CHAPTER 13

![]()

Backup Power Systems

The utility electrical supply is vulnerable to interruption, momentary or long term, possibly lasting for days. Adverse weather, flooding, system overload, terrorist attacks, power-pole breakage due to intoxicated or texting motorists, and all sorts of other catastrophes can disrupt the utility connection so that the home is without power.

Backup Power for the Home

You can meet this challenge by installing a backup power system. It is required for health-care facilities, where continuity of power is essential for life support and ongoing operations. Schools, hotels, office buildings, and industrial facilities generally have backup power, but for the home, it is usually optional. A small propane-fueled generator in a dedicated building is shown in Figure 13-1.

FIGURE 13-1 A small high-end generator.

If you are located in an area that experiences cold weather in the winter and you depend on electricity to heat your house, you will definitely want backup power. If there is an outage that lasts more than a few hours and it coincides with a dip in the temperature, the cost of repairing burst water pipes in finished walls and ceilings may well exceed the cost of installed backup power. Another consideration is the ongoing need for electricity to power the water pump. (If you have a municipal or gravity system, this is not a problem.)

After evaluating your needs, if you decide to put in a backup system, there are a few decisions to be made. A very low-end backup power system would consist of nothing more than a gasoline generator that is rolled out of the garage and started up outside to supply limited plug-in capability during an outage.

At the other end of the scale is a large diesel-powered generator in a permanent, dedicated building, sized to carry the full load, with automatic starting and an automatic transfer switch. There are intermediate solutions that are less costly, require a human operator, or power less than the full load. In this chapter, we will look at some of the options. Throughout, it is essential to consider safety above all. Designing and building a backup power system involve some serious electrical work, so it is necessary to research the whole area thoroughly. Don’t hesitate to bring in a licensed electrician who specializes in such installations if you are unsure of some of the details.

A Transfer Switch Is Needed

First and foremost, we must emphasize that the electrical energy from the backup power supply must not be allowed to backfeed into the utility distribution system. If the backup power is connected to the entrance panel in order to supply premises loads or indeed if it is connected to any part of the electrical system inside or outside the building, there is the distinct possibility that it will backfeed through the service entrance conductors into the utility lines. Moreover, because this power is applied to the output lugs of the utility pole- or pad-mounted transformer, this normally step-down device will become a step-up transformer, energizing the power line to a high voltage level and endangering the lives of utility workers who have every reason to believe that they are working on lines that are at ground potential.

It is not sufficient to rely on the main breaker to provide the needed isolation. The problem is that while the backup power is running, someone may come along and reset that switch. The isolation has to be absolutely failsafe because human lives depend on it.

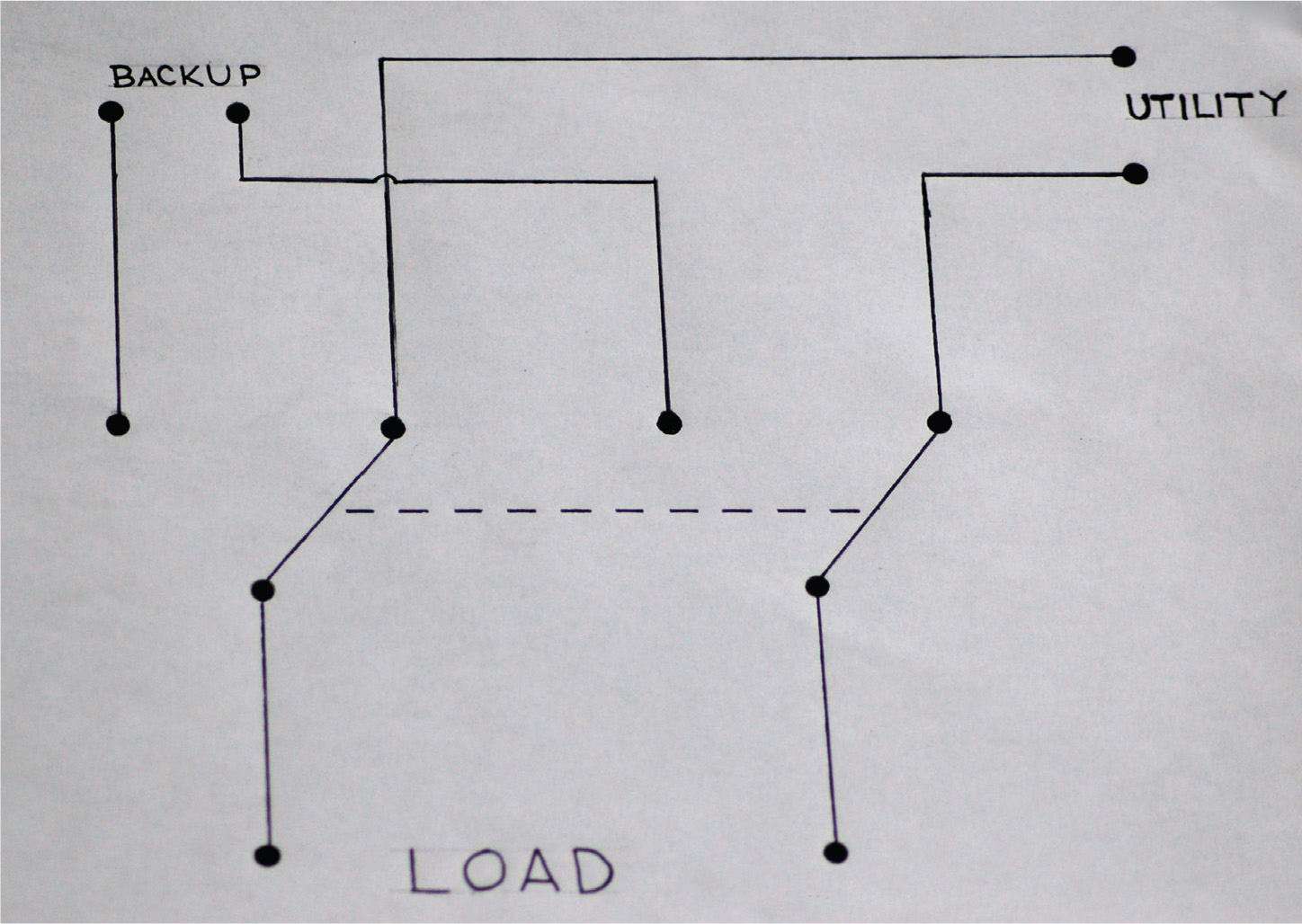

Totally reliable isolation of the backup power from the utility transformer and lines is provided by a transfer switch. A schematic diagram of such a switch is shown in Figure 13-2.

FIGURE 13-2 This transfer switch schematic shows the load (premises wiring) connected to the utility supply.

For a 120/240-volt single-phase service, this is essentially a double-pole, double-throw heavy-duty switch that is sized to carry the electrical load. It is a physical impossibility, when the transfer switch has been wired in place properly, for the entrance panel to be connected simultaneously to the backup power source and to the service-entrance conductors.

The transfer switch is usually in a separate enclosure from the entrance panel. The enclosure may be for indoor or outdoor use, and it may throw the entire premises load over to the backup power source or it may connect only selected circuits. The second of these types, shown in Figure 13-3, is often used because it is less expensive, and quite often, the backup power unit is not capable of powering the entire premises load. To attempt to do so would either stall the engine or trip an overcurrent device.

FIGURE 13-3 The automatic transfer switch often performs other functions, such as sensing a utility outage, starting the generator, and returning to utility power after the outage has ended.

An automatic transfer switch may include circuitry that detects a utility outage. Ignoring short-duration transients, it powers up the backup unit, which includes a starting battery and charging system. The backup unit is allowed to run a prescribed amount of time so that the engine warms up and output voltage stabilizes, whereupon the transfer switch is automatically thrown, and the building is powered up.

After utility power is restored and has stabilized, the transfer switch reconnects the entrance panel to the normal utility supply. The backup power-source engine is allowed to run a minute or so to cool down, and then it shuts down.

If only selected circuits are to be connected to the backup power source, they should be chosen so that essential loads have power. The electrical power necessary to heat the building, selected lighting, a motorized overhead garage door, water pump, any medical or life-support equipment, and other loads of your choosing should be included.

Fuel Options

The backup power supply should be carefully sized with an adequate safety margin to supply the selected loads. The type of power plant should be appropriate to the task. Gasoline is to be avoided for all but the smallest installations because handling gasoline can be hazardous in terms of fire.

Diesel fuel is less volatile. For a large building that is to be fully powered, it may make sense to have a diesel power plant with a free-standing fuel tank. A disadvantage of diesel is that diesel engines are difficult to start in cold weather. An engine heater will draw as much as 3,000 watts, so it is costly to keep it heated full time in winter waiting for an outage.

Many installations are run on bottled liquid propane gas (LPG), and this is found to be quite satisfactory. Moreover, a gasoline engine can be converted to run on LPG.

Every effort must be made to protect the occupants from exhaust fumes. The power plant, with a suitable housing, can be located outdoors as long as the exhaust is guarded so that there is no chance children or others will breathe the fumes or get burned by contact with the exhaust system. The power plant can be in a well-ventilated dedicated building. It must be exhausted to the outside, including the crankcase vent, and clearances from wood and other combustible materials must be maintained.

A common residential installation is an LPG-fired engine powering a 120/240-volt single-phase alternator. It is permanently mounted on a slab located a few feet from the building, not near a window or door. It is solidly bolted to the concrete slab. The electric line to the building is in polyvinyl chloride (PVC) conduit, which goes underground to the house. The LPG supply line is also buried. In forming up for the slab, it is necessary to provide electrical conduit for the power and any control conductors and a sleeve for the fuel supply.