5

wheels

Simple as they are, wheels are vital pieces for any Technic vehicle builder. They’re difficult to replace with other elements, their selection is limited, and they have a huge impact on the aesthetics and function of a model. In this chapter, I’ll discuss how to choose the right wheels for the job and how to get the most out of them.

what makes a wheel

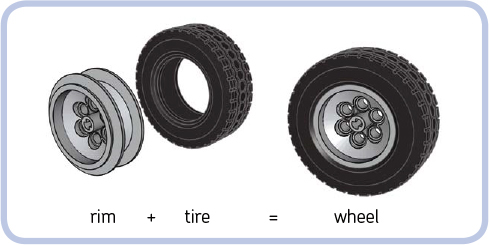

Most LEGO wheels are a combination of two pieces: a plastic rim and a rubber tire (see Figure 5-1). Many rim and tire combinations are unique, but some rims fit a number of tires (see Figure 5-2) and vice versa. You can find a list of popular LEGO rim and tire combinations at http://www.wheels.sariel.pl/.

Figure 5-1: The popular 62.4 mm × 20 mm wheel (right) combines two elements: a plastic rim and a rubber tire.

Figure 5-2: The 30.4 mm × 20 mm rim (leftmost) is one of the most versatile LEGO rims, fitting six different tires and effectively creating six different wheels.

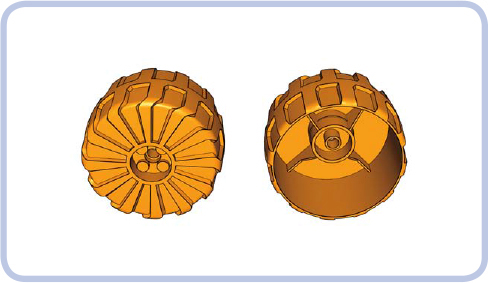

The rare exception to the “rim + tire = wheel” rule is the tireless rim. Consider the 54 mm × 30 mm wheel shown in Figure 5-3. It’s made so its outer rim replaces the tire. For this to work, the wheel must be solid plastic. I’ll discuss the functional pros and cons of plastic wheels in “Material” on page 48, but one of their benefits is that they can serve as decorative elements. For instance, they can be part of a jet engine nozzle in LEGO spaceships.

In addition to rims and tires, some wheels have wheel covers or hubcaps. These elements are purely decorative. They connect to the front or back of the rim, typically with an axle, effectively hiding the rim and becoming the most visible part of the wheel. They’re usually made to fit a specific rim, and they’re a simple way to re-create the look of specific car’s wheels. Often, they’re a simple solution to the problem of having an inappropriate rim for the model. The wheels in the 8145 Ferrari 599 GTB Fiorano set, shown in Figure 5-4, are a typical example of this approach.

Figure 5-3: The 54 mm × 30 mm wheel (front and back) is actually just a rim that acts as complete wheel. It doesn’t need a tire, and it’s often used as a decorative element.

Figure 5-4: The wheel on the right is a combination of the four elements shown on the left: an axle, a wheel cover, a rim, and a tire. Note that the axle is required to connect the cover to the rim.

tires

Tires are an important wheel component. They’re the only part that is supposed to come in contact with the ground, so they have a major impact on a wheel’s performance. Tires can be grouped into a few categories based on their shape, their filling, and the material they’re made of.

shape

Shape refers to a tire’s form when it’s viewed in profile, as shown in Figure 5-5. LEGO tires come in two basic shapes: balloon tires, which are oval-shaped, and regular tires, which are rectangular. The left tire in Figure 5-5 is an example of a balloon tire; the middle is a regular tire. Although these two tires are the same size, their shapes result in very different strengths and weaknesses.

Figure 5-5: A balloon tire (left) and a regular tire (middle). Although these two tires are identical in diameter, their shapes are very different: the balloon tire is oval and the regular one is rectangular. The tire on the right combines both characteristics but performs like a regular tire.

Some tires, such as the tire on the right in Figure 5-5, combine characteristics of the two shapes. Because a tire’s center has the most contact with the ground, these hybrids function largely like regular tires.

Tire shape affects a vehicle’s functionality in many ways. The biggest difference is that balloon tires work better off-road, because their shape ensures better contact with uneven surfaces. Regular tires, on the other hand, work better on road surfaces that are generally smooth and flat. Tire shape also affects rolling resistance (see Chapter 1). Balloon tires are more deformed than regular tires when they come in contact with surfaces, which gives them better traction but also requires higher torque to make the wheel roll.

Regular tires are the opposite: They provide less traction, but they also have lower rolling resistance and require less torque. In real life, you see the difference all the time. Balloon tires are common in off-road cars, whereas sport cars meant only for roads have regular tires. Traction is crucial for off-road vehicles, so it makes sense for them to take on the extra rolling resistance, even if it requires a more powerful engine. In contrast, road cars drive on optimized road surfaces, and tires that provide less traction free up more of the engine’s power for speed. And when road cars require increased traction, you can substitute wider tires or tires made of grippier material and still maintain the regular tire shape.

solid vs. hollow

After choosing the tire profile, you need to consider whether to choose a tire that is solid rubber or hollow with air inside. Solid tires have a smooth inner surface that wraps around the rim tightly, leaving nothing in between. These are rare in the LEGO world. Hollow tires, which are more widespread, have sidewalls that separate their inner surface from the rim, creating a gap inside that is filled with air. Hollow tires can be shallow or deep depending on the depth of the sidewalls (see Figures 5-6 and 5-7). With hollow tires, the sidewalls also hold the rim in place by overlapping the flanges on either side of the rim (see Figure 5-8). Solid tires, on the other hand, depend on friction between the rim and the tire inside for the same purpose; generally, this approach is less efficient. Note that if friction between the rim and tire is too low, the rim may start rotating inside the tire: This often occurs in off-road vehicles while negotiating obstacles.

Figure 5-6: A solid tire (left), a shallow hollow tire (middle), and a deep hollow tire (right). The tires are colored yellow to highlight their inner shape.

Figure 5-7: A solid tire (left) and a hollow tire (right). The red arrow shows the distance between the rim and the inner surface of the hollow tire, which is equal to the depth of the tire’s sidewalls.

Figure 5-8: A see-through view of a hollow tire with the rim inside. The red marks the gap inside the tire, which is filled with air. Note the flanges on either side of the rim that overlap with the tire’s sidewalls, helping to keep the rim inside the tire.

Solid and hollow tires also differ in rolling resistance and cushioning. Solid tires have practically no rolling resistance because there is no air to be compressed inside, making it difficult to deform a solid tire. But hollow tires are still quite hard, and they only become significantly deformed under large loads. The difference between the two is only noticeable with heavy vehicles. In addition, solid tires transfer significantly more vibration to the rims and then the chassis than hollow tires, because there is no air-filled gap to act as a cushion between the tire and the rim. The vehicle’s suspension system can absorb some of this vibration, but as a rule of thumb, solid tires are best suited for smooth, flat surfaces.

Note that LEGO’s hollow tires are pneumatic, meaning the air inside them is not pressurized. Real cars use pressurized tires because their walls are proportionally thinner and the wheels carry proportionally heavier loads. LEGO tires are pretty thick and LEGO cars are relatively light, so pneumatic tires are a better solution they provide better cushioning and they’re puncture proof. Pressurizing a LEGO tire is technically possible under certain conditions (for example, by sealing the tire and rim in an airtight connection and finding a way to feed air into the tire afterward), but there is no practical gain from doing so.

material

Another consideration is the material of the tires, but this choice is very simple. All modern LEGO tires are made of a complex compound of ingredients, which I’ll call “rubber” for simplicity. LEGO has undoubtedly experimented with its rubber composition and quite possibly improved it over the years, but the rubber retains its essential characteristics. Some early tires were made of a different material resembling compressed foam. This foam was lighter than rubber but provided inferior traction, and for some reason all tires of this kind were solid. They also had poor contact with the rim and were likely to start rotating inside it.

Then there are solid plastic wheels, mentioned earlier, that are made of the same material as regular LEGO pieces. These wheels have advantages and disadvantages. Plastic wheels have much worse traction than wheels with rubber tires, but they offer the advantages of reduced weight (rubber tires are usually heavy), zero ground resistance (the plastic is not deformed as easily as rubber), increased resistance to wear (plastic is more durable than rubber), and color consistency (unlike rubber tires, plastic wheels can be made in any regular LEGO color).

Figure 5-9 compares the three essential tire types: rubber, foam, and plastic. Note that rubber tires are subject to aging. This process takes years, but brand-new rubber tires are clearly softer and grippier than the older ones—a result of the gradual evaporation of the compound’s softening agent.

Figure 5-9: From left to right, the tires shown are a 10-year-old LEGO rubber tire, a brand-new rubber tire, a foam tire, and a solid plastic wheel.

size matters

The final critical consideration is a wheel’s size or its total diameter, which is measured from one outer edge to the other. Wheel size affects speed, acceleration, and several other properties of a vehicle. Table 5-1 summarizes some of the key differences between big and small wheels.

table 5-1: functional differences between tire sizes

|

small wheels |

big wheels |

top speed |

low |

high* |

acceleration |

high* |

low |

drivetrain stress |

low* |

high |

torque required |

low* |

high |

ground clearance |

small |

large* |

off-road performance |

poor |

good* |

* These properties are more desirable. |

||

To understand how size affects speed and acceleration, it’s useful to think about the wheel’s circumference, which is the total distance around the wheel and thus the distance a wheel travels by making one full rotation. The circumference (C) equals π multiplied by the wheel’s diameter, so a wheel’s travel distance is always a little more than three times its diameter. A wheel with a diameter of 3 studs has a circumference of C = 3.14 × 3 = 9.42 studs, meaning that a single revolution of that wheel lets it travel 9.42 studs. A wheel with a diameter of 9 studs has C = 3.14 × 9 = 28.26 studs.

Circumference is directly proportional to the wheel’s diameter: A three times larger wheel travels three times farther in a single revolution. This, in turn, means that a wheel’s diameter affects the top speed of a vehicle. If you drive your wheels with a motor that rotates them 10 times per minute, the 3-stud wheel will travel 94.2 studs, whereas the 9-stud wheel will travel 282.6 studs a minute. So, the bigger wheel, in theory, will move a vehicle at three times the speed of the smaller wheel. Of course, this assumes that the wheels have perfect traction and never slip.

However, there is no free lunch in physics. Everything comes at a cost, and this applies to the big wheels’ top speed as well. Bigger wheels allow for higher speeds, but they also require more torque to rotate. Compare a wheel to a lever. When a wheel rotates, it pushes itself against the surface at a pivot point just as a lever does (see Figure 5-10). The lever “pushes” a load, which is the surface in this case. I discuss levers in more detail in Chapter 8 when I talk about solutions for moving heavy loads. For now, you just need to know that the longer the lever, the harder it is to move something with it. The lever goes from the wheel axle to the ground, so in other words, the lever is equal to the length of the wheel’s radius, or half the diameter. Thus, the bigger the wheel, the more power is required to move it. In real life, you might have experienced this if you’ve ridden bicycles with big and small wheels. In motorized LEGO vehicles, this difference translates into a sluggish acceleration with bigger wheels because the motor must work harder to get the vehicle up to speed. This also means that a bigger wheel generates more stress in the vehicle’s drivetrain.

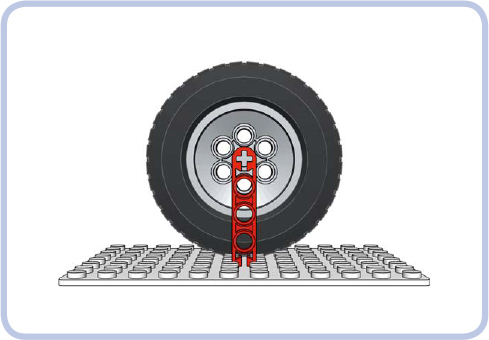

Figure 5-10: The way a wheel behaves on a surface can be compared to the action of a lever (shown in red) whose length is equal to the wheel’s radius. Imagine the lever rotating and applying force to move the surface.

Wheel size also determines ground clearance and off-road performance. In general, the bigger the wheel, the greater the ground clearance. This principle can be mitigated somewhat by using portal axles, which I’ll discuss in Chapter 17. Off-road performance, or how well a wheel handles obstacles, is also directly related to size: Bigger wheels have less chance of getting stuck in a hole, they can climb bigger obstacles, and they perform well on uneven terrain because they have more contact with the ground.

With the preceding characteristics in mind, it should be easier to choose the right wheels for your model. Choosing the biggest wheels possible—a natural temptation because big wheels look cool and usually mean bigger models—isn’t always the best decision. In many cases, you’ll do better with wheels that balance speed and performance over rough terrain against torque requirements.

beyond the basics

Sometimes the perfect wheel won’t be available. Many builders have found the selection of LEGO wheels lacking. If this is your situation, you have a few options. One is to 3D print your own wheels, but this is expensive and subject to limitations, which I’ll discuss in Chapter 22. Other options are to experiment with pairing different tires and rims that are not designed to work with each other or to look to other manufacturers for tires. The following sections discuss both options.

experimenting with rim and tire size

Although most LEGO tires are made to fit specific rims, you can still experiment. By doing so, you can change the shape of a LEGO tire and make it harder or heavier. This, in turn, can lower the vehicle’s center of gravity. Here are some ways you can experiment with the LEGO wheels:

![]() You can squeeze a tire between dishes or turntables that replace the rim, making the tire taller and narrower (see Figure 5-11).

You can squeeze a tire between dishes or turntables that replace the rim, making the tire taller and narrower (see Figure 5-11).

![]() You can build a custom rim. One method for doing this is to build a ring of angle joiners that goes inside the tire, changing its shape and making it harder.

You can build a custom rim. One method for doing this is to build a ring of angle joiners that goes inside the tire, changing its shape and making it harder.

![]() You can wrap a bigger tire around a smaller tire on the same rim, making the resulting tire harder and heavier.

You can wrap a bigger tire around a smaller tire on the same rim, making the resulting tire harder and heavier.

![]() You can stuff a tire with small tires or other LEGO pieces that will make it harder and heavier; if you’re not a purist, consider stuffing the tire with other materials, such as plasticine (modeling clay).

You can stuff a tire with small tires or other LEGO pieces that will make it harder and heavier; if you’re not a purist, consider stuffing the tire with other materials, such as plasticine (modeling clay).

![]() You can submerge the tire in water as you put the rim inside. This will create a wheel with a water-filled tire, which will be harder and heavier than an air-filled tire. Some leaking will occur between the rim and tire, but it can be minimized depending on the type of rim and tire and the load applied to the wheel.

You can submerge the tire in water as you put the rim inside. This will create a wheel with a water-filled tire, which will be harder and heavier than an air-filled tire. Some leaking will occur between the rim and tire, but it can be minimized depending on the type of rim and tire and the load applied to the wheel.

Figure 5-11: This model of the Ursus C360 3P tractor by Eric Trax has realistic-looking rear wheels that were created by squeezing LEGO Power Puller tires between two sets of dishes to make them taller and narrower.

when LEGO tires are not enough

Besides 3D printing a tire, another practical solution is to put third-party tires on LEGO rims. Some popular LEGO/RC combinations are shown in Figure 5-12. The best source of high-quality third-party tires are vendors of parts for RC models, such as Tamiya USA (http://www.tamiyausa.com/product/category.php?sub-id=71200) and US-based Pro-Line (http://www.prolineracing.com/) and RC4WD (http://www.store.rc4wd.com/), which sell a wide selection of tires in 1.55-inch, 1.7-inch, 1.9-inch, and 2.2-inch standards. The standard describes the inner diameter of a tire, and a popular standard with LEGO builders is the 1.9-inch standard, which fits the LEGO Technic Racing Medium rim. It’s a well-tried combination, so when you’re looking for 1.9-inch tires, you just need to pay attention to their width: The Technic Racing Medium rim is 34 mm wide, so you should look for tires that fall within a few millimeters of that width (RC tires are softer than LEGO tires and thus have a greater size tolerance). As shown in Figure 5-13, fitting 38.9 mm wide ROCK CRUSHER X/T 1.9-inch tires on the 34 mm wide Technic Racing Medium rim isn’t a problem. You’ll find a list of many popular LEGO rims and their widths at http://www.wheels.sariel.pl/.

Here’s how RC tires generally compare to LEGO tires:

![]() RC tires are grippier and offer superior traction due to a different rubber compound; the rim is also less likely to rotate inside RC tires if they are well-fitted.

RC tires are grippier and offer superior traction due to a different rubber compound; the rim is also less likely to rotate inside RC tires if they are well-fitted.

![]() RC tires are softer, which means they grip obstacles better, but they have higher rolling resistance and become more significantly deformed under heavy loads (see Figure 5-14).

RC tires are softer, which means they grip obstacles better, but they have higher rolling resistance and become more significantly deformed under heavy loads (see Figure 5-14).

![]() RC tires come with foam inserts that you can remove to make them extra soft (see Figure 5-15).

RC tires come with foam inserts that you can remove to make them extra soft (see Figure 5-15).

![]() Most RC tires look more realistic due to more accurate proportions (taller and narrower) and due to treads modeled after real wheels (see Figures 5-16 and 5-17). However, different proportions can mean they’re too narrow for a LEGO rim (see Figure 5-18).

Most RC tires look more realistic due to more accurate proportions (taller and narrower) and due to treads modeled after real wheels (see Figures 5-16 and 5-17). However, different proportions can mean they’re too narrow for a LEGO rim (see Figure 5-18).

![]() RC tires come in many shapes and sizes, but they usually cost more (note that most vendors sell RC tires by the pair).

RC tires come in many shapes and sizes, but they usually cost more (note that most vendors sell RC tires by the pair).

![]() RC tires come in a greater range of sizes than do LEGO tires (see Figure 5-12).

RC tires come in a greater range of sizes than do LEGO tires (see Figure 5-12).

Figure 5-12: Some popular RC tire/LEGO rim combinations

Figure 5-13: RC tires allow you to create bigger wheels at the cost of weight. Left to right are a LEGO Technic Racing Medium rim with a LEGO 94.3×38 R tire (diameter: 94.3 mm, total weight: 67 g), a ROCK CRUSHER X/T 1.9-inch tire by RC4WD (diameter: 108 mm, total weight: 107 g), and a Baja Claw TTC 1.9-inch tire by RC4WD (diameter: 122 mm, total weight: 126 g).

Figure 5-14: RC tires are softer and more prone to deforming than LEGO tires. Compare a ROCK CRUSHER X/T 1.9-inch tire by RC4WD (left) and a LEGO 94.3×38 R tire (right) with 2 kg of load applied.

![]() RC tires are usually noticeably heavier than LEGO tires of a similar size (see Figure 5-13), which can be a benefit because the weight lowers the vehicle’s center of gravity.

RC tires are usually noticeably heavier than LEGO tires of a similar size (see Figure 5-13), which can be a benefit because the weight lowers the vehicle’s center of gravity.

![]() Their softer, stickier material makes RC tires wear down a little faster and get dirtier and harder to clean.

Their softer, stickier material makes RC tires wear down a little faster and get dirtier and harder to clean.

![]() RC tires rarely fit LEGO rims perfectly, meaning that two identical tire/rim combinations can look a bit different.

RC tires rarely fit LEGO rims perfectly, meaning that two identical tire/rim combinations can look a bit different.

![]() RC tires are quite smelly when they’re brand new.

RC tires are quite smelly when they’re brand new.

![]() RC tires may be frowned upon by LEGO purists.

RC tires may be frowned upon by LEGO purists.

Figure 5-15: By default, RC tires come with foam inserts that you can remove to make them softer. Here’s a Dirt Grabber 1.9-inch tire by RC4WD next to its foam insert. Note that the insert weighs just 3 g, so it’s not worth it to remove it just to save some weight.

Figure 5-16: RC tires usually look more realistic than LEGO tires due to different proportions and treads. Compare the double LEGO 94.3×38 R tires (left) to the double Dirt Grabber 1.9-inch tires (right).

Figure 5-17: RC tires often look more realistic than LEGO tires, as evidenced by the 76023 Tumbler set, with a pair of LEGO 94.3×38 R tires on the right and a pair of Interco TSL SX Super Swamper XL 1.9-inch tires on the left. The Interco tires are actually miniature versions of the real Super Swamper tires used in the original Tumbler vehicle.

Figure 5-18: Because of its realistic proportions, a single Dirt Grabber 1.9-inch tire is too narrow—and two such tires are too wide—for a single LEGO Technic Racing Medium rim. Here’s an exploded and assembled view of the combination of rims I’ve used for two Dirt Grabber 1.9-inch tires: The dark grey dish acts as an inner edge of the rim.