Chapter 1

Introducing Integrated Circuits

IN THIS CHAPTER

![]() Examining the workings of integrated circuits

Examining the workings of integrated circuits

![]() Looking at IC packages

Looking at IC packages

![]() Learning how to use ICs in your circuits

Learning how to use ICs in your circuits

![]() Looking at the most popular types of integrated circuits

Looking at the most popular types of integrated circuits

On April 25, 1961, an engineer named Robert Noyce in Palo Alto, CA, got word that a patent application he had submitted a year before was finally approved. The patent was for a new type of device which would soon come to be known as an integrated circuit.

Exactly one month later, on May 25, President John F. Kennedy announced to the world that the United States was going to the moon.

What do these two events have in common? A lot. Without the integrated circuit, it’s doubtful NASA could have pulled off Kennedy’s challenge.

In May 1961, NASA had no idea how to get to the moon. But one thing NASA did know was that its moonship would need a computer like none the world had ever seen before. NASA would have to figure out a way to shrink a computer that at the time filled an entire room into a box about the size of a picnic basket.

And so the very first contract NASA awarded for the Apollo program was for the computer. Many more contracts would follow — for the command module, the lunar module, the launch vehicle, the space suit, and thousands of other vital elements that would all have to be built to make the moon landing possible. But NASA’s first priority was to build the computer.

The computer contract went to MIT, and the engineers there quickly decided that the only way to build the computer would be to take advantage of the brand-new technology of integrated circuits. NASA became the first large-scale user of integrated circuits.

In this chapter, you learn about the device that helped get us to the moon and then went on to change the world of electronics forever. You can learn how these devices are built, what they can do, and why they keep getting smaller and cheaper. You can also learn how to incorporate them into your own electronic projects.

What Exactly Is an Integrated Circuit?

An integrated circuit (also called an IC or just a chip) is an entire electronic circuit consisting of multiple individual components such as transistors, diodes, resistors, capacitors, and the conductive pathways that connect all the components, all made from a single piece of silicon crystal.

To be clear, an integrated circuit isn’t a really small circuit board that has components mounted on it. In an integrated circuit, the individual components are embedded directly into the silicon crystal. Previous circuit fabrication techniques relied on mounting smaller and smaller parts on smaller and smaller circuit boards, but an integrated circuit is all one piece. Instead of just two or three p-n junctions (as in a diode or a triode), an integrated circuit has thousands of individual p-n junctions. In fact, many modern integrated circuits have millions or even billions of them, all fashioned from a single piece of silicon.

The earliest integrated circuits were simple transistor amplifier circuits with just a few transistors, resistors, and capacitors. In fact, they weren’t much more complicated than the circuits you breadboarded in Book 2, Chapter 6.

Now, integrated circuits are unbelievably complex. At the time I wrote this, the most advanced Intel computer chip had 2.6 billion transistors.

Most of the integrated circuits you’ll work with for hobby projects will be much more modest, having something on the order of a few dozen transistors. For example, the 555 timer IC, which you learn about in Chapter 2 of this minibook, has 20 transistors, 2 diodes, and 15 resistors and costs about a dollar.

Looking at How Integrated Circuits Are Made

Every time I see an episode of Modern Marvels on The History Channel and they go on for an hour about topics like shovels or trucks or cold cuts or grease or dog food, I get mad and yell at my TV. Why don’t they do one about integrated circuits?

You don’t have to know how integrated circuits are made to use them, so you can skip this section if you want. However, the process is pretty interesting — certainly worthy of an episode of Modern Marvels.

The process for manufacturing an IC is complex, and varies depending on the type of chip being made. But the following process is typical:

- A large, cylindrical piece of silicon crystal is shaved into thin wafers about one-hundredth of an inch thick. Each of these wafers will be used to create several hundred or thousand finished integrated circuits.

- A special photoresist solution is deposited on top of the wafer.

- A mask is applied to over the photoresist. The mask is an image of the actual circuit, with some areas transparent to allow light through and others opaque to block the light.

- The wafer is exposed to intense ultraviolet light, which etches the wafer under the transparent portions of the mask but leaves the areas under the opaque parts of the mask untouched.

- The mask is removed and any remaining photoresist is cleaned off.

- The wafer is then exposed to a doping material, which creates n-type and p-type regions in the etched areas of the wafer. (For a review on doping and n-type and p-type semiconductors, please refer to Book 2, Chapter 5.)

- If the circuit design calls for multiple layers stacked on top of one another, the process is repeated for each layer until all of the layers have been created.

- The individual integrated circuits are then cut apart and mounted in their final packaging.

Here are a few other tidbits worth knowing about how integrated circuits are made:

- As you’ve probably seen on Intel commercials, the manufacturing process for integrated circuits is done in a clean room, where workers wear special suits and masks. This is necessary because at the scale of the integrated circuits, even the smallest speck of dust is enormous.

- Each integrated circuit goes through a variety of complicated quality tests after the circuit is finished. The manufacturing process is by no means perfect, so many are discarded.

Integrated Circuit Packages

Integrated circuits come in a variety of different package types, but nearly all the ICs you’ll work with in hobby electronics come in a type of package called dual inline package, or DIP. Figure 1-1 shows several ICs in DIP packages.

FIGURE 1-1: Most integrated circuits come in DIP packaging.

The phrase “DIP chip” is also sometimes used to describe ICs in DIP packages. It has a nice ring to it and sounds like something you would serve at a Super Bowl party.

A DIP package consists of a rectangular plastic or resin case that encloses the IC itself, with two rows of pins on the long sides of the rectangle. The pins on each side jut out a bit from the case, then turn straight down. This arrangement makes the package look like an insect. (In fact, one common way of wiring circuits that use DIP chips is to glue them to a board upside down and solder wires directly to the pins; this technique is called dead-bug wiring.)

The pins on each side of a DIP package are spaced exactly 0.1 inch apart, and the two rows of pins are usually spaced 0.3 inch apart, though some larger DIP packages may have wider spacing. In any event, the standard tenth-of-an-inch spacing is perfect for use with solderless breadboards, which have holes spaced at 0.1-inch intervals. In fact, the gap that runs down the center of a solderless breadboard happens to be 0.3 inch, which makes it easy to mount DIP chips such that they straddle the gap, as shown in Figure 1-2.

FIGURE 1-2: Solderless breadboards are designed with DIP chips in mind.

Each pin in a DIP package is numbered. Looking down on the package from above, and you’ll see an orientation mark, usually a notch, groove, or dot. Orient the package so that this mark is on the top, and pin 1 is immediately to the left of the mark. The pins are numbered counterclockwise, working down the left side and then back up the right side until you get to the last pin, which is immediately to the right of the orientation mark.

In case my explanation of DIP pin numbering doesn’t make sense, have a look at Figure 1-3.

FIGURE 1-3: Identifying the pins on a DIP package.

The DIP package in Figure 1-3 is for an eight-pin DIP. Larger DIPs have more pins, but the numbering scheme is always the same: Pin 1 is to the left of the orientation mark, and the remaining pins are numbered counterclockwise from pin 1.

Using ICs in Schematic Diagrams

In a schematic diagram, an IC is usually represented simply as a rectangle with circuit connections placed conveniently around the rectangle without regard for the physical positioning of the pins. Each pin connection is labeled, as shown in Figure 1-4.

FIGURE 1-4: An integrated circuit in a schematic diagram.

Notice that the pins in this schematic diagram aren’t in the same order as they are in the actual DIP package. Thus, when you build this circuit, you have to adjust the wiring layout to accommodate the pin arrangement of the DIP package.

Notice also that not all the pins on an Integrated Circuit are always used. Unused pins are usually omitted from the schematic diagram. For example, pin 5 is not used in the circuit shown in Figure 1-4, so it is omitted from the schematic.

Some integrated circuits contain two or more independent circuits that share a common power supply, sort of like conjoined twins. For example, the 556 dual timer chip contains two complete 555 timer circuits within a single 14-pin package. When chips like this are used in a circuit, the schematic diagram may show them separately. For example, Figure 1-5 shows a circuit that calls for a 556 dual timer chip, but each section of the timer is listed separately in the schematic.

FIGURE 1-5: Independent sections within a single IC are often shown separately in a schematic diagram.

Please don’t worry about the details of this circuit (or of the circuit shown in Figure 1-4). My intent here isn’t to explain how these circuits work, but only to show you how the integrated circuits are depicted in the schematic diagrams. You can learn more about how these circuits work in the next chapter.

Powering ICs

In most DIP integrated circuits, two of the pins are used to provide power to the circuit. One of these is designated for positive voltage, typically identified with the symbol VCC. The other is the ground pin. For example, the 555 timer chip (which you learn about in Chapter 2 of this minibook) requires a positive supply voltage between 4.5–15 V at pin 8, and pin 1 is connected to ground.

In the case of ICs that contain two or more separate circuits, the circuits usually share a common power supply. Thus, even though a 556 dual timer chip contains two separate 555 timer circuits, the chip has just one positive voltage pin and one ground pin.

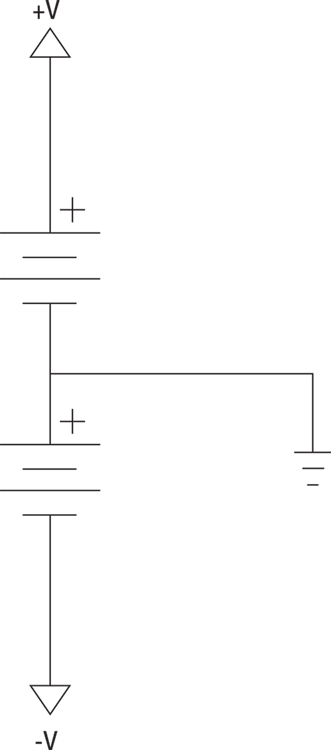

Also, you should be aware that some integrated circuits call for separate positive and negative supply voltages, not just a positive and a ground connection. You can create a power supply like that using the circuit shown in Figure 1-6.

FIGURE 1-6: A circuit for providing positive voltage, negative voltage, and ground connections.

Avoiding Static and Heat Damage

When you build a circuit board that contains one or more integrated circuits, be careful that you don’t damage the IC when you build your circuit. In particular, you should watch out for these two possible problems:

- Static discharge: Many integrated circuits can be damaged by static electricity discharged through your fingers when you handle the chips. As a result, make sure you discharge yourself by touching a grounded metal surface before handling an integrated circuit. You may also want to use an antistatic wristband when handling ICs.

-

Heat damage: Some integrated circuits are sensitive to heat, so you should take precautions whenever you solder an IC to a circuit board. If possible, attach an alligator clip or other type of heat sink to the pin to help dissipate some of the heat away from the IC itself.

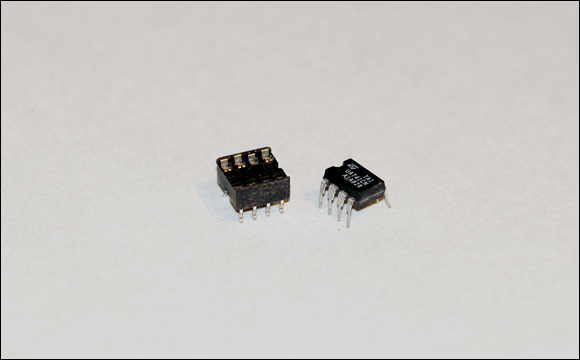

You can avoid soldering integrated circuits altogether by using DIP sockets such as the ones shown in Figure 1-7. When you use these sockets, you solder the socket to your circuit board. Then, once the socket is safely soldered in place, you simply insert the IC into the socket.

You can avoid soldering integrated circuits altogether by using DIP sockets such as the ones shown in Figure 1-7. When you use these sockets, you solder the socket to your circuit board. Then, once the socket is safely soldered in place, you simply insert the IC into the socket.

FIGURE 1-7: DIP sockets let you avoid soldering delicate integrated circuits.

Reading IC Data Sheets

Before you work with a specific type of IC, you should download a copy of the data sheet for the IC. An IC datasheet contains loads of useful information. In addition to basic information such as the manufacturer’s name and the IC part number, you’ll find information such as

- A description of what the circuit does.

- Detailed pinout descriptions that tell you the purpose of each pin.

- A diagram of the internal circuitry of the chip. For simple circuits, you may get the entire detailed diagram. For more complicated chips, you’ll get a conceptual diagram instead of a detailed schematic.

- Detailed electrical specifications, such as maximum voltage you can feed the circuit via the VCC pin or the maximum current loads for output pins.

- Operating conditions such as maximum and minimum temperatures.

- Charts and graphs that illustrate the circuit’s behavior for different operating conditions.

- Formulas for calculating operating characteristics of the circuit. For example, if the operation of the circuit depends on an external RC (resistor/capacitor) circuit, you’ll get formulas for calculating how these external components will affect the operation of the circuit.

- Sample circuit diagrams.

- Mechanical descriptions including dimensions.

IC datasheets are available from many sources on the Internet. Use a search engine such as Google to search for the IC part number and the word datasheet. For example, to find a datasheet for a 555 timer chip, search for 555 datasheet.

Popular Integrated Circuits

Literally thousands of different types of integrated circuits are available. Most of these were designed for very specific applications. However, many integrated circuits have been designed for general-purpose use and so are used in a wide variety of circuits.

In the sections that follow, I briefly describe some of the most popular general-purpose integrated circuits. All these ICs have been around for decades, but their multipurpose design, wide availability, and low cost have given them enduring popularity.

555 Timer

The 555 timer chip was invented in 1971 but remains today one of the most popular integrated circuits in use. By some estimates, more than a billion of them are made and sold every year.

As its name implies, the 555 is a timer circuit. The timing interval is controlled by an external resistor/capacitor (RC) network. In other words, by carefully choosing the values for the resistors and capacitors, you can vary the timing duration.

The 555 can be configured in several different ways. In one configuration (called monostable), it works like an egg timer: You set it, and then it goes off after a certain period of time has elapsed. In a different configuration (called astable), it works like a metronome, triggering pulses at regular intervals.

Besides the basic 555 chip, which comes in an 8-pin DIP package, you can also get a 556 dual timer, which contains two independent 555 timers in a single 14-pin DIP package. Because many common circuits call for two 555 timers working together, the 556 package is very popular.

You can learn more about the 555 and 556 timers in the next chapter.

741 and LM324 Op-Amp

An op-amp is a special type of amplifier circuit that has many applications throughout electronics. Although there are many different types of op-amp circuits, the 741 and LM324 are the most common.

The 741 is a single op-amp circuit in an eight-pin DIP package. It was first introduced in 1968 and is still one of the most widely used integrated circuits ever made. The 741 is one of those ICs that require both positive and negative voltage, as described earlier in the section, “Powering ICs.”

The LM324 was introduced in 1972. It consists of four separate op-amp circuits in a single 14-pin DIP package. Unlike the 741, the LM324 doesn’t require separate negative and positive voltage supplies.

You can learn more about op-amps in Chapter 3 of this minibook.

78xx Voltage Regulator

The 78xx is a family of simple voltage regulator integrated circuits. A voltage regulator is a circuit that accepts an input voltage that can vary within a certain range and produces an output voltage that is a constant value, regardless of fluctuations in the input voltage.

The xx in 78xx represents the actual voltage regulated by the chip. For example, a 7805 produces a 5 V output. The input voltage must be at least a couple of volts over the output voltage, and can be as high as 35 V.

74xx Logic Family

One of the primary uses for integrated circuits is for digital electronics, and the 74xx is one of the oldest and still most widely used families of digital integrated circuits. The 74xx family includes a wide variety of chips that provide basic building blocks for digital circuits. Thus, you won’t find complete microprocessors in the 74xx family. But you will find circuits such as logic gates, flip-flops, counters, buffers, and so on.