Glossary

“The beginning of wisdom is to call things by their right names.”

—CHINESE PROVERB

n means noun; v means verb

addendum (n) Radial distance from pitch circle to top of gear tooth.

allen screw (n) Special set screw or cap screw with hexagon socket in head.

allowance (n) Minimum clearance between mating parts.

alloy (n) Two or more metals in combination, usually a fine metal with a baser metal.

aluminum (n) A lightweight but relatively strong metal. Often alloyed with copper to increase hardness and strength.

anneal (v) To heat and cool gradually, to reduce brittleness and increase ductility.

arc weld (v) To weld by electric arc. The work is usually the positive terminal.

babbitt (n) A soft alloy for bearings, mostly of tin with small amounts of copper and antimony.

bearing (n) A supporting member for a rotating shaft.

bevel (n) An inclined edge, not at a right angle to the joining surface.

bolt circle (n) A circular centerline on a drawing, containing the centers of holes about a common center.

bore (v) To enlarge a hole with a boring mill.

boss (n) A cylindrical projection on a casting or a forging.

brass (n) An alloy of copper and zinc.

braze (v) To join with a hard solder of brass or zinc.

Brinell (n) A method of testing hardness of metal.

broach (n) A long cutting tool with a series of teeth that gradually increase in size that is forced through a hole or over a surface to produce a desired shape.

bronze (n) An alloy of eight or nine parts copper and one part tin.

buff (v) To finish or polish on a buffing wheel composed of fabric with abrasive powders.

burnish (v) To finish or polish by pressure on a smooth rolling or sliding tool.

burr (n) A jagged edge on metal resulting from punching or cutting.

bushing (n) A replaceable lining or sleeve for a bearing.

calipers (n) Instrument (of several types) for measuring diameters.

cam (n) A rotating member for changing circular motion to reciprocating motion.

carburize (v) To heat a low-carbon steel to approximately 2000 °F in contact with material that adds carbon to the surface of the steel, and to cool slowly in preparation for heat treatment.

case-harden (v) To harden the outer surface of a carburized steel by heating and then quenching.

castellate (v) To form like a castle, as a castellated shaft or nut.

casting (n) A metal object produced by pouring molten metal into a mold.

cast iron (n) Iron melted and poured into molds.

center drill (n) A special drill to produce bearing holes in the ends of a workpiece to be mounted between centers. Also called a “combined drill and countersink.”

chamfer (n) A narrow inclined surface along the intersection of two surfaces.

chase (v) To cut threads with an external cutting tool.

chill (v) To harden the outer surface of cast iron by quick cooling, as in a metal mold.

chip (v) To cut away metal with a cold chisel.

chuck (n) A mechanism for holding a rotating tool or workpiece.

coin (v) To form a part in one stamping operation.

cold rolled steel (CRS) (n) Open-hearth or Bessemer steel containing 0.12–0.20% carbon that has been rolled while cold to produce a smooth, quite accurate stock.

collar (n) A round flange or ring fitted on a shaft to prevent sliding.

color-harden (v) Same as case-harden, except that it is done to a shallower depth, usually for appearance only.

cotter pin (n) A split pin used as a fastener, usually to prevent a nut from unscrewing.

counterbore (v) To enlarge an end of a hole cylindrically with a counterbore.

countersink (v) To enlarge an end of a hole conically, usually with a countersink.

crown (n) A raised contour, as on the surface of a pulley.

cyanide (v) To surface-harden steel by heating in contact with a cyanide salt, followed by quenching.

dedendum (n) Distance from the pitch circle to the bottom of the tooth space.

development (n) Drawing of the surface of an object unfolded or rolled out on a plane.

diametral pitch (n) Number of gear teeth per inch of pitch diameter.

die (n) (1) Hardened metal piece shaped to cut or form a required shape in a sheet of metal by pressing it against a mating die; (2) also used for cutting small male threads. In a sense, a die is the opposite of a tap.

die casting (n) Process of forcing molten metal under pressure into metal dies or molds, producing a very accurate and smooth casting.

die stamping (n) Process of cutting or forming a piece of sheet metal with a die.

dog (n) A small auxiliary clamp for preventing work from rotating in relation to the face plate of a lathe.

dowel (n) A cylindrical pin, commonly used to prevent sliding between two contacting flat surfaces.

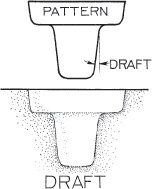

draft (n) The tapered shape of the parts of a pattern to permit it to be easily withdrawn from the sand or, on a forging, to permit it to be easily withdrawn from the dies.

draw (v) To stretch or otherwise to deform metal. Also to temper steel.

drill (v) To cut a cylindrical hole with a drill. A blind hole does not go through the piece.

drill press (n) A machine for drilling and other hole forming operations.

drop forge (v) To form a piece while hot between dies in a drop hammer or with great pressure.

face (v) To finish a surface at right angles, or nearly so, to the centerline of rotation on a lathe.

(FAO) (v) An instruction on a drawing to employ the desired surface finish on all surfaces.

feather (key) (n) A flat key, which is partly sunk in a shaft and partly in a hub, permitting the hub to slide lengthwise of the shaft.

file (v) To finish or smooth with a file.

fillet (n) An interior rounded intersection between two surfaces.

fin (n) A thin extrusion of metal at the intersection of dies or sand molds.

fit (n) Degree of tightness or looseness between two mating parts, as a loose fit, a snug fit, or a tight fit.

fixture (n) A special device for holding the work in a machine tool, but not for guiding the cutting tool. Compare with jig.

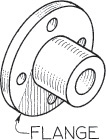

flange (n) A relatively thin rim around a piece.

flask (n) A box made of two or more parts for holding the sand in sand molding.

flute (n) Groove, as on twist drills, reamers, and taps.

forge (v) To force metal while it is hot to take on a desired shape by hammering or pressing.

galvanize (v) To cover a surface with a thin layer of molten alloy, composed mainly of zinc, to prevent rusting.

gasket (n) A thin piece of rubber, metal, or some other material, placed between surfaces to make a tight joint.

gate (n) The opening in a sand mold at the bottom of the sprue through which the molten metal passes to enter the cavity or mold.

graduate (v) To set off accurate divisions on a scale or dial.

grind (v) To remove metal by means of an abrasive wheel, often made of carborundum. Use chiefly where accuracy is required.

harden (v) To heat steel above a critical temperature and then quench in water or oil.

heat-treat (v) To change the properties of metals by heating and then cooling.

interchangeable (adj.) Refers to a part made to limit dimensions so that it will fit any mating part similarly manufactured.

jig (n) A device for guiding a tool in cutting a piece. Usually it holds the work in position. Compare with fixture.

journal (n) Portion of a rotating shaft supported by a bearing.

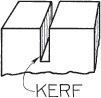

kerf (n) Groove or cut made by a saw.

key (n) A small piece of metal sunk partly into both shaft and hub to prevent rotation.

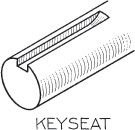

keyseat (n) A slot or recess in a shaft to hold a key.

keyway (n) A slot in a hub or portion surrounding a shaft to receive a key.

knurl (v) To impress a pattern of dents in a turned surface with a knurling tool to produce a better hand grip.

lap (v) To produce a very accurate finish by sliding contact with a lap, or piece of wood, leather, or soft metal impregnated with abrasive powder.

lathe (n) A machine used to shape metal or other materials by rotating against a tool.

lug (n) An irregular projection of metal, but not round as in the case of a boss, usually with a hole in it for a bolt or screw.

malleable casting (n) A casting that has been made less brittle and tougher by annealing.

mill (v) To remove material by means of a rotating cutter on a milling machine.

mold (n) The mass of sand or other material that forms the cavity into which molten metal is poured.

MS (n) Machinery steel, sometimes called mild steel, with a small percentage of carbon; cannot be hardened.

neck (v) To cut a groove called a neck around a cylindrical piece.

normalize (v) To heat steel above its critical temperature and then to cool it in air.

pack-harden (v) To carburize, then to case-harden.

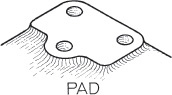

pad (n) A slight projection, usually to provide a bearing surface around one or more holes.

pattern (n) A model, usually of wood, used in forming a mold for a casting. In sheet metal work a pattern is called a development.

peen (v) To hammer into shape with a ballpeen hammer.

pickle (v) To clean forgings or castings in dilute sulfuric acid.

pinion (n) The smaller of two mating gears.

pitch circle (n) An imaginary circle corresponding to the circumference of the friction gear from which the spur gear was derived.

plane (v) To remove material by means of a planer.

planish (v) To impart a planished surface to sheet metal by hammering with a smooth-surfaced hammer.

plate (v) To coat a metal piece with another metal, such as chrome or nickel, by electrochemical methods.

polish (v) To produce a highly finished or polished surface by friction, using a very fine abrasive.

profile (v) To cut any desired outline by moving a small rotating cutter, usually with a master template as a guide.

punch (v) To cut an opening of a desired shape with a rigid tool having the same shape, by pressing the tool through the work.

quench (v) To immerse a heated piece of metal in water or oil to harden it.

rack (n) A flat bar with gear teeth in a straight line to engage with teeth in a gear.

ream (v) To enlarge a finished hole slightly to give it greater accuracy, with a reamer.

relief (n) An offset of surfaces to provide clearance for machining.

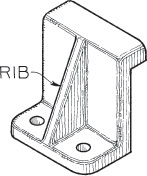

rib (n) A relatively thin flat member acting as a brace or support.

rivet (v) To connect with rivets or to clench over the end of a pin by hammering.

round (n) An exterior rounded intersection of two surfaces.

SAE Society of Automotive Engineers.

sandblast (v) To blow sand at high velocity with compressed air against castings or forgings to clean them.

scleroscope (n) An instrument for measuring hardness of metals.

scrape (v) To remove metal by scraping with a hand scraper, usually to fit a bearing.

shape (v) To remove metal from a piece with a shaper.

shear (v) To cut metal by means of shearing with two blades in sliding contact.

sherardize (v) To galvanize a piece with a coating of zinc by heating it in a drum with zinc powder, to a temperature of 575 °F–850 °F.

shim (n) A thin piece of metal or other material used as a spacer in adjusting two parts.

solder (v) To join with solder, usually composed of lead and tin.

spin (v) To form a rotating piece of sheet metal into a desired shape by pressing it with a smooth tool against a rotating form.

spline (n) A keyway, usually one of a series cut around a shaft or hole.

spotface (v) To produce a round spot or bearing surface around a hole, usually with a spotfacer. The spotface may be on top of a boss or it may be sunk into the surface.

sprue (n) A hole in the sand leading to the gate, which leads to the mold, through which the metal enters.

steel casting (n) Like cast iron casting except that in the furnace scrap steel has been added to the casting.

swage (v) To hammer metal into shape while it is held over a swage, or die, which fits in a hole in the swage block, or anvil.

sweat (v) To fasten metal together by the use of solder between the pieces and by the application of heat and pressure.

tap (v) To cut relatively small internal threads with a tap.

taper (n) Conical form given to a shaft or a hole. Also refers to the slope of a plane surface.

taper pin (n) A small tapered pin for fastening, usually to prevent a collar or hub from rotating on a shaft.

taper reamer (n) A tapered reamer for producing accurate tapered holes, as for a taper pin.

temper (v) To reheat hardened steel to bring it to a desired degree of hardness.

template or templet (n) A guide or pattern used to mark out the work, guide the tool in cutting it, or check the finished product.

tin (n) A silvery metal used in alloys and for coating other metals, such as tin plate.

tolerance (n) Total amount of variation permitted in limit dimension of a part.

trepan (v) To cut a circular groove in the flat surface at one end of a hole.

tumble (v) To clean rough castings or forgings in a revolving drum filled with scrap metal.

turn (v) To produce, on a lathe, a cylindrical surface parallel to the centerline.

twist drill (n) A drill for use in a drill press.

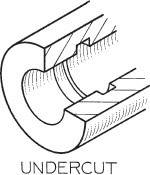

undercut (n) A recessed cut or a cut with inwardly sloping sides.

upset (v) To form a head or enlarged end on a bar or rod by pressure or by hammering between dies.

web (n) A thin flat part joining larger parts. Also known as a rib.

weld (v) Uniting metal pieces by pressure or fusion welding processes.

Woodruff (key) (n) A semicircular flat key.

wrought iron (n) Iron of low carbon content useful because of its toughness, ductility, and malleability.