12.7.3 Energy Balance

Using the energy flux, e, to carry out an energy balance on our annulus (Figure 12-15) with system volume 2πrΔrΔz, we have

(Energy flow in at r) = er Acr = er · 2πrΔz

(Energy flow in at z) = ez Acz = ez · 2πrΔr

(Energy0flowin0at0r)-(Energy0flowout0at0r+Δr)+(Energy0flowin0at0z)-(Energy0flowout0at0z+Δz)=(Accumu1ationof0energy0invo1ume0(2πrΔrΔz))

(er2πrΔz)|r-(er2πrΔz)|r+Δr+eZ2πrΔr|Z-eZ2πrΔr|z+Δz0=00

Dividing by 2πrΔrΔz and taking the limit as Δr and Δz → 0

The radial and axial energy fluxes are

er0=0qr+ΣWirHiez0=0qz+ΣWizHi

Substituting for the energy fluxes, er and ez

-1r∂[r[qr0+0ΣWir0Hi]]∂r-∂[qz+ΣWiz0Hi]∂z0=0000000000(12-50)

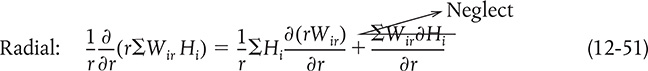

and expanding the convective energy fluxes, ΣWi Hi,

Axial:∂(ΣWiz0Hi)∂z0=0ΣHi∂Wiz∂z+ΣWiz∂Hi∂z000000000000000(12-52)

Because Ur and the gradient in the flux term Wir are small, we can neglect the last term in Equation (12-51) with regard to the other terms in the equation.

Substituting Equations (12-51) and (12-52) into Equation (12-50), we obtain upon rearrangement

Recognizing that the term in brackets is related to Equation (12-44) and is just the rate of formation of species i, ri, for steady-state conditions we have

Recalling

qr0=-Ke∂T∂r,qZ0=-Ke∂T∂z,∂Hi∂z=CPi∂T∂z,

and

ri0=0vi(-rA)ΣriHi0=0ΣviHi(-rA)=-ΔHRxrA

we have the energy in the form

where Wiz is given by Equation (12-42). Equation (12-54) would be coupled with the mole balance (Equation (12-45)), rate law, and stoichiometric equations to solve for the radial and axial concentration gradients. However, a great amount of computing time would be required. Let’s see if we can make some approximations to simplify the solution.

Some Initial Approximations

Assumption 1. Neglect the diffusive term in the axial direction, wrt, the convec-tive term in Equation (12-42) in the expression involving heat capacities

ΣCPiWiz0=0ΣCPi(0+UZCi)0=0ΣCPiCiUZ

With this assumption, Equation (12-54) becomes

For laminar flow, the velocity profile is

UZ0=02U0[1-(rR)2]00000000000(12-56)

where U0 is the average velocity inside the reactor.

Assumption 2. Assume that the sum CPm0=0ΣCPiCi0=0CA0ΣΘiCPi

Energy balance with radial and axial gradients

Equation (12-56) is the form we will use in our COMSOL problem. In many instances, the term CPm is just the product of the solution density (kg/m3) and the heat capacity of the solution (kJ/kg · K).

Coolant Balance

We also recall that a balance on the coolant gives the variation of coolant temperature with axial distance where Uht is the overall heat transfer coefficient and R is the reactor wall radius

Boundary and Initial Conditions

A. Initial conditions if other than steady state (not considered here) t = 0, Ci = 0, T = T0, for z > 0 all r

B. Boundary conditions

1) Radial

(a) At r = 0, we have symmetry ∂T / ∂r = 0 and ∂Ci / ∂r = 0.

(b) At the tube wall, r = R, the temperature flux to the wall on the reaction side equals the convective flux out of the reactor into the shell side of the heat exchanger.

-ke∂T∂r|R0=0U(T(R,z)-Ta)

−ke∂T∂r∣∣∣R0=0U(T(R,z)−Ta) (c) There is no mass flow through the tube walls ∂Ci/∂r = 0 at r = R.

2) Axial

(a) At the entrance to the reactor z = 0

T = T0 and Ci = Ci0

(b) At the exit of the reactor z = L

∂T∂z0=00000and000∂Ci∂z0=0

∂T∂z0=00000and000∂Ci∂z0=0

The preceding equations were used to describe and analyze flow and reaction in a tubular reactor with heat exchange as described in the following example, which can be found in the Expanded Material on the CRE Web site. What follows is only a brief outline of that example with a few results from the output of the COMSOL program.

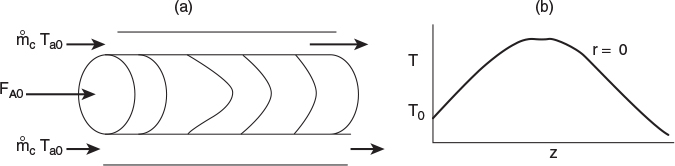

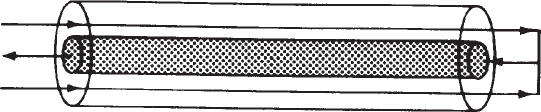

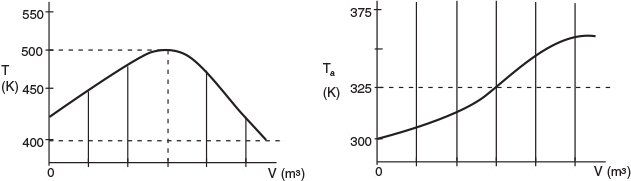

Example W12-8 Tubular reactor with axial and radial gradients.

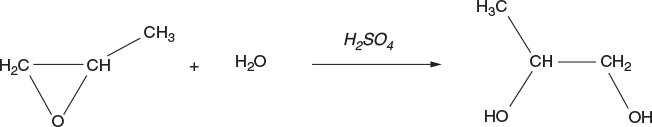

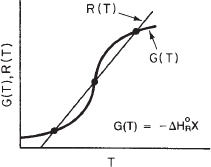

The liquid phase reaction was analyzed using COMSOL to study both axial and radial variations, and the details can be found on the home page of the CRE Web site, www.umich.edu/~elements/5e/index.html, by clicking on the Expanded Material for Chapter 12. The algorithm for this example can be found on the Web site: http://www.umich.edu/~elements/5e/12chap/expanded.html. Web Figure E12-8.1 is a screen shot from COMSOL of the base case reactor and reaction parameters. In the COMSOL LEP you are asked “What if...” questions about varying the base case parameters. Typical radial (a) and axial (b) temperature profiles for this example are shown in Figure 12-16.

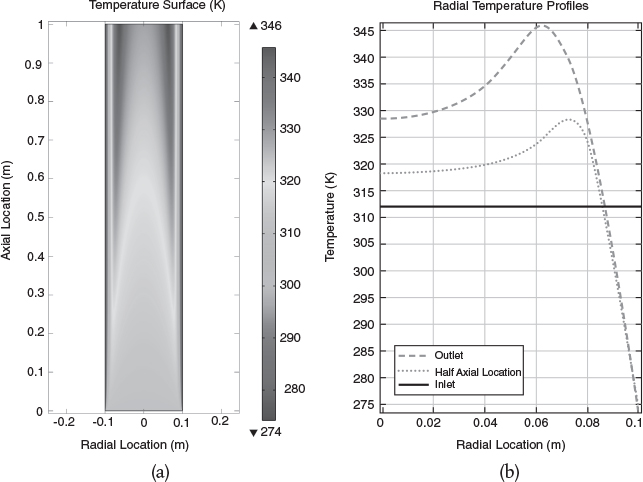

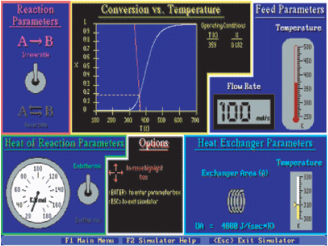

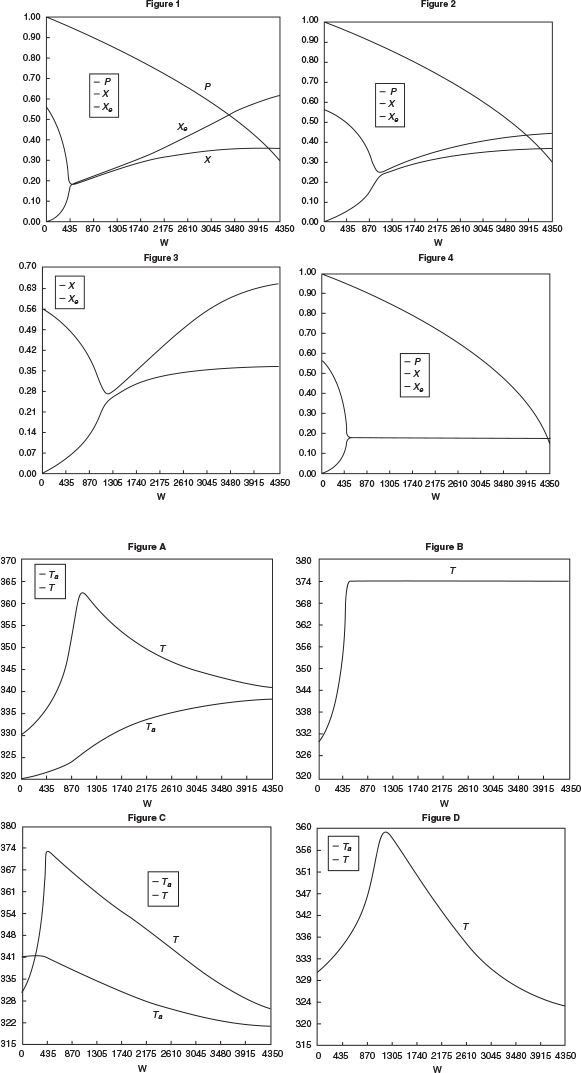

Results. The graphical solutions to the COMSOL code are shown in Figure 12-17.

Figure 12-17 (a) Temperature surface, (b) temperature surface profiles, (c) conversion surface, and (d) radial profile. (Continues)

The volumetric flow rate of water is 3.5 times the volumetric flow rate of the mixture of propylene oxide in methanol. Further details of this example are provided in the Chapter 12 Expanded Material on the CRE Web site: http://www.umich.edu/~elements/5e/12chap/expanded.html, http://www.umich.edu/~elements/5e/12chap/expanded_ch12_radial.pdf, and http://www.umich.edu/~elements/5e/12chap/comsol.html.

Analysis: One can observe from the temperature surface plot in Figure 12-17(a) how the temperature changes both axially and radially in the reactor from its entering temperature of 312 K. These same profiles can be found in color on the CRE Web site in the Web Modules. Be sure to note the predicted maximum and minimum in the temperature and concentration profiles in Figure 12-17(d). Near the wall, the temperature of the mixture is lower because of the cold wall temperature, which is cooled by the jacket. Consequently, the reaction rate will be lower, and thus the conversion will be lower. However, right next to the wall the flow velocity through the reactor is almost zero, due to the friction with the wall, so the reactants spend a longer time in the reactor; therefore, a greater conversion is achieved, as noted by the upturn right next to the wall.

CRE Web Site—COMSOL

In this interactive Web site and text you will be able to use the LEP COMSOL program instead of having to write your own code. To access these LEPs you don’t need to have COMSOL installed on your computer as you can access it through the CRE Web site. We use the COMSOL codes in a similar manner to the Polymath LEPs where you are able to vary the parameters to explore the radial variations in temperature, conversion, and concentration, in addition to axial profiles.

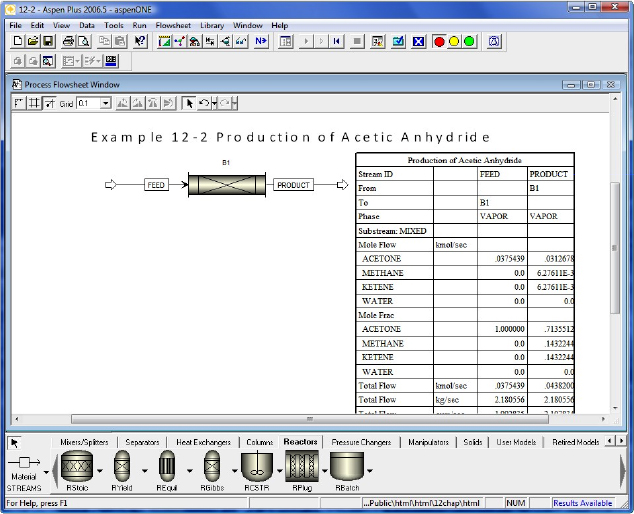

Also, other applications based on exercises from this book are found at the COMSOL Web site (www.comsol.com/ecre). These include the following applications: activation_energy based on the example Determination of Activation Energy in this book; cstr_startup from the exercise Startup of a CSTR; non_ideal_cstr based on the paragraph Real CSTR Modeled as Two CSTRs with Interchange; and non_isothermal_plug_flow based on the example Production of Acetic Anhydride.

12.8 Safety†

Scaling up exothermic chemical reactions can be very tricky. Tables 12-5 and 12-6 give reactions that have resulted in accidents and their causes, respectively.8 The reader should review the case histories of these reactions to learn how to avoid similar accidents.

Table 12-5 Incidence of Batch-Process Accidents

Process Type |

Number of Incidents in U.K., 1962-1987 |

Polymerization |

64 |

Nitration |

15 |

Sulfurization |

13 |

Hydrolysis |

10 |

Salt formation |

8 |

Halogenation |

8 |

Alkylation (Friedel-Crafts) |

5 |

Amination |

4 |

Diazolization |

4 |

Oxidation |

2 |

Esterification |

1 |

Total: |

134 |

Source: Courtesy of J. Singh, Chemical Engineering, 92 (1997).

Table 12-6 Causes of Batch Reactor Accidents in Table 12-5

Cause |

Contribution, % |

Lack of knowledge of reaction chemistry |

20 |

Problems with material quality |

9 |

Temperature-control problems |

19 |

Agitation problems |

10 |

Mis-charging of reactants or catalyst |

21 |

Poor maintenance |

15 |

Operator error |

5 |

Source: B. Venugopal, Chemical Engineering, 54 (2002).

Runaway reactions are the most dangerous in reactor operation, and a thorough understanding of how and when they could occur is part of the chemical reaction engineer’s responsibility. The reaction in the last example in this chapter could be thought of as running away. Recall that as we moved down the length of the reactor, none of the cooling arrangements could keep the reactor from reaching an extremely high temperature (e.g., 800 K). In the next chapter, we study case histories of two runaway reactions. One is the nitroaniline explosion discussed in Example E13-2 and the other is Example E13-6, concerning the recent (2007) explosion at T2 Laboratories. See Example 13-7 and videos on T2 Laboratories’ explosion and what caused it to happen (http://www.csb.gov/t2-laboratories-inc-reactive-chemical-explosion and https://www.youtube.com/watch?v=C561PCq5E1g).

† Also see http://umich.edu/~safeche.

8 Courtesy of J. Singh, Chemical Engineering, 92 (1997) and B. Venugopal, Chemical Engineering, 54 (2002).

There are many resources available for additional information on reactor safety and the management of chemical reactivity hazards. Guidelines for managing chemical reactivity hazards and other fire, explosion, and toxic release hazards are developed and published by the Center for Chemical Process Safety (CCPS) of the American Institute of Chemical Engineers. CCPS books and other resources are available at www.aiche.org/ccps. For example, the book Essential Practices for Managing Chemical Reactivity Hazards, written by a team of industry experts, is also provided free of charge by CCPS on the site www.info.knovel.com/ccps. A concise and easy-to-use software program that can be used to determine the reactivity of substances or mixtures of substances, the Chemical Reactivity Worksheet, is provided by the National Oceanic and Atmospheric Administration (NOAA) for free on its Web site, www.noaa.gov.

The Safety and Chemical Engineering Education (SAChE) program was formed in 1992 as a cooperative effort between the AIChE, CCPS, and engineering schools to provide teaching materials and programs that bring elements of process safety into the education of undergraduate and graduate students studying chemical and biochemical products and processes. The SAChE Web site (www.sache.org) has a great discussion of reactor safety with examples as well as information on reactive materials. These materials are also suitable for training purposes in an industrial setting.

The following instruction modules are available on the SAChE Web site (www.sache.org).

1. Chemical Reactivity Hazards: This Web-based instructional module contains about 100 Web pages with extensive links, graphics, videos, and supplemental slides. It can be used either for classroom presentation or as a self-paced tutorial. The module is designed to supplement a junior or senior chemical engineering course by showing how uncontrolled chemical reactions in industry can lead to serious harm, and by introducing key concepts for avoiding unintended reactions and controlling intended reactions.

2. Runaway Reactions: Experimental Characterization and Vent Sizing: This instruction module describes the ARSST and its operation, and illustrates how this instrument can easily be used to experimentally determine the transient characteristics of runaway reactions, and how the resulting data can be analyzed and used to size the relief vent for such systems.

3. Rupture of a Nitroaniline Reactor: This case study demonstrates the concept of runaway reactions and how they are characterized and controlled to prevent major losses.

4. Seveso Accidental Release Case History: This presentation describes a widely discussed case history that illustrates how minor engineering errors can cause significant problems; problems that should not be repeated. The accident was in Seveso, Italy, in 1976. It was a small release of a dioxin that caused many serious injuries.

Note: Access is restricted to SAChE members and universities

Membership in SAChE is required to view these materials. Virtually all u.S. universities and many non-U.S. universities are members of SAChE—contact your university SAChE representative, listed on the SAChE Web site, or your instructor or department chair to learn your university’s username and password. Companies can also become members—see the SAChE Web site for details.

Certificate Program

SAChE also offers several certificate programs that are available to all chemical engineering students. Students can study the material, take an online test, and receive a certificate of completion. The following two certificate programs are of value for reaction engineering:

1. Runaway Reactions: This certificate focuses on managing chemical reaction hazards, particularly runaway reactions.

2. Chemical Reactivity Hazards: This is a Web-based certificate that provides an overview of the basic understanding of chemical reactivity hazards.

Many students are taking the certificate test online and put the fact that they successfully obtained the certificate on their résumés.

More information on safety is given in the Summary Notes and Professional Reference Shelf on the Web. Particularly study the use of the ARSST to detect potential problems. These will be discussed in Chapter 13 Professional Reference Shelf R13.1 on the CRE Web site.

dTdV0=0(rA)[ΔHRx(T)]-Ua(T-Ta)∑FiCPi=Qg-Qr∑FiCPi00000000000(S12-1)

In terms of conversion

dTdV=(rA)[ΔHRx(T)]-Ua(T-Ta)FA0(∑ΘjCPj+XΔCP)=Qg-QrFA0(∑ΘjCPj+XΔCP)0000000(S12-2)

2. The temperature dependence of the specific reaction rate is given in the form

k(T)0=0k(T1)exp[ER(1T1-1T)]0=0K(T1)exp[ER(T-T1TT1)]0000000(S12-3)

3. The temperature dependence of the equilibrium constant is given by van’t Hoff’s equation for ΔCP = 0

KP(T)0=0KP(T2)exp[ΔHoRxR(1T2-1T)]0000000000(S12-4)

4. Neglecting changes in potential energy, kinetic energy, and viscous dissipation, and for the case of no work done on or by the system, large coolant flow rates (˙mc

UAFA0(Ta-T)-X[ΔHoRx(TR)+ΔCP(T-TR)]=∑ΘjCPj(T-Ti0)00000000000(S12-5)

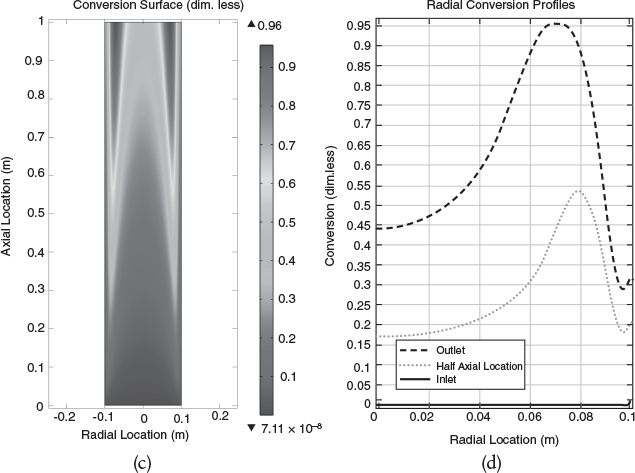

5. Multiple steady states

G(T)0=0(-ΔHoRx)(-rAVFA0)0=0(-ΔHoRx)(X)000(S12-6)

R(T)0=0CP0(1+k)(T-Tc)000000000(S12-7)

where K0=0UACP0FA00and0Tc=KTa+T01+K

6. When q multiple reactions are taking place and there are m species

7. Axial or radial temperature and concentration gradients. The following coupled, partial differential equations were solved using COMSOL:

and

CRE Web Site Materials

• Expanded Materials (http://www.umich.edu/~elements/5e/12chap/expanded.html)

1. COMSOL Example 12-8 (http://www.umich.edu/~elements/5e/12chap/expanded_ch12_radial.pdf)

2. Problems (http://www.umich.edu/~elements/5e/12chap/expanded_ch12_homeproblem.pdf)

• Learning Resources (http://www.umich.edu/~elements/5e/12chap/learn.html)

1. Summary Notes (http://www.umich.edu/~elements/5e/12chap/summary.html)

2. Self-Tests (http://www.umich.edu/~elements/5e/12chap/obj.html)

A. Exercises (http://umich.edu/~elements/5e/12chap/add.html)

B. i>clicker Questions (http://www.umich.edu/~elements/5e/12chap/iclicker_ch12_q1.html)

3. Web Module COMSOL Radial and Axial Gradients

(http://www.umich.edu/~elements/5e/12chap/comsol.html)

(http://www.umich.edu/~elements/5e/web_mod/radialeffects/index.htm)

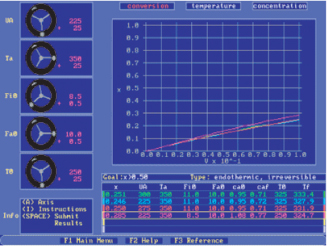

4. Interactive Computer Games

A. Heat Effects I

(http://www.umich.edu/~elements/5e/icm/heatfx1.html)

B. Heat Effects II

(http://www.umich.edu/~elements/5e/icm/heatfx2.html)

A. Example 12-2 (http://www.umich.edu/~elements/5e/software/aspen-example12-2.html) Formulated in AspenTech: Download AspenTech directly from the CRE Web site.

A step-by-step AspenTech tutorial is given on the CRE Web site.

B. Example CD 12-1 (http://www.umich.edu/~elements/5e/12chap/learn-cd12-1.html) ΔHRx(T) for Heat Capacities Expressed as Quadratic Functions of Temperature

C. Example CD 12-2 (http://www.umich.edu/~elements/5e/12chap/learn-cd12-2.html) Second-Order Reaction Carried Out Adiabatically in a CSTR

6. PFR/PBR Solution Procedure for a Reversible Gas-Phase Reaction (http://www.umich.edu/~elements/5e/12chap/learn-pfrpbr.html)

• Living Example Problem (http://www.umich.edu/~elements/5e/12chap/live.html)

1. Example T12-2 Algorithm for a PFR/PBR

2. Example 12-1 Isomerization of Normal Butane with Heat Exchange

3. Example 12-2 Production of Acetic Anhydride

4. Example 12-2Asp AspenTech Formulation

5. Example 12-3 Production of Propylene Glycol in an Adiabatic CSTR

6. Example 12-4 CSTR with Cooling Coil

7. Example 12-5 Parallel Reaction in a PFR with Heat Effects

8. Example 12-6 Multiple Reactions in a CSTR

9. Example 12-7 Complex Reactions

10. Example W12-8 COSMOL Radial Effects in a Tubular Reactor

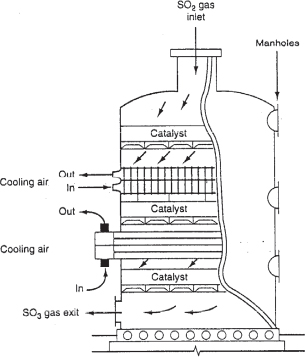

11. Example R12-1 Industrial Oxidation of SO2

12. Example 12-T12-3 PBR with Variable Coolant Temperature, Ta

• FAQs (Frequently Asked Questions (http://www.umich.edu/~elements/5e/12chap/faq.html)

• Professional Reference Shelf (http://www.umich.edu/~elements/5e/12chap/prof.html)

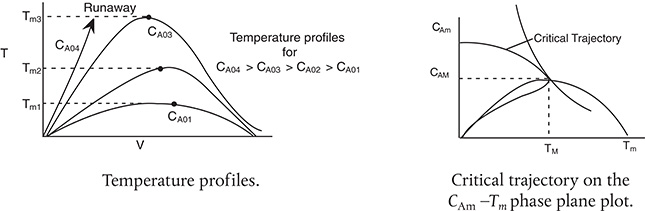

R12.1 Runaway in CSTR (http://www.umich.edu/~elements/5e/12chap/prof-runawayCSTR.html) and Plug-Flow Reactors (http://www.umich.edu/~elements/5e/12chap/prof-runawayPFR.html) Phase Plane Plots. We transform the temperature and concentration profiles into a phase plane.

The trajectory going through the maximum of the “maxima curve” is considered to be critical and therefore is the locus of the critical inlet conditions for CA and T corresponding to a given wall temperature.

R12.2 Steady-State Bifurcation Analysis (http://www.umich.edu/~elements/5e/12chap/prof-steady.html). In reactor dynamics, it is particularly important to find out if multiple stationary points exist or if sustained oscillations can arise.

R12.3 Heat Capacity as a Function of Temperature

(http://www.umich.edu/~elements/5e/12chap/pdf/CD-Ch08-VariableHeatCapacities.pdf). Combining the heat of reaction with the quadratic form of the heat capacity

CPi0=0αi+βTi+γT2i

we find that

Example 12-2 is reworked on the PRS for the case of variable heat capacities.

R12.4 Manufacture of Sulfuric Acid (http://www.umich.edu/~elements/5e/12chap/pdf/sulfuricacid.pdf). The details of the industrial oxidation of SO2 are described. Here, the catalyst quantities, the reactor configuration, and operating conditions are discussed, along with a model to predict the conversion and temperature profiles.

Questions and Problems

The subscript to each of the problem numbers indicates the level of difficulty: A, least difficult; D, most difficult.

In each of the questions and problems, rather than just drawing a box around your answer, write a sentence or two describing how you solved the problem, the assumptions you made, the reasonableness of your answer, what you learned, and any other facts that you want to include. See Preface Section G.2 for additional generic parts (x), (y), and (z) to the home problems.

Before solving the problems, state or sketch qualitatively the expected results or trends.

Questions

Q12-1A i>clicker. Go to the Web site (http://www.umich.edu/~elements/5e/12chap/iclicker_ch12_q1.html) and view five i>clicker questions. Choose one that could be used as is, or a variation thereof, to be included on the next exam. You also could consider the opposite case: explaining why the question should not be on the next exam. In either case, explain your reasoning.

Q12-2A Review Figure 12-13. Use this figure to write a few sentences (or at least draw on analogy) explaining why, when you strike the head of a safety match slowly on its pumice with little pressure, it may heat up a little, but does not ignite, yet when you put pressure on it and strike it rapidly, it does ignite. Thanks to Oscar Piedra-hita, Medellín, Colombia.

Q12-3A Read over the problems at the end of this chapter. Make up an original problem that uses the concepts presented in this chapter. To obtain a solution:

(a) Make up your data and reaction.

(b) Use a real reaction and real data. See Problem P5-1A for guidelines.

(c) Prepare a list of safety considerations for designing and operating chemical reactors. (See www.sache.org and www.siri.org/graphics.) The August 1985 issue of Chemical Engineering Progress may be useful for part (c).

Computer Simulations and Experiments

We will use the Living Example on the CRE Web site extensively to carry out simulations. Why carry out simulations to vary the parameters in the Living Example Problems? We do it in order to

• Get a more intuitive feel reactor system.

• Gain insight about the most sensitive parameters (e.g., E, KC) and how they affect outlet conditions.

• Learn how reactors are affected by different operating conditions.

• Simulate dangerous situations such as potential runaway reactions.

• Compare the model and parameters with experimental data.

• Optimize the reaction system.

P12-1A (a) LEP Table 12-2: Exothermic Reaction with Heat Exchange

Download the Polymath, MATLAB, or Wolfram codes for the algorithm and data given in Table T12-2 for the exothermic gas phase reversible reaction

given on the Web in the Living Example Problems (LEPs).

Vary the following parameters in the ranges shown in parts (i) through (xi). Write a paragraph describing the trends you find for each parameter variation and why they look the way they do. Use the base case for parameters not varied. The feedback from students on this problem is that one should use Wolfram on the Web in the LEP T12-2 as much as possible to carry out the parameter variations. For each part, write two or more sentences describing the trends.

Wolfram

(i)00010,000<EA<40,000

(ii)00020<CP1<60

(iii)000-30,000<ΔHoRx<-10,000

(iv)000FA0:1≤FA0≤80mol/s

(v)000Θ1:0.5≤ΘI≤4

(vi)000Uapb:0.1≤Uapb≤0.8ca1kg⋅s⋅K

(vii)000⋅mc:1≤⋅mc≤10000g/s

(viii) For the base case parameters, at what value of ΘI do the profiles of Xe and X separate, and why do they separate? Next set ΘI = 1.2 and vary α and describe what you find.

(ix) At what value of ΘI does the temperature start at 330 K and only decrease down the reactor?

(x) Starting with the base case, determine which parameter when changed only a small amount most dramatically affects the conversion and temperature profiles.

(xi) What parameter separates X and Xe the most?

(xii) Write a conclusion about what you found in your experiments (i) through (xi).

Polymath

(xiii) Vary T0: 310 K ≤ T0 ≤ 350 K and write a conclusion.

(xiv) Vary Ta: 300 K ≤ Ta ≤ 340 K and write a conclusion.

(xv) Repeat (i) for countercurrent coolant flow.

Hint: In analyzing the trends it might be helpful to plot X, Xe, and p as a function of W on the same graph and T and Ta as a function of W on the same graph.

(xvi) Repeat this problem for the case of constant Ta and adiabatic operation, and describe the most dramatic affect you find.

(b) Example 12-1: Butane Isomerization

Wolfram Co-current

(i) What parameter value brings T and Ta profiles close together?

(ii) What parameter when varied separates X and Xe the most?

(iii) What parameter keeps the X and Xe profiles the closest together?

(iv) The pump that circulates coolant flow can deliver a maximum flow of 500 kg/h. Due to design limitations, you need to maintain the exit reactor temperature below 325 K. Which thermal property of coolant will you change, and what is the new value? What would be the effect on conversion?

(v) For this reaction, on the Internet, you found different values of heat of reaction. How does heat of reaction affect conversion? What value of ΔHoRx

(vi) Write a conclusion about what you found in your experiments in (i) through (v).

Polymath Co-current

(vii) Let Qg0=0rAΔHRx0and0Qr0=0Ua0(T-Ta),

(viii) Vary the coolant flow rate (0<⋅mc<2,0000kg/h)

(ix) What is the entering value of the temperature Ta0 of the heat exchanger fluid below which the reaction will never “ignite"?

(x) Suppose the value of the equilibrium constant and heat of reaction were measured incorrectly and were found to be KC = 1,000 mol/dm3 at 330 K and HRx = -20,000 kJ/mol . How would your results change with regard to the original case?

(xi) Vary some of the other parameters and see if you can find unsafe operating conditions.

(xii) Plot Qr and Ta as a function of V necessary to maintain isothermal operation.

Polymath Countercurrent

(xiii) Describe and explain what happens to the X and Xe profiles as you vary ΔHRx.

(xiv) Describe what happens to the temperature profile T and Ta as you vary FA0.

(xv) Compare the variations in the profiles for X, Xe, T, and Ta when you change the parameter values for all four cases: adiabatic, countercurrent exchange, co-current exchange, and constant Ta. What parameters when changed only a small amount dramatically change the profiles?

(xvi) The heat exchanger is designed for a maximum temperature of 370 K. Which parameter will you vary so that at least 75% conversion is still achieved while maintaining temperature under safe limit?

(c) Example 12-2: Production of Acetic Anhydride-Endothermic Reaction Wolfram

(i) What parameter value when increased or decreased causes the reaction to die out the most quickly near the reactor entrance?

(ii) Which parameter, when varied most, drastically changes the profiles?

(iii) Adiabatic: How does the conversion change as heat capacity of A is increased?

(iv) Constant Ta: You find that conversion has decreased after 6 months of operation. You checked the flow rate and material properties and found that these values have not changed. Which parameter would have changed?

(v) Write two conclusions of what you learned from your experiments (i) through (iv).

Polymath

(vi) Let Qg0=0rAΔHRx0and0Qr0=0Ua(T-Ta),

(vii) Fix the reactor volume at 0.5 m3 and the entrance conditions at (T0 = 1050 K, Ta0 = 1250 K), and then make a table, Xe, X, Ta, and T for each of the heat exchange cases. Change the inlet conditions and determine which heat exchanger case gives the greatest differences in the conversion.

(viii) Repeat (vi) for V = 5 m3.

(ix) Plot Qg, Qr, and -rA versus V for all four cases on the same figure and describe what you find.

(x) For each of the four heat exchanger cases, investigate the addition of an inert I with a heat capacity of 50 J/mol · K, keeping FA0 constant and letting the other inlet conditions adjust accordingly (e.g., ε).

(xi) Vary the inert molar flow rate (i.e., ΘI, 0.0 < ΘI < 3.0 mol/s). Plot X and analyze versus ΘI.

(xii) Finally, vary the heat-exchange fluid temperature Ta0 (1,000 K < Ta0 < 1350 K). Write a paragraph describing what you find, noting interesting profiles or results.

(d) Example 12-2: AspenTech Formulation. Repeat Example 12-2 using AspenTech

(e) Example 12-3: Production of Propylene Glycol in a CSTR

Wolfram

(i) Vary activation energy (E) and find the values of E for which there are at least two solutions.

(ii) Vary the flow rate of FB0 to find the temperature at which the conversion is 0.8.

(iii) What is the operating range of inlet temperatures such that at least one steady state solution exists while maintaining the reactor temperature below 640°R? Describe how your answers would change if the molar flow rate of methanol were increased by a factor of 4.

(f) Example 12-4: CSTR with a Cooling Coil

Wolfram

(i) Explore how variation in activation energy (E) and heat of reaction, at reference temperature (ΔHoRx),

Polymath

(ii) The space time was calculated to be 0.01 minutes. Is this realistic? Decrease υ0 and both reaction rate constants by a factor of 100 and describe what you find.

(iii) Use Figure E12-3.2 and Equation (E12-4.4) to plot X versus T to find the new exit conversion and temperature.

(iv) Other data on the Jofostan chemical engineering Web site show ΔHoRx0=0-38,7000Btu/lb-mol0and0ΔCP0=0290Btu/lb-mol/F∘.

(v) Make a plot of conversion as a function of heat exchanger area. [0 < A < 200 ft2] and write a conclusion.

(g) Example 12-5: Parallel Reactions in a PFR with Heat Effects

Wolfram

(i) What should be the initial concentration of A so that the company can produce equal flow rates of B and C? Write a conclusion.

(ii) You need to provide heat transfer coefficient value to a company who will design heat exchanger for this reaction. What should be the optimum value so that selectivity of B is maximum at the end of reactor with 100% conversion of A?

Polymath

(iii) Why is there a maximum in temperature? How would your results change if there is a pressure drop with α = 1.05 dm-3?

(iv) What if the reaction is reversible with KC = 10 at 450 K?

(v) How would the selectivity change if Ua is increased? Decreased?

(h) Example 12-6: Multiple Reactions in a CSTR (Use the LEP)

Wolfram

(i) What is the maximum coolant temperature that can be kept so that at least one steady-state solution exits?

(ii) What is the operating range for inlet temperature of A for obtaining a steady-state solution?

(iii) Vary Ua between 10,000 and 80,000, and describe how the number of steady-state solutions changes.

(iv) Write a conclusion from carrying out experiments (i) through (iii).

(i) Example 12-7: Complex Reactions—Safety

Wolfram

(i) Co-current: Explore the temperature and molar flow profile when there is a pressure drop in the reactor. What will be the flow rate of product when pressure drop is 50%?

(ii) Co-current: Which parameter will you vary so that selectivity of C is equal to 1? What is the parameter value?

(iii) Constant Ta: How does the overall heat transfer coefficient affect the flow rate of product? Should it be kept minimum or maximum? Explain.

(iv) Constant Ta: Which are the variables that have virtually no effect on the profiles? Explain the reason.

(v) Adiabatic: You want to save capital cost by using a smaller volume reactor, i.e., 5 dm3 instead of 10 dm3. Which parameters you will vary to achieve exit reactant and product flow rates same as base case?

(vi) Write a conclusion of what you learned in experiments (i) through (v).

Polymath

(vii) Plot Qg and Qr as a function of V. How can you keep the maximum temperature below 700 K? Would adding inerts help and if so what should the flow rate be if CPI=100ca1/mo1/K?

(viii) Look at the Figures. What happened to species D? What conditions would you suggest to make more species D?

(ix) Make a table of the temperature (e.g., maximum T, Ta) and molar flow rates at two or three volumes, comparing the different heat-exchanger operations.

(x) Why do you think the molar flow rate of C does not go through a maximum? Vary some of the parameters to learn if there are conditions where it goes through a maximum. Start by increasing FA0 by a factor of 5.

(xi) Include pressure in this problem. Vary the pressure-drop parameter (0<αpb<0.09990dm-3)

(j) Review the steps and procedure by which we derived Equation (12-5) and then, by analogy, derive Equation (12-35).

(k) CRE Web site SO2 Example PRS-R12.4-1. Download the SO2 oxidation LEP R12-1. How would your results change if (1) the catalyst particle diameter were cut in half? (2) The pressure were doubled? At what particle size does pressure drop become important for the same catalyst weight, assuming the porosity doesn’t change? (3) You vary the initial temperature and the coolant temperature? Write a paragraph describing what you find.

(l) SAChE . Go to the SAChE Web site, www.sache.org. Your instructor or department chair should have the username and password to enter the SAChE Web site in order to obtain the modules with the problems. On the left-hand menu, select “SAChE Products.” Select the “All” tab and go to the module entitled, “Safety, Health and the Environment” (S, H & E). The problems are for KINETICS (i.e., CRE). There are some example problems marked “K” and explanations in each of the above S, H & E selections. Solutions to the problems are in a different section of the site. Specifically look at: Loss of Cooling Water (K-1), Runaway Reactions (HT-1), Design of Relief Values (D-2), Temperature Control and Runaway (K-4) and (K-5), and Runaway and the Critical Temperature Region (K-7). Go through the K problems and write a paragraph on what you have learned.

P12-2B (a) COMSOL

Use the COMSOL LEP on the Web site to explore radial effects in a tubular reactor. The Expanded Material on the Web site describes this LEP in detail (http://www.umich.edu/~elements/5e/12chap/expanded_ch12_radial.pdf). Tutorials on how to access and use COMSOL can be found at http://www.umich.edu/~elements/5e/12chap/comsol.html.

(i) Vary the heat transfer coefficient, U, and observe the effect on both the conversion and temperature profiles. Why is there an effect of U on the profiles at low values of U, but not at higher values of U?

(ii) What is the effect of thermal conductivity on the conversion? Should it be minimized or maximized?

(iii) What parameter would you vary so that the maximum of the radial conversion profile becomes 1? What is the value of that parameter?

(iv) How would your profiles change if the velocity profile was changed to plug flow (U = U0)? Based on your observations, which of the two profiles, viz., laminar flow and plug flow, would you recommend for a larger conversion? How does the change in velocity profile make an effect in the temperature profile?

(v) Intuitively, how do you expect the radial conversion to vary with diffusion coefficient? Explain the reason behind your intuition. Verify this by varying the diffusion coefficient. Investigate axial and radial conversion and write two conclusions.

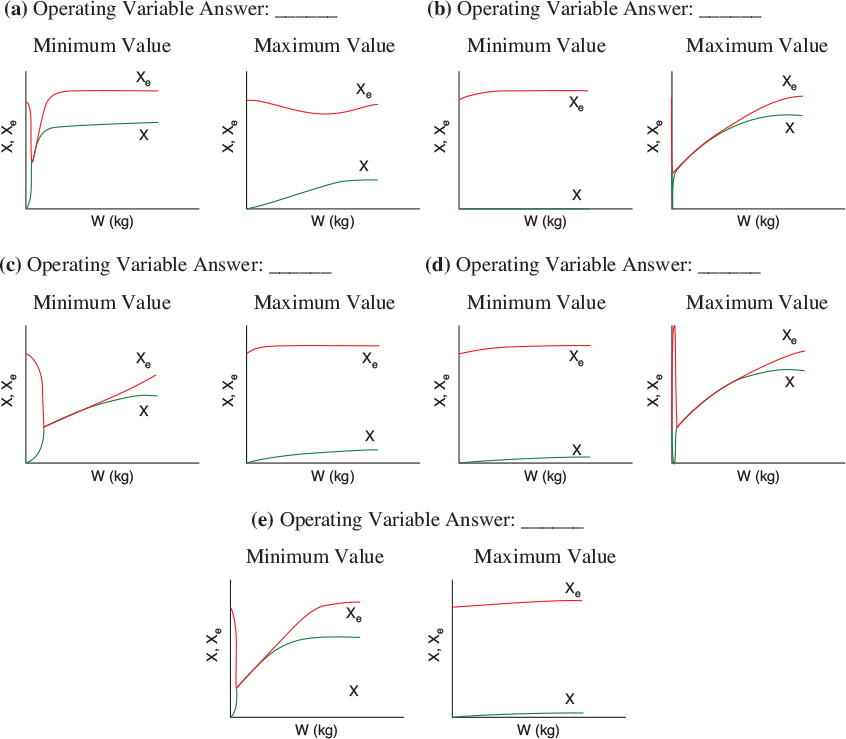

P12-3B Computer Experiments on a PFR for Reaction in Table 12-2.2. In order to develop a greater understanding of the temperature effects in PBRs, load the Living Example Problem Table 12-2, LEP T12-2, from the Web site to learn how changing the different parameters changes the conversion and temperature profiles.

This is a Sherlock Holmes Problem. Starting with the base case, one, and only one, parameter was varied between its maximum and minimum values to give the following figures. You need to decide what operating variable (e.g., T0) property value (e.g.,CPA),

K1,E,R,CT0,Ta,T0,T1,T2,KC2,ΘB,ΘI,ΔHoRx,CPA,CPB,CPC,Ua,pb

Interactive Computer Games

P12-4a Download the Interactive Computer Games (ICG) from the CRE Web site. Play the game, and then record your performance number for the module, which indicates your mastery of the material. Note: For simulation (b), only do the first three reactors, as reactors 4 and above do not work because of the technician tinkering with them.

(a) ICG Heat Effects Basketball 1 Performance #___________.

(b) ICG Heat Effects Simulation 2 Performance #___________.

Problems

P12-5C Safety Problem. The following is an excerpt from The Morning News, Wilmington, Delaware (August 3, 1977): “Investigators sift through the debris from blast in quest for the cause [that destroyed the new nitrous oxide plant]. A company spokesman said it appears more likely that the [fatal] blast was caused by another gas—ammonium nitrate—used to produce nitrous oxide.” An 83% (wt) ammonium nitrate and 17% water solution is fed at 200°F to the CSTR operated at a temperature of about 510°F. Molten ammonium nitrate decomposes directly to produce gaseous nitrous oxide and steam. It is believed that pressure fluctuations were observed in the system and, as a result, the molten ammonium nitrate feed to the reactor may have been shut off approximately 4 min prior to the explosion.

Assume that at the time the feed to the CSTR stopped, there was 500 lbm of ammonium nitrate in the reactor. The conversion in the reactor is believed to be virtually complete at about 99.99%.

Additional information (approximate but close to the real case):

ΔHoRx=-3360Btu/1bm0ammonium0nitrate0at0500F∘(constant)0000CP0=00.380Btu/1bm0ammonium0nitrate⋅F∘0000CP0=00.470Btu/1bm0of0steam⋅F∘-rAV0=0KCAV0=0KMVV0=0KM(1bm/h)

where M is the mass of ammonium nitrate in the CSTR (lbm) and k is given by the relationship below.

T (°F) |

510 |

560 |

k (h-1) |

0.307 |

2.912 |

The enthalpies of water and steam are

HW(200oF)0=01680Btu/1bmHg(500oF)0=012020Btu/1bm

(a) Can you explain the cause of the blast? Hint: See Problem P13-3B.

(b) If the feed rate to the reactor just before shutoff was 310 lbm of solution per hour, what was the exact temperature in the reactor just prior to shutdown? Hint: Plot Qr and Qg as a function of temperature on the same plot.

(c) How would you start up or shut down and control such a reaction? (Hint: See Problem P13-2B.)

(d) Explore this problem and describe what you find. For example, add a heat exchanger UA (T - Ta), choose values of UA and Ta, and then plot R(T) versus G(T)?

(e) Discuss what you believe to be the point of the problem. The idea for this problem originated from an article by Ben Horowitz.

P12-6B The endothermic liquid-phase elementary reaction

A + B → 2C

proceeds, substantially, to completion in a single steam-jacketed, continuous-stirred reactor (Table P12-6B). From the following data, calculate the steady-state reactor temperature:

Reactor volume: 125 gal

Steam jacket area: 10 ft2

Jacket steam: 150 psig (365.9°F saturation temperature)

Overall heat-transfer coefficient of jacket, U: 150 Btu/h · ft2 · °F

Agitator shaft horsepower: 25 hp

Heat of reaction, ΔHoRx0=0+20,000

TABLE P12-6B FEED CONDITIONS AND PROPERTIES

Component |

|||

A |

B |

C |

|

Feed (lb-mol/hr) |

10.0 |

10.0 |

0 |

Feed temperature (°F) |

80 |

80 |

— |

Specific heat (Btu/lb-molº°F)* |

51.0 |

44.0 |

47.5 |

Molecular weight |

128 |

94 |

111 |

Density (lbm/ft3) |

63.0 |

67.2 |

65.0 |

* Independent of temperature. (Ans: T = 199°F)

(Courtesy of the California Board of Registration for Professional & land surveyors.)

P12-7B Use the data in Problem P11-4A for the following reaction. The elementary, irreversible, organic liquid-phase reaction

A+B → C+I

is carried out in a flow reactor. An equal molar feed in A and B enters at 27°C, and the volumetric flow rate is 2 dm3/s and CA0 = 0.1 kmol/m3.

HoA(243K)=−20kcal/mol, H0B(273K)=−15kcal.mol,H0C(273K)=−41kcal/molCPA=CPB=15cal/mol⋅K CPc=cal/mol⋅Kk=0.01dm3mol⋅sat 300 K E=10.000 cal/molUa=20cal/m3/s/K ˙mc=50g/sTa0=450K CPcool=1cal/g/K

(a) Calculate the conversion when the reaction is carried out adiabatically in one 500-dm3 CSTR and then compare the results with the two adiabatic 250-dm3 CSTRS in series.

The reversible reaction (part (d) of P11-4a) is now carried out in a PFR with a heat exchanger. Plot and then analyze X, Xe, T, Ta, Qr, Qg, and the rate, -rA, for the following cases:

(b) Constant heat-exchanger temperature Ta

(c) Co-current heat exchanger Ta (Ans.: At V = 10 m3 then X = 0.36 and T = 442 K)

(d) Countercurrent heat exchanger Ta (Ans.: At V = 10 m3 then X = 0.364 and T = 450 K)

(e) Adiabatic operation

(f) Make a table comparing all your results (e.g., X, Xe, T, Ta). Write a paragraph describing what you find.

(g) Plot Qr and Ta as a function of V necessary to maintain isothermal operation.

P12-8A The gas-phase reversible reaction as discussed in P11-7B

A⇄B

is now carried out under high pressure in a packed-bed reactor with pressure drop. The feed consists of both inerts I and species A with the ratio of inerts to the species A being 2 to l. The entering molar flow rate of A is 5 mol/min at a temperature of 300 K and a concentration of 2 mol/dm3. Work this problem in terms of volume. Hint: V=W/ρB,rA=ρBr′A

Additional information:

FA0=5.0 mol/minT0=300 KΔHRX=−20,000 cal/molαρb=0.02 dm−3CA0=2mol/dm3T1=300 KKC=1,000 at 300 KCoolant¯C1=2 CA0K1=0.1min−2at 300 KCPB=160 cal/mol/K⋅mC=50 mol/minCP1=18 cal/mol/KCPA=160 cal/mol/KE =10,000cal/molUa=150 cal/dm3/min/KTa0=300 KV=40dm3PB= kg/dm3CPcool=20 cal/mol/K

Plot and then analyze X, Xe, T, Ta, and the rate (−rA) profiles in a PFR for the following cases. In each case, explain why the curves look the way they do.

(a) Co-current heat exchange

(b) Countercurrent heat exchange (Ans.: When V = 20 dm3 then X = 0.86 and Xe = 0.94)

(c) Constant heat-exchanger temperature Ta

(d) Compare and contrast each of the above results and the results for adiabatic operation (e.g., make a plot or a table of X and Xe obtained in each case).

(e) Vary some of the parameters, e.g., (0 < ΘΙ < 10) and describe what you find.

(f) Plot Qr and Ta as a function of V necessary to maintain isothermal operation.

P12-9a Algorithm for reaction in a PBR with heat effects and pressure drop

The elementary gas-phase reaction

A + B ⇄ 2C

in P11-8B is now continued and carried out in packed-bed reactor. The entering molar flow rates are FA0 = 5 mol/s, FB0 = 2FA0, and FI = 2FA0 with CA0 = 0.2 mol/dm3. The entering temperature is 325 K and a coolant fluid is available at 300 K.

Additional information:

CPA=CPB=CPC=20 cal/mol/Kk= 0.0002dm6kg⋅mol⋅s@300KCPA=18 cal/mol/Kα=0.00015kg−1Ua=320 Cals⋅m3⋅KE=25kcalmol˙mc=18 mol/sρb=1400kgm3ΔHRX=20kcalmol@298KCPCool=18 cal/mol(coolant)Kc=1000@305K

Plot X, Xe, T, Ta, and −rA down the length of the PFR for the following cases:

(a) Co-current heat exchange

(b) Countercurrent heat exchange

(c) Constant heat-exchanger temperature Ta

(d) Compare and contrast your results for (a), (b), and (c) along with those for adiabatic operation and write a paragraph describing what you find.

P12-10B Use the data and reaction in Problems P11-4A and P12-7A for the following reaction:

A+B → C+D

(a) Plot and then analyze the conversion, Qr, Qg, and temperature profiles up to a PFR reactor volume of 10 dm3 for the case when the reaction is reversible with KC = 10 m3/kmol at 450 K. Plot and then analyze the equilibrium conversion profile.

(b) Repeat (a) when a heat exchanger is added, Ua = 20 cal/m3/s/K, and the coolant temperature is constant at Ta = 450 K.

(c) Repeat (b) for both a co-current and a countercurrent heat exchanger. The coolant flow rate is 50 g/s, CPc=1cal/g⋅K

(d) Plot Qr and Ta as a function of V necessary to maintain isothermal operation.

(e) Compare your answers to (a) through (d) and describe what you find. What generalizations can you make?

(f) Repeat (c) and (d) when the reaction is irreversible but endothermic with ΔHoRx=6,000

P12-11B Use the reaction data in Problem P11-4a and P12-7a for the case when heat is removed by a heat exchanger jacketing the reactor. The flow rate of coolant through the jacket is sufficiently high that the ambient exchanger temperature is constant at Ta = 50°C.

A+B → C

(a) (1) Plot and then analyze the temperature conversion, Qr, and Qg profiles for a PBR with

Uaρb=0.08Js⋅kg-cat⋅K

where

ρb=bulk density of the catalyst(kg/m3)a=heat-exchange area per unit volume of reactor(m2/m3)U=overall heat-transfer coefficient(J/s⋅m2⋅K)

(2) How would the profiles change if Ua/ρb were increased by a factor of 3000?

(3) If there is a pressure drop with α = 0.019 kg-1?

(b) Repeat part (a) for co-current and countercurrent flow and adiabatic operation with ˙mc=0.2kg/s,CPC=5,000J/kg K

(c) Find X and T for a “fluidized” CSTR with 80 kg of catalyst.

UA=500Js⋅K,ρb=1kg/m3

(d) Repeat parts (a) and (b) for W = 80.0 kg, assuming a reversible reaction with a reverse specific reaction rate of

kr=0.2exp[ErR(1450-1T1](dm6kg-cat⋅mo1⋅s);Er=51.4kI/mol

Vary the entering temperature, T0, and describe what you find.

(e) Use or modify the data in this problem to suggest another question or calculation. Explain why your question requires either critical thinking or creative thinking. See Preface Section G and http://www.umich.edu/~scps.

P12-12C Derive the energy balance for a packed bed membrane reactor. Apply the balance to the reaction in Problem P11-5B

A ⇄ B + C

for the case when it is reversible with KC = 1.0 mol/dm3 at 300 K. Species C diffuses out of the membrane with kC = 1.5 s-1.

(a) Plot and then analyze the concentration profiles for different values of Kc when the reaction is carried out adiabatically.

(b) Repeat part (a) when the heat transfer coefficient is Ua = 30 J/s·kg-cat·K with Ta = 50°C.

P12-13B Circle the correct answer.

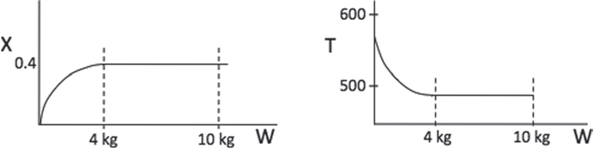

(a) The elementary reversible isomerization of A to B was carried out in a packed-bed reactor. The following profiles were obtained:

If the total entering volumetric flow rate remains constant, the addition of inerts to the feed stream will most likely

A) Increase conversion.

B) Decrease conversion.

C) Have no effect.

D) Insufficient information to tell

(b)

Which of the following statements are true?

A) The above reaction could be adiabatic.

B) The above reaction could be exothermic with constant cooling temperature.

C) The above reaction could be endothermic with constant heating temperature.

D) The above reaction could be second order.

(c) The conversion is shown below as a function of catalyst weight down a PBR.

Which of the following statements are false?

A) The reaction could be first-order endothermic and carried out adiabatically.

B) The reaction could be first-order endothermic and reactor is heated along the length with Ta being constant.

C) The reaction could be second-order exothermic and cooled along the length of the reactor with Ta being constant.

D) The reaction could be second-order exothermic and carried out adiabatically.

E) The reaction could be irreversible.

To view more conceptual problems similar to (a) - (c) above go to http://www.umich.edu/~ele-ments/5e/12chap/iclicker_ch12_q1.html.

P12-14A The irreversible reaction

A+B → C+D

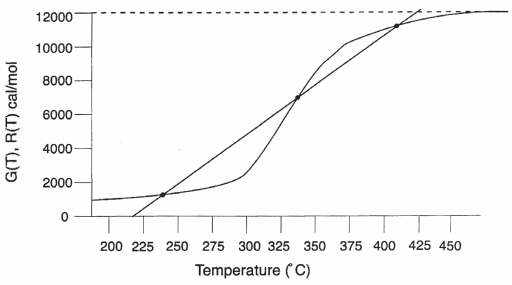

is carried out adiabatically in a CSTR. The “heat generated” G(T) and the “heat removed” R(T) curves are shown in Figure P12-14A.

(a) What is the ΔHRx of the reaction?

(b) What are the inlet ignition and extinction temperatures?

(c) What are all the temperatures in the reactor corresponding to the inlet ignition and extinction temperatures?

(d) What are the conversions at the ignition and extinction temperatures?

P12-15B The first-order, irreversible, exothermic liquid-phase reaction

A → B

is to be carried out in a jacketed CSTR. Species A and an inert I are fed to the reactor in equimolar amounts. The molar feed rate of A is 80 mol / min.

Additional information

Heat capacity of the inert: 30cal/mol⋅°Cτ=100 minHeat capacity ofA and B: 20 cal/mol⋅°CΔH°RX=−7500 cal/molUA: 8000 cal/min⋅°Ck=606 ×10−3 min−1at 350 KAmbient temperature, Ta:300 KE= 40,000 cal/mol⋅K

(a) What is the reactor temperature for a feed temperature of 450 K?

(b) Plot and then analyze the reactor temperature as a function of the feed temperature.

(c) To what inlet temperature must the fluid be preheated for the reactor to operate at a high conversion? What are the corresponding temperature and conversion of the fluid in the CSTR at this inlet temperature?

(d) Suppose that the fluid inlet temperature is now heated 5°C above the reactor temperature in part (c) and then cooled 20°C, where it remains. What will be the conversion?

(e) What is the inlet extinction temperature for this reaction system? (Ans.: T0 = 87°C.)

P12-16B The elementary reversible liquid-phase reaction

A ⇄ B

takes place in a CSTR with a heat exchanger. Pure A enters the reactor.

(a) Derive an expression (or set of expressions) to calculate G (T) as a function of the heat of reaction, equilibrium constant, temperature, and so on. Show a sample calculation for G (T ) at T = 400 K.

(b) What are the steady-state temperatures? (Ans.: 310, 377, 418 K.)

(c) Which steady states are locally stable?

(d) What is the conversion corresponding to the upper steady state?

(e) Vary the ambient temperature Ta and make a plot of the reactor temperature as a function of Ta, identifying the ignition and extinction temperatures.

(f) If the heat exchanger in the reactor suddenly fails (i.e., UA = 0), what would be the conversion and the reactor temperature when the new upper steady state is reached? (Ans.: 431 K.)

(g) What heat exchanger product, UA, will give the maximum conversion?

(h) Write a question that requires critical thinking and then explain why your question requires critical thinking. (Hint: See Preface Section G.)

(i) What is the adiabatic blowout flow rate, υ0 ?

(j) Suppose that you want to operate at the lower steady state. What parameter values would you suggest to prevent runaway, e.g., the upper SS?

Additional information

UA=3600 cal/min ⋅KE/R=20,000 KCPA=CPB=40 cal/mol⋅KV=10 dm3ΔH0RX=−80,000 cal/mol Aυ0=1 dm3/minKC=100 at 400 KFA0=10 mol/mink=1 min−1 at 400 KAmbient temperature, Ta=37°CFeed temperature, T0=37°C

P12-17B The reversible liquid phase reaction

A ⇄ B

is carried out in a 12-dm3 CSTR with heat exchange. Both the entering temperature, T0, and the heat exchange fluid, Ta, are at 330 K. An equal molar mixture of inerts and A enter the reactor.

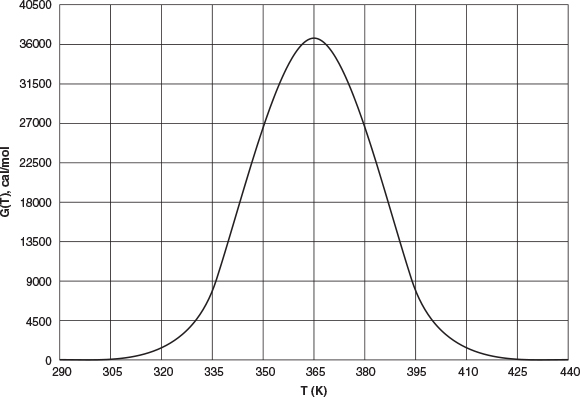

(a) Choose a temperature, T, and carry out a calculation to find G(T) to show that your calculation agrees with the corresponding G(T) value on the curve shown below at the temperature you choose.

(b) Find the exit conversion and temperature from the CSTR. X = ______ T = _____.

(c) What entering temperature T0 would give you the maximum conversion? T0 = _____ X = _____

(d) What would the exit conversion and temperature be if the heat-exchange system failed (i.e., U = 0)?

(e)Can you find the inlet ignition and extinction temperatures? If yes, what are they? If not, go on to the next problem.

(f) Use Preface Section G to ask another question.

Additional information

The G(T) curve for this reaction is shown below

CPA=CPB=100 cal/mol/K, CP1=150 cal/mol/Kk=0.001h−1at 300 Kwith E=30,000 cal/molFA0=10 mol/h, CA0=1 mol/dm3, υ0=10 dm3/hKC=5,000,000 at 300 KΔHRX=−42,000 cal/molUA=5000 cal/h/ K

P12-18C The elementary gas-phase reaction

2A ⇄ C

is carried out in a packed-bed reactor. Pure A enters the reactor at a 450-K flow rate of 10 mol/s, and a concentration of 0.25 mol/dm3. The PBR contains 90 kg of catalyst and is surrounded by a heat exchanger for which cooling fluid is available at 500 K. Compare the conversion achieved for the four types of heat exchanger operation: adiabatic, constant Ta, co-current flow, and countercurrent flow.

Additional information

α=0.019/kg−catCpc=20 J/mol/KUa/ρb=0.8 J/kg−cat⋅s⋅KFA0=10 mol/hΔHRX=−20,000J/molCA0=1 mol/dm3CPA=40 J/mol⋅Kυ0=10dm3/h

P12-19C A reaction is to be carried out in the packed-bed reactor shown in Figure P12-19C.

The reactants enter the annular space between an outer insulated tube and an inner tube containing the catalyst. No reaction takes place in the annular region. Heat transfer between the gas in this packed-bed reactor and the gas flowing countercurrently in the annular space occurs along the length of the reactor. The overall heat-transfer coefficient is 5 W/ m2 · K . Plot the conversion and temperature as a function of reactor length for the data given in reactor length for the data given in Problem P12-7B.

P12-20B The reaction

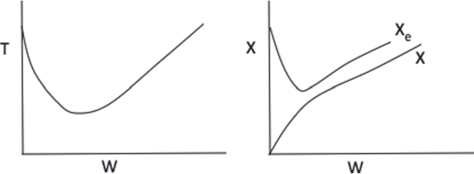

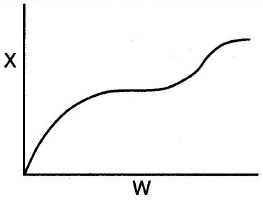

A + B ⇄ 2C

is carried out in a packed-bed reactor. Match the following temperature and conversion profiles for the four different heat-exchange cases: adiabatic, constant Ta, co-current exchange, and countercurrent exchange.

(a) Figure 1 matches Figure_____

(b) Figure 2 matches Figure_____

(c) Figure 3 matches Figure_____

(d) Figure 4 matches Figure_____

P12-21B The irreversible liquid-phase reactions

Reaction (1)A+B→2Cr1C=k1CCACBReaction (2)2B+C→Dr2D=k2DCBCC

are carried out in a PFR with heat exchange. The following temperature profiles were obtained for the reactor and the coolant stream:

The concentrations of A, B, C, and D were measured at the point down the reactor where the liquid temperature, T, reached a maximum, and they were found to be CA = 0.1, CB = 0.2, CC = 0.5, and CD = 1.5, all in mol/dm3. The product of the overall heat-transfer coefficient and the heat-exchanger area per unit volume, Ua, is 10 cal/s · dm3 · K. The entering molar flow rate of A is 10 mol/s.

CPA=CPB=CPC=30 cal/mol/KCPD=90 cal/mol/K, CP1=100 cal/mol/KΔHoRX1A=−50,000 cal/molAk1C=0.043dm3mol.s at 400KΔHoRX2B=+5000 cal/molBk2D=0.4dm3mol⋅sat 500K, with ER=5000 K

(a) What is the activation energy for Reaction (1)?

P12-22B The following elementary reactions are to be carried out in a PFR with a heat exchange with constant Ta:

2A+B→C ΔHRX1B=−10KJmol BA→D ΔHRX2A =+10kjmol AB+2C→E ΔHRX3C=−20kjmol C

The reactants all enter at 400 K. Only A and B enter the reactor. The entering concentration of A and B are 3 molar and 1 molar at a volumetric flow rate of 10 dm3/s.

Additional information

Ua=100J/dm3/s/Kk1A(400K)=1.0(dm3mol)2/sk2A(400K)=1.333S−1K3B(400K)=2(dm3mol)2/sCPA=10J/mol/KCPB=20 J/mol/KCPC=40 J/mol/KCPD=20J/mol/KCPE=100 J/mol/K

What constant coolant temperature, Ta, is necessary such that at the reactor entrance, i.e., V = 0, dTdV=0?

P12-23B The complex gas-phase reactions are elementary

(1) 2A⇆2B−r1A=k1A[C2A−CBKCA]ΔHRx1A=−20kj/moleA(2)2B+A→Cr2C=k2C[c2B CA]ΔHRx2B=+30kJ/mole B

and carried out in a PFR with a heat exchanger. Pure A enters at a rate of 5 mol/min, a concentration of 0.2 mol/dm3, and temperature 300 K. The entering temperature of an available coolant is 320 K.

Additional information

k1A1 = 50 dm3/mol · min@305 K with E1 = 8,000 J/mol

k2C2 = 4000 dm9/mol3 · min@310 K with E2 = 4,000 J/mol

KCA = 10 dm3/mol@315 K

Note: This is the equilibrium constant with respect to A in reaction 1 when using van Hoff’s equation, i.e., (S12-4),

Ua=200Jdm3⋅min KCPCool=10J/mol/KCPB=80J/mol/KCPC=100J/mol/K˙.mC=50g/minCPA=20J/mol/KR=8.31J/mol/K

The reactor volume is 10 dm3.

(a) Plot (FA, FB, FC) on one graph and (T and Ta) on another along the length of the reactor for adiabatic operation, heat exchange with constant Ta, and co-current and countercurrent heat exchange with variable Ta. Only turn in a copy of your code and output for co-current exchange.

Adiabatic operation

(b) What is the maximum temperature and at what reactor volume is it reached?

(c) At what reactor volume is the flow rate of B a maximum, and what is FBmax at this value?

Constant Ta

(d) What is the maximum temperature and at what reactor volume is it reached?

(e) At which reactor volume is the flow rate of B a maximum, and what is FBmax at this volume? Co-current exchange

(f) At what reactor volume does Ta become greater than T? Why does it become greater

Countercurrent exchange

(g) At what reactor volume does Ta become greater than T?

Hint: Guess Ta at entrance around 350 K.

P12-24B The elementary liquid-phase reactions

(1) A+ 2B → 2C

(2) A+C→ 2D

are carried out adiabatically in a 10 dm3 PFR. After streams A and B mix, species A enters the reactor at a concentration of CA0 = 2 mol/dm3 and species B at a concentration of 4 mol/dm3. The entering volumetric flow rate is 10 dm3/s.

Assuming you could vary the entering temperature between 300 K and 600 K, what entering temperture would you recommend to maximize the concentration of species C exiting the reactor? (±25°K). Assume all species have the same density.

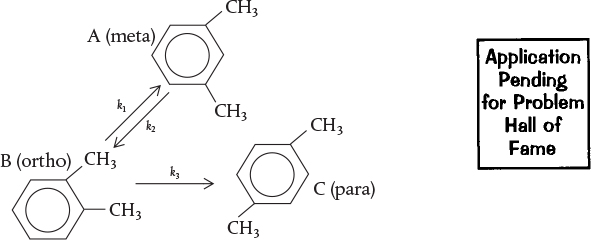

P12-25C Multiple reactions with heat effects. Xylene has three major isomers, m-xylene (A), o-xylene (B), and p-xylene (C). When m-xylene (A) is passed over a Cryotite catalyst, the following elementary reactions are observed. The reaction to form p-xylene is irreversible:

The feed to the reactor is pure m-xylene (A). For a total feed rate of 2 mol/min and the reaction conditions below, plot the temperature and the molar flow rates of each species as a function of catalyst weight up to a weight of 100 kg.

(a) Plot the concentrations of each of xylenes down the length (i.e., V) of a PBR.

(b) Find the lowest concentration of o-xylene achieved in the reactor.

(c) Find the maximum concentration of o-xylene in the reactor.

(d) Repeat part (a) for a pure feed of o-xylene (B). What is the maximum concentration of meta xylene and where does it occur in the reactor?

(e) Vary some of the system parameters and describe what you learn.

(f) What do you believe to be the point of this problem?

Additional information9

All heat capacities are virtually the same at 100 J/mol · K.

P12-26C Comprehensive problem on multiple reactions with heat effects. Styrene can be produced from ethylbenzene by the following reaction:

[J. Snyder and B. Subramaniam, Chem. Eng. Sci., 49, 5585 (1994)]. Ethylbenzene is fed at a rate of 0.00344 kmol/s to a 10.0-m3 PFR (PBR), along with inert steam at a total pressure of 2.4 atm. The steam/ethylbenzene molar ratio is initially, i.e., parts (a) to (c), 14.5 : 1 but can be varied.

Given the following data, find the exiting molar flow rates of styrene, benzene, and toluene along with SSt/BT for the following inlet temperatures when the reactor is operated adiabatically:

(a) T0 = 800 K

(b) T0 = 930 K

(c) T0 = 1100 K

(d) Find the ideal inlet temperature for the production of styrene for a steam/ethylbenzene ratio of 58:1. Hint: Plot the molar flow rate of styrene versus T0. Explain why your curve looks the way it does.

(e) Find the ideal steam/ethylbenzene ratio for the production of styrene at 900 K. Hint: See part (d).

(f) It is proposed to add a countercurrent heat exchanger with Ua = 100 kJ/m3/min/K, where Ta is virtually constant at 1000 K. For an entering stream to ethylbenzene ratio of 20, what would you suggest as an entering temperature? Plot the molar flow rates and SSt/BT.

(g) What do you believe to be the major points of this problem?

(h) Ask another question or suggest another calculation that can be made for this problem.

Additional information

Heat capacities

Methane 68 J/mol · K

Ethylene 90 J/mol·K

Benzene 201 J/mol · K

Toluene 249 J/mol · K

Styrene 273 J/mol · K

Ethylbenzene 299 J/mol·K

Hydrogen 30 J/mol · K

Steam 40 J/mol · K

9 Obtained from inviscid pericosity measurements.

ρ = 2137 kg/m3 of pelet

ϕ = 0.4

ΔHoRX1EB

ΔHoRX2EB

ΔHoRX3EB

Kp1=exp {b1+b2T+b3 ln (T)+[(b4T+b5) T +b6] T} atm with

b1=−17.34b4=−2.314×10−10K−3b2=−1.302×104Kb5=1.302×10−6K−2b3=5.051b6=−4.931×10−3K−1

The kinetic rate laws for the formation of styrene (St), benzene (B), and toluene (T), respectively, are as follows (EB = ethylbenzene).

r1St=ρ(1-(ϕ)exp(-0.08539-10,925KT)(PEB-PStPH2Kp1)(kmo1/m3⋅s)r2B=ρ(1-ϕ)exp(13.2392-25,000KT)(PEB)(kmo1/m3⋅s)r3T=ρ(1-ϕ)exp(0.2961-11,000KT)(PEBPH2)(kmo1/m3⋅s)

The temperature T is in Kelvin and Pi is in atm.

P12-27B The liquid-phase, dimer-quadmer series addition reaction

4 A → 2A2 → A4

can be written as

2A→A2-r1A=klAC2AΔHRxlA=-32.5kca1mo1A2A2→A4-r2A2=k2A2C2A2ΔHRx2A2=-27.5kca1mo1A2

and is carried out in a 10-dm3 PFR. The mass flow rate through the heat exchanger surrounding the reactor is sufficiently large so that the ambient temperature of the exchanger is constant at Ta = 315 K. The reactants enter at a temperature T0, of 300 K. Pure A is fed to the rector at a volumetric flow rate of 50 dm3/s and a concentration of 2 mol/dm3.

(a) Plot, compare, and analyze the profiles FA, FA , and FA down the length of the reactor up to 10 dm3.

(b) The desired product is A2 and it has been suggested that the current reactor may be too large. What reactor volume would you recommend to maximize FA ?

(c) What operating variables (e.g., T0, Ta) would you change and h2 w would you change them to make the reactor volume as small as possible and to still maximize FA ? Note any opposing factors in maximum production of A2. The ambient temperature and the inlet temperature must be kept between 0°C and 177°C.

Turn in your recommendation of reactor volume to maximize FA2

Supplementary Reading

1. An excellent development of the energy balance is presented in

ARIS, R., Elementary Chemical Reactor Analysis. Upper Saddle River, NJ: Prentice Hall, 1969, Chaps. 3 and 6.

FOGLER, JOSEPH, A Reaction Engineer’s Handbook of Thermochemical Data, Jofostan Press, Riça, Jofostan (2020).

2. Safety

CENTER FOR CHEMICAL PROCESS SAFETY (COPS), Guidelines for Chemical Reactivity Evaluation and Application to Process Design. New York: American Institute of Chemical Engineers (AIChE) 1995.

CROWL, DANIEL A., and JOSEPH F. LOUVAR, Chemical Process Safety: Fundamentals with Applications, 3rd ed. Upper Saddle River, NJ: Prentice Hall, 2011.

MELHEM, G. A., and H. G. FISHER, International Symposium on Runaway Reactions and Pressure Relief Design. New York: Center for Chemical Process Safety (CCPS) of the American Institute of Chemical Engineers (AIChE) and The Institution of Chemical Engineers, 1995.

See the Center for Chemical Process Safety (CCPS) Web site, www.aiche.org/ccps.

3. A number of example problems dealing with nonisothermal reactors may or may not be found in

BURGESS, THORNTON W., The Adventures of Jerry Muskrat. New York: Dover Publications, Inc., 1914.

FROMENT, G. F., and K. B. BISCHOFF, Chemical Reactor Analysis and Design, 3rd ed. New York: Wiley, 2010.

WALAS, S. M., Chemical Reaction Engineering Handbook of Solved Problems. Amsterdam: Gordon and Breach, 1995. See the following solved problems: Problem 4.10.1, page 444; Problem 4.10.08, page 450; Problem 4.10.09, page 451; Problem 4.10.13, page 454; Problem 4.11.02, page 456; Problem 4.11.09, page 462; Problem 4.11.03, page 459; Problem 4.10.11, page 463.

4. A review of the multiplicity of the steady state and reactor stability is discussed by

PERLMUTTER, D. D., Stability of Chemical Reactors. Upper Saddle River, NJ: Prentice Hall, 1972.

5. The heats of formation, Hi (T), Gibbs free energies, Gi (TR), and the heat capacities of various compounds can be found in

GREEN, DON W., and ROBERT H. PERRY, Perry’s Chemical Engineers’ Handbook, 8th ed. (Chemical Engineers Handbook). New York: McGraw-Hill, 2008.

LIDE DAVID R., CRC Handbook of Chemistry and Physics, 90th ed. Boca Raton, FL: CRC Press, 2009.