ORDER

THE SECOND LIFE OF YOUR OBJECTS

PLACE AN ORDER WITH I.MATERIALISE

MODEL OPTIMIZATION FOR POWDER 3D PRINTING

THE SECOND LIFE OF YOUR OBJECTS

Although 3D printing usually uses plastic, the environmental impact linked to this new local production technology can have positive results. The RE_ project (below) consists of making small accessories that are screw on and attach to existing objects in order to give them a new function. Thanks to this idea, an old jam jar can become a bird feeder, a piggy bank, a cup, or even a lemon squeezer.

For the moment, one of the most interesting aspects of 3D printing, from an environmental point of view, is the ability to create replacement parts for repairing defective objects. By repairing objects rather than replacing them, we increase their lifespan. Even if this seems like an obvious fact, our current consumption habits tend towards replacing defective objects rather than repairing them. The replacement or “upgrade” parts for a product can be manufactured locally thanks to digital fabrication, and they remove the costs and environmental impact linked to transportation, packaging, and stocking.

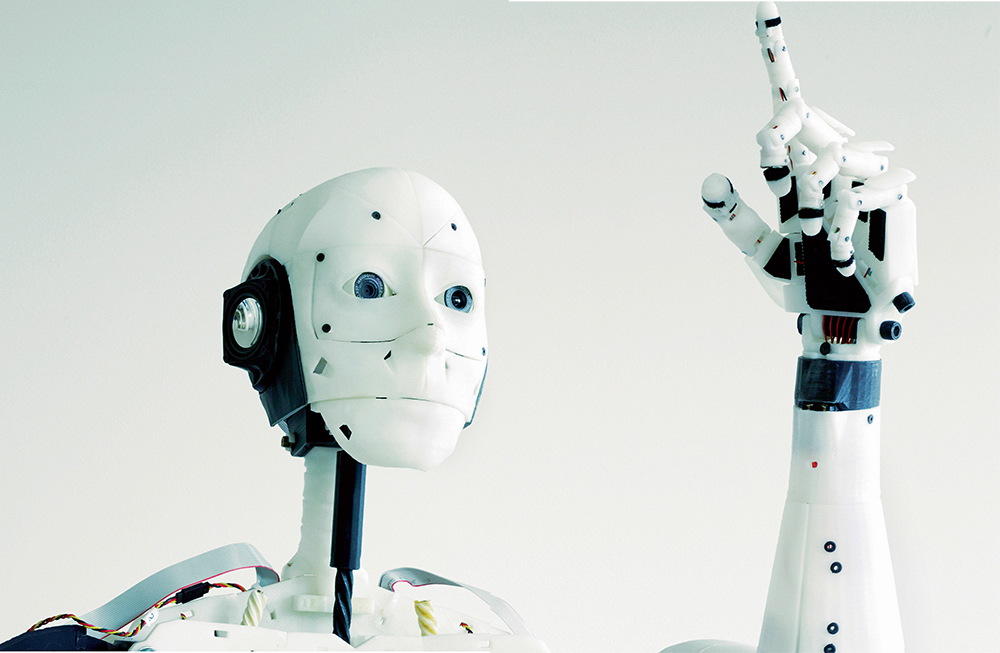

The InMoov project, created by Gael Langevin, is a good example of this close future. His open source humanoid robot is almost entirely made with 3D printing. If a piece breaks, it just has to be printed again. Tomorrow we might be able to order replacement vacuum parts from the local printer after receiving them by e-mail from the manufacturer. Today it is already possible to order your creations and those of others on 3D printing service sites online. Tomorrow... who knows, these services could be on your street! From your personal computer, you can personalize and order a “Bonne Maman” jar handle via the Sculpteo service: http://bit.ly/1p6vq0y

InMoov

By: Gael Langevin

3D printed on: BFB 3D Touch

Source: InMoov

© Fabrice Bouquet

www.inmoov.fr/

Bonne Maman Mug

By: le FabShop

3D printed on: Replicator 2

Source: Thingiverse

Thing: 310961

© le FabShop

Projet RE_

By: Samuel N. Bernier

3D printed on: UP! PP3DP

Source: Designer

© Samuel N. Bernier

3D PRINTING SERVICES

The three main worldwide platforms of online 3D printing were all born in Europe. They offer to load your models for printing, but also to order from creators’ stores or catalogs of items, some of which are customizable. These services will allow you to choose among several materials, fabrication methods, and delivery times. These platforms will immediately provide you with an estimate, but the more rushed you are, the higher the price will be.

I.MATERIALISE

This Belgian supplier offers an impressive catalog of 17 materials: you can print in gold, bronze, copper, or rubber, for example. Material specification sheets are useful for helping you to prepare your files knowing the physical constraints of the future object. Moreover, i.Materialise offers the Creation Corner; because a design or a photo does not magically transform into a 3D model, you can hire a designer or customize existing models. If you are using Autodesk’s 123D applications, know that you can even retrieve your models by connecting to your Autodesk account. i.Materialise is a subsidiary of the Belgian group Matérialise, the largest 3D printing factory in Europe, publisher of the famous 3D printing management software 3D Magics.

SCULPTEO

This French 3D printing service is easy to use and very comprehensive. It offers 3D printing in monochrome and colors and in materials such as plastic, alumide, resin, powder sintering, ceramics, and silver. A relevant and practical service for analyzing, retouching, and customizing your files is also available.

SHAPEWAYS

The Shapeways site offers a large collection of different 3D printed objects in a large number of materials and finishes. The platform also lets you offer your own designs for sale.

3DHUBS

This 3D printing service concept is highly innovative. Instead of offering factory-like 3D printing, like Shapeways, Sculpteo, and I.Materialise, 3D HUBS developed a worldwide network of 3D printer owners. A customer can go on their website, upload her design, and automatically receive 3D print service offers from the nearby hubs. This system allows faster digital manufacturing at a fraction of the price and, most of all, it’s local. You can become part of this community for free.

PLACE AN ORDER WITH I.MATERIALISE

Before starting, go to the materials list in i.Materialise: the maximum size of the printable pieces, the specifications, and even the photos in the overview will help you choose your options and prepare your file. Using the example of a scan created in the “Scan” exercise page 118, we will take a tour of the of the multicolored materials list.

All that’s left is to create an account and click on the “Upload your 3D model” button that appears on the home page to get to the file loading page. We will export our color scan in OBJ to get a textured object. Slide your file into the top left area of the page or use the “Upload” button, once again visible after you have chosen your unit of measurement (inches or mm).

After some calculations, your object will appear. A warning might appear: here they are telling us that the model is too big to be printed in the chosen material.

With the help of the maximum dimensions that the site then gives you, adjust the size of your model using the slider at the bottom left: you can also enter a percentage to make the model larger or smaller, or enter the dimensions in inches or millimeters to get a precise measurement that will be proportionally adjusted to X, Y, or Z. Finally, the “Scale to fit” button will automatically size your object to the maximum possible dimensions. At any time you can change the choice of material and change your settings.

The price of your order is updated in real time.

If you are satisfied, click “Add to cart” to take you to the ordering and payment pages.

Note that with other materials you will be offered a choice of finishes: once again, everything is indicated in the materials forms (link at the beginning of the exercise).

MODEL OPTIMIZATION FOR POWDER 3D PRINTING

The denser and heavier an object is, the more materials it uses, and therefore the higher the price. In SLS, the fabrication is done in a powder bath: if you decide to make an object that is hollow but closed, the non-hardened powder will still be stuck inside your piece (and unless you want to make maracas, you won’t be happy about that). You’ll have to make a piece that is hollow (a “shell”), but with a hole in order to remove the powder remaining on the inside. Let’s open Meshmixer.

Import your model. Let’s first give it a thickness and make it hollow. For a better view of what is happening, change the “Shader” for a transparent texture.

From the “Select” menu, surround the object with the “lasso” tool or use the select all shortcut (Control-A or Command-A).

It will turn orange and new options will appear on the menu. Choose “Select/Edit/Offset” (or Command/Control-D). Enter a negative value in millimeters to create an inner surface.

Click on “Accept”.

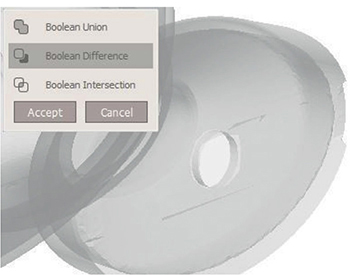

Import a cylinder via the “Meshmix” menu, scale it to a proper size, and put it in the place of your future hole (preferably in a place that will not be visible, like under the base of the bust). Stay in the transparent shader to make sure that you are not touching other walls and inadvertently giving them holes as well.

Select your object and then the cylinder by keeping the “Shift” key pressed. You can also enable the object browser in the view tool bar. A new “Edit” menu appears to offer the three boolean options. “Union” will merge your two objects, “Intersection” will only save the area where the two pieces are superimposed, “Difference”, which we will use, removes the contact zone between the object, along with the cylinder. Click on “Accept” to validate the boolean and export your hollowed model. With this trick, you can easily save up to 50% in powder 3D printing cost.