Chapter 11

Installing and Configuring Printers

THE FOLLOWING COMPTIA A+ 220-901 EXAM OBJECTIVES ARE COVERED IN THIS CHAPTER:

- ✓ 1.13 Install SOHO multifunction device/printers and configure appropriate settings.

- Use appropriate printer drivers for a given operating system

- Configuration settings

- Duplex

- Collate

- Orientation

- Quality

- Configuration settings

- Device sharing

- Wired

- USB

- Serial

- Ethernet

- Wireless

- Bluetooth

- 802.11(a,b,g,n,ac)

- Infrastructure vs. adhoc

- Integrated print server (hardware)

- Cloud printing/remote printing

- Wired

- Public/shared devices

- Sharing local/networked devices via Operating System settings

- TCP/Bonjour/AirPrint

- Data privacy

- User authentication on the device

- Hard drive caching

- Use appropriate printer drivers for a given operating system

- ✓ 1.14 Compare and contrast differences between the various print technologies and the associated imaging process.

- Laser

- Imaging drum, fuser assembly, transfer belt, transfer roller, pickup rollers, separate pads, duplexing assembly

- Imaging process: processing, charging, exposing, developing, transferring, fusing and cleaning

- Inkjet

- Ink cartridge, print head, roller, feeder, duplexing assembly, carriage and belt

- Calibration

- Thermal

- Feed assembly, heating element

- Special thermal paper

- Impact

- Print head, ribbon, tractor feed

- Impact paper

- Virtual

- Print to file

- Print to PDF

- Print to XPS

- Print to image

- Laser

- ✓ 1.15 Given a scenario, perform appropriate printer maintenance.

- Laser

- Replacing toner, applying maintenance kit, calibration, cleaning

- Thermal

- Replace paper, clean heating element, remove debris

- Impact

- Replace ribbon, replace print head, replace paper

- Inkjet

- Clean heads, replace cartridges, calibration, clear jams

- Laser

Let’s face it. No matter how much we try to get away from it, our society is dependent on paper. When we conduct business, we use different types of paper documents, such as contracts, letters, and, of course, money. And because most of those documents are created on computers, printers are inherently important. Even with electronic business being the norm in many situations, you will likely still have daily situations that require an old-fashioned hard copy of something.

Printers are electromechanical output devices that are used to put information from the computer onto paper. They have been around since the introduction of the computer. Other than the display monitor, the printer is the most popular peripheral purchased for a computer because a lot of people want to have paper copies of the documents that they create.

In this chapter, we will discuss the details of each major type of printing technology, including impact printers, inkjet printers, laser printers, thermal printers, and virtual printers. Once we cover the different types, we’ll talk about installing and configuring printers and finish up with a section on printer maintenance.

Understanding Print Technologies and Imaging Processes

Several types of printers are available on the market today. As with all other computer components, there have been significant advancements in printer technology over the years. Most of the time, when faced with the decision of purchasing a printer, you’re going to be weighing performance versus cost. Some of the higher-quality technologies, such as color laser printing, are rather expensive for the home user. Other technologies are less expensive but don’t provide the same level of quality.

In the following sections, you will learn about the various types of print technologies that you will see as a technician as well as their basic components and how they function. Specifically, we are going to look at five classifications of printing: impact, inkjet, laser, thermal, and virtual.

Impact Printers

The most basic type of printer is in the category known as impact printers. Impact printers, as their name suggests, use some form of impact and an inked ribbon to make an imprint on the paper. Impact printers also use a paper feed mechanism called a tractor feed that requires special paper. Perhaps you’ve seen it before—it’s continuous feed paper with holes running down both edges.

There are two major types of impact printers: daisy wheel and dot matrix. Each type has its own service and maintenance issues.

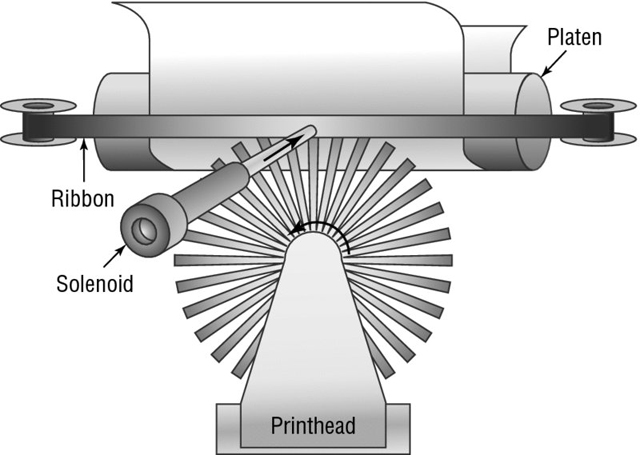

Daisy-Wheel Printers

The first type of impact printer we’re going to discuss is the daisy-wheel printer. This is one of the oldest printing technologies in use. These impact printers contain a wheel (called the daisy wheel because it looks like a daisy) with raised letters and symbols on each “petal” (see Figure 11.1). When the printer needs to print a character, it sends a signal to the mechanism that contains the wheel. This mechanism is called the print head. The print head rotates the daisy wheel until the required character is in place. An electromechanical hammer (called a solenoid) then strikes the back of the petal containing the character. The character pushes up against an inked ribbon that ultimately strikes the paper, making the impression of the requested character.

Figure 11.1 A daisy-wheel printer mechanism

Daisy-wheel printers were among the first types of impact printer developed. Their speed is rated by the number of characters per second (cps) they can print. The earliest printers could print only two to four characters per second. Aside from their poor speed, the main disadvantage of this type of printer is that it makes a lot of noise when printing—so much so, in fact, that special enclosures were developed to contain the noise. There is also no concept of using multiple fonts; the font is whatever the character on the wheel looks like.

The daisy-wheel printer has a few advantages, of course. First, because it is an impact printer, you can print on multipart forms (like carbonless receipts), assuming that they can be fed into the printer properly. Sometimes, you will hear this type of paper referred to as impact paper. Second, it is relatively inexpensive compared to the price of a laser printer of the same vintage. Finally, the print quality is easily readable; the level of quality was given a name: letter quality (LQ). Today, LQ might refer to quality that’s better than an old-school typewriter (if you’re familiar with them) but not up to inkjet standards.

Dot-Matrix Printers

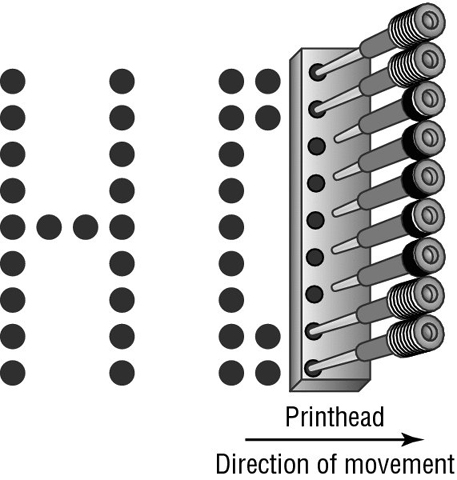

The other type of impact printer that we’ll discuss is the dot-matrix printer. These printers work in a manner similar to daisy-wheel printers, but instead of a spinning, character-imprinted wheel, the print head contains a row of pins (short, sturdy stalks of hard wire). These pins are triggered in patterns that form letters and numbers as the print head moves across the paper (see Figure 11.2).

Figure 11.2 Formation of images in a dot-matrix printer

The pins in the print head are wrapped with coils of wire to create a solenoid and are held in the rest position by a combination of a small magnet and a spring. To trigger a particular pin, the printer controller sends a signal to the print head, which energizes the wires around the appropriate print wire. This turns the print wire into an electromagnet, which repels the print pin, forcing it against the ink ribbon and making a dot on the paper. The arrangement of the dots in columns and rows creates the letters and numbers that you see on the page. Figure 11.2 shows this process.

The main disadvantage of dot-matrix printers is their image quality, which can be quite poor compared to the quality produced with a daisy wheel. Dot-matrix printers use patterns of dots to make letters and images, and the early dot-matrix printers used only nine pins to make those patterns. The output quality of such printers is referred to as draft quality—good mainly for providing your initial text to a correspondent or reviser. Each letter looked fuzzy because the dots were spaced as far as they could be and still be perceived as a letter or image. As more pins were crammed into the print head (17-pin and 24-pin models were eventually developed), the quality increased because the dots were closer together. Dot-matrix technology ultimately improved to the point that a letter printed on a dot-matrix printer was almost indistinguishable from daisy-wheel output. This level of quality is known as near letter quality (NLQ).

Dot-matrix printers are noisy, but the print wires and print head are covered by a plastic dust cover, making them quieter than daisy-wheel printers. They also use a more efficient printing technology, so the print speed is faster (typically starting around 72cps). Some dot-matrix printers (like the Epson DFX series) can print at close to a page per second! Finally, because dot-matrix printers are also impact printers, they can use multipart forms. Because of these advantages, dot-matrix printers quickly made daisy-wheel printers obsolete.

Inkjet

One of the most popular types of printers in use today is the inkjet printer. As opposed to impact printers, which strike the page, these printers spray ink on the page to form the image. Inkjet printers typically use a reservoir of ink, a pump, and a nozzle to accomplish this. Older ones were messy, noisy, and inefficient, but the technology is good enough now that you see plenty of photo printers using inkjet technology. You might also hear these types of printers referred to as bubble-jet printers, but that term is copyrighted by Canon. The main difference is that in a bubble-jet printer, droplets of ink are sprayed onto a page and form patterns that resemble the items being printed. You can think of it as spraying droplets of ink in a very high-definition dot-matrix pattern, although printer manufacturers would likely scoff at the comparison to an older technology.

In the following sections, you will learn the parts of an inkjet printer as well as how inkjet printers work.

Parts of a Typical Inkjet Printer

Inkjet printers are simple devices. They contain very few parts (even fewer than dot-matrix printers) and, as such, are inexpensive to manufacture. It’s common today to have a $40 to $50 inkjet printer with print quality that rivals that of basic laser printers.

The printer parts can be divided into the following categories:

- Print head/ink cartridge

- Head carriage, belt, and stepper motor

- Paper-feed mechanism

- Control, interface, and power circuitry

Print Head/Ink Cartridge

The first part of an inkjet printer is the one that people see the most: the print head. This part of a printer contains many small nozzles (usually 100 to 200) that spray the ink in small droplets onto the page. Many times, the print head is part of the ink cartridge, which contains a reservoir of ink and the print head in a removable package. Most color inkjet printers include multiple print heads, one for each of the CMYK(cyan, magenta, yellow, and black) print inks. The print cartridge must be replaced as the ink supply runs out.

Inside the ink cartridge are several small chambers. At the top of each chamber are a metal plate and a tube leading to the ink supply. At the bottom of each chamber is a small pinhole. These pinholes are used to spray ink on the page to form characters and images as patterns of dots, similar to the way a dot-matrix printer works but with much higher resolution.

There are two methods of spraying the ink out of the cartridge. Hewlett-Packard (HP) popularized the first method: When a particular chamber needs to spray ink, an electric signal is sent to the heating element, energizing it. The elements heat up quickly, causing the ink to vaporize. Because of the expanding ink vapor, the ink is pushed out of the pinhole and forms a bubble. As the vapor expands, the bubble eventually gets large enough to break off into a droplet. The rest of the ink is pulled back into the chamber by the surface tension of the ink. When another drop needs to be sprayed, the process begins again. The second method, developed by Epson, uses a piezoelectric element (either a small rod or a unit that looks like a miniature drum head) that flexes when energized. The outward flex pushes the ink from the nozzle; on the return, it sucks more ink from the reservoir.

When the printer is done printing, the print head moves back to its maintenance station. The maintenance station contains a small suction pump and ink-absorbing pad. To keep the ink flowing freely, before each print cycle, the maintenance station pulls ink through the ink nozzles using vacuum suction. The pad absorbs this expelled ink. The station serves two functions: to provide a place for the print head to rest when the printer isn’t printing and to keep the print head in working order.

Head Carriage, Belt, and Stepper Motor

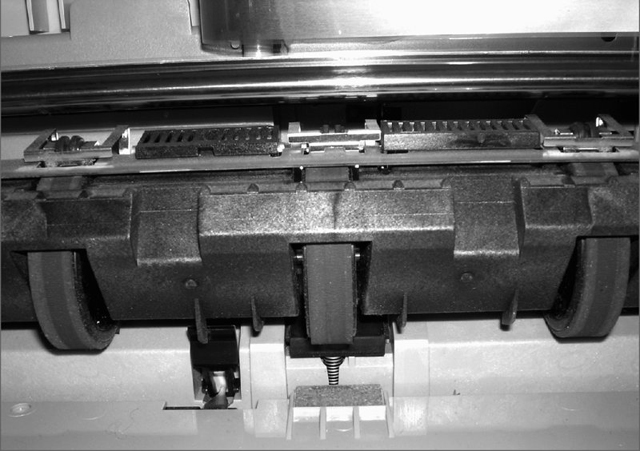

Another major component of the inkjet printer is the head carriage and the associated parts that make it move. The print head carriage is the component of an inkjet printer that moves back and forth during printing. It contains the physical as well as electronic connections for the print head and (in some cases) the ink reservoir. Figure 11.3 shows an example of a head carriage. Note the clips that keep the ink cartridge in place and the electronic connections for the ink cartridge. These connections cause the nozzles to fire, and if they aren’t kept clean, you may have printing problems.

Figure 11.3 A print head carriage (holding two ink cartridges) in an inkjet printer

The stepper motor and belt make the print head carriage move. A stepper motor is a precisely made electric motor that can move in the same very small increments each time it is activated. That way, it can move to the same position(s) time after time. The motor that makes the print head carriage move is also often called the carriage motor or carriage stepper motor. Figure 11.4 shows an example of a stepper motor.

Figure 11.4 A carriage stepper motor

In addition to the motor, a belt is placed around two small wheels or pulleys and attached to the print head carriage. This belt, called the carriage belt, is driven by the carriage motor and moves the print head back and forth across the page while it prints. To keep the print head carriage aligned and stable while it traverses the page, the carriage rests on a small metal stabilizer bar. Figure 11.5 shows the stabilizer bar, carriage belt, and pulleys.

Figure 11.5 Stabilizer bar, carriage belt, and pulleys in an inkjet printer

Paper-Feed Mechanism

In addition to getting the ink onto the paper, the printer must have a way to get the paper into the printer. That’s where the paper-feed mechanism comes in. The paper-feed mechanism picks up paper from the paper drawer and feeds it into the printer. This component consists of several smaller assemblies. First are the pickup rollers (see Figure 11.6), which are several rubber rollers with a slightly flat spot; they rub against the paper as they rotate and feed the paper into the printer. They work against small cork or rubber patches known as separator pads (see Figure 11.7), which help keep the rest of the paper in place so that only one sheet goes into the printer. The pickup rollers are turned on a shaft by the pickup stepper motor.

Figure 11.6 Inkjet pickup rollers

Figure 11.7 Inkjet separator pads

Sometimes the paper that is fed into an inkjet printer is placed into a paper tray, which is simply a small plastic tray in the front of the printer that holds the paper until it is fed into the printer by the paper-feed mechanism. On smaller printers, the paper is placed vertically into a paper feeder at the back of the printer; it uses gravity, in combination with feed rollers and separator pads, to get the paper into the printer. No real rhyme or reason dictates which manufacturers use these different parts; some models use them, and some don’t. Generally, more expensive printers use paper trays because they hold more paper. Figure 11.8 shows an example of a paper tray on an inkjet printer.

Figure 11.8 A paper tray on an inkjet printer

The final parts of the paper-feed mechanism are the paper-feed sensors. These components tell the printer when it is out of paper as well as when a paper jam has occurred during the paper-feed process. Figure 11.9 shows an example of a paper-feed sensor. Being able to identify the parts of an inkjet printer is an important skill for an A+ candidate. In Exercise 11.1, you will identify the parts of an inkjet printer. For this exercise, you’ll need an inkjet printer.

Figure 11.9 A paper-feed sensor on an inkjet printer

Control, Interface, and Power Circuitry

The final component group is the electronic circuitry for printer control, printer interfaces, and printer power. The printer control circuits are usually on a small circuit board that contains all of the circuitry to run the stepper motors the way the printer needs them to work (back and forth, load paper and then stop, and so on). These circuits are also responsible for monitoring the health of the printer and for reporting that information back to the PC.

The second power component, the interface circuitry (commonly called a port), makes the physical connection to whatever signal is coming from the computer (USB, serial, network, infrared, and so on) and also connects the physical interface to the control circuitry. The interface circuitry converts the signals from the interface into the datastream that the printer uses.

The last set of circuits the printer uses is the power circuits. Essentially, these conductive pathways convert 110V (in the United States) or 220V (in most of the rest of the world) from a standard wall outlet into the voltages that the inkjet printer uses, usually 12V and 5V, and distribute those voltages to the other printer circuits and devices that need it. This is accomplished through the use of a transformer. A transformer, in this case, takes the 110V AC current and changes it to 12V DC (among others). This transformer can be either internal (incorporated into the body of the printer) or external. Either design can be used in today’s inkjets, although the integrated design is preferred because it is simpler and doesn’t show the bulky transformer.

The Inkjet Printing Process

Before you print to an inkjet printer, you must ensure that the device is calibrated. Calibration is the process by which a device is brought within functional specifications. For example, inkjet printers need their print heads aligned so that they print evenly and don’t print funny-looking letters and unevenly spaced lines. The process is part of the installation for all inkjet printers. Printers will typically run a calibration routine every time you install new ink cartridges. You will only need to manually initiate a calibration if the printing alignment appears off.

Just as with other types of printing, the inkjet printing process consists of a set of steps that the printer must follow in order to put the data onto the page being printed. The following steps take place whenever you click the Print button in your favorite software (like Microsoft Word or Internet Explorer):

- You click the Print button (or similar) that initiates the printing process.

- The software from which you are printing sends the data to be printed to the printer driver that you have selected.

- The printer driver uses a page-description language to convert the data being printed into the format that the printer can understand. The driver also ensures that the printer is ready to print.

- The printer driver sends the information to the printer via whatever connection method is being used (USB, network, serial, and so on).

- The printer stores the received data in its onboard print buffer memory. A print buffer is a small amount of memory (typically 512KB to 16MB) used to store print jobs as they are received from the printing computer. This buffer allows several jobs to be printed at once and helps printing to be completed quickly.

- If the printer has not printed in a while, the printer’s control circuits activate a cleaning cycle. A cleaning cycle is a set of steps the inkjet printer goes through to purge the print heads of any dried ink. It uses a special suction cup and sucking action to pull ink through the print head, dislodging any dried ink or clearing stuck passageways.

- Once the printer is ready to print, the control circuitry activates the paper-feed motor. This causes a sheet of paper to be fed into the printer until the paper activates the paper-feed sensor, which stops the feed until the print head is in the right position and the leading edge of the paper is under the print head. If the paper doesn’t reach the paper-feed sensor in a specified amount of time after the stepper motor has been activated, the Out Of Paper light is turned on and a message is sent to the computer.

- Once the paper is positioned properly, the print head stepper motor uses the print head belt and carriage to move the print head across the page, little by little. The motor is moved one small step, and the print head sprays the dots of ink on the paper in the pattern dictated by the control circuitry. Typically, this is either a pattern of black dots or a pattern of CMYK inks that are mixed to make colors. Then the stepper motor moves the print head another small step; the process repeats all the way across the page. This process is so quick, however, that the entire series of starts and stops across the page looks like one smooth motion.

- At the end of a pass across the page, the paper-feed stepper motor advances the page a small amount. Then the print head repeats step 8. Depending on the model, either the print head returns to the beginning of the line and prints again in the same direction only or it moves backward across the page so that printing occurs in both directions. This process continues until the page is finished.

- Once the page is finished, the feed-stepper motor is actuated and ejects the page from the printer into the output tray. If more pages need to print, the process for printing the next page begins again at step 7.

- Once printing is complete and the final page has been ejected from the printer, the print head is parked (locked into rest position) and the print process is finished.

Some nicer models of inkjet printers will have a duplexing assembly attached to them, usually at the back of the printer. It’s used for two-sided printing. After the first page is printed, it’s fed into the duplexing assembly, turned over, and fed back into the paper feed assembly. Then the second page can be printed on the back side of the original piece of paper. It’s a fancy attachment that gives your inkjet more functionality.

Laser Printers

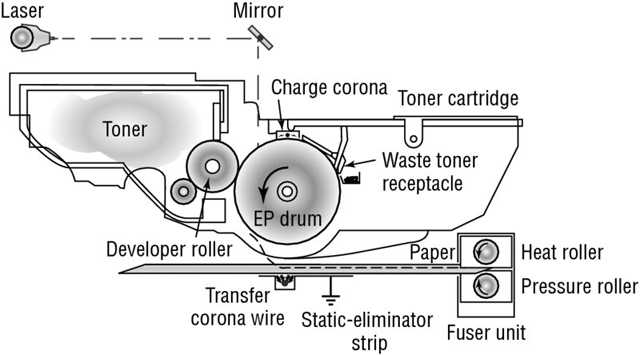

Laser printers and inkjet printers are referred to as page printers because they receive their print job instructions one page at a time rather than receiving instructions one line at a time. There are two major types of page printers that use the electrophotographic (EP) print process. The first uses a laser to scan the image onto a photosensitive drum, and the second uses an array of light-emitting diodes (LEDs) to create the image on the drum. Even though they write the image in different ways, both types still follow the EP print process. Since the A+ exam focuses on the EP print process and not on differences between laser and LED, we’ll focus on the same here.

Xerox, Hewlett-Packard, and Canon were pioneers in developing the laser printer technology we use today. Scientists at Xerox developed the electrophotographic (EP) process in 1971. HP introduced the first successful desktop laser printer in 1984 using Canon hardware that used the EP process. This technology uses a combination of static electric charges, laser light, and a black powdery ink-like substance called toner. Printers that use this technology are called EP process laser printers, or just laser printers. Every laser printer technology has its foundations in the EP printer process.

Let’s discuss the basic components of the EP laser printer and how they operate so that you can understand the way an EP laser printer works.

Basic Components

Most printers that use the EP process contain nine standard assemblies: the toner cartridge, laser scanner, high-voltage power supply, DC power supply, paper transport assembly (including paper-pickup rollers and paper-registration rollers), transfer corona, fusing assembly, printer controller circuitry, and ozone filter. Let’s discuss each of the components individually, along with a duplexing assembly, before we examine how they all work together to make the printer function.

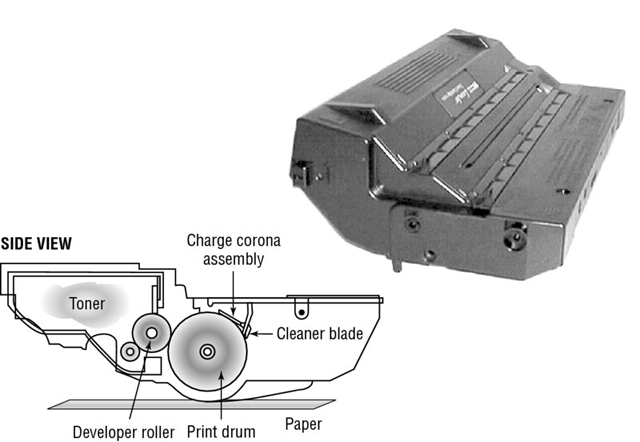

The Toner Cartridge

The EP toner cartridge (see Figure 11.10), as its name suggests, holds the toner. Toner is a black carbon substance mixed with polyester resins to make it flow better and iron oxide particles to make it sensitive to electrical charges. These two components make the toner capable of being attracted to the photosensitive drum and of melting into the paper. In addition to these components, toner contains a medium called the developer (also called the carrier), which carries the toner until it is used by the EP process. The toner cartridge also contains the EP print drum. This drum is coated with a photosensitive material that can hold a static charge when not exposed to light but cannot hold a charge when it is exposed to light—a curious phenomenon and one that EP printers exploit for the purpose of making images. Finally, the drum assembly contains a cleaning blade that continuously scrapes the used toner off the photosensitive drum to keep it clean.

Figure 11.10 An EP toner cartridge

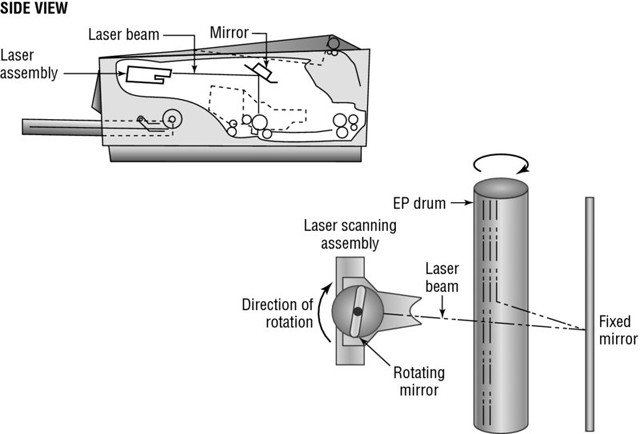

The Laser Scanning Assembly

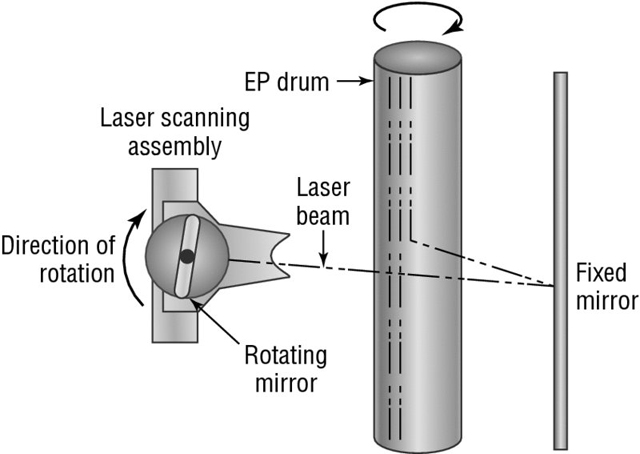

As we mentioned earlier, the EP photosensitive drum can hold a charge if it’s not exposed to light. It is dark inside an EP printer, except when the laser scanning assembly shines on particular areas of the photosensitive drum. When it does that, the drum discharges, but only in the area that has been exposed. As the drum rotates, the laser scanning assembly scans the laser across the photosensitive drum, writing the image onto it. Figure 11.11 shows the laser scanning assembly.

Figure 11.11 The EP laser scanning assembly (side view and simplified top view)

High-Voltage Power Supply (HVPS)

The EP process requires high-voltage electricity. The high-voltage power supply (HVPS) provides the high voltages used during the EP process. This component converts AC current from a standard wall outlet (120V and 60Hz) into higher voltages that the printer can use. This high voltage is used to energize both the charging corona and the transfer corona.

DC Power Supply (DCPS)

The high voltages used in the EP process can’t power the other components in the printer (the logic circuitry and motors). These components require low voltages, between +5VDC and +24VDC. The DC power supply (DCPS) converts house current into three voltages: +5VDC and –5VDC for the logic circuitry and +24VDC for the paper-transport motors. This component also runs the fan that cools the internal components of the printer.

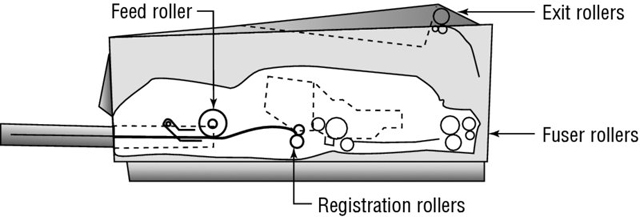

Paper-Transport Assembly

The paper-transport assembly is responsible for moving the paper through the printer. It consists of a motor and several rubberized rollers that each performs a different function.

The first type of roller found in most laser printers is the feed roller, or paper-pickup roller (see Figure 11.12). This D-shaped roller, when activated, rotates against the paper and pushes one sheet into the printer. This roller works in conjunction with a special rubber separator pad to prevent more than one sheet from being fed into the printer at a time.

Figure 11.12 Paper-transport rollers

Another type of roller that is used in the printer is the registration roller (also shown in Figure 11.12). There are actually two registration rollers, which work together. These rollers synchronize the paper movement with the image-formation process in the EP cartridge. The rollers don’t feed the paper past the EP cartridge until the cartridge is ready for it.

Both of these rollers are operated with a special electric motor known as an electronic stepper motor. This type of motor can accurately move in very small increments. It powers all of the paper-transport rollers as well as the fuser rollers.

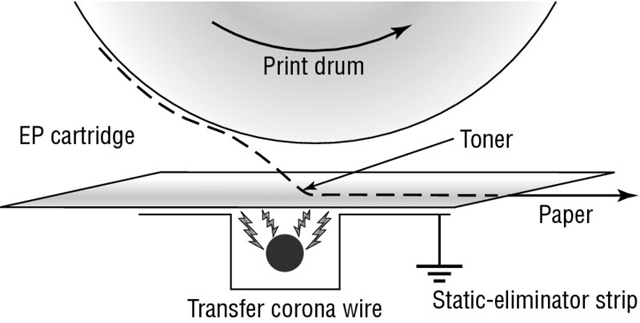

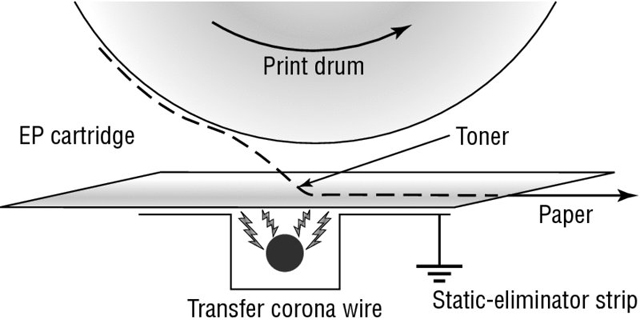

The Transfer Corona Assembly

When the laser writes the images on the photosensitive drum, the toner then sticks to the exposed areas; we’ll cover this in the section “Electrophotographic (EP) Print Process.” How does the toner get from the photosensitive drum onto the paper? The transfer corona assembly (see Figure 11.13) is given a high-voltage charge, which is transferred to the paper, which in turn pulls the toner from the photosensitive drum.

Figure 11.13 The transfer corona assembly

Included in the transfer corona assembly is a static-charge eliminator strip that drains away the charge imparted to the paper by the corona. If you didn’t drain away the charge, the paper would stick to the EP cartridge and jam the printer.

There are two types of transfer corona assemblies: those that contain a transfer corona wire and those that contain a transfer corona roller. The transfer corona wire is a small-diameter wire that is charged by the HVPS. The wire is located in a special notch in the floor of the laser printer (under the EP print cartridge). The transfer corona roller performs the same function as the transfer corona wire, but it’s a roller rather than a wire. Because the transfer corona roller is directly in contact with the paper, it supports higher speeds. For this reason, the transfer corona wire is infrequently used in laser printers today.

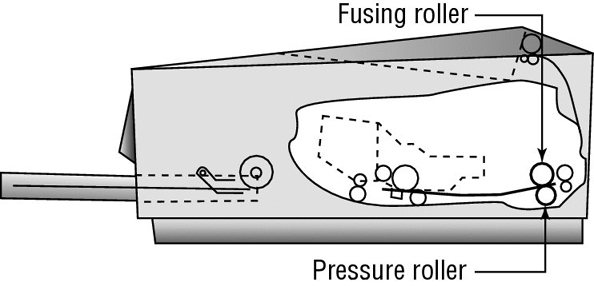

Fusing Assembly

The toner in the EP toner cartridge will stick to just about anything, including paper. This is true because the toner has a negative static charge and most objects have a net positive charge. However, these toner particles can be removed by brushing any object across the page. This could be a problem if you want the images and letters to stay on the paper permanently!

To solve this problem, EP laser printers incorporate a device known as a fuser (see Figure 11.14), which uses two rollers that apply pressure and heat to fuse the plastic toner particles to the paper. You may have noticed that pages from either a laser printer or a copier (which uses a similar device) come out warm. This is because of the fuser.

Figure 11.14 The fuser

The fuser is made up of three main parts: a halogen heating lamp, a Teflon-coated aluminum-fusing roller, and a rubberized pressure roller. The fuser uses the halogen lamp to heat the fusing roller to between 329° F (165° C) and 392° F (200° C). As the paper passes between the two rollers, the pressure roller pushes the paper against the fusing roller, which melts the toner into the paper.

Printer Controller Circuitry

Another component in the laser printer that we need to discuss is the printer controller assembly. This large circuit board converts signals from the computer into signals for the various assemblies in the laser printer using a process known as rasterizing. This circuit board is usually mounted under the printer. The board has connectors for each type of interface and cables to each assembly.

When a computer prints to a laser printer, it sends a signal through a cable to the printer controller assembly. The controller assembly formats the information into a page’s worth of line-by-line commands for the laser scanner. The controller sends commands to each of the components, telling them to wake up and begin the EP print process.

Ozone Filter

Your laser printer uses various high-voltage biases inside the case. As anyone who has been outside during a lightning storm can tell you, high voltages create ozone. Ozone is a chemically reactive gas that is created by the high-voltage coronas (charging and transfer) inside the printer. Because ozone is chemically reactive and can severely reduce the life of laser printer components, many older laser printers contain a filter to remove ozone gas from inside the printer as it is produced. This filter must be removed and cleaned with compressed air periodically (cleaning it whenever the toner cartridge is replaced is usually sufficient). Most newer laser printers don’t have ozone filters. This is because these printers don’t use transfer corona wires but instead use transfer corona rollers, which dramatically reduce ozone emissions.

Duplexing Assembly

Any laser printer worth its money today can print on both sides of the paper (as can some nicer models of inkjet printers, mentioned earlier). This is accomplished through the use of a duplexing assembly. Usually located inside or on the back of the printer, the assembly is responsible for taking the paper, turning it over, and feeding back into the printer so the second side can be printed.

Electrophotographic (EP) Print Process

The EP print process is the process by which an EP laser printer forms images on paper. It consists of seven major steps, each designed for a specific goal. Although many different manufacturers call these steps different things or place them in a different order, the basic process is still the same. Here are the steps in the order you will see them on the exam:

- Processing

- Charging

- Exposing (writing)

- Developing

- Transferring

- Fusing

- Cleaning

Before any of these steps can begin, however, the controller must sense that the printer is ready to start printing (toner cartridge installed, fuser warmed to temperature, and all covers in place). Printing cannot take place until the printer is in its ready state, usually indicated by an illuminated Ready LED light or a display that says something like 00 READY (on HP printers). The computer sends the print job to the printer, which begins processing the data as the first step to creating output.

Step 1: Processing

The processing step comprises two parts: receiving the image and creating the image. The computer sends the print job to the printer, which receives it via its print interface (USB, wireless, etc.). Then, the printer needs to create the print job in such a way that it can accurately produce the output.

If you think back to our discussion of dot-matrix printing earlier in this chapter, you might recall that dot-matrix printers produce images by creating one strip of dots at a time across the page. Laser printers use the same concept of rendering one horizontal strip at a time to create the image. Each strip across the page is called a scan line or a raster line.

A component of the laser printer called the Raster Image Processor (RIP) manages raster creation. Its responsibility is to generate an image of the final page in memory. How the raster gets created is dependent upon the page description language that your system is using, such as PostScript (PS) or Printer Control Language (PCL). Ultimately, this collection of lines is what gets written to the photosensitive drum and onto the paper.

Step 2: Charging

The next step in the EP process is charging (see Figure 11.15). In this step, a special wire or roller (called a charging corona) within the EP toner cartridge (above the photo sensitive drum) gets high voltage from the HVPS. It uses this high voltage to apply a strong, uniform negative charge (around –600VDC) to the surface of the photosensitive drum.

Figure 11.15 The charging step of the EP process

Step 3: Exposing (Writing)

Next is exposing the drum to the image, often referred to as the writing or exposing step. In this step, the laser is turned on and scans the drum from side to side, flashing on and off according to the bits of information that the printer controller sends it as it communicates the individual bits of the image. Wherever the laser beam touches, the photosensitive drum’s charge is severely reduced from –600VDC to a slight negative charge (around –100VDC). As the drum rotates, a pattern of exposed areas is formed, representing the image to be printed. Figure 11.16 shows this process.

Figure 11.16 The writing step of the EP process

At this point, the controller sends a signal to the pickup roller to feed a piece of paper into the printer, where it stops at the registration rollers.

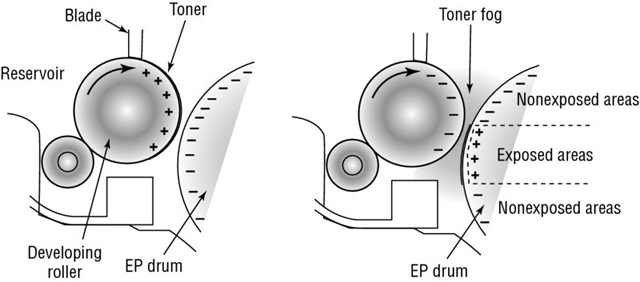

Step 4: Developing

Now that the surface of the drum holds an electrical representation of the image being printed, its discrete electrical charges need to be converted into something that can be transferred to a piece of paper. The EP process step that accomplishes this is developing (see Figure 11.17). In this step, toner is transferred to the areas that were exposed in the writing step.

Figure 11.17 The developing step of the EP process

A metallic roller called the developing roller inside an EP cartridge acquires a –600VDC charge (called a bias voltage) from the HVPS. The toner sticks to this roller because there is a magnet located inside the roller and because of the electrostatic charges between the toner and the developing roller. While the developing roller rotates toward the photosensitive drum, the toner acquires the charge of the roller (–600VDC). When the toner comes between the developing roller and the photosensitive drum, the toner is attracted to the areas that have been exposed by the laser (because these areas have a lesser charge, –100VDC). The toner also is repelled from the unexposed areas (because they are at the same –600VDC charge and like charges repel). This toner transfer creates a fog of toner between the EP drum and the developing roller.

The photosensitive drum now has toner stuck to it where the laser has written. The photosensitive drum continues to rotate until the developed image is ready to be transferred to paper in the next step.

Step 5: Transferring

At this point in the EP process, the developed image is rotating into position. The controller notifies the registration rollers that the paper should be fed through. The registration rollers move the paper underneath the photosensitive drum, and the process of transferring the image can begin; this is the transferring step.

The controller sends a signal to the charging corona wire or roller (depending on which one the printer has) and tells it to turn on. The corona wire/roller then acquires a strong positive charge (+600VDC) and applies that charge to the paper. Thus charged, the paper pulls the toner from the photosensitive drum at the line of contact between the roller and the paper because the paper and toner have opposite charges. Once the registration rollers move the paper past the corona wire, the static-eliminator strip removes all charge from that line of the paper. Figure 11.18 details this step. If the strip didn’t bleed this charge away, the paper would attract itself to the toner cartridge and cause a paper jam.

Figure 11.18 The transferring step of the EP process

The toner is now held in place by weak electrostatic charges and gravity. It will not stay there, however, unless it is made permanent, which is the reason for the fusing step.

Step 6: Fusing

The penultimate step before the printer produces the finished product is called fusing. Here the toner image is made permanent. The registration rollers push the paper toward the fuser rollers. Once the fuser grabs the paper, the registration rollers push for only a short time longer. The fuser is now in control of moving the paper.

As the paper passes through the fuser, the 350° F fuser roller melts the polyester resin of the toner, and the rubberized pressure roller presses it permanently into the paper (see Figure 11.19). The paper continues through the fuser and eventually exits the printer.

Figure 11.19 The fusing step of the EP process

Once the paper completely exits the fuser, it trips a sensor that tells the printer to finish the EP process with the cleaning step.

Step 7: Cleaning

In the last part of the laser print process, a rubber blade inside the EP cartridge scrapes any toner left on the drum into a used toner receptacle inside the EP cartridge, and a fluorescent lamp discharges any remaining charge on the photosensitive drum. (Remember that the drum, being photosensitive, loses its charge when exposed to light.) This step is called cleaning (see Figure 11.20).

Figure 11.20 The cleaning step of the EP process

The EP cartridge is constantly cleaning the drum. It may take more than one rotation of the photosensitive drum to make an image on the paper. The cleaning step keeps the drum fresh for each use. If you didn’t clean the drum, you would see ghosts of previous pages printed along with your image.

At this point, the printer can print another page, and the EP process can begin again.

Summary of the EP Print Process

Figure 11.21 provides a diagram of all of the parts involved in the EP printing process. Here’s a summary of the process, which you should commit to memory:

- The printer receives and processes the image and stores a page in memory.

- The printer places a uniform –600VDC charge on the photosensitive drum by means of a charging corona.

- The laser “paints” an image onto the photosensitive drum, discharging the image areas to a much lower voltage (–100VDC).

- The developing roller in the toner cartridge has charged (–600VDC) toner stuck to it. As it rolls the toner toward the photosensitive drum, the toner is attracted to (and sticks to) the areas of the photosensitive drum that the laser has discharged.

- The image is then transferred from the drum to the paper at its line of contact by means of the transfer corona wire (or corona roller) with a +600VDC charge. The static-eliminator strip removes the high, positive charge from the paper, and the paper, now holding the image, moves on.

- The paper then enters the fuser, where a fuser roller and the pressure roller make the image permanent. The paper exits the printer.

- The printer uses a rubber scraper to clean the photosensitive drum. At that point, it is ready to print the next page or it returns to the ready state.

Figure 11.21 The EP print process

Thermal Printers

The types of printers that you have learned about so far in this chapter account for 90 percent of all printers that are used with home or office computers and that you will see as a repair technician. The remaining 10 percent consist of other types of printers that primarily differ by the method they use to put colored material on the paper to represent what is being printed. Examples of these include solid ink, dye sublimation, and thermal printers. Keep in mind that, for the most part, these printers operate like other printers in many ways: They all have a paper-feed mechanism (sheet-fed or roll); they all require consumables such as ink or toner and paper; they all use the same interfaces, for the most part, as other types of printers; and they are usually about the same size.

Thermal printing technology is used in many point-of-sale terminals and older fax machines (newer fax machines usually use inkjet or laser technology). They print on a kind of special, waxy paper that comes on a roll; the paper turns black when heat passes over it. Thermal printers work by using a print head that is the width of the paper. When it needs to print, a heating element heats certain spots on the print head. The paper below the heated print head turns black in those spots. As the paper moves through the printer, the pattern of blackened spots forms an image on the page of what is being printed. Another type of thermal printer uses a heat-sensitive ribbon instead of heat-sensitive paper. A thermal print head melts wax-based ink from the ribbon onto the paper. These are called thermal transfer or thermal wax-transfer printers.

Thermal direct printers typically have long lives because they have few moving parts. The only unique part that you might not be as familiar with is the paper feed assembly, which oftentimes needs to accommodate a roll of paper instead of sheets. The paper is somewhat expensive, doesn’t last long (especially if it is left in a very warm place, like a closed car in summer), and produces poorer-quality images than the paper used by most of the other printing technologies.

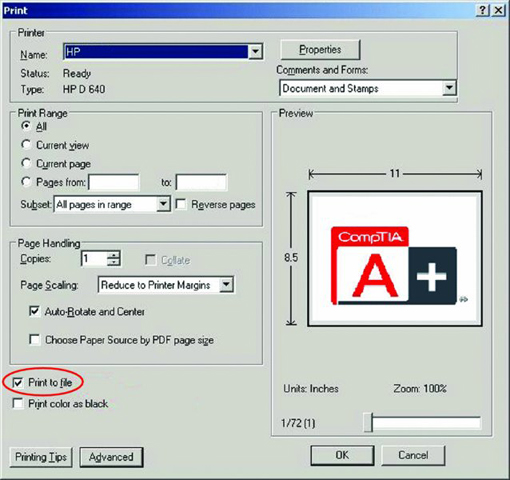

Virtual Printers

All of the print technologies that we have covered so far are physical technologies; that is, they do something to the paper to produce an image, by using ink, toner, or heat. The final technology that we need to cover is virtual printing, which sends the desired output to a file instead of to paper. From the end user’s standpoint, starting the print process is the same. They click Print in their application and the process starts. From there though, instead of sending the output to an electromechanical device, a new file containing the output is generated.

Printing to a file is nothing new; this option has been around for probably 20 years or more. You open the document (or other file) that you wanted to print, select Print, and a print window similar to the one shown in Figure 11.22 opens. Once there, you check the Print To File box, and then click OK. Then, choose where to save the file (just as saving any other file), and after you chose a destination, you are done. Some programs or operating systems would even let you print to an image (such as JPG) instead of a file, but the process works the same way.

Figure 11.22 Print To File option

It used to be that people only chose this option when the printer was not available. You could print your output to a file, take the file to a different machine that had a printer available, and print the file from that machine. Now, you might ask, why wouldn’t you just take the original file from the first computer to the second and print it from the application? That would make sense, but this method allowed you to print from a second computer that didn’t have the application in which you created the file installed on it. There was one big caveat; you had to be printing to the same type of printer using the same print driver as you used to publish the electronic print file; otherwise, it wouldn’t work. The upshot was that it was rarely, if ever, used.

Another option has emerged though, and this one is actually useful! Instead of printing to a generic file format that can be later used to produce a paper copy, you can print to a PDF file. Basically, you are just creating a PDF file using your application’s print function.

To print to PDF from Windows, you need to install an application that installs support for printing to PDF (the Windows operating system does not currently support this natively). There are no shortage of apps in the market that will do this; for example Adobe Acrobat (www.adobe.com), CutePDF Writer (www.cutepdf.com), and Nitro PDF (www.gonitro.com) will do the trick. When you install one of these apps, it will add the option to print to PDF as one of your available printers. After it’s installed, open an app, choose the print option, and you will get a screen similar to the one shown in Figure 11.23.

Figure 11.23 Printing to PDF

Select CutePDF Writer (or your version of it), and click Print. A window will pop up asking where you want to save the file. Save it and a PDF file is created for you. It’s as easy as that.

As we mentioned earlier, Windows does not come with the Print To PDF option by default. It does, however, come with the Print To XPS option (you can see the Microsoft XPS Document Printer option on the right side of Figure 11.23). An Open XML Paper Specification (XPS) file is Microsoft’s version of a PDF. It’s designed to be an open standard, like PDF, but it hasn’t really taken off in terms of popularity. In fact, with Windows 8, Microsoft included support for OpenXPS (OXPS), which is incompatible with the XPS reader included with Windows 7. In addition, Windows 8 includes a native PDF reader, so it seems that Microsoft isn’t heavily invested in supporting the XPS format itself.

Let’s go back to printing to an image for a minute. If your program doesn’t support printing to an image but you need the output of the file in an image format (JPG, TIF, PNG, or other), you can print the file as a PDF first, and then convert it to an image file. There are dozens of free image file converters on the Web.

To summarize, there are four potential options for printing to a virtual printer: print to file, print to image, print to PDF, and print to XPS. Of the four, the only one that you will likely find to be useful is print to PDF.

Installing and Configuring Printers

Odds are that if someone owns a computer, they own a printer as well. If they don’t, they have easy access to a printer at a library, work, or some other place. Many retailers and computer manufacturers make it incredibly easy to buy a printer because they often bundle a printer with a computer system as an incentive to get you to buy.

The A+ 220-901 exam will test your knowledge of the procedures to install printers. We’re going to break this section into two parts: printer interface components and installing and sharing printers.

Printer Interface Components

A printer’s interface is the collection of hardware and software that allows the printer to communicate with a computer. The hardware interface is commonly called a port. Each printer has at least one interface, but some printers have several to make them more flexible in a multiplatform environment. If a printer has several interfaces, it can usually switch between them on the fly so that several computers can print at the same time.

An interface incorporates several components, including its interface type and the interface software. Each aspect must be matched on both the printer and the computer. For example, if you have an older HP LaserJet 4L, it only has a parallel port. Therefore, you must use a parallel cable as well as the correct software for the platform being used (for example, a Macintosh HP LaserJet 4L driver if you connect it to a Macintosh computer).

Interface Types

When we say interface types, we’re talking about the ports used in getting the printed information from the computer to the printer. There are two major classifications here: wired and wireless. Wired examples are serial, parallel, USB, and Ethernet. Wireless options include 802.11 and Bluetooth. You’ve learned about these connections in earlier chapters, but now you will learn how they apply to printers.

Serial

When computers send data serially, they send it 1 bit at a time, one after another. The bits stand in line like people at a movie theater, waiting to get in. Old-time serial (RS-232) connections were painfully slow, but new serial technology (FireWire, Thunderbolt, and others) makes it a more viable option than parallel. While it’s quite common to see USB (another type of serial connection) printers on the market, it’s rare to find any other types of serial printers out there.

Parallel

When a printer uses parallel communication, it is receiving data 8 bits at a time over eight separate wires (one for each bit). Parallel communication was the most popular way of communicating from computer to printer for many years, mainly because it was faster than serial. In fact, the parallel port became so synonymous with printing that a lot of companies simply started referring to parallel ports as printer ports. Today though, parallel printers are becoming uncommon. The vast majority of wired printers that you see will be USB or Ethernet.

A parallel cable consists of a male DB25 connector that connects to the computer and a male 36-pin Centronics connector that connects to the printer. Most of the cables are shorter than 10′. Parallel cables should be IEEE 1284 compliant.

Universal Serial Bus (USB)

The most popular type of wired printer interface as this book is being written is the Universal Serial Bus (USB). In fact, it is the most popular interface for just about every peripheral. The convenience for printers is that it has a higher transfer rate than older serial or parallel connections, and it automatically recognizes new devices. And of course, USB is physically very easy to connect.

Ethernet

Many printers sold today have a wired Ethernet interface that allows them to be hooked directly to an Ethernet cable. These printers have an internal network interface card (NIC) and ROM-based software that allow them to communicate on the network with servers and workstations.

As with any other networking device, the type of network interface used on the printer depends on the type of network to which the printer is being attached. It’s likely that the only connection type that you will run into is RJ-45 for an Ethernet connection.

Wireless

The latest boon in printer interface technology is wireless. Clearly, people love their Wi-Fi because it enables them to roam around an office and still remain connected to one another and to their network. It logically follows that someone came up with the brilliant idea that it would be nice if printers could be that mobile as well—after all, many are on carts with wheels. Some printers have built-in Wi-Fi interfaces, while others can accept wireless network cards. Wi-Fi enabled printers support nearly all 802.11 standards (a, b, g, n, ac), and the availability of devices will mirror the current popularity of each standard.

The wireless technology that is especially popular among peripheral manufacturers is Bluetooth. Bluetooth is a short-range wireless technology; most devices are specified to work within 10 meters (33 feet). Printers such as the HP Officejet 100 mobile printer have Bluetooth capability.

When printing with a Bluetooth-enabled device (like a smartphone or tablet) and a Bluetooth-enabled printer, all you need to do is get within range of the device (that is, move closer), select the print driver from the device, and choose Print. The information is transmitted wirelessly through the air using radio waves and is received by the device.

Interface Software

Now that we’ve looked at the ways that you can connect your printer, it’s time to face a grim reality: Computers and printers don’t know how to talk to each other. They need help. That help comes in the form of interface software used to translate software commands into commands that the printer can understand.

There are two major components of interface software: the page-description language and the driver software. The page-description language (PDL) determines how efficient the printer is at converting the information to be printed into signals that the printer can understand. The driver software understands and controls the printer and must be written to communicate between a specific operating system and specific printer. It is very important that you use the correct interface software for your printer. If you use either the wrong page-description language or the wrong driver software, the printer will print garbage—or possibly nothing at all.

Page-Description Languages

A page-description language works just as its name implies: It describes the whole page being printed by sending commands that describe the text as well as the margins and other settings. The controller in the printer interprets these commands and turns them into laser pulses (or pin strikes). There are several printer communication languages in existence, but the three most common ones are PostScript, Printer Command Language (PCL), and Graphics Device Interface (GDI).

The first page-description language was PostScript. Developed by Adobe, it was first used in the Apple LaserWriter printer. It made printing graphics fast and simple. Here’s how PostScript works: The PostScript printer driver describes the page in terms of “draw” and “position” commands. The page is divided into a very fine grid (as fine as the resolution of the printer). When you want to print a square, a communication like the following takes place:

POSITION 1,42%DRAW 10%POSITION 1,64%DRAW10D% . . .

These commands tell the printer to draw a line on the page from line 42 to line 64 (vertically). In other words, a page-description language tells the printer to draw a line on the page, gives it the starting and ending points, and that’s that. Rather than send the printer the location of each and every dot in the line and an instruction at each and every location to print that location’s individual dot, PostScript can get the line drawn with fewer than five instructions. As you can see, PostScript uses commands that are more or less in English. The commands are interpreted by the processor on the printer’s controller and converted into the print-control signals.

PCL was developed by Hewlett-Packard in 1984 and originally intended for use with inkjet printers as a competitor to PostScript. Since then, its role has been expanded to virtually every printer type, and it’s a de facto industry standard.

GDI is actually a Windows component and is not specific to printers. Instead, it’s a series of components that govern how images are presented to both monitors and printers. GDI printers work by using computer processing power instead of their own. The printed image is rendered to a bitmap on the computer and then sent to the printer. This means that the printer hardware doesn’t need to be as powerful, which results in a less expensive printer. Generally speaking, the least expensive laser printers on the market are GDI printers.

The main advantage of page-description languages is that they move some of the processing from the computer to the printer. With text-only documents, they offer little benefit. However, with documents that have large amounts of graphics or that use numerous fonts, page-description languages make the processing of those print jobs happen much faster. This makes them an ideal choice for laser printers, although nearly every type of printer uses them.

Driver Software

The driver software controls how the printer processes the print job. When you install a printer driver for the printer you are using, it allows the computer to print to that printer correctly (assuming that you have the correct interface configured between the computer and printer). The driver must be written specifically for the operating system the computer is using and for the printer being used. In other words, Mac clients need a different driver than Windows clients do, even to print to the same printer.

When you need to print, you select the printer driver for your printer from a preconfigured list. The driver that you select has been configured for the type, brand, and model of printer as well as the computer port to which it is connected. You can also select which paper tray the printer should use as well as any other features the printer has (if applicable). Also, each printer driver is configured to use a particular page-description language.

Installing and Sharing Local Printers

Although every device is different, there are certain accepted methods used for installing almost all of them. The following procedure works for installing many kinds of devices:

- Attach the device using a local port (generally USB, but maybe parallel) and connect the power.

- Install and update the device driver and calibrate the device.

- Configure options and settings.

- Print a test page.

- Verify compatibility with the operating system and applications.

- Educate users about basic functionality.

Step 1: Attach the Device Using a Local Port and Connect the Power

When installing a printer, you must first take the device out of its packaging and set it up on a flat, stable surface. Then, with the device powered off, connect it to the host computer. Today, the vast majority of local printers are USB, but you will occasionally find ones that use different ports as well.

Once you have connected the device, connect power to it using whatever supplied power adapter comes with it. Some devices have their own built-in power supply and just need an AC power cord connecting the device to the wall outlet, while others rely on an external transformer and power supply. Finally, turn on the device.

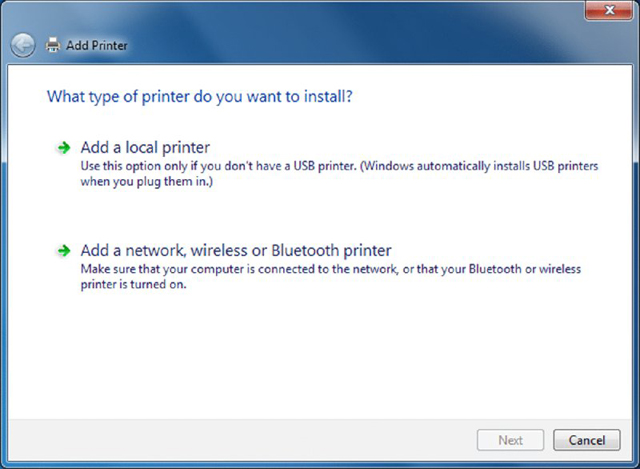

Step 2: Install and Update the Device Driver and Calibrate the Device

Once you have connected and powered up the device, boot up the computer and wait for Windows to recognize the device. Windows will pop up a screen similar to the one shown in Figure 11.24, and you will choose Add A Local Printer. This wizard will allow you to configure the driver for the printer (depending on the device). You can insert the driver CD or DVD that comes with the device and the wizard will guide you through the device driver installation. If Windows fails to recognize the device, you can use the Add A Printer Wizard (in Windows 7 and Windows 8/8.1) or the Add Printer Wizard (in older Windows versions) to troubleshoot the installation and to install the device drivers.

Figure 11.24 Adding a printer in Windows 7

Once the driver is installed, the device will function. But some devices, such as inkjet printers, must be calibrated. If the printer requires this step, it will tell you. You’ll need to walk through a few steps before the printer will print, but instructions will be provided either on your computer screen or on the printer’s display.

Each manufacturer’s process is different, but a typical alignment/calibration works like this:

- During software installation, the installation wizard asks you if you would like to calibrate now, to which you will respond Yes or OK.

- The printer prints out a sheet with multiple sets of numbered lines. Each set of lines represents an alignment instance.

- The software will ask you which set(s) looks the best. Enter the number and click OK or Continue.

- Some alignment routines end at this point. Others will reprint the alignment page and see if the alignment “took.” If not, you can reenter the number of the one that looks the best.

- Click Finish to end the alignment routine.

Step 3: Configure Options and Settings

Once you have installed the software and calibrated the device, you can configure any options that you would like for the printer. All of the settings and how to change them can be found online or in your user manual.

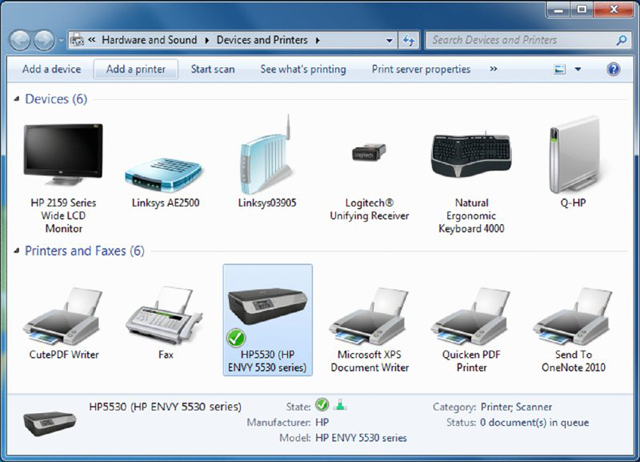

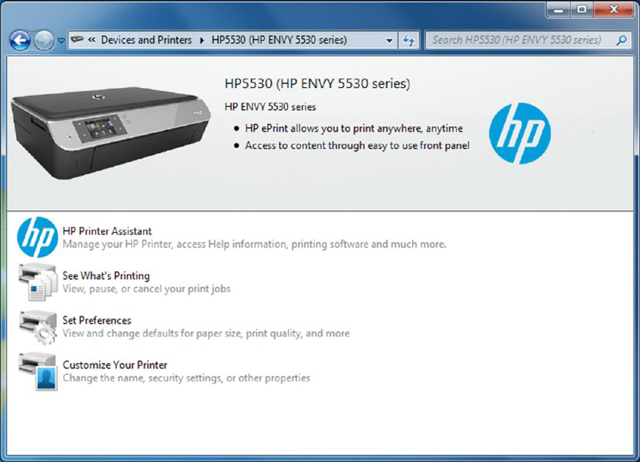

Where you configure specific printer properties depends a lot on the printer itself. As a rule of thumb, you’re looking for the Printer Properties or Printing Preferences applet. In Windows 7, if you click Start and then Devices And Printers, you will get a window similar to the one shown in Figure 11.25. At the top there is an option to add a device or a printer. If you double-click the printer icon, you will get another window (like the one in Figure 11.26) that lets you get to the printer’s configuration options.

Figure 11.25 Devices And Printers

Figure 11.26 Printer information and options

Various configuration features can be set from each menu option. In this example, there are three options in which you would probably be most interested. The first one, See What’s Printing, lets you look at and manage the print queue. This is something we’ll talk about more in Chapter 12. The second one, Set Preferences, gives you a number of settings related to print output. The third one, Customize Your Printer, is where you find the printer’s properties, shown in Figure 11.27.

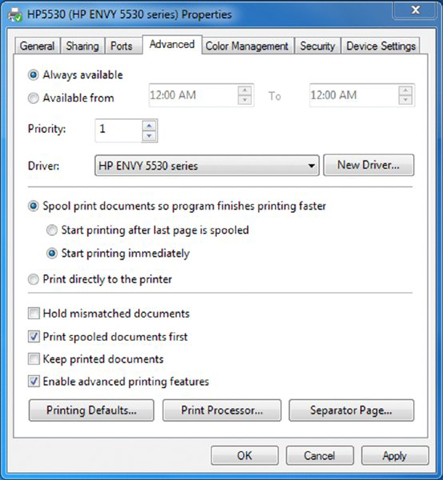

Figure 11.27 Printer Properties dialog box

From the Printer Properties dialog box, you can configure nearly any option that you want to for your printer. The Properties dialog box will be pretty much the same for any printer that you install, and we’ll cover a few options here in a minute. First though, notice the Preferences button on the General tab. Clicking this will produce a new window like the one in Figure 11.28. That window will have configuration options based on your specific model of printer.

Figure 11.28 Printing Preferences window

Now back to the Properties dialog box. The printer’s Properties dialog box is less about how the printer does its job and more about how people can access the printer. From the Properties dialog box, you can share the printer, set up the port that it’s on, configure when the printer will be available throughout the day, and specify who can use it. Let’s take a look at a few key tabs. We’ve already taken a look at the General tab, which has the Preferences button as well as the all-important Print Test Page button. It’s handy for troubleshooting!

Figure 11.29 shows the Sharing tab. If you want other users to be able to print to this printer, you need to share it. Notice the warnings above the Share This Printer check box. Those are important to remember. When you share the printer, you give it a share name. Network users can map the printer through their own Add Printer Wizard (choosing a networked printer) and by using the standard \computer_nameshare_name convention. User permissions are managed through the Security tab.

Figure 11.29 Printer Properties Sharing tab

One other important feature to call out on this tab is the Additional Drivers button. This one provides a description that is fairly self-explanatory.

Figure 11.30 shows the Ports tab. Here you can configure your printer port and add and delete ports. There’s also a check box to enable printer pooling. This would be used if you have multiple physical printers that operate under the same printer name.

Figure 11.30 Printer Properties Ports tab

Figure 11.31 shows the important Advanced tab of the printer Properties dialog box. On this tab, you can configure the printer to be available during only certain hours of the day. This might be useful if you’re trying to curtail after-hours printing of non-work-related documents, for example. You can also configure the spool settings. For faster printing, you should always spool the jobs instead of printing directly to the printer. However, if the printer is printing garbage, you can try printing directly to it to see if the spooler is causing the problem.

Figure 11.31 Printer Properties Advanced tab

Regarding the check boxes at the bottom, you will always want to print spooled documents first because that speeds up the printing process. If you need to maintain an electronic copy of all printed files, check the Keep Printed Documents check box. Keep in mind that this will eat up a lot of hard disk space.

Finally, the Printing Defaults button takes you to the Printing Preferences window (shown earlier in Figure 11.28). Print Processor lets you select alternate methods of processing print jobs (not usually needed), and Separator Page lets you specify a file to use as a separator page (a document that prints out at the beginning of each separate print job, usually with the user’s name on it), which can be useful if you have several (or several dozen) users sharing one printer.

Step 4: Print a Test Page

Once you have configured your printer, you are finished and can print a test page to test its output. Windows has a built-in function for doing just that. To print a test page, right-click the icon for the printer you installed from within the Devices And Printers window and click Printer properties. On the General tab of the Printer properties (shown in Figure 11.27), there will be a Print Test Page button. Click that button and Windows will send a test page to the printer. If the page prints, your printer is working. If not, double-check all of your connections. If they appear to be in order, then read ahead to Chapter 12 for troubleshooting tips.

Step 5: Verify Compatibility with Operating System and Applications

Once your printer is installed and you have printed a test page, everything else should work well, right? That’s usually true, but it’s good practice to verify compatibility with applications before you consider the device fully installed.

With printers, this process is rather straightforward. Open the application you’re wondering about and print something. For example, open up Microsoft Word, type in some gibberish (or open a real document if you want), and print it out. If you are running non-Microsoft applications (such as a computer-aided drafting program or accounting software) and have questions about their compatibility with the printer, try printing from those programs as well.

Step 6: Educate Users about Basic Functionality

Most users today know how to print, but not everyone knows how to install the right printer or how to print efficiently. This can be a significant issue in work environments.

Say your workplace has 10 different printers, and you just installed number 11. First, your company should use a naming process to identify the printers in a way that makes sense. Calling a printer HPLJ4 on a network does little to help users understand where that printer is in the building. After installing the printer, offer installation assistance to those who might want to use the device. Show users how to install the printer in Windows (or if printer installation is automated, let them know that they have a new printer and where it is). Also, let the users know the various options available on that printer. Can it print double-sided? If so, you can save a lot of paper. Show users how to configure that. Is it a color printer? Do users really need color for rough drafts of documents or presentations? Show users how to print in black and white on a color printer to save the expensive color ink or toner cartridges.

On the printer we’ve used as an example in this chapter, most of the options involving print output are located in Preferences (look back at Figure 11.28). Two of them are on the Printing Shortcut tab: Duplex (or Print On Both Sides) and Print Quality (Best, Normal, Draft). Orientation (Portrait or Landscape) is set on the Layout tab. This printer does not have a collate feature, which is used if you are printing several copies of a longer document. Collation will let you select whether you want it to print pages in order (1, 2, 3. . . 1, 2, 3. . . and so on) or multiple copies of the same page at once (1, 1, 1. . . 2, 2, 2. . . and so forth).

In Exercise 11.2, we’ll step through the process of installing a USB printer in Windows 7; the process will work in Windows XP and Vista as well.

Installing and Sharing Networked Printers

The previous section was about installing a printer attached to your local computer. There are advantages to that approach, such as being able to manage and control your own printer, not to mention having a printer at your own desk. That doesn’t happen often in the business world these days!

There are some big disadvantages as well. First, it means that all users who need to print to your device may need local accounts on your computer, unless you are on a domain or have configured a homegroup. If so, you will need to manage security for these accounts and the printer. Second, your computer is the print server. The print server is the device that hosts the printer and processes the necessary printer commands. This can slow your system down. Third, because your computer is the print server, if for any reason it’s turned off, no one will be able to print to that device.

There is another option, though. Instead of needing a specific computer to be the print server, why not make the print server part of the printer itself, or make it a separate network device that hosts the printers? That is exactly the principle behind network printing. Next, we will cover two types of network printing, local network printing and cloud printing, as well as talk about data privacy concerns with printing to public or shared printers.

Local Network Printing

The key to local network printing is that you are moving the print server from your computer to another location, accessible to other users on the network. Therefore, the print server needs a direct attachment to the network, via either a wired (RJ-45) or wireless connection. There are two major varieties of print servers that you will find. The first is incorporated into the printer itself (called an integrated print server), and the second is a separate hardware print server. If you are using a stand-alone print server, the printers attach to the print server, either physically or logically. In most cases, if a printer is capable of connecting directly to a network, it has the ability to be its own print server.

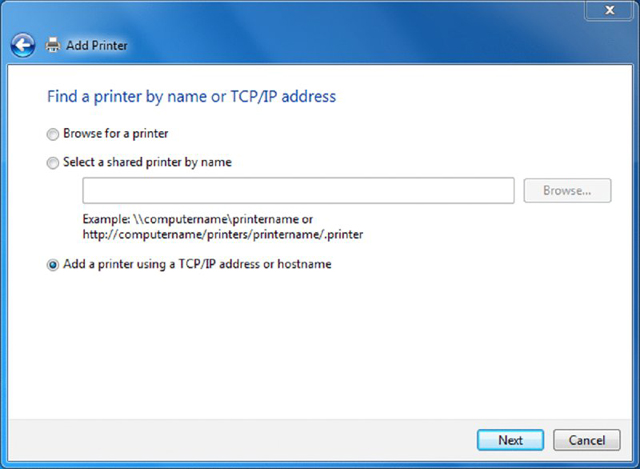

Installing and using a networked printer is very similar to installing and using a local printer. You need to ensure that both devices are plugged in, turned on, and attached to the network (either with an RJ-45 Ethernet connection or by using wireless). Probably the biggest difference is that when you install it, you need to tell your computer that you are adding a networked printer instead of a local one. For example, in Windows 7, when you open the Add Printer utility (shown in Figure 11.24), you choose Add A Network, Wireless, Or Bluetooth Printer instead of Add A Local Printer. From there, you will be asked to install the printer driver, just as you would if the printer were directly attached to your computer. Once it’s installed, you use it just as you would use a local printer, including setting the configuration options that we looked at in earlier sections. Every computer on the local network should be able to see and add the printer in the same way.

There are a few other ways that you can add shared networked printers, and they are by using TCP, Bonjour, and AirPrint.

TCP Printing

Printers that are network aware need IP addresses, so it makes sense that you can add a networked printer by using TCP/IP, also known as TCP printing. Exercise 11.3 walks you through the general process of installing a TCP printer, using Windows 7 as an example.

Figure 11.32 Adding a TCP printer

Some installations will ask you which TCP printing protocol you want to use: RAW or LPR. RAW (also called the Standard TCP/IP Port Monitor) is the default, and it uses TCP port 9100 by default. It also uses the SNMP protocol for bidirectional communication between the computer and the printer. LPR is older, and the protocol is included for use with legacy systems. It’s limited to source ports 721–731 and the destination port 515.

After the printer is installed, it will appear in your Devices And Printers window just as any other printer would.

There are a few advantages to using TCP printing. First, it sends the print jobs directly to the printer, so your system does not need to act as the print server or spend processing time dealing with formatting the print job. Second, it allows clients with different OSs, such as Linux or OS X, to add printers without worrying about intra-OS conflicts.

Bonjour

Apple introduced Bonjour in 2002 (then under the name Rendezvous) as an implementation of zero configuration networking. It’s designed to enable automatic discovery of devices and services on local networks using TCP/IP as well as to provide hostname resolution. Currently, it comes installed by default on Apple’s OS X and iOS operating systems. Bonjour makes it easy to discover and install printers that have been shared by other Bonjour-enabled clients on the network.

Even though Apple developed Bonjour, it does work on other operating systems. For example, it comes with iTunes and the Safari browser, so if you have either of those installed on your, say, Windows computer, odds are that you have Bonjour as well. Once installed, the Bonjour service starts automatically and scans the network looking for shared devices. Exercise 11.4 shows you how to see if Bonjour is installed in Windows.

Figure 11.33 Bonjour service is set to start automatically

Bonjour only works on a single broadcast domain, meaning that it will not find a printer or other device if it’s on the other side of a router from your computer. All major printer manufacturers support Bonjour technology.

If you are using a Mac, adding a Bonjour printer is easy. You open System Preferences ➢ Print And Scan, click the plus sign under Printers to open the Add Printer window, and look for the printer on the list. If the Mac doesn’t have the driver available, you will be asked to provide it. Otherwise, you’re done.

In order to add or share a Bonjour printer from Windows, you need to download Bonjour Print Services for Windows. It’s found on Apple’s support site at https:// support.apple.com/kb/dl999.

AirPrint

The one big complaint that Apple aficionados had about Bonjour was that it didn’t support printing from iPhones or iPads. In 2010, Apple introduced AirPrint to meet that need.

The idea behind AirPrint is quite simple. Mobile devices can automatically detect AirPrint-enabled printers on their local network and print to them without requiring the installation of a driver. To be fair, what Apple really did was eliminate the need for a specific printer driver to be installed on the client and replaced it with the AirPrint concept. Then it was up to the printer manufacturers to develop their own drivers that talked to AirPrint. HP was happy to oblige with its Photosmart Plus series, and other manufacturers soon followed. The list of AirPrint-enabled printers is available at https://support.apple.com/en-us/HT201311. From the end-user standpoint though, no driver is required.

There really is no installation process, and printing is easy. Just be sure that your mobile device is on the same local network as an AirPrint printer. When you attempt to print from your device, select the printer to which you want to print, and it should work.

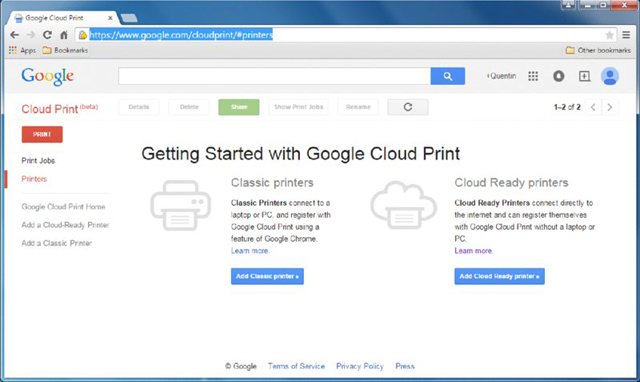

Cloud Printing

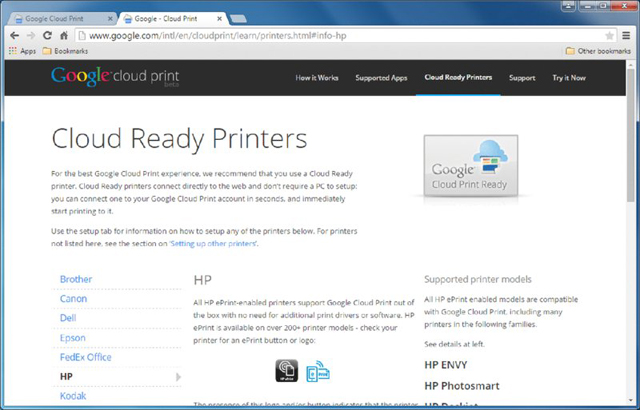

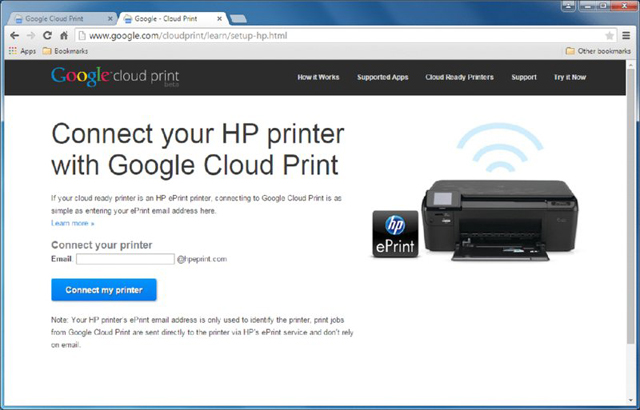

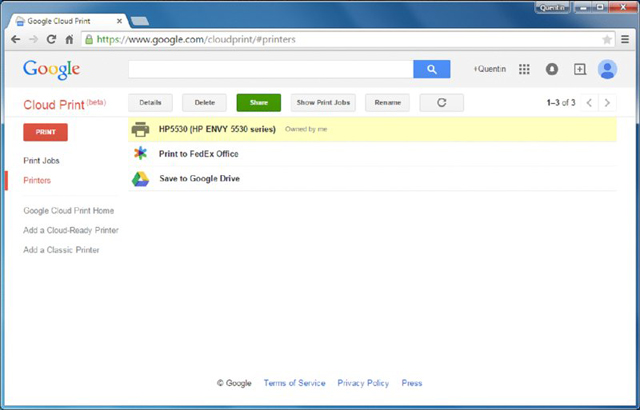

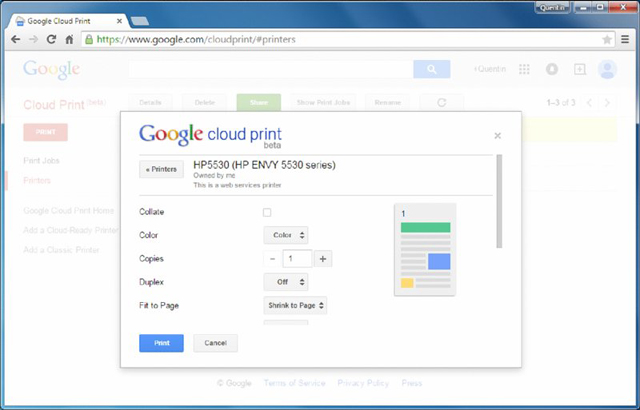

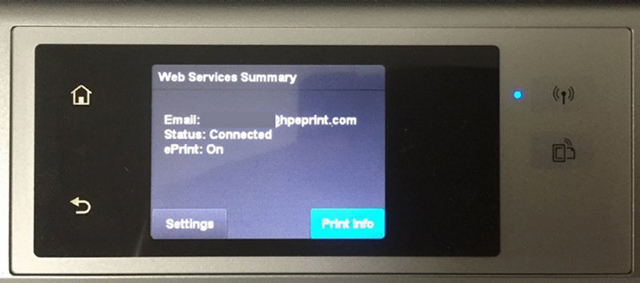

Through the first decade of the 2000s, it seemed like wireless networking was the hot new trend in computing. Now that technology has matured a bit, and the cloud has replaced it as the trend du jour. Not everyone knows what the cloud is or what the cloud does, but they think they are supposed to have it. The cloud would be a sad place if it didn’t support printing, but fortunately for us it does.