by minute based on the condition of the vehicle, the weather, the location, and the driving style. For example, your insurance premium might spike every time you take over control of the vehicle and drop if you use the vehicle’s autonomous capabilities. When AI and sensors can track vehicles continuously, the auto manufacturer can become the insurer.

That’s exactly what’s happening as Tesla begins to offer vehicle insurance. In Asia, Tesla has partnered with established insurers to offer customized auto insurance that accounts for its vehicles’ autopilot safety features. As Tesla advances toward fully autonomous vehicles, the company is in a unique position to actually compete with traditional P&C insurers. Tesla, with more complete data and better analytical technology, can offer lower insurance prices because it has the ability to offer micro-pricing more precisely than those insurers.11

The strategic implications stretch even beyond more precise pricing and claims estimation. You have probably guessed that if automation allows for continuous monitoring and analysis of vehicle behavior and performance, it enables a shift from insurance that pays for accidents after they happen to prevent the accidents in the first place. That requires extending process automation beyond claims analysis and pricing.

Willis Towers Watson recently announced a partnership with Roost, a maker of smart-home technologies such as cognitively automated security cameras and thermostats.12 The partnership aims to bring smart-home device companies and insurance companies together to allow property insurance companies to use AI and the IoT to better mitigate insurance losses for water and fire. Continuous monitoring and analysis of data flowing in from smart-home devices can allow for more precise property insurance pricing and claims analysis, but it can also mitigate insurance claims. An insurance company might offer policyholders a kit with the Roost smart smoke alarms and smart water-leak detectors, and an agreement to send notifications to customers’ smartphones when a suspected water leak or fire occurs. This cross-industry integration offers the possibility that insurance carriers can achieve insights from home telematics by capitalizing on the data already being gathered by the telematics companies, rather than making big investments in their own proprietary telematics, and enabling them to more quickly shift from loss reimbursement to risk mitigation.

Imagine how optimizing the human-automation combinations reinvent jobs throughout this process. There will be fewer field adjusters doing dangerous or tedious work, as AI shifts tasks to the customer and drones. Former risk and compliance managers will see routine tasks shift to bots that are less error prone or fraudulent, supported by sophisticated cognitive models that predict quality and compliance. In call centers, managers will shift from overseeing call details to operating sophisticated robo-advisers. Salespeople will spend less time explaining routine features to customers, because customers will use algorithmic bots that offer insurance products precisely tailored to their driving habits, location, and home features. Those algorithms will run on global platforms that link consumer products like phones and thermostats with the databases of retail, financial, and even entertainment and communications services companies.

But, none of this is possible without a clear and precise way to reinvent jobs. That requires a process like the one we have described in this and preceding chapters. (See the sidebar “A Checklist to Help Leaders Implement Automation.”)

Now you can see how to answer automation questions in your organization more completely and precisely. You can get beyond simplistic ideas or grand strategic visions that are impossible to execute and instead apply automation to work in a thoughtful and nuanced way that optimizes the value of work and the role of automation.

Optimizing human-automation combinations at the work level is vital. However, your work isn’t done there. Even the best work-level automation can fail without a supportive context. Once you optimize work automation, you must consider how that redefines your organization, the meaning of leadership, and your approach to work and careers. The next chapters address these topics.