14 ◾ The 5S Playbook

More oor markings: black-and-white oor tape, Maintenance Department.

Bubble wrap location and matching labels for proper placement ensures

correct items return. Area is clear when items are not in their place.

Set in Order ◾ 15

More oor markings: packaging cart and matching labels.

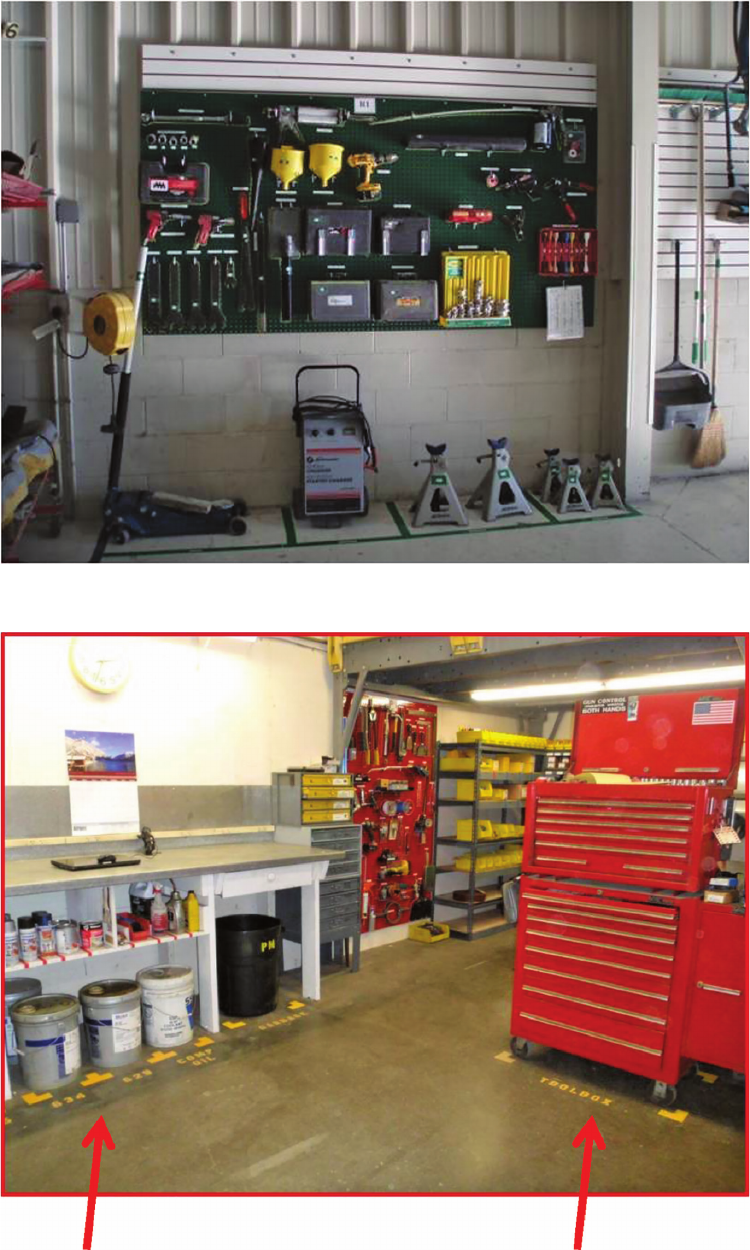

Maintenance Department used yellow corner markings and stencils.

16 ◾ The 5S Playbook

Service shop oor markings and corresponding color pictures on wall.

Always place “Keep Clear” designations in places where safety is a concern.

In this example, many states have regulatory requirements for the clear distance

in front of electrical panels.

Set in Order ◾ 17

Once you have completed the work area outline, aisleways, and locations for

items on the oor, progress upward and begin to organize the individual work-

benches, equipment, and tool locations. Before you start, do the following prepa-

ration steps to help ensure you set up the area properly:

1. Create a list of tools for each station, equipment, workbench, and so on.

2. Separate the pile into common and uncommon use items.

3. Create a list of supplies and other essentials in all workstations.

4. Stage the piles of required items and begin visual organization.

Chapter 6 provides a 10-step illustration on how to create a 5S shadow board.

18 ◾ The 5S Playbook

Tools

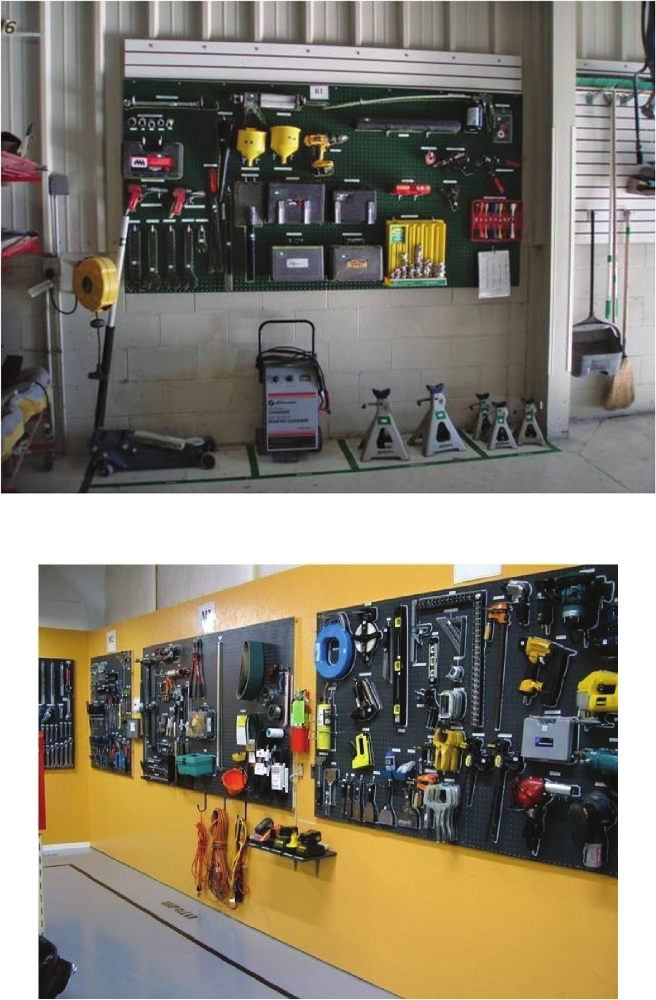

These are body shop tools.

These are maintenance tools.

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.