10

Fastening

In the Introduction, I tell how listening to the stories people told as they shared their tips inspired this book. There were two specific tips, though, that also inspired me to write this book. The first was a trick I saw for removing a broken lightbulb from a socket—a sticky (and potentially bloody) situation, right? You simply cut a potato in half, jam the slice o’ spud onto the broken bulb fragment in the socket, and then twist it out. I got the biggest charge from seeing that. It’s so smart, so simple, and the kind of clever hack that’s as much of a brain-treat flavored with human ingenuity as it is a worthy solution to a problem. A few days later, I had a similar inspired moment when I saw the first tip in this chapter about using a rubber band to help remove a stripped screw head. Seeing these two tips within a short span of time had a weird effect on me. It may sound corny, but tips like this that are such a simple and seemingly perfect solution to a problem have a lingering impact on me. I start seeing my world in a slightly different way; I start working in a slightly different way. This gave me the idea of putting together a collection of such insightful tips in the hope that, in looking through them, not only would the readers find dozens of ideas to improve their making activities, but it might also have the effect of inspiring people to see and think in a slightly different way. So, without further ado, here’s one of the tips that started it all, along with a dozen or so additional eye-opening ideas related to the fine art of fastening things together.

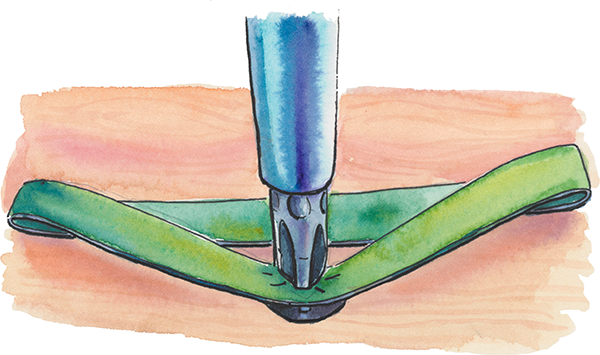

Using a Rubber Band on a Stripped Screw

Using a Rubber Band on a Stripped Screw

Got a screw with a stripped head? Place a wide rubber band over the head and unscrew as normal.

Hold a Screw in Place with Paper, a Comb, or a Pencil Eraser

Hold a Screw in Place with Paper, a Comb, or a Pencil Eraser

If you’re trying to get a small screw or bolt into place, but can’t quite grip it, just poke it through a scrap of paper and use the paper to hold it while you start to screw. Once the threads have taken, rip the paper away. You can also use a comb and place a small nail or brad between two teeth. And for holding small brads that can be too small to hold confidently in your hand, you can use a pencil eraser. Just poke the brad through the eraser, hold the pencil to position the brad, and then begin hammering. With the brad embedded in the workpiece, you can tear away the eraser and finish sinking your nail.

Twist Off that Zip Tie Tail

Twist Off that Zip Tie Tail

When trimming down the excess tail on a zip tie, don’t cut it. This will leave a sharp-edged tail that can scratch you. Use pliers or a multitool to twist the excess off, flush with where the lock is. This will sheer off the excess fairly cleanly and leave no scratchy tail. [SH]

Lube a Screw with Bar Soap

Lube a Screw with Bar Soap

This is a boatbuilder’s trick. If you lubricate a screw with soap, it goes in a lot easier and holds just as well. [TA]

Use Your Pencil as Lubricant

Use Your Pencil as Lubricant

If you’re in the field and need a lubricant, say to re-pin the hinge on a door, don’t forget that graphite (pencil lead) makes an excellent lubricant in a pinch.

Taping Slotted Drivers for Delicate Screws

Taping Slotted Drivers for Delicate Screws

If you’ve ever worked with brass screws, especially antique ones, you know that their heads can be soft and have a tendency to strip. You can help minimize the chance of this happening, and keep your screws unmarred, by wrapping a slotted driver with masking tape before working the screws. [JEP]

Turning Wood Screws Counterclockwise to Start Them

Turning Wood Screws Counterclockwise to Start Them

Make: contributor and toy designer Bob Knetzger, writes: “In order to avoid cross threading or stripping out wood screws that you’re going to remove and then screw back in, don’t just start turning the screw. Place it into the existing hole, but first turn it backward (counterclockwise), very sensitively, with just a tiny bit of inward pressure. At some point, you’ll feel the screw fall into the previous thread in the wood. Stop! Now turn the screw clockwise to tighten. This will prevent you from stripping out the wood!” [BK]

Cheating a Wrench

Cheating a Wrench

On the Classic Work YouTube channel, Ethan shows off some “mechanicin’” tips, including this leveraging classic known as “cheating a wrench.” Basically, you interlock one C-wrench with another to gain a much greater mechanical advantage. As he points out, you have to be careful to keep everything square or the wrenches could slip and you could break your wrist. If it’s carefully done, though, you’ll be amazed at how much pressure you can bring to bear.

Reducing Nail Gun Pressure on the Fly

Reducing Nail Gun Pressure on the Fly

Andy Birkey shares this fantastic nail gun tip that he says is commonly used in production shops. Sometimes, such as when you’re driving nails into very thin stock, the gun’s strong air pressure can drive the nail clean through the board. The normal thing to do would be to reset the PSI on your air compressor. But instead of having to walk to the compressor to adjust the pressure, you can simply angle the head of the gun to the side a little in order to dissipate some of the momentum with which the nail is driven into the workpiece. [AB]