10From the United States: Using POLCA to Eliminate Material Flow Chaos in an Aluminum Extrusion Operation

Guest authors: Jeff Cypher and Todd Carlson

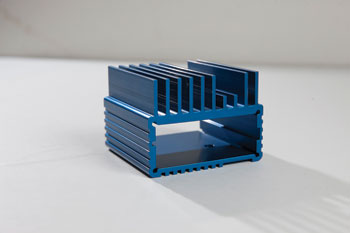

Located in Alexandria, Minnesota, Alexandria Industries (AI) started its operations in 1966 by providing a local boat manufacturer with lineal aluminum extrusions. Shortly after that, another Minnesota company needed precision-machined components. AI stepped up to the challenge, which resulted in AI being one of the first aluminum extrusion companies to have machining as part of its core capabilities. AI continued to develop a vertically integrated structure to align with its customers’ needs, including growth through strategic acquisitions based on customer requirements. In addition to its aluminum extrusion operations, AI now has capabilities of precision machining of ferrous and non-ferrous products, heatsinks, plastic injection, and foam-molding components, as well as finishing, high-level assemblies, and welding services (Figure 10.1). At the same time, AI has expanded its market far beyond the original marine products and now serves numerous other industry segments including electronics, medical, firearms, recreation, lighting, and solar and renewable energy.

Figure 10.1Examples of aluminum extrusions (left) and a heat sink enclosed housing (right).

AI currently has ISO-certified manufacturing locations in Minnesota, Indiana, and Texas producing high-quality, short-lead-time engineered products, with around 600 employees in total. These operations include four extrusion presses, with three located in Alexandria, Minnesota and one located in Indianapolis, Indiana. AI has many high production saws, several types of bending machines and stretch-forming equipment. Automation takes a prevalent role at AI, for example, through specialty machines that can punch, drill, tap, and cut parts in one operation. CNC Machining is accomplished at two of AI’s factories in Alexandria, Minnesota and in Carrollton, Texas, with a total of around 80 CNC machines, 30% of which are robotically tended. It is common for aluminum products to have finishing operations such as anodizing and painting, and all of AI’s finishing applications are completed by subcontractors at their facilities outside of AI. The typical process sequence within AI involves extruding, artificially aging, cutting, machining and/or fabrication, finishing (done outside AI), and finally packing. Since AI’s strategic focus is on make-to-order business, there are numerous variations of the “typical” process, leading to complexity of the job flows: in fact, AI currently has over 3,500 active extrusion dies resulting in more than 10,000 finished end items.

The Start of Our POLCA Journey

In the late 1990s, lead times in the extrusion industry were typically between 8 and 12 weeks, and AI’s lead time was in this range as well. This was an accepted industry standard, so AI felt that there was no reason to change. With the telecommunications collapse of the early 2000s, AI was looking for something that would strategically differentiate it from the competition. In 2002, Tom Schabel, president of AI, identified Quick Response Manufacturing (QRM) as a competitive strategy for AI because of QRM’s strengths in dealing with high-mix, low-volume and custom (HMLVC) production, which was AI’s core business.

The authors, along with a core team of people, were involved from the start with AI’s initiative to implement QRM, with Jeff Cypher acting as the QRM Steering Committee Champion. The original co-champions of the POLCA Implementation Team were Jason Bachman and Todd Carlson, and other members of that team were Brian Larson and Kurt Norling, both in manufacturing leadership. The rest of this article will take the reader through our personal journey.

In early 2004, a couple of years after starting QRM, we had several cells in place, both in manufacturing and the office, but we still had a material flow problem between the cells as well as between workcenters that were not in cells. We were a typical manufacturing facility utilizing an MRP (Push) scheduling system. Most of our product was made to order; however, to meet very short lead-time requirements for a few customers, we did make some product to forecast. Again, in line with a typical manufacturing facility, high work-in-process (WIP) and expediting were commonplace. In spite of our best attempts at expediting, we were still experiencing poor on-time delivery performance, resulting in customer dissatisfaction.

At this point, a number of us recalled reading the chapter on POLCA during our study of Rajan Suri’s book, Quick Response Manufacturing. A group of us re-read the chapter, but we still didn’t understand how POLCA would work for us, and the specifics of how we could implement it at AI. Fortunately, we all had a strong gut feeling that we had an environment that would benefit from application of POLCA, and we were also lucky to have Jason Bachman in the team, who tenaciously continued pushing us to pursue the concept. So, we decided that we needed some expert help to assist us with our first steps. We approached the Center for Quick Response Manufacturing at the University of Wisconsin–Madison for assistance. Two of the staff from the Center came to Alexandria to conduct a training session that included both the theory of POLCA as well as a hands-on POLCA simulation game where we “made” a high variety of products in a make-believe factory. Seeing the principles explained in slides, and experiencing the way POLCA worked for the pseudo-factory, drove the details home for us. After that training session, we knew that POLCA would work at AI.

But there were many remaining obstacles, and we still had a lot of work to do! One of the biggest issues was overcoming fear. Many people wanted to wait because we simply didn’t have the time to go through the changes—we were already running late and it seemed like we never had enough capacity. This point was raised repeatedly: “What if we implement POLCA and it doesn’t work? We’ll be even worse off than now!”

To overcome some of the fear, our team toured a facility that was using POLCA. The collaboration was mutual: each company invested in the effort to visit the other with a team of people. This was not trivial considering the companies are located 500 miles apart. The factory that we visited had not implemented QRM principles but was using POLCA, and it had greatly reduced their WIP and improved their material flow. The product flows in both factories were similar, and after seeing POLCA work for them, the AI team felt confident that POLCA would work for us as well. The team at the other company stressed that we should stop hesitating and “Just Do It!” We also gained some useful tips from visiting the other factory, including ideas for card layout, color-coding of cells, and use of Bullet Cards.

The other point we had to keep reminding ourselves, to overcome the fear of change, was that our current Push system obviously wasn’t working! We had experimented with a Pull system, but we soon realized that it wasn’t right for our business either. (Appendix C explains further why both Push and Pull approaches were not working in our HMLVC environment.) It was clear that we needed to try something different.

Experimenting with a Small-Scale POLCA Implementation

As a final way to overcome the fears of change or failure, the team decided to try POLCA in a small, mostly self-contained area of our operation. If it didn’t work, this would limit the damage. Specifically, we chose products going from one of our extrusion presses, the Loewy Press, to our Centerless Grinding cell. This seemed like a logical test case because this cell serviced one customer’s needs and we were performing poorly. We didn’t understand the reasons for poor performance because the product mix was relatively low and the customer had a consistent ordering pattern. In addition, our capacity matched demand, we had few quality issues, and it was a relatively simple manufacturing process. Therefore, it was clear that our current system was not working even in this simple situation.

This first POLCA loop took about six months to complete. Frankly, it didn’t need to take that long at all, but our fear of failing prolonged the process. There was a lot of investigating, education, and hesitation. As one instance of this, to calculate the number of POLCA cards in the loop, we used the formula from the above-mentioned POLCA chapter in Suri’s book. By the rules of what we had plugged into our MRP system, the formula recommended a number of cards that appeared to be way too many, and this caused some concern with the team members. So we went back to the drawing board and reevaluated the days of queue time and move time that had been put into our routings. We found that there was a lot of padding in these times, which had been put in place as a safety margin to allow for unexpected problems, errors, schedule changes, and so on. We decided that POLCA would alleviate many of these issues and so this safety margin was way too high. After reducing the days of queue and move time to only what was necessary for normal operations, the new information was plugged back into the formula. The result was a significantly lower number of cards. We were more comfortable with that and we used this as the starting point for the number of cards in the loop.

The team then looked at the product structure, which included the bill of material (BOM) and routing structure. The product going through this cell had five different shapes, each with two lengths and three colors, resulting in 30 part numbers. The BOMs and routings were designed to have pieces of each shape and length stocked (i.e., 10 part numbers of semi-finished stock) so that we could “quickly” produce a finished part in any color. After evaluating this process, it wasn’t as effective as we thought: a lot of MRP transactions were involved in tracking material going in and out of inventory, and despite the stocking attempts we still often didn’t have the right semi-finished goods!

Therefore, the first thing we did before starting POLCA was to change the product structure so that each of the 30 part numbers had its own BOM and routing from raw material (extrusion) to customer’s part (colored anodized). We also observed that due to historical policies based on economizing on changeover times at the extrusion press, the extrusion batch sizes were set at 960 pieces, while customer delivery quantities of the finished parts were 240 pieces, which again forced us to store the remaining pieces and be involved in inventory transactions. To ensure that a POLCA card would be associated with a specific order from start to finish, we decided to change the extrusion batch quantity to 240 to match the customer order size.

To summarize, we made three significant changes to the BOM and routings:

The queue times and move times in our routings were reduced to reflect the actual processes. Specifically, all “padding” was removed.

Stocking of intermediate (semi-finished) product was eliminated.

The extrusion batch size was changed to reflect the customer order quantity for finished product.

It was pointed out to us that the third item would increase the standard cost of the product. This was yet another potential obstacle, because from an accounting standpoint, these changes to support POLCA didn’t make sense. However, from our QRM training and book reading, we understood that this was an example of the situation where standard costing doesn’t account for the resulting reductions in cost through the reductions in WIP, stocked inventory, floor space, and expediting, and nor did it account for the market value of improved on-time delivery performance. We discussed these tradeoffs with the team members and AI’s management, and because of top management’s commitment to QRM and support for this type of thinking beyond standard costing, we were able to forge ahead with POLCA.

The points above highlight the fact that when you are designing your POLCA system, you shouldn’t simply instrument the current operation with POLCA. You should take a step back and think through what changes would make sense to better support POLCA operation.

System Design and Training

It was now time for the POLCA implementation team to develop the system and complete the training. We trained the leadership in the Loewy Press area, which was the first cell of the POLCA Loop, all of the personnel and leadership of the Centerless Grinding Cell (the second cell of the Loop), and the office cell involved with this product. Since the Loewy Press supplied product to other cells that would not be on POLCA, we explained that those jobs would be run based on the normal MRP dispatch list, attempting to keep as close to the MRP-assigned start dates, but the jobs on POLCA needed to obey the full Decision Time rules (Authorization Date plus POLCA card). Since we already had an MRP system with start date calculations, we used this to create the Authorization Dates as well. However, in order to have some safety margin as we started up the POLCA system, we decided that the Authorization Date for jobs on POLCA would be three days earlier than the MRP calculated start date. For example, if the MRP start date for a given job at extrusion was November 10, the job would actually be Authorized from November 7. Since there was just one simple loop involved we decided to go with the Release-and-Flow version of POLCA, so that the downstream cell did not need to use Authorization Dates.

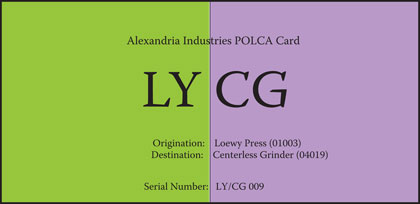

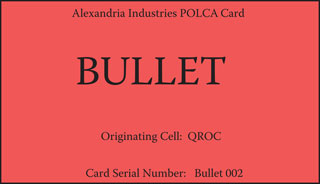

We then designed and printed the POLCA cards, including four Bullet Cards (Figures 10.2 and 10.3). Next, we spent some time in both these production areas so that everyone could see the tools and discipline required for POLCA. This included:

Where the free POLCA cards would be placed, on a POLCA Board at the first cell (Figure 10.4);

How a POLCA card would be incorporated into the shop packet once it was associated with a launched job, and where the shop packet along with the card would be placed on the baskets used to carry the product through the production areas (Figure 10.5);

Marking where the WIP would be placed as it progressed through the two cells;

How the POLCA card would be returned: we decided that the team in the second cell would be responsible for returning the card to the upstream cell as soon as they were finished with the job. (This worked fine for us and we have continued with this rule for all POLCA loops implemented subsequently.)

Figure 10.2POLCA card for the first loop.

Figure 10.3One of the bullet cards (QROC refers to the Quick Response Office Cell responsible for a set of products).

Figure 10.4POLCA Board for placing the cards (this picture is for the current situation with more POLCA loops in place, but the original board was similar to this).

Figure 10.5POLCA cards placed in shop packets, which are then placed in the baskets used for transporting material.

Following the training and the specification of these details on the shop floor, the team and the shop personnel felt confident about how the system would work. It was finally time to implement!

System Startup and Early Results

At the startup, we still had inventory of semi-finished products, so we had to institute a short-term policy to work through this stock. What we did might be helpful to other readers going through a similar startup. We started by giving the full set of POLCA cards to the scheduler. When the scheduler saw that an order needed material that wasn’t already in stock he would issue a POLCA card to enable production at the upstream cell. On the other hand, if the material was already in semi-finished stock, he would place a POLCA card on the basket of material and have it delivered to the downstream cell as if it had arrived from upstream. In this way, we bled down the stock and then moved to fully make-to-order production, following the full POLCA rules for these products.

The transition from Push to POLCA was relatively smooth, and the speed of the transition was astonishing. It didn’t take long for us to see that POLCA was going to work in our environment. Floor space started to visibly clear up as WIP went down, and our delivery performance started improving. Amazingly, in less than two months this first POLCA loop had already achieved the following results:

Floor space occupied by WIP in this area shrank from 250 square feet to 63 square feet: a 75% reduction!

The value of WIP in this loop went from $27,720 down to $6,930, also a 75% reduction.

Team leaders and managers noticed that expediting efforts were reduced dramatically.

Traditionally, manufacturing companies have stuffed themselves with inventory, thinking that this would improve their ability to serve customers. When our first POLCA results were tallied, what was amazing to all of us was that we had less inventory, and yet we had a much higher service level to our clients! These results were unambiguous enough to convince us that we should implement POLCA for the rest of the shop floor.

Extending POLCA to the Whole Factory

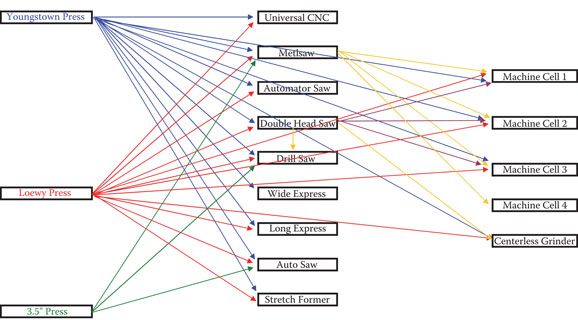

After the success with the initial POLCA loop, we went through the same process for the next four loops. Thanks to our learning from the first loop, implementation time for these loops was cut down to about eight weeks. After these loops were implemented, most shop employees were either part of a POLCA loop or certainly aware of POLCA and what we were accomplishing with it, and were prepared for additional loops to be put in place. As a result, the next set of loops—around 30—were implemented very quickly. The final set of loops is shown in Figure 10.6. Some of the boxes in the figure represent cells, while others are standalone machines. Our experience demonstrates that you can use POLCA with or without cells, or with a combination of cells and individual workcenters. POLCA has worked well for us since we instrumented the entire factory, and, as explained at the end of this chapter, the results have continued to pour in.

Figure 10.6Full set of POLCA loops at the factory in Alexandria. To keep the figure less crowded, arrows are used for each loop. Each arrow represents a POLCA loop with the direction indicating the upstream and downstream cells.

What We Learned, and Advice to Other Practitioners

We were among the first companies in the world to implement POLCA, and we only visited one other company before our implementation, so we had to learn many things by ourselves along the way. We would like to share some of these lessons to help others succeed in their POLCA implementations, and to potentially shave some time off the implementation process.

As mentioned earlier, don’t just instrument your current operation with POLCA. Think about how POLCA works and whether you need to make some changes first, to better support the system’s operation. Thinking through how POLCA works thus gives you a chance to step back and reexamine your current operating norms.

When you are putting in a POLCA loop, don’t sweat about whether the number of cards in the loop is perfect: after implementation of a loop, it is easy to tell if the number of cards is correct, and also easy to adjust this number. We found that the formula for calculating the number of cards was a very good starting point, as long as you check and remove any unnecessary padding in the planned lead times (as explained earlier). You can confidently go with this number and start. If you are constantly starving the downstream cell, add a card or two. If you consistently have too many cards—witnessed by the fact that the needed card is always available to the cell—and the downstream cell seems to be overloaded and accumulating a lot of WIP, remove cards one at a time until it appears that the upstream cell is occasionally being shut down to let the downstream cell catch up. In our case, the formula for number of cards worked well enough that in some loops we did not need to adjust the number of cards at all. In other loops, we adjusted the number of cards very little. Hence our final advice on this point is that you don’t need to spend a lot of time worrying if you have the correct number of cards in each loop. Just get going, and then it’s easy to fine tune!

Also, don’t stress on deciding on the number of Bullet Cards. As a reminder, the purpose of a Bullet Card is to take care of unplanned or unusual circumstances when an order needs to be expedited without having to wait on the normal POLCA decision rules. This will typically happen when there is an urgent unanticipated customer requirement and management feels it is important to service this customer without delay. As explained in Chapter 6, the Bullet Card allows a job to flow quickly through the whole shop floor. We had four office cells, each servicing orders for a segment of customers, and we issued one Bullet Card to each of the office cells. This meant that if a particular office cell used its Bullet Card for an order, it could not release another “bullet” order until this card was returned to the office cell after the previous bullet order had been completed. The idea was to impose some restraints on using this card, and for an office cell to think carefully before it “played its card.” In the beginning, the office cells thought that four Bullet Cards were too little; each cell felt that having just one Bullet Card wouldn’t come close to being enough for its needs. However, the office personnel had not anticipated the performance improvements that result with POLCA, which dramatically enhanced our ability to service customer needs. In fact, after POLCA had been in place in the whole factory for about six months, we realized that even just two Bullet Cards, shared by all four office cells, would have sufficed! However, implementing four cards was the right thing to do, as it took the politics out of the decisions, with each cell controlling its own card.

We recommend that you implement an audit plan for the number of cards. This is similar to the auditing needed for a 5S or ISO system. Manufacturing involves a lot of materials and movements, and cards have a way of disappearing among all this. As explained in Chapters 5 and 9, cards need to have serial numbers, and the audit needs to identify the location of all cards. Not only will the audit pinpoint missing cards, but over time statistical analysis will show if loops have frequently unused cards (too many cards) or almost never have unused cards (too few cards) and this can help fine-tune the numbers as well. As with any auditing system, once confidence is gained, the frequency of audits can be reduced. We started with weekly audits. After four weeks, we switched this to monthly. Then after the first quarter, we extended this to quarterly audits, which is where it remains now.

Be prepared to adjust your scheduling process: POLCA will change how you schedule your manufacturing. Your frequency of scheduling may change (for example, every shift versus every day, or every other day versus every week). You may find that you have less discussion between the office and manufacturing. The manufacturing communication will be different between portions of the organization. Regardless of how it changes for your particular situation, it will change, but for the better. So, be prepared, be flexible, and embrace it!

Don’t feel like you have to implement overlapping POLCA loops to be deemed successful. At AI, we found great value even in single POLCA loops. Our manufacturing leadership grasped the concept of single POLCA loops very easily and their ownership was apparent very early in the process.

Stay tenacious and disciplined. In 2015, AI got extremely busy and we ran out of capacity. As the chaos grew, we found ourselves trying to outthink the system. We stopped using POLCA in a disciplined fashion. We thought that we could better control the job flow manually. It is easy to predict what happened next. On-time delivery diminished and WIP increased. Along with that came other sins. We found that we were expediting more and moving WIP around because it was in the way of what we needed to work on next. Compounding these challenges was the hiring of many new employees and the changing of manufacturing leadership. As these happened, we did a poor job of training the newcomers on POLCA principles and maintaining focus. Looking back, it is clear that reverting to processes that didn’t work previously is not the answer! Hence our advice is that you should stick with the POLCA system and rules regardless of business conditions.

POLCA should be part of your orientation for new employees, particularly for people involved in production areas. We have developed a 45-minute simulation that shows how POLCA works and the advantages of utilizing it at AI.

Impact of POLCA on Our Organization

Implementing POLCA had more profound and far-reaching consequences than we had expected. It fundamentally transformed our manufacturing methodology. The changes from implementing POLCA resulted in a better understanding and deeper penetration of QRM principles. It proved the value of batch-size reduction and queue-time removal, both of which had previously been difficult to do on faith alone. In combination, the cutting of batch sizes, removal of queue time, and reduction of stocking levels was a scary journey. However, the result was that it broke down standard costing barriers and promoted QRM activities, resulting in the intended gains. In 2002, before starting our QRM journey, our sales averaged $274 per square foot of manufacturing floor space. In 2012 this number had grown to $434 per square foot—a 60% increase! Most of this increase came from a reduction in WIP—which can directly be attributed to POLCA—and in place of the nonproductive WIP we could put more productive resources on the shop floor, significantly increasing our output in the same space.

Also, as compared with the 8–12 week lead times for extrusions mentioned at the start of this chapter, our extrusion-only lead time is now just one week. And in addition, our on-time delivery is almost perfect. The anecdote that follows helps to drive home the impact of all these improvements.

A few months before we implemented POLCA, the Plant Manager grabbed one of the office cell members by the shoulder one day and led her through a particular production area while asking, “What am I supposed to do with all of this material?” The press would run large batches so that this area could work over the weekend. We would then send an entire truckload to an outside supplier on Monday morning, and Purchasing would call us and ask why we plugged up the supplier. The supplier would then work hard on expediting this big order and send all the material to the customer. However, four different parts need to be assembled together at the customer’s site for them to have one finished unit. After the customer received product from our supplier, he would call us and ask why we sent a truckload of material of one of the parts, because he could not do any assembly without the other three!

After we put this product line on POLCA, the effort that we put in to satisfy this customer is virtually nonexistent. The customer orders material, Manufacturing produces it, we ship it in the right quantities and mix, and the Plant Manager hasn’t asked that office cell member about these products since that eventful day before we started POLCA.

About the Author

Jeff Cypher is Director of Business Integration at Alexandria Industries. He has over 20 years of experience in business systems and materials management, and has actively participated in Alexandria Industries’ QRM journey. Alexandria Industries has four divisions and Jeff is assisting in the integration of the Business Systems and implementing QRM principles.

Todd Carlson is the Corporate Capacity and CNC Robotics Manager at Alexandria Industries. He has been responsible for implementing automation in the machine shop, managing the operations of the shop, and also actively engaged in Alexandria Industries’ QRM journey for over 15 years. Todd is assisting in bringing automation to each of the four divisions of Alexandria Industries, and balancing the capacities and workloads at each location. Todd has a B.S. in Manufacturing Engineering and an M.B.A., both from St. Cloud State University.