15

Spills, Forensic Evaluation, and Case Studies

15.1 Introduction

Spill studies provide information on the likelihood of soil and groundwater impacts related to unconventional oil and gas operations. To evaluate environmental impacts of spills and leaks, evidence needs to be collected. Examples of the types of evidence to prove environmental impacts and damages can come from a variety of sources: photographs or documents identifying a chemical release, groundwater geochemistry that matches the contaminants found in the air or subsurface with a source of those industrial compounds, laboratory analytical reports identifying industrial chemicals in groundwater, visually stained soil that matches the fluid leakage from an aboveground storage tank, reliable eyewitness reports of spills and leaks verified with photographs and written reports, interviews with knowledgeable persons, and regulatory agency inspection reports. This chapter will explore spills and methods used for forensic evaluation and present a number of case studies.

15.2 Spill Studies

Spill studies were performed to evaluate the number of spills associated with drilling and production activities at states with active unconventional oil and gas operations. Common spill pathways have been documented (Figure 15.1; Table 15.1). Because the Williston Basin in North Dakota, Montana, and nearby states and provinces is so distant from the refineries on the east and gulf coasts and pipeline access is limited, rail is the primary transportation method for conveying Bakken crude oil to the market. Rail accidents and the spill details are reviewed in this chapter. Once the spill occurs, forensic techniques are used to identify sources of contaminants in surface and groundwater sources.

Figure 15.1 Example of common spill pathways (no scale implied).

Source: Modified after Patterson et al. (2017).

Table 15.1 Common causes of spills and leaks.

| Common pathway and system or process | Causes with a few examples | ||||

| Pathway (alphabetical) | System or process | Equipment failures | Human errors | Environmental conditions | Unknown or not identified |

| Completion activity | Blender, manifold, storage containers | Corrosion, valves, etc. | Punctured with forklift, valve position, poor worker training inadequate worker training | Freezing temperatures, bad weather: sleet, snow, rain | Explain: |

| Drilling activity | Active mud system, drill rig, shaker, | Mud pumps | Improperly stored chemicals and wastes, inadequate worker training | Formation breakdown, excessive formation pressure, lost circulation, lightening | Explain: |

| Heater treater | Separate gas from liquid or water from crude oil | Pop‐off valve | Valve position, vandalism | Freezing or excessive heat conditions, bad weather, lightening | Explain: |

| Flowlines | Carry oil, gas, and coproduced water from wellhead to production separator | Connection, corrosion, fused joint, failed weld connection, scale buildup | Accidental break in lines, disconnected flowline, incorrect line or valve position, vandalism | Animal, freezing or excessive heat conditions, groundwater rising, unstable land surface, rockslide | Explain: |

| Pits | Storage of drilling muds, HVHF operation wastes, coproduced water, etc. | Leaks caused by liner tear, pump failure, broken gauge, broken pump or valve | Improper or inadequate liner, lack of inspection and maintenance, not lined | Flood, heavy rain, freezing conditions, snow melt, overflows from stormwater | Explain: |

| Pumps, generators, and motors | Move fluids or gases at the well site and production facilities | Damaged pumps, generators, and motors; scale buildup | Improper sizing of equipment, lack of inspection and maintenance, lack of worker training | Water or snow damage of equipment, heavy rain, freezing or excessive heat conditions | Explain: |

| Stuffing box | Box to divert crude oil to the flowline for a well with artificial lift using a sucker rod pump | Packing failed, polished rod damaged | Lack of inspection and maintenance | Freezing or excessive temperatures | Explain: |

| Tanks | Storage of drilling muds, HVHF operation wastes, coproduced water, produced oil | Corrosion, gasket damage, broken gauge, damaged heater treater, flowline plugged, damaged valve | Miscommunication, transportation delay, valve position incorrect | Animal freezing or excessive heat conditions, groundwater rising, unstable land surface, rockslide, lightening | Explain: |

| Transportation | Vehicles for loading and unloading chemicals and supplies; transporting oil, gas, and wastes; in transit accidents, on‐site accidents | Gauge failure, gasket leak, broken seals, damaged valves | Driver inattention, incorrect valve position, vehicle accident on‐site or off‐site, illegal dumping of wastes | Dangerous road conditions: rain, snow, fog, sleet, freezing temperatures, flooding or landslides on roadways | Explain: |

| Wellhead | Blowout preventer, free water knockout, separator, well casing, well communication, wellhead | Corrosion, damaged gaskets, damaged fire tube heater, broken valves | Valve position, vandalism, inadequate worker training | Explain: | |

Two spill studies (Table 15.2) were performed from public data compiled for unconventional oil and gas wells.

Table 15.2 Spill studies using public data.

| Spill study | States evaluated | Study period |

| US EPA (2015a, b, c, d, e) | Colorado and Pennsylvania | 2006–2012 |

| Patterson et al. (2017) | Colorado, New Mexico, North Dakota, and Pennsylvania | 2005–2014 |

15.2.1 US EPA Study

Detailed national statistics (US EPA 2015e) about spills at hydraulic fracturing sites are not available, but using the following state information, estimates can be made: on‐site spills at the HVHF well pads range from an estimate of one spill for every 100 wells in Colorado to between 0.4 and 12.2 spills per 100 wells in Pennsylvania (US EPA 2015e). If the Pennsylvania and Colorado estimates are representative, the number of spills in the United States could range from about 100–3 700 spills yearly, assuming 25 000–30 000 new unconventional oil and gas wells are fractured each year. The US EPA characterized volumes and causes of hydraulic fracturing‐related spills identified from selected state and industry data sources. US EPA (2015f) compiled incidents of spills over the period of January 2006 to April 2012 in 11 states and included 151 cases in which fracturing fluids or chemicals were spilled on or near a HVHF well pad. These cases from only 11 states underestimate the total fracturing fluid and chemical spills in the United States during this period. The reported volume of fracturing fluids or HVHF chemicals spilled ranged from 5 gal to more than 19 000 gal (19–72 000 l), with an average volume of 420 gal (1 600 L) per spill. Spill causes are due to (i) equipment failure, (ii) human error, (iii) failure of container integrity, and (iv) unknown or other causes not specified or causes such as weather and vandalism. The most common cause was equipment failure and more specifically blowout preventer failure, equipment corrosion, and failed valves. Greater than 30% of the 151 total spills of chemicals or fracturing fluid were from fluid storage units such as aboveground storage tanks, totes, and trailers (US EPA 2015g). As there is no data, unreported spill volumes were not estimated.

15.2.2 Patterson and Others (2017)

In a 10‐year study related to unconventional oil and gas spills, Patterson et al. (2017) reviewed similar publicly available data from Colorado, New Mexico, North Dakota, and Pennsylvania between 2005 and 2014; some of the data were likely included in the US EPA (2015a, b, c, d, e) study. During 2005–2014, data from 31 481 HVHF wells were evaluated for documented spills. The analysis of the public records in the 4 states identified a total of 6647 during the 10‐year period. The study noted 2–16% of wells were reported to have a spill each year. The liquids spilled included petroleum hydrocarbons, chemical‐laden water, hydraulic fracturing fluids, and other substances. The average spill volume ranged from 0.5 m3 in Pennsylvania to a high of 1294 gal (4.9 m3) in New Mexico. The largest spills exceeded 26 417 gal (100 m3). A significant number of the spills, 75–94%, occurred within the first 36 months of well life when the unconventional oil and gas wells were drilled and completed and had their largest production volumes. Across all four states in the study, 50% of spills were related to storage and moving fluids through flowlines. The study also found that a significant portion of spills, 53% in North Dakota and 26% in Colorado, occur at well sites that have already reported at least one spill incident. More rigorous equipment inspections, improved emergency response training, better communication on safe chemical handling practices, additional spill prevention measures, and a higher level of regulatory oversight could help to reduce spillage at well sites with multiple spills.

It should be noted that the data reviewed were not uniformly described in the state data files and reporting rates varied by state, affecting the overall spill rates and consistency, illustrating the high value of having standardized public data (Patterson et al. 2017). The state reporting the highest level of spills was North Dakota with recorded 4453 incidents. North Dakota had a high level of drilling activity during that period because any spill bigger than 42 US gallons (0.16 m3) or the volume of a standard US oil barrel has to be reported, which likely increases the number of spills compared with the other states with higher minimum reportable spill volumes (Patterson et al. 2017). The data is summarized in Tables 15.3, 15.4, 15.5, and 15.6.

Table 15.3 Summary of incidents from State Data.a

Source: From Patterson et al. (2017).

| State | Number of incidents (2005–2014) | Reportable quantity |

| North Dakota | 4453 | 42 gal (0.16 m3) |

| Pennsylvania | 1293 | >15 gal based on concentration (only saltwater) |

| Colorado | 475 | 210 gal (0.79 m3) |

| New Mexico | 426 | 210 gal (0.79 m3) |

| Total | 6647 |

a Reportable quantity is variable. For example, in North Dakota, any off‐site spill must be reported, but only on‐site spills exceeding 42 gal are reported. During the study period, spill information for Pennsylvania was compiled from notice of violations (NOV) data. By 2016, Pennsylvania changed legislation to collect data on spills.

Table 15.4 Sources of spills (2005–2014) from State Data.

Source: From Patterson et al. (2017).

| Causal mechanism | Number of spills | % of data |

| Equipment failure | 1749 | 26 |

| Human error | 705 | 11 |

| Environmental conditions | 94 | 1 |

| Unknown or other causes not specified | 4099 | 62 |

| Total | 6647 | 100 |

Table 15.5 Pathway of spills (2005–2014) from State Data.

Source: From Patterson et al. (2017).

| Pathway | Number of spills | % of data |

| Blowout | 89 | 1 |

| Blowout preventer | 10 | 0 |

| Drill rig | 46 | 1 |

| Flowline | 1393 | 21 |

| Free water knockout | 15 | 0 |

| Heater treater | 407 | 6 |

| Pit | 322 | 5 |

| Pump | 166 | 2 |

| Separator | 60 | 1 |

| Shaker | 17 | 0 |

| Storage container | 29 | 0 |

| Stuffing box | 320 | 5 |

| Tank | 1405 | 21 |

| Transport | 519 | 8 |

| Unknown | 1322 | 20 |

| Well casing | 28 | 0 |

| Well communication | 2 | 0 |

| Wellhead | 48 | 1 |

| Total | 6647 | 100 |

Table 15.6 Spills 2005–2014 from well communication pathway from State Data.

Source: From Patterson et al. (2017).

| Location | API | Wellbore | Spud | Spill | Volume (gal) | Cause | Water impact |

| North Dakota | 33‐0561‐00491 | Horizontal | 2006 | 2012 | 3 780 gal (14.3 m3) | Human error | No |

| New Mexico | 30‐015‐40814 | Horizontal | 2013 | 2013 | 98 280 gal. (372.0 m3) | Human error | No |

Even with a possible spill pathway, there were only two documented spills through well communication between 2005 and 2014.

The study also looked at setbacks. In total, 7% of all spills were within 100 ft (30.5 m) setback of a stream or creek, 13.3% were within 200 ft (61.0 m) setback, 20.4% were within 300 ft (91.4 m), and 47.1% were within 750 ft (228.6 m) setback. The state with the smallest setback regulation is Pennsylvania at 100 ft (30.5 m), and 5.3% of the spills in the state were within this distance to a creek or stream (Patterson et al. 2017).

15.3 Spill Settlement Case Study

In a spill case, the release of untreated fluids related to unconventional shale gas operations was discovered by an inspector with the Pennsylvania Department of Environmental Protection (PADEP) during a routine inspection of the Penn Township facility in 2010. The PADEP inspector noted wastewater spilling from an open valve from a series of interconnected tanks. At the time, the operator of the facility, XTO, stored wastewater generated from unconventional gas operations in Pennsylvania at its Penn Township Lycoming County, Pennsylvania, facility.

Eventually the US EPA was brought in to investigate the incident. When the settlement was finally announced in Washington, D.C., on 18 July 2013, XTO Energy, Inc., a subsidiary of Exxon Mobil Corporation, had released between 6 300 gal (23.8 m3) and 57 373 gal (217.2 m3) of flowback fluids and coproduced water into waters of the United States on 16 November 2010. The settlement resolved an alleged violation of the Clean Water Act (CWA) relating to the release from the XTO facility used for wastewater storage of HVHF fluids and associated gas production liquids. Based on an US EPA groundwater and stream sampling program, the spill impacted a tributary of the Susquehanna River for a period of ~65 days. Laboratory analysis revealed that elevated levels of strontium, chloride, bromide, barium, and total dissolved solids (TDS) were present in both the surface stream and subsurface spring, which had a hydraulic connection to the tributary (US EPA 2013a).

The full implementation of the injunctive relief measures were designed to prevent about 131 787 US tons (119 555 metric tons) of TDS from entering surface waters in Pennsylvania and West Virginia according to the US EPA (2013a). XTO reductions in TDS were attributed to recycling more than half of the total flowback fluids and coproduced waters from the XTO Pennsylvania unconventional gas extraction operations. XTO was also required to dispose of fluids at a National Pollution Discharge Elimination System (NPDES) permitted facility with a federally enforceable permit limit for TDS of 500 milligrams per liter (mg l−1) per month or less. XTO was required to implement the best practices of tank management and submit progress reports in 36 months to US EPA with regulatory compliance verification. XTO also paid a $100 000 civil penalty to the federal government.

US EPA (2013a) estimated the costs for XTO compliance would be on the order of $20 million to develop and implement a comprehensive plan to improve wastewater management practices to recycle, properly dispose of, and prevent releases of fluids generated from unconventional gas operations in Pennsylvania and West Virginia. XTO was required to install a continuous, remote monitoring system for all of its permanent production located throughout Pennsylvania and West Virginia with alarms to immediately alert operators in the event of any future releases. XTO also was required to actively monitor interconnected wastewater storage tanks located throughout Pennsylvania and West Virginia.

15.3.1 Rail Case Studies

There has been a major increase in unconventional crude oil production in North Dakota and nearby states and there has been a general lack of available pipeline capacity from oil fields to refineries on the East and Gulf Coast of the United States and rail transportation of crude oil across North America. The increase in unconventional crude oil production and associated rail transportation is reflected in the modest 9 500 unit cars used in 2008 compared to 435 560 unit cars used in 2013 (Congressional Research Service 2014). Even though several high‐profile accidents (see Table 15.7, Appendix I) have resulted in significant damage to public welfare and the environment, the overall trend of accidents is decreasing due to improved railcar design, increased infrastructure, improved procedures, better worker training, more regulatory oversight, and other factors. The potential for a catastrophic release along rail lines still remains high, and the safety and environmental risks of transporting Bakken crude oil by rail have increased due to larger volumes of product shipped and the larger distances traveled. On average Bakken crude oil shipments are transported over 1000 mi from point of origin in the Williston Basin to the major refineries on the US coasts (DOT 2013).

The Bakken crude oil characteristics were evaluated by the Pipeline and Hazardous Materials Safety Administration (PHMSA) and the Federal Railroad Administration (FRA) by testing 135 samples from August 2013 to May 2014, and the findings showed that the unconventional oil character is consistent with those of a class III flammable liquid, PG I or II, with a predominance of PG I, the most dangerous class of class III flammable liquids (PHMSA 2014). Although this lightweight sweet crude oil does not exhibit the characteristics of a flammable gas, corrosive liquid, or toxic material, it is more volatile than most other types of crude oil, which correlates to increased ignitability and flammability.

The volatility tests by the PHMSA tests indicate that the Bakken contains flammable dissolved gases that raise the vapor pressure and lower the flash point and reduce the initial boiling point of the oil. These characteristics reflect higher concentrations of light‐end hydrocarbons, which tend to vaporize. DOT requested the American Fuel & Petrochemical Manufacturers (AFPM) to conduct a survey of members to address questions raised by DOT. AFPM also collected data from chemical analysis of ~1400 samples of Bakken crude oil. The two chemical studies (PHMSA and AFPM) show some of the natural variations typical of the Bakken crude oil (AFPM 2014; PHMSA 2014).

15.3.2 Bakken Crude Oil Characteristics: Two Studies

A summary of Bakken crude oil characteristics is shown in Table 15.8.

Table 15.8 Physical and chemical characteristics of Bakken crude oil.

Source: After PHMSA (2014).

| Parameter | PHMSA valuesa | AFPM valuesb | Comments |

| Flash point | <32 to <73 °F (<0 to <23 °C) | −74.2 to 122 °F (−59 to 50 °C) | Medium danger (DOT packing group I or II) |

| Initial boiling point | 85–104 °F (29–40 °C) | 36–152 °F (2.2–66.9 °C) | Low boiling point |

| Light ends | Butane: 2.4–3% | (C2–C5: 7.2%) | High gas content |

| Pentane: 0.6–1.2% | Flammable gas content: max: 12.0% | ||

| Hydrogen sulfide (H2S) | <5 ppm | Most reported below 10 ppm; avg.: 3 580 ppm; one reported max. level of 23 000 ppm | Mostly low H2S, with reported high H2S |

| API gravity | 39.9–43.8 | 42 | Lightweight crude |

| Reid vapor pressure | 8.7–11.8 lb in2 absolute (psia) (60.0–81.4 Kpa) | 15.4 psia (106.2 Kpa) | High vapor pressure |

| Corrosivity | Not reported | NACEc B+ or B++ |

|

| Rail tank car pressures on delivery | Not reported | Maximum 11.3 psig (77.9 Kpa) | |

| Number of samples | 135 | ~1400 |

b American Fuel & Petrochemical Manufacturers (AFPM) (2014).

c National Association of Corrosion Engineers (NACE) test method 172. Generally, a NACE value of B+ or B++ is required for transportation via pipeline (AFPM 2014).

Because of the volatility of the Bakken crude oil, there is an increased safety risk of a major accident due to the significant volume being transported, the routes and the extremely long distances the oil is transported by rail. Trains transporting Bakken crude oil are called unit trains, and they commonly contain more than 100 tank cars, carrying at least 2.5 million gallons (9464 m3) within a single train. Unit trains only carry a single type of product, in this case flammable Bakken crude oil. The crude shipments are transported over a thousand miles (1609 km) from the Williston Basin in North Dakota to coastal US refineries.

Dissolved flammable gases within the Bakken crude oil are released into the vapor space of rail tank cars as the ambient temperature increases. In the event of a spill or catastrophic release, the gases trapped in the rail tank car vapor space increase flammability and inhalation hazard risks. The main hazard associated with Bakken crude oil in a rail accident is flammability, resulting in explosions, fireballs, and pool fires. A major aboveground tank rupture or pipeline leak may result in an explosion and fireball after the spilled Bakken crude oil vaporizes and contacts an ignition source. A photo of the Casselton, North Dakota, fireball shows the explosion in process (Figure 15.2). The pileup of Bakken crude oil tanker cars south of Aliceville, Alabama, (US EPA 2013b) shows the extent of the derailment into the wetland environment (Figure 15.3).

Figure 15.2 On 8 Nov 2013, a train carrying Bakken crude oil derailed south of Aliceville, Alabama, into the adjacent wetlands. The derailment caused 23 tanker cars to be derailed; many were caught on fire and several of the cars were breached. (US EPAOSC 2013).

Figure 15.3 A massive fireball followed the derailment and explosion of two unit trains, one carrying 106 cars of Bakken crude oil in Casselton, North Dakota, on 30 December 2013 (US Pipeline and Hazardous Materials Safety Administration 2013).

15.3.3 Summary of Bakken Crude Oil Spill Incidents

Bakken crude oil rail accidents are summarized in Table 15.9 (MassDEP 2015).

Table 15.9 Summary of rail accidents.

| Rail accident and date | Date | Description | Volume | Outcome |

| Lac‐Mégantic, Quebec | 7/6/13 | A Canadian Pacific Railway 74 runaway train derailment of (63) 30 000 gal (114 m3) railcars containing Bakken crude oil en route to the Irving Oil Refinery in St. John’s New Brunswick, Canada | About 1.7 million gal (6435 m3) were either burned or released into the environment with an estimated 26 000 gal (98 m3) spilling into the nearby Chaudière River. Oil flowed in storm sewers, manholes, basements, and other subsurface conduits or structures. About 150 000 cy (114 683 m3) soil removed and 50 million gal (189 271 m3) water treated |

|

| Aliceville, Alabama | 11/7/13 | Derailment of Alabama and Gulf Coast Railway 25 train, 23 breached into wetland. Train was carrying 2.7 million gal (10 221 m3) of Bakken crude oil | 630 000 gal (2 385 m3) of crude oil either spilled or burned. 11 000 gal (41.6 m3) oil was recovered and 5 000 US tons (4 536 metric tons) of soil excavated from rail bed and adjacent wetland |

|

| Casselton, North Dakota | 12/30/13 | Eastbound BNSF Railway crude oil unit train with 106 cars collided with a westbound BNSF unit train carrying grain. The car collision caused 20 Bakken crude oil tank cars to derail. 18 were breached | 400 000 gal (1 514 m3) of crude oil was released |

|

| Lynchburg, Virginia | 4/30/14 | CSXT 13‐unit cars of a 105‐car train derailed; 3‐unit cars submerged in James River | 30 000 gal (114 m3) released, 3 cars submerged in the James River |

|

| Plaster Rock, New Brunswick | 1/7/14 | 19‐unit cars of a Canadian National Railway 122 unit freight train derailed with 9 Bakken crude oil units and liquefied petroleum gas (butane and propane). Two unit tank cars were breached, resulting in the fire | A defective wheel caused the derailment of the train. Older tank cars were punctured by couplers. About 60 760 gal (230 m3) of Bakken crude oil spilled fueling a massive fire (Abdelwahab 2015). 5000 tons (4536 metric tons) of impacted soil were removed |

|

| Luther, Oklahoma | 8/22/08 | 14 unit cars of a BSNF 110 car train carrying Bakken crude oil derailed. 3 unit cars breached and remainder leaked crude | 80 746 gal (305.6 m3) released, 3 cars breached remainder leaked and caught fire |

|

| Parker Prairie, Minnesota | 3/27/13 | 14‐unit cars of a Canadian Pacific 94 car unit train derailed. 1 car breached and 2 additional cars leaked while on their side following derailment | 30 000 gal (113.5 m3) released on to frozen soil |

|

15.3.4 Fate and Transport of Spilled Crude

The major migration pathways from a surface Bakken crude oil spill from a rail accident or tank failure (Table 15.10) might include a variety of media to sample depending on the active processes ().

modified after MassDEP (2015)

Table 15.10 Processes, media, and recommended sample type for oil spills.

| Process | Media | Sample type |

| Evaporation | Into air | Air samples |

| Volatilization | ||

| Dispersion | ||

| Infiltration | Into soil | Soil and soil vapor samples |

| Direct surface release | Into streams, rivers, lakes, coastal waters, outer harbors, open water ditches, wetlands | Water and soil samples |

| Leaching from shallow soil | Into groundwater | Groundwater samples |

| Transport in groundwater | Migration in groundwater | |

| Partitioning between media (API 2001, 2005, 2011) | Characteristics | Sample type |

|

|

Air samples |

| Water samples | ||

|

|

Air samples |

| Water samples | ||

| Water samples | ||

| Water samples | ||

| Soil samples | ||

|

|

Soil samples |

| Activity | Critical data | Example decisions |

| Spill emergency response | Volume of the released oil | Type of equipment, staff, evacuation criteria |

| Type of crude oil – physical and chemical properties | Type of equipment | |

| Dispersal rate of crude oil | Type of equipment | |

| Receiving media (air, soil, and/or water) | Type of equipment, access | |

| Topography of the terrain | Movement of oil | |

| Weather, especially wind and temperature | Movement of oil | |

| Process of crude oil spill into water body | Description of process | Estimated process time (determined by site‐specific conditions) |

| Process | Forces | Stage |

| Spreading of crude oil on water (US EPA 2004) | Gravity and inertial forces control the spreading of crude oil across the surface | Stage 1 |

| Process of crude oil spill into water body | Inertial forces become negligible in comparison with viscous drag across the surface | Stage 2 |

| Process | Interfacial forces become dominant and are the driving force to propel oil spreading | Stage 3 |

| Dissolution | Water soluble portions of crude oil may dissolve into the surrounding water | Hours to days |

| Natural dispersion | Oil slick broken up by waves and turbulence | Hours to days |

| Emulsification | Water‐in‐oil emulsion formed from Bakken crude oil in water | Days to months |

| Biodegradation | Biologic consumption of spilled Bakken crude oil and by‐products that require food source, electron acceptor, and microbial communities | Optimal reaction rate days to years. Cold climates (Alaska) can retard biodegradation rates to decades |

| Photooxidation | Direct photooxidation: crude oil reacts chemically with oxygen in water or in the atmosphere either breaking down into soluble products or forming persistent compounds called tars | Reaction rates weeks to years |

| Emulsification | Indirect photooxidation (lighter crude oil portion, volatilize to air | Lighter crude oil portion will volatilize into air. Reaction rates days to months |

| Sedimentation and sinking | Heavier ends of Bakken crude oil will adhere to sediment | Days to years |

| Burning | Process | Duration |

| Combustion | Controlled and uncontrolled burning of crude oil from tank car spills | Hours to weeks |

15.3.5 Combustion

Intentional (or uncontrolled) burning of Bakken crude oil released during train accidents emits the following hazardous compounds into the air (Lemieux et al. 2004). Those compounds which are not shown in the table are sulfur dioxide, carbon monoxide, and particulates; these are common in Bakken crude oil emissions from burns (Table 15.11).

Table 15.11 Combustion of Bakken crude oil and estimated emissions.

Source: Lemieux et al. (2004).

| Compound | Emissions (mg kg−1 burned) |

| Benzene | 251 |

| Formaldehyde | 139 |

| Naphthalene | 44 |

| Benzo(a)pyrene | 1 |

| Total dioxins and furans | 0.000 428 |

15.3.6 DOT‐117 Tank Car Design

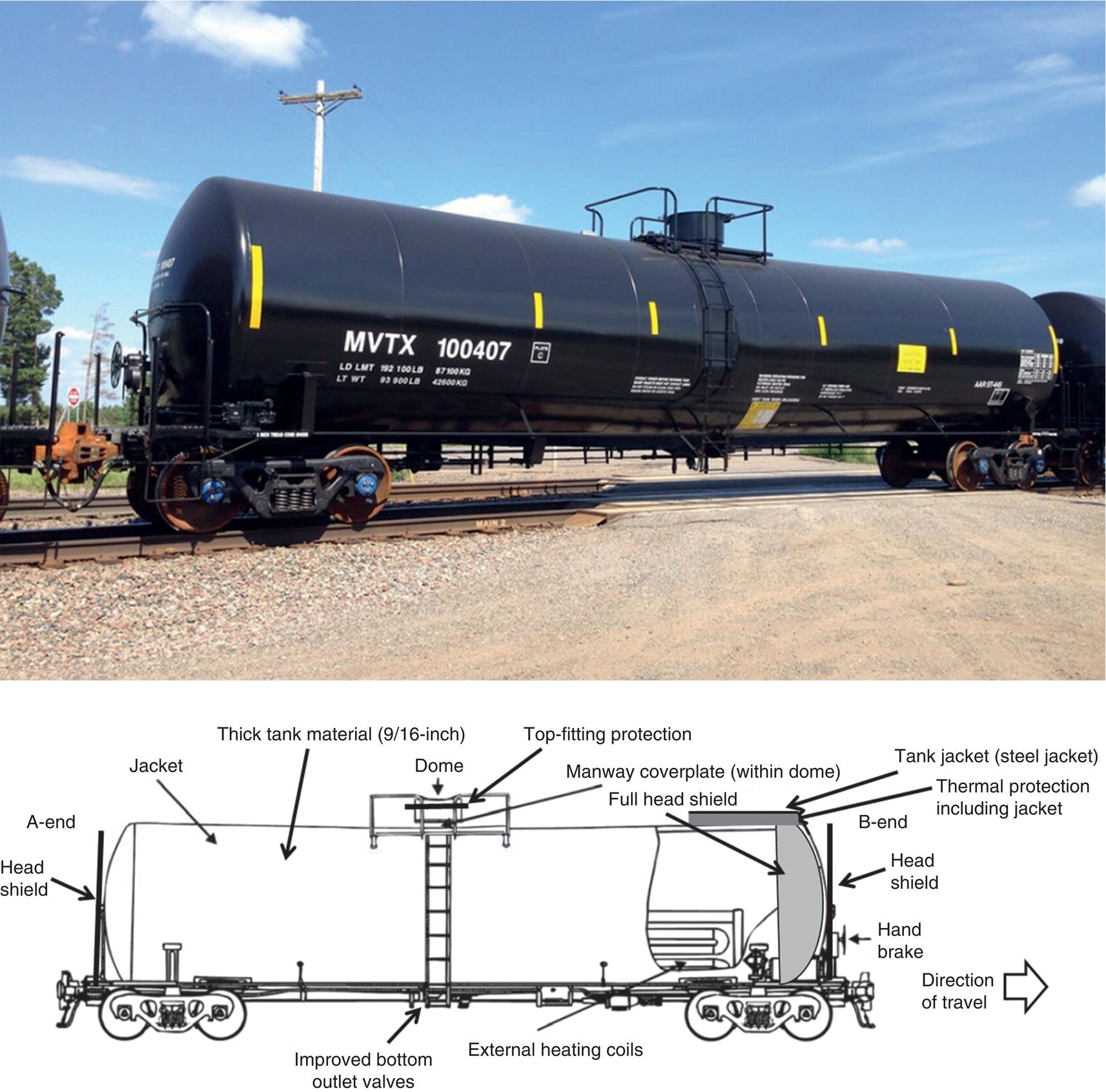

The 2013 train disaster in Lac‐Mégantic, Quebec, proved the need for improved safety in tank car design, while transporting Bakken crude and other flammable substances. Unlike in DOT‐111 tank cars, new regulations were developed effective 1 October 2015 for DOT‐117 tank cars, which feature improvements for unpressurized tank car design to transport flammable liquids such as crude oil and ethanol (DOT 2016; NTSB 2015; PHMSA 2017). The DOT‐117 (Figure 15.4) standard includes the following:

- Normalized steel heads and shields.

- ½‐in full head shields (full height).

- Tank material: head and shell thickness (9/16 in).

- Top fittings protection.

- ½‐in ceramic insulation.

- Steel jackets (complete).

- High flow pressure relief valve.

- Improved bottom outlet valve handle.

Figure 15.4 After 1 October 2015, DOT‐117 (TC‐117 in Canada) is the new standard for all new unpressurized tank cars in use on North American railroads. Photo of DOT‐117 tank car (NTSB 2015) (above). DOT‐117 diagram with improvements listed (below).

15.4 Violations

PADEP keeps records for administrative and environmental health and safety (ESH) violations. From 2009 to 2015, there have been thousands of violations (Table 15.12). The top 20 violations provide insight into the types of challenges operators are facing in maintaining best management practices such as creating and implementing a written erosion and sediment control plan (ESCP) when earth disturbance activities will affect an area of more than 5000 ft2 (465 m2) or more.

Table 15.12 Number and type of administrative, environmental, health, and safety violations.

Source: From PDEP (2017).

| Description of violation | Type of violation | Total number of violations | Total number of wells |

| Failure to properly store, transport, process, or dispose of a residual waste | Environmental health and safety | 490 | 401 |

| Oil and Gas Act (OGA) 223 – General. Used only when a specific OGA code cannot be used | Administrative | 349 | 183 |

| Failure to minimize accelerated erosion, implement erosion and sediment (E&S) plan, and maintain E&S controls. Failure to stabilize site until total site restoration under OGA Sec 206(c)(d) | Environmental health and safety | 315 | 251 |

| Failure to adopt pollution prevention measures required or prescribed by the Department of Environmental Protection (DEP) by handling materials that create a danger of pollution | Environmental health and safety | 292 | 246 |

| Failure to properly control or dispose of industrial or residual waste to prevent pollution of the waters of Pennsylvania | Environmental health and safety | 243 | 207 |

| Pit and tanks not constructed with sufficient capacity to contain polluting substances | Administrative | 222 | 193 |

| Failure to report defective, insufficient, or improperly cemented casing within 24 hours or submit plan to correct within 30 days | Administrative | 175 | 158 |

| Discharge of pollution to waters of the state | Environmental health and safety | 155 | 125 |

| Clean Streams Law (CSL) – General. Used only when a specific CSL code cannot be used | Administrative | 149 | 121 |

| Failure to post permit number, operator name, address, and telephone number in a conspicuous manner at the site during drilling | Administrative | 135 | 121 |

| Failure to maintain 2′ freeboard in an impoundment | Administrative | 107 | 82 |

| Failure to submit well record within 30 days of completion of drilling | Administrative | 100 | 98 |

| Failure to notify DEP of pollution incident. No phone call made forthwith | Administrative | 87 | 80 |

| Impoundment not structurally sound, impermeable, 3rd party protected, >20″ (51 cm) of seasonal high groundwater table | Administrative | 79 | 69 |

| E&S plan not adequate | Administrative | 70 | 64 |

| Improperly lined pit | Administrative | 70 | 61 |

| Failure to design, implement, or maintain best management practices (BMPs) to minimize the potential for accelerated erosion and sedimentation | Administrative | 69 | 53 |

| Failure to post pit approval number | Administrative | 64 | 63 |

| Failure to install, in a permanent manner, the permit number on a completed well | Administrative | 63 | 58 |

| Failure to plug a well upon abandonment | Administrative | 61 | 58 |

15.5 Forensic Analysis

Forensic analysis depends on information on the variations in chemical composition, physical attributes, or other factors that can differentiate contaminated water, soil, or gas samples from another. Forensic analysis is used in areas with unconventional oil and gas drilling and production activities, as well as rail accidents to identify the origin or source of contamination. Sometimes the answers to forensic analysis suggest that unconventional oil and gas operations are not causative or related to conditions in aging domestic water wells, but rather that natural conditions or native compounds such as methane or metals, such as iron, may contribute to the poor quality of domestic water. Other differentiating factors helpful to forensic analysis include the ratio of certain elements or compounds in two or more samples or the relationship between various isotopes in compared samples.

15.5.1 Gas Chromatograms

It has been estimated that an average crude oil has about 100 000 different compounds and the use of ultrahigh‐resolution mass analysis can separate and identify tens of thousands of these compounds (Marshall and Rodgers 2008). A gas chromatograph (GC), a primary tool in chemical laboratory business, can identify about 1000 compounds in crude oil. Chemists even use the term “fingerprint” evaluation for the forensic task of examining laboratory data to determine and differentiate sample sources, weathering, or other processes that may have modified sample characteristics. GCs have long been used to “fingerprint” crude oils for geochemical differentiation (McCaffrey et al. 2011, 2017). The number of possible analytes for coproduced water is exceedingly large (Figure 15.5). The relative abundance or ratios of specific elements or compounds and their isotopes to other analytes, the amount of weathering in a sample, or even the low concentrations of tentatively identified compounds (TICs) are all used in the multiple lines of evidence to identify the sources of hydrocarbons and other contaminants.

Figure 15.5 Coproduced water has a variety of chemical characteristics that might be used to help identify the source of the water (Hayes and Severin 2012).

15.5.2 Tentatively Identified Compounds (TICs)

Laboratory‐reported TICs from VOC and SVOC analyses can sometimes provide clues to the presence of chemicals, which may help to identify potential sources of contamination. TICs are compounds that can be detected by the laboratory analytical methods, but, without the analysis of standards, these chemicals cannot be confirmed or reliably quantified. To be identified as a TIC, a chromatogram peak has to have an area of at least 10% as large as the area of the nearest internal standard as well as a match quality >80% (US EPA 2015e). The TIC match quality is based on the number and ratio of the major fragmentation ions. A TIC value of 99 is a perfect match. Although the TIC report is essentially a qualitative report, an estimated concentration can be calculated based on a response factor of 1.00 and the area of the nearest internal standard. Frequently, TICs are representative of a class of compounds rather than indicating a specific compound (US EPA 2015e), and in some cases, TICs can be useful in providing diagnostic forensic information. An example might be a TIC of 2‐butoxyethanol (C6H14O2), a glycol ether that could be used as a hydraulic surfactant or foaming agent. Although the TIC indicates minute quantities below standard reporting levels, the presence of 2‐butoxyethanol can be important nonetheless. In the absence of other potential chemical sources, 2‐butoxyethanol could, with other lines of supporting evidence, provide a chemical source from HVHF operations. An example VOC analysis chromatogram shows four TICs identified: acetic acid, toluene, heptane, and D‐limonene (Figure 15.6). The joint presence or specific industrial uses of the TICs may help to provide evidence of the source of the contaminants.

Figure 15.6 Tentatively identified compounds (TICs) from this volatile organic compound (VOC) analysis lists chemicals with low concentrations, which might otherwise be missed. Example VOCs in this printout include acetic acid and D‐limonene, which have component retention times of 6.1480 and 11.2388 minutes, respectively.

15.5.3 Piper Diagrams

Specific ion chemistry, when plotted on a piper diagram, can be used to help differentiate between multiple sources of water, using anion and cation ratios (Figure 15.7; Table 15.13). The piper diagram shows data from the US EPA Northeast Pennsylvania retrospective case study (US EPA 2015a), which is described later in this chapter. Piper diagrams can frequently be used to identify water sources related to specific aquifers, fluids used in unconventional oil and gas operations, or waters used in agricultural or industrial activities, based on dissolved anions and cations. The three points of the cation plot (left side of Figure 15.7) are calcium, magnesium, and sodium plus potassium cations. The points of the anion plot are sulfate, chloride, and bicarbonate and carbonate anions. The two triangular‐shaped ternary plots are then projected upward onto a diamond plot. The diamond plot is a graph of the anions (sulfate and chloride/total anions) and cations (sodium and potassium/total cations). In this case, water containing different ratios of dissolved salts have been identified using the piper diagram.

Figure 15.7 Typical piper diagram showing cations and anions present in water.

Source: Data from the US EPA Northeast Pennsylvania retrospective case study US EPA (2015a).

Table 15.13 List of major ions, trace metals, nutrients, physical properties, selected analytical method, and detection limits.

Source: From Reilly (2014).

| Major cations | Method | Detection limit |

| Sodium – Na+ | EPA 200.7 | 0.05, 0.5 |

| Potassium – K+ | EPA 200.7 | 0.5 |

| Calcium – Ca2+ | EPA 200.7 | 0.01, 0.1 |

| Magnesium – Mg2+ | EPA 200.7 | 0.01, 0.1 |

| Barium – Ba2+ | EPA 200.7 | 0.01 |

| Strontium – Sr2+ | EPA 200.7 | 0.01 |

| Manganese – Mn2+ | EPA 200.7 | 0.01 |

| Iron – Fe2+ | EPA 200.7 | 0.01 |

| Aluminum – Al3+ | EPA 200.7 | 0.02 |

| Major anions | ||

| Chloride – Cl− | EPA 300.0 | 0.5, 0.9, 1 |

| Bromide – Br− | EPA 300.0 | 0.1 |

| Sulfate – SO42− | EPA 300.0 | 0.9, 1.8 |

| Trace metal | ||

| Arsenic – As | EPA 200.8 | 0.001 |

| Nutrients | ||

| Nitrate–nitrite as N | EPA 353.2 | 0.2, 0.3 |

| Total Kjeldahl nitrogen | SM 4500 Norg B/SM 4500 NH3 B&C | 0.84 |

| Total nitrogen | Calculation | 0.89 |

| Physical properties | ||

| Alkalinity as CaCO3 | EPA 310.2 | 2, 10 |

| Total dissolved solids | SM 2540 C | 5, 10, 20 |

15.5.4 Biomarkers

Biomarkers, complex molecules derived originally from formerly living organisms, are found in petroleum and include pristane, phytane, porphyrin, steranes, and triterpanes. There is little change in their structures where they are detected in the range of several hundred mg l−1 or parts per million (ppm) (Peters et al. 2007a, b). Biomarkers have been used for a variety of chemical fingerprinting studies relating to the origin of the petroleum, the types of the precursor organic matter in the petroleum source rock, the correlation of the crude oil with the organic material found in the source rocks, the environmental conditions of sediment deposition, the assessment of thermal maturity, the thermal history of the crude oil, the degree of biodegradation, the later alteration, and the information as to the age of the source rock (Fingas 2010).

Used as biomarkers for phytoplankton, isoprenoids pristane and phytane primarily originate from the phytol side chain of the chlorophyll molecule (Didyk et al. 1978; Volkman and Maxwell 1986) and their identification can be useful (Figure 15.8). Biomarker compounds are usually identified using gas chromatography‐mass spectrometry (GC‐MS) techniques. Although isoprenoids may comprise <5% of diesel fuel, these branched alkanes have a chemical structure that generally inhibits biodegradation, so they are usually preserved and can be relied upon as diagnostic compounds.

Figure 15.8 Biomarkers pristane and phytane are sourced from chlorophyll and are frequently preserved and present in crude oil and refined petroleum hydrocarbon products (Zafiriou et al. 1977).

15.5.4.1 Compound‐Specific Isotope Analysis

When organic compounds, including petroleum hydrocarbons, degrade in the environment, the ratio of stable isotopes will often change over time. Different leaks or spills of the same material at different times may have different isotopic fingerprints or signatures that can be used for identification. Weathering processes include evaporation, emulsification, adsorption, dispersion, dissolution, oxidation–reduction reactions, and biodegradation. Compound‐specific isotope analysis (CSIA) is the technique used to assess biodegradation and source identification of organic contaminants in groundwater (Hunkeler et al. 2008). The CSIA uses a GC with an isotope‐ratio mass spectrometer (GC‐IRMS) to better differentiate comingled plumes of the same chemical compounds (Figure 15.9).

Figure 15.9 GC‐IRMS is used for compound‐specific isotope analysis of carbon compounds (Hunkeler et al. 2008).

CSIA is based on the concept that atoms of a specific element must have the same number of protons and electrons, but they can have a different number of neutrons. When atoms differ only in the number of neutrons, they are referred to as isotopes of each other. If a particular isotope is not radioactive, it is called a stable isotope. Because they differ in the number of neutrons, a mass spectrometer is used to identify different isotopes of the same element, which differ in mass (Hunkeler et al. 2008). CSIA is also used to evaluate naturally occurring organic compounds such as aromatic compounds, diamondoids, isoprenoids, and n‐alkanes.

15.5.4.2 CSIA of Biomarkers

CSIA of biomarkers (CSIA‐B) is used for source correlation to determine the source of two or more crude oil mixtures. Although produced crude oil, nearby surface seeps, and crude oil generated from the original source rocks may have similar physical characteristics, CSIA‐B can be used to measure specific biomarker steranes and hopanes to differentiate the source.

15.5.5 Chemical and Biological Transformations

Some parent compounds, such as tetrachloroethene (PCE), tetrachloroethane (PCA), and 1,2‐dichloroethane (1,2‐DCA), show transformations related to biological or abiotic processes (Figure 15.10). These compounds are industrial cleaners and solvents.

Figure 15.10 Transformations of contaminants, in this case, chlorinated aliphatic hydrocarbons (NJEHD 2005).

A variety of compounds that are likely to be encountered at the well pad such as benzene, toluene, ethylbenzene, and xylene (BTEX) compounds are naturally found in crude oil as well as refined products such as gasoline, diesel, and kerosene. Sorption, volatilization, and other abiotic processes also transform chemicals over time. BTEX compounds can degrade with both the faster aerobic or slower anaerobic biodegradation pathways (Figure 15.11).

Figure 15.11 Dominant terminal electron‐accepting process, electron acceptors, and typical chemical species responses.

Source: From US EPA (2013c) as modified from AFCEE (2004) and Bouwer and McCarty (1984).

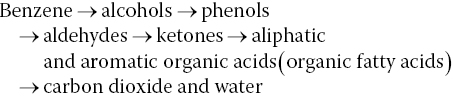

For an aerobic biodegradation process, benzene ultimately breaks down to carbon dioxide and water through this general process:

The co‐metabolic degradation pathway occurs when microbial communities using one compound as an energy source produce an enzyme that chemically transforms and degrades another compound present at the same location. In some cases, analytical chemistry such as US EPA Method 8260B/C GC‐MS and understanding redox conditions can be used to explain degradation products and the ratio of parent compound to degradation products. However, not all compounds can be identified by current laboratory analytical methods.

A variety of molecular diagnostic tools can identify microbial communities and site‐specific organisms. Direct DNA isolation from soil or water samples, denaturing gradient gel electrophoresis (DGGE), polymerase chain reaction (PCR) methods, enzyme activity probes (EAPs), and nucleic acid hybridization (NAH) are a few of the molecular biology techniques providing information on the biological communities in areas with contaminated soil or groundwater. Using these advanced biochemical diagnostic tools can enable more cost‐effective and efficient bioremediation, as well as providing more biochemical evidence of microbial activity in the subsurface and possible parent chemicals and source locations.

15.5.6 Chemical Ratios

Chemical ratios have been used successfully to distinguish among various sources of stray gas. There are multiple salinity sources in the environment (Vengosh et al. 2011), and detailed geochemistry is needed to evaluate the potential salt sources (Table 15.14). The household compound, sodium chloride (NaCl) or common table salt, also provides a good example of the complexities of source identification in the subsurface. For example, the ratio of bromide/chloride (Br/Cl) to chloride can be used to differentiate among background groundwater, groundwater affected by septic sources, and groundwater affected by road salt, backflow, and brine waters (Kight and Siegel 2011).

Table 15.14 Chemical ratios to identify salt sources.

Source: From Vengosh et al. (2011).

| Salt sources | Water type | Chemical compositions |

| Road salt deicing | NaCl water type | Na/Cl ratio = 1 |

| Br/Cl ratio is low | ||

| B/Cl ratio is low | ||

| Domestic waste water and septic tanks | NaCl water type | Na/Cl ratio is ≥1 |

| NO3 is high | ||

| Br/Cl ratio is low | ||

| B/Cl ratio is high | ||

| Acid mine drainage | CaSO4 water type | B/Cl ratio is high |

| pH is low | ||

| Natural saline groundwater | Depends on water type source | Ratios vary on source |

| Coal ash leachates | CaSO4 water type | High Ca, High pH |

| B/Cl ratio is very high | ||

| High‐volume hydraulic fracturing (HVHF) fluids | Depends on water type source; salts added | High Ca, Sr, B, Ba concentrations |

| Marcellus brines | CaCl water type | Na/Cl ratio is <1 |

| Br/Cl ratio is high | ||

| B/Cl ratio is high |

15.5.7 Geochemical Tracers

Geochemical tracers are a specific substance used to trace the course of a process. It may be an element or compound that can be tracked and identified throughout chemical or biological processes by its chemical characteristics such as unusual isotopic mass, radioactivity, or inert behavior. An ideal geochemical tracer may have some of the following characteristics (Lalor and Pitt 1999):

- It can be detected at low concentrations.

- Small variations in tracer concentrations can be differentiated between two or more water sources.

- Tracers generally have stable behavior, so concentrations of the tracer do not attenuate much over time due to physical, chemical, or biological processes.

- A tracer is diagnostic of specific processes or from particular water sources.

- There is an ease of measurement with adequate detection limits.

- Tracers generally accepted standard method of analysis.

- Good sensitivity and repeatability for the tracer tests.

For hydraulic fracturing specialty chemical additives, some of the specific synthetic organic compounds can be used as tracers. However, due to the proprietary nature of many of the chemical additives as well as harsh geochemical conditions in deep shale basin environments, there may be few chemical additives that can serve as tracers.

15.5.7.1 2‐n‐Butoxyethanol Tracer Case Study

Foaming domestic water wells nearby a Marcellus Shale well pad were described in one case near Marcellus Shale gas wells in Pennsylvania. To figure out the source of the foam, samples of almost 30 flowback fluids or coproduction waters were provided, from unconventional natural gas wells drilled in the Marcellus Shale, before treatment at a brine wastewater remediation plant. A sample of drilling foam (M‐I SWACO Platinum Air Foam) from a Schlumberger company was obtained and analyzed. And samples from several domestic wells and a spring were obtained and analyzed (Llewellyn et al. 2015).

One compound in flowback fluids, 2‐n‐butoxyethanol (2‐BE; Chemical Abstracts Service (CAS) number 111‐76‐2), was positively identified in one of the domestic water wells containing an unidentified foaming agent at nanogram‐per‐liter concentrations. The same compound was also identified in the drilling additive and surfactant AirFoam HD. Compound 2‐BE was detected using a new analytical technique, comprehensive 2D gas chromatography coupled to time‐of‐flight mass spectrometry (GCxGC‐TOFMS). Although it does provide an ultralow detection capability, the analytical method is not common or commercially available (Llewellyn et al. 2015).

There have been no reports showing 2‐BE as a naturally occurring compound in waters from the area (Leenheer et al. 1982). In a study of 4 wells in the area, one nearby domestic water well contained about 0.42 ng l−1 2‐BE before purging, and another well contained about 0.086 ng l−1 2‐BE after purging; No 2‐BE was detected in the other two groundwater wells. A few of the 30 flowback/production water samples were positively identified as containing 2‐BE (Llewellyn et al. 2015). There are other industrial sources of 2‐BE besides its use at unconventional oil and gas well sites. A fully miscible, clear liquid with an ether‐like odor at thresholds of 0.10–0.40 ppm in air, 2‐BE is also used as an industrial solvent for paints and surface coatings and is an ingredient for paint thinners, cosmetics, degreasers, dyes, soaps, and herbicides (Llewellyn et al. 2015). In this case, chemicals like 2‐BE could be potentially used as geochemical tracers. The source of the ng l−1 concentrations of 2‐BE foaming agent in the domestic water wells would require more analysis and multiple lines of evidence.

15.5.8 Isotopes

Isotopes are natural variations of a specific element that contains equal number of protons but different number of neutrons in their nuclei, thus isotopes of the same element have varying relative atomic mass but have almost identical chemical properties.

15.5.8.1 Hydrogen and Oxygen Isotopes

Stable isotopes of water are measured as the ratios of the two most stable and abundant isotopes of each element. Most hydrogen (1H) atoms have 1 proton and no neutrons for an atomic weight of 1. The relative abundance of 1H is 99.9885%. Heavy hydrogen, which is the less common isotope of the lightest element (0.0115% relative abundance), also called deuterium (2H or D), has 1 proton and 1 neutron for an atomic weight of 2. Tritium of 3H has 2 neutrons and 1 proton for an atomic weight of 3. Hydrogen also has isotopes from 4H to 7H, which are rare and unstable, but 1H and 2H represent virtually 100% of all hydrogen atoms. The stable isotope ratio of hydrogen is the ratio of 2H (0.0115% of all hydrogen atoms) to 1H (99.9885% of all hydrogen atoms). The 2H/1H ratio is about 0.000 115.

Most oxygen atoms (99.757%) are 16O, which has 8 protons and 8 neutrons for an atomic weight of 16. Heavy oxygen (18O) has 8 protons and 10 neutrons for an atomic weight of 18. Heavy oxygen has a relative abundance of 0.205%. There are other isotopes of oxygen (for example17O), but 16O and 18O represent 99.962% of all oxygen atoms. The stable isotope ratio of oxygen is the ratio of the less common 18O (0.205% of all oxygen atoms) to the more common 16O, which includes 99.757% of all oxygen atoms. The 18O/16O ratio is about 0.002 055.

15.5.8.2 Carbon and Methane Isotopes

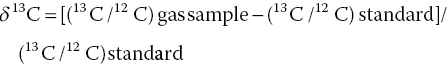

Carbon isotopes are notated as δ13C and pronounced “delta carbon thirteen.” Schoell (1980) showed that the ratio of heavy hydrogen (deuterium) (δ2H CH4); 0/00 (relative to Vienna Standard Mean Ocean Water (VSMOW)) compared with carbon (δ13CCH4); 0/00 (relative to Vienna Pee Dee Belemnite (VPDB)) could be used to differentiate methane samples based on origin. The methane source zones based on hydrogen and carbon isotope data from dozens of researchers were compiled (Coleman et al. (1993) based on data from Schoell (1980)). Thermogenic methane derived from the Marcellus Shale has a relatively consistent carbon to hydrogen isotopic ratio (Figure 15.12). Other stable isotope data using carbon and hydrogen isotopes from north central and northeast Pennsylvania (Baldassar 2011a, b) show background stray gas from the northeastern Pennsylvania in Potter, Tioga, Bradford, and Chemung counties (and from the literature) to display much greater variability than the methane sourced from the Marcellus Shale (Saba 2013). Forensic methods have been developed to differentiate methane sources (Table 15.15).

Figure 15.12 Carbon vs. hydrogen isotopes: biogenic and thermogenic methane.

Source: Saba (2013); used by permission.

Table 15.15 Forensic methods to differentiate methane sources.

| Microbial methane acetate fermentation: marsh gas and landfill gas | ||

| Isotope | Fraction | Range |

| Carbon 13C | δ13C of CH4 | −40 to −62 0/00 |

| Heavy hydrogen (deuterium) | δ2H of CH4 | −270 to −350 0/00 |

| Microbial methane: CO2 reduction called drift gas | ||

| Isotope | Fraction | Range |

| Carbon 13C | δ13C of CH4 | −62 to −90 0/00 |

| Heavy hydrogen (deuterium) | δ2H of CH4 | −180 to −240 0/00 |

| Thermogenic methane: natural gas from the shale gas sources | ||

| Isotope | Fraction | Range |

| Carbon 13C | δ13C of CH4 | −26 to −50 0/00 |

| Heavy hydrogen (deuterium) | δ2H of CH4 | −110 to −250 0/00 |

A stable carbon isotope relates to the gas sample, compared with the standard, as in the following equation (Saba 2013):

The stable carbon isotope of methane is expressed as parts per thousands (0/00). δ13C will vary in time related to depositional history: vegetation type, productivity, and organic carbon content and burial. The standard for δ13C is Vienna Pee Dee Belemnite (VPDB). Collected from the banks of the Pee Dee River in South Carolina, the original Pee Dee Belemnite (PDB) contained extinct fossilized belemnite shells. Since the original rock sample has been consumed completely through analysis, other reference standards were calibrated to the original PDB sample. Carbon isotope values are still reported relative to PDB using the term “VPDB” to show the values that have been normalized to the standard. The standard for δ2H is the oxygen ratios that are measured are compared relative to Vienna Standard Mean Ocean Water (VSMOW). Isotopic compositions of both oxygen and hydrogen are reported against the VSMOW standard.

15.5.9 Forensic Isotope Analysis

A wide variety of other available soluble isotopes, such as lithium, boron, strontium, radium, and others, can undergo forensic analysis. These available soluble isotopes are used in unconventional oil and gas source studies. Isotopic forms have been discovered for every element, and there are 275 isotopes of the 81 stable elements and over 800 radioactive isotopes (Thomas 2013). The isotope abundance measurements are obtained from Rosman and Taylor (1999). Stable isotopic analysis has been used to evaluate stable isotopes in the water cycle (Gat and Gonfiantini 1981) as well as differentiate rainwater (Dansgaard 1964), groundwater (Gat 1971), and surface water (Muir and Coplen 1981).

Isotope mass and abundance is described in Henderson and McIndoe (2005). Dissolved isotope chemical analysis is used in unconventional resource studies and source identification (Table 15.16). Using the dissolved isotopes for forensics is based on the theory that stable isotopes for water such as oxygen δ18O and hydrogen δ2H and dissolved salt isotopes such as boron 11B/10B, strontium 87Sr/86Sr, and radium 228Ra/226Ra in shale waters differ from those in shallow groundwater, surface water, or other water sources.

Table 15.16 Selected isotopes used in differentiating sources of water or methane related to unconventional oil and gas operations.

| Isotope name | Chemical symbol | Mass of atom (u) | % abundance | No. of neutrons | No. of protons |

| Hydrogen (protium) | (1H) | 1.007 825 | 99.9885 | 0 | 1 |

| Deuterium | (2H, or D) | 2.014 102 | 0.0115 | 1 | 1 |

| Tritium | (3H, or T) | 3.016 049 | Not available | 2 | 1 |

| Lithium‐6 | 6Li | 6.015 121 4 | 7.59 | 3 | 3 |

| Lithium‐7 | 7Li | 7.016 003 0 | 92.41 | 4 | 3 |

| Boron‐10 | 10B | 10.012 936 9 | 19.9 | 5 | 5 |

| Boron‐11 | 11B | 11.009 305 4 | 80.1 | 6 | 5 |

| Carbon‐12 | (12C) | 12 | 98.93 | 6 | 6 |

| Carbon‐13 | (13C) | 13.003 354 826 | 1.07 | 7 | 6 |

| Carbon‐14 | (14C) | 14.003 242 | Not available | 8 | 6 |

| Nitrogen‐14 | 14N | 14.003 074 002 | 99.632 | 7 | 7 |

| Nitrogen‐15 | 15N | 15.000 108 97 | 0.368 | 8 | 7 |

| Oxygen‐16 | 16O | 15.994 914 63 | 99.757 | 8 | 8 |

| Oxygen‐17 | 17O | 16.999 131 2 | 0.038 | 9 | 8 |

| Oxygen‐18 | 18O | 17.999 160 3 | 0.205 | 10 | 8 |

| Sulfur‐32 | 32S | 31.972 070 70 | 94.93 | 16 | 16 |

| Sulfur‐33 | 33S | 32.971 458 43 | 0.76 | 17 | 16 |

| Sulfur‐34 | 34S | 33.967 866 65 | 4.29 | 18 | 16 |

| Sulfur‐36 | 36S | 35.967 080 62 | 0.02 | 20 | 16 |

| Chlorine‐35 | 35Cl | 34.968 852 72 | 75.78 | 18 | 17 |

| Chlorine‐35 | 37Cl | 36.965 902 62 | 24.22 | 20 | 17 |

| Bromine‐79 | 79Br | 78.918 336 1 | 50.69 | 44 | 35 |

| Bromine‐80 | 80Br | 80.916 289 | 49.31 | 46 | 35 |

| Strontium‐84 | 84Sr | 83.913 430 | 0.56 | 46 | 38 |

| Strontium‐86 | 86Sr | 85.909 267 2 | 9.86 | 48 | 38 |

| Strontium‐87 | 87Sr | 86.908 884 1 | 7.00 | 49 | 38 |

| Strontium‐88 | 88Sr | 87.905 618 8 | 82.58 | 50 | 38 |

| Lead‐202 | 202Pb | Unstable | Not available | 120 | 82 |

| Lead‐204 | 204Pb | 203.973 020 | 1.4 | 122 | 82 |

| Lead‐206 | 206Pb | 205.974 440 | 24.1 | 124 | 82 |

| Lead‐207 | 207Pb | 206.975 872 | 22.1 | 125 | 82 |

| Lead‐208 | 208Pb | 207.976 627 | 52.4 | 126 | 82 |

| Radium‐226 | 226Ra | 226.025 403 | 100 | 138 | 88 |

| Radium‐228 | 228Ra | 228.031 063 | Trace | 140 | 88 |

15.5.10 Boron and Strontium Isotope Ratios

Some researchers have shown that the Marcellus Shale has a δ11B value of 32–33‰ and a 87Sr/86Sr value of 0.7115. These values, obtained from the Catskill Formation in eastern Pennsylvania, differ from shallow groundwater isotope values of 13.1–28.1‰ for δ11B and 0.712 01–0.715 53 for 87Sr/86Sr (Saba 2013). Based on these distinct ratios of boron, lithium, strontium, and selected other isotopes, flowback fluid of unconventional oil and gas operations can frequently be differentiated from the conventional coproduced water and water from other sources. These characteristics make these elements boron and lithium, which frequently occur naturally in shale formations useful in forensic analysis. When unconventional oil and gas operators inject hydraulic fracturing fluids under high pressure into a black organic‐rich shale formation, not only are the petroleum hydrocarbons released, but also soluble elements such as boron and lithium that are attached to clay minerals within the shale formation are also released during the HVHF operations. Boron and lithium are carried to the surface mixed in with the flowback fluids. Boron and lithium have distinctive isotopic fingerprints and are stable both in the deep shale basin and at the surface, making them suitable as forensic tracers. Boron (B), lithium (Li), and chloride (Cl−): [B/Cl, Li/Cl, δ11B vs. δ7Li] are useful in characterizing the flowback fluids from other water sources. In a study based on 39 hydraulic fracturing flowback fluids and coproduced water samples from the Marcellus and Fayetteville black shale formations (Warner et al. 2014), the ratio of B/Cl (>0.001), Li/Cl (>0.002), δ11B (25–31 ‰), and δ7Li (6–10 ‰) compositions of the flowback fluids was distinct in most cases from the coproduced waters collected from conventional oil and gas wells. Certain elements or compounds are more likely to be identified with flowback fluids. To reinforce the use of these elements in forensic work, a comparison of general isotope ratios of boron and lithium (Table 15.17) was used effectively to differentiate conventional coproduced water from seawater, unconventional HVHF flowback fluid from unconventional oil and gas operations, and global river waters (Warner et al. 2014).

Table 15.17 General isotope ratios of boron and lithium illustrate the general concept of produced fluid differentiation.

Source: Concept and data based on Warner et al. (2014).

| Source of water | δ11B (0/00) | δ7Li (0/00) |

| River water | 10 | 20 |

| HVHF flowback water | 27 | 10 |

| Seawater | 39 | 31 |

| Conventional coproduced water | 46 | 16 |

Values are approximate.

15.5.11 Radioactive Isotopes

Isotopes of radioactive elements have been analyzed as part of the evaluation of naturally occurring radioactive materials (NORM) and technologically enhanced naturally occurring radioactive materials (TENORM) at unconventional and conventional oil and gas fields. NORM and TENORM are generally in sludges, wastes, or by‐products which is enriched with radioactive elements such as radium, uranium, thorium, and potassium and the associated decay products. US EPA regulates radionuclides based on concentration in liquids in micrograms/liter (μg l−1) or parts per billion (ppb). A picocurie, or pCi, is a standard measure of the intensity of radioactivity or how frequently a radioactive particle is released in a sample of radioactive material. The background levels of NORM in Pennsylvania measured in groundwater ranged from <0.1 to 167 picocuries per liter (pCi l−1) for gross alpha (α), 0.6–270 pCi l−1 for gross beta (β), and <0.6–172 pCi l−1 for combined radium (Saba 2013; USGS 2000). These ranges contain background concentrations greater than US EPA’s maximum contaminant levels (MCLs) of 15, 4, and 5 pCi l−1 for gross alpha, beta, and combined radium, respectively. Generally, NORM samples should be collected, and the concentrations should be compared with MCLs and background levels. In other cases where NORM values have been established, the NORM background levels even in oil and gas production areas are well below MCLs.

Marcellus Shale flowback fluids and coproduced waters from gas production wells in central and western Pennsylvania show elevated concentrations of 226Ra and 228Ra in some of the flowback brines, with total 226Ra+228Ra concentrations ranging from 73 to 6540 pCi l−1; these concentrations exceed US EPA’s MCL (5 pCi l−1) by 13–1300 times (US EPA 2015b; Haluszczak et al. 2013; Rowan et al. 2011). Gross radioactivity and specific radionuclides including gross α radioactivity, gross β radioactivity, and the radium isotopes 226Ra and 228Ra were evaluated in southwest Pennsylvania by US EPA (2015b). The main α emitting radionuclides in the natural decay series are 238U, 234U, 230Th, 226Ra, 210Po, 232Th, and 228Th. The major β emitting radionuclides are 210Pb, 228Ra, and 40K (Bonotto et al. 2009). US EPA (2015b) noted that naturally occurring radioactivity in groundwater is produced primarily by the radioactive decay of 238U and 232Th. Having a half‐life of 4.5 × 109 years, the 238U atom and its decay series products include 226Ra and 222Rn. Flowback fluids or coproduced waters may contain some level of background radioactive elements, as in the case of the Marcellus Shale (US EPA 2015b). Levels of radioactivity and specific radioactive isotope ratios can be used to evaluate whether flowback fluids or coproduced waters have mixed with shallow groundwater or surface water resources.

Radium‐containing barite, called radiobarite, has been a documented constituent of some scale and sludge deposits that are generated in oil and gas field production equipment (Zielinski et al. 2001). Radium‐bearing saline formation water pumped to the surface along with crude oil can form a barite precipitate on production equipment surfaces. Age estimates can be calculated based on their decay: short‐lived 228Ra has a half‐life of 5.76 years, which is short compared to the significantly longer half‐life of 1600 years for 226Ra. Present activity ratios of 228Ra/226Ra in radiobarite‐rich scale or highly contaminated soil are compared with initial ratios at the time of radiobarite precipitation. Radium isotopes can be used to determine the age and source of radioactive barite at oil field production sites (Zielinski et al. 2001). Radioactivity levels in some oil field equipment and in soils contaminated by radium‐bearing scale and sludge can be high enough in some cases to pose a potential health threat, and evaluation of site‐specific data reduces the risks of uncertainty. Radioisotope information can be used to help identify water or fluid sources.

15.5.12 Case Studies

In a variety of case studies, included below, isotopic analysis, chemical ratios, other forensic information, and multiple lines of evidence are used to identify sources of water or contamination.

| Location | Main study | Target zone | Counties |

| North California | Ulrick (2017) | Marcellus Shale | Various |

15.5.12.1 Water Isotope Case Study in Northern California

A stable isotope water study in the San Francisco Bay area of northern California was conducted by Jim Ulrick (2017) to differentiate water sources that included tap water, recycled water, rain water, and water from swimming pools. Over a period of 14 years, Ulrick collected 181 water samples for stable isotope ratio analyses. Monthly rainfall samples were also collected for volume‐weighted composite 2012 water‐year stable isotope values. An additional 28 isotope ratios of water from selected water sources from the area were compiled from data in other reports (Muir and Coplen 1981; Newhouse et al. 2004).

In the Ulrick study, a sample stable isotope ratio is measured and compared to the VSMOW, an internationally known reference. Delta (δ) notation is used to show the difference between the sample and VSMOW measurements. The δ values are expressed as parts per thousand or per mil (‰) because the differences are minute. For example, a positive δ value of +10 ‰ for oxygen (δ18O = +10 ‰) means that the sample is enriched in 18O by 10 ‰ compared to VSMOW. The δ18O and δ2D% ratios of precipitation worldwide vary as a function of temperature, elevation, and latitude, and plot along the global meteoric water line (GMWL) (Figure 15.13).

Figure 15.13 Stable isotope ratios of water to differentiate water sources.

Source: After Ulrick (2017); used by permission.

Main Findings: The five sources of water are clearly differentiated based on the ratio of heavy oxygen enrichment compared with heavy hydrogen enrichment (Ulrick 2017).

15.5.12.2 Water Isotope Case Study in Northeast Pennsylvania

| Location | Main study | Target zone | Counties |

| Northeast Pennsylvania | Reilly (2014) | Marcellus Shale | Tioga, Bradford, Lycoming, and Sullivan |

A geochemical study (Reilly 2014; Reilly et al. 2015) was performed using stable isotope analysis of groundwater samples collected in 2012–2013 from 21 groundwater wells in Tioga, Bradford, Lycoming, and Sullivan counties in northeastern Pennsylvania. The groundwater wells were identified by their owners as possibly being contaminated from nearby unconventional gas operations. Water samples from the 21 wells were compared with geochemical data from historical groundwater, Marcellus Formation flowback fluids, and other sources of contaminated waters (Reilly 2014; Reilly et al. 2015). The water analyses included sodium (Na), potassium (K), calcium (Ca), magnesium (Mg), barium (Ba), strontium (Sr), manganese (Mn), iron (Fe), aluminum (Al), chloride (Cl), bromide (Br), sulfate (SO4), arsenic (As), nitrate–nitrite as N, total Kjeldahl nitrogen, total nitrogen, alkalinity, and TDS.

Road salt, animal waste, septic effluent, and Marcellus Formation flowback fluids (Figure 15.14) plotted on a trilinear diagram (piper plot) show that the flowback fluids are limited to areas on the chart that can be identified based on the specific pattern.

Figure 15.14 A Cl/Br vs. Cl cross‐plot with all data points and group averages, along with groundwater 2 Standard Deviation lines marked with the mean and a mark on the chloride axis indicating the secondary maximum contaminant level (250 mg l−1).

Source: After Reilly (2014); used by permission.

The study found that the cause of the 21 well owner complaints was related to natural geochemical conditions in the aquifer or, in the case of one well and possibly others, was impacted by either septic effluent or animal waste. Earlier water sampling studies in the area in 1980 showed 11% of groundwater samples to be impacted by septic effluent. The ion concentrations from the 21 wells did not exceed US EPA primary or secondary contaminant levels and were within the range established during the groundwater study performed in 1980 in the area. Common exceedances in water quality were related to the natural geochemistry of the Catskill and Lock Haven aquifers, which are naturally high in manganese and iron (Reilly et al. 2015).

Main Findings: The study concluded that no evidence exists that groundwater in the 21 wells tested was impacted by Marcellus Formation drilling, hydraulic fracture operations, or gas production activities. The study showed that water well owner complaints in the study area are not uncommon and aquifer qualities related to naturally occurring dissolved minerals such as iron or manganese can impact water quality, as can the conditions of the water wells and proximity to animal wastes and fecal matter. Based on the reaction of well owners to hydraulic fracturing operations in the general area, better communication and information transfer between the operators, regulatory agencies, and the public are needed (Reilly et al. 2015). Improvements to water well quality can be accomplished by understanding the well water chemistry and through regular well maintenance such as well redevelopment, chlorination practices, or water treatment.

15.6 Prospective and Retrospective Case Studies

Prospective case studies involve evaluation of areas that have not yet been drilled and are not impacted by other industrial processes to determine whether oil and gas development contaminates groundwater and surface water resources. Prospective case studies are designed to allow sampling and characterization of a site before, during, and after drilling and hydraulic fracture operations, including the full water cycle: water acquisition, drilling, hydraulic fracture operations, fluid injection, flowback, and coproduction of fluids and gases. Prospective studies tend to take longer to complete, are usually costlier, and may have less bias than retrospective case studies. Generally, prospective case studies follow the following development (Ford and Briskin 2013):

- Site selection.

- Baseline monitoring.

- HVHF well pad installation.

- HVHF well drilling and completion.

- Hydraulic fracturing.

- Flowback management.

- Oil–as production and coproduced waste management.

A water quality monitoring project for a prospective case study would be designed to sample nearby downgradient private wells and surface water bodies (Figure 15.15) before drilling or industrial activities would commence. Baseline sampling is a key component of case studies. A new constructed network of monitoring wells could be placed in locations that would intercept potential groundwater flow from the well pad to downgradient receptors. The monitoring wells installed in different aquifers could obtain local information such as individual groundwater zone depth and preferred flow pathways, flow rates, and flow directions. Data from field meters/kits and laboratory analytical tests should be regularly collected to evaluate changes in water quality over time and assess the fate and transport of potential chemical contaminants. Although two prospective case studies were originally planned by US EPA, the studies were eventually canceled.

Figure 15.15 Conceptual model for prospective case study near an HVHF well pad (no scale implied).

Source: Modified after Ford and Briskin (2013).

In contrast with prospective case studies, retrospective case studies involve studying areas where potential impacts of an activity, such as hydraulic fracture operations, have occurred and some level of impact has been noted. The studies may evaluate data and determine whether or not the hydraulic fracture operations are the cause of potential impacts to water resources. Historic oil and gas production operations have occurred in areas where unlined mud pits may have been used or other releases may have occurred. Isolating the environmental impacts of fluid releases from new drilling activities and processes from historic practices can be difficult. Retrospective case studies frequently lack baseline data, such as site‐specific water quality data, which is useful to correlate water resource impacts with definitive causes or sources. Even with these types of limitations, potential vulnerabilities to water resources can still be described.

15.6.1 US EPA Retrospective Case Study

Congress urged US EPA to study the relationship between HVHF operations and potable water resources in December 2009. US EPA planned for retrospective case studies by asking stakeholders across the nation to participate in identifying specific locations for potential case studies. From comments provided at US EPA meetings as well as electronic or written concerns or complaints from the public, over 40 possible locations were nominated for inclusion in the US EPA research. Possible case study locations were prioritized based on US EPA criteria, including proximity of the case study location to the population and drinking water supplies, the amount of reported evidence of water quality impacts, environmental and health concerns, and information gaps that could be filled at each possible case study location. The US EPA also wanted the selected case study areas to represent diversity in the following categories:

- Geographic and geologic characteristics.

- Populations at risk.

- Hydrogeologic and water resource conditions.

- Land uses.

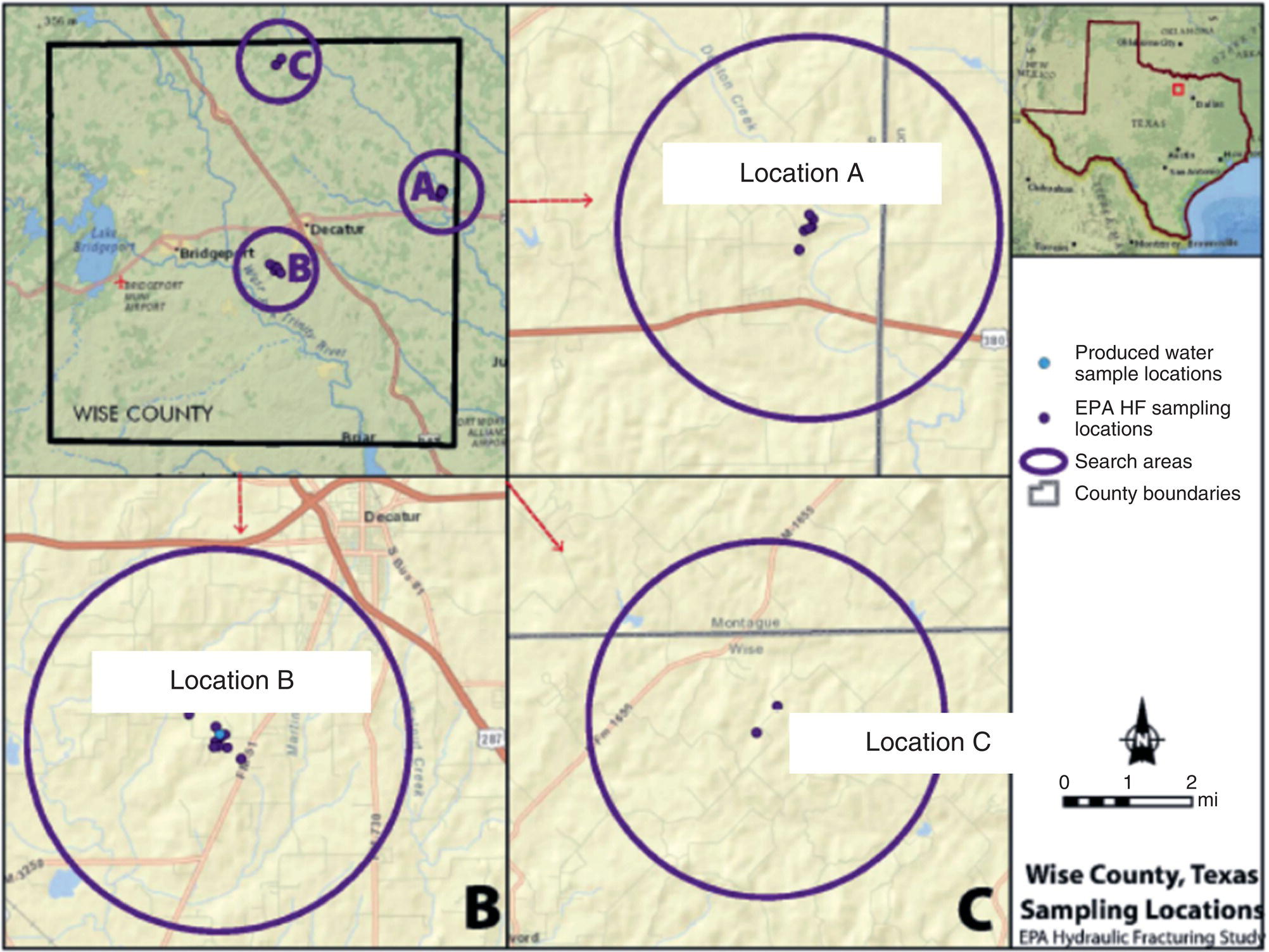

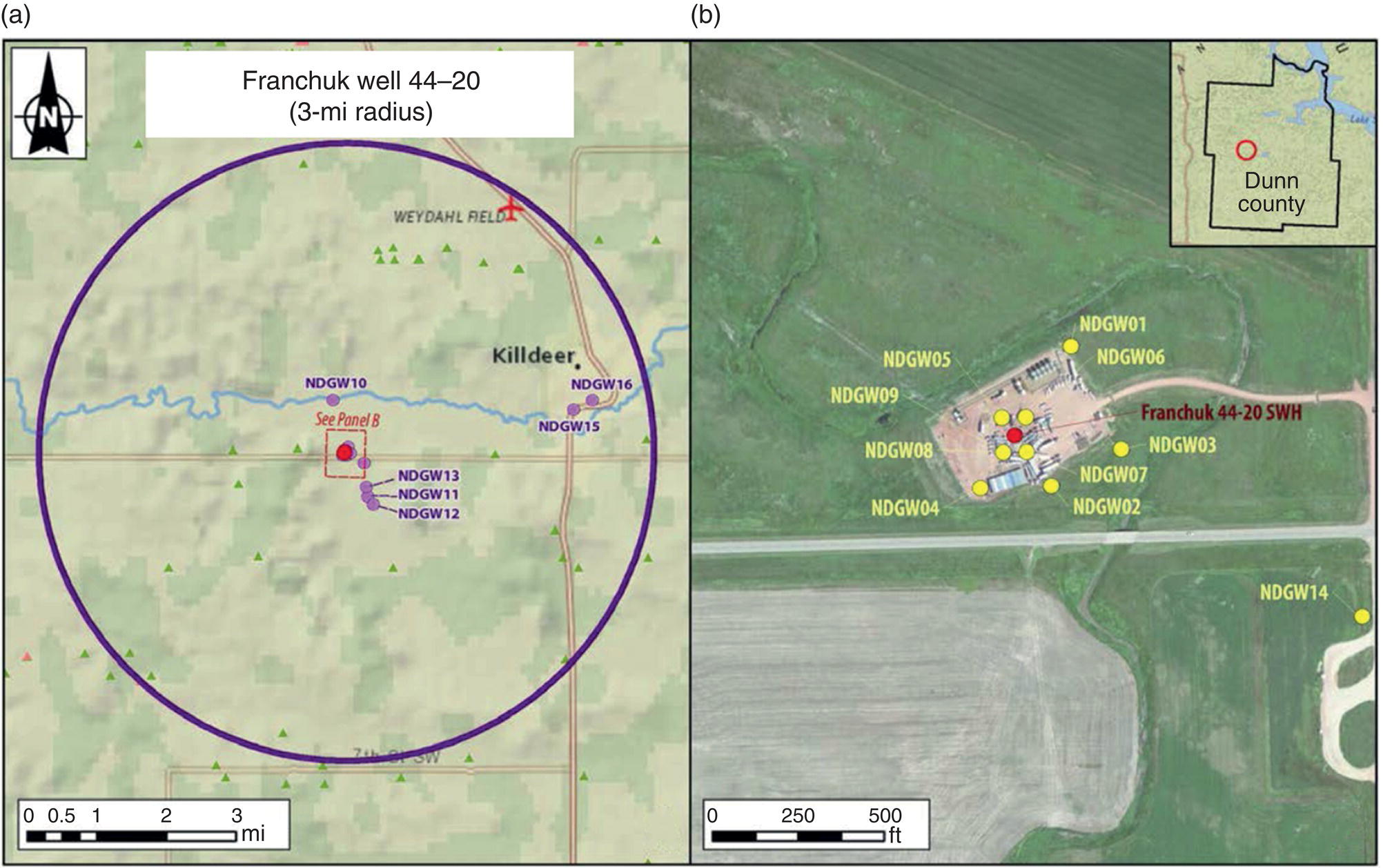

US EPA reviewed the information and finalized five case study areas where hydraulic fracture operations have already occurred and alleged examples of water resource contamination are well documented. The five case study locations (Figure 15.16) included two sites in Pennsylvania, one site in Texas, one site in Colorado, and one site in North Dakota (Table 15.18).

Figure 15.16 Locations of US EPA retrospective case studies and associated hydrocarbon reservoirs (US EPA 2015a, b, c, d, e).

Table 15.18 Summary of US EPA case study locations.

| US EPA case study location | Unconventional reservoir | Counties |

| Northeast Pennsylvania | Marcellus Shale | Bradford and Susquehanna |

| Southwest Pennsylvania | Marcellus Shale | Washington |

| North Texas | Barnett Shale | Wise and Denton |

| West North Dakota | Bakken Shale | Dunn (largest town: Killdeer) |

| Southeast Colorado | Raton Basin Coalbed methane | Las Animas and Huerfano |

The examples of water quality concerns used for the selection of the five case study sites were based on complaints, which were typical of the types of issues that were reported to the agency during the 2010 and 2011 stakeholder meetings. Water and air quality degradation complaints can be related to industrial activities or possibly other causes such as biological, geochemical, or structural processes. The US EPA study with five retrospective sites was planned to evaluate the complaints and to try to correlate the key factors that could be associated with the frequency and severity of alleged drinking water quality degradation from hydraulic fracture operations.

The US EPA examined five operations of the hydraulic fracturing water life cycle:

- Water acquisition – possible impacts related to large‐volume surface or groundwater extraction.

- Chemical mixing – possible environmental impacts at the well pad.

- Well injection – possible impacts related to the injection of specialized chemicals and hydraulic fracturing on water resources.

- Flowback and coproduced fluids and gases – possible impacts of surface spills or subsurface leakage and migration of fluids or gases into beneficial use aquifers and surface water sources.

- Wastewater treatment and waste disposal – possible impacts of incomplete treatment of wastes on water sources.